Strength of Chemically Stabilized Sewage Sludge—Some Inferences from Recent Studies

Abstract

:1. Introduction

2. Composition of Sewage and Wastewater Sludge

3. Previous Studies on the Strength of Treated Sewage Sludge

- (a)

- Hydration reaction. The main ingredient used for hydration-based hardening is OPC (e.g., [8,9,10,11,13,14,22,23,24]), which undergoes hydration-hardening to produce calcium silicate hydrate and calcium aluminate hydrate. Moreover, [11] used sulphoaluminate cement, which also undergoes hydration reaction to produce similar hydration products (e.g., [25]). In some studies, quicklime (CaO) and gypsum were also used (e.g., [11,12,22,24]). However, while quicklime hydrates under water, the reaction does not result in the hardening of admixture. Calcined gypsum, also known as “plaster of Paris”, undergoes hydration-hardening in contact with water, but hydrated gypsum does not. It is unclear if these studies used calcined or hydrated gypsum. Moreover, they were used in relatively small quantities, typically 5% or less of the total mass of binder, as activators or dehydrating agent. Hence, their contribution to the production of cementitious chemicals is thus likely to be relatively small compared to the other components in the binder, such as OPC.

- (b)

- Pozzolanic reaction. The pozzolanic materials used for treatment include OPC, ground granulated blast furnace slag (GGBS) (e.g., [12]), steel slag, lime (e.g., [10,18,24]), and bentonite (e.g., [14,26]). The pozzolanic reaction typically occurs between lime (CaO) and pozzolans, in the presence of water. The main pozzolans are silica (SiO2) and alumina (Al2O3). The reaction between silica and hydrated lime can be summarized by the equation

