Natural and Synthetic Polymer Fillers for Applications in 3D Printing—FDM Technology Area

Abstract

:1. Short Introduction about 3D Printing by FDM/FFF Technique and Role of Fillers

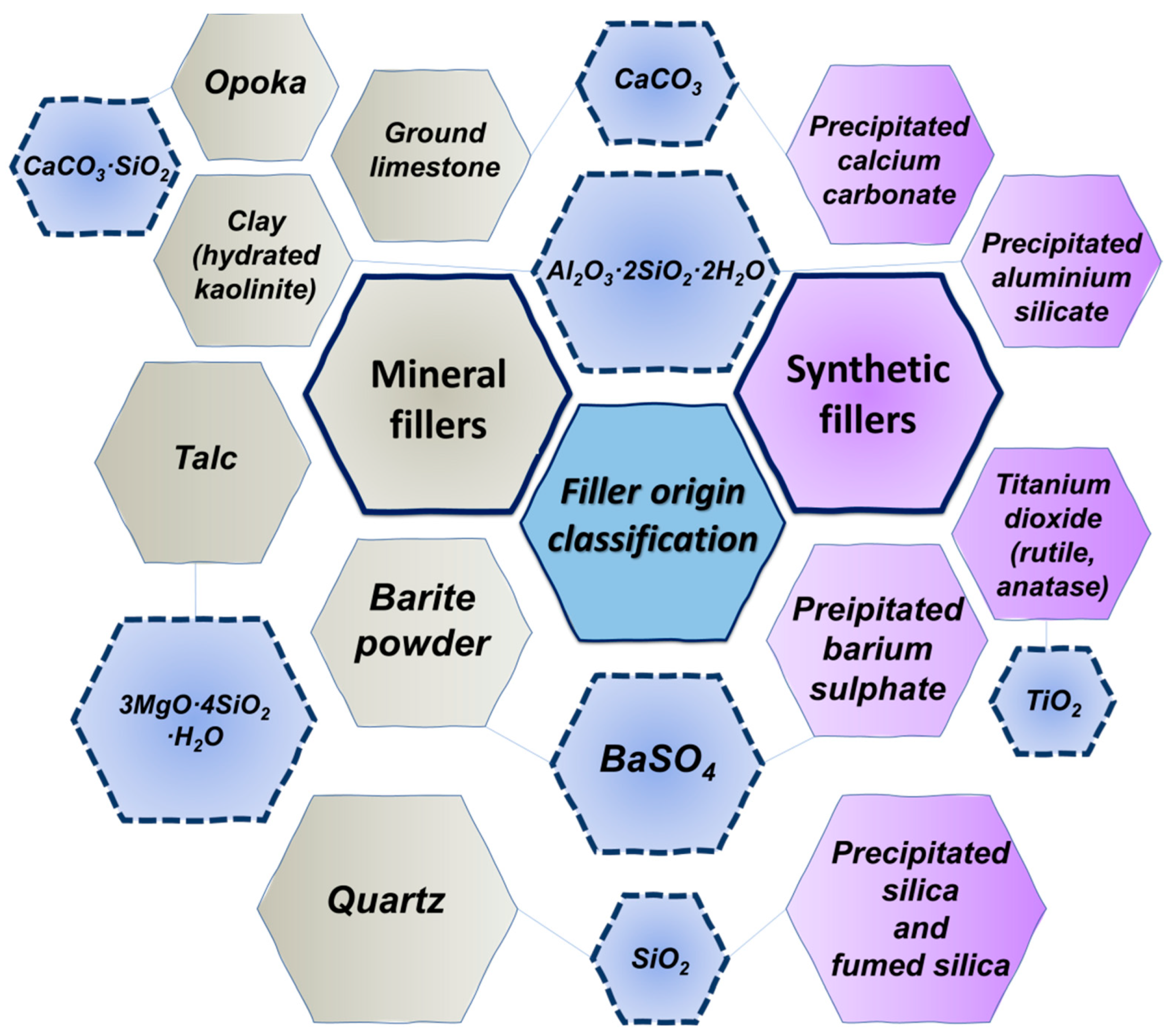

2. Classification of the Fillers

- -

- Origin;

- -

- Chemical composition;

- -

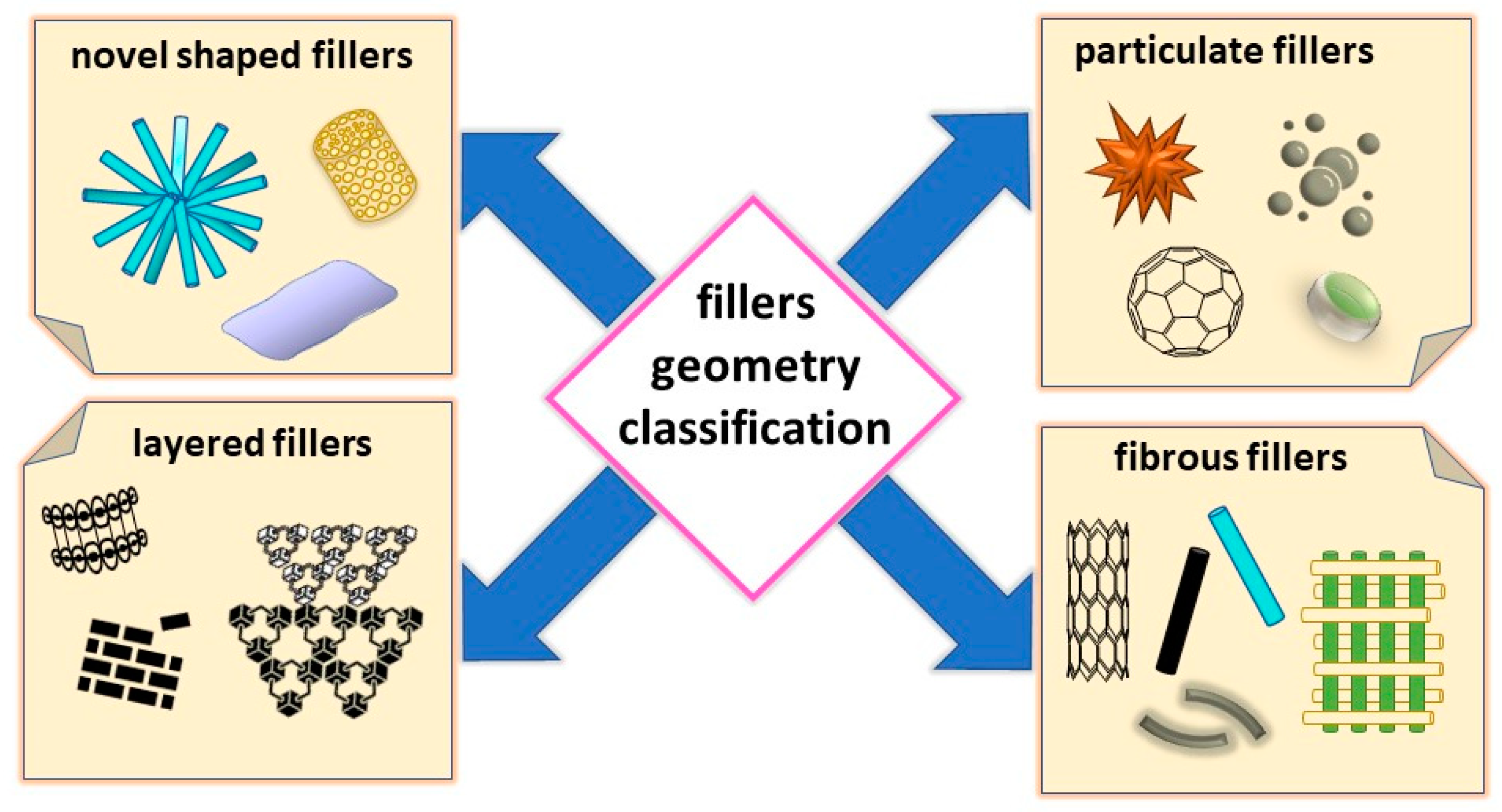

- Shape;

- -

- Size and aspect ratio;

- -

- The effects they exert on the matrix material (intended function) or their price relative to the matrix polymer.

- -

- Particulate: spherical, cubical, and others of AR ≈1 (calcite, spherical silica);

- -

- Blocks of AR up to ≈4 (barite);

- -

- Plates of AR 4–30 (kaolin, talc);

- -

- Flakes of AR 50–200 (aluminium, mica, graphite, montmorillonite);

- -

- -

- Fibres, nanotubes, nanowires, nanorods, nanowhiskers; AR of 20–1000+ (glass fibres, basalt fibres, carbon nanotubes Ag nanowires, TiO2 nanorods, cellulose nanowhiskers) [35];

- -

- Other, complex shapes, including porous and mesoporous powders, urchin-like hydroxyapatite powder, nanocluster powders, tetrapod-like whiskers, core-sheath fibres, or microcapsules [36].

- -

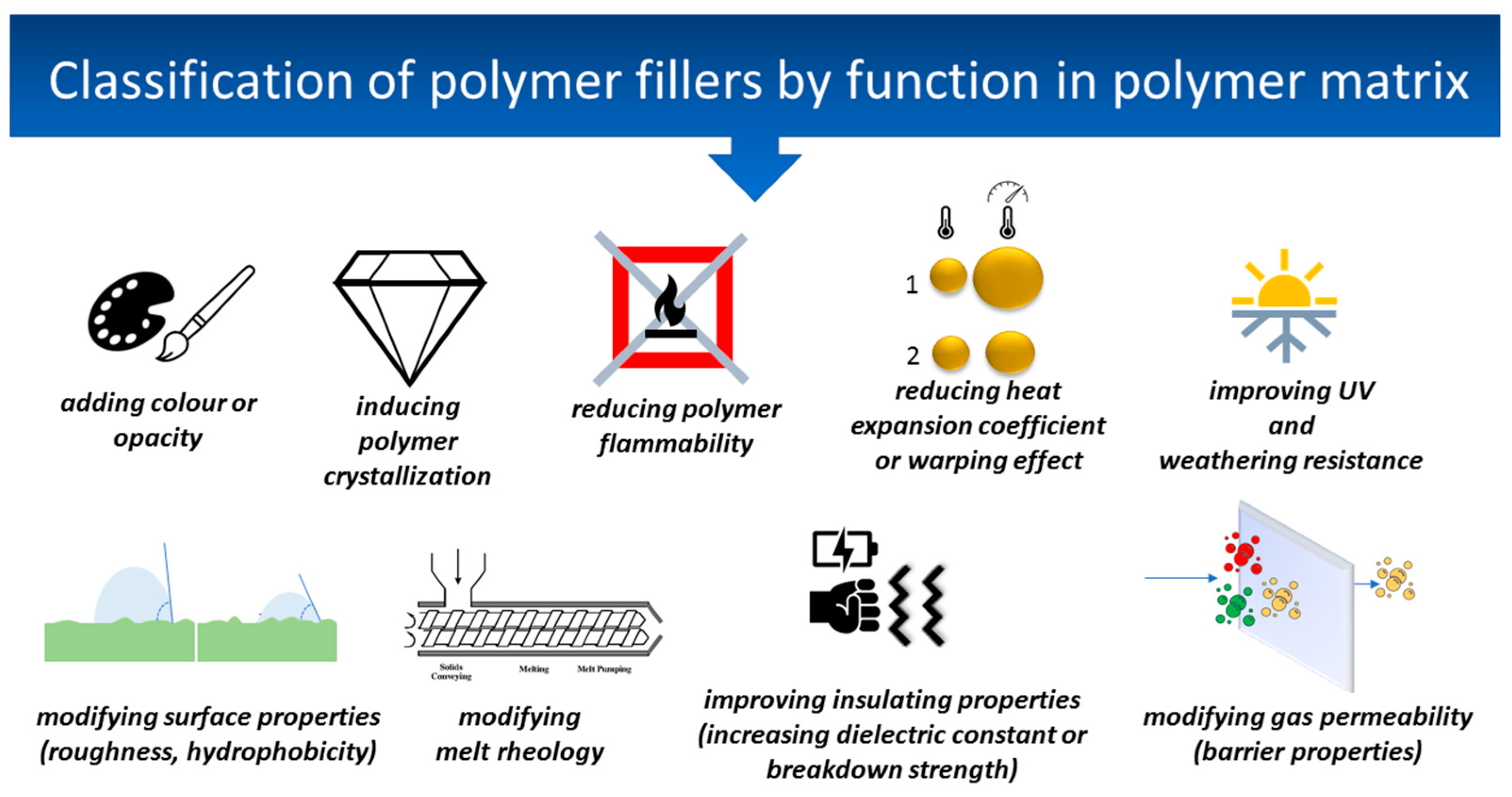

- Mechanical reinforcement of the polymer matrix (increasing Young’s modulus, tensile strength, toughness, impact resistance, abrasion resistance, hardness);

- -

- Improving thermal and thermomechanical behaviour (increasing glass transition temperature and heat deflection/softening temperature, storage modulus or damping factor, reducing thermal conductivity);

- -

- Reducing heat expansion coefficient or warping effect;

- -

- Improving insulating properties (increasing breakdown strength or modifying dielectric constant), or conductive properties (conductive fillers);

- -

- Modifying gas permeability/barrier properties;

- -

- Inducing polymer crystallisation;

- -

- Reducing polymer flammability;

- -

- Modifying melt rheology;

- -

- Modifying surface properties (roughness, hydrophobicity);

- -

- Improving UV and weathering resistance;

- -

- Adding colour or opacity.

