New Mitigation Strategies for Cement Prehydration

Abstract

:1. Introduction

2. Materials and Methods

2.1. Production of Treated Cements

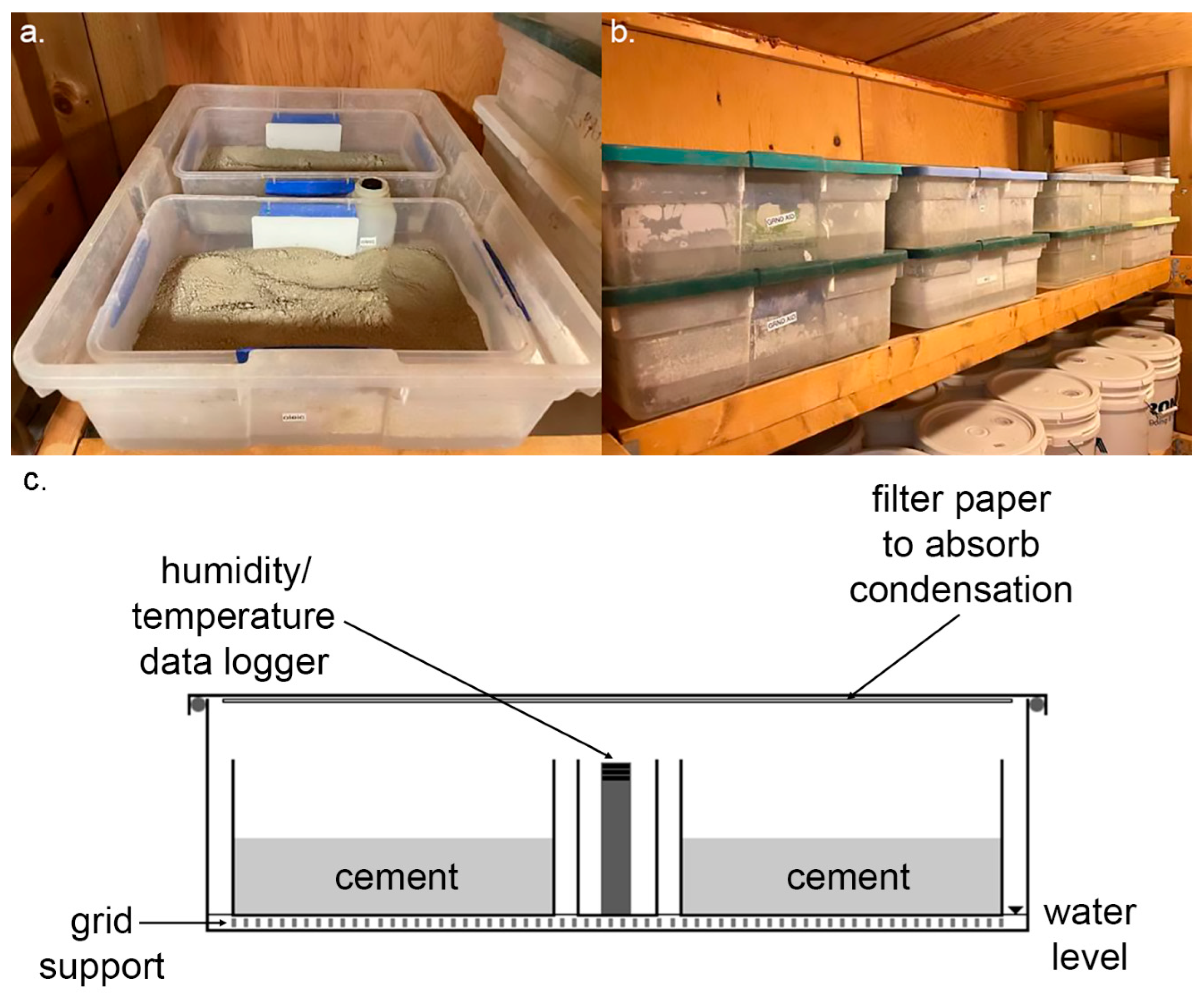

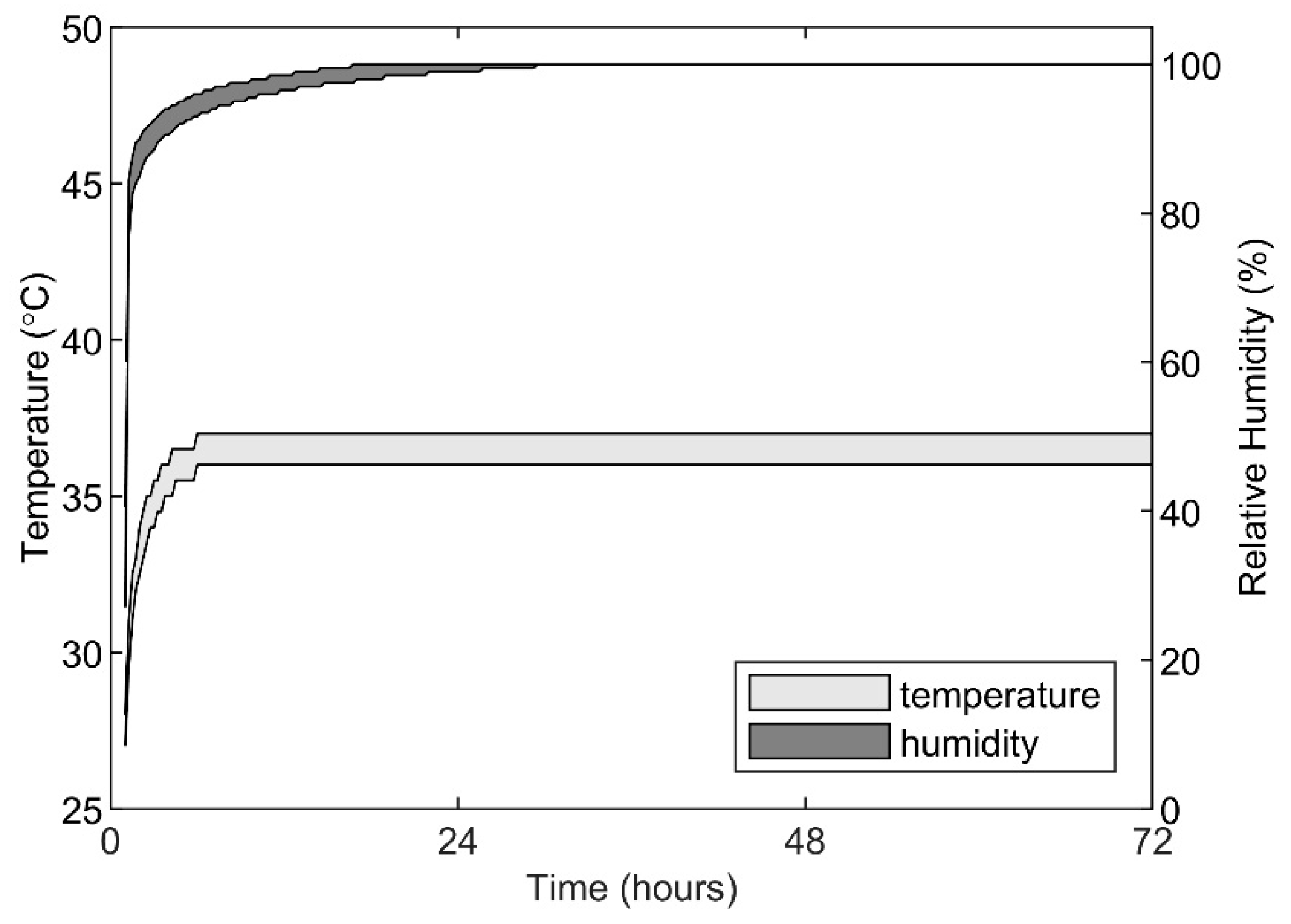

2.2. Accelerated Aging

2.3. Microstructural Characterization

2.4. Fresh and Hardened Mortar Testing

2.5. Paste and Mortar Calorimetry

2.6. Clinker Milling

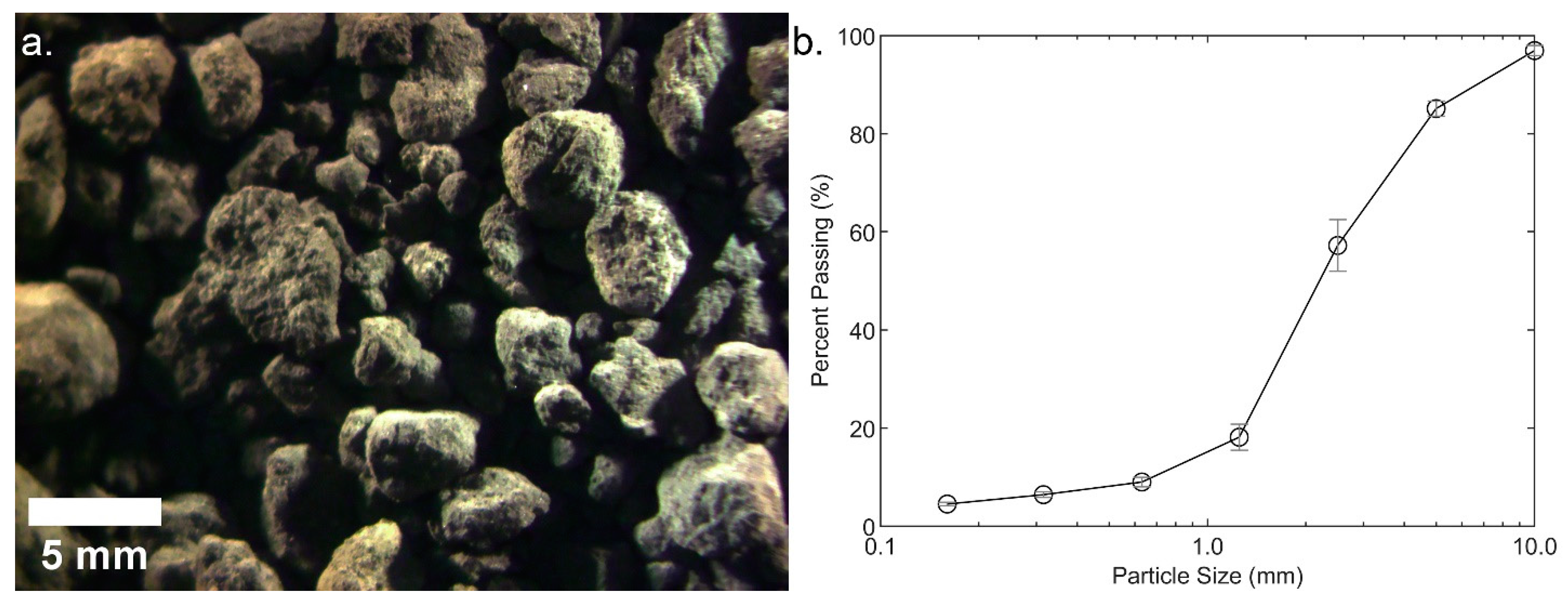

3. Results

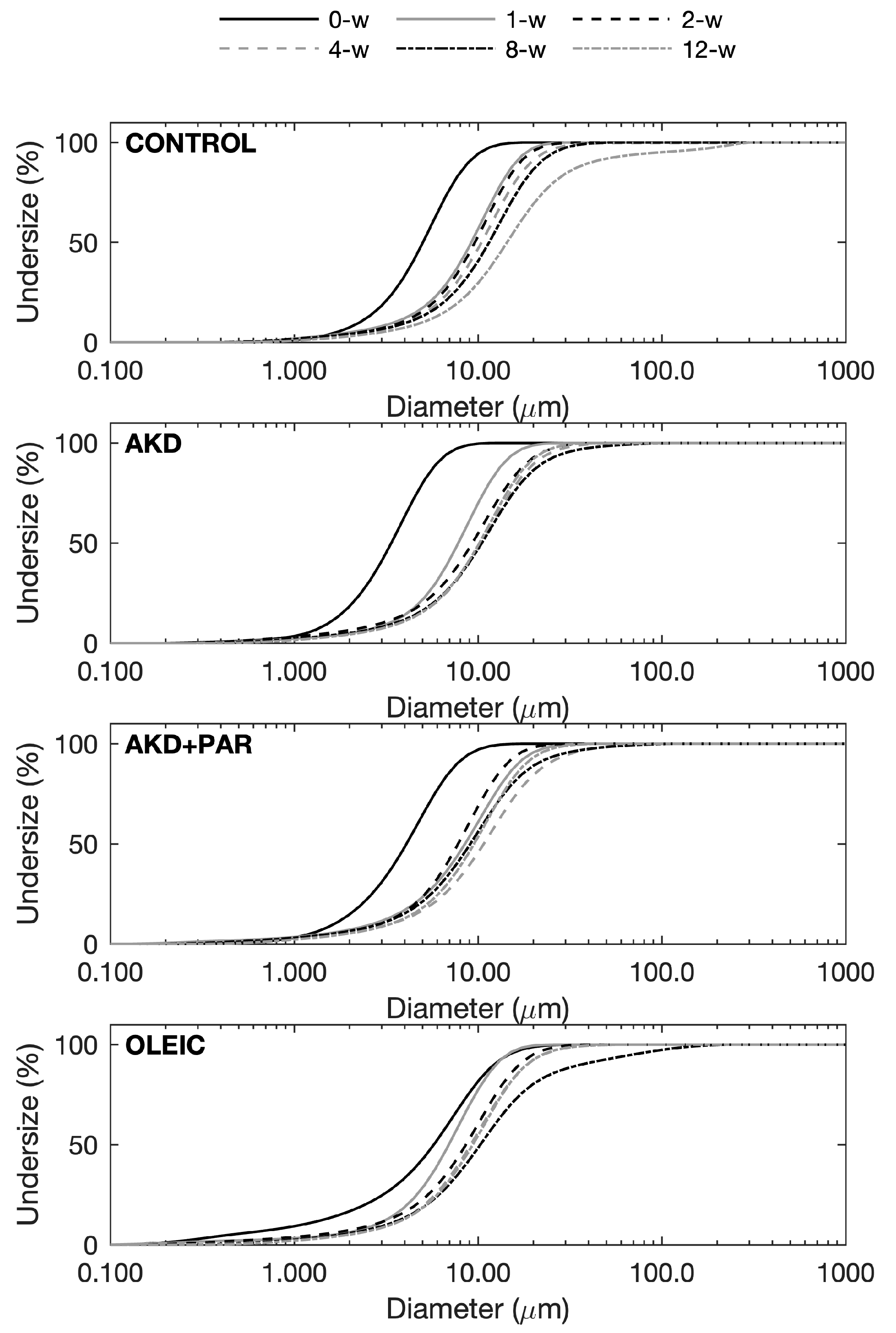

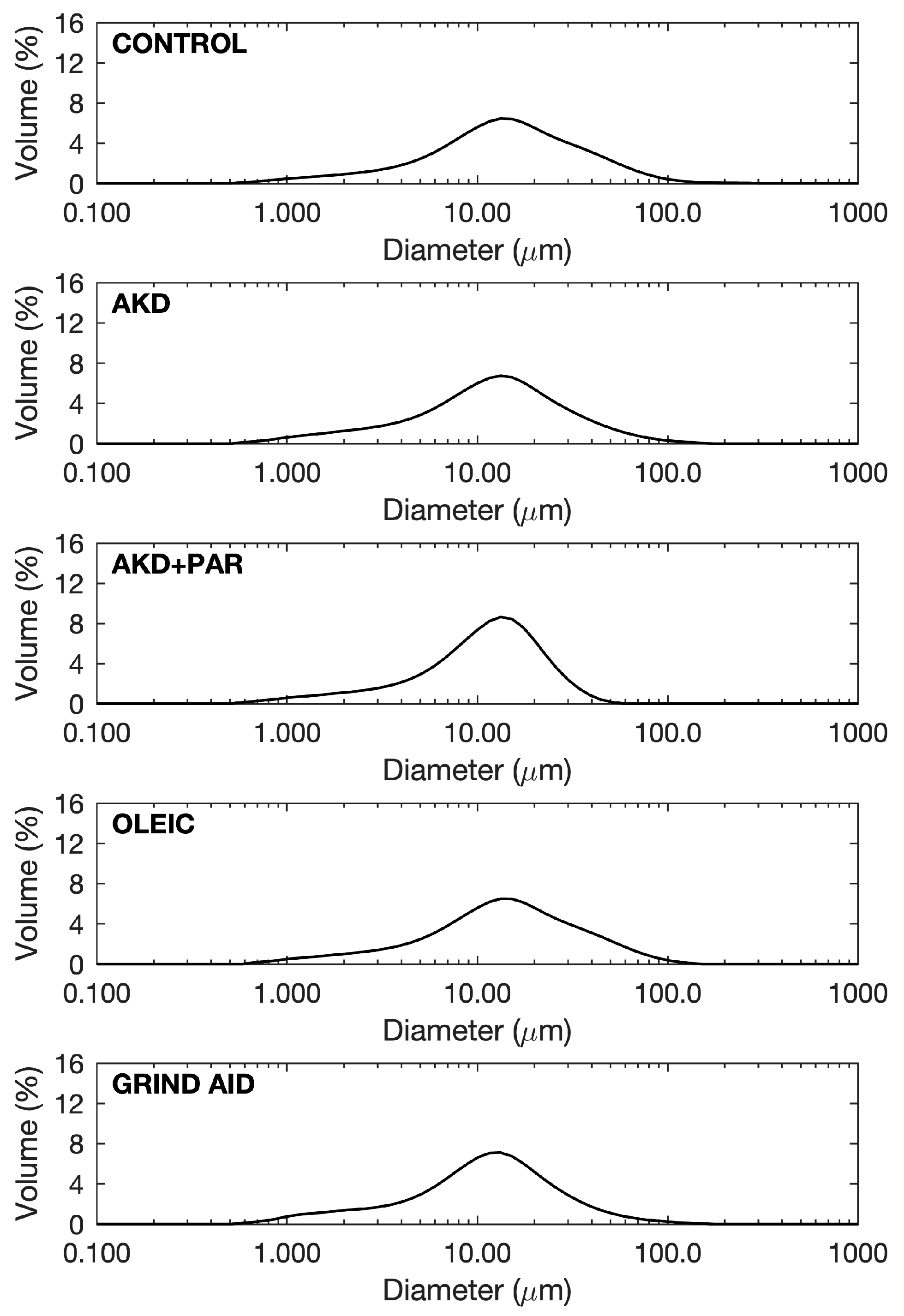