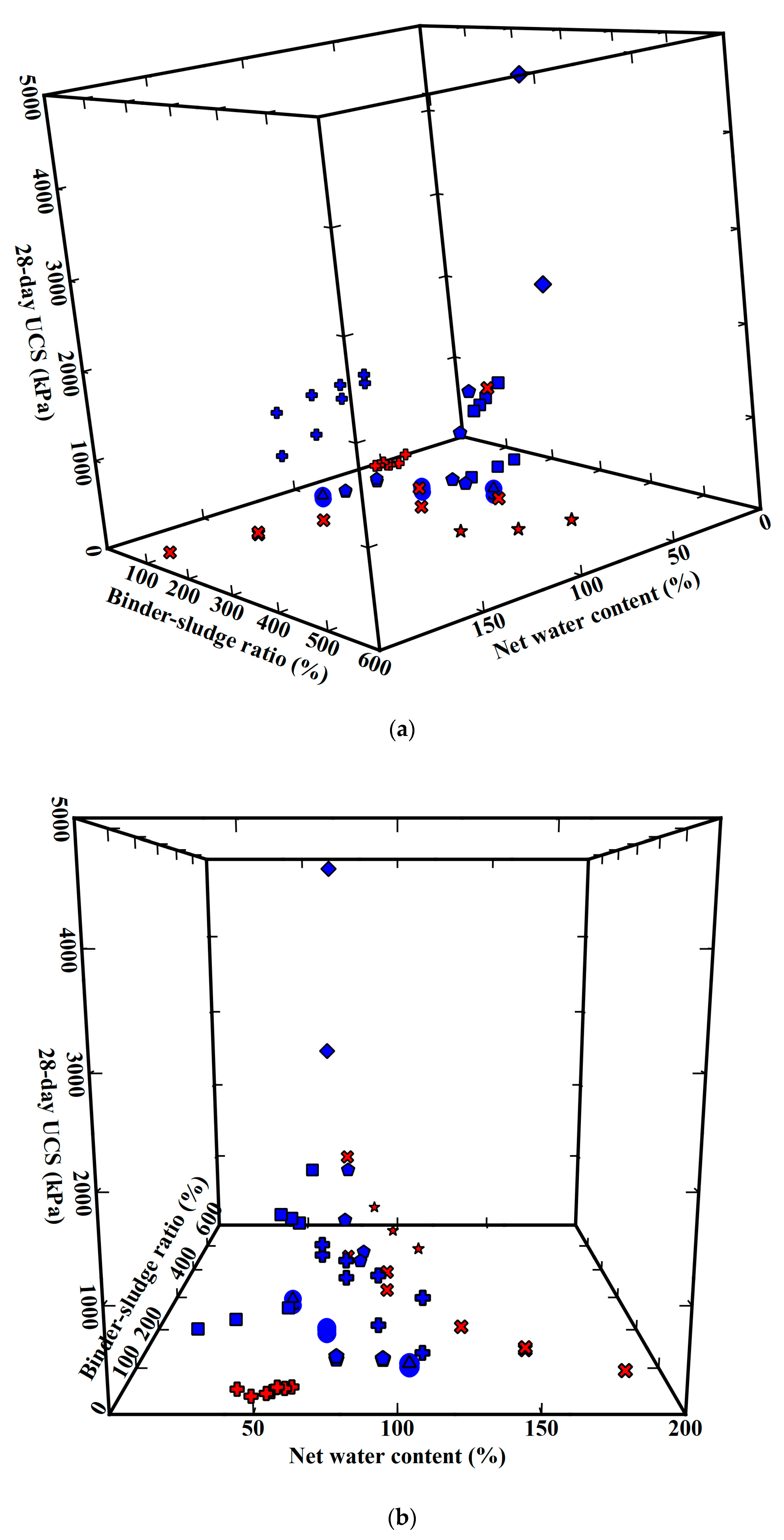

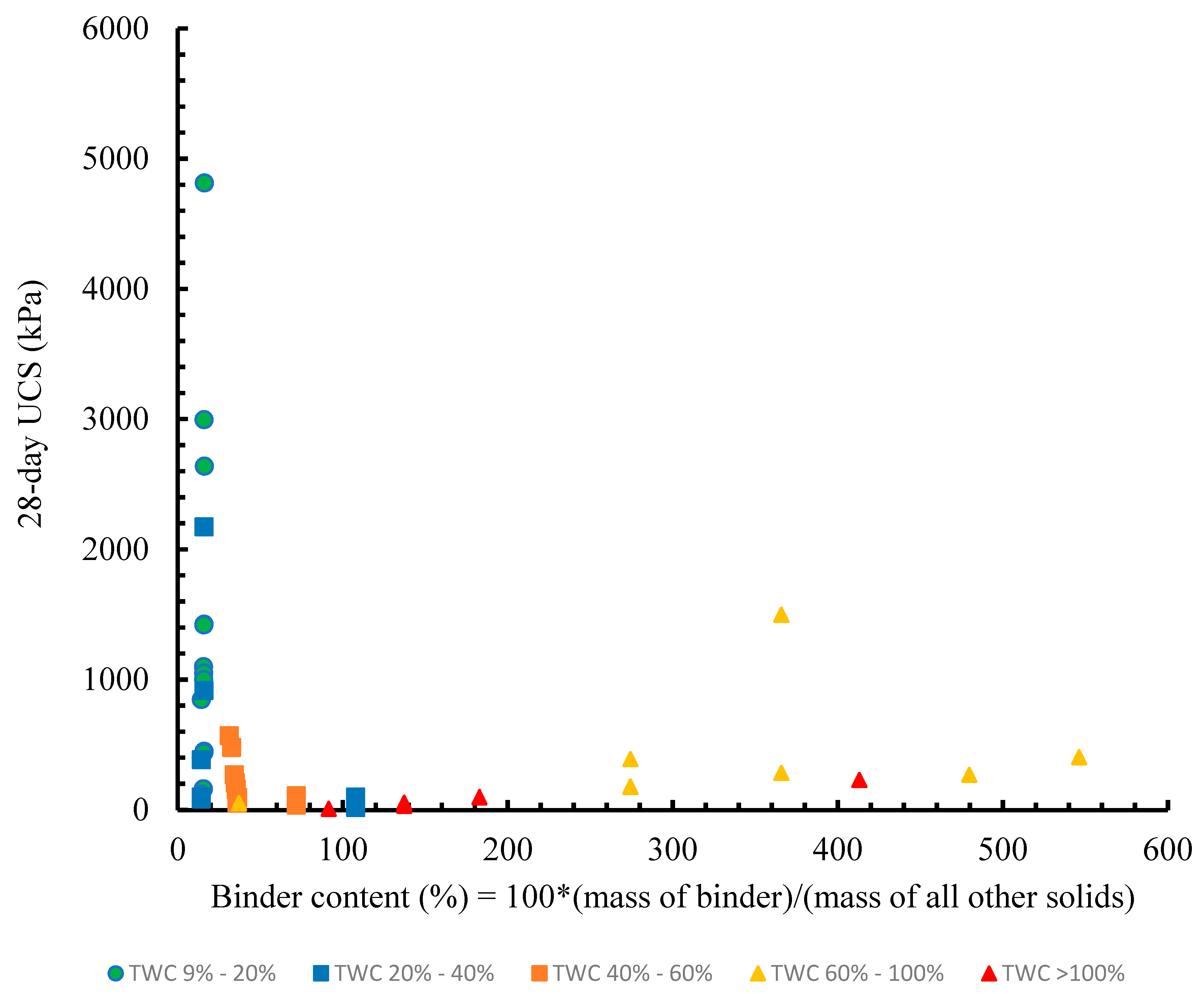

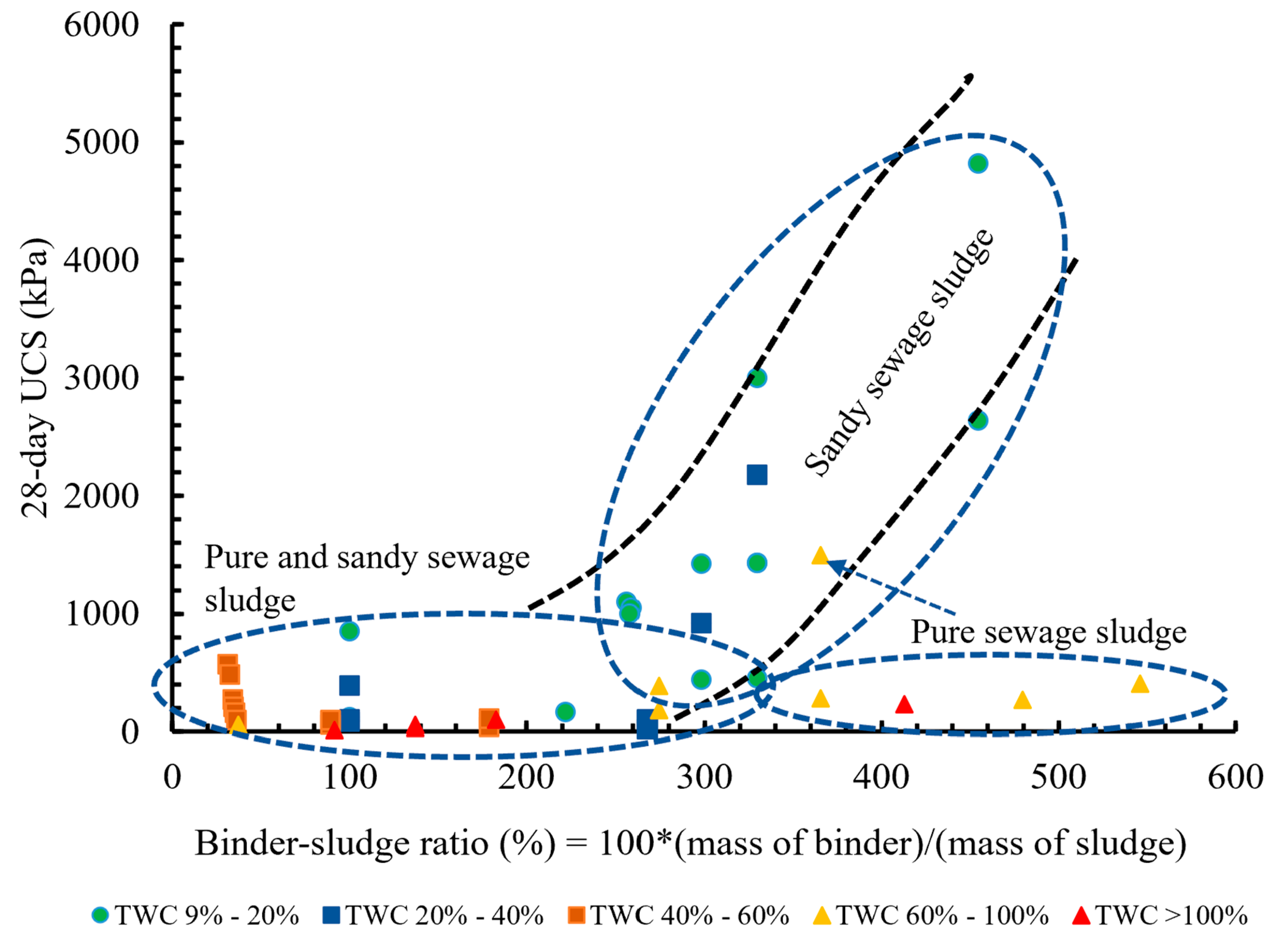

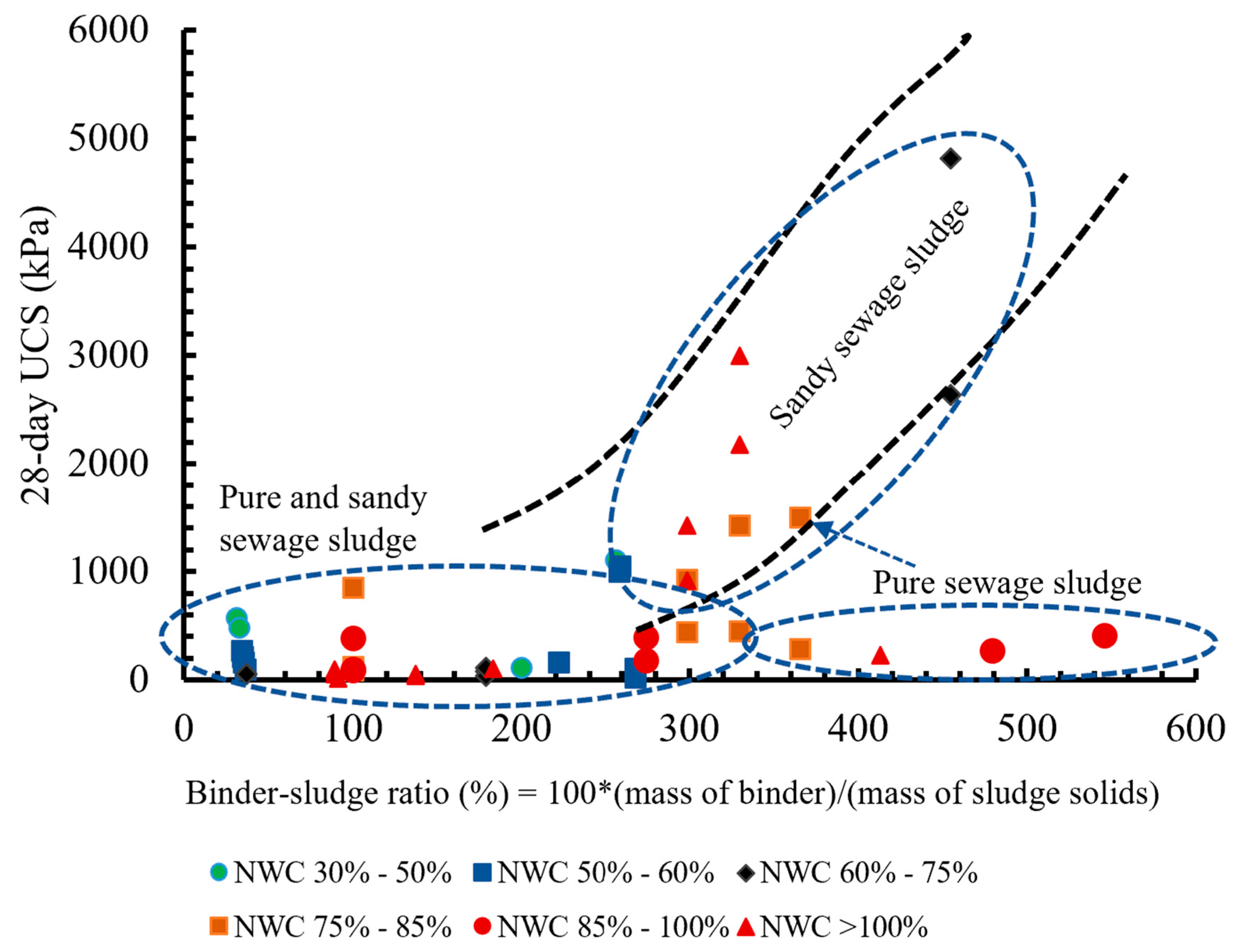

4. Bases of Comparison

5. Proposed Framework

5.1. Binder Content and Binder-Sludge Ratio

5.2. Postulated Structure and Strength of Treated Sandy Sewage Sludge (Coarse, Hard Particulate Inclusion in Sludge)

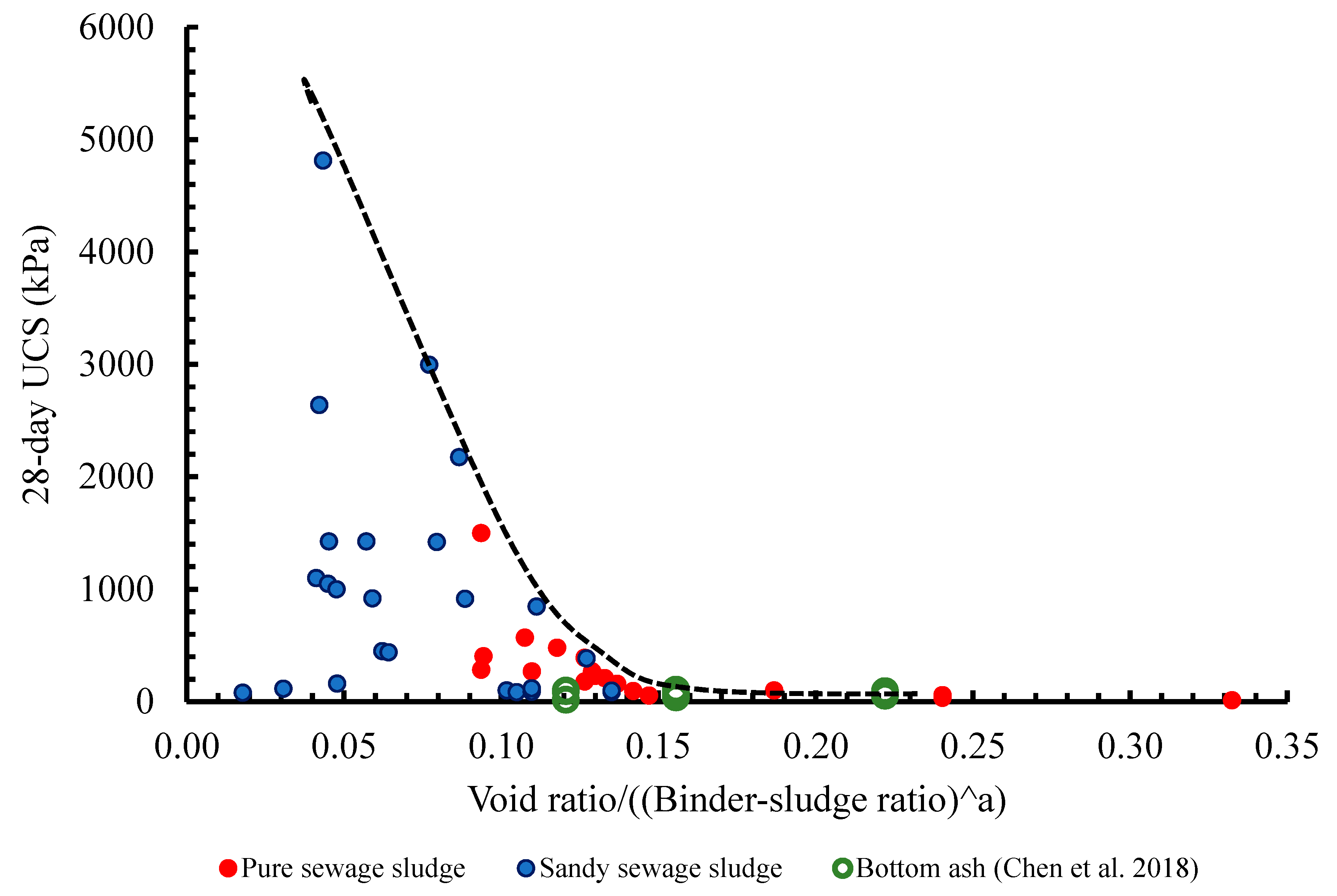

5.3. Void Ratio as a Possible Characterising Parameter

6. Conclusions

- (a)

- The binder-sludge ratio is a relevant parameter, as it quantifies a contributory factor to the strength of the cementitious matrix. This may diminish in significance as the content of coarse, hard particles increases.

