The Use of Recycled and Secondary Aggregates to Achieve a Circular Economy within Geotechnical Engineering

Abstract

:1. Introduction

2. The Ethos of the Circular Economy as Motivation for the Use of Alternative Aggregates

2.1. Primary, Recycled and Secondary Aggregates

2.1.1. Primary Aggregates

2.1.2. Recycled and Secondary Aggregates

2.1.3. End-of-Waste Status

- the substance or object is commonly used for specific purposes;

- there is an existing market or demand for the substance or object;

- the use is lawful (substance or object fulfils the technical requirements for the specific purposes and meets the existing legislation and standards applicable to products);

- the use will not lead to overall adverse environmental or human health impacts.

2.2. Perceived Barriers to the Use of Recycled and Secondary Aggregates

2.2.1. Financial Aspects of AAs

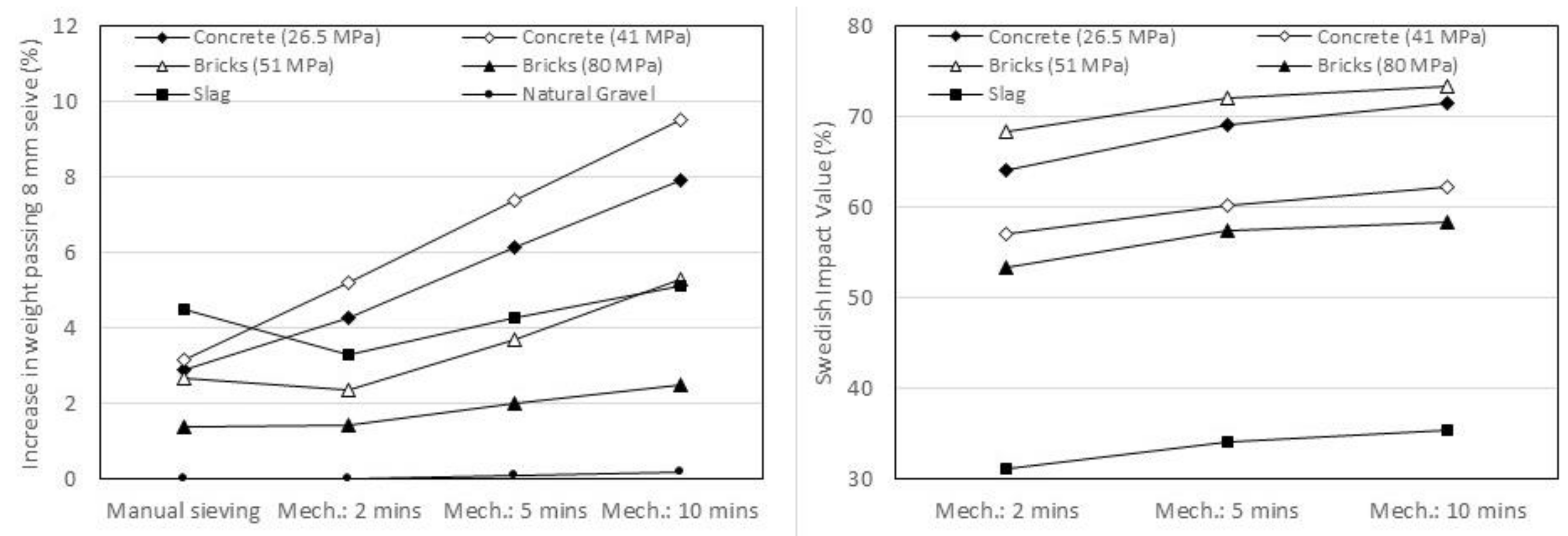

2.2.2. Appropriateness of Specification Testing When Assessing Suitability of an Aggregate for Geotechnical Applications

2.2.3. Los Angeles Coefficient

3. Examples of the Utilisation of Wastes as Alternative Aggregates in Geotechnical Engineering and an Alternative that Potentially Could Be Used

3.1. Scrap Tyres

3.2. Construction and Demolition Waste

Bermondsey Dive Under

3.3. Recycled Crushed Glass

3.4. Incinerated Waste By-Products

3.4.1. MSWIBA and MSWIFA

3.4.2. Sewage Sludge Ash (SSA)

3.4.3. APCr

4. Conclusions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AAs | alternative aggregates (comprising recycled and/or secondary aggregates) |

| ACT | accelerated carbonation treatment |

| APCr | air pollution control residue |

| BDU | Bermondsey Dive Under |

| CCA | crushed concrete aggregate |

| CDW | Construction and Demolition Waste |

| CE | circular economy |

| EfW | energy from waste |

| EoW | End of Waste |

| LA | Los Angeles coefficient |

| MSWIBA | municipal solid waste incinerator bottom ash |

| MSWIFA | municipal solid waste incinerator fly ash |

| PA | primary aggregate |

| PFA | pulverised fuel ash |

| RA | recycled aggregate |

| SA | secondary aggregate |

| SSA | sewage sludge ash |

| WGC | waste glass cullet |

References

- HM Government. Our Waste, Our Resource: A Strategy for England; Government of the United Kingdom: London, UK, 2018.

- Vieira, C.; Pereira, P.M. Use of recycled construction and demolition materials in geotechnical applications: A review. Resour. Conserv. Recycl. 2015, 103, 192–204. [Google Scholar] [CrossRef]

- Drew, L.J.; Langer, W.H.; Sachs, J.S. Environmentalism and Natural Aggregate Mining. Nat. Resour. Res. 2002, 11, 19–28. [Google Scholar] [CrossRef]

- Dhir, R.K.; de Brito, J.; Mangabhai, R.; Lye, C.Q. Introduction. In Sustainable Construction Materials; Woodhead Publishing: Sawston, UK, 2017; pp. 1–8. [Google Scholar]

- British Geological Survey. World Mineral Production 2008–2012; British Geological Survey: Nottingham, UK, 2017. [Google Scholar]

- Eurostat. Generation of Waste by Economic Activity. 2019. Available online: https://ec.europa.eu/eurostat/tgm/table.do?tab=table&init=1&plugin=1&language=en&pcode=ten00106 (accessed on 20 July 2020).

- Faleschini, F.; Zanini, M.A.; Pellegrino, C.; Pasinato, S. Sustainable management and supply of natural and recycled aggregates in a medium-size integrated plant. Waste Manag. 2016, 49, 146–155. [Google Scholar] [CrossRef] [PubMed]

- Carpenter, A.; Gardner, K.; Fopiano, J.; Benson, C.; Edil, T. Life cycle based risk assessment of recycled materials in roadway construction. Waste Manag. 2007, 27, 1458–1464. [Google Scholar] [CrossRef] [PubMed]

- U.S. Geological Society. Materials Flow. 2019. Available online: https://www.usgs.gov/centers/nmic/materials-flow (accessed on 10 September 2021).