3.1. Particle Size Distribution

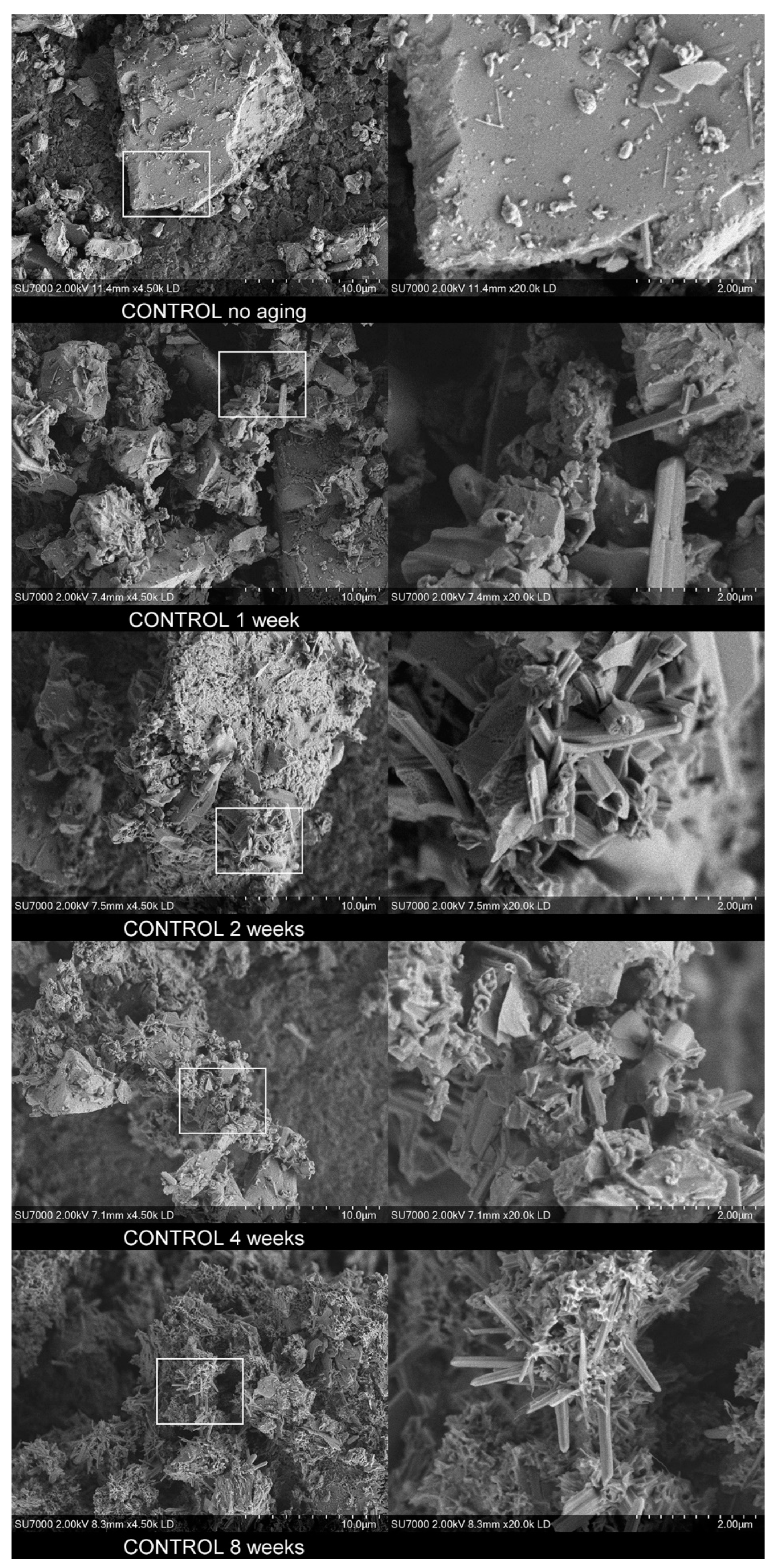

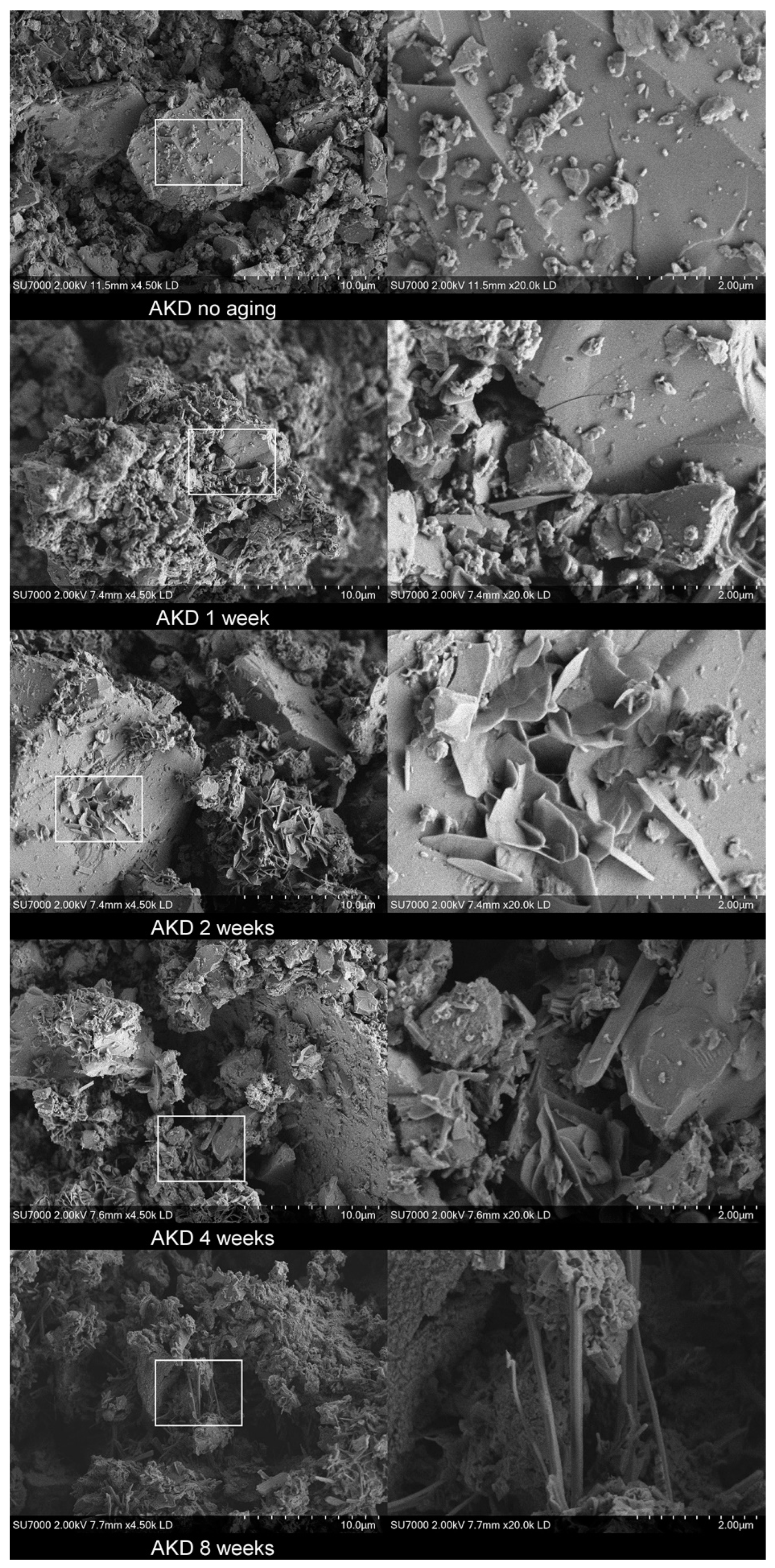

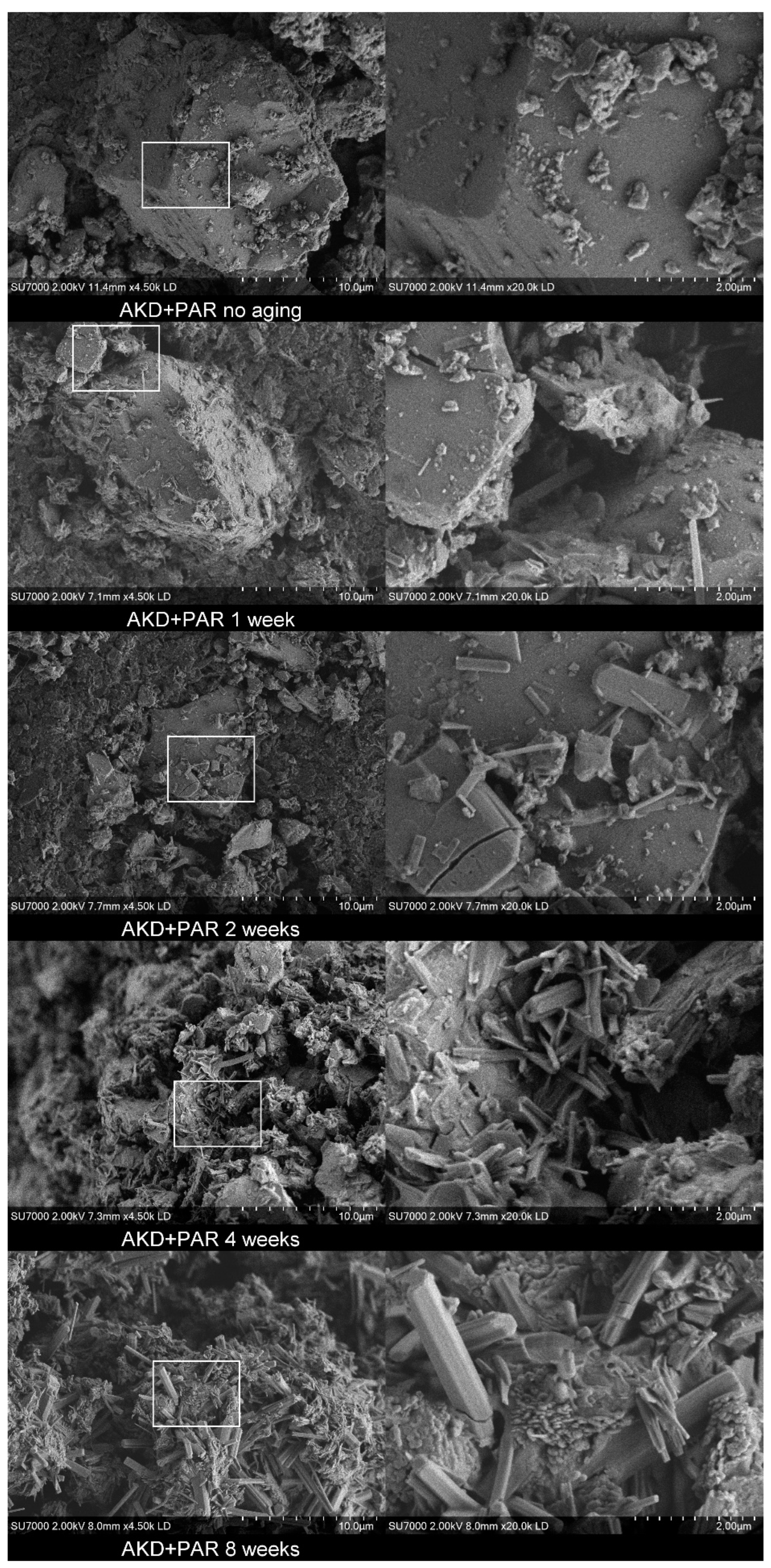

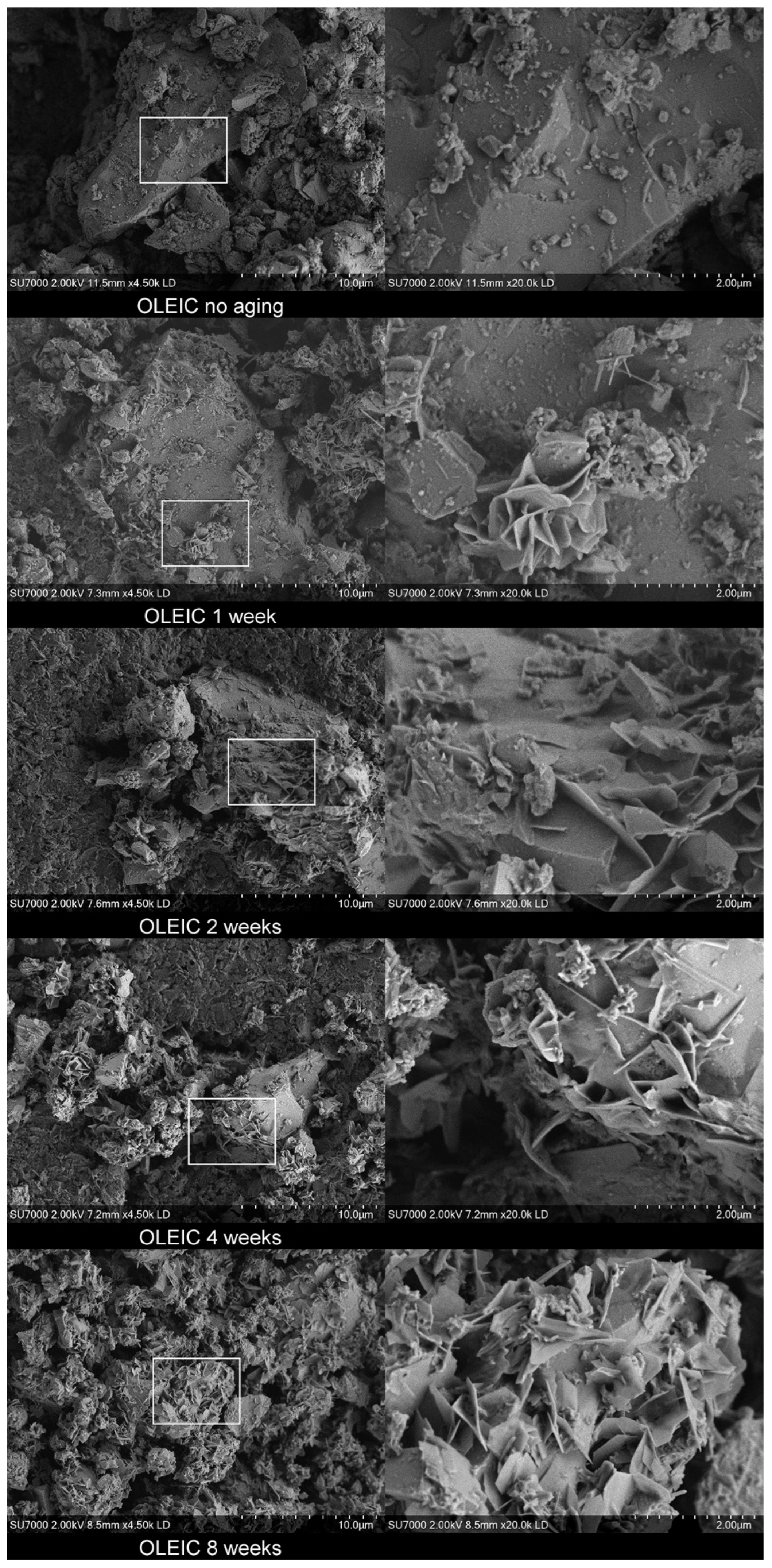

3.2. Scanning Electron Microscopy

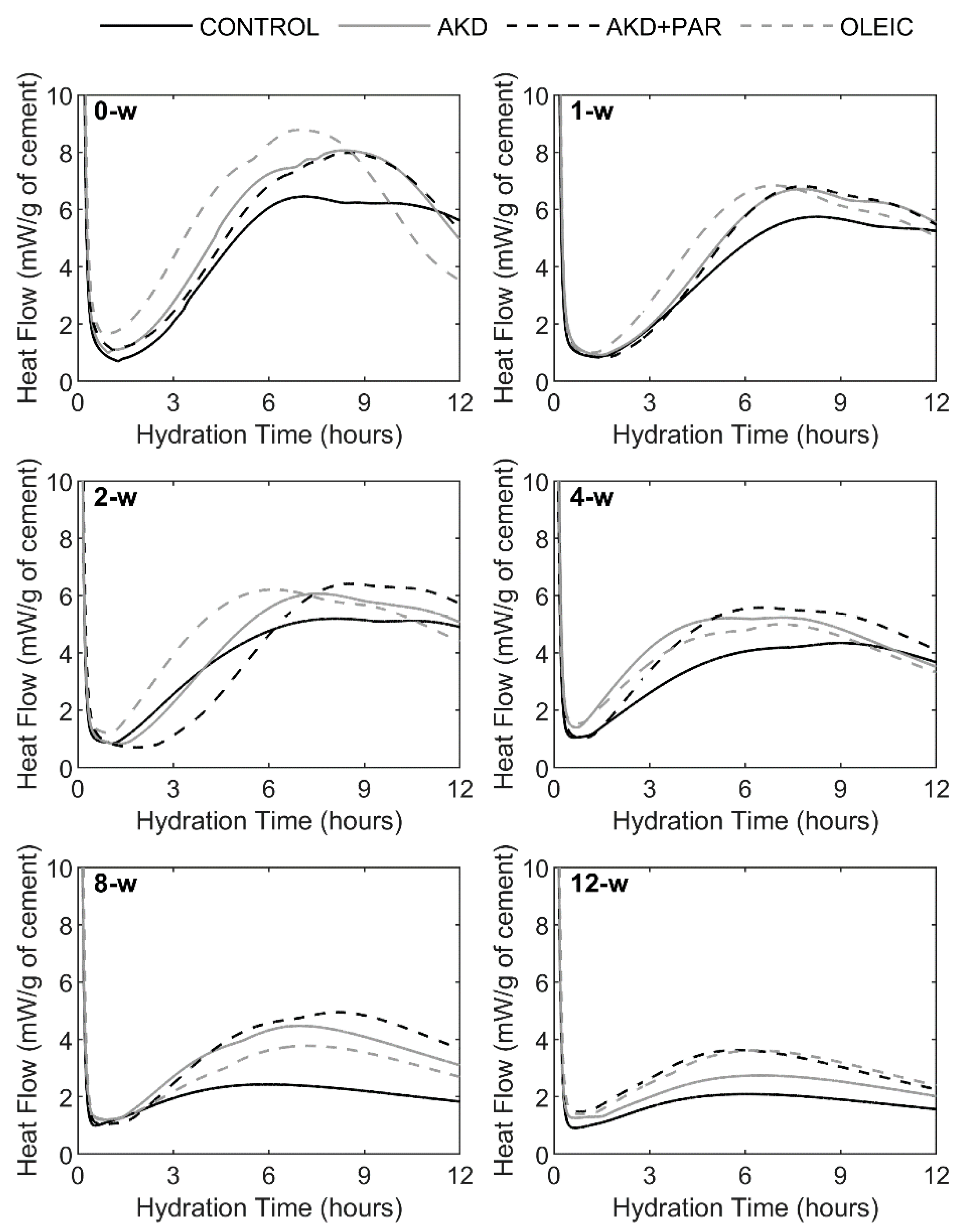

3.3. Paste Calorimetry

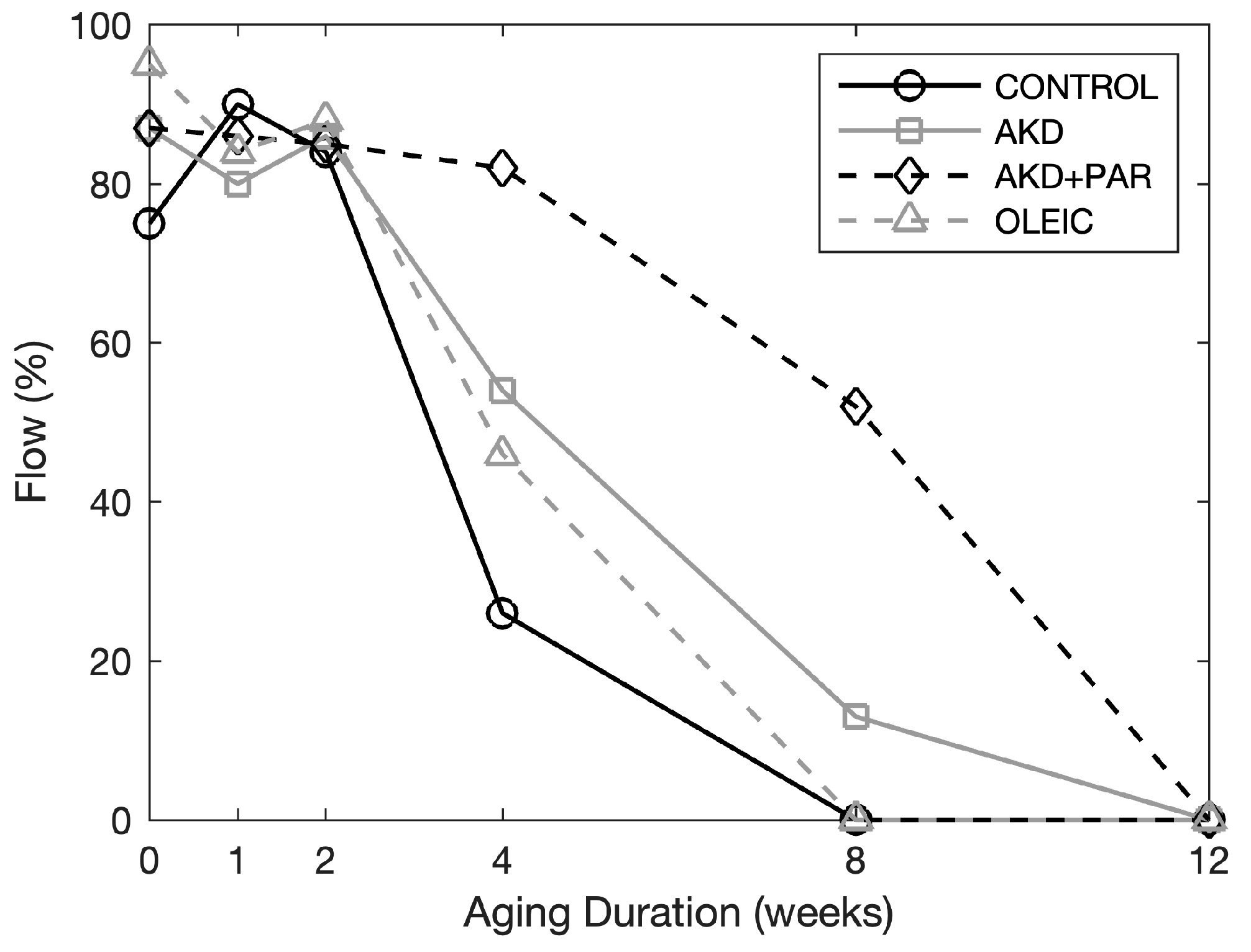

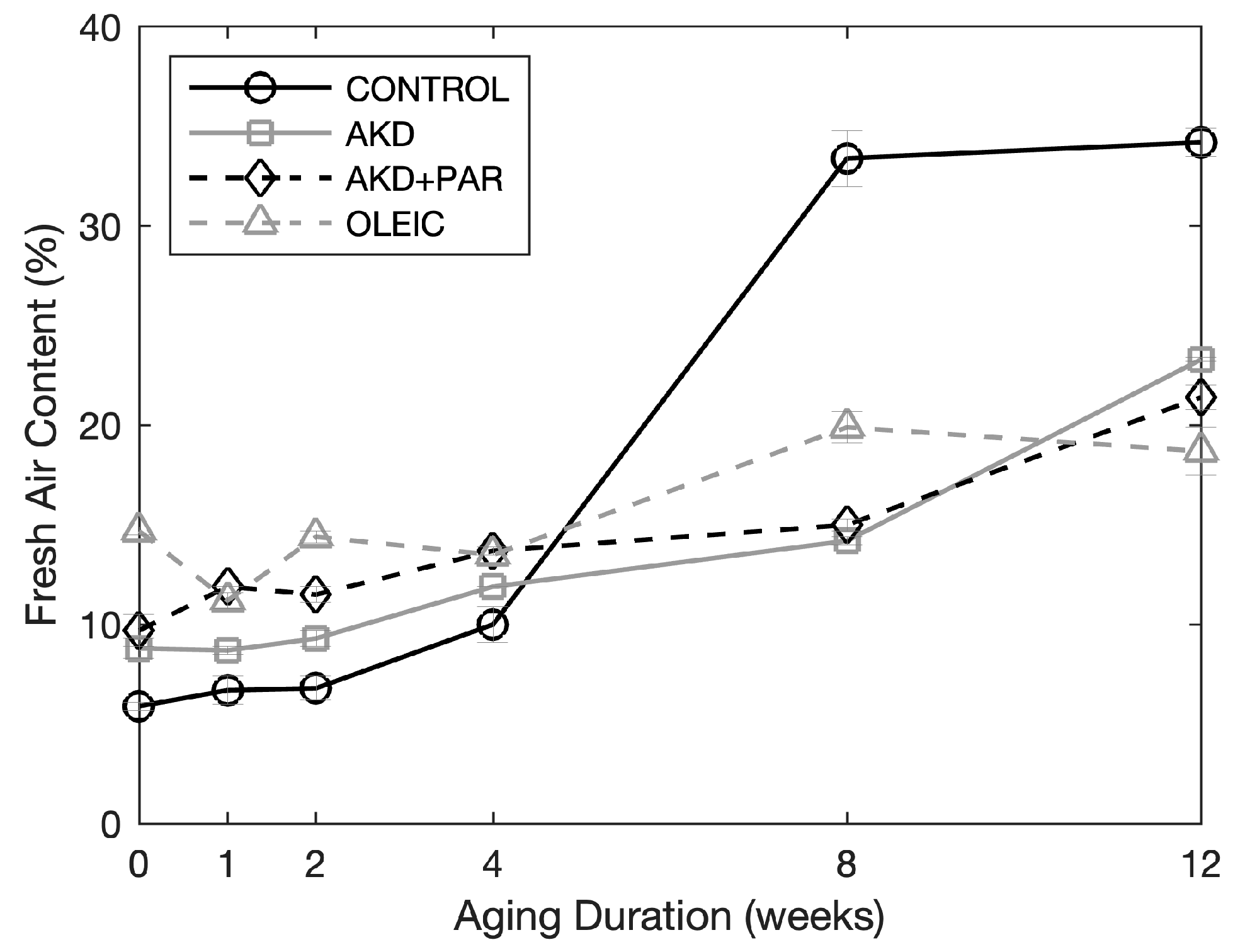

3.4. Mortar Fresh Properties

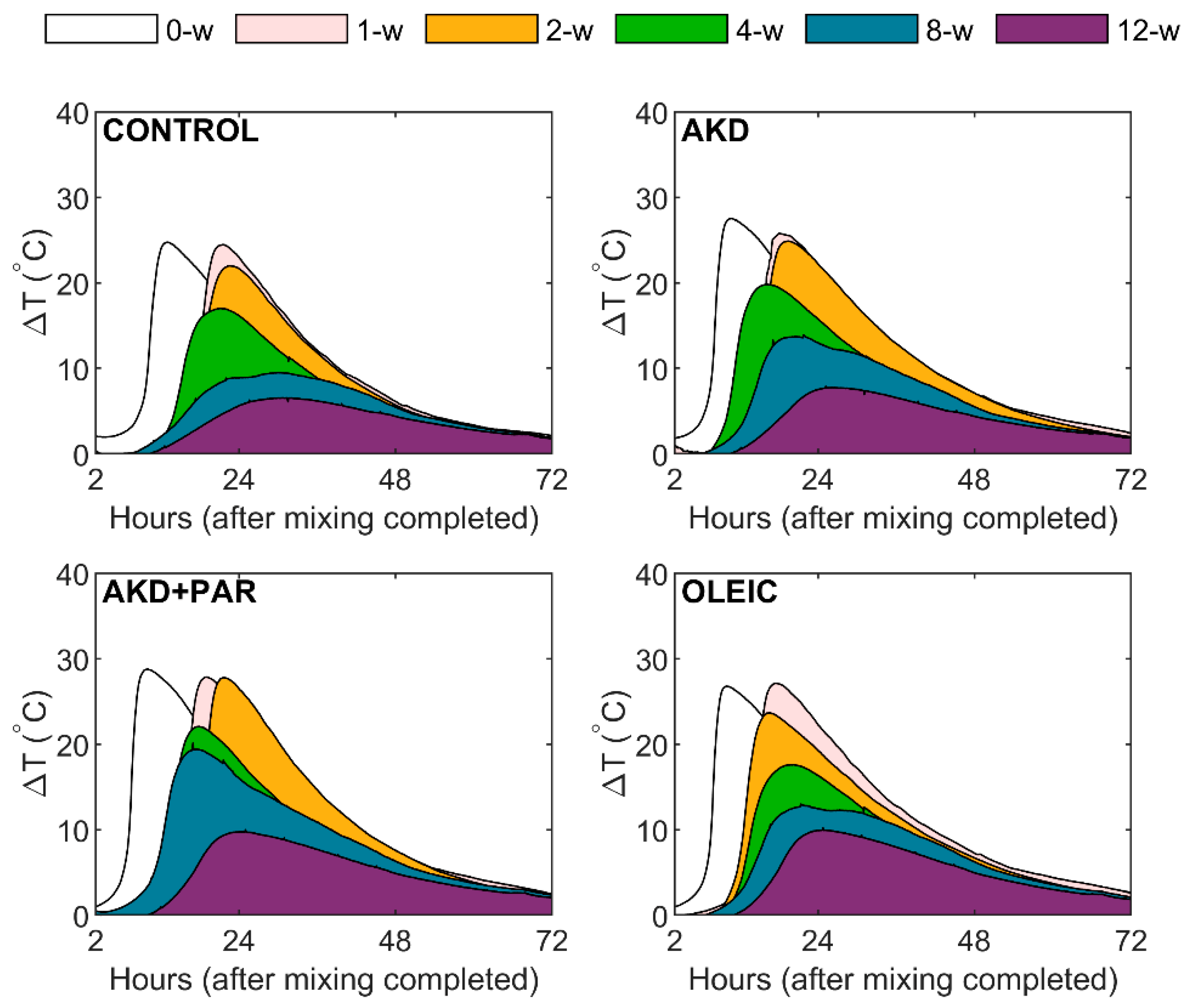

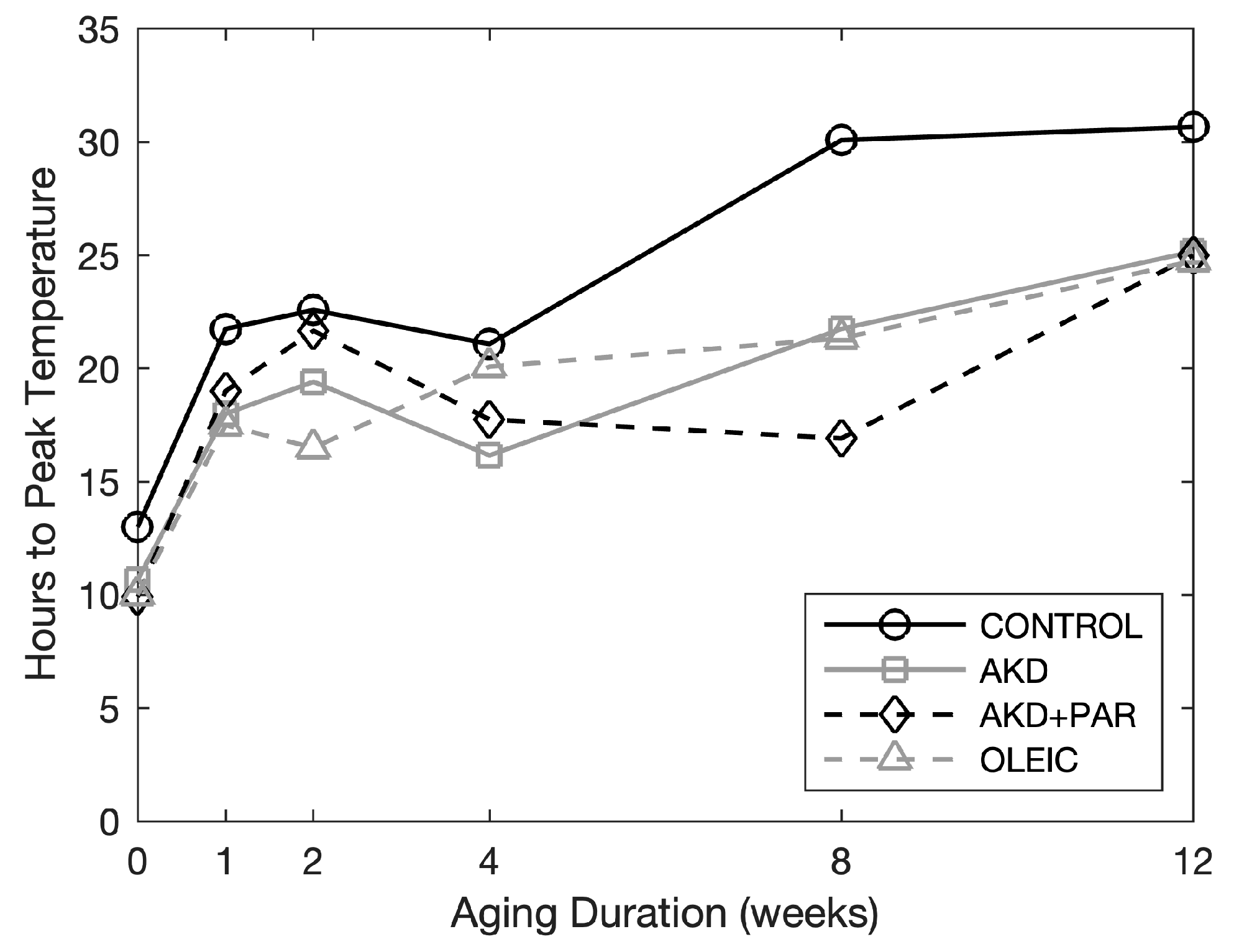

