Material and Environmental Aspects of Concrete Flooring in Cold Climate

Abstract

:1. Introduction

1.1. Moisture-Related Aspects of Concrete Flooring

1.2. Environmental Aspects of Concrete Flooring

1.3. Analyzing the Environmental Impact of Concrete Floors

“Environmental Product Declaration is an international term for the environmental impact analysis declaration of a product. An EPD is a type III declaration, which means that it quantitatively (with numbers and data) describes the product’s environmental impact during the entire life cycle (LCA based) and is produced according to one of the standards in the ISO 14040 series, alternatively based on the European standard EN 15804. It should be reviewed and verified by an independent third party and can be registered and published in e.g., the international EPD system, see also www.environdec.com. The declaration produced using Svensk Betong’s EPD tool is therefore formally not an EPD but an environmental declaration with the same content and produced in the same way as an EPD. Only when it is reviewed by a third party and registered does it become an EPD.”

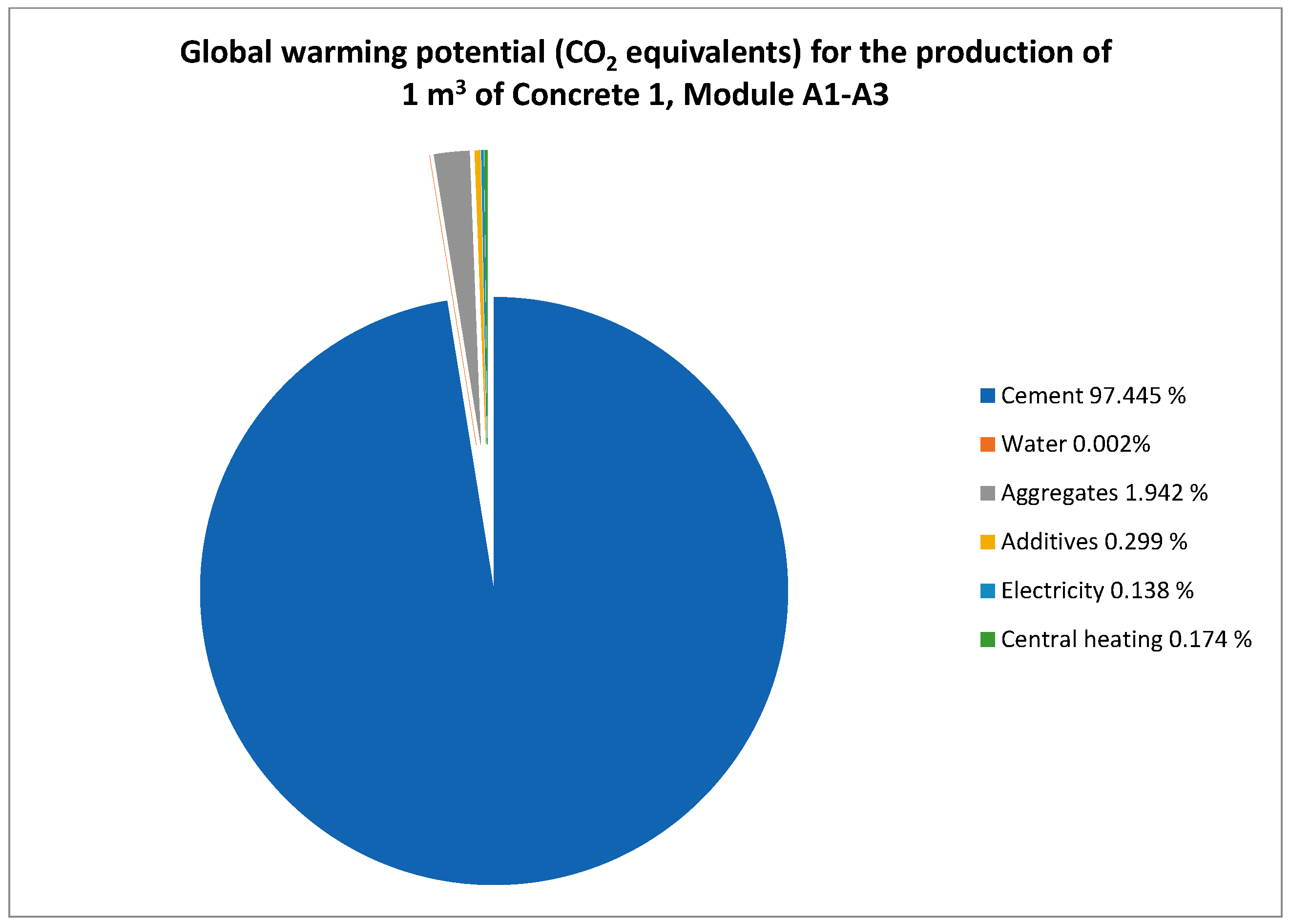

1.3.1. Global Warming Potential (GWP 100 Years)

1.3.2. Ozone Depletion Potential

1.3.3. Acidification Potential

1.3.4. Eutrophication Potential

1.3.5. Photochemical Oxidant Creation Potential

1.3.6. Total Primary Energy

1.4. Purpose of the Paper

2. Materials and Methods

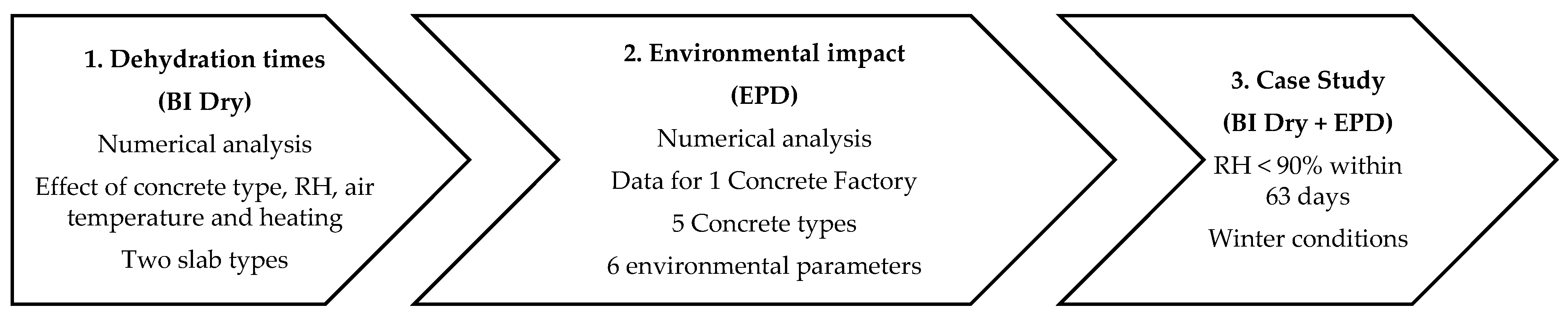

2.1. General Description of the Study

- The use of a fast-dehydrating concrete with a low water-cement ratio.

- Heating of the floor slab using cast-in heating cables.

