A Statistically Based Methodology to Estimate the Probability of Encountering Rock Blocks When Tunneling in Heterogeneous Ground

Abstract

:1. Introduction

2. The PBE Code

3. Application Example

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jee, W.W.; Ha, S.G. Feasible Boulder treatment methods for soft ground shielded TBM. In Underground Space—The 4th Dimension of Metropolises; Taylor & Francis Group: Abingdon, UK, 2007; pp. 217–222. [Google Scholar]

- Hunt, S.W. Tunneling in Cobbles and Boulders. In Proceedings of the Breakthroughs in Tunneling Short Course, Chicago, IL, USA, 14–16 August 2017; pp. 1–46. [Google Scholar]

- Dong, W.; Pimentel, E.; Anagnostou, G. Experimental Investigations into the Mechanical Behaviour of the Breccias around the Proposed Gibraltar Strait Tunnel. Rock Mech. Rock Eng. 2013, 46, 923–944. [Google Scholar] [CrossRef] [Green Version]

- Marinos, V. Tunnel behaviour and support associated with the weak rock masses of flysch. J. Rock Mech. Geotech. Eng. 2014, 6, 227–239. [Google Scholar] [CrossRef] [Green Version]

- Montoya-Araque, E.A.; Suarez-Burgoa, L.O. Automatic generation of tortuous failure surfaces in block-in-matrix materials for 2D slope stability assessments. Comput. Geotech. 2019, 112, 17–22. [Google Scholar] [CrossRef]

- Sonmez, H.; Ercanoglu, M.; Kalender, A.; Dagdelenler, G.; Tunusluoglu, C. Predicting uniaxial compressive strength and deformation modulus of volcanic bimrock considering engineering dimension. Int. J. Rock Mech. Min. Sci. 2016, 86, 91–103. [Google Scholar] [CrossRef]

- Kalender, A.; Sonmez, H.; Medley, E.; Tunusluoglu, C.; Kasapoglu, K. An approach to predicting the overall strengths of unwelded bimrocks and bimsoils. Eng. Geol. 2014, 183, 65–79. [Google Scholar] [CrossRef]

- Xu, Y.; Cai, M. Numerical study on the influence of cross-sectional shape on strength and deformation behaviors of rocks under uniaxial compression. Comput. Geotech. 2017, 84, 129–137. [Google Scholar] [CrossRef]

- Coli, N.; Tanzini, M. Characterization of the “Chaotic Complex” (Northern Apennines, Italy). In Rock Mechanics for Resources, Energy and Environment; Taylor & Francis Group: London, UK, 2013; pp. 111–116. [Google Scholar]

- Napoli, M.L.; Barbero, M.; Scavia, C. Effects of block shape and inclination on the stability of melange bimrocks. Bull. Eng. Geol. Environ. 2021, 80, 7457–7466. [Google Scholar] [CrossRef]

- Napoli, M.L.; Barbero, M.; Scavia, C. Slope stability in heterogeneous rock masses with a block-in-matrix fabric. In Proceedings of the ISRM 2019, Foz do Iguassu, Brazil, 13–18 September 2019; pp. 3482–3489. [Google Scholar]

- Kanji, M.A. Critical issues in soft rocks. J. Rock Mech. Geotech. Eng. 2014, 6, 186–195. [Google Scholar] [CrossRef] [Green Version]

- Hunt, S.W.; Del Nero, D.E. Two Decades of Advances Investigating, Baselining and Tunneling in Bouldery Ground. In Proceedings of the World Tunneling Congress, Vancouver, BC, Canada; 2010; pp. 1–8. [Google Scholar]

- Tarkoy, P.J. The boulder facts of life. In Proceedings of the World Tunneling Congress, Agra, India, 22–24 September 2008; pp. 25–28. [Google Scholar]

- Medley, E.W. Bimrocks—Part 2: Case histories and Practical Guidelines. Newsl. Hell. Soc. Soil Mech. Geotech. Eng. 2007, 8, 26–31. [Google Scholar]

- Barla, G.; Pelizza, S. TBM tunnelling in difficult ground conditions. In Proceedings of the GeoEng 2000, International Conference on Geotechnical & Geological Engineering, Melbourne, Australia, 19–24 November 2000. [Google Scholar]

- DiPonio, M.A.; Chapman, D.; Bournes, C. EPB tunnel boring machine design for boulder conditions. In Proceedings of the Rapid Excavation and Tunneling Conference, Toronto, ON, Canada, 11 June 2007; pp. 215–228. [Google Scholar]