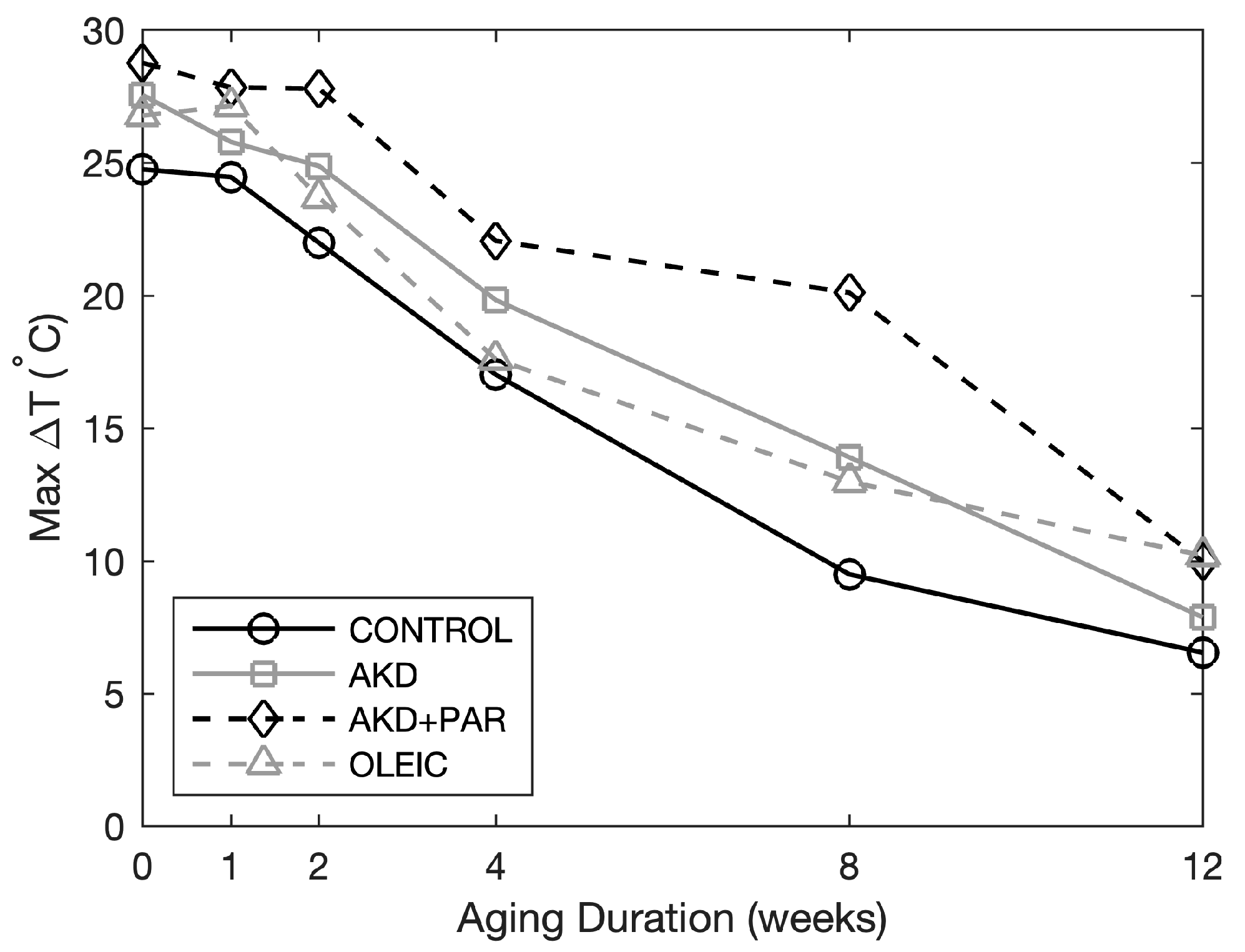

3.5. Mortar Semi-Adiabatic Calorimetry

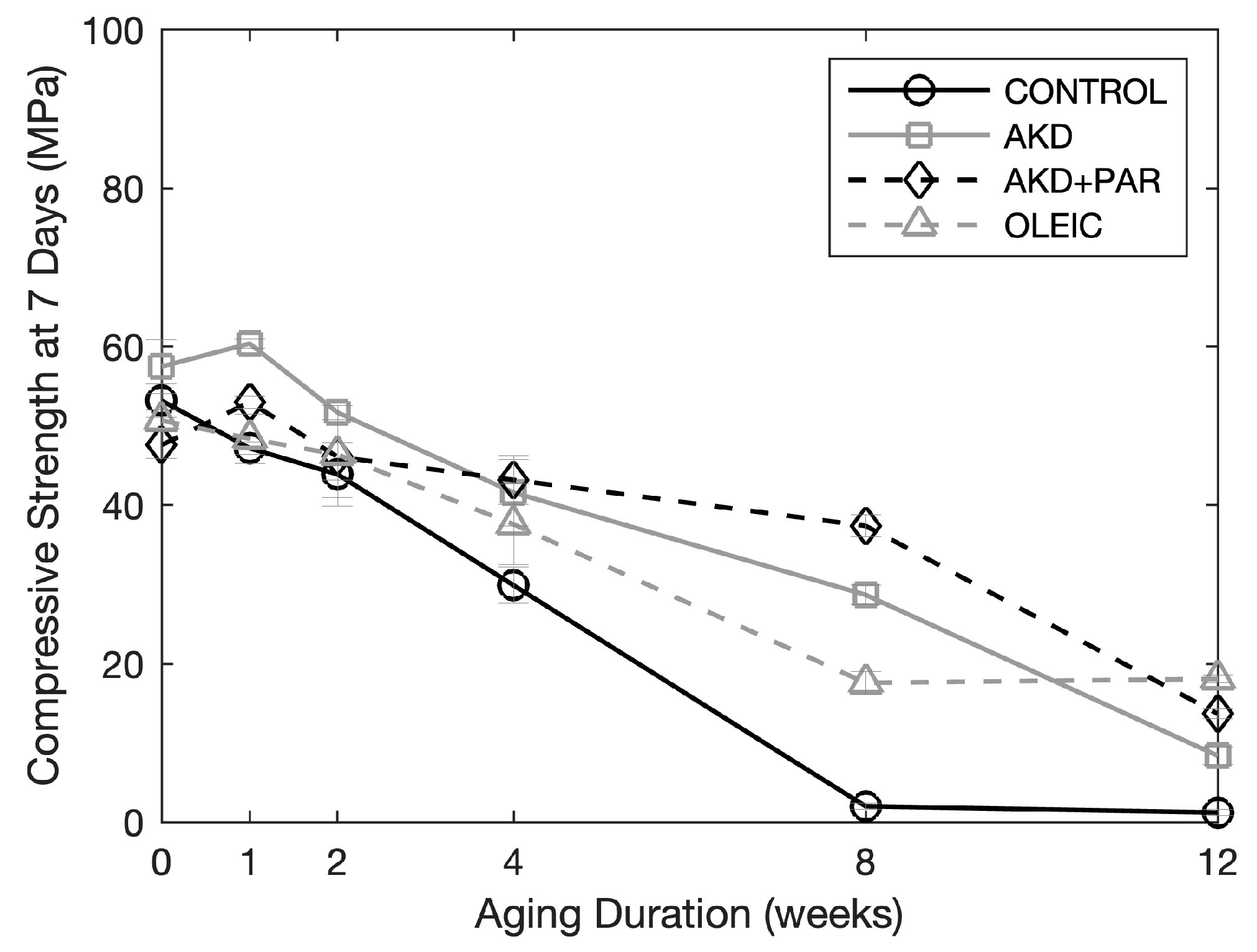

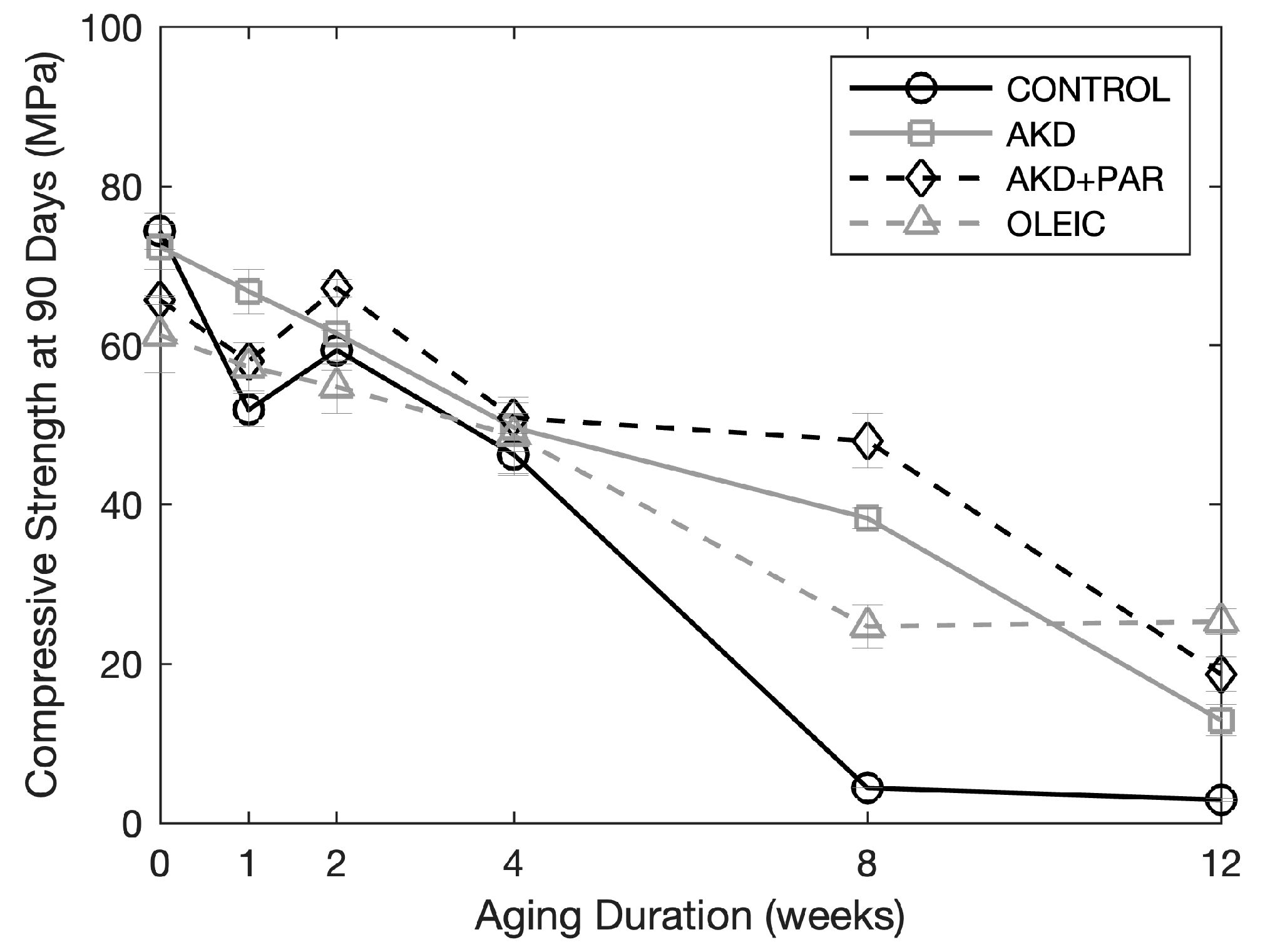

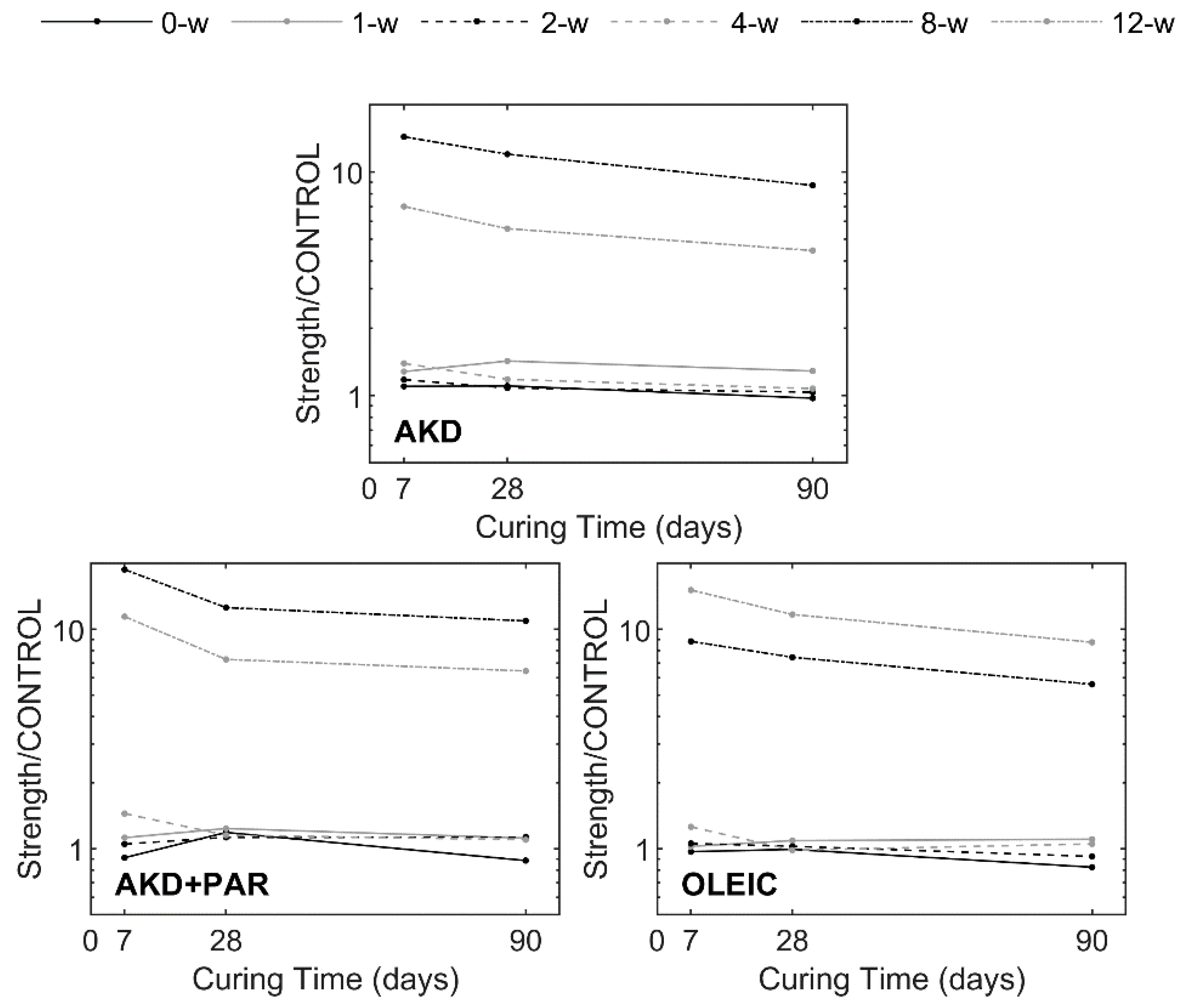

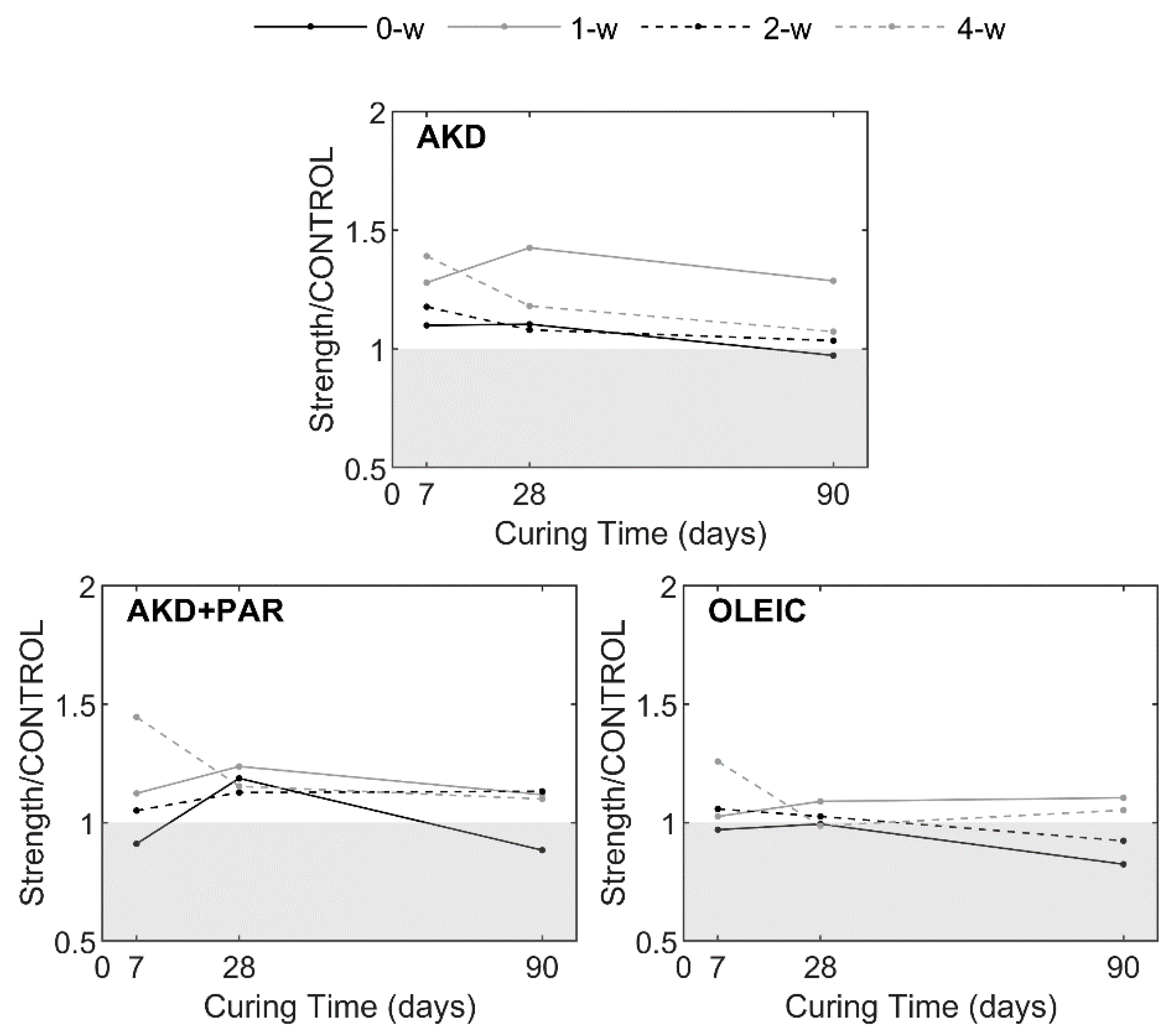

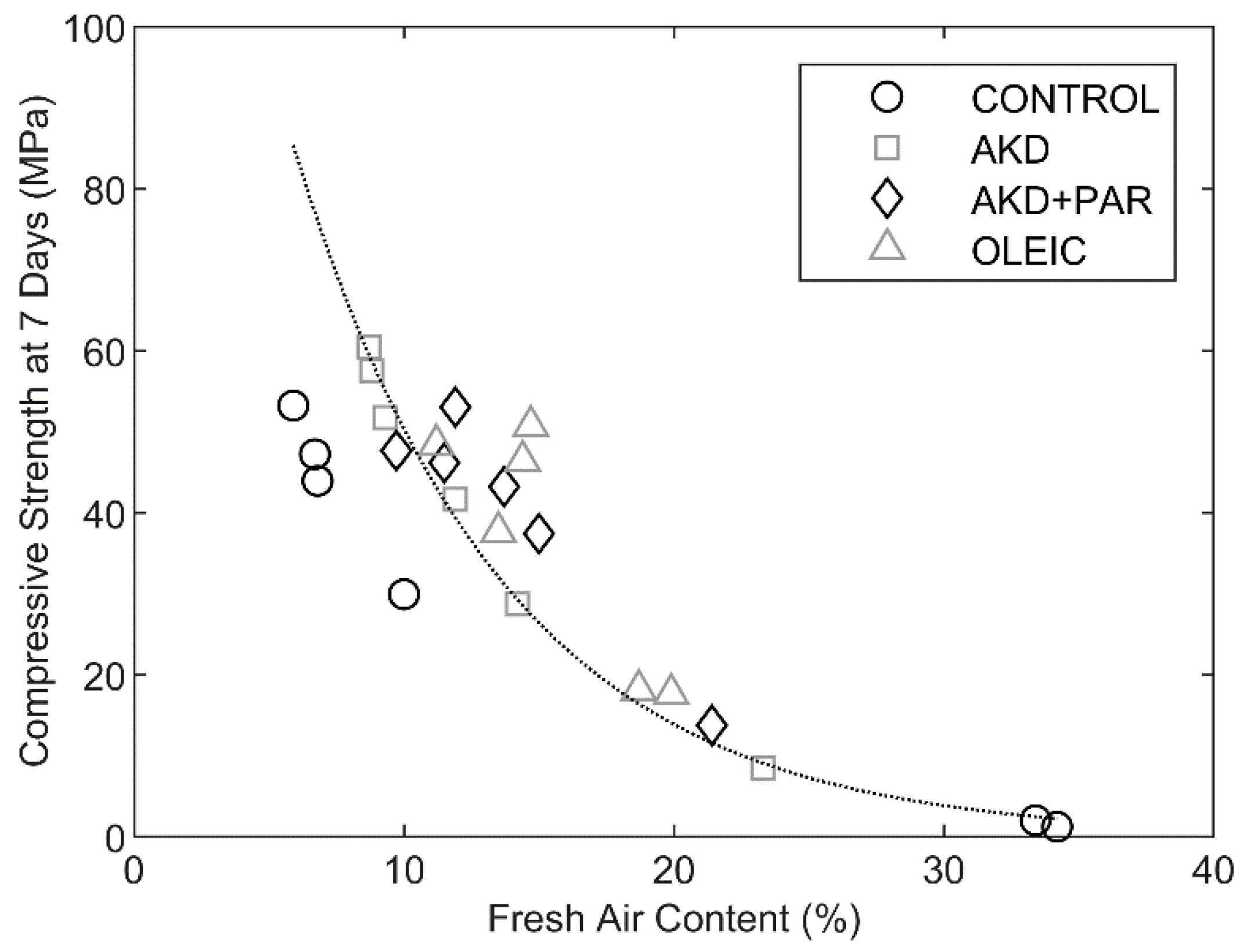

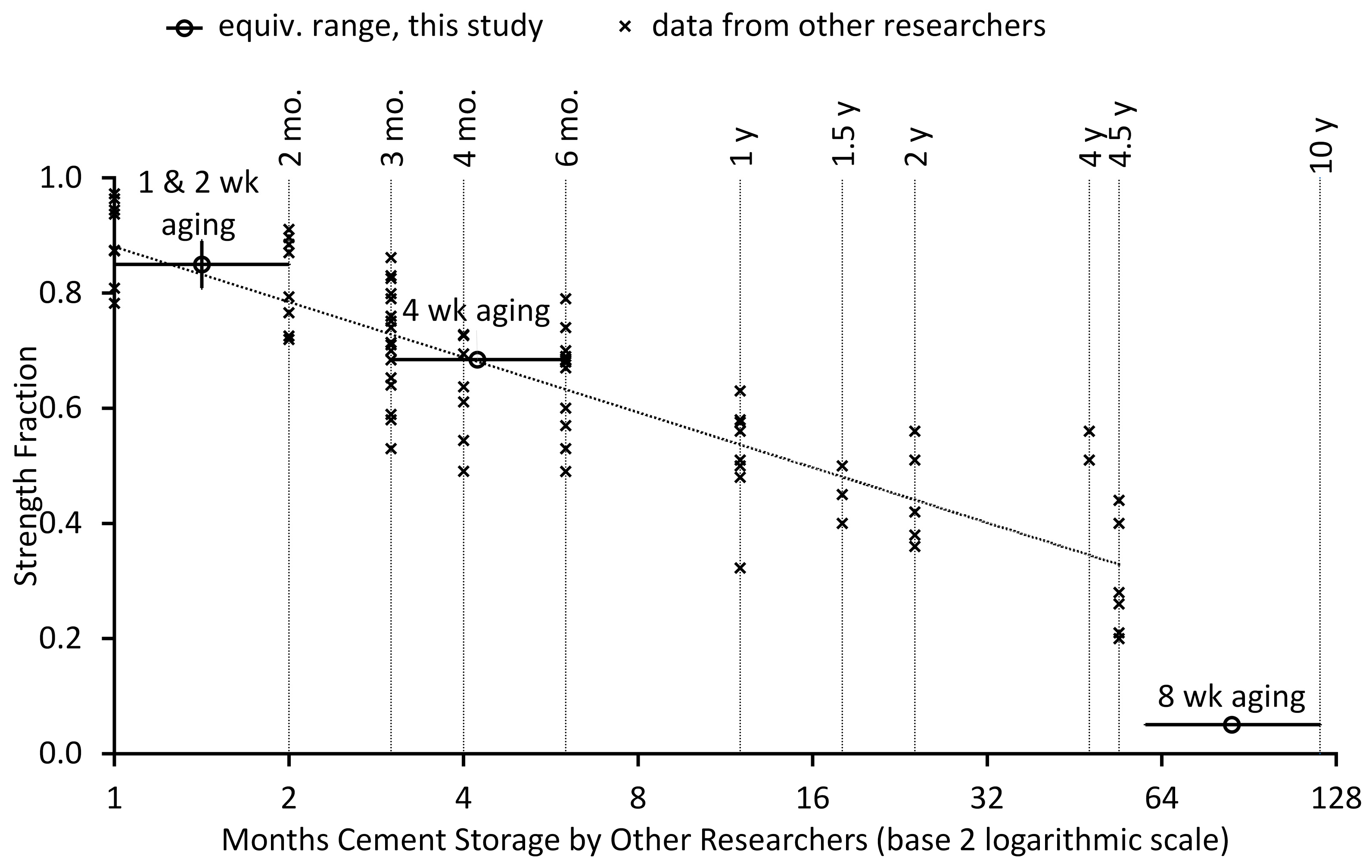

3.6. Compressive Strength

3.7. Clinker Milling

4. Discussion

4.1. Particle Agglomeration

4.2. Paste Calorimetry

4.3. Mortar Fresh Properties

4.4. Effect of Prehydration on Hardened Mortar Properties

