Experimental Comparison between Hydrokinetic Turbines: Darrieus vs. Gorlov †

Abstract

:1. Introduction

2. Materials and Methods

- Hydrokinetic turbines.

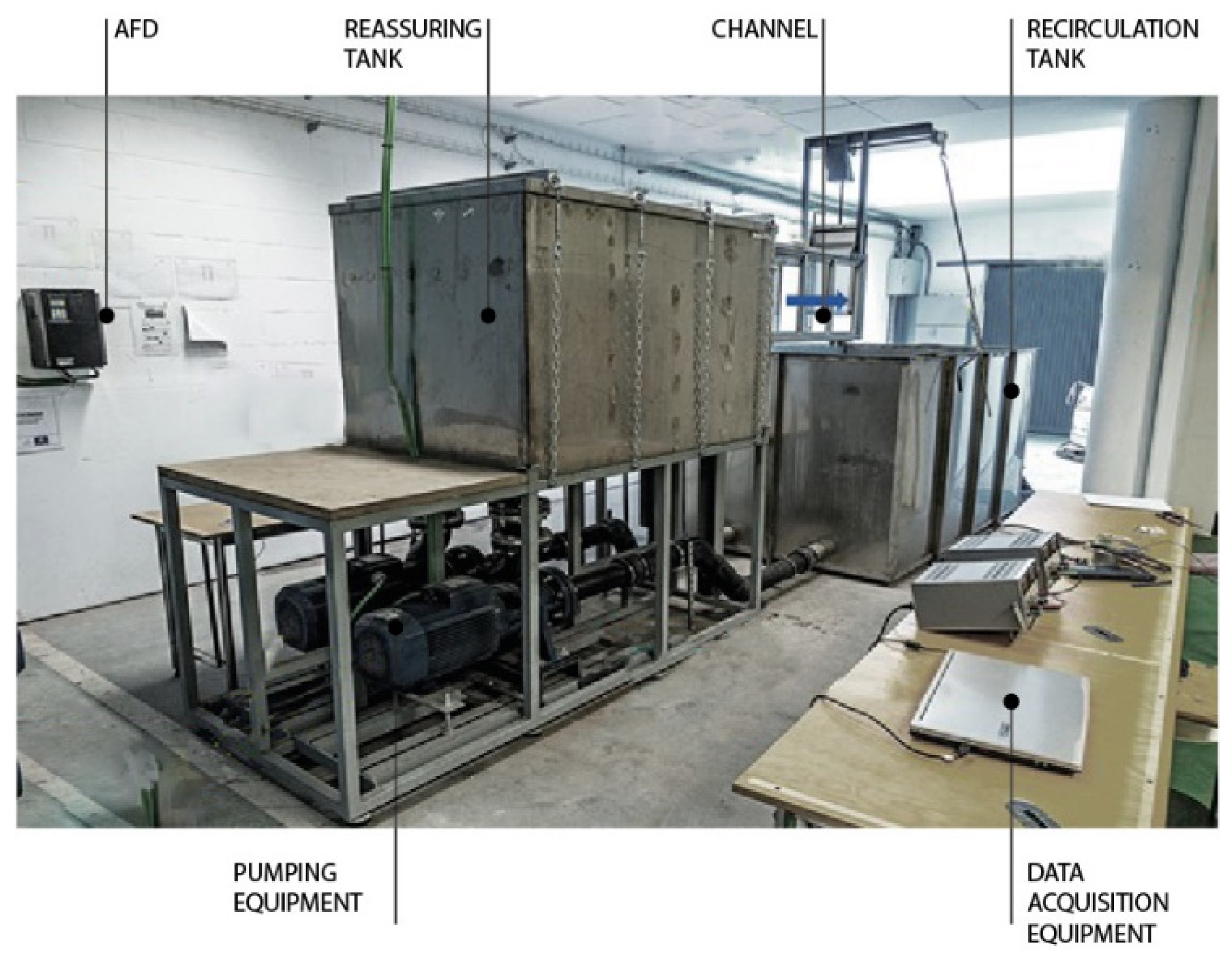

- Hydrodynamic tunnel.