- Silva, R.; de Brito, J.; Dhir, R. Availability and processing of recycled aggregates within the construction and demolition supply chain: A review. J. Clean. Prod. 2017, 143, 598–614. [Google Scholar] [CrossRef] [Green Version]

- Silva, R.; de Brito, J.; Dhir, R. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–207. [Google Scholar] [CrossRef]

- Gunning, P.J.; Hills, C.D.; Carey, P.J. Accelerated carbonation treatment of industrial wastes. Waste Manag. 2010, 30, 1081–1090. [Google Scholar] [CrossRef] [PubMed]

- Gunning, P.J.; Hills, C.D.; Carey, P.J.; Antemir, A. Secondary aggregate from waste treated with carbon dioxide. Proc. ICE Constr. Mater. 2011, 164, 231–239. [Google Scholar] [CrossRef]

- Gunning, P.J.; Hills, C.D.; Carey, P.J. Production of lightweight aggregate from industrial waste and carbon dioxide. Waste Manag. 2009, 29, 2722–2728. [Google Scholar] [CrossRef]

- Gunn, A.G.; Bate, R.; Jackson, N.E.; Ward, J.; Marker, B.R.; Brown, T.J.; Highley, D.E. Managing Aggregates Supply in England; Open Report; Geological Survey: Nottingham, UK, 2008. [Google Scholar]

- Bloodworth, A.; Scott, P.; McEvoy, F. Digging the backyard: Mining and quarrying in the UK and their impact on future land use. Land Use Policy 2009, 26, S317–S325. [Google Scholar] [CrossRef] [Green Version]

- Brown, T.; McEvoy, F.; Ward, J. Aggregates in England—Economic contribution and environmental cost of indigenous supply. Resour. Policy 2011, 36, 295–303. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Lo, C.Y.; Xiao, J. Bringing recycled aggregate to its full potential. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2013, 166, 128–136. [Google Scholar] [CrossRef]

- Dhir, R.K.; de Brito, J.; Silva, R.V.; Lye, C.Q. Availability of Recycled Aggregates. In Sustainable Construction Materials; Elsevier: Amsterdam, The Netherlands, 2019; pp. 35–56. [Google Scholar]

- Bhatty, J.I.; Reid, K.J. Moderate strength concrete from lightweight sludge ash aggregates. Int. J. Cem. Compos. Light Concrete 1989, 11, 179–187. [Google Scholar] [CrossRef]

- Khalaf, F.M.; Devenny, A.S. Recycling of Demolished Masonry Rubble as Coarse Aggregate in Concrete: Review. J. Mater. Civ. Eng. 2004, 16, 331–340. [Google Scholar] [CrossRef]

- Frigione, M. Recycling of PET bottles as fine aggregate in concrete. Waste Manag. 2010, 30, 1101–1106. [Google Scholar] [CrossRef]

- Cavalline, T.L.; Weggel, D.C. Recycled brick masonry aggregate concrete: Use of brick masonry from construction and demolition waste as recycled aggregate in concrete. Struct. Surv. 2013, 31, 160–180. [Google Scholar] [CrossRef]

- Jani, Y.; Hogland, W. Waste glass in the production of cement and concrete—A review. J. Environ. Chem. Eng. 2014, 2, 1767–1775. [Google Scholar] [CrossRef]

- Hassan, K.E.-G.; Reid, J.M.; Al-Kuwari, M.S. Recycled aggregates in structural concrete—A Qatar case study. Proc. Inst. Civ. Eng. Constr. Mater. 2016, 169, 72–82. [Google Scholar] [CrossRef]

- Petrounias, P.; Rogkala, A.; Giannakopoulou, P.P.; Lampropoulou, P.; Xanthopoulou, V.; Koutsovitis, P.; Koukouzas, N.; Lagogiannis, I.; Lykokanellos, G.; Golfinopoulos, A. An Innovative Experimental Petrographic Study of Concrete Produced by Animal Bones and Human Hair Fibers. Sustainability 2021, 13, 8107. [Google Scholar] [CrossRef]

- Petrounias, P.; Giannakopoulou, P.P.; Rogkala, A.; Lampropoulou, P.; Tsikouras, B.; Rigopoulos, I.; Hatzipanagiotou, K. Petrographic and Mechanical Characteristics of Concrete Produced by Different Type of Recycled Materials. Geosciences 2019, 9, 264. [Google Scholar] [CrossRef] [Green Version]

- Lazarevic, D.; Buclet, N.; Brandt, N. The application of life cycle thinking in the context of European waste policy. J. Clean. Prod. 2012, 29-30, 199–207. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector. A literature review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Lederer, J.; Trinkel, V.; Fellner, J. Wide-scale utilization of MSWI fly ashes in cement production and its impact on average heavy metal contents in cements: The case of Austria. Waste Manag. 2017, 60, 247–258. [Google Scholar] [CrossRef]

- O’Mahony, M.M.; Milligan, G.W.E. Use of recycled materials in subbaselayers. Transp. Res. Rec. 1991, 1310, 73–80. [Google Scholar]

- BRE. Construction and Demolition Waste: Good Buildings Guide Part 1; Building Research Establishment: Garston, UK, 2003. [Google Scholar]

- Ajayi, S.O.; Oyedele, L.O. Policy imperatives for diverting construction waste from landfill: Experts’ recommendations for UK policy expansion. J. Clean. Prod. 2017, 147, 57–65. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.-D.; Zeng, C.-C.; Liu, J.; Diao, H. Measured Settlement of Highways Improved by Lightweight Backfilling Without Road Closure. Arab. J. Sci. Eng. 2016, 41, 3889–3896. [Google Scholar] [CrossRef]

- Ellis, S.J. Recycling in Transportation. Transportation geotechnics. In Proceedings of the Symposium Transportation Geotechnics, Nottingham, UK, 11 September 2003. [Google Scholar]

- Thompson, A.; Harris, K.; Knapman, D.; Marker, B.; Poole, J.; Higgs, J. Reasons for the Decline in Aggregate Reserves in England; Capita Symonds Ltd.: East Grinstead, UK, 2008. [Google Scholar]

- HMSO. The Aggregates Levy (General) Regulations; HMSO: Richmond, UK, 2002; Volume 761, pp. 1–20. [Google Scholar]

