Atomic Force Microscopy’s Application for Surface Structure Investigation of Materials Synthesized by Laser Powder Bed Fusion

Abstract

1. Introduction

2. Materials and Methods

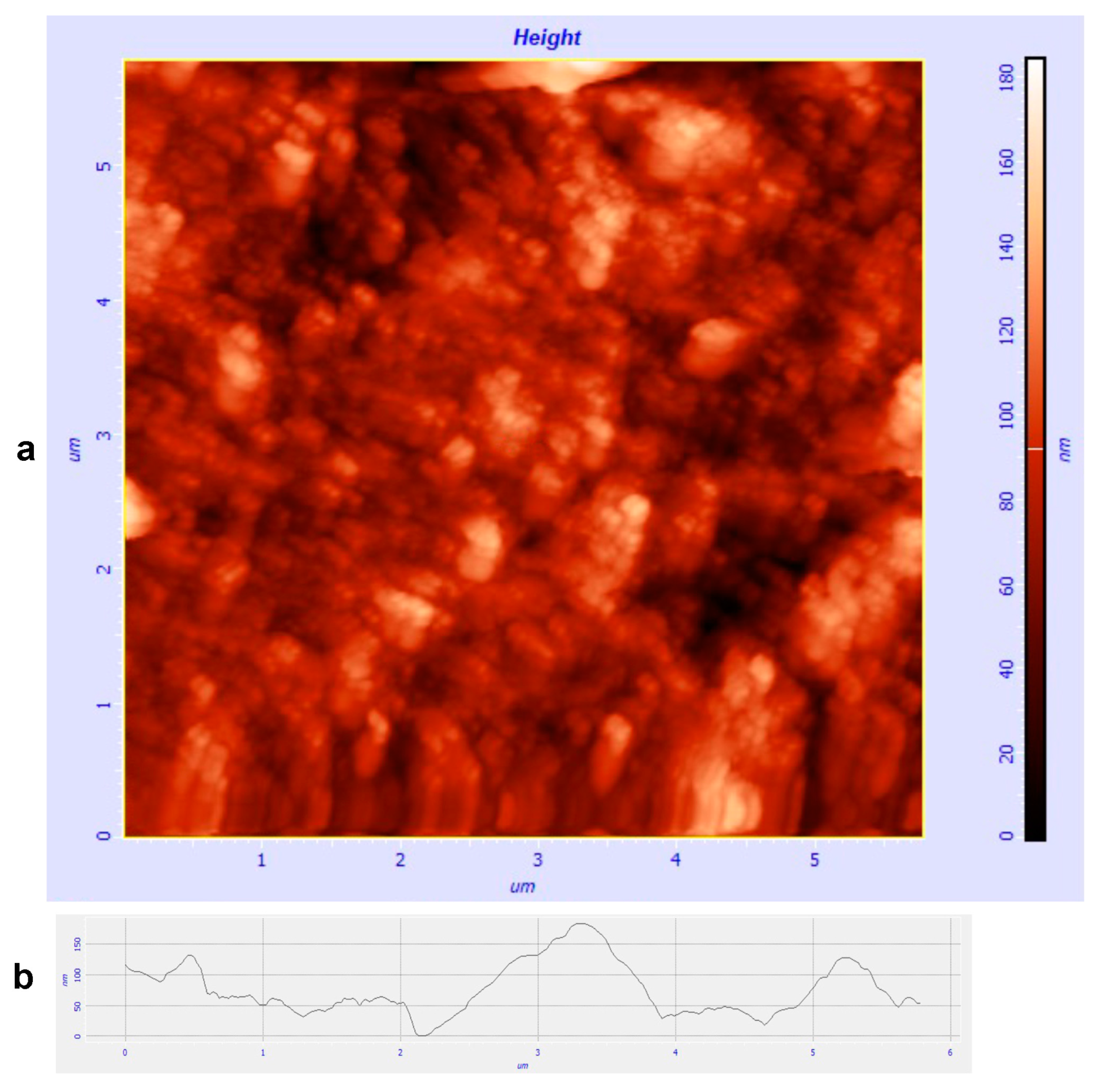

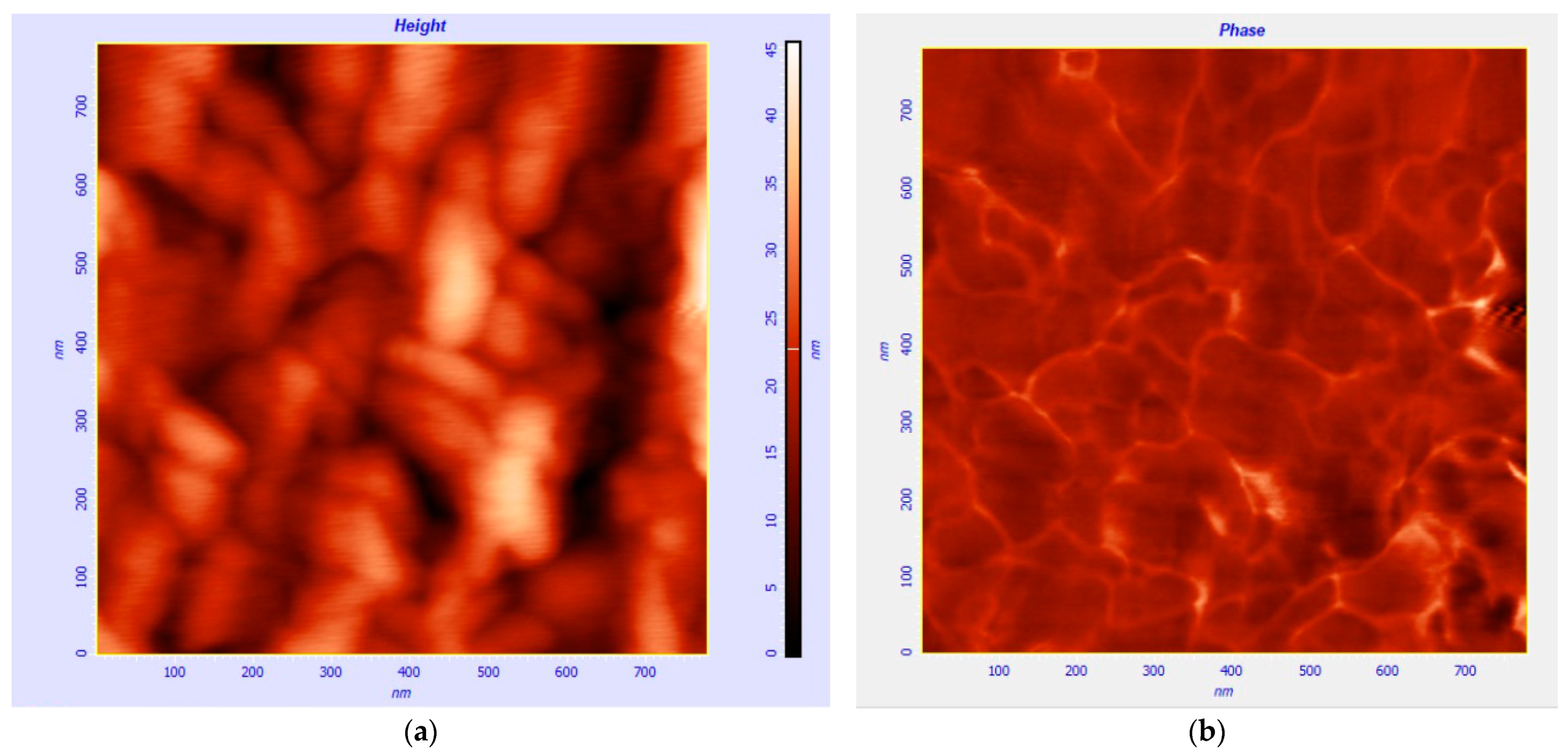

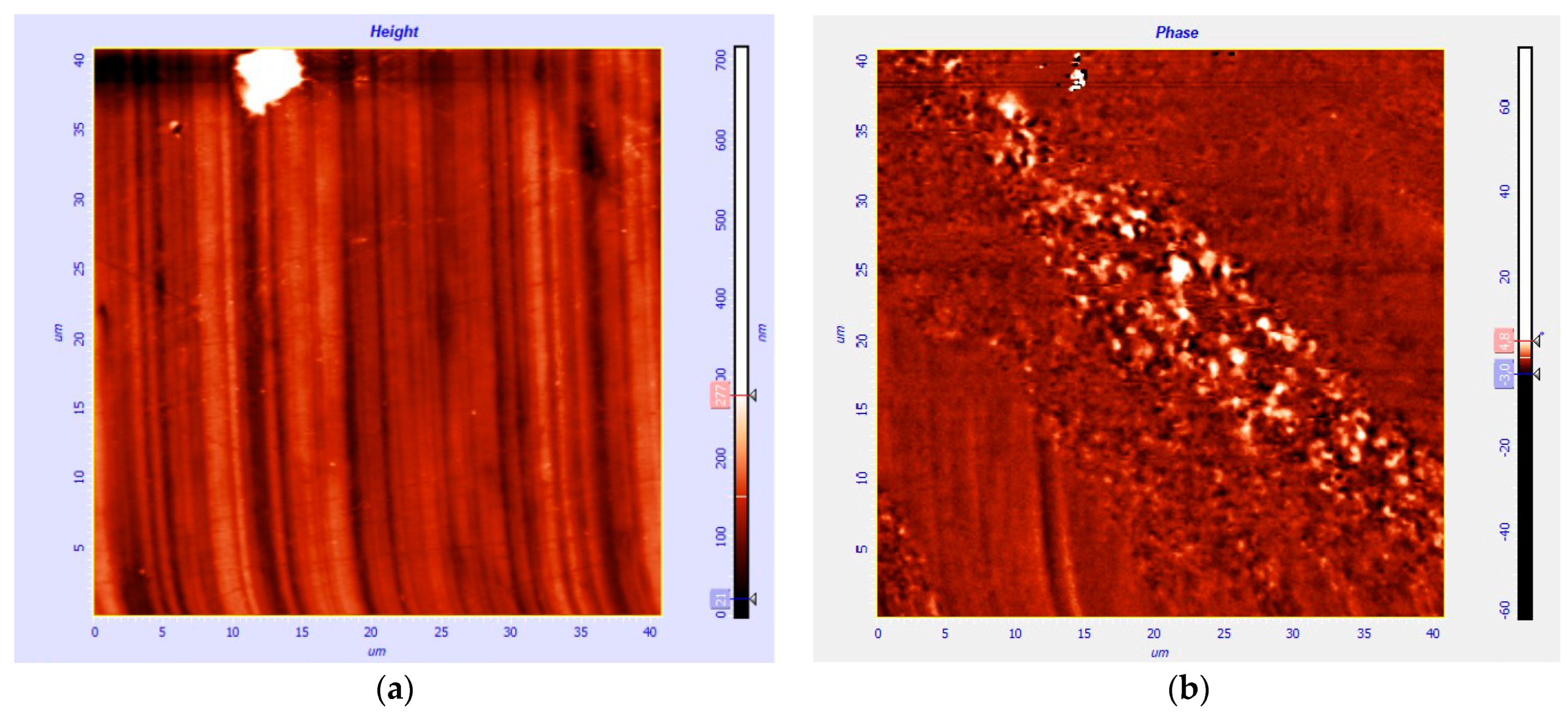

3. Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Durai Murugan, P.; Vijayananth, S.; Natarajan, M.P.; Jayabalakrishnan, D.; Arul, K.; Jayaseelan, V.; Elanchezhian, J. A Current State of Metal Additive Manufacturing Methods: A Review. Mater. Today Proc. 2022, 59, 1277–1283. [Google Scholar] [CrossRef]