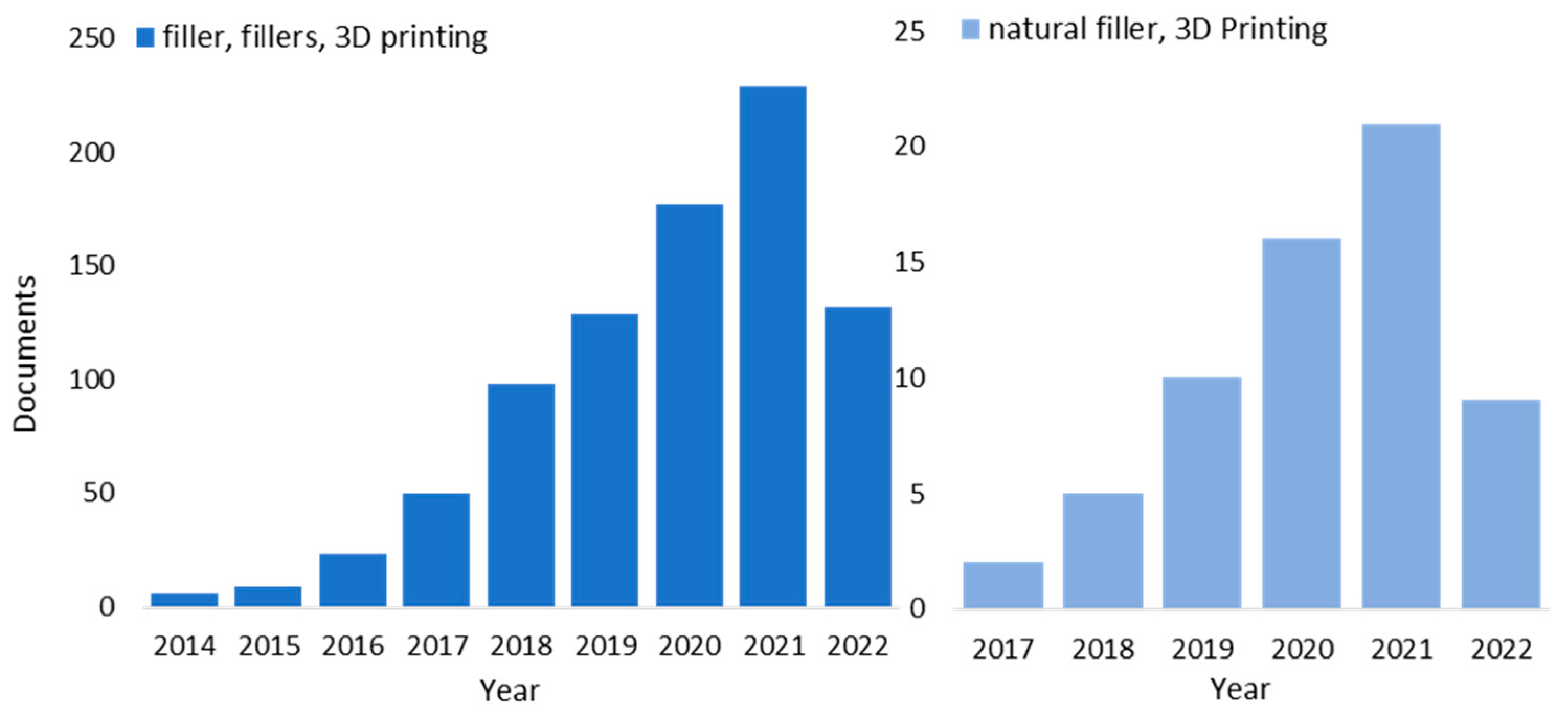

3. Statistical Presentation of the Application of Fillers in Materials for 3D Printing Based on the SCOPUS Database

4. Mineral and Natural Fillers in 3D Printing Thermoplastics

4.1. Diatoms

4.2. Calcite

4.3. Natural Fibres

4.3.1. General Considerations

4.3.2. PLA-Based Composites

4.3.3. Other Polymer Matrices Reinforced with Natural Fibres

4.4. Other Natural Fillers

5. Synthetic Fillers in 3D Printing of Thermoplastics

5.1. TiO2

5.2. Glass Fibres

5.3. Carbon Fibres

5.3.1. General Considerations

5.3.2. PLA-Based Composites

5.3.3. ABS-Based Composites

5.3.4. Polyamide-Based Composites

5.3.5. PETG-Based Composites

5.3.6. PEEK-Based Composites

5.3.7. Continuous CF-Reinforced Systems

5.4. Basalt Fibres

5.5. Nanosilica (Aerosil, etc.)

5.6. Carbon Materials-Graphene, Graphite, Soot

5.7. Other Fillers

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ABS | Acrylonitrile–butadiene–styrene terpolymer |

| AM | Additive Manufacturing |

| APTES | 3-aminopropyltriethoxysilane |

| AR | Aspect ratio |

| BF | Basalt fibres |

| CAGR | Cumulative annual growth rate |

| CB | Carbon black |

| cFF | Continuous flax fibres |

| CLTE | Coefficient of thermal expansion |

| CNFRB | Continuous natural fibre-reinforced biocomposites |

| CNT | Carbon nanotubes |

| COP | Cyclo-olefin polymer |

| CPC | Cork polymer composites |

| DMA | Dynamic Mechanical Analysis |

| DMTA | Dynamic Mechanical Thermal Analysis |

| DSC | Differential Scanning Calorimetry |

| EDX | Energy-dispersive X-ray spectroscopy |

| EMI | Electromagnetic interference |

| EPDM-g-MAH | Ethylene-propylene-diene monomers polymer grafted with maleic anhydride |

| EVA | Ethylene-vinyl acetate copolymer |

| FDM | Fused Deposition Modelling |

| FF | Flax fibres |

| FFF | Fused Filament Fabrication |

| FRP | Fibre-reinforced plastic |

| FT-IR | Fourier-Transform Infrared |

| FTO | Fluorine-doped tin oxide |

| GF | Glass fibres |

| GNP | Graphene nanoplatelet |

| GO | Graphene oxide |

| HA | Hydroxyapatite |

| HBC | Hygromorph biocomposite |

| HDPE | High-density polyethylene |

| HDPE-g-MA | High-density polyethylene grafted with maleic anhydride |

| ITO | Indium-doped tin oxide |

| LDPE | Low-density polyethylene |

| LLDPE | Linear low density polyethylene |

| MAPLA | Maleic anhydride-grafted PLA |

| MAPP | Maleic acid-grafted polypropylene |

| MATMOS | 3-methacryloxypropyltrimethoxysilane |

| MFI | Melt-flow index |

| MWCNT | Multi-wall carbon nanotubes |

| NFRP | Natural fibre-reinforced plastics |

| PA12 | Polyamide 12 |

| PA6 | Polyamide 6 |

| Pac | Polyamide copolymer |

| PAH | Polycyclic aromatic hydrocarbon |

| PAN | Polyacrylonitrile |

| PBAT | Poly(butylene adipate terephthalate) |

| PBS | Poly(butylene succinate) |

| PBSA | Poly(butylene succinate adipate) |

| PBT | Poly(butylene terephthalate) |

| PC | Polycarbonate |

| PCL | Polycaprolactone |

| PEEK | Polyetheretherketone |

| PEG | Poly(ethylene glycol) |

| PEI | Polyethyleneimine |

| PET | Poly(ethylene terephthalate) |

| PETG | Poly(ethylene terephthalate) modified with cyclohexyl-1,4-dimethanol |

| PLA | Poly(lactic acid) |

| PLGA | Poly(lactic-co-glycolic acid) |

| PMMA | Poly(methyl methacrylate) |

| POE-g-MA | Polyolefin grafted with maleic anhydride |

| PP | Polypropylene |

| PDLGA | poly(D,L-lactic-co-glycolic acid) |

| PTC | Positive temperature coefficient |

| PVA | Poly(vinyl alcohol) |

| PVDF | Poly(vinylidene difluoride) |

| PVPA | Poly(vinylphosphonic acid) |

| rABS | Recycled ABS |

| rPP | Recycled polypropylene |

| rPS | Recycled polystyrene |

| RT | Room temperature |

| SCP | Saturated calomel electrode |

| SEM | Scanning Electon Microscopy |

| SPDR | Split post dielectric resonator |

| SWCNT | Single-wall carbon nanotubes |

| Tg | Glass transition temperature |

| TG | Thermogravimetry |

| TLCP | Thermoplastic liquid crystalline polymer |

| Tmax | Temperature of maximal rate of mass loss from TG |

| TPU | Thermoplastic polyurethane |

| TPU | Thermoplastic polyurethane |

| XRD | X-ray Diffractometry |

References

- Hull, C. Apparatus for Production of Three-Dimensional Object by Stereolithography. U.S. Patent 4,575,330, 11 March 1986. [Google Scholar]

- Nguyen, N.A.; Bowland, C.C.; Naskar, A.K. A general method to improve 3D-printability and inter-layer adhesion in lignin-based composites. Appl. Mater. Today 2018, 12, 138–152. [Google Scholar] [CrossRef]

- Vaidya, A.A.; Collet, C.; Gaugler, M.; Lloyd-Jones, G. Integrating softwood biorefinery lignin into polyhydroxybutyrate composites and application in 3D printing. Mater. Today Commun. 2019, 19, 286–296. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D printing of polymers containing natural fillers: A review of their mechanical properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef]

- Grand View Research, 3D Printing Market Size, Share & Trends Analysis Report by Component (Hardware, Software, Services), by Printer Type, by Technology, by Software, by Application, by Vertical, by Region, and Segment Forecasts, 2022–2030; Research and Markets: Dublin, Ireland, 7 July 2022.

- Murphy, S.V.; Atala, A. 3D bioprinting of tissues and organs. Nat. Biotechnol. 2014, 32, 773–785. [Google Scholar] [CrossRef]

- Tan, D.K.; Maniruzzaman, M.; Nokhodchi, A. Advanced pharmaceutical applications of hot-melt extrusion coupled with fused deposition modelling (FDM) 3D printing for personalised drug delivery. Pharmaceutics 2018, 10, 203. [Google Scholar] [CrossRef]

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of additive manufacturing technologies and applications in the aerospace industry. In Additive Manufacturing for the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2019; pp. 7–31. [Google Scholar]

- Yadav, D.K.; Srivastava, R.; Dev, S. Design fabrication of ABS part by FDM for automobile application. Mater. Today Proc. 2020, 26, 2089–2093. [Google Scholar] [CrossRef]

- Short, D.B. Use of 3D printing by museums: Educational exhibits, artifact education, and artifact restoration 3D. Print Addit Manuf 2015, 2, 209–215. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, X.; Zhao, W.; Wang, G.; Liu, B. An Overview of Research on FDM 3D Printing Process of Continuous Fiber Reinforced Composites. J. Phys. Conf. Ser. 2019, 1213, 052037. [Google Scholar] [CrossRef]

- De Leon, A.C.; Chen, Q.; Palaganas, N.B.; Palaganas, J.O.; Manapat, J.; Advincula, R.C. High performance polymer nanocomposites for additive manufacturing applications. React. Funct. Polym. 2016, 103, 141–155. [Google Scholar] [CrossRef]

- Afrose, M.F.; Masood, S.H.; Nikzad, M.; Iovenitti, P. Effects of part build orientations on fatigue behaviour of FDM-processed PLA material. Adv. Mater. Res. 2014, 1, 21–28. [Google Scholar] [CrossRef]

- Tran, P.; Ngo, T.D.; Ghazlan, A.; Hui, D. Biomaterial 3D printing and numerical analysis of bio-inspired composite structures under in-plane and transverse loadings. Compos. Part B Eng. 2017, 108, 210–223. [Google Scholar] [CrossRef]

- Sharma, K.; Raghavan, J. Proceedings of the Canadian Society for Mechanical Engineering International Congress. Can. J. Respir. Ther. 2020, 57, 32–38. [Google Scholar]

- Dawoud, M.; Taha, I.; Ebeid, S.J. Mechanical behaviour of ABS: An experimental study using FDM and injection moulding techniques. J. Manuf. Process. 2016, 21, 39–45. [Google Scholar] [CrossRef]

- Ahn, S.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef]

- Kam, M.; İpekçi, A.; Şengül, Ö. Investigation of the Effect of FDM Process Parameters on Mechanical Properties of 3D Printed PA12 Samples Using Taguchi Method. J. Thermoplast. Compos. Mater. 2021, 1–19. [Google Scholar] [CrossRef]

- Tanikella, N.G.; Wittbrodt, B.; Pearce, J.M. Tensile strength of commercial polymer materials for fused filament fabrication 3D printing. Addit. Manuf. 2017, 15, 40–47. [Google Scholar] [CrossRef]

