Experimental Study of Scouring and Deposition Characteristics of Riprap at Embankment Toe Due to Overflow

Abstract

:1. Introduction

1.1. Factors Affecting Scour at Embankment Toe

1.2. Local Scour Protection with Ripraps

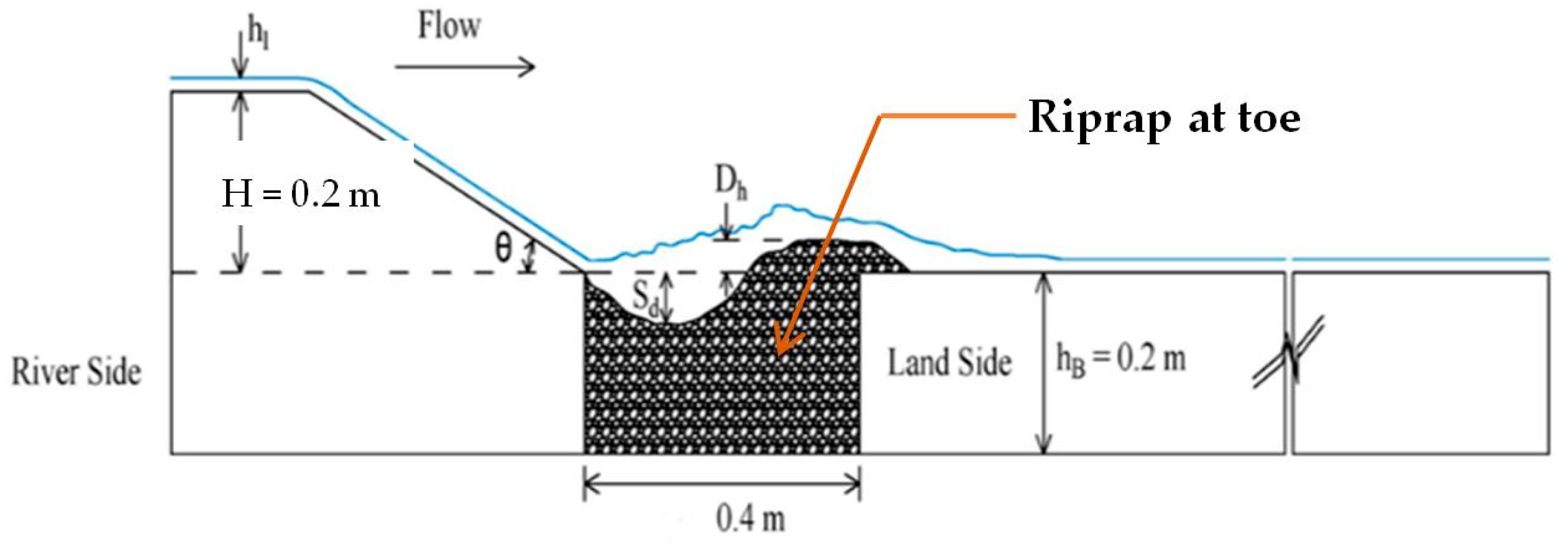

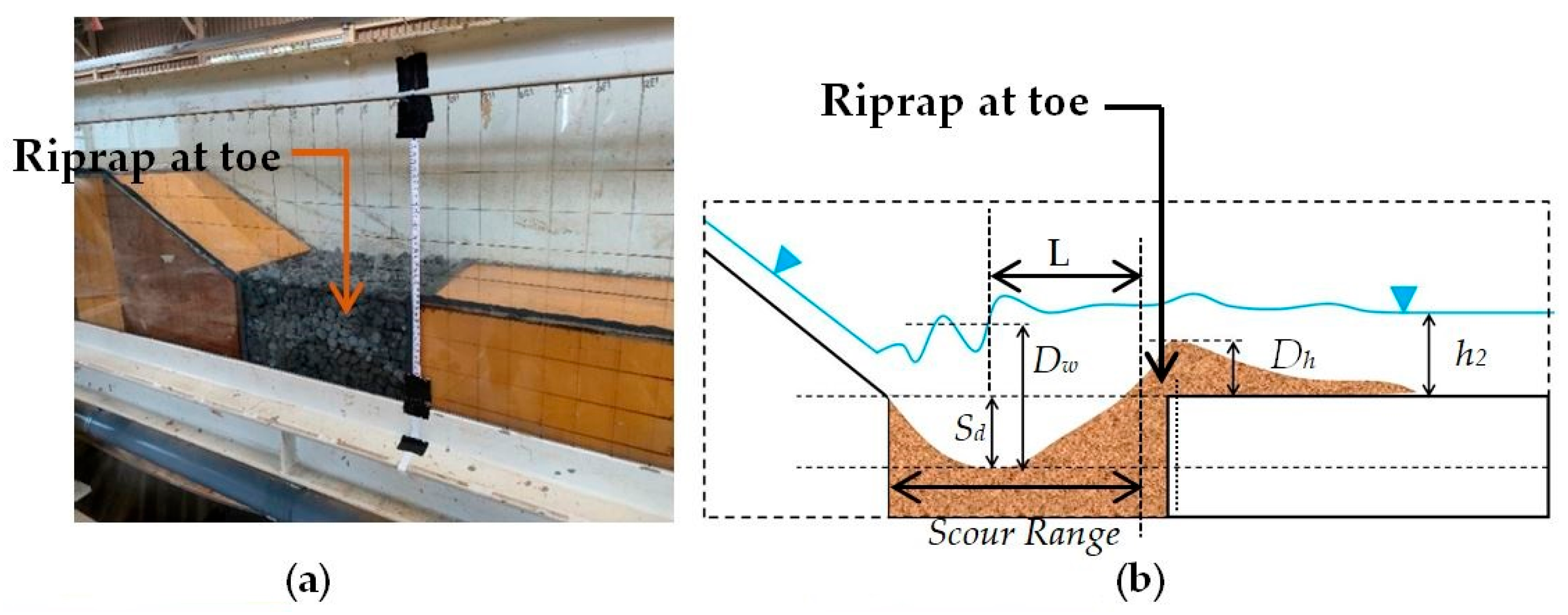

2. Materials and Methods

- h2 = water depth at the section after the scour hole;

- h1 = hc = critical water depth;

- V2 = flow velocity corresponding to h2, and B is the channel width;

- V1 = flow velocity at the end of the embankment crest;

- g = gravitational acceleration.

- Q = Q/b = flow discharge per unit width;

- b = B = embankment width or channel width.