- Attaran, M. The Rise of 3-D Printing: The Advantages of Additive Manufacturing over Traditional Manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Zhang, H.; Vallabh, C.K.P.; Zhao, X. Registration and Fusion of Large-Scale Melt Pool Temperature and Morphology Monitoring Data Demonstrated for Surface Topography Prediction in LPBF. Addit. Manuf. 2022, 58, 103075. [Google Scholar] [CrossRef]

- Chowdhury, S.; Yadaiah, N.; Prakash, C.; Ramakrishna, S.; Dixit, S.; Gupta, L.R.; Buddhi, D. Laser Powder Bed Fusion: A State-of-the-Art Review of the Technology, Materials, Properties & Defects, and Numerical Modelling. J. Mater. Res. Technol. 2022, 20, 2109–2172. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D Printing of Aluminium Alloys: Additive Manufacturing of Aluminium Alloys Using Selective Laser Melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Ahn, B. Microstructural Tailoring and Enhancement in Compressive Properties of Additive Manufactured Ti-6Al-4V Alloy through Heat Treatment. Materials 2021, 14, 5524. [Google Scholar] [CrossRef]

- Jeyaprakash, N.; Saravana Kumar, M.; Yang, C.-H.; Cheng, Y.; Radhika, N.; Sivasankaran, S. Effect of Microstructural Evolution during Melt Pool Formation on Nano-Mechanical Properties in LPBF Based SS316L Parts. J. Alloys Compd. 2024, 972, 172745. [Google Scholar] [CrossRef]

