3.1.1. The Impact of Differences in Dump Height

One of the important factors influencing the stability of internal waste dumps is dump elevation. The height of the internal waste dump in Baganuur coal mine was considered to be between 30 m and 45 m. This study determined the influence of the stability of the internal dump at heights of 30 m, 35 m, 40 m, and 45 m using Rocscience Phase2 and Slide.

When the height of the internal dump is set at 30 m, the FEM SRF is 0.86, the Bishop method SRF = 0.749, the Janbu simplified method SRF = 0.737, and the Spencer simplified method SRF = 0.745. Maximum shear strength is observed at the peak and shear strength increases at the top of the internal dump. Furthermore, shear strength comes from the top to toe area.

When the height is increased to 35 m, the FEM SRF = 0.77, the Bishop method SRF = 0.653, the Janbu simplified method SRF = 0.640, and the Spencer simplified method SRF = 0.648. The maximum shear strength of the peak increased, and the dump displacement increased. The shear strength of the toe area of the internal dump increased towards the center section.

In the numerical models, after a further 5 m increase in the dump height to 40 m, the FEM SRF = 0.65, the Bishop method SRF = 0.587, the Janbu simplified method SRF = 0.576, and the Spencer simplified method SRF = 0.581. The maximum shear strength of the peak increased, and the dump displacement increased. The shear strength of the toe area of the internal dump increased towards the center section.

Table 3 shows the measure of the internal waste dump height with 5m differences.

The peak of the 45 m internal waste dump (

Figure 4) was close to that of the 40 m internal waste dump. The shear strength of the toe area increased and the FEM SRF = 0.65, the Bishop method SRF = 0.587, the Janbu simplified method SRF = 0.576, and the Spencer simplified method SRF = 0.581. Therefore, the internal dump does not meet the stability requirements.

3.1.2. The Impact of Differences in the Dip Angle of the Dump

A failed dump slope with an initial height of 35 m and a 38° slope angle was simulated using the determined strength parameters. The average height of the “Baganuur” coal mine internal waste dump is 35 m. Therefore, the purpose of this numerical model was to determine the influence of an appropriate difference in dump dip parameters at a dip angle of 5°. The FEM and LEM were used to test dip angles between 28° and 48°.

At a dump dip angle of 28° and height of 35 m (

Figure 5), there was a slight displacement at the top of the internal dump and no strong shear strength at the peak area. The numerical model results all show SRF values over 1, i.e., the FEM SRF = 1.18, the Bishop method SRF = 1.066, the Janbu simplified method SRF = 1.057, and the Spencer simplified method SRF = 1.063. This means that this dip angle is safe in terms of slope stability.

At a dump dip angle of 33° and height of 35 m, there is slight displacement at the top of the internal dump and strong maximum shear strength at the peak area. The FEM SRF = 0.96, the Bishop method SRF = 0.88, the Janbu simplified method SRF = 0.871, and the Spencer simplified method SRF = 0.877; these are all close to SRF 1. However, this does not mean that this is a safe dump dip angle.

When a displacement of 43° is simulated, the FEM SRF = 0.62, the Bishop method SRF = 0.549, the Janbu simplified method SRF = 0.538, and the Spencer simplified method SRF = 0.543; these are all below the critical SRF value of 1 at a height of 35 m.

In the last numerical model, simulating a 48° dump dip and 35 m height, there is too much displacement at the top of the dump to toe area and strong maximum shear strength at the peak area. The results of the numerical model show that the FEM SRF = 0.50, the Bishop method SRF = 0.438, the Janbu simplified method SRF = 0.427, and the Spencer simplified method SRF = 0.434. These results are far from the SRF value of 1 and show that the waste dump will continue to slide down.

Table 4 shows the measure of the internal waste dump dip angle with 5° differences.

3.1.3. Design of the Internal Dump

The design of the internal dump should be safe and economical. The primary aim of creating an internal dump is to provide effective and stable working conditions for mining and to facilitate proper handling of the overburden. The design of an overburden dump prevents accidents and is environmentally friendly.

Maintaining the stability of an internal dump slope has several benefits. It has a significant impact on the future stability of the mine, the safety of the equipment, the safety of the workers, and the economy. Therefore, it is important to determine and test the correct parameters based on the physio-mechanical data of the “Baganuur” lignite coal mine internal rock dump due to the instability and landslides occurring in this mine.