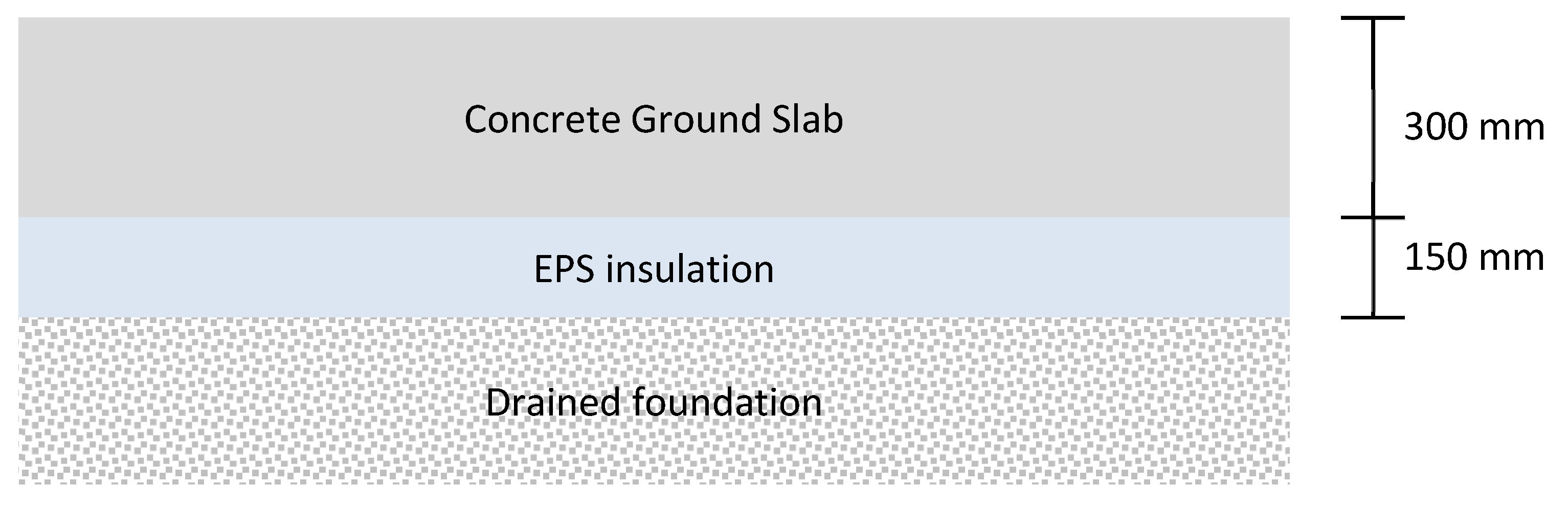

2.1.1. Ground Slab Details

2.1.2. Intermediate Slab Details

2.2. Study of the Dehydration Time

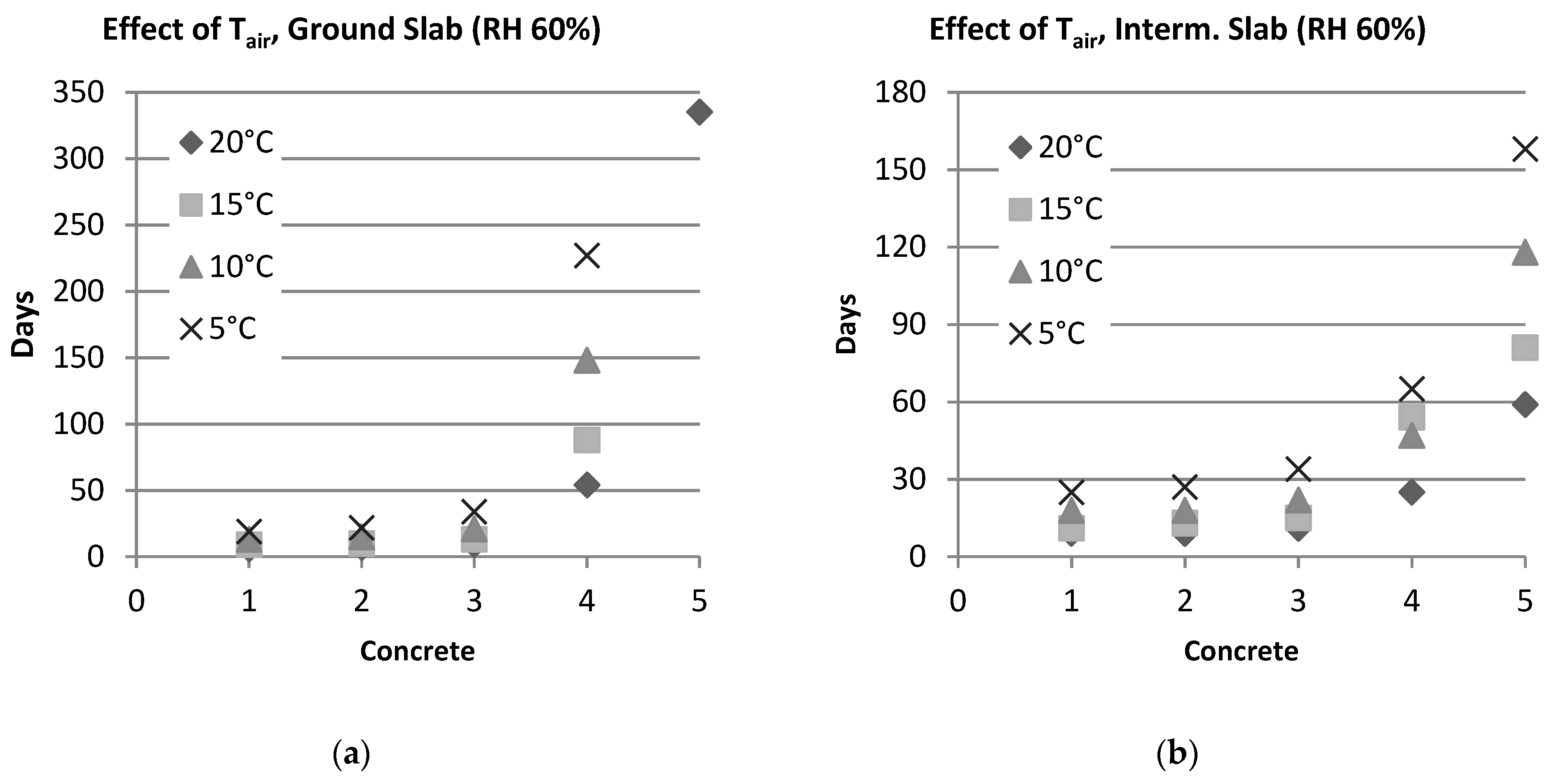

- Concrete quality (water-cement ratio 0.34–0.53);

- Air temperature (5–20 °C);

- Humidity (RH 30–80%);

- Type of slab (ground slab and intermediate slabs);

- Heating cable setup (power, p = 0–50 W/m; spacing, s = 0.1–0.5 m).