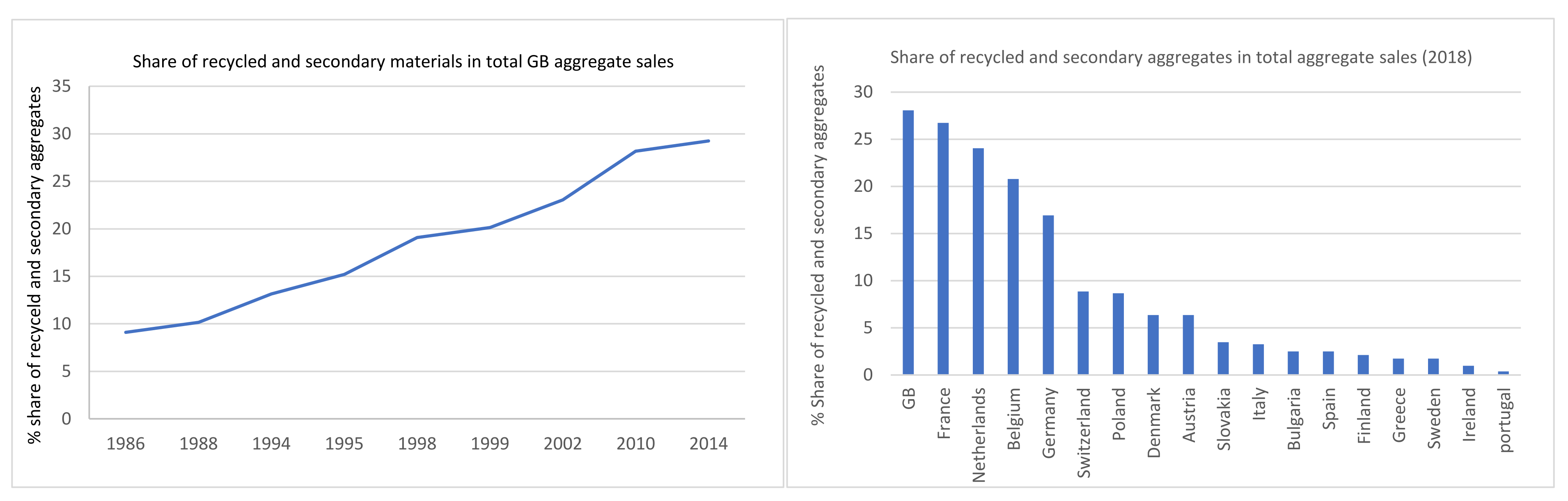

- Mineral Products Association. The Mineral Products Industry at a Glance—2016 Edition. 2016. Available online: Contribution_of_Recycled_and_Secondary_Materials_to_Total_Aggs_Supply_in_GB (accessed on 15 October 2021).

- Tangtinthai, N.; Heidrich, O.; Manning, D.A. Role of policy in managing mined resources for construction in Europe and emerging economies. J. Environ. Manag. 2019, 236, 613–621. [Google Scholar] [CrossRef]

- Sas, W.; Głuchowski, A.; Radziemska, M.; Dziecioł, J.; Szymański, A. Environmental and geotechnical assessment of the steel slags as a material for road structure. Materials 2015, 8, 4857–4875. [Google Scholar] [CrossRef] [PubMed]

- Sakai, S.I.; Yano, J.; Hirai, Y.; Asari, M.; Yanagawa, R.; Matsuda, T.; Yoshida, H.; Yamada, T.; Kajiwara, N.; Suzuki, G.; et al. Waste prevention for sustainable resource and waste management. J. Mater. Cycles Waste Manag. 2017, 19, 1295–1313. [Google Scholar] [CrossRef] [Green Version]

- Ministry of Land, Infrastructure, Transport and Tourism. White Paper on Land, Infrastructure, Transport and Tourism in Japan. 2019. Available online: https://www.mlit.go.jp/en/statistics/white-paper-mlit-2019.html (accessed on 20 July 2020).

- Andersen, M.S. An introductory note on the environmental economics of the circular economy. Sustain. Sci. 2007, 2, 133–140. [Google Scholar] [CrossRef]

- Mankelow, J.M.; Bide, T.P.; Sen, M.A.; Raycraft, E.; Cameron, D.G. Collation of the Results of the 2014 Aggregate Minerals Survey for England and Wales; British Geological Survey Commissioned Report; British Geological Survey: Nottingham, UK, 2016; pp. 1–160. [Google Scholar]

- Royal, A.; Jefferson, I. Use of Wastes, Recycled Aggregates and Secondary Aggregates in Geotechnical Engineering Applications. NexGen Technol. Min. Fuel Ind. 2017, 1, 719. [Google Scholar]

- Poulikakos, L.; Papadaskalopoulou, C.; Hofko, B.; Gschösser, F.; Falchetto, A.C.; Bueno, M.; Arraigada, M.; Sousa, J.; Ruiz, R.; Petit, C.; et al. Harvesting the unexplored potential of European waste materials for road construction. Resour. Conserv. Recycl. 2017, 116, 32–44. [Google Scholar] [CrossRef]

- Serridge, C.J. Achieving sustainability in vibro stone column techniques. Proc. Inst. Civ. Eng. Eng. Sustain. 2005, 158, 211–222. [Google Scholar] [CrossRef]

- Mohajerani, A.; Vajna, J.; Cheung, T.H.H.; Kurmus, H.; Arulrajah, A.; Horpibulsuk, S. Practical recycling applications of crushed waste glass in construction materials: A review. Constr. Build. Mater. 2017, 156, 443–467. [Google Scholar] [CrossRef]

- Ellis, S.; Goodwin, A.; Laycock, E.; Hurst, C. Use of crushed brick in reinforced earth railway structures. Proc. Inst. Civ. Eng. Constr. Mater. 2016, 169, 93–105. [Google Scholar] [CrossRef] [Green Version]

- Reddy, S.B.; Krishna, A.M.; Reddy, K. Sustainable Utilization of Scrap Tire Derived Geomaterials for Geotechnical Applications. Indian Geotech. J. 2017, 48, 251–266. [Google Scholar] [CrossRef]

- Mineral Products Association. Profile of the Mineral Products Industry—2020 Edition. 2020. Available online: Profile_of_the_UK_Mineral_Products_Industry_2020_Spread.pdf(mineralproducts.org) (accessed on 15 October 2021).

- Ismail, S.; Hoe, K.W.; Ramli, M. Sustainable Aggregates: The Potential and Challenge for Natural Resources Conservation. Procedia Soc. Behav. Sci. 2013, 101, 100–109. [Google Scholar] [CrossRef] [Green Version]

- Langer, W.H. Managing and Protecting Aggregate Resources; USGS: Reston, VI, USA, 2002.