- Angelopoulos, P.M.; Samouhos, M.; Taxiarchou, M. Functional fillers in composite filaments for fused filament fabrication; a review. Mater. Today Proc. 2021, 37, 4031–4043. [Google Scholar] [CrossRef]

- Lee, C.H.; Padzil, F.N.B.M.; Lee, S.H.; Ainun, Z.M.A.; Abdullah, L.C. Potential for Natural Fiber Reinforcement in PLA Polymer Filaments for Fused Deposition Modeling (FDM) Additive Manufacturing: A Review. Polymers 2021, 13, 1407. [Google Scholar] [CrossRef]

- Ju, D.; Meichun, L.; Ling, Z.; Sunyoung, L.; Changtong, M.; Xinwu, X.; Qinglin, W.J. The influence of grafted cellulose nanofibers and postextrusion annealing treatment on selected properties of poly(lactic acid) filaments for 3D printing. Polym. Sci. Part B Polym. Phys. 2017, 55, 847–885. [Google Scholar]

- Gama, N.; Magina, S.; Barros-Timmons, A.; Ferreira, A. Enhanced Compatibility between Coconut Fibers/PP via Chemical Modification for 3D Printing. Prog. Addit. Manuf. 2021, 7, 213–223. [Google Scholar] [CrossRef]

- Lin, W.; Qiuling, C.; Ying, C. Study on the properties of coffee carbon filament yarns. Adv. Mater. Res. 2013, 821, 64–67. [Google Scholar]

- Awalluddin, D.; Mohd Ariffin, M.A.; Osman, M.H.; Hussin, M.W.; Ismail, M.A.; Lee, H.-S.; Abdul Shukor Lim, N.H. Mechanical properties of different bamboo species. MATEC Web Conf. 2017, 138, 01024. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K.; Pappu, A. Hybrid. Polymer Composite Materials. Processing; Woodhead Publishing: Oxford, UK, 2017. [Google Scholar]

- Chang, B.P.; Gupta, A.; Muthuraj, R.; Mekonnen, T.H. Bioresourced Fillers for Rubber Composite Sustainability: Current Development and Future Opportunities. Green Chem. 2021, 23, 5337–5378. [Google Scholar] [CrossRef]

- Xanthos, M. Functional Fillers for Plastics: Second, Updated and Enlarged Edition; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2010. [Google Scholar]

- Xu, H.; Cheng, H.; McClements, D.J.; Chen, L.; Long, J.; Jin, Z. Enhancing the Physicochemical Properties and Functional Performance of Starch-Based Films Using Inorganic Carbon Materials: A Review. Carbohydr. Polym. 2022, 295, 119743. [Google Scholar] [CrossRef] [PubMed]

- Bayne, S.C.; Heymann, H.O.; Swift, E.J. Update on Dental Composite Restorations. J. Am. Dent. Assoc. 1994, 125, 687–701. [Google Scholar] [CrossRef]

- Wypych, G. Handbook of Fillers; ChemTec Publishing: Toronto, ON, Canada, 2016; Volume 938. [Google Scholar]

- DeArmitt, C.; Rothon, R. Particulate fillers, selection and use in polymer composites. In Encyclopedia of Polymers and Composites; Springer: Heidelberg/Berlin, Germany, 2015; pp. 1–19. [Google Scholar]

- Yan, Q.; Dai, W.; Gao, J.; Tan, X.; Lv, L.; Ying, J.; Lu, X.; Lu, J.; Yao, Y.; Wei, Q.; et al. Ultrahigh-Aspect-Ratio Boron Nitride Nanosheets Leading to Superhigh In-Plane Thermal Conductivity of Foldable Heat Spreader. ACS Nano 2021, 15, 6489–6498. [Google Scholar] [CrossRef]

- Jan, R.; Habib, A.; Abbasi, H.Y. High Aspect Ratio Graphene Nanosheets Cause a Very Low Percolation Threshold for Polymer Nanocomposites. Acta Phys. Pol. A 2016, 129, 478–481. [Google Scholar] [CrossRef]

- Yang, H.; Chen, T.; Wang, H.; Bai, S.; Guo, X. One-Pot Rapid Synthesis of High Aspect Ratio Silver Nanowires for Transparent Conductive Electrodes. Mater. Res. Bull. 2018, 102, 79–85. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, H.; Sun, H.; Liu, Y.; Liu, W.; Su, B.; Li, S. The Development of Filler Morphology in Dental Resin Composites: A Review. Materials 2021, 14, 5612. [Google Scholar] [CrossRef]

- Harper, C.A. Handbook of Plastics Technologies: The Complete Guide to Properties and Performance; McGraw-Hill Companies, Inc.: New York, NY, USA, 2006. [Google Scholar]

- Zglobicka, I.; Chmielewska, A.; Topal, E.; Kutukova, K.; Gluch, J.; Krüger, P.; Kilroy, C.; Swieszkowski, W.; Kurzydlowski, K.J.; Zschech, E. 3D Diatom—Designed and Selective Laser Melting (SLM) Manufactured Metallic Structures. Sci. Rep. 2019, 9, 19777. [Google Scholar] [CrossRef]

- Nanni, A.; Messori, M. Thermo-mechanical properties and creep modelling of wine lees filled Polyamide 11 (PA11) and Polybutylene succinate (PBS) bio-composites. Compos. Sci. Technol. 2020, 188, 107974. [Google Scholar] [CrossRef]

- Aggarwal, S.; Johnson, S.; Saloni, D.; Hakovirta, M. Novel 3D Printing Filament Composite Using Diatomaceous Earth and Polylactic Acid for Materials Properties and Cost Improvement. Compos. Part B Eng. 2019, 177, 107310. [Google Scholar] [CrossRef]

- Han, R.; Buchanan, F.; Julius, M.; Walsh, P.J. Filament Extrusion of Bioresorbable PDLGA for Additive Manufacturing Utilising Diatom Biosilica to Inhibit Process-Induced Thermal Degradation. J. Mech. Behav. Biomed. Mater. 2021, 116, 104265. [Google Scholar] [CrossRef] [PubMed]

- Han, R.; Buchanan, F.; Ford, L.; Julius, M.; Walsh, P.J. A Comparison of the Degradation Behaviour of 3D Printed PDLGA Scaffolds Incorporating Bioglass or Biosilica. Mater. Sci. Eng. C 2021, 120, 111755. [Google Scholar] [CrossRef] [PubMed]

- Dobrosielska, M.; Przekop, R.; Sztorch, B.; Brząkalski, D.; Zgłobicka, I.; Łępicka, M.; Dobosz, R.; Kurzydłowski, K. Biogenic Composite Filaments Based on Polylactide and Diatomaceous Earth for 3D Printing. Materials 2020, 13, 4632. [Google Scholar] [CrossRef]

- Rodriguez-Blanco, J.D.; Shaw, S.; Benning, L.G. The Kinetics and Mechanisms of Amorphous Calcium Carbonate (ACC) Crystallization to Calcite, Viavaterite. Nanoscale 2011, 3, 265–271. [Google Scholar] [CrossRef]

- Shafiur Rahman, G.M.; Aftab, H.; Shariful Islam, M.; Mukhlish, M.Z.B.; Ali, F. Enhanced Physico-Mechanical Properties of Polyester Resin Film Using CaCO3 Filler. Fibers Polym. 2016, 17, 59–65. [Google Scholar] [CrossRef]

- Adeosun, S.O.; Usman, M.A.; Akpan, E.I.; Dibie, W.I. Characterization of LDPE Reinforced with Calcium Carbonate—Fly Ash Hybrid Filler. J. Miner. Mater. Charact. Eng. 2014, 02, 334–345. [Google Scholar] [CrossRef]

- Donate, R.; Monzón, M.; Alemán-Domínguez, M.E.; Ortega, Z. Enzymatic Degradation Study of PLA-Based Composite Scaffolds. Rev. Adv. Mater. Sci. 2020, 59, 170–175. [Google Scholar] [CrossRef]

- Dong, M.; Qu, C.; Zhang, S.; Chou, B.; Gao, D. Application of PP in fused deposition modeling process. China Synth. Resin Plast. 2019, 36, 23–30. [Google Scholar]

- Zárybnická, L.; Ševčík, R.; Pokorný, J.; Machová, D.; Stránská, E.; Šál, J. CaCO3 Polymorphs Used as Additives in Filament Production for 3D Printing. Polymers 2022, 14, 199. [Google Scholar] [CrossRef] [PubMed]

- Shang, W.; Liu, Q.; He, E.; Chen, S. Study on Properties of Polymers Packed by Aragonite Whisker. In Proceedings of the 6th International Conference on Properties and Applications of Dielectric Materials, Xi’an, China, 21–26 June 2000; Volume 2, p. 431. [Google Scholar]

- Lin, Y.; Chen, H.; Chan, C.-M.; Wu, J. Effects of coating amount and particle concentration on the impact toughness of polypropylene/CaCO3 nanocomposites. Eur. Polym. J. 2011, 47, 294–304. [Google Scholar] [CrossRef]

- Yang, K.; Yang, Q.; Li, G.; Zhang, Y.; Zhang, P. Mechanical Properties and Morphologies of Polypropylene/Single-Filler or Hybrid-Filler Calcium Carbonate Composites. Polym. Eng. Sci. 2007, 47, 95–102. [Google Scholar] [CrossRef]

- Sudeepan, J.; Kumar, K.; Barman, T.K.; Sahoo, P. Study of Tribological Behavior of ABS/CaCO 3 Composite Using Grey Relational Analysis. Procedia Mater. Sci. 2014, 6, 682–691. [Google Scholar] [CrossRef] [Green Version]

- Kotlarz, M.; Jordan, R.; Wegner, E.; Dobrzyński, P.; Neunzehn, J.; Lederer, A.; Wolf-Brandstetter, C.; Pamula, E.; Scharnweber, D. One step 3D printing of surface functionalized composite scaffolds for tissue engineering applications. Acta Bioeng. Biomech. 2018, 20, 35–45. [Google Scholar] [PubMed]

- Varga, P.; Lorinczy, D.; Toth, L.; Pentek, A.; Nyitrai, M.; Maroti, P. Novel PLA-CaCO3 Composites in Additive Manufacturing of Upper Limb Casts and Orthotics—A Feasibility Study. Mater. Res. Express 2019, 6, 045317. [Google Scholar] [CrossRef]

- Kasuga, T.; Maeda, H.; Kato, K.; Nogami, M.; Hata, K.; Ueda, M. Preparation of Poly(Lactic Acid) Composites Containing Calcium Carbonate (Vaterite). Biomaterials 2003, 24, 3247–3253. [Google Scholar] [CrossRef]

- Castilho, M.; Moseke, C.; Ewald, A.; Gbureck, U.; Groll, J.; Pires, I.; Teßmar, J.; Vorndran, E. Direct 3D Powder Printing of Biphasic Calcium Phosphate Scaffolds for Substitution of Complex Bone Defects. Biofabrication 2014, 6, 015006. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical Properties of Components Fabricated with Open-Source 3-D Printers under Realistic Environmental Conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Gang, F.; Ye, W.; Ma, C.; Wang, W.; Xiao, Y.; Liu, C.; Sun, X. 3D Printing of PLLA/Biomineral Composite Bone Tissue Engineering Scaffolds. Materials 2022, 15, 4280. [Google Scholar] [CrossRef]

- Neumann, R.; Neunzehn, J.; Hinueber, C.; Flath, T.; Schulze, F.P.; Wiesmann, H.-P. 3D-Printed Poly-ε-Caprolactone-CaCO3-Biocomposite-Scaffolds for Hard Tissue Regeneration. Express Polym. Lett. 2019, 13, 2–17. [Google Scholar] [CrossRef]

- Babilotte, J.; Guduric, V.; Le Nihouannen, D.; Naveau, A.; Fricain, J.-C.; Catros, S. 3D Printed Polymer-Mineral Composite Biomaterials for Bone Tissue Engineering: Fabrication and Characterization. J. Biomed. Mater. Res. Part B Appl. Biomater. 2019, 107, 2579–2595. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhou, Y.; Lin, L.; Corker, J.; Fan, M. Overview of 3D Additive Manufacturing (AM) and Corresponding AM Composites. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106114. [Google Scholar] [CrossRef]

- Shanmugam, V.; Rajendran, D.J.J.; Babu, K.; Rajendran, S.; Veerasimman, A.; Marimuthu, U.; Singh, S.; Das, O.; Neisiany, R.E.; Hedenqvist, M.S.; et al. The Mechanical Testing and Performance Analysis of Polymer-Fibre Composites Prepared through the Additive Manufacturing. Polym. Test. 2021, 93, 106925. [Google Scholar] [CrossRef]

- Subramaniyan, M.; Karuppan, S.; Eswaran, P.; Appusamy, A.; Naveen Shankar, A. State of Art on Fusion Deposition Modeling Machines Process Parameter Optimization on Composite Materials. Mater. Today Proc. 2021, 45, 820–827. [Google Scholar] [CrossRef]

- Muthe, L.P.; Pickering, K.; Gauss, C. A Review of 3D/4D Printing of Poly-Lactic Acid Composites with Bio-Derived Reinforcements. Compos. Part C Open Access 2022, 8, 100271. [Google Scholar] [CrossRef]