- 40 W/m2—cables with an output of 20 W/m and a center distance of 0.5 m;

- 100 W/m2—cables with the power 50 W/m and the center distance 0.5 m;

- 200 W/m2—cables with an output of 20 W/m and a center distance of 0.1 m;

- 500 W/m2—cables with an output of 50 W/m and a center distance of 0.1 m.

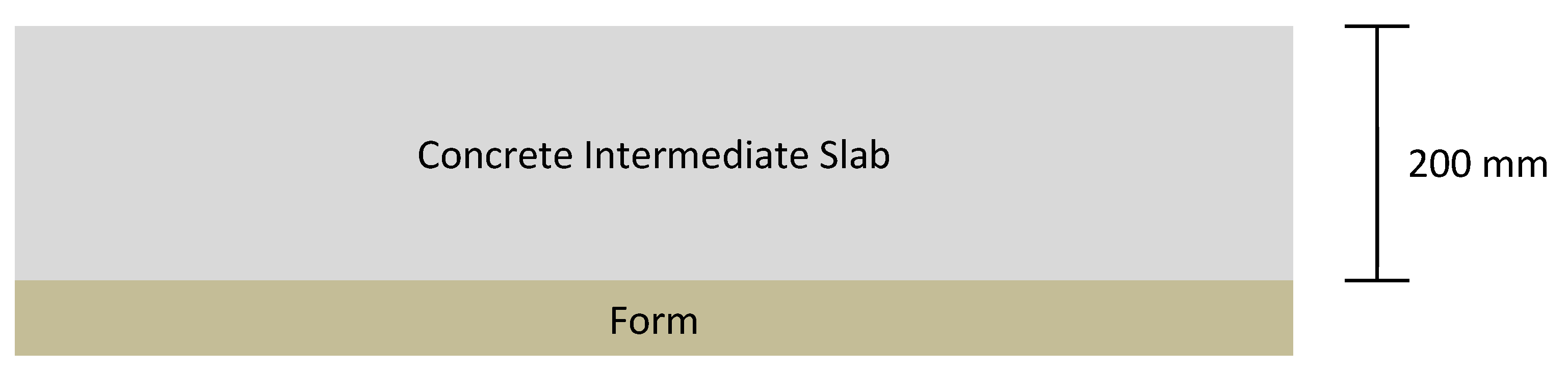

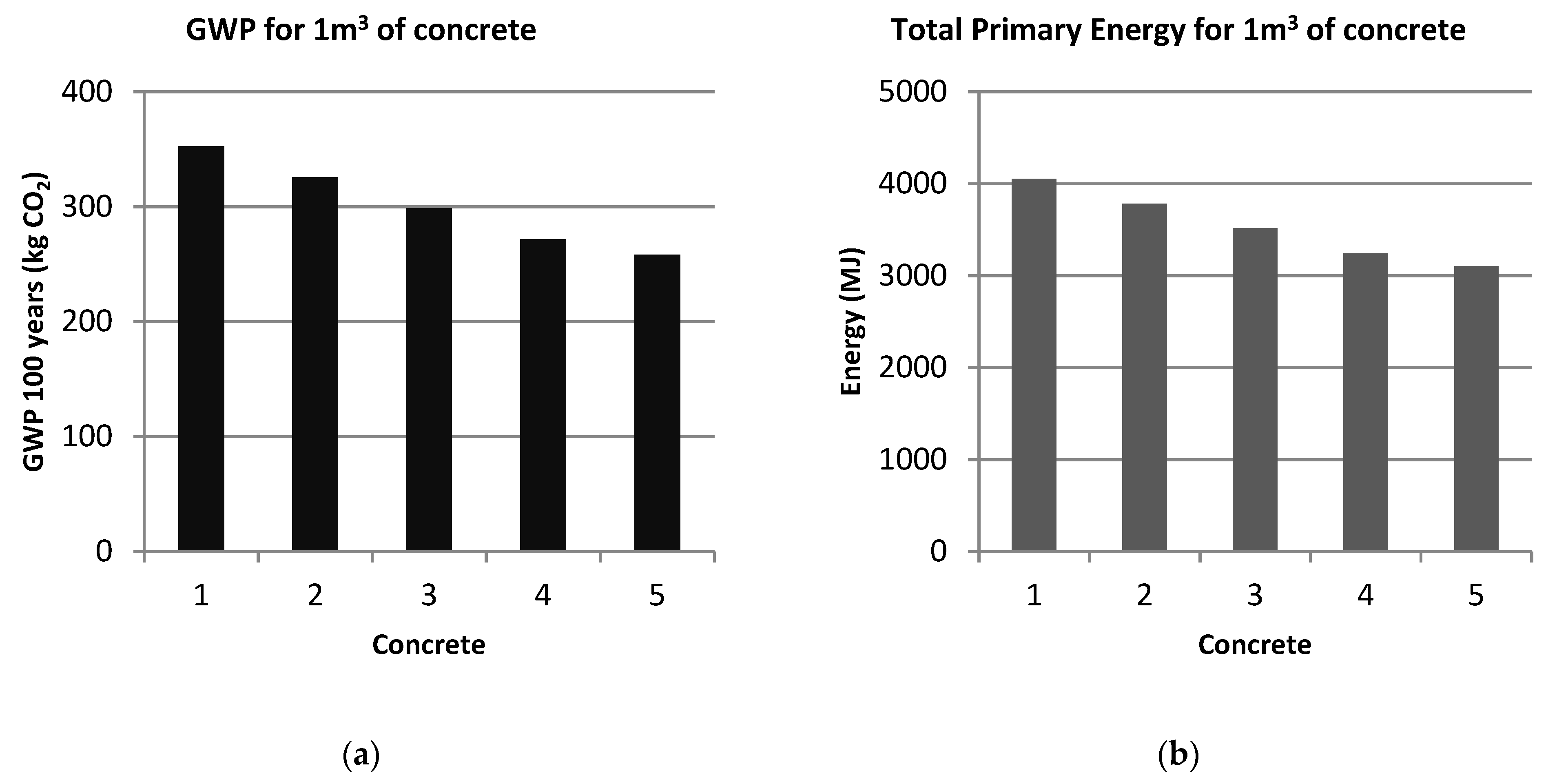

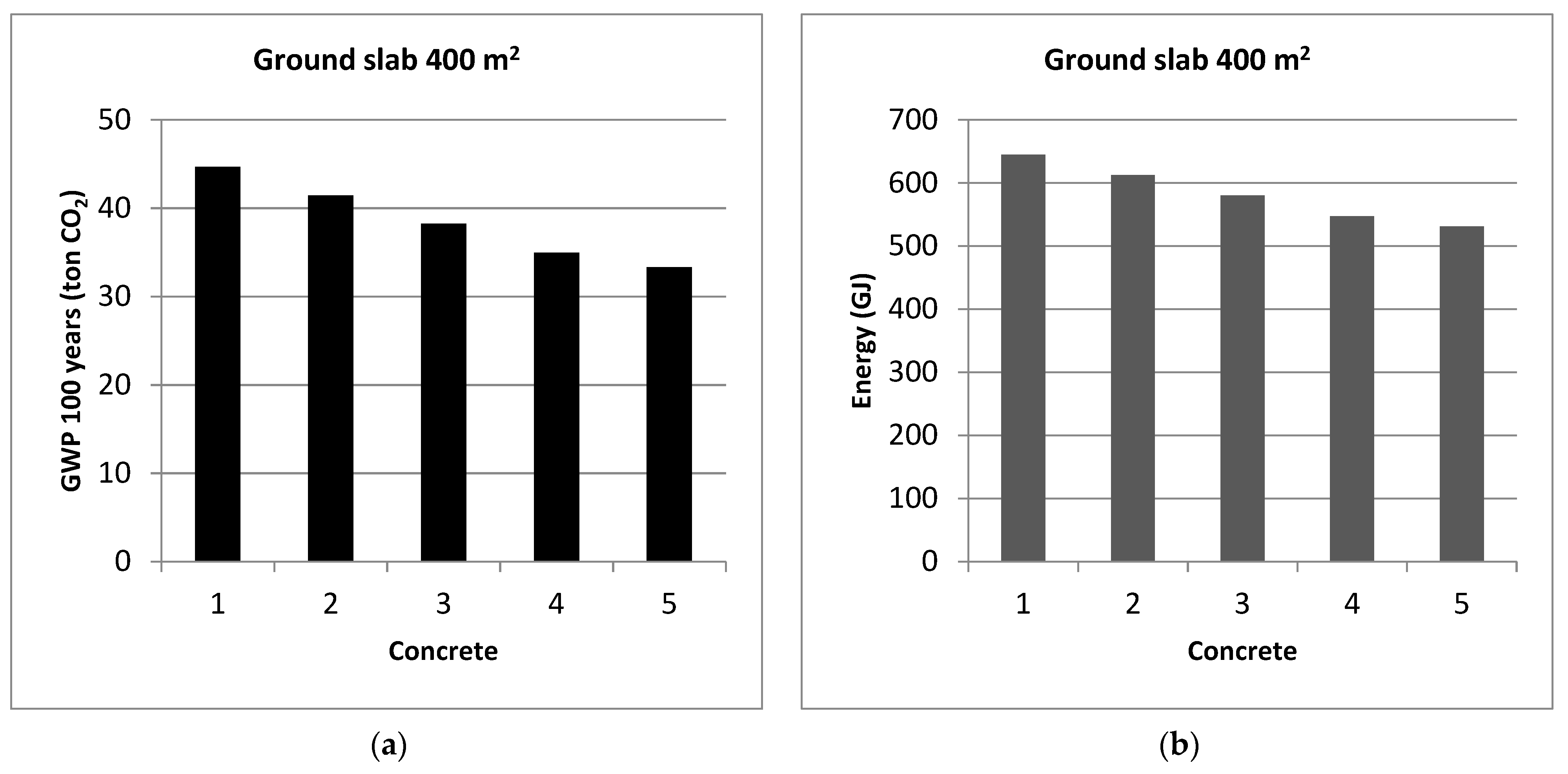

2.3. Study of the Environmental Impact

2.4. Input for Environmental Calculations

3. Results

3.1. Study of Dehydration Times

- Concrete quality (Concrete 1–5);

- Type of slab (ground slab or intermediate slab);

- Air temperature (+5, +10, +15, or +20 °C);

- Relative humidity of the air (30, 40, 50, 60, 70, or 80%);

- Impact of heating cables (0, 20 or 50 W/m, with a center spacing of 100 or 500 mm).