- Baker, D.; Hendy, R. Planning for sustainable construction aggregate resources in Australia. In Proceedings of the QUT Research Week, Brisbane, Australia, 4–5 July 2005. [Google Scholar]

- Hossain, U.; Poon, C.S.; Lo, I.M.C.; Cheng, J.C. Comparative environmental evaluation of aggregate production from recycled waste materials and virgin sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Zuo, C.; Birkin, M.; Clarke, G.; McEvoy, F.; Bloodworth, A. Reducing carbon emissions related to the transportation of aggregates: Is road or rail the solution? Transp. Res. Part A Policy Pr. 2018, 117, 26–38. [Google Scholar] [CrossRef] [Green Version]

- Cowell, R.; Owens, S. Suitable Locations: Equity and Sustainability in the Minerals Planning Process. Reg. Stud. 1998, 32, 797–811. [Google Scholar] [CrossRef]

- Mankelow, J.M.; Oyo-Ita, D.; Birkin, M. Assessing the carbon footprint of transporting primary aggregates. In Proceedings of the 15th Extractive Industry Geology Conference; Scott, P.W., Walton, G., Eds.; EIG Conferences Ltd.: Warwick, UK, 2010; pp. 41–45. [Google Scholar]

- Thomas, A.; Lombardi, D.R.; Hunt, D.; Gaterell, M. Estimating carbon dioxide emissions for aggregate use. Proc. Inst. Civ. Eng. Eng. Sustain. 2009, 162, 135–144. [Google Scholar] [CrossRef]

- Tranter, R.; Jefferson, I.; Ghataora, G. The Use of Recycled Aggregate in Vibro-Stone Columns—A UK Perspective. In Proceedings of the GeoCongress, New Orleans, LA, USA, 9–12 March 2008; pp. 630–637. [Google Scholar] [CrossRef]

- Padfield, A.M.; Carey, P.J.; Hills, C.D.; Poole, A.B. Reuse of quarry fines in production of secondary aggregates. In Engineering Sustainability; ICE: London, UK, 2004; pp. 3–8. [Google Scholar]

- Nash, H.A. The Revised Directive on Waste: Resolving Legislative Tensions in Waste Management? J. Environ. Law 2008, 21, 139–149. [Google Scholar] [CrossRef]

- Velzeboer, I.; Van Zomeren, A. End of Waste Criteria for Inert Aggregates in Member States; ECN: Petten, The Netherlands, 2017; p. 43. [Google Scholar]

- Environment Agency. Aggregates from Inert Waste: End of Waste Briteria for the Production of Aggregates from Inert Waste; WRAP: Banbury, UK, 2013; pp. 1–24. [Google Scholar]

- Styring, P.; Wilson, I.A.G.; Brun, T.; Knippels, H.; Armstrong, K.; Travaly, Y.; Kramer, D.; Saussez, G.; Bolscher, H. A Vision for Smart CCU Transformations in Europe: Using CO2 as a Resource; Smart CO2 Transformation: Ebook-; 2015. Available online: https://co2-utilization.net/fileadmin/user_upload/SCOT_Vision.pdf (accessed on 15 October 2021).

- Cardoso, R.; Silva, R.V.; de Brito, J.; Dhir, R. Use of recycled aggregates from construction and demolition waste in geotechnical applications: A literature review. Waste Manag. 2016, 49, 131–145. [Google Scholar] [CrossRef]

- Tam, V.W. On the effectiveness in implementing a waste-management-plan method in construction. Waste Manag. 2008, 28, 1072–1080. [Google Scholar] [CrossRef] [Green Version]

- Bolden, J.; Abu-Lebdeh, T.; Fini, E. Utilization of recycled and waste materials in various construction applications. Am. J. Environ. Sci. 2013, 9, 14–24. [Google Scholar] [CrossRef]

- Reid, J.M.; Chandler, J.W.E. Recycling in Transport Infrastructure; Transport Research Laboratory: Berks, UK, 2001. [Google Scholar]

- Winch, G.M. How innovative is construction? Comparing aggregated data on construction innovation and other sectors—A case of apples and pears. Construction. Manag. Econ. 2003, 21, 651–654. [Google Scholar] [CrossRef]

- Tangkar, M.; Arditi, D. Innovation in the construction industry. Civ. Eng. Dimens. 2000, 2, 96–103. [Google Scholar]

- Oyedele, L.O.; Ajayi, S.O.; Kadiri, K.O. Use of recycled products in UK construction industry: An empirical investigation into critical impediments and strategies for improvement. Resour. Conserv. Recycl. 2014, 93, 23–31. [Google Scholar] [CrossRef]

- Schouenborg, B. Standardisation in Europe: Still Some Barriers to Overcome Before a Routine Use of Recycled Aggregates and Aggregates from Secondary Sources Can be Achieved? In Proceedings of the 7th International Conference on the Bearing Capacity of Roads, Railways and Airfields, Trondheim, Norway, 25–27 June 2005; p. 4. [Google Scholar]

- Schouenborg, B.; Aurstad, J.; Pétursson, P. Test methods adapted to alternative aggregates. In Proceedings of the International RILEM Conference on the Use of Recycled Materials in Buildings and Structures, Barcelona, Spain, 9–11 November 2004. [Google Scholar]

- Söderholm, P. Resources, Conservation and Recycling Taxing virgin natural resources: Lessons from aggregates taxation in Europe. Resour. Conserv. Recycl. 2011, 55, 911–922. [Google Scholar] [CrossRef]

- Transport Research Laboratory. Final Report for Publication Alt-Mat Contract No.: RO-97-SC.2238; Transport Research Laboratory: Berks, UK, 2001; pp. 1–190. [Google Scholar]

- Steele, D.P. Ground Engineering as Potential End Uses for Recycled and Secondary Aggregates; Waste and Resources Action Programme: Banbury, UK, 2004. [Google Scholar]

- Mitchell, J.; Soga, K. Fundamentals of Soil Behavior, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2005; p. 85. [Google Scholar]

- Gomes Correia, A.; Winter, M.G.; Puppala, A.J. A review of sustainable approaches in transport infrastructure geotechnics. Transp. Geotech. 2016, 7, 21–28. [Google Scholar] [CrossRef] [Green Version]

- Skarzynska, K.M. Reuse of Coal-Mining Wastes in Civil Engineering. 2. Utilization of Minestone. Waste Manag. 1995, 15, 83–126. [Google Scholar] [CrossRef]

- Britsh Standards. Tests for Mechanical and Physical Properties of Aggregates, Part 2: Methods for the Determination of Resistance to Fragmentation; Britsh Standards: London, UK, 2010. [Google Scholar]

- Tam, V.W.; Tam, C.M. A review on the viable technology for construction waste recycling. Resour. Conserv. Recycl. 2006, 47, 209–221. [Google Scholar] [CrossRef] [Green Version]