Materials and Equipment

3. Results

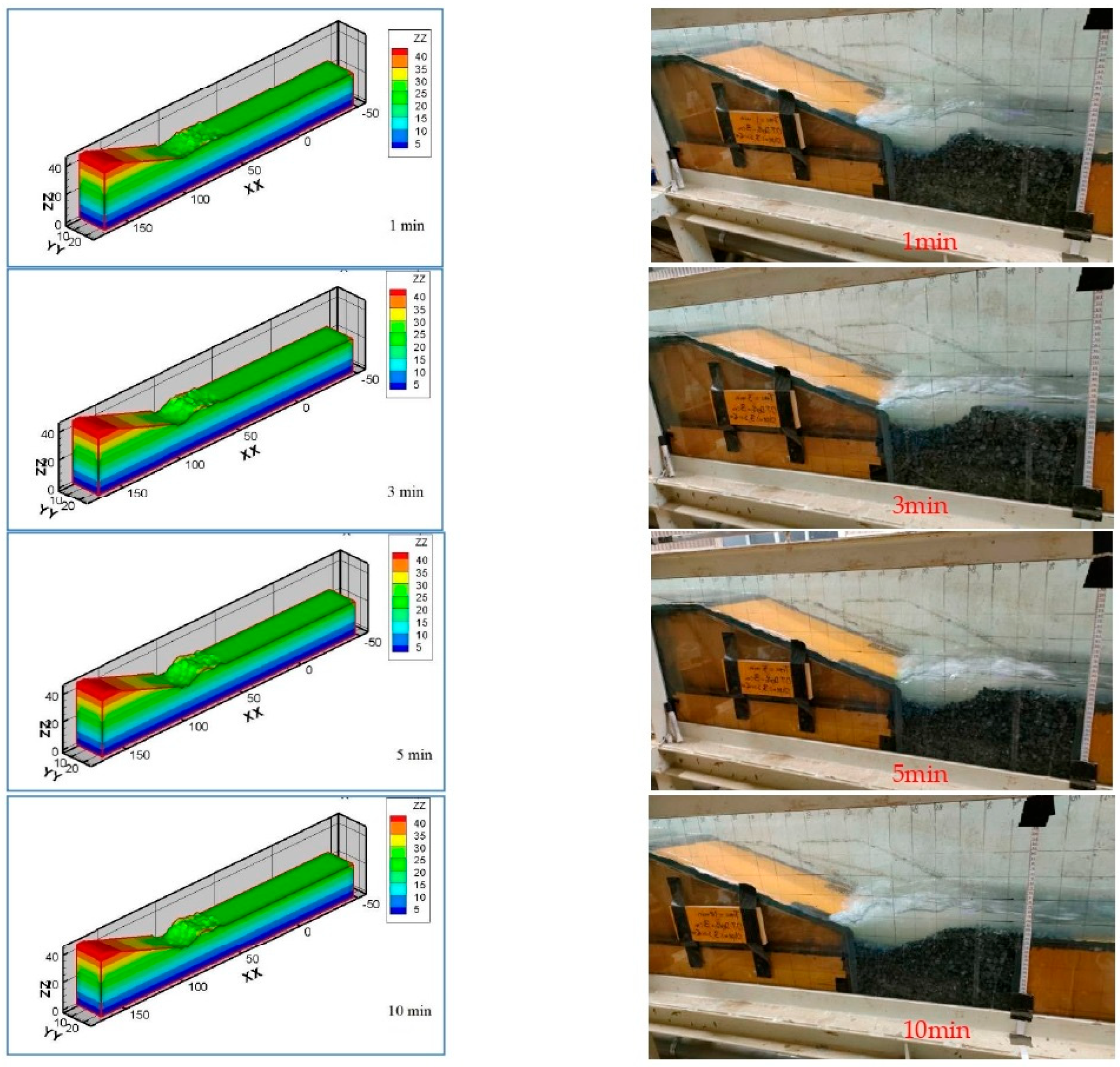

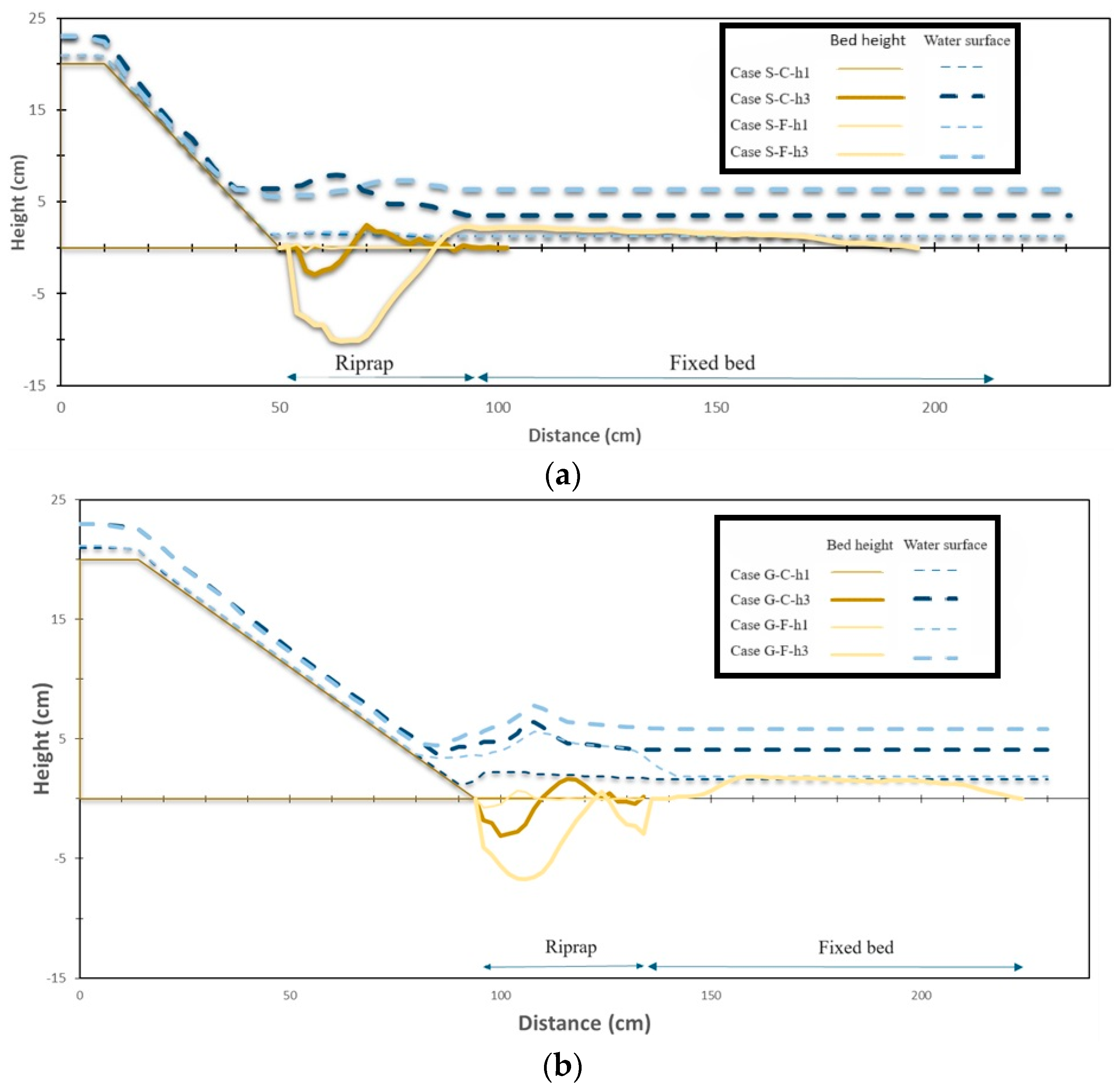

3.1. Typical Development of Scour and