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abrams, D.A. Effect of Storage of Cement, Bulletin 6; Structural Materials Research Laboratory, Lewis Institute: Chicago, IL, USA, 1920; 28p. [Google Scholar]

- Sprung, S. Effect of storage conditions on the properties of cement. Zem-Kalk-Gips 1978, 6, 305–309. [Google Scholar]

- Berdov, G.; Ilyiina, L. Activatziya tzementov deistviem dobavok electrolitov (Cement activation by electrolyte additives), Mezhdunarodniy Zhurnal Prikladnikh i Fundamentalnikh Issledovaniy. Int. J. Appl. Basic Res. 2010, 9, 55–57. [Google Scholar]

- Ilyiina, L. Povisheniye Eksplutatzionnikh Kharakteristik Stroitelnikh Materialov na Osnove Tzementa Dlitelnogo Khraneniya (Improvement of Performance of Building Materials Based on Cement after Its Long-Term Storage). Doctoral Dissertation, Siberian State University of Architecture and Civil Engineering, Novosibirsk, Russia, 2011. [Google Scholar]

- Lovely, K.M.; Chacko, A. A study on strength characteristics of ordinary portland cement due to storage. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 612–616. [Google Scholar]

- Getachew, B.; Adugna, T.; Assefa, S. Investigation on the effect of storage time due to moisture absorption of cement on the properties of concrete. Int. J. Dev. Res. 2018, 8, 18558–18561. [Google Scholar]

- Ma’aruf, A.; Nuruddeen, M.M.; Mukhtar, H.K. Effects of cement prehydration on concrete properties. Int. J. Eng. Sci. Res. IJESR/ICRIT-IV Spec. Issue 2018, 4, 15–20. [Google Scholar]

- Ibrahim, A.J. The effect of storage period on the physical and mechanical properties of cement. Civ. Environ. Res. 2018, 10, 71–84. [Google Scholar]

- Silva, D.A.; Thomas, J.; Kazmierczak, D.; Cheung, J. Pre-hydration of cement: Global survey and laboratory results. ZKG Int. 2018, 6, 55–60. [Google Scholar]

- Schmidt, G.; Bier, T.A.; Wutz, K.; Maier, M. Characterization of the ageing behavior of premixed dry mortars and its effect on their workability properties. ZKG Int. 2007, 60, 94–103. [Google Scholar]