- Arulrajah, A.; Piratheepan, J.; Aatheesan, T.; Bo, M.W. Geotechnical Properties of Recycled Crushed Brick in Pavement Applications. J. Mater. Civ. Eng. 2011, 23, 1444–1452. [Google Scholar] [CrossRef]

- Rahman, A.; Imteaz, M.; Arulrajah, A.; Disfani, M.M. Suitability of recycled construction and demolition aggregates as alternative pipe backfilling materials. J. Clean. Prod. 2014, 66, 75–84. [Google Scholar] [CrossRef]

- Koohmishi, M. Drainage potential of degraded railway ballast considering initial gradation and intrusion of external fine materials. Soils Found. 2019, 59, 2265–2278. [Google Scholar] [CrossRef]

- Cooley, L.A.; James, R.S.; Cooley, J.L.A. Micro-Deval Testing of Aggregates in the Southeast. Transp. Res. Rec. J. Transp. Res. Board 2003, 1837, 73–79. [Google Scholar] [CrossRef]

- Highways England. Manual of Contract Documents for Highway Works; Specification for Highway Works Series 600; Highways England: Birmingham, UK, 2016; Volume 1. [Google Scholar]

- Winter, M.G. A conceptual framework for the recycling of aggregates and other wastes. Proc. Inst. Civ. Eng. Munic. Eng. 2002, 151, 177–187. [Google Scholar] [CrossRef]

- Zukri, A.; Nazir, R. Sustainable materials used as stone column filler: A short review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 342, 012001. [Google Scholar] [CrossRef]

- Dhir, R.K.; Dyer, T.D.; Paine, K.A. Dismantling barriers: Roles for research in realising markets for construction and demolition wastes. In Proceedings of the 1st International Conference on Sustainable Construction: Waste Management, Singapore, 10–12 June 2004; pp. 1–22. [Google Scholar]

- Nowak, P.; Gilbert, P. Earthworks: A Guide, 2nd ed.; ICE Publishing: London, UK, 2015. [Google Scholar]

- Graettinger, A.J.; Johnson, P.W.; Sunkari, P.; Duke, M.C.; Effinger, J. Recycling of plastic bottles for use as a lightweight geotechnical material. Manag. Environ. Qual. Int. J. 2005, 16, 658–669. [Google Scholar] [CrossRef]

- Baic, I.; Koziol, W.; Machniak, L. Aggregates from mineral wastes. E3S Web Conf. 2016, 8, 1068. [Google Scholar] [CrossRef] [Green Version]

- González-Corrochano, B.; Alonso-Azcárate, J.; Rodas, M. Production of lightweight aggregates from mining and industrial wastes. J. Environ. Manag. 2009, 90, 2801–2812. [Google Scholar] [CrossRef] [PubMed]

- Perera, S.; Arulrajah, A.; Wong, Y.C.; Horpibulsuk, S.; Maghool, F. Utilizing recycled PET blends with demolition wastes as construction materials. Constr. Build. Mater. 2019, 221, 200–209. [Google Scholar] [CrossRef]

- Amrani, M.; Taha, Y.; Elghali, A.; Benzaazoua, M.; Kchikach, A.; Hakkou, R. An experimental investigation on collapsible behavior of dry compacted phosphate mine waste rock in road embankment. Transp. Geotech. 2021, 26, 100439. [Google Scholar] [CrossRef]

- Amrani, M.; Taha, Y.; El Haloui, Y.; Benzaazoua, M.; Hakkou, R. Sustainable Reuse of Coal Mine Waste: Experimental and Economic Assessments for Embankments and Pavement Layer Applications in Morocco. Minerals 2020, 10, 851. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C.; Panicker, V.J. Recycling of waste tire rubber as aggregate in concrete: Durability-related performance. J. Clean. Prod. 2016, 112, 504–513. [Google Scholar] [CrossRef]

- Ramarad, S.; Khalid, M.; Ratnam, C.; Chuah, A.L.; Rashmi, W. Waste tire rubber in polymer blends: A review on the evolution, properties and future. Prog. Mater. Sci. 2015, 72, 100–140. [Google Scholar] [CrossRef]

- Cecich, V.; Gonzales, L.; Hoisaeter, A.; Williams, J.; Reddy, K. Use of Shredded Tires as Lightweight Backfill Material for Retaining Structures. Waste Manag. Res. 1996, 14, 433–451. [Google Scholar] [CrossRef]

- Ahn, I.-S.; Cheng, L. Tire derived aggregate for retaining wall backfill under earthquake loading. Constr. Build. Mater. 2014, 57, 105–116. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Sharma, J.P.; Yadav, J.S. Geotechnical Properties of Dune sand-Waste Tires Composite. Mater. Today Proc. 2017, 4, 9851–9855. [Google Scholar] [CrossRef]

- Ayothiraman, R.; Soumya, S. Model tests on the use of tyre chips as aggregate in stone columns. Proc. Inst. Civ. Eng. Ground Improv. 2015, 168, 187–193. [Google Scholar] [CrossRef]

- Al-Bared, M.A.M.; Marto, A.; Latifi, N. Utilization of Recycled Tiles and Tyres in Stabilization of Soils and Production of Construction Materials—A State-of-the-Art Review. KSCE J. Civ. Eng. 2018, 22, 3860–3874. [Google Scholar] [CrossRef]

- Moo-Young, H.; Sellasie, K.; Zeroka, D.; Sabnis, G. Physical and Chemical Properties of Recycled Tire Shreds for Use in Construction. J. Environ. Eng. 2003, 129, 921–929. [Google Scholar] [CrossRef]

- Hazarika, H.; Yasuhara, K.; Kikuchi, Y.; Karmokar, A.K.; Mitarai, Y. Multifaceted potentials of tire-derived three dimensional geosynthetics in geotechnical applications and their evaluation. Geotext. Geomembr. 2010, 28, 303–315. [Google Scholar] [CrossRef]

- Reddy, S.B.; Krishna, A.M. Recycled Tire Chips Mixed with Sand as Lightweight Backfill Material in Retaining Wall Applications: An Experimental Investigation. Int. J. Geosynth. Ground Eng. 2015, 1, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Cetin, H.; Fener, M.; Gunaydin, O. Geotechnical properties of tire-cohesive clayey soil mixtures as a fill material. Eng. Geol. 2006, 88, 110–120. [Google Scholar] [CrossRef]

- Pierce, C.; Blackwell, M. Potential of scrap tire rubber as lightweight aggregate in flowable fill. Waste Manag. 2003, 23, 197–208. [Google Scholar] [CrossRef]

- Reddy, S.B.; Kumar, P.D.; Krishna, A.M. Evaluation of the Optimum Mixing Ratio of a Sand-Tire Chips Mixture for Geoengineering Applications. J. Mater. Civ. Eng. 2016, 28, 6015007. [Google Scholar] [CrossRef]