- Data acquisition system.

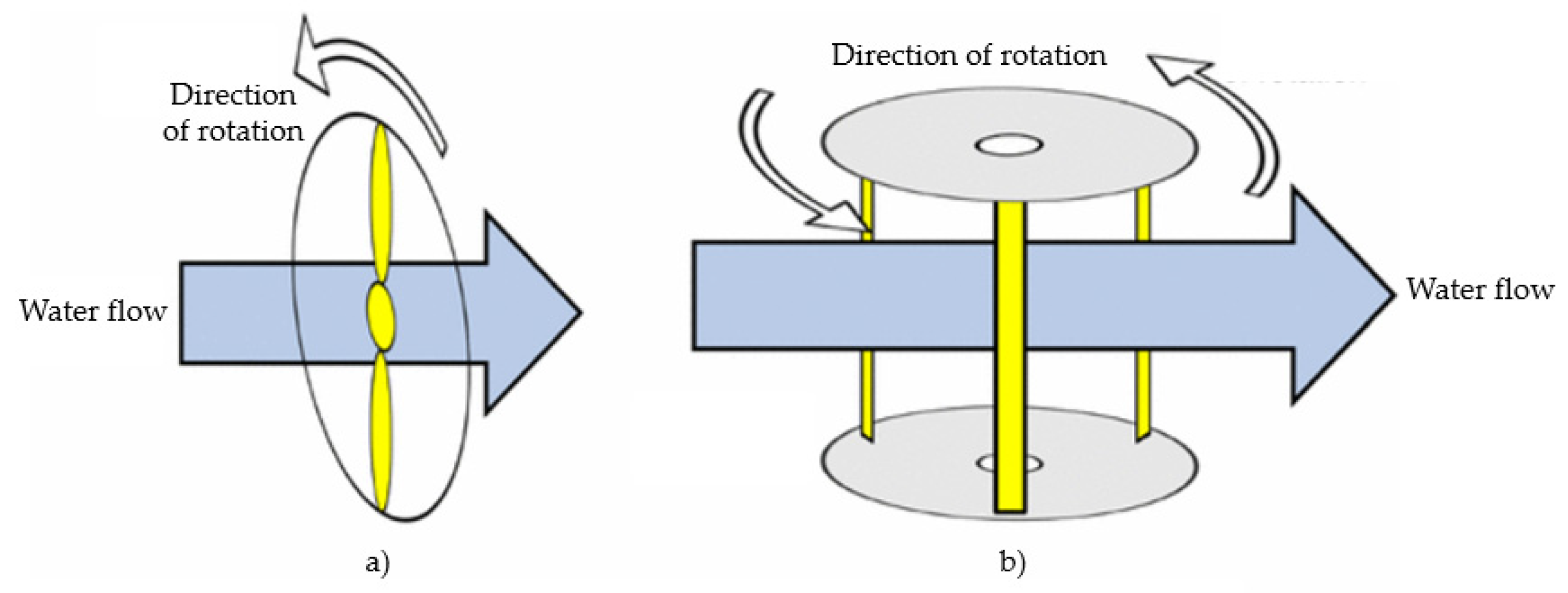

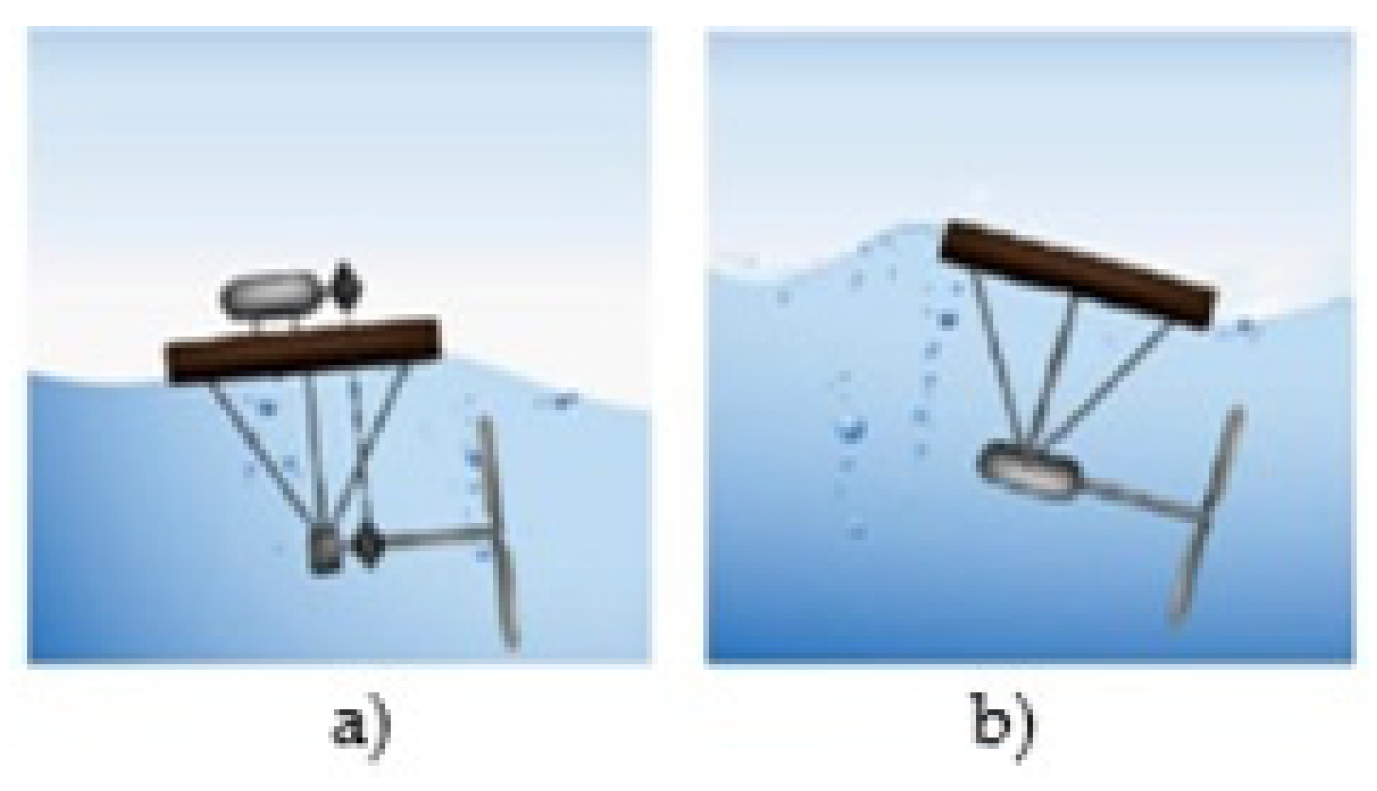

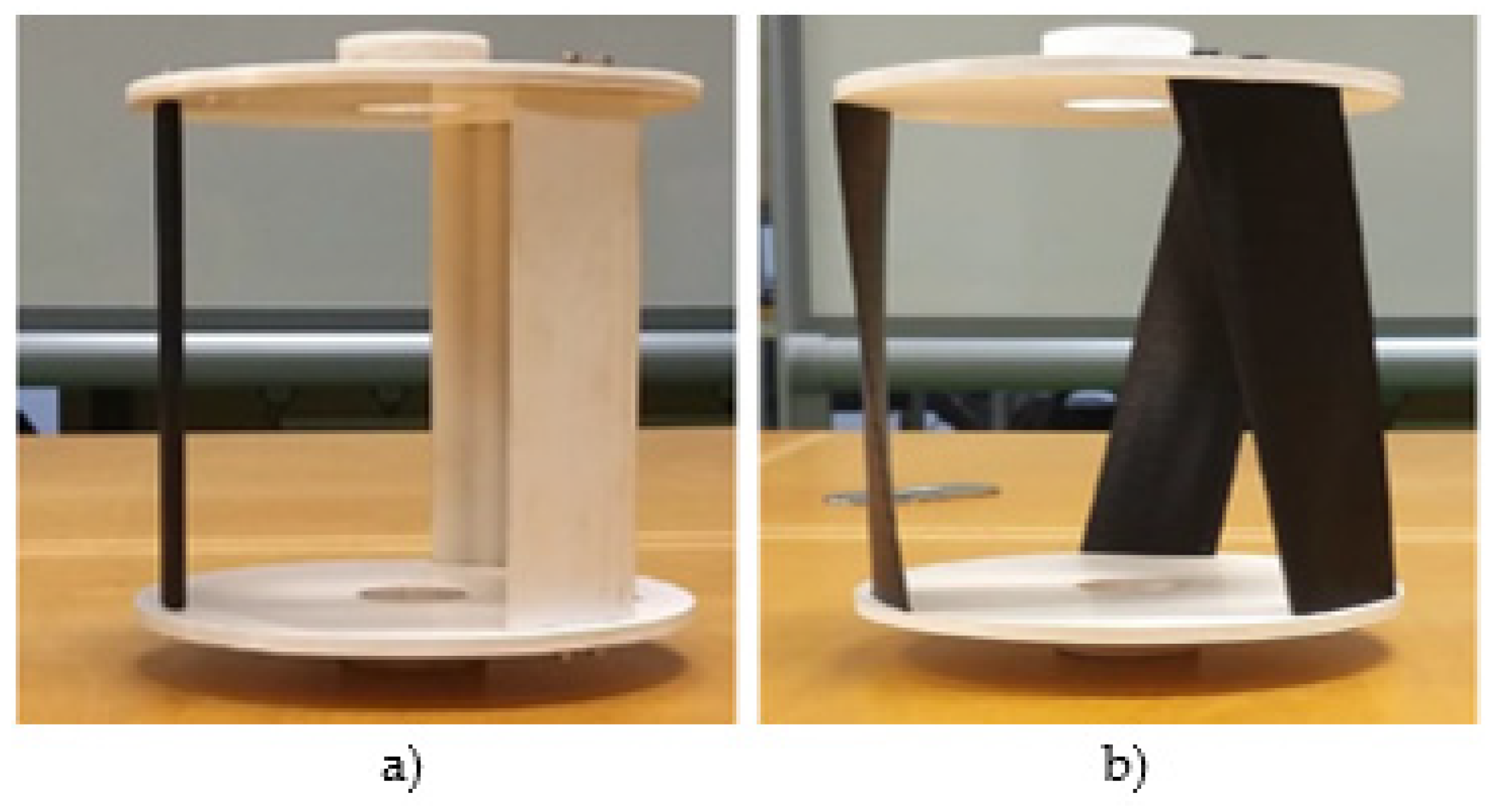

2.1. Hydrokinetic Turbines

2.2. Hydrodynamic Tunnel

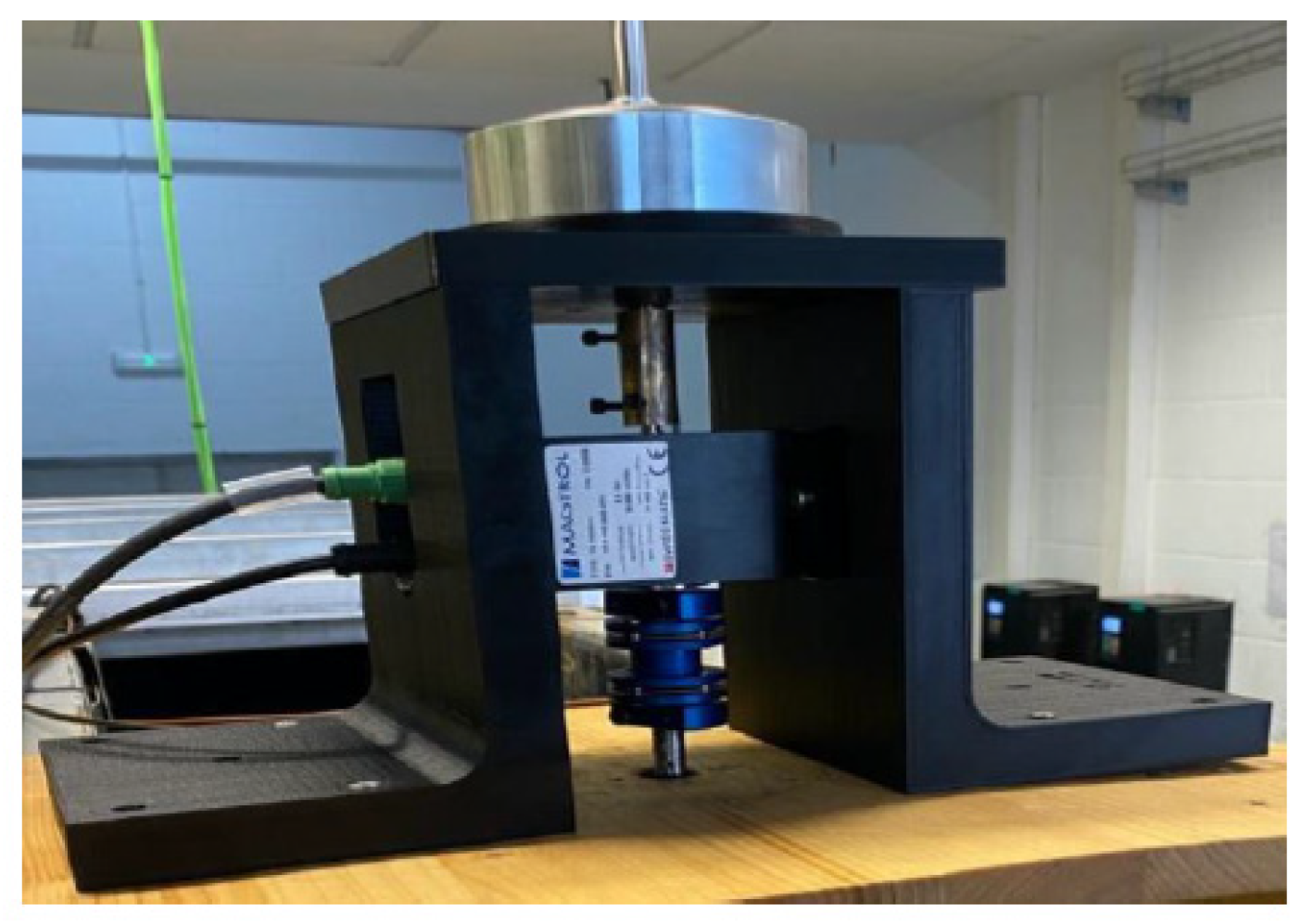

2.3. Data Acquisition System

- Torque measuring equipment.

- Electric brake.

- Data acquisition software.

2.4. Methodology

- The turbine to be characterized was placed inside the methacrylate box (Figure 9). The rotor was positioned at the correct elevation and coupled to the torque meter through the rotation axis.

- Once the whole assembly was placed inside the hydraulic channel, the water circulation was started so that the turbine began to rotate. At that moment, the first measurement called “no-load” was performed, where the voltage of the electric brake is 0 V, so no braking torque is applied to the turbine. Under these conditions, the mechanical power is zero but the rotational speed is maximum.

- Subsequently, by means of the current source, the electrical intensity of the brake was increased in 1 V intervals during 35 s. For each of the measurements, a value of mechanical torque and rotational speed was obtained. The characterization of the power stage continued until the turbine stopped rotating.