In the “Baganuur” open cast coal mine, the average computed waste dump dip angle is 38°. Based on the numerical data provided earlier, the critical SRF was under 1 and the impacts of displacement and shear stress were considered. However, in this numerical model, we considered the impact of changes in dump height with the safe angle of 28° obtained through the numerical models. The dump heights that had the strongest influence on the slope stability at the internal dip angle were selected for subsequent numerical models. Studying the effects of changes in dump height by using the computed dip angle of the current waste dump is of practical and theoretical importance. This section was tested with a dump dip angle of 28° and by changing the dump height by 5 m between 30 m and 50 m.

Figure 6 shows a deformation vector in the direction of the slide obtained after using the slide situation tool in the Rocscience Phase2 software. The simulation considered a height of 35 m and a dip of 26°. The face of the internal dump exhibited a slight displacement. The critical SRFs obtained show that the slope is stable: the FEM SRF = 1.21, the Bishop method SRF = 1.118, the Janbu simplified method SRF = 1.092, and the Spencer simplified method SRF = 1.113.

The dump height was increased by 10 m to 40 m in the numerical models. The reason for this is that we already tested the dump parameters of 28° dip angle and 35 m dump height in a previous numerical model. The displacement from the peak of the internal dump and the peak shear stress slightly increased. The simulation results were as follows: the critical FEM SRF = 1.13, the Bishop method SRF = 1.062, the Janbu simplified method SRF = 1.052, and the Spencer simplified method SRF = 1.059. This means that it is possible to increase both the safety and capacity of the dump. The results from the four different methods show that the waste dump is stable at a height of 40 m and dip angle of 28°.

When the dump height increased by another 5 m to 45 m, the peak shear stress increased. In addition, the displacement increased from the peak to the toe. The critical FEM SRF = 1.09, the Bishop method SRF = 0.975, the Janbu simplified method SRF = 0.963, and the Spencer simplified method SRF = 0.969. Here, the slope stability decreased, and the result of the Bishop method is over SRF 1, but the other three methods, Bishop, Janbu, and Spencer, are under SRF 1. The results of these last three methods show that the internal dumps would slide.

At a height of 50 m (

Figure 7), the maximum shear stress reached the peak area, and the same displacement increased from the peak, at the center area, and at the toe. The results were similar to those of the previous numerical model, where the dump height was 45 m. The FEM SRF = 1.065, the Bishop method SRF = 0.926, the Janbu simplified method SRF = 0.915, and the Spencer simplified method SRF = 0.920. Slope stability decreased, and the Bishop method obtained an SRF value over 1, but the other three methods, Bishop, Janbu, and Spencer, all obtained SRF values under 1. The results of the last three methods show that it is possible that the internal dump will slide.

The numerical simulation results showed a slight shear stress in the toe area. According to the FEM results, the internal dip is stable when the dump height is 50 m. However, based on the Bishop, Janbu, and Spencer methods, dump heights over 45 m and 50 m are unstable.

The factor of safety (FS) for each numerical method, with a dump angle of 28° (DA28°) and a 5 m increment in dump height from DH 30 m to DH 50 m, is summarized in

Table 5.

The safety berm in an internal dump is the most important part of estimating the operational plan. In this study, the impact of safety berms of widths between 0 m (without a safety berm) and 15 m on the internal dump site was studied. In the “Baganuur” coal mine, the current average safety berm is 5 m wide.

Without a safety berm, using the internal dump parameters of 28° dip angle and 45 m height, the FEM SRF = 1.05, the Bishop method SRF = 0.941, the Janbu simplified method SRF = 0.927, and the Spencer simplified method SRF = 0.935.

With a 10 m safety berm, when the internal dump parameters were 28° dip angle and 45 m height, the FEM SRF = 1.12, the Bishop method SRF = 1.038, the Janbu simplified method SRF = 1.025, and the Spencer simplified method SRF = 1.031. The numerical model results show an SRF value greater than 1, showing that this is safe.

Figure 8 shows that using a 15 m safety berm improves the capacity and stability of the internal dump. The FEM SRF = 1.15, the Bishop method SRF = 1.068, the Janbu simplified method SRF = 1.054, and the Spencer simplified method SRF = 1.061. The numerical model results all show an SRF value over 1, showing that this is safe.

The factor of safety (FS) for each numerical method, with a dump angle of 28° (DA28°), a dump height of 45 m, and a safety berm width from 0 m to 15 m, is summarized in

Table 6.

Without a safety berm, with the internal dump parameters of 28° dip angle and 45 m height, the FEM SRF = 1.03, the Bishop method SRF = 0.958, the Janbu simplified method SRF = 0.945, and the Spencer simplified method SRF = 0.952. The peak of the internal dump shear stress increased. However, the results of the FEM showed that it was still stable.