3.1.1. The Air Temperatures Effect on Dehydration Times

3.1.2. The Relative Humidity’s Effect on Dehydration Times

3.1.3. The Effect of Internal Heating Cables on Dehydration Times

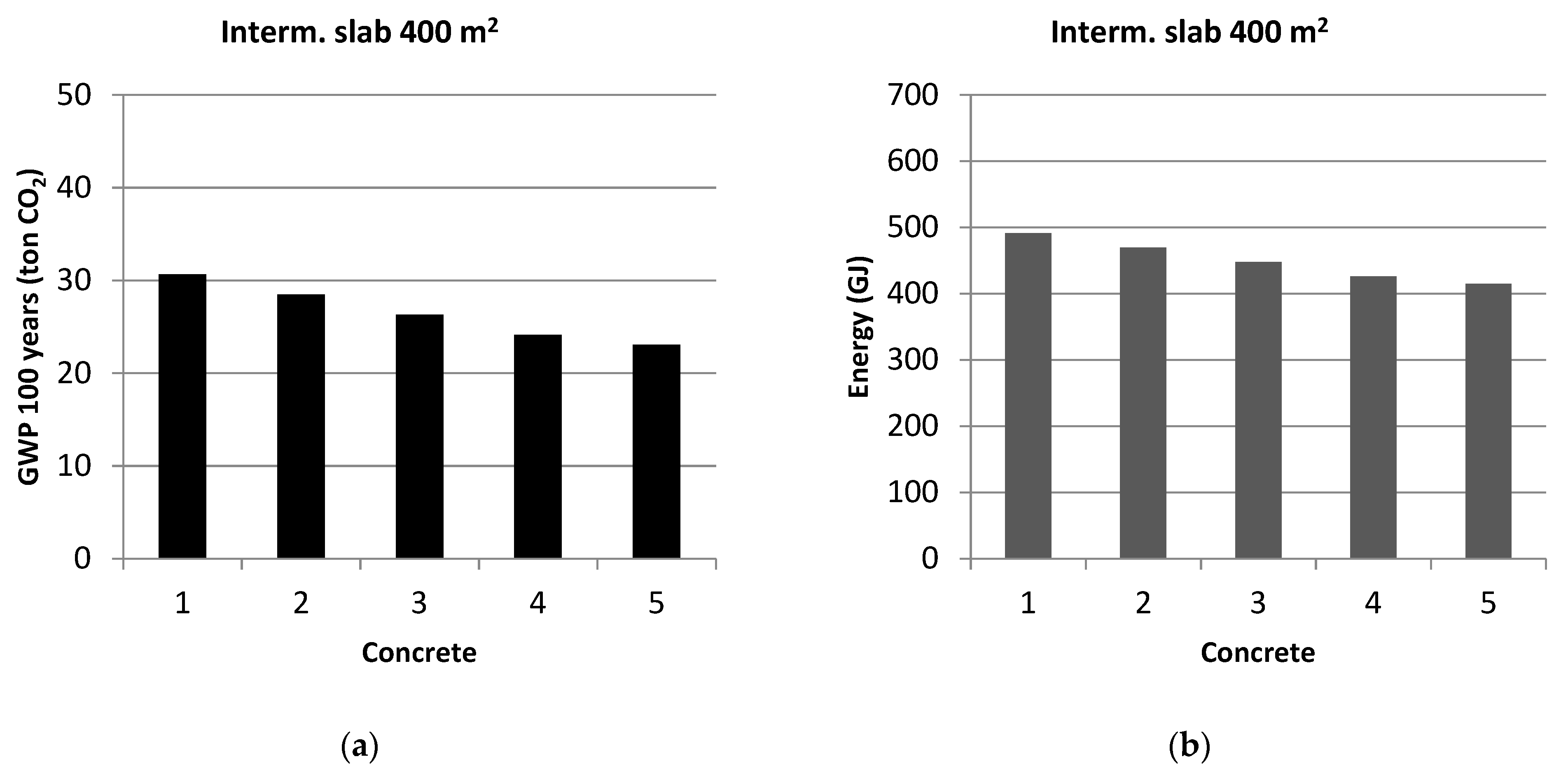

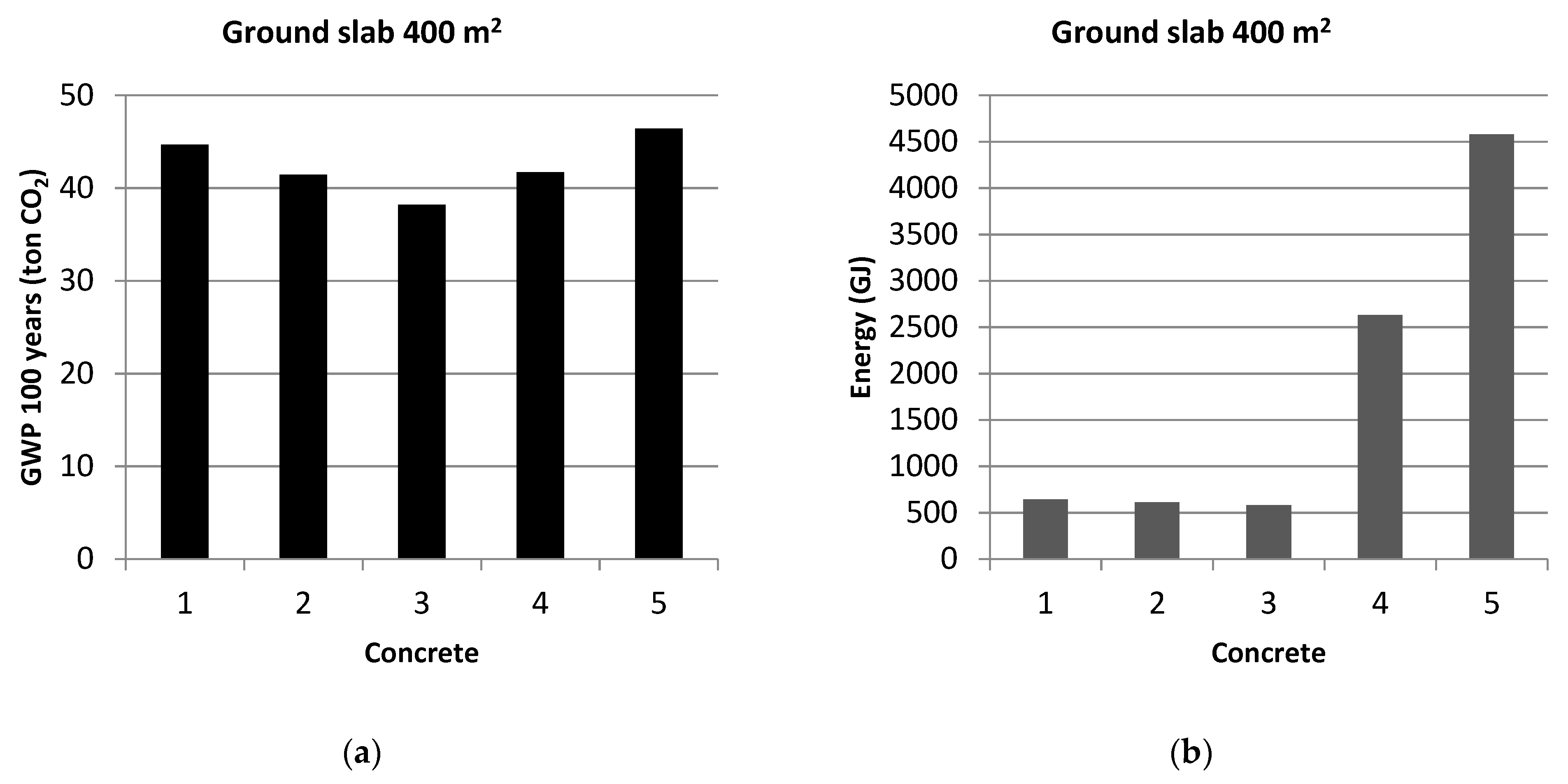

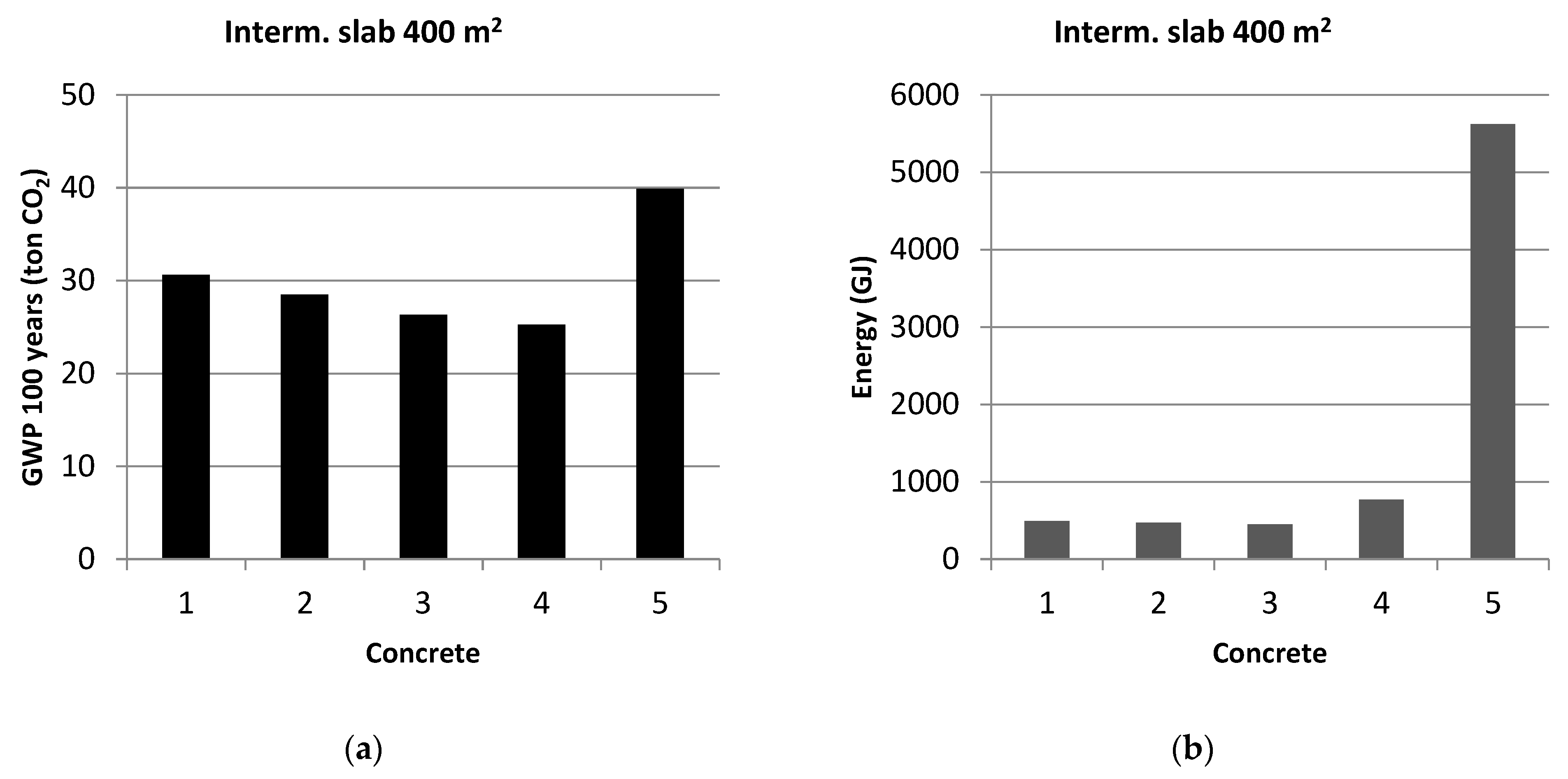

3.2. Study of Environmental Impacts

4. Case Study

5. Discussion

- Concrete quality (water-cement ratio 0.34–0.53);

- Ambient air temperature (5–20 °C);

- Ambient relative humidity (RH 30–80%);

- Type of slab (ground slab and intermediate slabs);

- Heating cable setup (power, P = 0–50 W/m; spacing, s = 0.1–0.5 m).

6. Conclusions

- Heating cables can be used to reduce the dehydration time of a concrete slab in a cold climate, but the method is inefficient from an energy perspective.

- The dehydration process can also be accelerated by choosing a lower water-cement ratio in cold climate construction, but this option results in higher environmental impacts.

- A thorough environmental analysis can help to reduce the environmental impact of concrete construction.

- The study supported The Swedish Housing Agency’s recommendation that environmental investigations covering the construction stage in the life cycle perspective (Modules A1–A5) are needed to better understand the environmental impact of different construction alternatives.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Szymanowski, J. Evaluation of the Adhesion between Overlays and Substrates in Concrete Floors: Literature Survey, Recent Non-Destructive and Semi-Destructive Testing Methods, and Research Gaps. Buildings 2019, 9, 203. [Google Scholar] [CrossRef] [Green Version]

- Bažant, Z.P.; Najjar, L.J. Drying of concrete as a nonlinear diffusion problem. Cem. Concr. Res. 1971, 1, 461–473. [Google Scholar] [CrossRef]