- (b)

- Coarse, hard particulate inclusions in the sludge do not participate in the cementitious reactions, but their presence can enhance strength gain through frictional contacts and interlocking.

- (c)

- The overall void ratio, defined as the volume of voids in the cementitious matrix normalised by the overall volume, is also a relevant parameter which quantifies the combined effect of the coarse particulate inclusions and the cementitious matrix.

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Chertow, M. The ecology of recycling. UN Chron. 2012, 46, 56–60. [Google Scholar] [CrossRef]

- Boutouil, M.; Levacher, D. Multifactorial study of macroscopic properties of solidified sludge. Part II: Porosity. Proc. Inst. Civ. Eng.-Ground Improv. 2002, 6, 13–21. [Google Scholar] [CrossRef]

- Boutouil, M.; Levacher, D. Effect of high initial water content on cement-based sludge solidification. Proc. Inst. Civ. Eng.-Ground Improv. 2005, 9, 169–174. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Canato, M.; Abba, A.; Miino, M.C. Biosolids: What are the different types of reuse? J. Clean. Prod. 2019, 238, 117844. [Google Scholar] [CrossRef] [Green Version]

- DG ENV. Disposal and Recycling Routes for Sewage Sludge. In Scientific and Technical Sub-Component Report; European Commission DG Environment: Brussels, Belgium, 2001. [Google Scholar]

- Marmo, L. Sewage sludge in the EU. Presented at the Researching the Sludge Directive—A Conference on Sewage Sludge, Brussels, Belgium, 30–31 October 2001. [Google Scholar]

- Pritchard, D.L.; Penney, N.; McLaughlin, M.J.; Rigby, H.; Schwarz, K. Land application of sewage sludge (biosolids) in Australia: Risks to the environment and food crops. Water Sci. Technol. 2010, 62, 48–57. [Google Scholar] [CrossRef] [Green Version]

- Malliou, O.; Katsioti, M.; Georgiadis, A.; Katsiri, A. Properties of stabilized/solidified admixtures of cement and sewage sludge. Cem. Concr. Compos. 2007, 29, 55–61. [Google Scholar] [CrossRef]