Deposition Characteristics

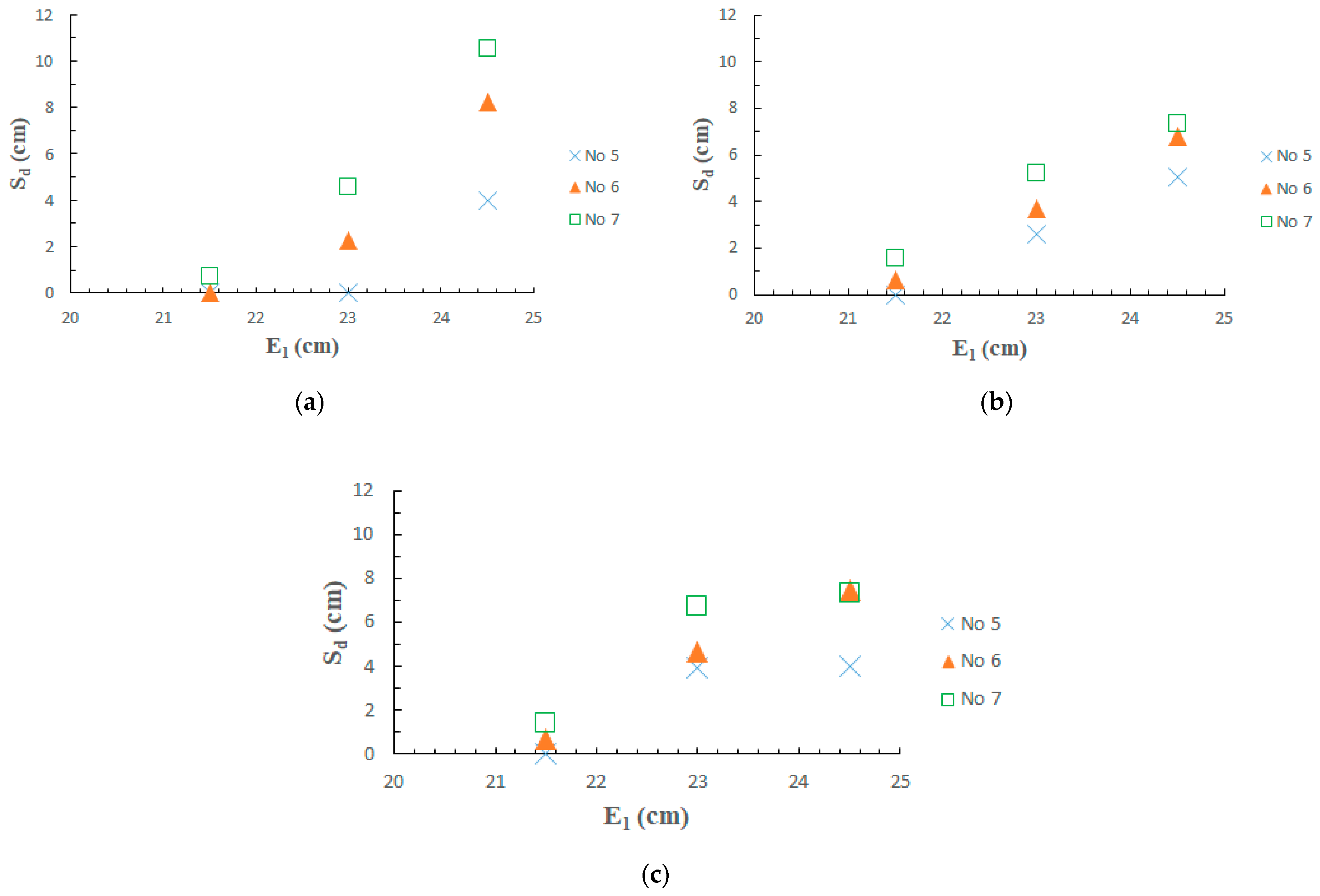

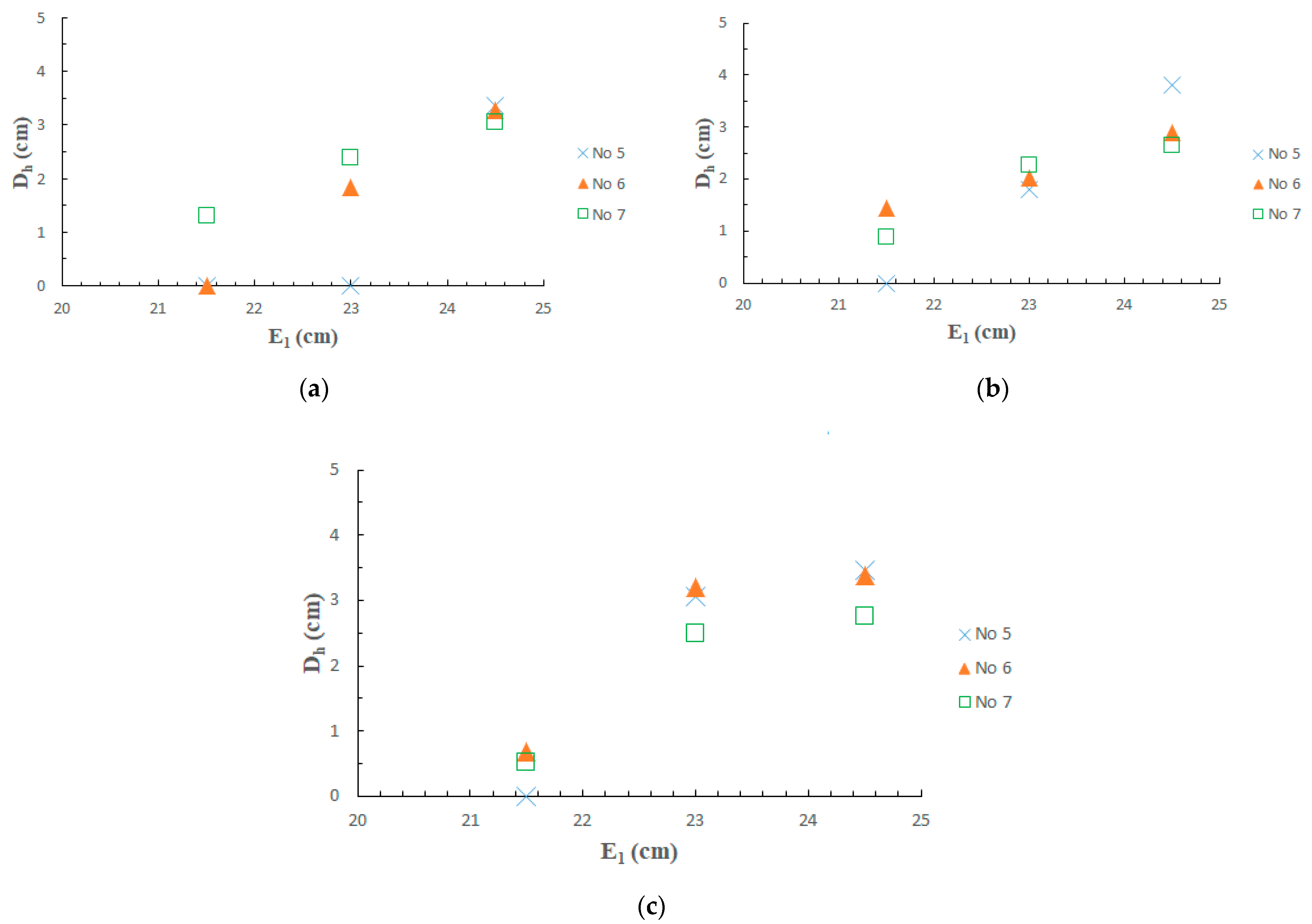

3.2. Effect of Energy Head on Scour Depths

