- Article

Principal Component and Multiple Linear Regression Analysis for Predicting Strength in Fiber-Reinforced Cement Mortars

- Enea Mustafaraj,

- Erion Luga and

- Khaled Younes

- + 2 authors

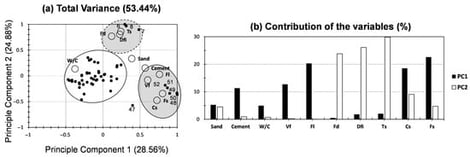

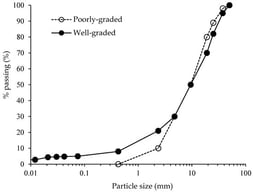

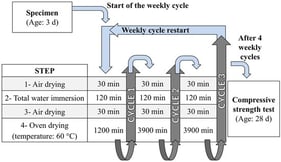

Accurate prediction of the mechanical performance of fiber-reinforced cement mortars (FRCM) is challenging because fiber geometry and properties vary widely and interact with the cement matrix in a non-trivial way. In this study, we propose an interpretable, computationally light framework that combines principal component analysis (PCA) with multiple linear regression (MLR) to predict compressive strength (Cs) and flexural strength (Fs) from mix proportions and fiber parameters. The literature-based dataset of 52 mortar mixes reinforced with polypropylene, steel, coconut, date palm, and hemp fibers was compiled and analyzed, covering Cs = 4.4–78.6 MPa and Fs = 0.75–16.7 MPa, with fiber volume fraction Vf = 0–15% and fiber length Fl = 4.48–60 mm. PCA performed on the full dataset showed that PC1–PC2 explain 53.4% of the total variance; a targeted variable-selection strategy increased the captured variance to 73.0% for the subset used for regression model development. MLR models built using PC1 and PC2 achieved good accuracy in the low-to-mid strength range, while prediction errors increased for higher-strength mixes (approximately Cs ≳ 60 MPa and Fs ≳ 10 MPa). On an independent validation dataset (n = 10), the refined model achieved mean absolute percentage errors of 11.3% for Fs and 18.5% for Cs. The proposed PCA-MLR approach provides a transparent alternative to more complex data-driven predictors, and it can support preliminary screening and optimization of fiber-reinforced mortar designs for durable structural and repair applications.

5 February 2026