- Teriö, O.; Hämäläinen, J.; Uotila, U.; Sorri, J.; Saari, A. Moisture and building processes in Finland. In Proceedings of the CIB World Building Congress 2016: Creating Built Environments of New Opportunities, Tampere, Finland, 3 June 2016; Tampere University of Technology: Tampere, Finland, 2016; pp. 907–917. [Google Scholar]

- Kanare, H.M. Concrete Floors and Moisture; Portland Cement Association: Skokie, IL, USA, 2005. [Google Scholar]

- Amundson, J.A.; Pashina, B.J.; Swor, T.E. Analyzing Moisture Problems In Concrete Slabs. Concr. Constr. 1997. Available online: http://advancedmoisturecontrol.com/library/analyzingmoistureprobs.pdf (accessed on 16 March 2023).

- De Ceukelaire, L. Concrete surface deterioration due to the expansion by the formation of jarosite. Cem. Concr. Res. 1991, 21, 563–574. [Google Scholar] [CrossRef]

- Nassar, R.U.D.; Saeed, D.; Singh, N. Strategies to enhance the moisture-barrier qualities of concrete mixtures to improve their durability. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Persson, B. Compatibility between flooring materials and concrete. Mater. Struct. 2002, 35, 170–182. [Google Scholar] [CrossRef]

- Laticrete. Drying of Concrete, TDS-1183; Laticrete Pty Ltd.: Virginia, Australia, 2021. [Google Scholar]

- Mirza, J.; Mirza, M.S.; Lapointe, R. Laboratory and field performance of polymer-modified cement-based repair mortars in cold climates. Constr. Build. Mater. 2002, 16, 365–374. [Google Scholar] [CrossRef]

- Kivekäs, L.; Huovinen, S.; Leivo, M. Concrete under Arctic Conditions; VTT Technical Research Centre of Finland: Espoo, Finland, 1985; ISSN 0358-5077. [Google Scholar]

- Chen, S.; Lu, W.; Olofsson, T.; Dehghanimohammadabadi, M.; Emborg, M.; Nilimaa, J.; Wang, Y.; Feng, K. Concrete Construction: How to Explore Environmental and Economic Sustainability in Cold Climates. Sustainability 2020, 12, 3809. [Google Scholar] [CrossRef]