- Nightingale, D.; Green, W. An unresolved riddle: Tire chips, two roadbeds, and spontaneous reactions. In Testing Soil Mixed with Waste or Recycled Materials ASTM STP 1275; Wasemiller, M., Hoddinot, K., Eds.; American Society for Testing and Materials: West Conshohocken, PA, USA, 1997; pp. 265–285. [Google Scholar]

- Edil, T.B. A Review of Mechanical and Chemical Properties pof Shredded Tires and Soil Mixtures. In Proceedings of the ASCE Civil Engineering Conference and Exposition, Baltimore, MA, USA, 19–21 October 2004; pp. 1–21. [Google Scholar]

- Anbazhagan, P.; Manohar, D.R.; Rohit, D. Influence of size of granulated rubber and tyre chips on the shear strength characteristics of sand–rubber mix. Géoméch. Geoengin. 2017, 12, 266–278. [Google Scholar] [CrossRef]

- Foose, G.J.; Benson, C.H.; Bosscher, P.J. Sand Reinforced with Shredded Waste Tires. J. Geotech. Eng. 1996, 122, 760–767. [Google Scholar] [CrossRef]

- Edil, T.B.; Fox, P.J.; Ahl, S.W. Hydraulic conductivity and compressibility of waste tire chips. In Proceedings of the 15th Annual Madison Waste Conference, Madison, WI, USA, 23–24 September 1992; pp. 49–61. [Google Scholar]

- Akbulut, S.; Arasan, S.; Kalkan, E. Modification of clayey soils using scrap tire rubber and synthetic fibers. Appl. Clay Sci. 2007, 38, 23–32. [Google Scholar] [CrossRef]

- Tweedie, J.; Humphrey, D.N.; Sandford, T.C. Tyre Chips as Lightweight Backfill for Retaining Walls—Phase II; New England Transportation Consortium: Augusta, ME, USA, 1998. [Google Scholar]

- Tam, V.W. Comparing the implementation of concrete recycling in the Australian and Japanese construction industries. J. Clean. Prod. 2009, 17, 688–702. [Google Scholar] [CrossRef]

- DEFRA. UK Statistics on Waste. Governmental Statistical Service, (September). 2019; pp. 1–10. Available online: https://www.gov.uk/government/collections/waste-and-recycling-statistics (accessed on 15 October 2021).

- Jefferson, I.; Gaterell, M.; Thomas, A.M.; Serridge, C.J. Emissions assessment related to vibro stone columns. Proc. Inst. Civ. Eng. Ground Improv. 2010, 163, 71–77. [Google Scholar] [CrossRef]

- Tatsuoka, F.; Tomita, Y.-I.; Iguchi, Y.; Hirakawa, D. Strength and stiffness of compacted crushed concrete aggregate. Soils Found. 2013, 53, 835–852. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, A.; Ugai, K.; Kamei, T. Investigation of recycled gypsum in conjunction with waste plastic trays for ground improvement. Constr. Build. Mater. 2011, 25, 208–217. [Google Scholar] [CrossRef]

- Mueller, A.; Schnell, A.; Ruebner, K. The manufacture of lightweight aggregates from recycled masonry rubble. Constr. Build. Mater. 2015, 98, 376–387. [Google Scholar] [CrossRef] [Green Version]

- Chidiroglou, I.; O’Flaherty, O.; Goodwin, A. Shear behaviour of crushed concrete and bricks. Constr. Mater. 2009, 162, 141–149. [Google Scholar] [CrossRef] [Green Version]

- Disfani, M.; Arulrajah, A.; Bo, M.; Hankour, R. Recycled crushed glass in road work applications. Waste Manag. 2011, 31, 2341–2351. [Google Scholar] [CrossRef]

- Ali, M.M.Y.; Arulrajah, A. Potential Use of Recycled Crushed Concrete-Recycled Crushed Glass Blends in Pavement Subbase Applications. In Proceedings of the GeoCongress, Oakland, CA, USA, 25–29 March 2012; pp. 3662–3671. [Google Scholar]

- Arulrajah, A.; Piratheepan, J.; Disfani, M.M.; Bo, M.W. Geotechnical and Geoenvironmental Properties of Recycled Construction and Demolition Materials in Pavement Subbase Applications. J. Mater. Civ. Eng. 2013, 25, 1077–1088. [Google Scholar] [CrossRef]

- Disfani, M.M.; Arulrajah, A.; Ali, M.M.Y.; Bo, M.W. Fine recycled glass: A sustainable alternative to natural aggregates. Int. J. Geotech. Eng. 2011, 5, 255–266. [Google Scholar] [CrossRef]

- Arulrajah, A.; Ali, M.M.Y.; Disfani, M.M.; Horpibulsuk, S. Recycled-Glass Blends in Pavement Base/Subbase Applications: Laboratory and Field Evaluation. J. Mater. Civ. Eng. 2014, 26, 7. [Google Scholar] [CrossRef]

- Disfani, M.M.; Arulrajah, A.; Bo, M.; Sivakugan, N. Environmental risks of using recycled crushed glass in road applications. J. Clean. Prod. 2012, 20, 170–179. [Google Scholar] [CrossRef]

- Testa, M.; Malandrino, O.; Sessa, M.R.; Supino, S.; Sica, D. Long-Term Sustainability from the Perspective of Cullet Recycling in the Container Glass Industry: Evidence from Italy. Sustainability 2017, 9, 1752. [Google Scholar] [CrossRef] [Green Version]

- Butler, J.H.; Hooper, P. Glass Waste. Waste 2011, 151–165. [Google Scholar] [CrossRef]

- Ooi, P.S.K.; Li, M.M.W.; Sagario, M.L.Q.; Song, Y. Shear Strength Characteristics of Recycled Glass. Transp. Res. Rec. J. Transp. Res. Board 2008, 2059, 52–62. [Google Scholar] [CrossRef]

- Amiri, S.T.; Nazir, R.; Dehghanbanadaki, A. Experimental Study of Geotechnical Characteristics of Crushed Glass Mixed with Kaolinite Soil. Int. J. Geomate 2018, 14, 170–176. [Google Scholar] [CrossRef]

- Majdinasab, A.; Yuan, Q. Post-consumer cullet and potential engineering applications in North America. Resour. Conserv. Recycl. 2019, 147, 1–9. [Google Scholar] [CrossRef]

- WRAP. Realising the Value of Recovered Glass: An Update; WRAP: Banbury, UK, 2008. [Google Scholar]

