Abstract

Wood is a material of biological origin of fundamental importance for artisan and industrial uses. In outdoor environments, it is very attractive, but easily subjected to degradation. A valid alternative to chemical preservatives is thermal modification. The aim of this study is to evaluate ayous wood industrially subjected to thermal modification (215 °C) in order to emphasize the influence of heat treatment on selected physical and mechanical characteristics. As a result of the heat treatment, the physical and mechanical properties are generally reduced: the density in natural wood (TQ) was 379 kg/m3, in heat treated wood (TT) 319 kg/m3; the basic density in TQ was 327 kg/m3, in TT 299 kg/m3; the axial compression strength of TT was reduced by 18.1%; and the static bending strength of TT was reduced by 41.4% compared to untreated wood at 10% equilibrium moisture content (EMC). In addition, the samples, under the same environmental conditions in the laboratory, reached the equilibrium moisture content of 10% in TQ and 4% in TT.

1. Introduction

Ayous wood is obtained from the species Triplochiton scleroxylon K. Schum, widely diffused in tropical areas of central western Africa with uneven annual rainfall distribution [1,2]. The major exporting countries are Cameroon, Ghana, Ivory Coast, Niger and Nigeria; for some of them, ayous wood export is crucial because it represents the largest portion of total wood export [3]. Appreciation and diffusion for this wood on the occidental market is due to the low cost compared to similar species produced in Europe. An important use of ayous wood is for realizing outdoor coverings of buildings, especially in northern and central Europe. Outdoor uses expose wood to the main degradation agents such as UV, moisture and biological attacks [4,5], and ayous wood is a low durable wood. To improve the durability of a material, preservatives are generally needed, which can limit the effects caused by wood degradation agents. A valid alternative to chemical preservatives is the thermal modification of wood [6]. Thermo treatment is a physical-chemical alteration realized by exposing the wood to a high temperature for some hours [7,8]. Thermal modified wood properties are related to the heat treatment cycle; cycles with different temperatures and times of exposure originate materials with different characteristics [9]. Heat treated wood is less hygroscopic due to a lower quantity of free polar sites. Other effects of heat treatment are color alteration—change in darker tones is generally more appreciated [10,11]—and increased durability [12].

The aim of this study is to evaluate ayous wood (Triplochiton scleroxylon K. Schum), which was industrially subjected to thermal modification in order to emphasize the influence of heat treatment at 215 °C on selected physical and mechanical characteristics, with a comparison with untreated wood coming from the same area (Cameroon).

2. Materials and Methods

The wood comes from a natural forest—it is FSC (Forest Stewardship Council) certified for forest management and chain of custody. Untreated and heat-treated samples were used. The thermal modification was conducted on planks of ayous wood in an industrial system that used a slight initial vacuum in an autoclave (Model TVS 6000 WDE Maspell srl, Terni, Italy) and a treatment temperature of 215 °C for three hours.

Untreated as well as modified wood samples were subjected to mechanical tests at the equilibrium moisture content (EMC) of the laboratory conditions. The properties were further calculated at 12% moisture content when required and possible, as indicated in the standards for comparison to the literature. Laboratory tests were conducted following the reference standards UNI ISO 13061-1, UNI ISO 13061-2, ISO 13061-3, ISO 13061-13, UNI EN 1534, and UNI ISO 3787 for the tests and UNI ISO 3129 for the sample realization [13,14,15,16,17,18,19].

Analyzed physical characteristics were wood density, basic density, linear shrinkage and volumetric shrinkage. Sample dimensions were measured with a digital caliper (±0.01 mm), and mass was recorded at a precision scale ± 0.001 g. Samples were dried using a ventilated oven at 103 ± 2 °C for 24 + 6 h, according to the reference standard. Demineralized water was used to reach the maximum swelling. Applied formulas to define physical properties were reported in the reference standards [13,14,16,19].

Determined mechanical properties were axial compression strength, static bending strength and Brinell hardness.

For the axial compression strength test, samples were measured and weighed, then they were put between the steel plates of the testing machine. The load was applied such that the sample was broken in 1.5–2 min. After the test, samples were weighed and dried in an oven at 103 °C for 24 + 6 h to determine moisture content and wood density according to the reference standard. Applied formulas are reported in the reference standards [13,14,18,19]. For the static bending strength test, samples’ length and the median section were measured; the load was applied such that the sample was broken in 1.5–2 min. After the test, a piece used to determine wood density and moisture content was cut from every sample. Applied formulas are reported in the reference standards [13,14,15,19].