- Gwildis, U.; Aguilar, J.; Mosavat, K. TBM Tool Wear Analysis for Cutterhead Configuration and Resource Planning in Glacial Geology. In Proceedings of the North American Tunneling Conference, Washington, DC, USA, 24–27 June 2018. [Google Scholar]

- Moritz, B.; Grossauer, K.; Schubert, W. Short term prediction of system behaviour of shallow tunnels in heterogeneous ground. Felsbau 2004, 22, 44–52. [Google Scholar]

- Button, E.A.; Riedmueller, G. Shallow Tunneling in a Tectonic Mélange: Rock Mass Characterization and Data Interpretation. In Proceedings of the 5th North American Rock Mechanics Symposium, Toronto, ON, Canada, 7–10 July 2002; pp. 1125–1132. [Google Scholar]

- Li, C.; Zhang, D.; Du, S.-S.; Shi, B. Computed tomography based numerical simulation for triaxial test of soil–rock mixture. Comput. Geotech. 2016, 73, 179–188. [Google Scholar] [CrossRef]

- Hunt, S.W. Managing Risk of Tunneling in Cobbly, Bouldery Ground. In Proceedings of the TAC 2014: Tunnelling in a Resource Driven World, Vancouver, BC, Canada, 26–28 October 2014. [Google Scholar]

- Napoli, M.L.; Barbero, M.; Scavia, C. Tunneling in heterogeneous rock masses with a block-in-matrix fabric. Int. J. Rock Mech. Min. Sci. 2021, 138, 104655. [Google Scholar] [CrossRef]

- Frank, G.; Chapman, D.R. A new model for characterizing the cobble and boulder fraction for soft ground tunneling. In Proceedings of the Rapid Excavation and Tunneling Conference, Seattle, WA, USA, 27–29 June 2005; pp. 780–791. [Google Scholar]

- Goss, C.M. Predicting boulder cutting in soft ground tunneling. In North American Tunneling; Ozdemir, L., Ed.; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Nagahama, H. Technical note fractal fragment size distribution for brittle rocks. Int. J. Rock Mech. Geomech. 1993, 30, 469–471. [Google Scholar] [CrossRef]

- Riedmüller, G.; Brosch, F.J.; Klima, K.; Medley, E.W. Engineering Geological Characterization of Brittle Faults and. Felsbau 2001, 19, 13–19. [Google Scholar]

- Medley, E.W. The Engineering Characterization of Melanges and Similar Block-in-Matrix Rocks (Bimrocks). Ph.D. Thesis, University of California, Berkeley, CA, USA, 1994. [Google Scholar]

- Medley, E.W. Uncertainty in estimates of block volumetric proportions in melange bimrocks. In Proceedings of the International Symposium on Engineering Geology and the Environment, Athens, Greece, 23 June 1997; pp. 267–272. [Google Scholar]

- Napoli, M.L.; Milan, L.; Barbero, M.; Scavia, C. Identifying uncertainty in estimates of bimrocks volumetric proportions from 2D measurements. Eng. Geol. 2020, 278, 105831. [Google Scholar] [CrossRef]

- Napoli, M.L.; Barbero, M.; Ravera, E.; Scavia, C. A stochastic approach to slope stability analysis in bimrocks. Int. J. Rock Mech. Min. Sci. 2018, 101, 41–49. [Google Scholar] [CrossRef]

- Barbero, M.; Bonini, M.; Borri-Brunetto, M. Three-Dimensional Finite Element Simulations of Compression Tests on Bimrock. In Proceedings of the 12th International Conference of International Association for Computer Methods and Advances in Geomechanics (IACMAG), Goa, India, 1–6 October 2008; pp. 631–637. [Google Scholar]

- Wakabayashi, J.; Medley, E.D.; Wilcox, G.; Risden, C. Tunnels through Fault Rocks and Tectonic Melanges: A Short Course for Engineering Geologists and Geotechnical Engineers; Association of Engineering Geologist: San Francisco, CA, USA, 2002. [Google Scholar]