3.3. Effect of Energy Head on Deposition Height

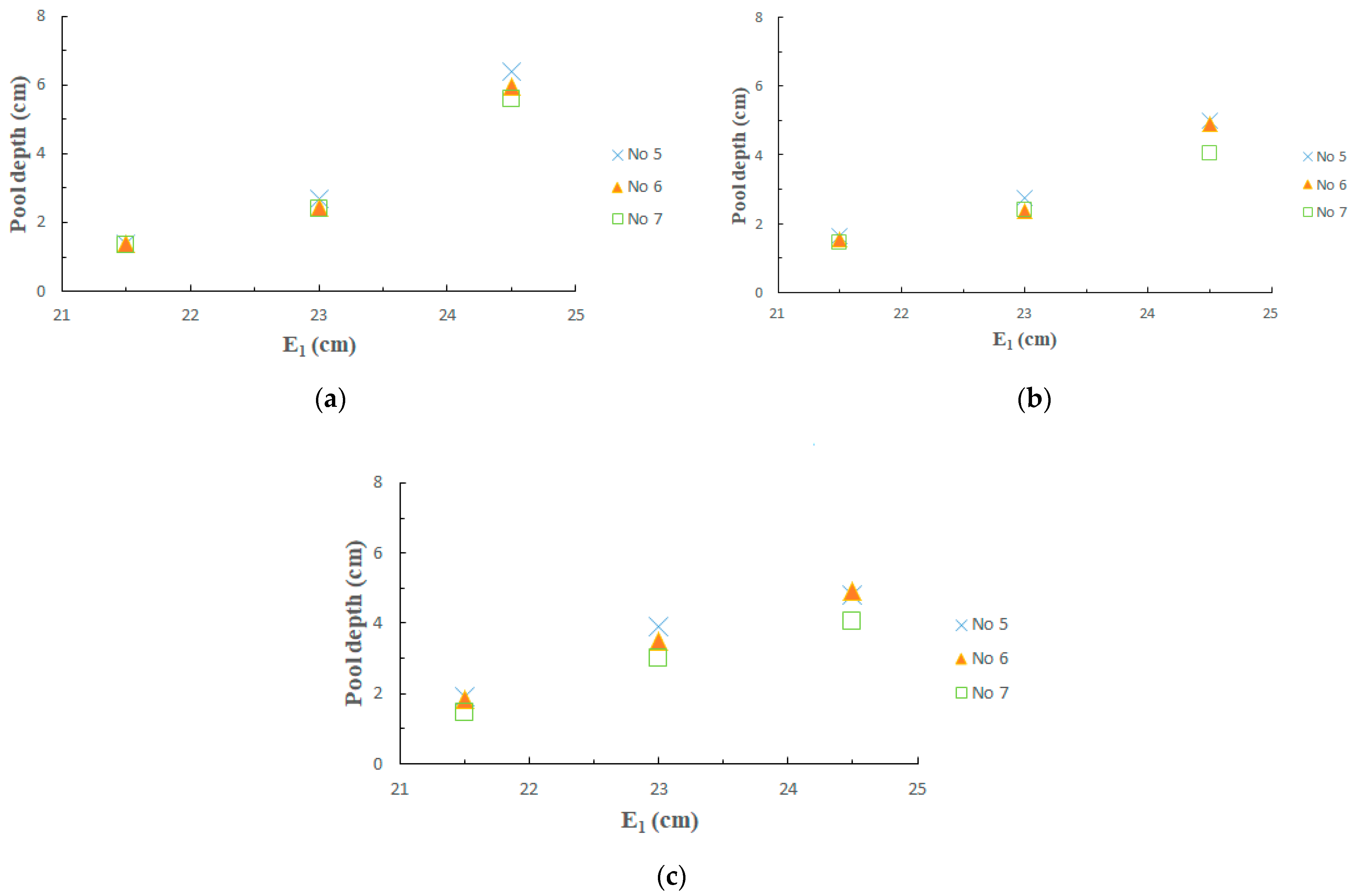

3.4. Effect of Energy Head on Plunge Pool Depth

4. Discussion

4.1. Effect of Riprap Size, Tailwater, and Flow Structure on Scour Phenomenon

4.2. Relationship between Energy Head and Energy Dissipation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schmocker, L. The failure of embankment dams due to overtopping. J. Hydraul. Res. 2009, 47, 288. [Google Scholar] [CrossRef]