For the Brinell hardness test, samples were loaded with 1 kN for 25 s; the load was applied such that the maximum load of 1 kN was reached in 15 s from the start. The samples were left to rest for at least three minutes after load application. Then, two diameters of the indentation were measured: one parallel to fiber direction, and the second perpendicular to fiber direction. Applied formulas to define the Brinell hardness are reported in the reference standards [13,17,19].

3. Results and Discussion

The selected physical properties of untreated wood are shown in Table 1. The obtained results were similar to the values of other authors [20,21,22,23,24].

Table 1.

Physical properties of untreated wood (MC = moisture content).

The selected mechanical properties of untreated wood are presented in Table 2. Even the mechanical characteristics, as expected, were similar to those reported in the literature [20,21].

Table 2.

Mechanical properties of untreated wood (MC = moisture content).

The selected physical properties of thermally treated wood are presented in Table 3. Heat-treatment adversely influenced them. In detail, wood density was reduced from 0.39 to 0.32 g/cm3; basic density was reduced from 0.33 to 0.30 g/cm3; and volumetric shrinkage was reduced from 7.8% in untreated wood to 3.3% in heat-treated wood. Therefore, the performed heat treatment induced a decrease in these characteristics of 18%, 9%, and 58%, respectively.

Table 3.

Physical properties of heat-treated wood (MC = moisture content).

The mechanical properties of thermally treated samples are reported in Table 4. Like the physical features, a general reduction in the studied mechanical properties was observed in heat-treated wood, as widely reported in other wood species [9,25,26]. These values are overestimated as they were indicated at the equilibrium moisture content of the laboratory conditions.

Table 4.

Mechanical properties of heat-treated wood (MC = moisture content).

Axial compression strength was reduced from 36.6 in untreated wood to 34.2 MPa; in heat-treated wood, static bending strength was reduced from 61.1 to 37.6 MPa; and Brinell hardness was reduced from 12.21 N/mm2 to 8.30 N/mm2. The reduction, compared to untreated wood at 10% EMC, was, respectively, 18.1%, 41.4% and 32%. However, the data presented at the same laboratory conditions indicated the differences in the behavior of both untreated and thermally treated wood, which must be considered different even if they come from the same species. Akundele et al. [27] observed a stability improvement in heat treated ayous wood at 160 and 200 °C.