- Medley, E.W. Orderly Characterization of Chaotic Franciscan Melanges. Felsbau 2001, 19, 20–33. [Google Scholar]

| Parameter | Variable | Assigned Value | |

|---|---|---|---|

| Length of the control area | [m] | B | 32.5 |

| Height of the control area | [m] | H | 32.5 |

| Tunnel radius | [m] | R_t | 3.25 |

| Circular crown thickness | [m] | R_ext | 0.8 |

| Tunnel x–y coordinates | [m] | coord_t | B/2 =16.25 H/2 =16.25 |

| Threshold area class 1 (equivalent diameter of 0.15 m) | [m2] | A_thr1 | 0.0177 |

| Threshold area class 2 (equivalent diameter of 0.3 m) | [m2] | A_thr2 | 0.0707 |

| Threshold area class 3 (equivalent diameter of 0.5 m) | [m2] | A_thr3 | 0.1963 |

| Threshold area class 4 (equivalent diameter of 0.75 m) | [m2] | A_thr4 | 0.4418 |

| Threshold area class 5 (equivalent diameter of 1 m) | [m2] | A_thr5 | 0.7854 |

| Threshold area class 6 (equivalent diameter of 1.5 m) | [m2] | A_thr6 | 1.7663 |

| Block content | [-] | BC | 0.02 |

| Minimum expected clast dimension | [m] | a | 0.075 |

| Maximum expected clast dimension | [m] | b | 3 |

| Fractal dimension | [-] | D | −1.75 |

| Number of configurations to generate | [-] | z | 500 |

| TUNNEL Equivalent clast diameter [m] | P0 blocks [%] | P1 blocks [%] | P2 blocks [%] | P3 blocks [%] | P4 blocks [%] | P5 blocks [%] | P6 blocks [%] | P≥7 blocks [%] | Average number of blocks |

| 0.15–0.30 | 49.4 | 31.4 | 13.8 | 4.4 | 0.8 | 0 | 0.2 | 0 | 0.77 |

| 0.30–0.50 | 67.4 | 27.8 | 4.0 | 0.6 | 0.2 | 0 | 0 | 0 | 0.38 |

| 0.50–0.75 | 79.0 | 19.4 | 1.4 | 0.2 | 0 | 0 | 0 | 0 | 0.23 |

| 0.75–1.0 | 86.6 | 13.0 | 0.2 | 0.2 | 0 | 0 | 0 | 0 | 0.14 |

| 1.0–1.5 | 84.4 | 15.4 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0.16 |

| >1.5 | 90.8 | 8.2 | 1 | 0 | 0 | 0 | 0 | 0 | 0.10 |

| CIRCULAR CROWN Equivalent clast diameter [m] | P0 blocks [%] | P1 blocks [%] | P2 blocks [%] | P3 blocks [%] | P4 blocks [%] | P5 blocks [%] | P6 blocks [%] | P≥7 blocks [%] | Average number of blocks |

| 0.15–0.30 | 65.4 | 27.8 | 5.8 | 0.8 | 0.2 | 0 | 0 | 0 | 0.43 |

| 0.30–0.50 | 77.6 | 20.4 | 2.0 | 0 | 0 | 0 | 0 | 0 | 0.24 |

| 0.50–0.75 | 87.4 | 12.0 | 0.6 | 0 | 0 | 0 | 0 | 0 | 0.13 |

| 0.75–1.0 | 93.6 | 6.4 | 0 | 0 | 0 | 0 | 0 | 0 | 0.06 |

| 1.0–1.5 | 86.6 | 13.0 | 0.4 | 0 | 0 | 0 | 0 | 0 | 0.14 |

| >1.5 | 97.6 | 2.4 | 0 | 0 | 0 | 0 | 0 | 0 | 0.02 |

| Parameter | Output File Name | |

|---|---|---|

| Total number of intersecting blocks | [-] | Total_IB * |

| Total intersection area | [m2] | A_int * |

| Total number of intersecting blocks greater than the threshold value, A_thr1 | [-] | N_crit_IB * |

| Intersection area of all the blocks greater than the threshold value | [m2] | A_int_cr * |

| Probability of finding n intersecting blocks greater than the threshold value during the excavation | [%] | Probability * (Table 2) |

| Average number of intersecting blocks greater than the threshold value during the excavation | [-] | N_Average * (Table 2) |

| Graphical representation of the cumulative distribution function F(d)-d | [-] | CDF |