- Cestero, J.A.F.; Imran, J.; Chaudhry, M.H. Experimental Investigation of the Effects of Soil Properties on Levee Breach by Overtopping. J. Hydraul. Eng. 2015, 141, 04014085. [Google Scholar] [CrossRef]

- Billah, M.M.; Yagisawa, J. Applicability of Energy Based and Stress Based Headcut Migration Model to Earthen Embankment with Stratified Sub-surface. In Proceedings of the ICCESD 2022, KUET, Khulna, Bangladesh, 10–12 February 2022; p. 136. [Google Scholar]

- Liu, Z.; Li, T.; Ding, Y.; Jiang, S. A soil tensile strength based headcut migration model of breach side slope. Water 2020, 12, 2666. [Google Scholar] [CrossRef]

- Afreen, T.; Binh, Y. Investigation of Scour Pattern Downstream. J. Jpn. Soc. Civ. Eng. Ser. B1 (Hydraul. Eng.) 2015, 59, 175–180. [Google Scholar]

- Billah, M.; Yagisawa, J. Headcut Migration in Earthen Embankment Induced by Varying Sub-surface and Seepage State under Overflow. Geotech. Geol. Eng. 2023, 41, 4659–4676. [Google Scholar] [CrossRef]

- Billah, M.; Yagisawa, J. Experimental investigation on effect of initial phreatic line position inside earthen embankment on headcut migration during overtopping flow. J. Jpn. Soc. Civ. Eng. Ser. B1 (Hydraulic Eng.) 2020, 76, I_565–I_570. [Google Scholar] [CrossRef] [PubMed]

- Jayaratne, M.P.R.; Premaratne, B.; Adewale, A.; Mikami, T.; Matsuba, S.; Shibayama, T.; Esteban, M.; Nistor, I. Failure mechanisms and local scour at coastal structures induced by Tsunami. Coast. Eng. J. 2016, 58, 1640017. [Google Scholar] [CrossRef]

- Zhao, G.; Visser, P.J.; Peeters, P.; Vrijling, H.K. Prediction of Headcut Erosion Development on the Breach Slope. In Proceedings of the ICSE6, Paris, France, 27–31 August 2012; pp. 1257–1264. [Google Scholar]

- Johnson, E.B.; Testik, F.Y.; Ravichandran, N.; Schooler, J. Levee scour from overtopping storm waves and scour counter measures. Ocean Eng. 2013, 57, 72–82. [Google Scholar] [CrossRef]

- Nishikawa, S.; Yagisawa, J. Effect of Hard-Erodible Soil Layer on Scour Around Embankment Toe Due to Overtopping Flow. J. Jpn. Soc. Civ. Eng. Ser. B1 (Hydraul. Eng.) 2020, 76, 1165–1170. (In Japanese) [Google Scholar] [CrossRef] [PubMed]

- Elalfy, E.; Tabrizi, A.A.; Chaudhry, M.H. Numerical and Experimental Modeling of Levee Breach Including Slumping Failure of Breach Sides. J. Hydraul. Eng. 2018, 144, 04017066. [Google Scholar] [CrossRef]

- Sarmiento, J.; Guanche, R.; Iturrioz, A.; Ojanguren, T.; Ávila, A.; Yanes, C. Experimental evaluation of dynamic rock scour protection in morphodynamic environments for offshore wind jackets. Energies 2021, 14, 3379. [Google Scholar] [CrossRef]

- Pham, M.-T.; Pham, D.-D.; Vu, D.-L.; Dias, D. Embankments Reinforced by Vertical Inclusions on Soft Soil: Numerical Study of Stress Redistribution. Geotechnics 2023, 3, 1279–1293. [Google Scholar] [CrossRef]

- Pagliara, S.; Palermo, M.; Carnacina, I. Live-bed scour downstream of block ramps for low densimetric Froude numbers. Int. J. Sediment Res. 2012, 27, 337–350. [Google Scholar] [CrossRef]

- Pagliara, S.; Kurdistani, S.M. Scour downstream of cross-vane structures. J. Hydro-environ. Res. 2013, 7, 236–242. [Google Scholar] [CrossRef]

- Farhoudi, J.; Smith, K.V.H. Local scour profiles downstream of hydraulic jump. J. Hydraul. Res. 1985, 23, 343–358. [Google Scholar] [CrossRef]