- Heriyanto; Pahlevani, F.; Sahajwalla, V. From waste glass to building materials—An innovative sustainable solution for waste glass. J. Clean. Prod. 2018, 191, 192–206. [Google Scholar] [CrossRef]

- Cuelho, E.; Mokwa, R.; Obert, K.; Miller, A. Comparative Analysis of Micro-Deval, LA Abrasion, and Sulfate Soundness Tests. Transp. Res. Board 2008, 1638, 1–17. [Google Scholar]

- Vieitez, E.R.; Eder, P.; Villanueva, A.; Saveyn, H. End-of-Waste Criteria for Glass Cullet: Technical Proposals; JRC Scientific and Technical Reports; European Commission: Geneva, Switzerland, 2011; 124p. [Google Scholar]

- Guthrie, P.; Coventry, S.; Woolveridge, C.; Hillier, S.; Collins, R. The Reclaimed and Recycled Construction Materials Handbook; CIRIA: London, UK, 1999. [Google Scholar]

- Landris, T.L. Recycled Glass and Dredged Materials; Engineer Research and Development Center: Vicksburg, MS, USA, 2007; Volume 12, Available online: https://books.google.com/books?id=K1qdNwAACAAJ&pgis=1 (accessed on 15 October 2021).

- Vegas, I.; Ibañez, J.; José, J.S.; Urzelai, A. Construction demolition wastes, Waelz slag and MSWI bottom ash: A comparative technical analysis as material for road construction. Waste Manag. 2008, 28, 565–574. [Google Scholar] [CrossRef]

- Bethanis, S.; Cheeseman, C.R. Production of lightweight aggregate from incinerator bottom ash and pulverised fuel ash. WIT Trans. Ecolol. Envion. 2004, 78, 10. [Google Scholar]

- Lynn, C.J.; Ghataora, G.S.; Obe, R.K.D. Municipal incinerated bottom ash (MIBA) characteristics and potential for use in road pavements. Int. J. Pavement Res. Technol. 2017, 10, 185–201. [Google Scholar] [CrossRef]

- Cheeseman, C.; Makinde, A.; Bethanis, S. Properties of lightweight aggregate produced by rapid sintering of incinerator bottom ash. Resour. Conserv. Recycl. 2005, 43, 147–162. [Google Scholar] [CrossRef]

- Lynn, C.J.; Ghataora, G.S.; Dhir, R.K. Environmental impacts of MIBA in geotechnics and road applications. Environ. Geotech. 2018, 5, 31–55. [Google Scholar] [CrossRef]

- Bethanis, S.; Cheeseman, C.R.; Sollars, C.J. Effect of Sintering Temperature on the Properties and Leaching of Incinerator Bottom Ash. Waste Manag. Res. 2004, 22, 255–264. [Google Scholar] [CrossRef]

- Lynn, C.J.; Obe, R.K.D.; Ghataora, G.S. Municipal incinerated bottom ash characteristics and potential for use as aggregate in concrete. Constr. Build. Mater. 2016, 127, 504–517. [Google Scholar] [CrossRef]

- BSI. Lightweight Aggregates BS EN 13055:2016; BSI Standards Publication: London, UK, 2016. [Google Scholar]

- Arulrajah, A.; Disfani, M.M.; Maghoolpilehrood, F.; Horpibulsuk, S.; Udonchai, A.; Imteaz, M.; Du, Y.-J. Engineering and environmental properties of foamed recycled glass as a lightweight engineering material. J. Clean. Prod. 2015, 94, 369–375. [Google Scholar] [CrossRef]

- Davies, L.; Bull, J.; Kucki, T. Lightweight backfill materials in integral bridge construction. Proc. Inst. Civ. Eng. Bridg. Eng. 2014, 167, 3–16. [Google Scholar] [CrossRef]

- Swamy, R.N.; Lambert, G.H. The microstructure of Lytag Aggregate. Int. J. Cem. Compos. Lightweight Concr. 1981, 3, 4. [Google Scholar] [CrossRef]

- Donatello, S.; Cheeseman, C.R. Recycling and recovery routes for incinerated sewage sludge ash (ISSA): A review. Waste Manag. 2013, 33, 2328–2340. [Google Scholar] [CrossRef]

- British Standards. BSI Standards Publication Tests for Mechanical and Physical Properties of Aggregates Part 6: Determination of Particle Density and Water Absorption; British Standards: London, UK, 2013. [Google Scholar]

- Halliday, J.E.; Jones, M.R.; Dyer, T.D.; Dhir, R.K. Potential use of UK sewage sludge ash in cement-based concrete. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2012, 165, 57–66. [Google Scholar] [CrossRef]

- Cheeseman, C.; Virdi, G. Properties and microstructure of lightweight aggregate produced from sintered sewage sludge ash. Resour. Conserv. Recycl. 2005, 45, 18–30. [Google Scholar] [CrossRef]

- Smol, M.; Kulczycka, J.; Henclik, A.; Gorazda, K.; Wzorek, Z. The possible use of sewage sludge ash (SSA) in the construction industry as a way towards a circular economy. J. Clean. Prod. 2015, 95, 45–54. [Google Scholar] [CrossRef]

- Ukwattage, N.L.; Ranjith, P.G.; Yellishetty, M.; Bui, H.H.; Xu, T. A laboratory-scale study of the aqueous mineral carbonation of coal fly ash for CO2 sequestration. J. Clean. Prod. 2015, 103, 665–674. [Google Scholar] [CrossRef]

- Gunning, P.; Hills, C.D. Carbon Negative: First Commercial Application of Accelerated Carbonation Technology. 2014. Available online: http://gala.gre.ac.uk/13580/1/13580_Hills_Carbon_negative_first_commercial_application_%28conf._paper%29_AAM__2014.pdf (accessed on 15 October 2021).

| Aggregate | LA Coefficient |

|---|---|

| Natural Gravel | 36 |

| Flint Gravel | 22 |

| Quartzite Gravel | 19 |

| Latite Basalt | 15 |

| Limestone | 20–43 |

| Natural Granite | 27 |

| Dolerite | 12–16 |

| Quartz Diorite | 22 |

| Gritstone | 18 |

| Material | Tyre Particle Size (mm) | Average Unit Weight (Mg/m3) | Specific Gravity | φ′ (°) | Cohesion (kPa) | Reference |

