The Interplay of Processing-Related Influences on the Formation of Volume Holographic Gratings in a Free-Surface Epoxy-Based Recording Material

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation and Pre-Exposure Treatment

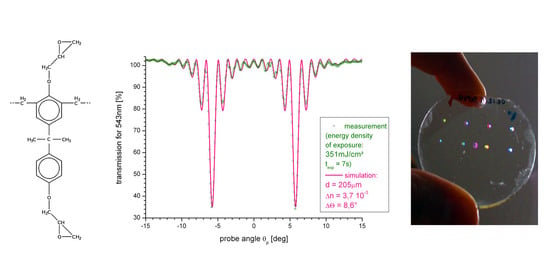

2.1.1. Guest–Host System

2.1.2. Sensitization

2.1.3. Crosslinking and Glass Transition Temperature

2.1.4. Spinning and Prebake

2.2. Holographic Exposure and Post-Processing Treatment

2.3. Analysis of Final Holographic Gratings

3. Results and Discussion

3.1. Influence of Prebake

3.2. Influence of Dark Storage

3.3. Impact of Pre-Exposure and Exposure Duration on Layer Thickness

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sabel, T.; Lensen, M.C. Volume Holography: Novel Materials, Methods and Applications. In Holographic Materials and Optical Systems; Naydenova, I., Babeva, T., Nazarova, D., Eds.; InTech: Rijeka, Croatia, 2017; pp. 3–25. [Google Scholar]

- Guo, J.; Gleeson, M.R.; Sheridan, J.T. A Review of the Optimisation of Photopolymer Materials for Holographic Data Storage. Phys. Res. Int. 2012, 2012, 803439. [Google Scholar] [CrossRef]

- Malallah, R.; Li, H.; Kelly, D.P.; Healy, J.J.; Sheridan, J.T. A Review of Hologram Storage and Self-Written Waveguides Formation in Photopolymer Media. Polymers 2017, 9, 337. [Google Scholar] [CrossRef] [PubMed]

- Mikulchyk, T.; Murphy, K.; Walsh, J.; Martin, S.; Cody, D.; Naydenova, I. Improving the Angular Visibility of Photopolymer-Based Reflection Holograms for Sensing Applications. Sensors 2023, 23, 4275. [Google Scholar] [CrossRef]

- Zezza, P.; Lucío, M.I.; Fernández, E.; Maquieira, Á.; Bañuls, M.-J. Surface Micro-Patterned Biofunctionalized Hydrogel for Direct Nucleic Acid Hybridization Detection. Biosensors 2023, 13, 312. [Google Scholar] [CrossRef] [PubMed]

- Rogers, B.; Mikulchyk, T.; Oubaha, M.; Cody, D.; Martin, S.; Naydenova, I. Improving the Holographic Recording Characteristics of a Water-Resistant Photosensitive Sol-Gel for Use in Volume Holographic Optical Elements. Photonics 2022, 9, 636. [Google Scholar] [CrossRef]

- Bruder, F.-K.; Fäcke, T.; Rölle, T. The Chemistry and Physics of Bayfol® HX Film Holographic Photopolymer. Polymers 2017, 9, 472. [Google Scholar] [CrossRef] [PubMed]

- Sabel, T.; Orlic, S.; Pfeiffer, K.; Ostrzinski, U.; Grützner, G. Free-surface photopolymerizable recording material for volume holography. Opt. Mater. Express 2013, 3, 329–338. [Google Scholar] [CrossRef]

- Galli, P.; Evans, R.A.; Bertarelli, C.; Bianco, A. High fidelity holographic recording with cyclic allylic sulfide monomer. Proc. SPIE 2020, 11367, 123–130. [Google Scholar]

- Sabel-Grau, T.; Tyushina, A.; Babalik, C.; Lensen, M.C. UV-VIS Curable PEG Hydrogels for Biomedical Applications with Multifunctionality. Gels 2022, 8, 164. [Google Scholar] [CrossRef]

- Barachevsky, V.A. The Current Status of the Development of Light-Sensitive Media for Holography (a Review). Opt. Spectrosc. 2018, 124, 373–407. [Google Scholar] [CrossRef]

- Gumayan, E.G.; Dimzon, I.K.D.; Guerrero, R.A. Chitosan from crab shell waste for soft lithography of bioplastic diffraction gratings. Appl. Opt. 2023, 62, 2487–2492. [Google Scholar] [CrossRef] [PubMed]