- Khalifa, M.; Anandhan, S.; Wuzella, G.; Lammer, H.; Mahendran, A.R. Thermoplastic Polyurethane Composites Reinforced with Renewable and Sustainable Fillers—A Review. Polym.-Plast. Technol. Mater. 2020, 59, 1751–1769. [Google Scholar] [CrossRef]

- Suárez, L.; Castellano, J.; Díaz, S.; Tcharkhtchi, A.; Ortega, Z. Are Natural-Based Composites Sustainable? Polymers 2021, 13, 2326. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Mohan, N.; Senthil, P.; Vinodh, S.; Jayanth, N. A Review on Composite Materials and Process Parameters Optimisation for the Fused Deposition Modelling Process. Virtual Phys. Prototyp. 2017, 12, 47–59. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Harussani, M.M.; Hakimi, M.Y.A.Y.; Haziq, M.Z.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Nurazzi, N.M.; et al. Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications. Polymers 2021, 13, 1326. [Google Scholar] [CrossRef] [PubMed]

- Badgar, K.; Abdalla, N.; El-Ramady, H.; Prokisch, J. Sustainable Applications of Nanofibers in Agriculture and Water Treatment: A Review. Sustainability 2022, 14, 464. [Google Scholar] [CrossRef]

- Wasti, S.; Adhikari, S. Use of Biomaterials for 3D Printing by Fused Deposition Modeling Technique: A Review. Front. Chem. 2020, 8, 315. [Google Scholar] [CrossRef] [PubMed]

- Velu, R.; Raspall, F.; Singamneni, S. 3D Printing Technologies and Composite Materials for Structural Applications. In Green Composites for Automotive Applications; Koronis, G., Silva, A., Eds.; Woodhead Publishing: Duxford, UK, 2019; pp. 171–196. [Google Scholar]

- Murawski, A.; Diaz, R.; Inglesby, S.; Delabar, K.; Quirino, R.L. Synthesis of Bio-Based Polymer Composites: Fabrication, Fillers, Properties, and Challenges. Lect. Notes Bioeng. 2019, 29–55. [Google Scholar] [CrossRef]

- Gharde, S.; Surendren, A.; Korde, J.M.; Saini, S.; Deoray, N.; Goud, R.; Nimje, S.; Kandasubramanian, B. Recent Advances in Additive Manufacturing of Bio-Inspired Materials. In Biomanufacturing; Prakash, C., Singh, S., Singh, R., Ramakrishna, S., Pabla, B.S., Puri, S., Uddin, M.S., Eds.; Springer: Cham, Switzerland, 2019; pp. 35–68. [Google Scholar]

- Le Duigou, A.; Correa, D.; Ueda, M.; Matsuzaki, R.; Castro, M. A Review of 3D and 4D Printing of Natural Fibre Biocomposites. Mater. Des. 2020, 194, 108911. [Google Scholar] [CrossRef]

- Zhao, X.; Copenhaver, K.; Wang, L.; Korey, M.; Gardner, D.J.; Li, K.; Lamm, M.E.; Kishore, V.; Bhagia, S.; Tajvidi, M.; et al. Recycling of Natural Fiber Composites: Challenges and Opportunities. Resour. Conserv. Recycl. 2022, 177, 105962. [Google Scholar] [CrossRef]

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive Manufacturing of Natural Fiber Reinforced Polymer Composites: Processing and Prospects. Compos. Part B Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- Li, M.; Pu, Y.; Thomas, V.M.; Yoo, C.G.; Ozcan, S.; Deng, Y.; Nelson, K.; Ragauskas, A.J. Recent Advancements of Plant-Based Natural Fiber–Reinforced Composites and Their Applications. Compos. Part B Eng. 2020, 200, 108254. [Google Scholar] [CrossRef]

- Tonk, R. Natural Fibers for Sustainable Additive Manufacturing: A State of the Art Review. Mater. Today Proc. 2020, 37, 3087–3090. [Google Scholar] [CrossRef]

- Deb, D.; Jafferson, J.M. Natural Fibers Reinforced FDM 3D Printing Filaments. Mater. Today Proc. 2021, 46, 1308–1318. [Google Scholar] [CrossRef]

- Ganguly, A.; Shankar, S.; Das, A.; Shukla, M.; Swaroop, C.; Bhardwaj, T. Natural Fibre Reinforced Composites: A Review Based on Additive Manufacturing Routes and Biodegradability Perspective. Mater. Today Proc. 2022, 62, 131–135. [Google Scholar] [CrossRef]

- Kopparthy, S.D.S.; Netravali, A.N. Review: Green Composites for Structural Applications. Compos. Part C Open Access 2021, 6, 100169. [Google Scholar] [CrossRef]

- Mangat, A.S.; Singh, S.; Gupta, M.; Sharma, R. Experimental Investigations on Natural Fiber Embedded Additive Manufacturing-Based Biodegradable Structures for Biomedical Applications. Rapid Prototyp. J. 2018, 24, 1221–1234. [Google Scholar] [CrossRef]

- Sekar, V.; Fouladi, M.H.; Namasivayam, S.N.; Sivanesan, S. Additive Manufacturing: A Novel Method for Developing an Acoustic Panel Made of Natural Fiber-Reinforced Composites with Enhanced Mechanical and Acoustical Properties. J. Eng. 2019, 2019, 4546863. [Google Scholar] [CrossRef] [Green Version]

- Mazzanti, V.; Mollica, F. A Review of Wood Polymer Composites Rheology and Its Implications for Processing. Polymers 2020, 12, 2304. [Google Scholar] [CrossRef]

- Suriani, M.J.; Ilyas, R.A.; Zuhri, M.Y.M.; Khalina, A.; Sultan, M.T.H.; Sapuan, S.M.; Ruzaidi, C.M.; Wan, F.N.; Zulkifli, F.; Harussani, M.M.; et al. Critical Review of Natural Fiber Reinforced Hybrid Composites: Processing, Properties, Applications and Cost. Polymers 2021, 13, 3514. [Google Scholar] [CrossRef]

- Shahinur, S.; Sayeed, M.M.A.; Hasan, M.; Sayem, A.S.M.; Haider, J.; Ura, S. Current Development and Future Perspective on Natural Jute Fibers and Their Biocomposites. Polymers 2022, 14, 1445. [Google Scholar] [CrossRef]

- Rajendran Royan, N.R.; Leong, J.S.; Chan, W.N.; Tan, J.R.; Shamsuddin, Z.S.B. Current State and Challenges of Natural Fibre-Reinforced Polymer Composites as Feeder in FDM-Based 3D Printing. Polymers 2021, 13, 2289. [Google Scholar] [CrossRef]

- Ahmed, W.; Alnajjar, F.; Zaneldin, E.; Al-Marzouqi, A.H.; Gochoo, M.; Khalid, S. Implementing FDM 3D Printing Strategies Using Natural Fibers to Produce Biomass Composite. Materials 2020, 13, 4065. [Google Scholar] [CrossRef]

- Aida, H.J.; Nadlene, R.; Mastura, M.T.; Yusriah, L.; Sivakumar, D.; Ilyas, R.A. Natural Fibre Filament for Fused Deposition Modelling (FDM): A Review. Int. J. Sustain. Eng. 2021, 14, 1988–2008. [Google Scholar] [CrossRef]

- Devarajan, B.; LakshmiNarasimhan, R.; Venkateswaran, B.; Mavinkere Rangappa, S.; Siengchin, S. Additive Manufacturing of Jute Fiber Reinforced Polymer Composites: A Concise Review of Material Forms and Methods. Polym. Compos. 2022, 46, 1308–1318. [Google Scholar] [CrossRef]

- Rajeshkumar, G.; Arvindh Seshadri, S.; Devnani, G.L.; Sanjay, M.R.; Siengchin, S.; Prakash Maran, J.; Al-Dhabi, N.A.; Karuppiah, P.; Mariadhas, V.A.; Sivarajasekar, N.; et al. Environment Friendly, Renewable and Sustainable Poly Lactic Acid (PLA) Based Natural Fiber Reinforced Composites—A Comprehensive Review. J. Clean. Prod. 2021, 310, 127483. [Google Scholar] [CrossRef]

- Palmqvist, E.; Hahn-Hägerdal, B. Fermentation of Lignocellulosic Hydrolysates. II: Inhibitors and Mechanisms of Inhibition. Bioresour. Technol. 2000, 74, 25–33. [Google Scholar] [CrossRef]

- Mastura, M.T.; Nadlene, R.; Jumaidin, R.; Kudus, S.A.; Mansor, M.R.; Firdaus, H.M.S. Concurrent Material Selection of Natural Fibre Filament for Fused Deposition Modeling Using Integration of Analytic Hierarchy Process/Analytic Network Process. J. Renew. Mater. 2022, 10, 1221–1238. [Google Scholar] [CrossRef]

- Le Duigou, A.; Fruleux, T.; Matsuzaki, R.; Chabaud, G.; Ueda, M.; Castro, M. 4D Printing of Continuous Flax-Fibre Based Shape-Changing Hygromorph Biocomposites: Towards Sustainable Metamaterials. Mater. Des. 2021, 211, 110158. [Google Scholar] [CrossRef]

- Fruleux, T.; Castro, M.; Sauleau, P.; Matsuzaki, R.; Le Duigou, A. Matrix Stiffness: A Key Parameter to Control Hydro-Elasticity and Morphing of 3D Printed Biocomposite. Compos. Part A Appl. Sci. Manuf. 2022, 156, 106882. [Google Scholar] [CrossRef]

- Le Duigou, A.; Chabaud, G.; Matsuzaki, R.; Castro, M. Tailoring the Mechanical Properties of 3D-Printed Continuous Flax/PLA Biocomposites by Controlling the Slicing Parameters. Compos. Part B Eng. 2020, 203, 108474. [Google Scholar] [CrossRef]

- Stoof, D.; Pickering, K.; Zhang, Y. Fused Deposition Modelling of Natural Fibre/Polylactic Acid Composites. J. Compos. Sci. 2017, 1, 8. [Google Scholar] [CrossRef]

- Yaguchi, Y.; Takeuchi, K.; Waragai, T.; Tateno, T. Durability Evaluation of an Additive Manufactured Biodegradable Composite with Continuous Natural Fiber in Various Conditions Reproducing Usage Environment. Int. J. Autom. Technol. 2020, 14, 959–965. [Google Scholar] [CrossRef]

- Cai, R.; Lin, H.; Cheng, P.; Zhang, Z.; Wang, K.; Peng, Y.; Wu, Y.; Ahzi, S. Investigation on Dynamic Strength of 3D-Printed Continuous Ramie Fiber Reinforced Biocomposites at Various Strain Rates Using Machine Learning Methods. Polym. Compos. 2022, 43, 5235–5249. [Google Scholar] [CrossRef]

- Regalla, S.P.; Karwa, S.S.; Rajesh, S.; Shyam, P.V.; Shrivastava, P.N. Strength and Fracture Behaviour of Polymer Matrix Composite Layered Structures Made by Additive Manufacturing. Mater. Today Proc. 2020, 28, 1030–1038. [Google Scholar] [CrossRef]

- Jamadi, A.H.; Razali, N.; Petrů, M.; Taha, M.M.; Muhammad, N.; Ilyas, R.A. Effect of Chemically Treated Kenaf Fibre on Mechanical and Thermal Properties of PLA Composites Prepared through Fused Deposition Modeling (FDM). Polymers 2021, 13, 3299. [Google Scholar] [CrossRef] [PubMed]

- Taborda-Ríos, J.A.; López-Botello, O.; Zambrano-Robledo, P.; Reyes-Osorio, L.A.; Garza, C. Mechanical Characterisation of a Bamboo Fibre/Polylactic Acid Composite Produced by Fused Deposition Modelling. J. Reinf. Plast. Compos. 2020, 39, 932–944. [Google Scholar] [CrossRef]

- Rafiee, M.; Abidnejad, R.; Ranta, A.; Ojha, K.; Karakoç, A.; Paltakari, J. Exploring the Possibilities of FDM Filaments Comprising Natural Fiber-Reinforced Biocomposites for Additive Manufacturing. AIMS Mater. Sci. 2021, 8, 524–537. [Google Scholar] [CrossRef]

- Dogru, A.; Sozen, A.; Neser, G.; Seydibeyoglu, M.O. Effects of Aging and Infill Pattern on Mechanical Properties of Hemp Reinforced PLA Composite Produced by Fused Filament Fabrication (FFF). Appl. Sci. Eng. Prog. 2021, 14, 651–660. [Google Scholar] [CrossRef]

- Kesentini, Z.; El Mahi, A.; Rebiere, J.-L.; El Guerjouma, R.; Beyaoui, M.; Haddar, M. Effect of Hydric Aging on the Static and Vibration Behavior of 3D Printed Bio-Based Flax Fiber Reinforced Poly-Lactic Acid Composites. Polym. Polym. Compos. 2022, 30, 09673911221081826. [Google Scholar] [CrossRef]