- Stein, O.R.; Julien, P.Y.; Alonso, C.V. Mechanics of jet scour downstream of a headcut. J. Hydraul. Res. 1993, 31, 723–738. [Google Scholar] [CrossRef]

- Taylor, P.; Dargahi, B. Scour development downstream of a spillway. J. Hydraul. Res. 2003, 41, 417–426. [Google Scholar] [CrossRef]

- Hameed, M.M.; Khaleel, F.; Alomar, M.K.; Razali, S.F.M.; AlSaadi, M.A.; Al-Ansari, N. Introducing high-order response surface method for improving scour depth prediction downstream of weirs. Appl. Water Sci. 2024, 14, 120. [Google Scholar] [CrossRef]

- Lagasse, P.F.; Clopper, P.E.; Zevenbergen, L.W.; Ruff, J.F. Riprap Design Criteria, Recommended Specifications, and Quality Control. Natl. Coop. Highw. Res. Progr. Rep. 2008, 568, 226. Available online: https://hdl.handle.net/20.500.11970/100041 (accessed on 10 July 2024).

- Ruh-Ming, L.; MacArthur, R.; Cotton, G. Sizing riprap for the protection of approach embankments & spur dikes and limiting the depth of scour at bridge piers & abutments. Lit. Rev. Arizona Case Hist. 1989, 1, 3–25. [Google Scholar]

| Case No. | Height of Embankment | Downstream Slope of Embankment | Riprap | Overtopping Flow Depth | Case ID (Slope—Riprap—Flow Depth) | |

|---|---|---|---|---|---|---|

| H (cm) | (V:H) | Size | d50 (mm) | h (cm) | ||

| 1 | 20 | 1:2 (Steep) | No. 5 (coarse gravel) | 16.41 | 1 | S-C-h1 |

| 2 | 2 | S-C-h2 | ||||

| 3 | 3 | S-C-h3 | ||||

| 4 | No. 6 (medium gravel) | 8.48 | 1 | S-M-h1 | ||

| 5 | 2 | S-M-h2 | ||||

| 6 | 3 | S-M-h3 | ||||

| 7 | No. 7 (fine or granule) | 3.39 | 1 | S-F-h1 | ||

| 8 | 2 | S-F-h2 | ||||

| 9 | 3 | S-F-h3 | ||||

| 10 | 20 | 1:3 (Moderate) | No. 5 | 16.41 | 1 | M-C-h1 |

| 11 | 2 | M-C-h2 | ||||

| 12 | 3 | M-C-h3 | ||||

| 13 | No. 6 | 8.48 | 1 | M-M-h1 | ||

| 14 | 2 | M-M-h2 | ||||

| 15 | 3 | M-M-h3 | ||||

| 16 | No. 7 | 3.39 | 1 | M-F-h1 | ||

| 17 | 2 | M-F-h2 | ||||

| 18 | 3 | M-F-h3 | ||||

| 19 | 20 | 1:4 (Gentle) | No. 5 | 16.41 | 1 | G-C-h1 |

| 20 | 2 | G-C-h2 | ||||

| 21 | 3 | G-C-h3 | ||||

| 22 | No. 6 | 8.48 | 1 | G-M-h1 | ||

| 23 | 2 | G-M-h2 | ||||

| 24 | 3 | G-M-h3 | ||||

| 25 | No. 7 | 3.39 | 1 | G-F-h1 | ||

| 26 | 2 | G-F-h2 | ||||

| 27 | 3 | G-F-h3 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Biruni, A.R.M.; Billah, M.M.; Yagisawa, J. Experimental Study of Scouring and Deposition Characteristics of Riprap at Embankment Toe Due to Overflow. Geotechnics 2024, 4, 773-785. https://doi.org/10.3390/geotechnics4030040

Al-Biruni ARM, Billah MM, Yagisawa J. Experimental Study of Scouring and Deposition Characteristics of Riprap at Embankment Toe Due to Overflow. Geotechnics. 2024; 4(3):773-785. https://doi.org/10.3390/geotechnics4030040

Chicago/Turabian StyleAl-Biruni, Abu Raihan Mohammad, Md Masum Billah, and Junji Yagisawa. 2024. "Experimental Study of Scouring and Deposition Characteristics of Riprap at Embankment Toe Due to Overflow" Geotechnics 4, no. 3: 773-785. https://doi.org/10.3390/geotechnics4030040