- Berramdane, K.G.; Ramírez, M.; Zezza, P.; Lucío, M.I.; Bañuls, M.-J.; Maquieira, Á.; Morales-Vidal, M.; Beléndez, A.; Pascual, I. Processing of Holographic Hydrogels in Liquid Media: A Study by High-Performance Liquid Chromatography and Diffraction Efficiency. Polymers 2022, 14, 2089. [Google Scholar] [CrossRef] [PubMed]

- Pacheco, K.; Aldea-Nunzi, G.; Pawlicka, A.; Nunzi, J.-M. The Formation of Volume Transmission Gratings in Acrylamide-Based Photopolymers Using Curcumin as a Long-Wavelength Photosensitizer. Polymers 2023, 15, 1782. [Google Scholar] [CrossRef] [PubMed]

- Sheridan, J.T.; Kostuk, R.; Fimia, A.; Wang, Y. Roadmap on Holography. J. Opt. 2020, 22, 65. [Google Scholar] [CrossRef]

- Sabel, T. Volume hologram formation in SU-8 photoresist. Polymers 2017, 9, 198. [Google Scholar] [CrossRef] [PubMed]

- Yin, K.; Xiong, J.; He, Z.; Wu, S.-T. Patterning Liquid-Crystal Alignment for Ultrathin Flat Optics. ACS Omega 2020, 5, 31485–31489. [Google Scholar] [CrossRef]

- Roy, D.; Cambre, J.N.; Sumerlin, B.S. Future perspectives and recent advances in stimuli-responsive materials. Prog. Polym. Sci. 2010, 35, 278–301. [Google Scholar] [CrossRef]

- Colburn, W.S.; Haines, K.A. Volume Hologram Formation in Photopolymer Materials. Appl. Opt. 1971, 10, 1636–1641. [Google Scholar] [CrossRef]

- Gallego, S.; Fernández, R.; Márquez, A.; Ortuño, M.; Neipp, C.; Gleeson, M.R.; Sheridan, J.T.; Beléndez, A. Two diffusion photopolymer for sharp diffractive optical elements recording. Opt. Lett. 2015, 40, 3221–3224. [Google Scholar] [CrossRef]

- Sheridan, J.T.; Downey, M.; Neill, F.O. Diffusion-based model of holographic grating formation in photopolymers: Generalized non-local material responses. J. Opt. A Pure Appl. Opt. 2001, 3, 477–488. [Google Scholar] [CrossRef]

- Sabel-Grau, T.; Tyushina, A.; Rahman, R.; Babalik, C.; Zhang, Z.; Lensen, M.C. Volume Holographic Structuring of Special Hydrogel Films by Photochemical Crosslinking. In Holography; Rosen, J., Ed.; IntechOpen: Rijeka, Croatia, 2022; pp. 199–215. [Google Scholar]

- Fernández, R.; Gallego, S.; Márquez, A.; Neipp, C.; Calzado, E.M.; Francés, J.; Morales-Vidal, M.; Beléndez, A. Complex Diffractive Optical Elements Stored in Photopolymers. Polymers 2019, 11, 1920. [Google Scholar] [CrossRef] [PubMed]

- Sabel-Grau, T. Influence of Pre-Exposure on the Material Response of Epoxy-Based Volume Holographic Recording Material. Polymers 2022, 14, 2193. [Google Scholar] [CrossRef] [PubMed]

- Jeong, Y.-C.; Lee, S.; Park, J.-K. Holographic diffraction gratings with enhanced sensitivity based on epoxy-resin photopolymers. Opt. Express 2007, 15, 1497–1504. [Google Scholar] [CrossRef] [PubMed]

- Sabel, T.; Zschocher, M. Transition of refractive index contrast in course of grating growth. Sci. Rep. 2013, 3, 2552. [Google Scholar] [CrossRef]

- Liu, S.; Gleeson, M.R.; Guo, J.; Sheridan, J.T. High Intensity Response of Photopolymer Materials for Holographic Grating Formation. Macromolecules 2010, 43, 9462–9472. [Google Scholar] [CrossRef]

- Bruder, F.-K.; Fäcke, T.; Hansen, S.; Manecke, C.; Rewitz, C.; Rölle, T.; Orselli, E.; Wewer, B. On the impact of incoherent pre-exposure on vHOE recording in Bayfol HX film for see-through applications. In SPIE 10558, Practical Holography XXXII: Displays, Materials, and Applications; Bjelkhagen, H.I., Bove, V.M., Eds.; SPIE: Bellingham, WA, USA, 2018; p. 18. [Google Scholar]