- Mazur, K.E.; Borucka, A.; Kaczor, P.; Gądek, S.; Bogucki, R.; Mirzewiński, D.; Kuciel, S. Mechanical, Thermal and Microstructural Characteristic of 3D Printed Polylactide Composites with Natural Fibers: Wood, Bamboo and Cork. J. Polym. Environ. 2021, 30, 2341–2354. [Google Scholar] [CrossRef]

- Mangat, A.S.; Singh, S. Characterization of Natural Fibre-Embedded Biodegradable Porous Structures Prepared with Fused Deposition Process. J. Thermoplast. Compos. Mater. 2018, 32, 761–777. [Google Scholar] [CrossRef]

- Sekar, V.; Eh Noum, S.Y.; Sivanesan, S.; Putra, A.; Kassim, D.H.; Wong, Y.S.; Chin, K.C. Effect of Perforation Volume on Acoustic Absorption of the 3D Printed Micro-Perforated Panels Made of Polylactic Acid Reinforced with Wood Fibers. J. Phys. Conf. Ser. 2021, 2120, 012039. [Google Scholar] [CrossRef]

- Sekar, V.; Eh Noum, S.Y.; Sivanesan, S.; Putra, A.; Chin Vui Sheng, D.D.; Kassim, D.H. Effect of Thickness and Infill Density on Acoustic Performance of 3D Printed Panels Made of Natural Fiber Reinforced Composites. J. Nat. Fibers 2021, 1–9. [Google Scholar] [CrossRef]

- Balla, V.K.; Tadimeti, J.G.D.; Kate, K.H.; Satyavolu, J. 3D Printing of Modified Soybean Hull Fiber/Polymer Composites. Mater. Chem. Phys. 2020, 254, 123452. [Google Scholar] [CrossRef]

- Ariel Leong, J.J.; Koay, S.C.; Chan, M.Y.; Choo, H.L.; Tshai, K.Y.; Ong, T.K. Composite Filament Made from Post-Used Styrofoam and Corn Husk Fiber for Fuse Deposition Modeling. J. Nat. Fibers 2021, 1–16. [Google Scholar] [CrossRef]

- Costa, I.L.; Pereira, P.H.; Claro, A.M.; Amaral, N.C.D.; Barud, H.d.S.; Ribeiro, R.B.; Mulinari, D.R. 3D-Printing Pen from Valorization of Pine Cone Residues as Reinforcement in Acrylonitrile Butadiene Styrene (ABS): Microstructure and Thermal Properties. J. Thermoplast. Compos. Mater. 2021, 1–20. [Google Scholar] [CrossRef]

- Ahmad, M.N.; Wahid, M.K.; Maidin, N.A.; Ab Rahman, M.H.; Osman, M.H.; Alis@Elias, I.F. Mechanical Characteristics of Oil Palm Fiber Reinforced Thermoplastics as Filament for Fused Deposition Modeling (FDM). Adv. Manuf. 2020, 8, 72–81. [Google Scholar] [CrossRef]

- Han, S.N.M.F.; Taha, M.M.; Mansor, M.R.; Rahman, M.A.A. Investigation of Tensile and Flexural Properties of Kenaf Fiber-Reinforced Acrylonitrile Butadiene Styrene Composites Fabricated by Fused Deposition Modeling. J. Eng. Appl. Sci. 2022, 69, 52. [Google Scholar] [CrossRef]

- Balla, V.K.; Tadimeti, J.G.D.; Sudan, K.; Satyavolu, J.; Kate, K.H. First Report on Fabrication and Characterization of Soybean Hull Fiber: Polymer Composite Filaments for Fused Filament Fabrication. Prog. Addit. Manuf. 2020, 6, 39–52. [Google Scholar] [CrossRef]

- Carrete, I.A.; Quiñonez, P.A.; Bermudez, D.; Roberson, D.A. Incorporating Textile-Derived Cellulose Fibers for the Strengthening of Recycled Polyethylene Terephthalate for 3D Printing Feedstock Materials. J. Polym. Environ. 2020, 29, 662–671. [Google Scholar] [CrossRef]

- Morales, M.; Atencio Martinez, C.; Maranon, A.; Hernandez, C.; Michaud, V.; Porras, A. Development and Characterization of Rice Husk and Recycled Polypropylene Composite Filaments for 3D Printing. Polymers 2021, 13, 1067. [Google Scholar] [CrossRef] [PubMed]

- Morales, M.A.; Maranon, A.; Hernandez, C.; Porras, A. Development and Characterization of a 3D Printed Cocoa Bean Shell Filled Recycled Polypropylene for Sustainable Composites. Polymers 2021, 13, 3162. [Google Scholar] [CrossRef]

- Tao, Y.; Wang, H.; Li, Z.; Li, P.; Shi, S.Q. Development and Application of Wood Flour-Filled Polylactic Acid Composite Filament for 3D Printing. Materials 2017, 10, 339. [Google Scholar] [CrossRef]

- Xie, G.; Zhang, Y.; Lin, W. Plasticizer Combinations and Performance of Wood Flour–Poly(Lactic Acid) 3D Printing Filaments. BioResources 2017, 12, 6736–6748. [Google Scholar] [CrossRef]

- Bi, H.; Ren, Z.; Guo, R.; Xu, M.; Song, Y. Fabrication of Flexible Wood Flour/Thermoplastic Polyurethane Elastomer Composites Using Fused Deposition Molding. Ind. Crop Prod. 2018, 122, 76–84. [Google Scholar] [CrossRef]

- Kariz, M.; Sernek, M.; Obućina, M.; Kuzman, M.K. Effect of Wood Content in FDM Filament on Properties of 3D Printed Parts. Mater. Today Commun. 2018, 14, 135–140. [Google Scholar] [CrossRef]

- Le Guen, M.-J.; Hill, S.; Smith, D.; Theobald, B.; Gaugler, E.; Barakat, A.; Mayer-Laigle, C. Influence of Rice Husk and Wood Biomass Properties on the Manufacture of Filaments for Fused Deposition Modeling. Front. Chem. 2019, 7, 735. [Google Scholar] [CrossRef] [Green Version]

- Tran, T.N.; Bayer, I.S.; Heredia-Guerrero, J.A.; Frugone, M.; Lagomarsino, M.; Maggio, F.; Athanassiou, A. Cocoa Shell Waste Biofilaments for 3D Printing Applications. Macromol. Mater. Eng. 2017, 302, 1700219. [Google Scholar] [CrossRef]

- Girdis, J.; Gaudion, L.; Proust, G.; Löschke, S.; Dong, A. Rethinking Timber: Investigation into the Use of Waste Macadamia Nut Shells for Additive Manufacturing. JOM 2016, 69, 575–579. [Google Scholar] [CrossRef]

- Brites, F.; Malça, C.; Gaspar, F.; Horta, J.F.; Franco, M.C.; Biscaia, S.; Mateus, A. Cork Plastic Composite Optimization for 3D Printing Applications. Procedia Manuf. 2017, 12, 156–165. [Google Scholar] [CrossRef]

- Gnanamani Sankaravel, S.; Syed, R.B.; Manivachakan, V. In Vitro and Mechanical Characterization of PLA/Egg Shell Biocomposite Scaffold Manufactured Using F Used Deposition Modeling Technology for Tissue Engineering Applications. Polym. Compos. 2021, 43, 173–186. [Google Scholar] [CrossRef]

- Flores-Hernandez, C.G.; Velasco-Santos, C.; Hernandez-Zea, A.L.; Gomez-Guzman, O.; Yañez-Limon, J.M.; Rivera-Armenta, J.L.; Martinez-Hernandez, A.L. Low Concentrations for Significant Improvements in Thermal and Thermomechanical Properties of Poly(Lactic Acid)–Keratin Biocomposites Obtained by Extrusion and 3D Printing. J. Nat. Fibers 2020, 19, 1715–1728. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Gulino, E.F.; Alaimo, G.; Morreale, M. Green Composites Based on PLA and Agricultural or Marine Waste Prepared by FDM. Polymers 2021, 13, 1361. [Google Scholar] [CrossRef]

- Martin, O.; Avérous, L. Poly(Lactic Acid): Plasticization and Properties of Biodegradable Multiphase Systems. Polymer 2001, 42, 6209–6219. [Google Scholar] [CrossRef]

- Huneault, M.A.; Li, H. Morphology and Properties of Compatibilized Polylactide/Thermoplastic Starch Blends. Polymer 2007, 48, 270–280. [Google Scholar] [CrossRef]

- Zhou, L.; Zhao, G.; Feng, Y.; Yin, J.; Jiang, W. Toughening Polylactide with Polyether-Block-Amide and Thermoplastic Starch Acetate: Influence of Starch Esterification Degree. Carbohydr. Polym. 2015, 127, 79–85. [Google Scholar] [CrossRef]

- Hossain, M.I.; Chowdhury, M.A.; Zahid, M.S.; Sakib-Uz-Zaman, C.; Rahaman, M.L.; Kowser, M.A. Development and Analysis of Nanoparticle Infused Plastic Products Manufactured by Machine Learning Guided 3D Printer. Polym. Test. 2021, 106, 107429. [Google Scholar] [CrossRef]

- Olam, M.; Tosun, N. 3D-Printed Polylactide/Hydroxyapatite/Titania Composite Filaments. Mater. Chem. Phys. 2022, 276, 125267. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Mascolo, I.; Modano, M. On the Applicability of Composite PA6-TiO2 Filaments for the Rapid Prototyping of Innovative Materials and Structures. Compos. Part B Eng. 2018, 143, 132–140. [Google Scholar] [CrossRef]

- Soundararajan, R.; Jayasuriya, N.; Girish Vishnu, R.G.; Guru Prassad, B.; Pradeep, C. Appraisal of Mechanical and Tribological Properties on PA6-TiO2 Composites through Fused Deposition Modelling. Mater. Today Proc. 2019, 18, 2394–2402. [Google Scholar] [CrossRef]

- Kumar Tiwary, V.; Arunkumar, P.; Kulkarni, P.M. Micro-Particle Grafted Eco-Friendly Polymer Filaments for 3D Printing Technology. Mater. Today Proc. 2020, 28, 1980–1984. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Maniadi, A.; Koudoumas, E.; Liebscher, M.; Tzounis, L. Mechanical Properties of 3D-Printed Acrylonitrile–Butadiene–Styrene TiO2 and ATO Nanocomposites. Polymers 2020, 12, 1589. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Tzounis, L.; Mountakis, N.; Kechagias, J.; Grammatikos, S. Optimization of the Filler Concentration on Fused Filament Fabrication 3D Printed Polypropylene with Titanium Dioxide Nanocomposites. Materials 2021, 14, 3076. [Google Scholar] [CrossRef]

- Car, F.; Brnadić, G.; Tomašić, V.; Vrsaljko, D. Advanced Preparation Method of Monolithic Catalyst Carriers Using 3D-Printing Technology. Prog. Addit. Manuf. 2022, 7, 797–808. [Google Scholar] [CrossRef]

- Sevastaki, M.; Suchea, M.P.; Kenanakis, G. 3D Printed Fully Recycled TiO2-Polystyrene Nanocomposite Photocatalysts for Use against Drug Residues. Nanomaterials 2020, 10, 2144. [Google Scholar] [CrossRef] [PubMed]

- Viskadourakis, Z.; Sevastaki, M.; Kenanakis, G. 3D Structured Nanocomposites by FDM Process: A Novel Approach for Large-Scale Photocatalytic Applications. Appl. Phys. A 2018, 124, 585. [Google Scholar] [CrossRef]

- Sangiorgi, A.; Gonzalez, Z.; Ferrandez-Montero, A.; Yus, J.; Sanchez-Herencia, A.J.; Galassi, C.; Sanson, A.; Ferrari, B. 3D Printing of Photocatalytic Filters Using a Biopolymer to Immobilize TiO2Nanoparticles. J. Electrochem. Soc. 2019, 166, H3239–H3248. [Google Scholar] [CrossRef]

- Zhou, R.; Han, R.; Bingham, M.; O’Rourke, C.; Mills, A. 3D printed, plastic photocatalytic flow reactors for water purification. Photochem. Photobiol. Sci. 2022, 21, 1585–1600. [Google Scholar] [CrossRef]

- Li, K.; de Rancourt de Mimérand, Y.; Jin, X.; Yi, J.; Guo, J. Metal Oxide (ZnO and TiO2) and Fe-Based Metal–Organic-Framework Nanoparticles on 3D-Printed Fractal Polymer Surfaces for Photocatalytic Degradation of Organic Pollutants. ACS Appl. Nano Mater. 2020, 3, 2830–2845. [Google Scholar] [CrossRef]

- McQueen, A.D.; Ballentine, M.L.; May, L.R.; Laber, C.H.; Das, A.; Bortner, M.J.; Kennedy, A.J. Photocatalytic Degradation of Polycyclic Aromatic Hydrocarbons in Water by 3D Printed TiO2 Composites. ACS EST Water 2021, 2, 137–147. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, R.; Singh, M.; Singh, T.; Batish, A. Multi Material 3D Printing of PLA-PA6/TiO2 Polymeric Matrix: Flexural, Wear and Morphological Properties. J. Thermoplast. Compos. Mater. 2020, 1–20. [Google Scholar] [CrossRef]