- Mohamad, N.; Muthusamy, K.; Embong, R.; Kusbiantoro, A.; Hashim, M.H. Environmental impact of cement production and Solutions: A review. Mater. Today Proc. 2022, 48, 741–746. [Google Scholar] [CrossRef]

- Mehta, K.P. Reducing the environmental impact of concrete. Concr. Int. 2001, 23, 61–66. [Google Scholar]

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Van den Heede, P.; De Belie, N. Environmental impact and life cycle assessment (LCA) of traditional and ‘green’concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Kim, T.H.; Chae, C.U. Environmental Impact Analysis of Acidification and Eutrophication Due to Emissions from the Production of Concrete. Sustainability 2016, 8, 578. [Google Scholar] [CrossRef] [Green Version]

- Wałach, D. Analysis of Factors Affecting the Environmental Impact of Concrete Structures. Sustainability 2021, 13, 204. [Google Scholar] [CrossRef]

- Kim, T.; Tae, S.; Chae, C.U. Analysis of Environmental Impact for Concrete Using LCA by Varying the Recycling Components, the Compressive Strength and the Admixture Material Mixing. Sustainability 2016, 8, 389. [Google Scholar] [CrossRef] [Green Version]

- Mohammad, M.; Masad, E.; Al-Ghamdi, S.G. 3D Concrete Printing Sustainability: A Comparative Life Cycle Assessment of Four Construction Method Scenarios. Buildings 2020, 10, 245. [Google Scholar] [CrossRef]

- Palumbo, E.; Soust-Verdaguer, B.; Llatas, C.; Traverso, M. How to Obtain Accurate Environmental Impacts at Early Design Stages in BIM When Using Environmental Product Declaration. A Method to Support Decision-Making. Sustainability 2020, 12, 6927. [Google Scholar] [CrossRef]

- Del Borghi, A. LCA and communication: Environmental product declaration. Int. J. Life Cycle Assess. 2013, 18, 293–295. [Google Scholar] [CrossRef] [Green Version]

- ISO 14025; Environmental Labels and Declarations—Type III Environmental Declarations—Principles and Procedures. International Organization for Standardization: Geneva, Switzerland, 2006.