- Rani, S.U.; Kesavan, D.; Kamaraj, M. Evaluation of Influence of Microstructural Features of LPBF Ti-6Al-4 V on Mechanical Properties for an Optimal Strength and Ductility. J. Alloys Compd. 2023, 960, 170575. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive Manufacturing of Metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Zheng, T.; Pan, S.; Murali, N.; Li, B.; Li, X. Selective Laser Melting of Novel 7075 Aluminum Powders with Internally Dispersed TiC Nanoparticles. Mater. Lett. 2022, 319, 132268. [Google Scholar] [CrossRef]

- Liu, G.; Zhou, S.; Wang, C.; Chen, S.; Sun, D.; Chen, A.; Li, Z.; Yan, C.; Shi, Y. Fabrication and Characterization of SiC/Al Composites Prepared by Laser Powder Bed Fusion (LPBF) Combined with Vacuum Pressure Infiltration. Mater. Des. 2023, 236, 112495. [Google Scholar] [CrossRef]

- Spierings, A.B.; Ozherelkov, D.Y.; Kneubühler, F.; Eremin, S.A.; Pelevin, I.A.; Nalivaiko, A.Y.; Petrov, E.A.; Gromov, A.A.; Wegener, K. Laser Powder Bed Fusion of AlSi10Mg-Based Composites with Graphene and Nanodiamond Additions. J. Alloys Compd. 2023, 947, 169421. [Google Scholar] [CrossRef]

- Li, S.; Yue, X.; Li, Q.; Peng, H.; Dong, B.; Liu, T.; Yang, H.; Fan, J.; Shu, S.; Qiu, F.; et al. Development and Applications of Aluminum Alloys for Aerospace Industry. J. Mater. Res. Technol. 2023, 27, 944–983. [Google Scholar] [CrossRef]

- Bai, J.; Yang, Y.; Wen, C.; Chen, J.; Zhou, G.; Jiang, B.; Peng, X.; Pan, F. Applications of Magnesium Alloys for Aerospace: A Review. J. Magnes. Alloys 2023, 11, 3609–3619. [Google Scholar] [CrossRef]

- Sanchez, S.; Smith, P.; Xu, Z.; Gaspard, G.; Hyde, C.J.; Wits, W.W.; Ashcroft, I.A.; Chen, H.; Clare, A.T. Powder Bed Fusion of Nickel-Based Superalloys: A Review. Int. J. Mach. Tools Manuf. 2021, 165, 103729. [Google Scholar] [CrossRef]

- Alkhatib, S.E.; Sercombe, T.B. High Strain-Rate Response of Additively Manufactured Light Metal Alloys. Mater. Des. 2022, 217, 110664. [Google Scholar] [CrossRef]

- Qin, Y.; Wen, P.; Guo, H.; Xia, D.; Zheng, Y.; Jauer, L.; Poprawe, R.; Voshage, M.; Schleifenbaum, J.H. Additive Manufacturing of Biodegradable Metals: Current Research Status and Future Perspectives. Acta Biomater. 2019, 98, 3–22. [Google Scholar] [CrossRef]

- Bernhardt, A.; Schneider, J.; Schroeder, A.; Papadopoulous, K.; Lopez, E.; Brückner, F.; Botzenhart, U. Surface Conditioning of Additively Manufactured Titanium Implants and Its Influence on Materials Properties and in Vitro Biocompatibility. Mater. Sci. Eng. C 2021, 119, 111631. [Google Scholar] [CrossRef]

- Chernyshikhin, S.V.; Mahato, B.; Shiverskii, A.V.; Pelevin, I.A.; Dubinin, O.N.; Egorov, V.Y.; Abaimov, S.G.; Shishkovsky, I.V. In-Plane Measurements and Computational Fluid Dynamics Prediction of Permeability for Biocompatible NiTi Gyroid Scaffolds Fabricated via Laser Powder Bed Fusion. Int. J. Bioprinting 2023, 10, 0119. [Google Scholar] [CrossRef]

- Nagarajan, B.; Hu, Z.; Song, X.; Zhai, W.; Wei, J. Development of Micro Selective Laser Melting: The State of the Art and Future Perspectives. Engineering 2019, 5, 702–720. [Google Scholar] [CrossRef]