- Nájera, S.E.; Michel, M.; Kim, N.-S. 3D Printed PLA/PCL/TiO2 Composite for Bone Replacement and Grafting. MRS Adv. 2018, 3, 2373–2378. [Google Scholar] [CrossRef]

- Brounstein, Z.; Yeager, C.M.; Labouriau, A. Development of Antimicrobial PLA Composites for Fused Filament Fabrication. Polymers 2021, 13, 580. [Google Scholar] [CrossRef]

- Horst, D.J.; Tebcherani, S.M.; Kubaski, E.T.; de Almeida Vieira, R. Bioactive Potential of 3D-Printed Oleo-Gum-Resin Disks: B. Papyrifera, C. Myrrha, and S. Benzoin Loading Nanooxides—TiO2, P25, Cu2O, and MoO3. Bioinorg. Chem. Appl. 2017, 2017, 6398167. [Google Scholar] [CrossRef] [PubMed]

- Ding, L.; Lu, W.; Zhang, J.; Yang, C.; Wu, G. Preparation and Performance Evaluation of Duotone 3D-Printed Polyetheretherketone as Oral Prosthetic Materials: A Proof-of-Concept Study. Polymers 2021, 13, 1949. [Google Scholar] [CrossRef] [PubMed]

- Dong, E.; Zhao, Z.; Wang, M.; Xie, Y.; Li, S.; Shao, P.; Cheng, L.; Xu, R.X. Three-Dimensional Fuse Deposition Modeling of Tissue-Simulating Phantom for Biomedical Optical Imaging. J. Biomed. Opt. 2015, 20, 121311. [Google Scholar] [CrossRef]

- Castro, J.; Rojas, E.; Ross, A.; Weller, T.; Wang, J. High-k and Low-Loss Thermoplastic Composites for Fused Deposition Modeling and Their Application to 3D-Printed Ku-Band Antennas. In Proceedings of the 2016 IEEE MTT-S International Microwave Symposium (IMS), San Francisco, CA, USA, 22–27 May 2016. [Google Scholar]

- Castro, J.; Rojas-Nastrucci, E.A.; Ross, A.; Weller, T.M.; Wang, J. Fabrication, Modeling, and Application of Ceramic-Thermoplastic Composites for Fused Deposition Modeling of Microwave Components. IEEE Trans. Microw. Theory Tech. 2017, 65, 2073–2084. [Google Scholar] [CrossRef]

- Li, H.; Watson, J.C. Continuous Glass Fibers for Reinforcement. Encycl. Glass Sci. Technol. Hist. Cult. 2021, 1, 95–109. [Google Scholar]

- Jones, F.R.; Huff, N.T. The Structure and Properties of Glass Fibers. In Handbook of Properties of Textile and Technical Fibres, 2nd ed.; Bunsell, A.R., Ed.; Woodhead Publishing: Duxford, UK, 2018; pp. 757–803. [Google Scholar]

- Goh, G.D.; Dikshit, V.; Nagalingam, A.P.; Goh, G.L.; Agarwala, S.; Sing, S.L.; Wei, J.; Yeong, W.Y. Characterization of Mechanical Properties and Fracture Mode of Additively Manufactured Carbon Fiber and Glass Fiber Reinforced Thermoplastics. Mater. Des. 2018, 137, 79–89. [Google Scholar] [CrossRef]

- Shulga, E.; Karamov, R.; Sergeichev, I.S.; Konev, S.D.; Shurygina, L.I.; Akhatov, I.S.; Shandakov, S.D.; Nasibulin, A.G. Fused Filament Fabricated Polypropylene Composite Reinforced by Aligned Glass Fibers. Materials 2020, 13, 3442. [Google Scholar] [CrossRef]

- Sodeifian, G.; Ghaseminejad, S.; Yousefi, A.A. Preparation of Polypropylene/Short Glass Fiber Composite as Fused Deposition Modeling (FDM) Filament. Results Phys. 2019, 12, 205–222. [Google Scholar] [CrossRef]

- Carneiro, O.S.; Silva, A.F.; Gomes, R. Fused Deposition Modeling with Polypropylene. Mater. Des. 2015, 83, 768–776. [Google Scholar] [CrossRef]

- Benal, M.G.M.; GS, P.K.; Tambrallimath, V.; HR, G.; Khan, T.Y.; Rajhi, A.A.; Baig, M.A.A. Influence of Short Glass Fibre Reinforcement on Mechanical Properties of 3D Printed ABS-Based Polymer Composites. Polymers 2022, 14, 1182. [Google Scholar]

- Zhong, W.; Li, F.; Zhang, Z.; Song, L.; Li, Z. Short Fiber Reinforced Composites for Fused Deposition Modeling. Mater. Sci. Eng. A 2001, 301, 125–130. [Google Scholar] [CrossRef]

- Ranganathan, S.; Rangasamy Suguna Thangaraj, H.N.; Vasudevan, A.K.; Shanmugan, D.K. Analogy of Thermal Properties of Polyamide 6 Reinforced with Glass Fiber and Glass Beads through FDM Process. SAE Tech. Pap. Ser. 2019, 1–6. [Google Scholar] [CrossRef]

- Luke, S.S.; Soares, D.; Marshall, J.V.; Sheddden, J.; Keleş, Ö. Effect of Fiber Content and Fiber Orientation on Mechanical Behavior of Fused Filament Fabricated Continuous-Glass-Fiber-Reinforced Nylon. Rapid Prototyp. J. 2021, 27, 1346–1354. [Google Scholar] [CrossRef]

- Dickson, A.N.; Barry, J.N.; McDonnell, K.A.; Dowling, D.P. Fabrication of Continuous Carbon, Glass and Kevlar Fibre Reinforced Polymer Composites Using Additive Manufacturing. Addit. Manuf. 2017, 16, 146–152. [Google Scholar] [CrossRef]

- Chabaud, G.; Castro, M.; Denoual, C.; Le Duigou, A. Hygromechanical Properties of 3D Printed Continuous Carbon and Glass Fibre Reinforced Polyamide Composite for Outdoor Structural Applications. Addit. Manuf. 2019, 26, 94–105. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Recycling of Fiberglass Wind Turbine Blades into Reinforced Filaments for Use in Additive Manufacturing. Compos. Part B Eng. 2019, 175, 107101. [Google Scholar] [CrossRef]

- Li, X.; Ni, Z.; Bai, S.; Lou, B. Preparation and Mechanical Properties of Fiber Reinforced PLA for 3D Printing Materials. IOP Conf. Ser. Mater. Sci. Eng. 2018, 322, 022012. [Google Scholar] [CrossRef]

- Chen, K.; Yu, L.; Cui, Y.; Jia, M.; Pan, K. Optimization of Printing Parameters of 3D-Printed Continuous Glass Fiber Reinforced Polylactic Acid Composites. Thin-Walled Struct. 2021, 164, 107717. [Google Scholar] [CrossRef]

- Akhoundi, B.; Behravesh, A.H.; Nabipour, M.; Saed, A.B. Additive manufacturing of glass-fiber reinforced composites using fdm 3d printer. In Proceedings of the 25th Annual International Conference on Mechanical Engineering, Tarbiat Modares University, Tehran, Iran, 2–7 May 2017. [Google Scholar]

- Wang, P.; Zou, B.; Ding, S.; Li, L.; Huang, C. Effects of FDM-3D Printing Parameters on Mechanical Properties and Microstructure of CF/PEEK and GF/PEEK. Chin. J. Aeronaut. 2020, 34, 236–246. [Google Scholar] [CrossRef]

- Brown, K.R.; Harrell, T.M.; Skrzypczak, L.; Scherschel, A.; Wu, H.F.; Li, X. Carbon Fibers Derived from Commodity Polymers: A Review. Carbon 2022, 196, 422–439. [Google Scholar] [CrossRef]

- Liu, Y.; Zwingmann, B.; Schlaich, M. Carbon Fiber Reinforced Polymer for Cable Structures—A Review. Polymers 2015, 7, 2078–2099. [Google Scholar] [CrossRef]

- Choi, D.; Kil, H.-S.; Lee, S. Fabrication of Low-Cost Carbon Fibers Using Economical Precursors and Advanced Processing Technologies. Carbon 2019, 142, 610–649. [Google Scholar] [CrossRef]

- Rajak, D.K.; Wagh, P.H.; Linul, E. Manufacturing Technologies of Carbon/Glass Fiber-Reinforced Polymer Composites and Their Properties: A Review. Polymers 2021, 13, 3721. [Google Scholar] [CrossRef] [PubMed]

- El Magri, A.; El Mabrouk, K.; Vaudreuil, S.; Ebn Touhami, M. Mechanical Properties of CF-Reinforced PLA Parts Manufactured by Fused Deposition Modeling. J. Thermoplast. Compos. Mater. 2019, 34, 581–595. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Hu, Y.; Wang, H. Additive Manufacturing of Carbon Fiber-Reinforced Plastic Composites Using Fused Deposition Modeling: Effects of Process Parameters on Tensile Properties. J. Compos. Mater. 2016, 51, 451–462. [Google Scholar] [CrossRef]

- Sanei, S.H.R.; Popescu, D. 3D-Printed Carbon Fiber Reinforced Polymer Composites: A Systematic Review. J. Compos. Sci. 2020, 4, 98. [Google Scholar] [CrossRef]

- Ansari, A.A.; Kamil, M. Izod Impact and Hardness Properties of 3D Printed Lightweight CF-Reinforced PLA Composites Using Design of Experiment. Int. J. Lightweight Mater. Manuf. 2022, 5, 369–383. [Google Scholar] [CrossRef]

- Blanco, I.; Cicala, G.; Recca, G.; Tosto, C. Specific Heat Capacity and Thermal Conductivity Measurements of PLA-Based 3D-Printed Parts with Milled Carbon Fiber Reinforcement. Entropy 2022, 24, 654. [Google Scholar] [CrossRef]

- Bakis, C.E.; Haluza, R.T.; Bartolai, J.; Kim, J.J.; Simpson, T.W. Assessment of Anisotropic Mechanical Properties of a 3D Printed Carbon Whisker Reinforced Composite. Adv. Compos. Mater. 2019, 28, 545–560. [Google Scholar] [CrossRef]

- Ferreira, R.T.L.; Amatte, I.C.; Dutra, T.A.; Bürger, D. Experimental Characterization and Micrography of 3D Printed PLA and PLA Reinforced with Short Carbon Fibers. Compos. Part B Eng. 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Ivey, M.; Melenka, G.W.; Carey, J.P.; Ayranci, C. Characterizing Short-Fiber-Reinforced Composites Produced Using Additive Manufacturing. Adv. Manuf. Polym. Compos. Sci. 2017, 3, 81–91. [Google Scholar] [CrossRef]

- Durga Prasada Rao, V.; Rajiv, P.; Navya Geethika, V. Effect of Fused Deposition Modelling (FDM) Process Parameters on Tensile Strength of Carbon Fibre PLA. Mater. Today: Proc. 2019, 18, 2012–2018. [Google Scholar] [CrossRef]

- Al Zahmi, S.; Alhammadi, S.; ElHassan, A.; Ahmed, W. Carbon Fiber/PLA Recycled Composite. Polymers 2022, 14, 2194. [Google Scholar] [CrossRef]

- Vakharia, V.S.; Singh, M.; Salem, A.; Halbig, M.C.; Salem, J.A. Effect of Reinforcements and 3-D Printing Parameters on the Microstructure and Mechanical Properties of Acrylonitrile Butadiene Styrene (ABS) Polymer Composites. Polymers 2022, 14, 2105. [Google Scholar] [CrossRef] [PubMed]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly Oriented Carbon Fiber–Polymer Composites via Additive Manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive Manufacturing of Carbon Fiber Reinforced Thermoplastic Composites Using Fused Deposition Modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Love, L.J.; Kunc, V.; Rios, O.; Duty, C.E.; Elliott, A.M.; Post, B.K.; Smith, R.J.; Blue, C.A. The Importance of Carbon Fiber to Polymer Additive Manufacturing. J. Mater. Res. 2014, 29, 1893–1898. [Google Scholar] [CrossRef]

- Wang, K.; Li, S.; Rao, Y.; Wu, Y.; Peng, Y.; Yao, S.; Ahzi, S. Flexure Behaviors of ABS-Based Composites Containing Carbon and Kevlar Fibers by Material Extrusion 3D Printing. Polymers 2019, 11, 1878. [Google Scholar] [CrossRef]

- Verdejo de Toro, E.; Coello Sobrino, J.; Martínez Martínez, A.; Miguel Eguía, V.; Ayllón Pérez, J. Investigation of a Short Carbon Fibre-Reinforced Polyamide and Comparison of Two Manufacturing Processes: Fused Deposition Modelling (FDM) and Polymer Injection Moulding (PIM). Materials 2020, 13, 672. [Google Scholar] [CrossRef]

- Chicos, L.-A.; Pop, M.A.; Zaharia, S.-M.; Lancea, C.; Buican, G.R.; Pascariu, I.S.; Stamate, V.-M. Infill Density Influence on Mechanical and Thermal Properties of Short Carbon Fiber-Reinforced Polyamide Composites Manufactured by FFF Process. Materials 2022, 15, 3706. [Google Scholar] [CrossRef]