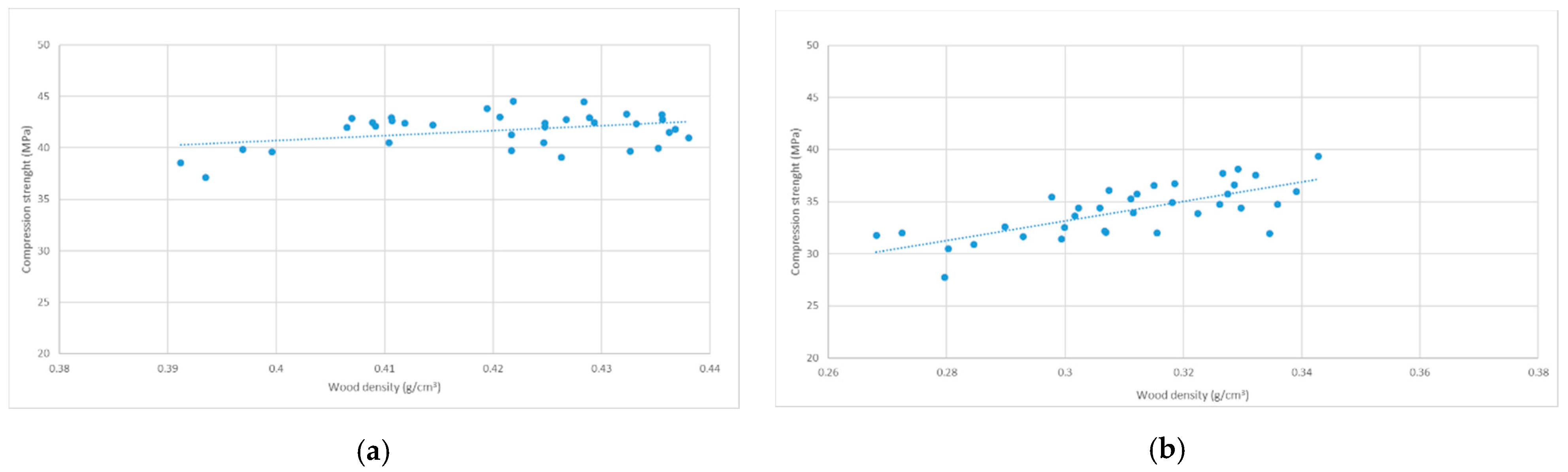

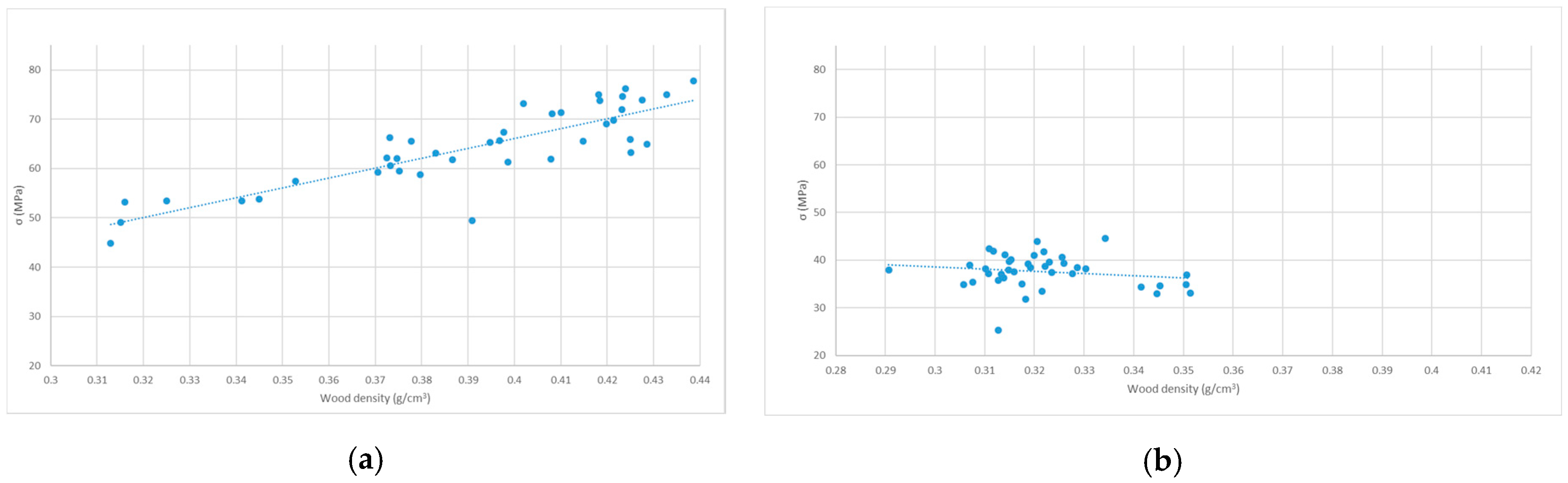

The axial compression (Figure 1) shows an increasing trend in the function of wood density both in untreated and heat-treated wood. However, the increasing trend of the static bending strength in the function of wood density was only shown in untreated wood (Figure 2).

Figure 1.

Compressive strength as a function of density in ayous wood. (a) Untreated wood; (b) thermally treated wood. (a): y = 47.91x + 21.58; R2 = 0.1392. (b): y = 93.07x + 5.2294; R2 = 0.5165.

Figure 2.

Bending strength as a function of density in ayous wood. (a) Untreated wood; (b) thermally treated wood. (a) y = 200.38x − 14.065; R2 = 0.7273. (b) y = −44.492x + 51.896; R2 = 0.0279.

It was observed that the equilibrium moisture content of untreated wood was 10%, whereas heat-treated wood reached 4% of moisture content, exposed to the same laboratory environmental conditions. This evidence was due to the chemical modifications that make the treated wood less hygroscopic [9,28,29]. Fabiyi et al. [30] found a decrease in water absorption due to the reduction in the number of hydroxyl groups in ayous wood treated at moderately high temperatures. Thermal modification improves the durability of wood exposed to degradation agents [12,31].