- Sabel, T. Spatial Frequency Response of Epoxy-Based Volume Holographic Recording Material. Molecules 2019, 2, 1018. [Google Scholar] [CrossRef]

- Morales-Vidal, M.; Ramírez, M.; Sirvent, D.; Martínez Guardiola, F.; Álvarez, M.; Pascual, I. Efficient and stable holographic gratings stored in an environmentally friendly photopolymer. In Proceedings of the IV International Conference on Applications of Optics and Photonics, Lisbon, Portugal, 31 May–4 June 2019; p. 202. [Google Scholar]

- Sheridan, J.T.; Lawrence, J.R. Nonlocal-response diffusion model of holographic recording in photopolymer. J. Opt. Soc. Am. A 2000, 17, 1108–1114. [Google Scholar] [CrossRef]

- Sabel, T. Spatially resolved analysis of Bragg selectivity. Appl. Sci. 2015, 5, 1064–1075. [Google Scholar] [CrossRef]

- Wang, Y.; Bachman, M.; Sims, C.E.; Li, G.P.; Allbritton, N.L. Simple Photografting Method to Chemically Modify and Micropattern the Surface of SU-8 Photoresist. Langmuir 2006, 22, 2719–2725. [Google Scholar] [CrossRef]

- Curtis, K.; Psaltis, D. Recording of multiple holograms in photopolymer films. Appl. Opt. 1992, 31, 7425–7428. [Google Scholar] [CrossRef]

- Odian, G. Ring-Opening Polymerization. In Principles of Polymerization; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2004; pp. 544–618. [Google Scholar]

- Turunen, M.; Laurila, T.; Kivilahti, J. Reactive blending approach to modify spin coated epoxy film: PART II: Crosslinking kinetics. J. Appl. Polym. Sci. 2006, 101, 3689–3696. [Google Scholar] [CrossRef]

- Ramesh, N.; Duda, J.L. Diffusion in polymers below the glass transition temperature: Comparison of two approaches based on free volume concepts. Korean J. Chem. Eng. 2000, 17, 310–317. [Google Scholar] [CrossRef]

- Rabarot, M.; Bablet, J.; Ruty, M.; Kipp, M.; Chartier, I.; Dubarry, C. Thick SU-8 photolithography for BioMEMS. In Micromachining and Microfabrication Process Technology VIII; Yasaitis, J.A., Perez-Maher, M.A., Karam, J.M., Eds.; SPIE: Bellingham, WA, USA, 2003; Volume 4979, pp. 382–393. [Google Scholar]

- Moharam, M.G.; Gaylord, T.K. Rigorous coupled-wave analysis of planar-grating diffraction. J. Opt. Soc. Am. 1981, 71, 811–818. [Google Scholar] [CrossRef]

- Sakhno, O.V.; Goldenberg, L.M.; Smirnova, T.M.; Stumpe, J. Holographic patterning of organic-inorganic photopolymerizable nanocomposites. In Optical Materials in Defence Systems Technology; SPIE: Bellingham, WA, USA, 2009; Volume 7487. [Google Scholar]

- Piazzolla, S.; Jenkins, B.K. Holographic grating formation in photopolymers. Opt. Lett. 1996, 21, 1075–1077. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sabel-Grau, T. The Interplay of Processing-Related Influences on the Formation of Volume Holographic Gratings in a Free-Surface Epoxy-Based Recording Material. Macromol 2023, 3, 211-223. https://doi.org/10.3390/macromol3020013

Sabel-Grau T. The Interplay of Processing-Related Influences on the Formation of Volume Holographic Gratings in a Free-Surface Epoxy-Based Recording Material. Macromol. 2023; 3(2):211-223. https://doi.org/10.3390/macromol3020013

Chicago/Turabian StyleSabel-Grau, Tina. 2023. "The Interplay of Processing-Related Influences on the Formation of Volume Holographic Gratings in a Free-Surface Epoxy-Based Recording Material" Macromol 3, no. 2: 211-223. https://doi.org/10.3390/macromol3020013

APA StyleSabel-Grau, T. (2023). The Interplay of Processing-Related Influences on the Formation of Volume Holographic Gratings in a Free-Surface Epoxy-Based Recording Material. Macromol, 3(2), 211-223. https://doi.org/10.3390/macromol3020013