- Zhang, Z.; Gkartzou, E.; Jestin, S.; Semitekolos, D.; Pappas, P.-N.; Li, X.; Karatza, A.; Zouboulis, P.; Trompeta, A.-F.; Koutroumanis, N.; et al. 3D Printing Processability of a Thermally Conductive Compound Based on Carbon Nanofiller-Modified Thermoplastic Polyamide 12. Polymers 2022, 14, 470. [Google Scholar] [CrossRef] [PubMed]

- Imeri, A.; Fidan, I.; Allen, M.; Wilson, D.A.; Canfield, S. Fatigue Analysis of the Fiber Reinforced Additively Manufactured Objects. Int. J. Adv. Manuf. Technol. 2018, 98, 2717–2724. [Google Scholar] [CrossRef]

- Justo, J.; Távara, L.; García-Guzmán, L.; París, F. Characterization of 3D Printed Long Fibre Reinforced Composites. Compos. Struct. 2018, 185, 537–548. [Google Scholar] [CrossRef]

- Kováčová, M.; Kozakovičová, J.; Procházka, M.; Janigová, I.; Vysopal, M.; Černičková, I.; Krajčovič, J.; Špitalský, Z. Novel Hybrid PETG Composites for 3D Printing. Appl. Sci. 2020, 10, 3062. [Google Scholar] [CrossRef]

- Ferreira, I.; Vale, D.; Machado, M.; Lino, J. Additive Manufacturing of Polyethylene Terephthalate Glycol/Carbon Fiber Composites: An Experimental Study from Filament to Printed Parts. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2018, 233, 1866–1878. [Google Scholar] [CrossRef]

- Valvez, S.; Silva, A.P.; Reis, P.N.B. Optimization of Printing Parameters to Maximize the Mechanical Properties of 3D-Printed PETG-Based Parts. Polymers 2022, 14, 2564. [Google Scholar] [CrossRef]

- Valvez, S.; Silva, A.P.; Reis, P.N.B. Compressive Behaviour of 3D-Printed PETG Composites. Aerospace 2022, 9, 124. [Google Scholar] [CrossRef]

- Mansour, M.; Tsongas, K.; Tzetzis, D.; Antoniadis, A. Mechanical and Dynamic Behavior of Fused Filament Fabrication 3D Printed Polyethylene Terephthalate Glycol Reinforced with Carbon Fibers. Polym.-Plast. Technol. Eng. 2018, 57, 1715–1725. [Google Scholar] [CrossRef]

- Wang, P.; Zou, B.; Ding, S.; Huang, C.; Shi, Z.; Ma, Y.; Yao, P. Preparation of Short CF/GF Reinforced PEEK Composite Filaments and Their Comprehensive Properties Evaluation for FDM-3D Printing. Compos. Part B Eng. 2020, 198, 108175. [Google Scholar] [CrossRef]

- Patterson, A.E.; Pereira, T.R.; Allison, J.T.; Messimer, S.L. IZOD Impact Properties of Full-Density Fused Deposition Modeling Polymer Materials with Respect to Raster Angle and Print Orientation. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 235, 1891–1908. [Google Scholar] [CrossRef]

- Gupta, A.; Fidan, I.; Hasanov, S.; Nasirov, A. Processing, Mechanical Characterization, and Micrography of 3D-Printed Short Carbon Fiber Reinforced Polycarbonate Polymer Matrix Composite Material. Int. J. Adv. Manuf. Technol. 2020, 107, 3185–3205. [Google Scholar] [CrossRef]

- Lamin, W.M.; Bussamra, F.L.; Ferreira, R.T.; Sales, R.C.; Baldo, J.E. Linear Translaminar Fracture Characterization of Additive Manufactured Continuous Carbon Fiber Reinforced Thermoplastic. J. Thermoplast. Compos. Mater. 2021, 1–28. [Google Scholar] [CrossRef]

- Hu, Q.; Duan, Y.; Zhang, H.; Liu, D.; Yan, B.; Peng, F. Manufacturing and 3D Printing of Continuous Carbon Fiber Prepreg Filament. J. Mater. Sci. 2017, 53, 1887–1898. [Google Scholar] [CrossRef]

- Hao, W.; Liu, Y.; Zhou, H.; Chen, H.; Fang, D. Preparation and Characterization of 3D Printed Continuous Carbon Fiber Reinforced Thermosetting Composites. Polym. Test. 2018, 65, 29–34. [Google Scholar] [CrossRef]

- Luo, M.; Tian, X.; Shang, J.; Zhu, W.; Li, D.; Qin, Y. Impregnation and Interlayer Bonding Behaviours of 3D-Printed Continuous Carbon-Fiber-Reinforced Poly-Ether-Ether-Ketone Composites. Compos. Part A Appl. Sci. Manuf. 2019, 121, 130–138. [Google Scholar] [CrossRef]

- Yu, T.; Zhang, Z.; Song, S.; Bai, Y.; Wu, D. Tensile and Flexural Behaviors of Additively Manufactured Continuous Carbon Fiber-Reinforced Polymer Composites. Compos. Struct. 2019, 225, 111147. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, K.; Neto, V.; Peng, Y.; Valente, R.; Ahzi, S. Interfacial Behaviors of Continuous Carbon Fiber Reinforced Polymers Manufactured by Fused Filament Fabrication: A Review and Prospect. Int. J. Mater. Form. 2022, 15, 18. [Google Scholar] [CrossRef]

- Blok, L.G.; Longana, M.L.; Yu, H.; Woods, B.K.S. An Investigation into 3D Printing of Fibre Reinforced Thermoplastic Composites. Addit. Manuf. 2018, 22, 176–186. [Google Scholar] [CrossRef]

- Sang, L.; Han, S.; Li, Z.; Yang, X.; Hou, W. Development of short basalt fiber reinforced polylactide composites and their feasible evaluation for 3D printing applications. Compos. Part B Eng. 2019, 164, 629–639. [Google Scholar] [CrossRef]

- Sang, L.; Han, S.; Peng, X.; Jian, X.; Wang, J. Development of 3D-printed basalt fiber reinforced thermoplastic honeycombs with enhanced compressive mechanical properties. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105518. [Google Scholar] [CrossRef]

- Yu, S.; Bale, H.; Park, S.; Hwang, J.Y.; Hong, S.H. Anisotropic microstructure dependent mechanical behavior of 3D-printed basalt fiber-reinforced thermoplastic composites. Compos. Part B Eng. 2021, 224, 109184. [Google Scholar] [CrossRef]

- Yu, S.; Hwang, Y.H.; Hwang, J.Y.; Hong, S.H. Analytical Study on the 3D-Printed Structure and Mechanical Properties of Basalt Fiber-Reinforced PLA Composites Using X-Ray Microscopy. Compos. Sci. Technol. 2019, 175, 18–27. [Google Scholar] [CrossRef]

- Kurniawan, D.; Kim, B.S.; Lee, H.Y.; Lim, J.Y. Towards improving mechanical properties of basalt fiber/polylactic acid composites by fiber surface treatments. Compos. Interfaces 2015, 22, 553–562. [Google Scholar] [CrossRef]

- Balaji, K.V.; Shirvanimoghaddam, K.; Rajan, G.S.; Ellis, A.V.; Naebe, M. Surface treatment of Basalt fiber for use in automotive composites. Mater. Today Chem. 2020, 17, 100334. [Google Scholar]

- Zotti, A.; Zuppolini, S.; Tábi, T.; Grasso, M.; Ren, G.; Borriello, A.; Zarrelli, M. Effects of 1D and 2D Nanofillers in Basalt/Poly(Lactic Acid) Composites for Additive Manufacturing. Compos. Part B Eng. 2018, 153, 364–375. [Google Scholar] [CrossRef]

- Arslan, C.; Dogan, M. Effect of fiber amount on mechanical and thermal properties of (3-aminopropyl) triethoxysilane treated basalt fiber reinforced ABS composites. Mater. Res. Express 2019, 6, 115340. [Google Scholar] [CrossRef]

- Coughlin, N.; Drake, B.; Fjerstad, M.; Schuster, E.; Waege, T.; Weerakkody, A.; Letcher, T. Development and mechanical properties of basalt fiber-reinforced acrylonitrile butadiene styrene for in-space manufacturing applications. J. Compos. Sci. 2019, 3, 89. [Google Scholar] [CrossRef] [Green Version]

- Dowling, D.P.; Abourayana, H.M.; Brantseva, T.; Antonov, A.; Dobbyn, P.J. Enhancing the mechanical performance of 3D-printed basalt fiber-reinforced composites using in-line atmospheric plasma pretreatments. Plasma Processes Polym. 2020, 17, 1900143. [Google Scholar] [CrossRef]

- Bailly, M.; Kontopoulou, M.; El Mabrouk, K. Effect of Polymer/Filler Interactions on the Structure and Rheological Properties of Ethylene-Octene Copolymer/Nanosilica Composites. Polymer 2010, 51, 5506–5515. [Google Scholar] [CrossRef]

- Babanzadeh, S.; Mehdipour-Ataei, S.; Mahjoub, A.R. Effect of Nanosilica on the Dielectric Properties and Thermal Stability of Polyimide/SiO2Nanohybrid. Des. Monomers Polym. 2012, 16, 417–424. [Google Scholar] [CrossRef]

- Wu, G.; Liu, S.; Jia, H.; Dai, J. Preparation and Properties of Heat Resistant Polylactic Acid (PLA)/Nano-SiO2 Composite Filament. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2016, 31, 164–171. [Google Scholar] [CrossRef]

- Gong, Z.; Huang, J.; Fan, J.; Chen, X.; Wang, H.; Chen, Y. A Super-Toughened Poly(Lactic Acid)-Based Thermoplastic Vulcanizate through Incorporating Modified SiO2 Nanoparticles. Compos. Sci. Technol. 2022, 226, 109558. [Google Scholar] [CrossRef]

- Gong, Z.; Huang, J.; Fan, J.; Chen, X.; Wang, H.; Chen, Y. Super-Tough Poly(Lactic Acid)-Based Thermoplastic Vulcanizate Based on Selective Dispersion and in Situ Compatibilization of Commercial Reinforcing Fillers and Its Application in Three-Dimensional Printing. Ind. Eng. Chem. Res. 2021, 61, 359–371. [Google Scholar] [CrossRef]

- Kodali, D.; Umerah, C.O.; Idrees, M.O.; Jeelani, S.; Rangari, V.K. Fabrication and Characterization of Polycarbonate-Silica Filaments for 3D Printing Applications. J. Compos. Mater. 2021, 55, 4575–4584. [Google Scholar] [CrossRef]

- Ramachandran, M.G.; Rajeswari, N. Influence of Nano Silica on Mechanical and Tribological Properties of Additive Manufactured PLA Bio Nanocomposite. Silicon 2021, 14, 703–709. [Google Scholar] [CrossRef]

- Sharma, A.; Singholi, A.K.S. Effect of Nanosilica on Shape Memory and Mechanical Characterization of Polylactic Acid Wood Composite. Polym. Compos. 2021, 42, 2502–2510. [Google Scholar] [CrossRef]

- Sharma, A.; Singholi, A.K.S. Shape Memory and Mechanical Characterization of Polylactic Acid Wood Composite Fabricated by Fused Filament Fabrication 4D Printing Technology. Mater. Und Werkst. 2021, 52, 635–643. [Google Scholar] [CrossRef]

- Seng, C.T.; A/L Eh Noum, S.Y.; A/L Sivanesan, S.K.; Yu, L.-J. Reduction of Hygroscopicity of PLA Filament for 3D Printing by Introducing Nano Silica as Filler. In Proceedings of the 13th International Engineering Research Conference 13th Eureca 2019, Selangor Darul Ehsan, Malaysia, 27 November 2019. [Google Scholar]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Tzounis, L.; Mountakis, N.; Korlos, A.; Fischer-Griffiths, P.E.; Grammatikos, S. On the Mechanical Response of Silicon Dioxide Nanofiller Concentration on Fused Filament Fabrication 3D Printed Isotactic Polypropylene Nanocomposites. Polymers 2021, 13, 2029. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Mountakis, N.; Tzounis, L.; Liebscher, M.; Grammatikos, S.A. Enhanced Mechanical, Thermal and Antimicrobial Properties of Additively Manufactured Polylactic Acid with Optimized Nano Silica Content. Nanomaterials 2021, 11, 1012. [Google Scholar] [CrossRef]

- Novoselov, K.S. Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef]

- Joudeh, N.; Linke, D. Nanoparticle Classification, Physicochemical Properties, Characterization, and Applications: A Comprehensive Review for Biologists. J. Nanobiotechnol. 2022, 20, 1–29. [Google Scholar] [CrossRef] [PubMed]

- Farmand, M.; Jahanpeyma, F.; Gholaminejad, A.; Azimzadeh, M.; Malaei, F.; Shoaie, N. Carbon Nanostructures: A Comprehensive Review of Potential Applications and Toxic Effects. 3 Biotech 2022, 12, 159. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Fu, K. Polymer-Based Filament Feedstock for Additive Manufacturing. Compos. Sci. Technol. 2021, 213, 108876. [Google Scholar] [CrossRef]