- Katsioti, M.; Katsiotis, N.; Rouni, G.; Bakirtzis, D.; Loizidou, M. The effect of bentonite/cement mortar for the stabilization/solidification of sewage sludge containing heavy metals. Cem. Concr. Compos. 2008, 30, 1013–1019. [Google Scholar] [CrossRef]

- Lucena, L.C.F.L.; Juca, J.F.T.; Soares, J.B.; Portela, M.G. Potential Uses of Sewage Sludge in Highway Construction. J. Mater. Civ. Eng. 2014, 26, 040140511. [Google Scholar]

- Chen, Y.; He, X.; Wang, P.; Wan, Y.; Tan, X. Experimental Study of Moisture Content Effect on Geotechnical Properties of Solidified Municipal Sludge. Adv. Polym. Technol. 2020, 2020, 8794076. [Google Scholar] [CrossRef] [Green Version]

- He, J.; Zhang, L.; Zhang, C. Durability Analysis of Sludge Solidified with Soda Residue Subjected to Dry-Wet and Freeze-Thaw Cycles. Adv. Civ. Eng. 2021, 2021, 9960416. [Google Scholar] [CrossRef]

- Boura, P.; Katsioti, M.; Tsakiridis, P.; Katsiri, A. Stabilization/Solidification of Sewage Sludge. In Proceedings of the International Conference, BIOSOLIDS 2003 Waste-Water Sludge as a Resource, Trondheim, Norway, 23–25 June 2003; pp. 465–471. [Google Scholar]

- Lin, C.; Zhu, W.; Han, J. Geotechnical Properties of Solidified Sludge by Mixing Cement and Calcium-Bentonite. In Proceedings of the International Foundation Congress and Equipment Expo—Contemporary Topics in Ground Modification, Problem Soils, and Geo-Support, Orlando, FL, USA, 15–19 March 2009; pp. 281–288. [Google Scholar]

- Stehouwer, R. What Is Sewage Sludge and What Can Be Done with It? Penn State Extension. 15 September 2010. Available online: https://extension.psu.edu/what-is-sewage-sludge-and-what-can-be-done-with-it (accessed on 12 September 2021).

- Zou, J.; Dai, Y.; Pan, K.; Jiang, B.; Tian, C.; Tian, G.; Zhou, W.; Wang, L.; Wang, X.; Fu, H. Recovery of silicon from sewage sludge for production of high-purity nano-SiO2. Chemosphere 2013, 90, 2332–2339. [Google Scholar] [CrossRef] [PubMed]

- Jagaba, A.H.; Shuaibu, A.; Umaru, I.; Musa, S.; Lawal, I.M.; Abubakar, S. Stabilization of Soft Soil by Incinerated Sewage Sludge Ash from Municipal Wastewater Treatment Plant for Engineering Construction. Sustain. Struct. Mater. 2019, 2, 32–44. [Google Scholar]

- Pan, S.C.; Tseng, D.H. Sewage sludge ash characteristics and its potential applications. Water Sci. Technol. 2001, 44, 261–267. [Google Scholar] [CrossRef]

- Tao, J.; Wu, S.; Sun, L.; Tan, X.; Yu, S.; Zhang, Z. Composition of Waste Sludge from Municipal Wastewater Treatment Plant. Procedia Environ. Sci. 2012, 12, 964–971. [Google Scholar] [CrossRef] [Green Version]

- Odell, R.T.; Thornburn, T.H.; McKenzie, L.J. Relationships of Atterberg limits to some other properties of Illinois soils. Soil Sci. Soc. Am. J. 1960, 24, 297–300. [Google Scholar] [CrossRef]

- Gui, Y.; Zhang, Q.; Qin, X.; Wang, J. Influence of Organic Matter Content on Engineering Properties of Clays. Adv. Civ. Eng. 2021, 2021, 6654121. [Google Scholar] [CrossRef]

- Zhu, X.; Li, F.; Zhang, J.; Wu, S. Physicochemical properties of stabilized sewage sludge admixtures by modified steel slag. Open Chem. 2018, 16, 583–590. [Google Scholar] [CrossRef]

- Cheilas, A.; Katsioti, M.; Georgiades, A.; Malliou, O.; Teas, C.; Haniotakis, E. Impact of hardening conditions on to stabilized/solidified products of cement–sewage sludge–jarosite/alunite. Cem. Concr. Compos. 2007, 29, 263–269. [Google Scholar] [CrossRef]

- Chen, P.; Feng, B.; Lin, Y.; Lin, C. Solidification and Stabilization of Sewage Sludge and MSWI Bottom Ash for Beneficial Use as Construction Materials. J. Mater. Civ. Eng. 2019, 331, 04018351. [Google Scholar] [CrossRef]