3. Results

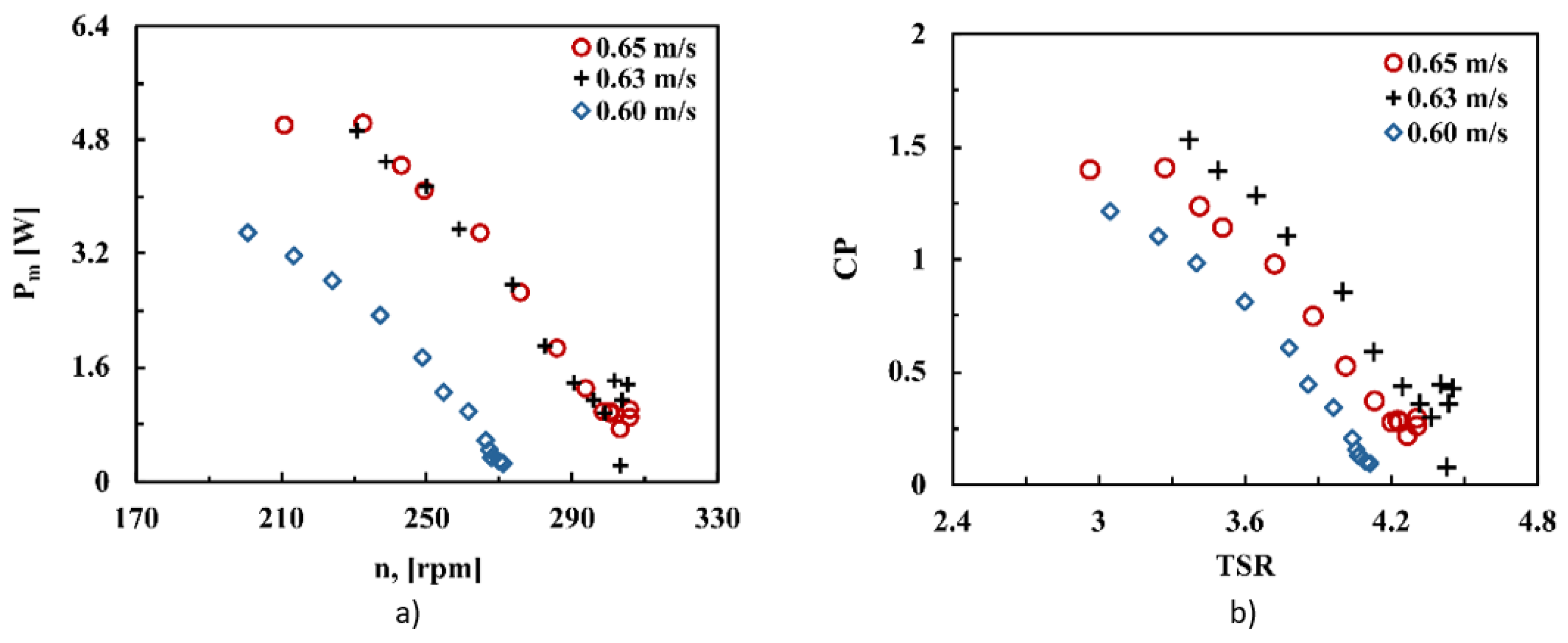

3.1. Darrieus Type Rotor Characterization

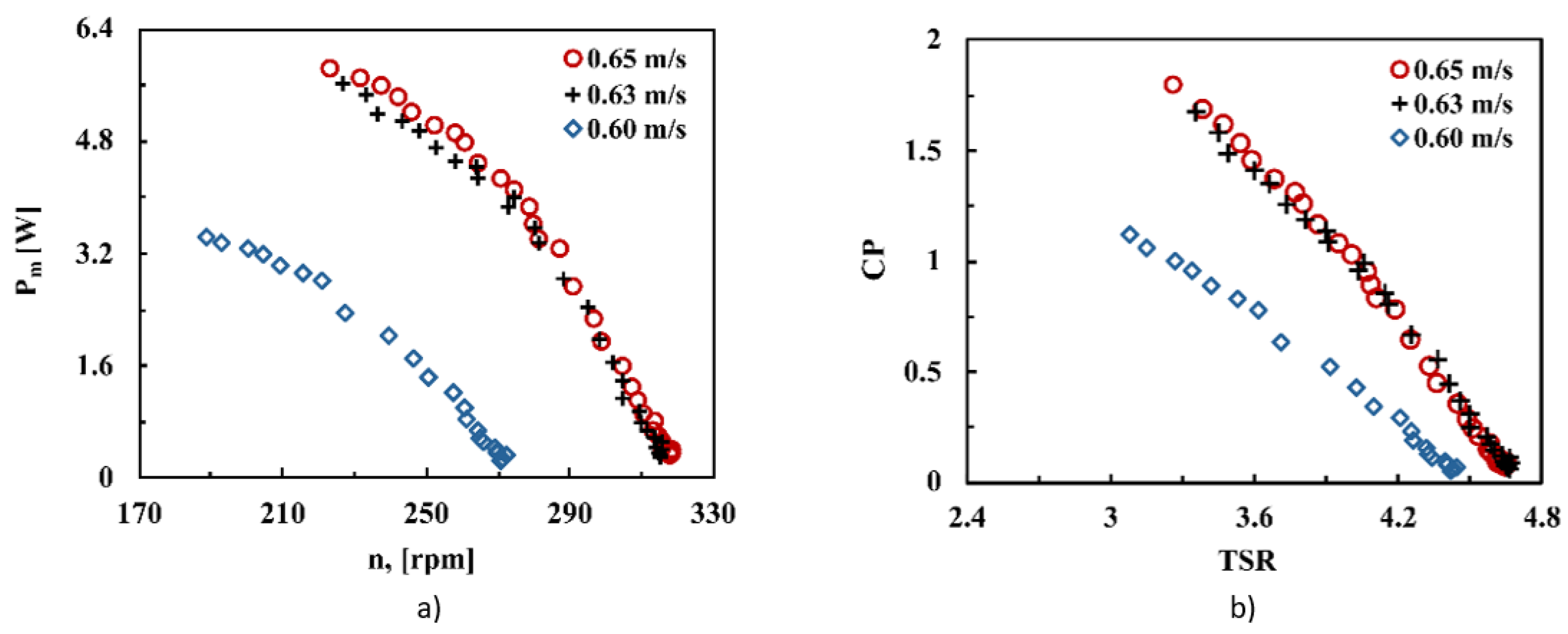

3.2. Gorlov Type Rotor Characterization

3.3. Rotor Comparison

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- dos Santos, I.F.S.; Camacho, R.G.R.; Tiago Filho, G.L.; Botan, A.C.B.; Vinent, B.A. Energy Potential and Economic Analysis of Hydrokinetic Turbines Implementation in Rivers: An Approach Using Numerical Predictions (CFD) and Experimental Data. Renew. Energy 2019, 143, 648–662. [Google Scholar] [CrossRef]

- Brun, P.; Terme, L.; Barillier, A. Paimpol-Bréhat: Development of the First Tidal Array in France. In Marine Renewable Energy Handbook; Wiley-ISTE: London, UK, 2013; ISBN 9781848213326. [Google Scholar]

- Lago, L.I.; Ponta, F.L.; Chen, L. Advances and Trends in Hydrokinetic Turbine Systems. Energy Sustain. Dev. 2010, 14, 287–296. [Google Scholar] [CrossRef]

- Goundar, J.N.; Ahmed, M.R. Marine Current Energy Resource Assessment and Design of a Marine Current Turbine for Fiji. Renew. Energy 2014, 65, 14–22. [Google Scholar] [CrossRef]