|---|---|---|---|---|---|---|

| Tyre shreds | 25–305 | 0.64 | 1.24 | 21 | 7.7 | 125 |

| Tyre shreds | 25–305 | 0.62 | 1.27 | 26 | 4.3 | 125 |

| Tyre shreds | 25–305 | 0.62 | 1.14 | 19 | 11.5 | 125 |

| Tyre shreds | 25–305 | 0.63 | 1.23 | 25 | 8.6 | 125 |

| Tyre shreds | 0.85–12.5 | - | - | 27 | 7 | 108 |

| Tyre-Sand mix (20% tyre) | 5.6–8 | 1.580 | - | 40–41 | - | 121 |

| Tyre-Sand mix (30% Tyre) | 9.5–12 | 1.550 | - | 40–41 | - | 121 |

| Tyre shreds | 10 × 10 × 20 | 0.65 | 1.08 | 28 | - | 115 |

| Tyre-Sand mix (10% tyre) | 10 × 10 × 20 | 1.460 | 2.25 | 51 | - | 115 |

| Tyre-Sand mix (20% tyre) | 10 × 10 × 20 | 1.400 | 1.94 | 52 | - | 115 |

| Tyre-Sand mix (30% tyre) | 10 × 10 × 20 | 1.320 | 1.82 | 56 | - | 115 |

| Tyre-Sand mix (40% tyre) | 10 × 10 × 20 | 1.230 | 1.71 | 51 | - | 115 |

| Tyre-Sand mix (50% tyre) | 10 × 10 × 20 | 1.040 | 1.53 | 44 | - | 115 |

| Characteristics | Crushed Brick [130] | Crushed Brick [90] | Red Brick [52] | Yellow Brick [52] | Limits for Fill Types [90] | ||

|---|---|---|---|---|---|---|---|

| 1A | 6I and 6J | 6N and 6P | |||||

| Gravel % | 54 | 53 | 92 | 93 | 95–100% < 125 mm | 100% < 125 mm, 85–100% < 75 mm, 25–100% < 14 mm, | 100% < 75 mm |

| Sand % | 40 | 38 | 8 | 7 | 15–100% < 2 mm, 9–100% < 0.6 mm | ||

| Fine % | 6 | 9 | <15% | <15% | <15% | ||

| Particle density (Mg/m3) | - | - | 2.32 | 2.37 | - | - | - |

| Angle of friction φ′ | 48 | 51–57 | 47.5 | 32 | specified by design (<36%) | ||

| Cohesion (kPa) | - | - | 15 (0 at low stresses) | 49 (0 at low stresses) | specified by design | ||

| LA (%) | 36 | 33–35 | 37 | 34 | No limits for type 1A, 6L and 6J fills (for 1C general fill and 6P structural fill <50, for 6F1/6F2 capping <60 and 6N structural fill <40) | ||

| Maximum dry density (kg/m3) | 1973 | 1900–2200 | 1500 | 1470 | specified by design | ||

| Optimum water content | 11.25 | 12–13.5 | 9 | 14.5 | specified by design | ||

| Country | Reuse | Recycle | Landfill |

|---|---|---|---|

| USA | 0 | 28 | 72 |

| Australia | 0 | 37 | 63 |

| Japan | 0 | 14 | 86 |

| China | 50 | 50 | |

| EU | 5 | 64 | 31 |

| Type of Glass | Total Produced (Mt) | Waste Glass Generated (Mt) | Total Recycled (Mt) |

|---|---|---|---|

| Container/packaging | 21 | 17 | 8 |

| Flat (e.g., windows) | 9.5 | 5.1 | 2.9 |

| Domestic (e.g., tableware) | 1.5 | 0.8 | 0.5 |

| Misc. (insulation wood, optical, filament fibres) | 5.4 | 2.9 | n/a |

| Characteristic | Particle Size (Coarse ≤ 19 mm, Medium ≤ 9.5 mm, Fine ≤ 4.75 mm) | ||||

| Coarse [134] | Medium [13,134] | Medium | Fine [133] | Fine [134] | |

| Specific Gravity | 2.5 | 2.5 | 2.48–2.49 | 2.48 | 2.48 |

| Flakiness % | 94.7 | 85.4 | - | - | - |

| Modified Proctor Values | - | ||||

| Maximum Density kN/m3 | - | 19.5 | 17.9 | 17.4 | 17.5 |

| Optimum water content % | - | 8.8 | - | 10.5 | 10 |

| CBR (%) | - | 31–32 | - | - | 42–46 |

| LA (%) | 27.7 | 25.4 | - | 25 | 24.8 |

| φ′ (from Direct Shear Test) (°) | - | - | - | - | - |

| φ′ (σn = 30–120 kPa) | - | 52–53 | - | - | - |

| φ′(σn = 60–240 kPa) | - | 50–51 | - | - | - |

| φ′(σn=120–480 kPa) | - | - | - | - | - |

| φ′ (from CD Triaxial Test) (°) | - | - | 47.5 | 37 | - |

| φ′ (σ’c = 30–120 kPa) | - | 42 | - | - | 40 |

| φ′(σ’c = 60–240 kPa) | - | 41 | - | - | 38 |

| φ′(σ’c = 120–480 kPa) | - | 41 | - | - | 35 |

| Property | SSA (Sintered at 1060 °C, 1% clay) | Lytag |

|---|---|---|

| Mean Density (Mg/ m3) | 1.35 | 1.43 |

| Compressive Strength (MPa) | 7.5 | 7.0 |

| Water Absorption (%) | 8 | 13 |

| Material (Particle Size Range 4–16 mm) | Mean Bulk Density (Mg/m3) | Mean Compressive Strength (Individual Pellets) (MPa) | Water Absorption (%) | LA (%) |

|---|---|---|---|---|

| Carbonated APCr(164) | 1.025 | 0.26 | 18.8 | 39 |

| Carbonated MSWI/APCR (+sand and cement) (13)(165) | 0.900 | 0.20 | 29 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perkins, L.; Royal, A.C.D.; Jefferson, I.; Hills, C.D. The Use of Recycled and Secondary Aggregates to Achieve a Circular Economy within Geotechnical Engineering. Geotechnics 2021, 1, 416-438. https://doi.org/10.3390/geotechnics1020020

Perkins L, Royal ACD, Jefferson I, Hills CD. The Use of Recycled and Secondary Aggregates to Achieve a Circular Economy within Geotechnical Engineering. Geotechnics. 2021; 1(2):416-438. https://doi.org/10.3390/geotechnics1020020

Chicago/Turabian StylePerkins, Lisa, Alexander C. D. Royal, Ian Jefferson, and Colin D. Hills. 2021. "The Use of Recycled and Secondary Aggregates to Achieve a Circular Economy within Geotechnical Engineering" Geotechnics 1, no. 2: 416-438. https://doi.org/10.3390/geotechnics1020020

APA StylePerkins, L., Royal, A. C. D., Jefferson, I., & Hills, C. D. (2021). The Use of Recycled and Secondary Aggregates to Achieve a Circular Economy within Geotechnical Engineering. Geotechnics, 1(2), 416-438. https://doi.org/10.3390/geotechnics1020020