4. Conclusions

The modification of mechanical and physical properties was related to alterations induced by the industrial thermal treatment at 215 °C. The physical characteristics benefit from the heat treatment above all for the reduction in shrinkage and for the greater stability to thermo-hygrometric variations. These effects are due to the deterioration of chemical structure and cell wall compounds induced by the high temperature. Confirmation of this hypothesis comes from the reduction in the equilibrium moisture content of the material. Further studies about this issue can contribute to determine the influence of the specific thermal cycle on the physical and mechanical properties of ayous wood.

Author Contributions

Conceptualization, A.L.M. and R.P.; methodology, A.L.M., R.P.; validation, A.L.M., and E.G.; formal analysis, A.L.M.; investigation, A.L.M., E.G., D.T.; resources, A.L.M.; data curation, A.L.M., E.G., R.P.; writing—original draft preparation, A.L.M., E.G.; writing—review and editing, A.L.M., E.G., R.P.; visualization, funding acquisition, A.L.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors thank Vasto Legno spa who donated the industrially heat-treated and untreated wooden planks used in this project.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Palla, F.; Louppe, D. Obeché. Forafri, Libreville, Gabon & Cirad-Forȇt, Edition Juin; CIRAD: Montpellier, France, 2002; Volume 3, pp. 1–6. [Google Scholar]

- Hall, J.B.; Bada, S.O. The Distribution and Ecology of Obeche (Triplochiton scleroxylon). Br. Ecol. Soc. J. Ecol. 1979, 67, 543–564. [Google Scholar] [CrossRef]

- ITTO (International Tropical Timber Organization). Status of Tropical Forest Management 2005; ITTO Technical Series 24; International Tropical Timber Organization: Yokohama, Japan, 2006; 302p. [Google Scholar]

- Brischke, C.; Meyer, L.; Alfredsen, G.; Humar, M.; Francis, L.; Flate, P.-O.; Larsson-Brelid, P. Natural Durability of Timber Exposed Above Ground—A Survey. Drv. Ind. 2013, 64, 113–129. [Google Scholar] [CrossRef]

- Humar, M.; Kržišnik, D.; Lesar, B.; Brischke, C. The performance of wood decking after five years of exposure: Verification of the combined effect of wetting ability and durability. Forests 2019, 10, 903. [Google Scholar] [CrossRef]

- Humar, M.; Lesar, B.; Kržišnik, D. Moisture Performance of Façade Elements Made of Thermally Modified Norway Spruce Wood. Forests 2020, 11, 348. [Google Scholar] [CrossRef]

- Hill, C.A.S. Wood Modification: Chemical, Thermal and Other Processes; John Wiley and Sons: Hoboken, NJ, USA, 2006; ISBN 9780470021729. [Google Scholar]

- Jones, D.; Sandberg, D.; Goli, G.; Todaro, L. Wood Modification in Europe: A State-of-the-Art about Processes, Products and Applications; Content CC BY-SA 4.0 International, Metadata CC0 1.0 Universal; Firenze University Press (www.fupress.com): Firenze, Italy, 2019; ISSN 2704-5846. (online); ISBN 978-88-6453-970-6. (online PDF). [Google Scholar]

- Esteves, B.M.; Pereira, H.M. Wood modification by heat treatment: A review. Bioresources 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Ayadi, N.; Lejeune, F.; Charrier, F.; Charrier, B.; Merlin, A. Color stability of heat-treated wood during artificial weathering. Holz als Roh- und Werkstoff 2003, 61, 221–226. [Google Scholar] [CrossRef]

- Lo Monaco, A.; Pelosi, C.; Agresti, G.; Picchio, R.; Rubino, G. Influence of thermal treatment on selected properties of chestnut wood and full range of its visual features. Drewno 2020, 63, 5–24. [Google Scholar] [CrossRef]

- Candelier, K.; Thevenon, M.-F.; Petrissans, A.; Dumarcay, S.; Gerardin, P.; Petrissans, M. Control of wood thermal treatment and its effects on decay resistance: A review. Ann. For. Sci. 2016, 73, 571–583. [Google Scholar] [CrossRef]

- Ente Nazionale Italiano di Unificazione. UNI ISO 13061-1 Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens Determination of Moisture Content for Physical and Mechanical Tests; Ente Nazionale Italiano di Unificazione: Milano, Italy, 2017. [Google Scholar]