- Foster, C.W.; Down, M.P.; Zhang, Y.; Ji, X.; Rowley-Neale, S.J.; Smith, G.C.; Kelly, P.J.; Banks, C.E. 3D Printed Graphene Based Energy Storage Devices. Sci. Rep. 2017, 7, 42233. [Google Scholar] [CrossRef]

- Bustillos, J.; Montero, D.; Nautiyal, P.; Loganathan, A.; Boesl, B.; Agarwal, A. Integration of Graphene in Poly(Lactic) Acid by 3D Printing to Develop Creep and Wear-Resistant Hierarchical Nanocomposites. Polym. Compos. 2017, 39, 3877–3888. [Google Scholar] [CrossRef]

- Caminero, M.Á.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J.; Reverte, J.M.; Becar, J.P. Additive Manufacturing of PLA-Based Composites Using Fused Filament Fabrication: Effect of Graphene Nanoplatelet Reinforcement on Mechanical Properties, Dimensional Accuracy and Texture. Polymers 2019, 11, 799. [Google Scholar] [CrossRef]

- Sweeney, C.B.; Lackey, B.A.; Pospisil, M.J.; Achee, T.C.; Hicks, V.K.; Moran, A.G.; Teipel, B.R.; Saed, M.A.; Green, M.J. Welding of 3D-Printed Carbon Nanotube–Polymer Composites by Locally Induced Microwave Heating. Sci. Adv. 2017, 3, e1700262. [Google Scholar] [CrossRef] [Green Version]

- Ivanov, E.; Kotsilkova, R.; Xia, H.; Chen, Y.; Donato, R.; Donato, K.; Godoy, A.; Di Maio, R.; Silvestre, C.; Cimmino, S.; et al. PLA/Graphene/MWCNT Composites with Improved Electrical and Thermal Properties Suitable for FDM 3D Printing Applications. Appl. Sci. 2019, 9, 1209. [Google Scholar] [CrossRef]

- Foo, C.Y.; Lim, H.N.; Mahdi, M.A.; Wahid, M.H.; Huang, N.M. Three-Dimensional Printed Electrode and Its Novel Applications in Electronic Devices. Sci. Rep. 2018, 8, 7399. [Google Scholar] [CrossRef]

- Chen, Q.; Mangadlao, J.D.; Wallat, J.; De Leon, A.; Pokorski, J.K.; Advincula, R.C. 3D Printing Biocompatible Polyurethane/Poly(Lactic Acid)/Graphene Oxide Nanocomposites: Anisotropic Properties. ACS Appl. Mater. Interfaces 2017, 9, 4015–4023. [Google Scholar] [CrossRef]

- Kim, K.; Park, J.; Suh, J.; Kim, M.; Jeong, Y.; Park, I. 3D Printing of Multiaxial Force Sensors Using Carbon Nanotube (CNT)/Thermoplastic Polyurethane (TPU) Filaments. Sens. Actuators A Phys. 2017, 263, 493–500. [Google Scholar] [CrossRef]

- Christ, J.F.; Aliheidari, N.; Ameli, A.; Pötschke, P. 3D Printed Highly Elastic Strain Sensors of Multiwalled Carbon Nanotube/Thermoplastic Polyurethane Nanocomposites. Mater. Des. 2017, 131, 394–401. [Google Scholar] [CrossRef]

- Xiang, D.; Zhang, X.; Li, Y.; Harkin-Jones, E.; Zheng, Y.; Wang, L.; Zhao, C.; Wang, P. Enhanced Performance of 3D Printed Highly Elastic Strain Sensors of Carbon Nanotube/Thermoplastic Polyurethane Nanocomposites via Non-Covalent Interactions. Compos. Part B Eng. 2019, 176, 107250. [Google Scholar] [CrossRef]

- Podsiadły, B.; Matuszewski, P.; Skalski, A.; Słoma, M. Carbon Nanotube-Based Composite Filaments for 3D Printing of Structural and Conductive Elements. Appl. Sci. 2021, 11, 1272. [Google Scholar] [CrossRef]

- Sezer, H.K.; Eren, O. FDM 3D Printing of MWCNT Re-Inforced ABS Nano-Composite Parts with Enhanced Mechanical and Electrical Properties. J. Manuf. Process. 2019, 37, 339–347. [Google Scholar] [CrossRef]

- Dorigato, A.; Moretti, V.; Dul, S.; Unterberger, S.H.; Pegoretti, A. Electrically Conductive Nanocomposites for Fused Deposition Modelling. Synth. Met. 2017, 226, 7–14. [Google Scholar] [CrossRef]

- Shofner, M.L.; Rodríguez-Macías, F.J.; Vaidyanathan, R.; Barrera, E.V. Single Wall Nanotube and Vapor Grown Carbon Fiber Reinforced Polymers Processed by Extrusion Freeform Fabrication. Compos. Part A Appl. Sci. Manuf. 2003, 34, 1207–1217. [Google Scholar] [CrossRef]

- Wei, X.; Li, D.; Jiang, W.; Gu, Z.; Wang, X.; Zhang, Z.; Sun, Z. 3D Printable Graphene Composite. Sci. Rep. 2015, 5, 11181. [Google Scholar] [CrossRef]

- Dul, S.; Fambri, L.; Pegoretti, A. Fused Deposition Modelling with ABS–Graphene Nanocomposites. Compos. Part A Appl. Sci. Manuf. 2016, 85, 181–191. [Google Scholar] [CrossRef]

- Singh, R.; Singh, H.; Farina, I.; Colangelo, F.; Fraternali, F. On the Additive Manufacturing of an Energy Storage Device from Recycled Material. Compos. Part B Eng. 2019, 156, 259–265. [Google Scholar] [CrossRef]

- Aumnate, C.; Pongwisuthiruchte, A.; Pattananuwat, P.; Potiyaraj, P. Fabrication of ABS/Graphene Oxide Composite Filament for Fused Filament Fabrication (FFF) 3D Printing. Adv. Mater. Sci. Eng. 2018, 2018, 2830437. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, B.; Fu, F.; You, F.; Dong, X.; Dai, M. Resistivity and Its Anisotropy Characterization of 3D-Printed Acrylonitrile Butadiene Styrene Copolymer (ABS)/Carbon Black (CB) Composites. Appl. Sci. 2017, 7, 20. [Google Scholar] [CrossRef]

- Berretta, S.; Davies, R.; Shyng, Y.T.; Wang, Y.; Ghita, O. Fused Deposition Modelling of High Temperature Polymers: Exploring CNT PEEK Composites. Polym. Test. 2017, 63, 251–262. [Google Scholar] [CrossRef]

- Gonçalves, J.; Lima, P.; Krause, B.; Pötschke, P.; Lafont, U.; Gomes, J.; Abreu, C.; Paiva, M.; Covas, J. Electrically Conductive Polyetheretherketone Nanocomposite Filaments: From Production to Fused Deposition Modeling. Polymers 2018, 10, 925. [Google Scholar] [CrossRef]

- Zhu, D.; Ren, Y.; Liao, G.; Jiang, S.; Liu, F.; Guo, J.; Xu, G. Thermal and Mechanical Properties of Polyamide 12/Graphene Nanoplatelets Nanocomposites and Parts Fabricated by Fused Deposition Modeling. J. Appl. Polym. Sci. 2017, 134, 45332. [Google Scholar] [CrossRef]

- Han, J.Y.; Chen, T.; Baird, D.G. Generation of Nylon Copolymer Reinforced with Carbon Nanotubes and Thermotropic Liquid Crystalline Polymers for Use in Fused Filament Fabrication. Polym. Compos. 2021, 42, 4328–4341. [Google Scholar] [CrossRef]

- Gnanasekaran, K.; Heijmans, T.; van Bennekom, S.; Woldhuis, H.; Wijnia, S.; de With, G.; Friedrich, H. 3D Printing of CNT- and Graphene-Based Conductive Polymer Nanocomposites by Fused Deposition Modeling. Appl. Mater. Today 2017, 9, 21–28. [Google Scholar] [CrossRef]

- Kwok, S.W.; Goh, K.H.H.; Tan, Z.D.; Tan, S.T.M.; Tjiu, W.W.; Soh, J.Y.; Ng, Z.J.G.; Chan, Y.Z.; Hui, H.K.; Goh, K.E.J. Electrically Conductive Filament for 3D-Printed Circuits and Sensors. Appl. Mater. Today 2017, 9, 167–175. [Google Scholar] [CrossRef]

- Han, J.Y.; Chen, T.; Mu, Q.; Baird, D.G. Thermotropic Liquid Crystalline Polymer Reinforced Polypropylene Composites Enhanced with Carbon Nanotubes for Use in Fused Filament Fabrication. Polym. Compos. 2021, 42, 4115–4127. [Google Scholar] [CrossRef]

- Kennedy, Z.C.; Christ, J.F.; Evans, K.A.; Arey, B.W.; Sweet, L.E.; Warner, M.G.; Erikson, R.L.; Barrett, C.A. 3D-Printed Poly(Vinylidene Fluoride)/Carbon Nanotube Composites as a Tunable, Low-Cost Chemical Vapour Sensing Platform. Nanoscale 2017, 9, 5458–5466. [Google Scholar] [CrossRef]

- Yang, L.; Chen, Y.; Wang, M.; Shi, S.; Jing, J. Fused Deposition Modeling 3D Printing of Novel Poly(Vinyl Alcohol)/Graphene Nanocomposite with Enhanced Mechanical and Electromagnetic Interference Shielding Properties. Ind. Eng. Chem. Res. 2020, 59, 8066–8077. [Google Scholar] [CrossRef]

- Kumar, N.; Jain, P.K.; Tandon, P.; Pandey, P.M. Additive Manufacturing of Flexible Electrically Conductive Polymer Composites via CNC-Assisted Fused Layer Modeling Process. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 175. [Google Scholar] [CrossRef]

- Castles, F.; Isakov, D.; Lui, A.; Lei, Q.; Dancer, C.E.J.; Wang, Y.; Grant, P.S. Microwave dielectric characterisation of 3D-printed BaTiO3/ABS polymer composites. Sci. Rep. 2016, 6, 22714. [Google Scholar] [CrossRef] [PubMed]

- Khatri, B.; Lappe, K.; Habedank, M.; Mueller, T.; Megnin, C.; Hanemann, T. Fused Deposition Modeling of ABS-Barium Titanate Composites: A Simple Route towards Tailored Dielectric Devices. Polymers 2018, 10, 666. [Google Scholar] [CrossRef] [PubMed]

- Malakooti, M.H.; Julé, F.; Sodano, H.A. Printed Nanocomposite Energy Harvesters with Controlled Alignment of Barium Titanate Nanowires. ACS Appl. Mater. Interfaces 2018, 10, 38359–38367. [Google Scholar] [CrossRef]

- Kim, H.; Fernando, T.; Li, M.; Lin, Y.; Tseng, T.-L.B. Fabrication and characterization of 3D printed BaTiO3/PVDF nanocomposites. J. Compos. Mater. 2017, 52, 197–206. [Google Scholar] [CrossRef]

- Kim, H.; Torres, F.; Villagran, D.; Stewart, C.; Lin, Y.; Tseng, T.L.B. 3D printing of BaTiO3/PVDF composites with electric in situ poling for pressure sensor applications. Macromol. Mater. Eng. 2017, 302, 1700229. [Google Scholar] [CrossRef]

- Paspali, A.; Bao, Y.; Gawne, D.T.; Piestert, F.; Reinelt, S. The influence of nanostructure on the mechanical properties of 3D printed polylactide/nanoclay composites. Compos. Part B Eng. 2018, 152, 160–168. [Google Scholar] [CrossRef]

- Lee, C.H.; Yeoh, C.K.; Hamzah, K.A.; Teh, P.L. Mechanical Properties of Copper Ferrite CuFe2O4-Polymer Composite Fabricated Using 3D Printer. Mater. Sci. Forum 2017, 888, 203–208. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sztorch, B.; Brząkalski, D.; Pakuła, D.; Frydrych, M.; Špitalský, Z.; Przekop, R.E. Natural and Synthetic Polymer Fillers for Applications in 3D Printing—FDM Technology Area. Solids 2022, 3, 508-548. https://doi.org/10.3390/solids3030034

Sztorch B, Brząkalski D, Pakuła D, Frydrych M, Špitalský Z, Przekop RE. Natural and Synthetic Polymer Fillers for Applications in 3D Printing—FDM Technology Area. Solids. 2022; 3(3):508-548. https://doi.org/10.3390/solids3030034

Chicago/Turabian StyleSztorch, Bogna, Dariusz Brząkalski, Daria Pakuła, Miłosz Frydrych, Zdeno Špitalský, and Robert E. Przekop. 2022. "Natural and Synthetic Polymer Fillers for Applications in 3D Printing—FDM Technology Area" Solids 3, no. 3: 508-548. https://doi.org/10.3390/solids3030034

APA StyleSztorch, B., Brząkalski, D., Pakuła, D., Frydrych, M., Špitalský, Z., & Przekop, R. E. (2022). Natural and Synthetic Polymer Fillers for Applications in 3D Printing—FDM Technology Area. Solids, 3(3), 508-548. https://doi.org/10.3390/solids3030034