- EN 15804; 2019—Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- Byfors, K. Swedish Concrete Associations EPD-Tool; Svensk Betong: Stockholm, Sweden, 2018. [Google Scholar]

- Boverket. Development of Rules for Climate Declarations of Buildings: Proposal of A Road Map and Limit Values; The Swedish Housing Agency (Boverket): Karlskrona, Sweden, 2020; ISBN 978-91-7563-701-3. [Google Scholar]

- Liljenström, C.; Malmqvist, T.; Erlandsson, M.; Fredén, J.; Larsson, G.; Brogren, M. The Climate Impact of Construction: Life Cycle Calculation of Climate Impact and Energy Use for A Newly Produced Energy-Efficient Apartment Building in Concrete; IVL Swedish Environmental Institute: Stockholm, Sweden, 2015. [Google Scholar]

- RICS. Whole Life Carbon Assessment for the Built Environment, 1st ed.; The Royal Institution of Chartered Surveyors (RICS): London, UK, 2017; ISBN 978-1-78321-208-8. [Google Scholar]

- IPCC. Climate Change 2013: The Physical Science Basis. In Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Stocker, T.F., Qin, D., Plattner, G.-K., Tignor, M., Allen, S.K., Boschung, J., Nauels, A., Xia, Y., Bex, V., Midgley, P.M., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2013; 1535p. [Google Scholar]

- Betongindustri. BI Dry Software—Tutorial for the Production of Drying Forecasts; Betongindustri, Heidelberg Cement Group: Stockholm, Sweden, 2016. [Google Scholar]

- Jonasson, J.-E.; Carlsson, C.A.; Mjörnell, K. Model for Calculating Humidity in Modern Concrete at Variable Temperature; Bygg & Teknik: Dalarna, Sweden, 2005. (In Swedish) [Google Scholar]

- Jonasson, J.-E.; Carlsson, C.A.; Mjörnell, K. Calculation of Dehydration for Concrete with Byggcement; Bygg & Teknik: Dalarna, Sweden, 2005. (In Swedish) [Google Scholar]

- Hedlund, H.; Jonasson, J.-E. Heat and Maturity Development for PK Cement; Technical Report; Luleå University of Technology: Luleå, Sweden, 1993; Volume 13. (In Swedish) [Google Scholar]

- Cementa. Environmental Data Sheet: Average Cement CEM II/A-LL 42.5 R; Cementa AB, Heidelberg Cement Group: Stockholm, Sweden, 2012. [Google Scholar]

- Stripple, H. Life Cycle Assessment of Road—A Pilot Study for Inventory Analysis; IVL Swedish Environmental Research Institute: Göteborg, Sweden, 2001. [Google Scholar]

- Angervall, T.; Flysjö, A.; Mattsson, B. Comparison of Drinking Water: General Life Cycle Assessment; The Institute for Food and Biotechnology (SIK): Stockholm, Sweden, 2004. (In Swedish) [Google Scholar]

- EFCA. EFCA Environmental Declaration—Plasticizing Admixtures; European Federation of Concrete Admixtures Associations Ltd. (EFCA): Berlin, Germany, 2006. [Google Scholar]

- EUMEPS. Environmental Product Declaration—Expanded Polystyrene (EPS) Foam Insulation; European Association of EPS (EUMEPS): Brussels, Belgium, 2013. [Google Scholar]

- Boulter, P.G.; McCrae, I.S. ARTEMIS: Assessment and reliability of transport emission models and inventory systems—Final Report. In TRL Published Project Report; TRL Limited: Brussels, Belgium, 2007. [Google Scholar]

- Cooper, D.; Gustafsson, T. Methodology for calculating emissions from ships: 1. In Update of Emission Factors; SMHI Swedish Meteorological and Hydrological Institute: Norrköping, Sweden, 2004. [Google Scholar]

- European Comission. Quantification of Emissions from Ships Associated with Ship Movements between Ports in the European Community; Entec UK Ltd.: London, UK; IVL Swedish Environmental Research Institute: Göteborg, Sweden, 2002. [Google Scholar]

- Fagerlund, G. Concrete as a Construction Material. In Concrete and Environment: Facts from Concrete Forum; Gillberg, B., Fagerlund, G., Jönsson, Å., Tillman, A.-M., Eds.; Svensk Byggtjänst: Stockholm, Sweden, 1999; pp. 14–48. [Google Scholar]

- Gode, J.; Martinsson, F.; Hagberg, L.; Öman, A.; Höglund, J.; Palm, D. Environmental Fact Book 2011: Estimated Emission Factors for Fuels, Electricity, Heat and Transport in Sweden; Värmeforsk Service AB: Stockholm, Sweden, 2011; ISSN 1653-1248. (In Swedish) [Google Scholar]

- Itten, R.; Frischknecht, R.; Stucki, M. Life Cycle Inventories of Electricity Mixes and Grid; Paul Scherrer Institut (PSI): Uster, Switzerland, 2014. [Google Scholar] [CrossRef]

- Emborg, E. Environmental Concrete for Sustainable Construction: An Analysis of Concrete Mixtures with More Environmentally Friendly Admixtures. Bachelor’s Thesis, Dalarna University, Falun, Sweden, 3 July 2014. (In Swedish). [Google Scholar]

- Kim, T.H.; Chae, C.U.; Kim, G.H.; Jang, H.J. Analysis of CO2 Emission Characteristics of Concrete Used at Construction Sites. Sustainability 2016, 8, 348. [Google Scholar] [CrossRef] [Green Version]

- Latawiec, R.; Woyciechowski, P.; Kowalski, K.J. Sustainable Concrete Performance—CO2-Emission. Environments 2018, 5, 27. [Google Scholar] [CrossRef] [Green Version]

- Marey, H.; Kozma, G.; Szabó, G. Effects of Using Green Concrete Materials on the CO2 Emissions of the Residential Building Sector in Egypt. Sustainability 2022, 14, 3592. [Google Scholar] [CrossRef]

- Vázquez-Calle, K.; Guillén-Mena, V.; Quesada-Molina, F. Analysis of the Embodied Energy and CO2 Emissions of Ready-Mixed Concrete: A Case Study in Cuenca, Ecuador. Materials 2022, 15, 4896. [Google Scholar] [CrossRef] [PubMed]