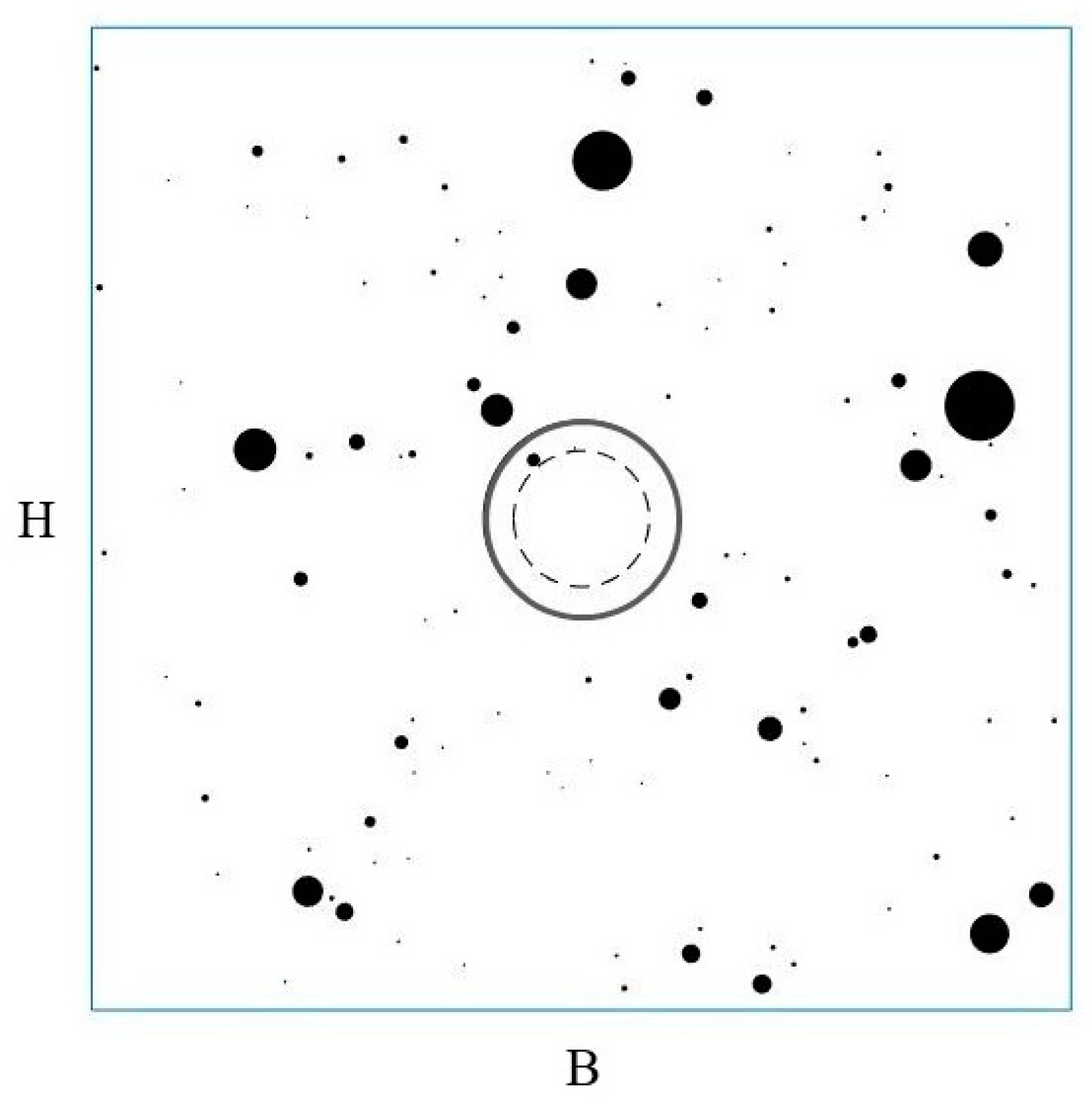

| Graphical representation of the configurations generated | [-] | Configuration 1 up to z (Figure 5) |

| List of input variables and values assigned | [-] | Info_viewer |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Napoli, M.L.; Barbero, M.; Fontana, R. A Statistically Based Methodology to Estimate the Probability of Encountering Rock Blocks When Tunneling in Heterogeneous Ground. Mining 2021, 1, 241-250. https://doi.org/10.3390/mining1030016

Napoli ML, Barbero M, Fontana R. A Statistically Based Methodology to Estimate the Probability of Encountering Rock Blocks When Tunneling in Heterogeneous Ground. Mining. 2021; 1(3):241-250. https://doi.org/10.3390/mining1030016

Chicago/Turabian StyleNapoli, Maria Lia, Monica Barbero, and Roberto Fontana. 2021. "A Statistically Based Methodology to Estimate the Probability of Encountering Rock Blocks When Tunneling in Heterogeneous Ground" Mining 1, no. 3: 241-250. https://doi.org/10.3390/mining1030016