- Finazzi, V.; Berti, F.; Guillory II, R.J.; Petrini, L.; Previtali, B.; Demir, A.G. Patient-Specific Cardiovascular Superelastic NiTi Stents Produced by Laser Powder Bed Fusion. Procedia CIRP 2022, 110, 242–246. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, J.; Kang, L.; Tian, J.; Zhang, X.; Hu, J.; Huang, Y.; Liu, F.; Wang, H.; Wu, Z. An Overview of 3D Printed Metal Implants in Orthopedic Applications: Present and Future Perspectives. Heliyon 2023, 9, e17718. [Google Scholar] [CrossRef] [PubMed]

- Whitesides, G.M. The Origins and the Future of Microfluidics. Nature 2006, 442, 368–373. [Google Scholar] [CrossRef]

- Hirt, L.; Reiser, A.; Spolenak, R.; Zambelli, T. Additive Manufacturing of Metal Structures at the Micrometer Scale. Adv. Mater. 2017, 29, 1604211. [Google Scholar] [CrossRef]

- Gale, W.F.; Newcomb, S.B.; Totemeier, T.C.; Vander Voort, G.F. Metallography. In Smithells Metals Reference Book; Elsevier: Amsterdam, The Netherlands, 2004; pp. 10-1–10-87. [Google Scholar]

- Pelevin, I.A.; Ozherelkov, D.Y.; Nalivaiko, A.Y.; Bodyakova, A.I.; Chernyshikhin, S.V.; Zotov, B.O.; Korshunov, A.V.; Gromov, A.A. AlSi10Mg/AlN Interface Grain Structure after Laser Powder Bed Fusion. Metals 2022, 12, 2152. [Google Scholar] [CrossRef]

- Keya, T.; Bikmukhametov, I.; Shmatok, A.; Harvill, G.; Brewer, L.N.; Thompson, G.B.; Andurkar, M.; Thompson, S.M.; O’Donnell, V.; Gahl, J.; et al. Evolution of Microstructure and Its Influence on the Mechanical Behavior of LPBF Inconel 625 upon Direct Aging. Manuf. Lett. 2023, 35, 732–742. [Google Scholar] [CrossRef]

- Qin, H.; Fallah, V.; Dong, Q.; Brochu, M.; Daymond, M.R.; Gallerneault, M. Solidification Pattern, Microstructure and Texture Development in Laser Powder Bed Fusion (LPBF) of Al10SiMg Alloy. Mater. Charact. 2018, 145, 29–38. [Google Scholar] [CrossRef]

- Abd Mutalib, M.; Rahman, M.A.; Othman, M.H.D.; Ismail, A.F.; Jaafar, J. Scanning Electron Microscopy (SEM) and Energy-Dispersive X-Ray (EDX) Spectroscopy. In Membrane Characterization; Elsevier: Amsterdam, The Netherlands, 2017; pp. 161–179. [Google Scholar]

- Ernould, C.; Beausir, B.; Fundenberger, J.-J.; Taupin, V.; Bouzy, E. Applications of the Method. In Advances in Imaging and Electron Physics; Elsevier: Amsterdam, The Netherlands, 2022; Volume 223, pp. 155–215. [Google Scholar]

- Barmak, K. Crystal Orientation Mapping in Scanning and Transmission Electron Microscopes. In Metallic Films for Electronic, Optical and Magnetic Applications; Elsevier: Amsterdam, The Netherlands, 2014; pp. 39–66. [Google Scholar]

- García-Moreno, F.; Neu, T.R.; Kamm, P.H.; Banhart, J. X-ray Tomography and Tomoscopy on Metals: A Review. Adv. Eng. Mater. 2023, 25, 2201355. [Google Scholar] [CrossRef]

- Gulati, K.; Adachi, T. Profiling to Probing: Atomic Force Microscopy to Characterize Nano-Engineered Implants. Acta Biomater. 2023, 170, 15–38. [Google Scholar] [CrossRef]

- Li, M. Fundamentals and Methods of Atomic Force Microscopy for Biophysics. In Atomic Force Microscopy for Nanoscale Biophysics; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1–42. [Google Scholar]

- MQP-S-11-9-20001. Available online: https://mqitechnology.com/product/mqp-s-11-9-20001/ (accessed on 30 August 2024).