- Kinsey, T.; Dumas, G. Impact of Channel Blockage on the Performance of Axial and Cross-Flow Hydrokinetic Turbines. Renew. Energy 2017, 103, 239–254. [Google Scholar] [CrossRef]

- Espina-Valdés, R.; Fernández-Jiménez, A.; Fernández Francos, J.; Blanco Marigorta, E.; Álvarez-Álvarez, E. Small Cross-Flow Turbine:Design and Testing in High Blockage Conditions. Energy Convers. Manag. 2020, 213, 112863. [Google Scholar] [CrossRef]

- Patel, V.; Eldho, T.I.; Prabhu, S.V. Velocity and Performance Correction Methodology for Hydrokinetic Turbines Experimented with Different Geometry of the Channel. Renew. Energy 2019, 131, 1300–1317. [Google Scholar] [CrossRef]

- Rubio, C.; Lizarazo, G. Diseño de Un Prototipo de Turbina Eólica Clase Híbrido Para Bajas Corrientes de Aire. Revista Cubana De Ingeniería 2017, 8, 30–37. [Google Scholar] [CrossRef]

- Dhadwad, A.; Balekar, A.; Nagrale, P. Literature Review on Blade Design of Hydro-Microturbines. Int. J. Sci. Eng. Res. 2014, 5, 72–75. [Google Scholar]

- Asr, M.T.; Nezhad, E.Z.; Mustapha, F.; Wiriadidjaja, S. Study on Start-up Characteristics of H-Darrieus Vertical Axis Wind Turbines Comprising NACA 4-Digit Series Blade Airfoils. Energy 2016, 112, 528–537. [Google Scholar] [CrossRef]

- Kumar, A.; Saini, R.P. Performance Parameters of Savonius Type Hydrokinetic Turbine—A Review. Renew. Sustain. Energy Rev. 2016, 64, 289–310. [Google Scholar] [CrossRef]

- Bachant, P.; Wosnik, M. Performance Measurements of Cylindrical- and Spherical-Helical Cross-Flow Marine Hydrokinetic Turbines, with Estimates of Exergy Efficiency. Renew. Energy 2015, 74, 318–325. [Google Scholar] [CrossRef]

| SC-Darrieus | Gorlov | |

|---|---|---|

| Height (m) | 0.15 | 0.15 |

| Diameter (m) | 0.175 | 0.175 |

| Chord (m) | 0.05 | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Espina-Valdés, R.; Gharib-Yosry, A.; Ferraiuolo, R.; Fernández-Jiménez, A.; Fernández-Pacheco, V.M. Experimental Comparison between Hydrokinetic Turbines: Darrieus vs. Gorlov. Environ. Sci. Proc. 2022, 21, 26. https://doi.org/10.3390/environsciproc2022021026

Espina-Valdés R, Gharib-Yosry A, Ferraiuolo R, Fernández-Jiménez A, Fernández-Pacheco VM. Experimental Comparison between Hydrokinetic Turbines: Darrieus vs. Gorlov. Environmental Sciences Proceedings. 2022; 21(1):26. https://doi.org/10.3390/environsciproc2022021026

Chicago/Turabian StyleEspina-Valdés, Rodolfo, Ahmed Gharib-Yosry, Roberta Ferraiuolo, Aitor Fernández-Jiménez, and Victor Manuel Fernández-Pacheco. 2022. "Experimental Comparison between Hydrokinetic Turbines: Darrieus vs. Gorlov" Environmental Sciences Proceedings 21, no. 1: 26. https://doi.org/10.3390/environsciproc2022021026

APA StyleEspina-Valdés, R., Gharib-Yosry, A., Ferraiuolo, R., Fernández-Jiménez, A., & Fernández-Pacheco, V. M. (2022). Experimental Comparison between Hydrokinetic Turbines: Darrieus vs. Gorlov. Environmental Sciences Proceedings, 21(1), 26. https://doi.org/10.3390/environsciproc2022021026