- Ente Nazionale Italiano di Unificazione. UNI ISO 13061-2 Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens Determination of Density for Physical and Mechanical Tests; Ente Nazionale Italiano di Unificazione: Milano, Italy, 2017. [Google Scholar]

- International Organization for Standardization. ISO 13061-3 Determination of Ultimate Tensile Strength in Static Bending—Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens; International Organization for Standardization: Geneve, Switzerland, 2014. [Google Scholar]

- International Organization for Standardization. ISO 13061-13 Determination of Radial and Tangential Shrinkage—Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens; International Organization for Standardization: Geneve, Switzerland, 2016. [Google Scholar]

- Ente Nazionale Italiano di Unificazione. UNI EN 1534 Wood Flooring and Parquet—Determination of Resistance to Indentation—Test Method; Ente Nazionale Italiano di Unificazione: Milano, Italy, 2020. [Google Scholar]

- Ente Nazionale Italiano di Unificazione. UNI ISO 3787 Wood—Test Methods—Determination of Ultimate Stress in Compression Parallel to Grain; Ente Nazionale Italiano di Unificazione: Milano, Italy, 1985. [Google Scholar]

- International Organization for Standardization. ISO 3129 Wood—Sampling Methods and General Requirements for Physical and Mechanical Testing of Small Clear Wood Specimens; International Organization for Standardization: Geneve, Switzerland, 2019. [Google Scholar]

- Giordano, G. Tecnologia del Legno; UTET: Torino, Italy, 1988; Volume 3/II, pp. 1091–1093. [Google Scholar]

- Gérard, J.; Kouassi, A.E.; Daigremont, C.; Détienne, P.; Fouquet, D.; Vernay, M. Synthèse sur les caracteristiques technologiques de référence des principaux bois commerciaux africains. CIRAD-Forȇt 1998, 11, 1–189. [Google Scholar]

- Simo Tagne, M. Experimental Characterization of the Influence of Water Content on the Density and Shrinkage of Tropical Woods Coming from Cameroon and Deduction of their Fiber Saturation Points. Int. J. Sci. Res. 2014, 3, 510–515. [Google Scholar]

- Allegretti, O.; Ferrari, S. Characterizing of the drying behaviour of some temperate and tropical hardwoods. In Proceedings of the 1st International Scientific Conference on Hardwood, Quebec City, QC, Canada, 24–26 September 2007; pp. 285–290. [Google Scholar]

- Olorunnisola, A.O. Design of Structural Elements with Tropical Hardwoods, Chapter 2 “Anatomy and Physical Properties of Tropical Woods”; Springer International Publishing: Cham, Switzerland, 2018; pp. 7–29. [Google Scholar]

- Yildiz, S.; Gezer, U.C. Mechanical and chemical behavior of spruce wood modified by heat. Build. Environ. 2006, 41, 1762–1766. [Google Scholar] [CrossRef]

- Priadi, T.; Hiziroglu, S. Characterization of heat-treated wood species. Mater. Design 2013, 49, 575–582. [Google Scholar] [CrossRef]

- Adekunle, I.; Samuel, O.; Fabiyi, J.; Amos, O. Effect of thermal and chemical modifications on the dimensional stability of Triplochiton scleroxylon (Obeche) wood. Mater. Sci. 2015, 13, 101–107. [Google Scholar]

- Korkut, D.S.; Guller, B. The effects of heat treatment on physical properties and surface roughness of red-bud maple (Acer trautvetteri Medw.) wood. Bioresour. Technol. 2008, 99, 2846–2851. [Google Scholar] [CrossRef] [PubMed]

- Aytin, A.; Korkut, S. Effect of thermal treatment on the swelling and surface roughness of common alder and wych elm wood. J. For. Res. 2016, 27, 225–229. [Google Scholar] [CrossRef]

- Fabiyi, J.S.; Ogunleye, B.M. Mid-infrared spectroscopy and dynamic mechanical analysis of heat-treated obeche (Triplochiton scleroxylon) wood. Maderas Ciencia y Tecnologia 2015, 17, 5–16. [Google Scholar] [CrossRef]

- Gérardine, P. New alternatives for wood preservation based on thermal and chemical modification of wood. Ann. For. Sci. 2016, 73, 559–570. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).