- Winnefeld, F. Calcium Sulfoaluminate Cement: An example of a low CO2–Alternative to Portland Cement. In Proceedings of the WTA Colloquium Effect of Climate Change on Built Heritage, Eindhoven, The Netherlands, 11–12 March 2010; WTA-Publications: Eindhoven, The Netherlands, 2010; Volume 34, pp. 95–108. [Google Scholar]

- Katsioti, M.; Giannikos, D.; Tsakiridis, P.E.; Tsibouki, Z. Properties and hydration of blended cements with mineral alunite. Constr. Build. Mater. 2009, 23, 1011–1021. [Google Scholar] [CrossRef]

- Chew, S.H.; Kamruzzaman, A.H.M.; Lee, F.H. Physicochemical and engineering behavior of cement treated clays. J. Geotech. Geoenviron. Eng. 2004, 130, 696–706. [Google Scholar] [CrossRef]

- FHWA. Recycled Materials in the Highway Environment. In User Guidelines for Waste and Byproduct Materials in Pavement Construction (FHWA-RD-97-148); U.S. Federal Highway Administration: Washington, DC, USA, 2016. [Google Scholar]

- Kim, Y.Y.; Do, T.H. Effect of bottom ash particle size on strength development in composite geomaterial. Eng. Geol. 2012, 139–140, 85–91. [Google Scholar] [CrossRef]

- Xiao, H.; Lee, F.H.; Chin, K.G. Yielding of cement-treated marine clay. Soils Found. 2014, 54, 488–501. [Google Scholar] [CrossRef] [Green Version]

- Nakata, Y.; Kato, Y.; Hyodo, M.; Hyde, A.F.L.; Murata, H. One-Dimensional Compression Behaviour of Uniformly Graded Sand Related to Single Particle Crushing Strength. Soils Found. 2001, 41, 39–51. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.K.; Lee, H.K. Use of power plant bottom ash as fine and coarse aggregates in high-strength concrete. Constr. Build. Mater. 2011, 25, 1115–1122. [Google Scholar] [CrossRef]

- Bolton, M.D. A Guide to Soil Mechanics; Macmillan Education UK: London, UK, 1979. [Google Scholar]

- Taylor, D.W. Fundamentals of Soil Mechanics; John Wiley & Sons, Inc.: New York, NY, USA, 1948. [Google Scholar]

- Schofield, A.; Wroth, P. Critical State Soil Mechanics; McGraw-Hill: New York, NY, USA, 1968. [Google Scholar]

- Tyagi, A.; Xiao, H.; Chin, K.G.; Lee, F.H. Model for predicting the unit weight of cement-treated soils. Soils Found. 2019, 59, 1921–1932. [Google Scholar] [CrossRef]

- Kek, H.Y.; Pan, Y.; Ng, Y.C.H.; Lee, F.H. An approach for modelling spatial variability in permeability of cement-admixed soil. Acta Geotech. 2021, 16, 4007–4026. [Google Scholar] [CrossRef]

| Authors | Sludge Type | Binder(s) | Results |

|---|---|---|---|

| [14] | Dewatered wastewater sludge. PI = 256%, water content = 314–357% [this is the water content of the raw, that is untreated, sludge]. Organic content = 42.8%. | Sludge:OPC:bentonite = 1:0:0.5 to 1:0.4:0.4. | Strength ranges from ~12 kPa to ~500 kPa [for OPC and bentonite content of 40% and 40%, respectively]. Initial water content has significant effect on final strength, especially at high OPC content. |

| [22] | Dewatered sewage sludge. Water content = 78%. | OPC and modified steel slag, which consists of steel slag, activator (consisting mainly of Al2O3, SiO2 and CaO) and gypsum. Binder content ~20%. | 14-day strength of treated sludge: With 20% modified steel slag 74.5 kPa With OPC 29.5 kPa). |

| [11] | Sewage sludge. Water content = 83%, organic content = 38%. | Proprietary binder Sulphoaluminate-based cement: OPC:CaO:gypsum:lithium salt = 0.30:0.60:0.05:0.049:0.001. Binder:sludge solids content = 118%. | Dependent upon initial moisture:

|

| [12] | Sewage sludge. LL = 380%, PL = 63%, water content = 566%. SiO2 45%, Al2O3 16.4%, CaO 5.6%. Sludge has a shortage of CaO. | Sludge solids:soda residue:GGBS:CaO = 1:2 to 3.33:1.33:0.8.Total binder:sludge solid ratio = 4.13 to 5.46:1. Total water content = 85.8% to 68.2%. Note: this is very high binder: sludge ratio. | Unconfined compressive strength range:

|

| Authors | Sludge Type | Binder(s) | Results |

|---|---|---|---|

| [13] | Mixture of dried sewage sludge (from wastewater treatment plants Psyttalia and Metamorphosis) and sand. Total organic content 30% (Psyttalia) and 10% (Metamorphosis). Sand content (sand/(sludge + sand)) from 86%–95%. | OPC + jarosite/alunite. Binder:sludge ratio = 100% to 333%. Binder:(sludge + sand) = 14.4% to 15.8%. Total water content from ~18% to ~21%. | 28-day strength range: ~86 kPa (for binder:pure sludge ratio of 100%) to 3000 kPa (binder:pure sludge ratio 300%). |

| [7] | Mixture of dried sewage sludge (from wastewater treatment plant Metamorphosis) and sand. Total organic content 10%. Sand content from 91.6% to 95.2%. | Binder consists of OPC with 0.5% to 1.5% of CaCl2 (bihydrate) and Ca(OH)2. Binder:sludge ratio = 100% to 333%. Binder:(sludge + sand) = 14.4% to 15.8%. Total water content from ~3.7% to ~11%. | 28-day strength range: 80 kPa (for binder:sludge ratio of 1.82; binder/(sludge + sand) = 15.3%) to 1426 kPa (binder:sludge ratio of 333%; binder/(sludge + sand) = 15.9%). |

| [23] | Mixture of dried sewage sludge (from wastewater treatment plant Metamorphosis) and sand. Total organic content 10%. Sand content 96.5%. | OPC+jarosite/alunite. Binder: sludge ratio = 454%. Binder:(sludge + sand) = 16%. Total water content from ~8.3%. | 28-day strength range: ~2.64 MPa to 4.814 MPa under different curing conditions. |

| [9] | Mixture of dried sewage sludge (from wastewater treatment plants Psyttalia and Metamorphosis) and sand. Total organic content 30% (Psyttalia) and 10% (Metamorphosis). Sand content from 86–95%. There is little or no Si or Al in the sludge | OPC and OPC+bentonite. Binder:sludge ratios: (a) 100% for sludge solids from Psyttalia or Metamorphosis; (b) 294% for wet Psyttalia sludge; (c) 333% for wet Metamorphosis sludge. | 28-day strength range: 85 kPa (binder:sludge ratio 100% to 1.4 MPa (binder:sludge ratio 333%). showed higher compressive strength than the minimum limit of the 350 kPa at 28 days. |

| [10] | Sludge-soil containing 10% sewage sludge and 90% sandy soil. Sludge: LL = 40%, PL = 27%, natural water content = 22%. Silica content 28.5%. Alumina content 13.2%. Soil consists of 91% sand and 9% fines. LL~23%, PL~17%. Natural moisture content = 16%. Sand content in sludge-soil mixture = 81.9%. | 3 types of binders used; lime, OPC and asphaltic emulsion. Binder content 2% to 8%. | 28-day strength: Lime: 1000 kPa–1300 kPa. OPC: 489 kPa–1200 kPa [at low content, lime works better than cement. At higher content, they have similar strength] Asphaltic emulsion: 851 kPa to 1016 kPa. |

| [24] | Mixture of (a) Sewage sludge. Organic content = 34.5%, water content = 198%; and (b) MSWI bottom ash. Water content = 14.9%. Bottom ash has large grain size, similar to sand. Ash:Sludge = 0.5 to 2.0. Ash content = 33.3% to 66.7%. | Three types of binders used: OPC, lime and gypsum, used separately. Binder:sludge ratio from 0.3 to 0.9. Total water content = ~48% to ~86% (roughly) | 28-day strength of treated soil: (a) For lime: ~20 kPa to 55 kPa. (b) For OPC: ~80 kPa to ~90 kPa. (c) For gypsum: ~90 kPa to ~110 kPa. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, S.M.; He, L.; Goh, S.H.; Lee, F.H. Strength of Chemically Stabilized Sewage Sludge—Some Inferences from Recent Studies. Geotechnics 2021, 1, 573-587. https://doi.org/10.3390/geotechnics1020026

Lim SM, He L, Goh SH, Lee FH. Strength of Chemically Stabilized Sewage Sludge—Some Inferences from Recent Studies. Geotechnics. 2021; 1(2):573-587. https://doi.org/10.3390/geotechnics1020026

Chicago/Turabian StyleLim, Sin Mei, Linqiao He, Siang Huat Goh, and Fook Hou Lee. 2021. "Strength of Chemically Stabilized Sewage Sludge—Some Inferences from Recent Studies" Geotechnics 1, no. 2: 573-587. https://doi.org/10.3390/geotechnics1020026

APA StyleLim, S. M., He, L., Goh, S. H., & Lee, F. H. (2021). Strength of Chemically Stabilized Sewage Sludge—Some Inferences from Recent Studies. Geotechnics, 1(2), 573-587. https://doi.org/10.3390/geotechnics1020026