When a 10 m width safety berm was simulated with the internal dump parameters of 28° dip angle and 45 m height, the FEM SRF = 1.09, the Bishop method SRF = 0.984, the Janbu simplified method SRF = 0.973, and the Spencer simplified method SRF = 0.980. The results are similar to those obtained without a safety berm at a height of 50 m.

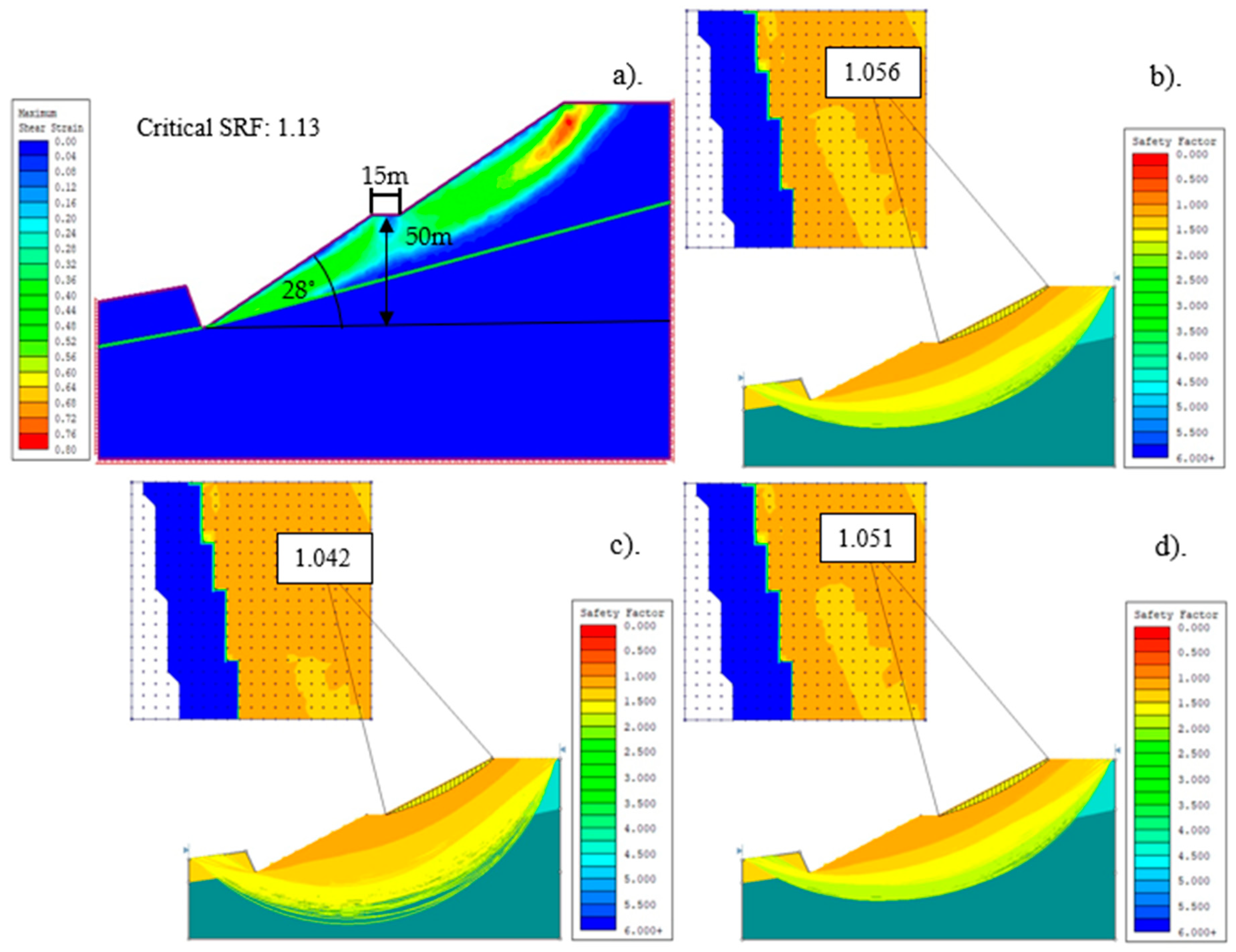

The last numerical model results show that the SRF value of the four different methods is over 1, which means that it is possible to stabilize and increase the parameters of the internal dump. The results (

Figure 9) were as follows: FEM SRF = 1.13, Bishop method SRF = 1.056, Janbu simplified method SRF = 1.042, and Spencer simplified method SRF = 1.051.

The factor of safety (FS) for each numerical method with a dump angle of 28° (DA28°), a dump height of 50 m, and a safety berm from 0 m to 15 m is summarized in

Table 7.