- Tait, M.W.; Cheung, W.M. A Comparative Cradle-to-Gate Life Cycle Assessment of Three Concrete Mix Designs. Int. J. Life Cycle Assess. 2016, 21, 847–860. [Google Scholar] [CrossRef] [Green Version]

- Novakova, I.; Perumal, P.; Cwirzen, A.; Wallevik, O.H. Low Carbon Concrete Possibilities: EPD and Regulations in Northern Periphery and Arctic. Mater. Proc. 2023, 13, 14. [Google Scholar] [CrossRef]

- Silfwerbrand, J. Concrete and Sustainability–Some Thoughts from a Swedish Horizon. Nord. Concr. Res. 2020, 63, 79–87. [Google Scholar] [CrossRef]

- Byggindustrier, S. Construction Drying: A handbook from Sveriges Byggindustrier; Sveriges Byggindustrier: Malmö, Sweden, 2012. (In Sewdish) [Google Scholar]

- Aïtcin, P.C. Cements of yesterday and today: Concrete of tomorrow. Cem. Concr. Res. 2000, 30, 1349–1359. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L.; Lin, E. Emerging energy-efficiency and CO2 emission-reduction technologies for cement and concrete production: A technical review. Renew. Sustain. Energy Rev. 2012, 16, 6220–6238. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Meng, D.; Wang, Y. Finite-element simulation of hydration and creep of early-age concrete materials. J. Mater. Civ. Eng. 2014, 26, 05014006. [Google Scholar] [CrossRef]

- Han, Y.; Lin, R.-S.; Wang, X.-Y. Compressive Strength Estimation and CO2 Reduction Design of Fly Ash Composite Concrete. Buildings 2022, 12, 139. [Google Scholar] [CrossRef]

- Golewski, G.L. Green Concrete Based on Quaternary Binders with Significant Reduced of CO2 Emissions. Energies 2021, 14, 4558. [Google Scholar] [CrossRef]

| Greenhouse Gas | CO2 Equivalents |

|---|---|

| CO2 | 1 |

| CH4 | 28 |

| N2O | 265 |

| Chemical Compound | Designation | CCl3F Equivalents |

|---|---|---|

| CCl3F | R-11 | 1 |

| CClF2-Cl | R-12 | 1 |

| CClF2-F | R-13 | 1 |

| CClF2-H | R-22 | 0.05 |

| CO2 | R-744 | 0 |

| Chemical Compound | SO2 Equivalents |

|---|---|

| SO2 | 1 |

| NH3 | 1.88 |

| NO2 | 0.7 |

| Chemical Compound | PO43− Equivalents |

|---|---|

| PO43− | 1 |

| NO2 | 0.13 |

| NH3 | 0.35 |

| COD | 0.022 |

| Chemical Compound | C2H4 Equivalents |

|---|---|

| C2H4 | 1 |

| CO | 0.027 |

| C2H6 | 0.123 |

| C7H8 | 0.637 |

| Concrete | Water-Cement Ratio |

|---|---|

| Concrete 1 | 0.34 |

| Concrete 2 | 0.38 |

| Concrete 3 | 0.43 |

| Concrete 4 | 0.47 |

| Concrete 5 | 0.53 |

| Winter Case | Concrete | RH (%) | P (W/m2) | |||||||||

| (Tair = 5 °C) | 30 | 40 | 50 | 60 | 70 | 80 | 0 | 40 | 100 | 200 | 500 | |

| Concrete 1 | ||||||||||||

| Concrete 2 | ||||||||||||

| Concrete 3 | ||||||||||||

| Concrete 4 | ||||||||||||

| Concrete 5 | ||||||||||||

| Summer Case | Concrete | RH (%) | P (W/m2) | |||||||||

| (Tair = 20 °C) | 30 | 40 | 50 | 60 | 70 | 80 | 0 | 40 | 100 | 200 | 500 | |

| Concrete 1 | ||||||||||||

| Concrete 2 | ||||||||||||

| Concrete 3 | ||||||||||||

| Concrete 4 | ||||||||||||

| Concrete 5 | ||||||||||||

| Temperature Effect | Concrete | Tair (°C) | ||||||||||

| 5 | 10 | 15 | 20 | |||||||||

| Concrete 1 | ||||||||||||

| Concrete 2 | ||||||||||||

| Concrete 3 | ||||||||||||

| Concrete 4 | ||||||||||||

| Concrete 5 | ||||||||||||

| Life Cycle Module | Description |

|---|---|

| A1—Raw material supply | Raw material/input material included in the finished concrete frame. In addition to the concrete components (cement, aggregate, water, and additives), the cellular plastic insulation for the base plate was also included. The EPD parameters were taken from [34,35,36,37,38]. |

| A2—Transportation of raw materials to production facilities | Transport of input material to concrete factory. In this case, all transport could be performed by either cargo ship or truck. The EPD parameters were taken from [39,40,41]. |

| A3—Manufacturing of construction materials | Manufacturing of concrete. When manufacturing 1 m3 of concrete, approximately 15 kWh of energy is used [42]. In this study, real factory data were used, and the energy for concrete production was roughly half district heating and half electricity. The EPD parameters were taken from [43,44]. |

| A4—Transportation of products to the construction site | Transport of concrete and EPD insulation to the construction site. The concrete was transported by concrete truck (capacity of 6 m3), and the insulation was transported by truck. The transports also included the return distance. |

| A5—Construction and installation | Production of joists. In some cases, electric heating cables or building fans were used to raise the temperature and, thus, speed up the drying process. The EPD parameters were taken from [44]. |

| Material | Transportation Vehicle | Transportation Distance |

|---|---|---|

| Cement | Cargo ship, 10,000 dwt, regional Truck bulk 22t cargo, SE | 350 6 km |

| Aggregates | Truck bulk 33t cargo, SE | 37 km |

| Additives | Truck goods 12–22t last, EU | 493 km |

| EPS insulation | Truck bulk 22t last, SE | 100 km |

| Mixed concrete | Concrete truck, 6 m3 | 35 km |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nilimaa, J.; Zhaka, V. Material and Environmental Aspects of Concrete Flooring in Cold Climate. Constr. Mater. 2023, 3, 180-201. https://doi.org/10.3390/constrmater3020012

Nilimaa J, Zhaka V. Material and Environmental Aspects of Concrete Flooring in Cold Climate. Construction Materials. 2023; 3(2):180-201. https://doi.org/10.3390/constrmater3020012

Chicago/Turabian StyleNilimaa, Jonny, and Vasiola Zhaka. 2023. "Material and Environmental Aspects of Concrete Flooring in Cold Climate" Construction Materials 3, no. 2: 180-201. https://doi.org/10.3390/constrmater3020012

APA StyleNilimaa, J., & Zhaka, V. (2023). Material and Environmental Aspects of Concrete Flooring in Cold Climate. Construction Materials, 3(2), 180-201. https://doi.org/10.3390/constrmater3020012