- Pelevin, I.A.; Terekhin, E.A.; Ozherelkov, D.Y.; Tereshina, I.S.; Karpenkov, D.Y.; Bochkanov, F.Y.; Chernyshikhin, S.V.; Nalivaiko, A.Y.; Gromov, A.A. New Scanning Strategy Approach for Laser Powder Bed Fusion of Nd-Fe-B Hard Magnetic Material. Metals 2023, 13, 1084. [Google Scholar] [CrossRef]

- Hooper, P.A. Melt Pool Temperature and Cooling Rates in Laser Powder Bed Fusion. Addit. Manuf. 2018, 22, 548–559. [Google Scholar] [CrossRef]

- Kim, H.-J.; Jang, Y.R.; Lee, H.-S.; Cho, J.-W.; Jang, T.; Eo, D.-R.; Lee, W. Microstructural Investigation of Nanocrystalline Nd-Fe-B Magnets Fabricated by Laser Powder Bed Fusion. Mater. Charact. 2024, 216, 114228. [Google Scholar] [CrossRef]

- Tereshina, I.S.; Pelevin, I.A.; Tereshina, E.A.; Burkhanov, G.S.; Rogacki, K.; Miller, M.; Kudrevatykh, N.V.; Markin, P.E.; Volegov, A.S.; Grechishkin, R.M.; et al. Magnetic Hysteresis Properties of Nanocrystalline (Nd,Ho)-(Fe,Co)-B Alloy after Melt Spinning, Severe Plastic Deformation and Subsequent Heat Treatment. J. Alloys Compd. 2016, 681, 555–560. [Google Scholar] [CrossRef]

- Andreeva, N.V.; Filimonov, A.V.; Rudskoi, A.I.; Burkhanov, G.S.; Tereshina, I.S.; Politova, G.A.; Pelevin, I.A. A Study of Nanostructure Magnetosolid Nd–Ho–Fe–Co–B Materials via Atomic Force Microscopy and Magnetic Force Microscopy. Phys. Solid State 2016, 58, 1862–1869. [Google Scholar] [CrossRef]

- Ohnesorge, F.; Binnig, G. True Atomic Resolution by Atomic Force Microscopy Through Repulsive and Attractive Forces. Science 1993, 260, 1451–1456. [Google Scholar] [CrossRef]

- Tosoni, O.; Mendonça, E.B.; Reijonen, J.; Antikainen, A.; Schäfer, L.; Riegg, S.; Gutfleisch, O. High-Coercivity Copper-Rich Nd-Fe-B Magnets by Powder Bed Fusion Using Laser Beam Method. Addit. Manuf. 2023, 64, 103426. [Google Scholar] [CrossRef]

- Goll, D.; Trauter, F.; Bernthaler, T.; Schanz, J.; Riegel, H.; Schneider, G. Additive Manufacturing of Bulk Nanocrystalline FeNdB Based Permanent Magnets. Micromachines 2021, 12, 538. [Google Scholar] [CrossRef]

| Characteristic | AFM | SEM | TEM |

|---|---|---|---|

| Advantages |

|

|

|

| Disadvantages |

|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pelevin, I.A.; Kaminskaya, T.P.; Chernyshikhin, S.V.; Larionov, K.B.; Dzidziguri, E.L. Atomic Force Microscopy’s Application for Surface Structure Investigation of Materials Synthesized by Laser Powder Bed Fusion. Compounds 2024, 4, 562-570. https://doi.org/10.3390/compounds4030034

Pelevin IA, Kaminskaya TP, Chernyshikhin SV, Larionov KB, Dzidziguri EL. Atomic Force Microscopy’s Application for Surface Structure Investigation of Materials Synthesized by Laser Powder Bed Fusion. Compounds. 2024; 4(3):562-570. https://doi.org/10.3390/compounds4030034

Chicago/Turabian StylePelevin, Ivan A., Tatiana P. Kaminskaya, Stanislav V. Chernyshikhin, Kirill B. Larionov, and Ella L. Dzidziguri. 2024. "Atomic Force Microscopy’s Application for Surface Structure Investigation of Materials Synthesized by Laser Powder Bed Fusion" Compounds 4, no. 3: 562-570. https://doi.org/10.3390/compounds4030034

APA StylePelevin, I. A., Kaminskaya, T. P., Chernyshikhin, S. V., Larionov, K. B., & Dzidziguri, E. L. (2024). Atomic Force Microscopy’s Application for Surface Structure Investigation of Materials Synthesized by Laser Powder Bed Fusion. Compounds, 4(3), 562-570. https://doi.org/10.3390/compounds4030034