- Ramge, P.; Schmidt, W.; Kühne, H.-C. Effect of the storage of cement on early properties of cementitious systems. In Proceedings of the International Conference on Advances in Cement and Concrete Technology in Africa, Johannesburg, South Africa, 28–31 January 2013; pp. 339–347. [Google Scholar]

- Whittaker, M.; Dubina, E.; Al-Mutawa, F.; Arkless, L.; Plank, J.; Black, L. The effect of prehydration on the engineering properties of CEM I Portland cement. Adv. Cem. Res. 2013, 25, 12–20. [Google Scholar] [CrossRef]

- Adamtsevich, A.; Eremin, A.; Pustovgar, A.; Pashkevich, S.; Nefedov, S. Research on the effect of prehydration of portland cement stored in normal conditions. Appl. Mech. Mater. 2014, 670–671, 376–381. [Google Scholar] [CrossRef]

- Theisen, K.; Johansen, V. Prehydration and strength development of Portland cement. Am. Ceram. Soc. Bull. 1975, 54, 787–791. [Google Scholar]

- Goswami, G.; Mohapatra, B.; Panda, J.D. Gypsum dehydration during comminution and its effect on cement properties. J. Am. Ceram. Soc. 1990, 73, 721–723. [Google Scholar] [CrossRef]

- Den, C.-S.; Breen, C.; Yarwood, J.; Habesch, S.; Phipps, J.; Craster, B.; Maitland, G. Aging of oilfield cement at high humidity: A combined FEG-ESEM and Raman microscope investigation. J. Mater. Chem. 2002, 12, 3105–3112. [Google Scholar] [CrossRef]

- Hartmann, F.A.; Mengel, L.C.; Plank, J.P. Effects of exposure to atmospheric moisture and CO2 on the performance of a ternary binder system and chemical admixtures in a self-levelling underlayment. Constr. Build. Mater. 2022, 350, 128911. [Google Scholar] [CrossRef]

- Jensen, O.M.; Hansen, P.F.; Lachowski, E.E.; Glasser, F.P. Clinker mineral hydration at reduced relative humidities. Cem. Concr. Res. 1999, 29, 1505–1512. [Google Scholar] [CrossRef]

- Dubina, E.; Wadsö, L.; Plank, J. A sorption balance study of water vapour sorption on anhydrous cement minerals and cement constituents. Cem. Concr. Res. 2011, 41, 1196–1204. [Google Scholar] [CrossRef]

- Dubina, E.; Black, L.; Sieber, R.; Plank, J. Interaction of water vapour with anhydrous cement minerals. Adv. Appl. Ceram. 2013, 109, 260–268. [Google Scholar] [CrossRef]

- Dubina, E.; Plank, J.; Black, L.; Wadsö, L. Impact of environmental moisture on C3A polymorphs in the absence and presence of CaSO4 · 0·5 H2O. Adv. Cem. Res. 2014, 26, 29–40. [Google Scholar] [CrossRef]

- Ylmén, R.; Jäglid, U. Carbonation of portland cement studied by diffuse reflection Fourier transform infrared spectroscopy. Int. J. Concr. Struct. Mater. 2013, 7, 119–125. [Google Scholar] [CrossRef]

- Stoian, J.; Oey, T.; Bullard, J.W.; Huang, J.; Kumar, A.; Balonis, M.; Terrill, J.E.; Neithalath, N.; Sant, G. New insights into the prehydration of cement and its mitigation. Cem. Concr. Res. 2015, 70, 94–103. [Google Scholar] [CrossRef]

- Dubina, E.; Plank, J.; Black, L. Impact of water vapour and carbon dioxide on surface composition of C3A polymorphs studied by X-ray photoelectron spectroscopy. Cem. Concr. Res. 2015, 73, 36–41. [Google Scholar] [CrossRef]

- Maciel, M.H.; Romano, R.C.O.; Pileggi, R.G. Hy_Surf model: Viscoelastic evolution in Portland cement suspensions during the early-age hardening. Cem. Concr. Res. 2023, 174, 107342. [Google Scholar] [CrossRef]

- Korovkin, M.; Eroshkina, N. Influence of superplasticizer on cement grinding and its activity reduction during storage. Procedia Eng. 2016, 150, 1600–1604. [Google Scholar] [CrossRef]

- Pique, T.M.; Baueregger, S.; Plank, J. Influence of temperature and moisture on the shelf-life of cement admixed with redispersible polymer powder. Constr. Build. Mater. 2016, 115, 336–344. [Google Scholar] [CrossRef]

- Khigerovich, M. Method of Producing Hydrophobic Cements. Russian Patent RU 84554, 31 December 1950. [Google Scholar]

- Khigerovich, M. Gidrofobnyi Tsement i Gidrofobno-Plastifitsiruyushchie Dobavki (Hydrophobic Cement and Hydrophobically Plasticizing Additives); Gosudarstvennoe Izdatel’stvo Literatury po Stroitel’nym Materialam: Moscow, Russia, 1957; 208p. [Google Scholar]

- Stoll, U.W. Hydrophobic cement. In ASTM STP205: Cement and Concrete; American Society for Testing Materials: Philadelphia, PA, USA, 1958; pp. 7–15. [Google Scholar]

- Khigerovich, M.; Baier, V. Gidrofobno-Plastifitsiruyushchie Dobavki Dlya Tsementov, Rastvorov i Betonov (Hydrophobically-Plasticizing Additives for Cements, Mortars and Concretes); Stroyizdat: Moscow, Russia, 1979; 125p. [Google Scholar]

- Dvorkin, L.; Dvorkin, O. Stroitelniye Mineralnie Vyachshuschiye Materiali (Mineral Construction Binding Materials); Infra-Ingeneriya: Moscow, Russia, 2011; 541p. [Google Scholar]

- Vektaris, B.; Kaziliūnas, A.A.; Striūgienė, I. Aging of dry cement mixes for finishing purposes. Mater. Sci. 2013, 3, 326–330. [Google Scholar] [CrossRef]

- Griffin, D.F.; Lorman, W.R. Interim Report on Hydrophobic Cement; U. S. Project NY 430 030-8.02, Technical Note N-303; Naval Civil Engineering Research and Evaluation Laboratory: Port Hueneme, CA, USA, 1957; 14p. [Google Scholar]

- Albayrak, A.T.; Muzaffer, Y.; Gurkaynak, M.A.; Gurkey, I. Investigation of the effects of fatty acids on the compressive strength of the concrete and the grindability of the cement. Cem. Concr. Res. 2005, 35, 400–404. [Google Scholar] [CrossRef]

- Maltese, C.; Pistolesi, A.; Bravo, A.; Cella, F.; Cerulli, T.; Salvioni, D. A case history: Effect of moisture on the setting behaviour of a Portland cement reacting with an alkali-free accelerator. Cem. Concr. Res. 2007, 37, 856–865. [Google Scholar] [CrossRef]

- Winnefeld, F. Influence of cement aging and addition time on the performance of superplasticizers. ZKG Int. 2008, 61, 68–77. [Google Scholar]

- Dubina, E.; Plank, J. Influence of moisture- and CO2-induced aging in cement on the performance of admixtures used in construction chemistry. ZKG Int. 2012, 65, 60–68. [Google Scholar]

- Sun, Z.; Shui, L.; Yang, H.; Liu, Y.; Ji, Y. Effect of prehydration on properties of cement and interaction between prehydrated cement and polycarboxylate superplasticizer. J. Chin. Ceram. Soc. 2016, 44, 647–650. [Google Scholar] [CrossRef]

- Meier, M.R.; Napharatsamee, T.; Plank, J. Dispersing performance of superplasticizers admixed to aged cement. Constr. Build. Mater. 2017, 139, 232–240. [Google Scholar] [CrossRef]

- Hartmann, F.A.; Plank, J. New insights into the effects of aging on Portland cement hydration and on retarder performance. Constr. Build. Mater. 2021, 274, 122104. [Google Scholar] [CrossRef]

- Ferraz, D.F.; Martho, A.C.R.; Burns, E.G.; Romano, R.C.O.; Pileggi, R.G. Effect of prehydration of Portland cement on the superplasticizer consumption and the impact on the rheological properties and chemical reaction. Rev. Ibracon Estrut. Mater. 2023, 16, e16210. [Google Scholar] [CrossRef]

- Sivakumar, R.; Halee, B.; Suraneni, P. Effect of calcium sulfoaluminate cement prehydration on hydration and strength gain of calcium sulfoaluminate cement-ordinary portland cement mixtures. Cem. Concr. Comp. 2020, 112, 103694. [Google Scholar] [CrossRef]

- Kerienė, J.; Antonovič, V.; Stonys, R.; Boris, R. The influence of the aging of calcium aluminate cement on the properties of mortar. Constr. Build. Mater. 2019, 205, 387–397. [Google Scholar] [CrossRef]

- Lv, L.; Šavija, B.; Li, L.; Cui, H.; Han, N.; Xing, F. Prehydration of calcium sulfoaluminate (CSA) clinker at different relative humidities. Cem. Concr. Res. 2021, 144, 106423. [Google Scholar] [CrossRef]

- Ozersky, A.; Khomyakov, A.; Peterson, K. Extended shelf life cement: Principles, microstructural analysis, and physical-mechanical properties of the cement and concrete. Constr. Build. Mater. 2021, 266 Pt B, 121202. [Google Scholar] [CrossRef]

- Ozersky, A.; Khomyakov, A. Cement and Process for Producing Self-Protecting Cement. World Patent WO 2020/073119 A1, 16 April 2020. [Google Scholar]

- Ozersky, A.; Khomyakov, A.; Zhao, P.; Herzog Bromerchenkel, L.; Chernoloz, O.; Peterson, K. Increasing the Shelf Life of Portland Cement. In Smart & Sustainable Infrastructure: Building a Greener Tomorrow; Banthia, N., Soleimani-Dashtaki, S., Mindess, S., Eds.; RILEM Bookseries; Springer: Cham, Switzerland, 2023; Volume 48. [Google Scholar] [CrossRef]

- CAN/CSA-A3000-18; Cementitious Materials Compendium. CSA Group: Toronto, ON, Canada, 2018; 246p.

- ASTM C778-21; Standard Specification for Standard Sand. American Society for Testing and Materials: West Conshohocken, PA, USA, 2021; 3p.

- ASTM C1437-20; Standard Test Method for Flow of Hydraulic Cement Mortar. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020; 2p.

- ASTM C185-20; Standard Test Method for Air Content of Hydraulic Cement Mortar. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020; 4p.

- ASTM C109/C109M-21; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube Specimens). American Society for Testing and Materials: West Conshohocken, PA, USA, 2021; 12p.

- ASTM C204-18e1; Standard Test Methods for Fineness of Hydraulic Cement by Air-Permeability Apparatus. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020; 11p.

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 3rd ed.; McGraw-Hill: New York, NY, USA, 2006; p. 649. [Google Scholar]

- PaperIndex|Contact Paper Industry Suppliers, Exporters, Manufacturers, and Wholesalers Online|B2B Marketplace of the Global Pulp & Paper Industry|USA, Canada, China, India, Indonesia|South/North America, Europe, Asia. 2024. PaperIndex. Available online: https://www.paperindex.com/ (accessed on 23 April 2024).

- Paraffin Wax Prices|Current and Forecast|Intratec.us. 2024. Intratec. Available online: https://www.intratec.us/chemical-markets/paraffin-wax-price (accessed on 23 April 2024).

| Cement ID | Materials | Density (kg/m3) |

|---|---|---|

| CONTROL | CSA Type HE [49] Portland cement | 3150 |

| AKD | HE + 0.15 wt.% alkyl ketene dimer (AKD) wax | 3070 |

| AKD + PAR | HE + 0.15 wt.% AKD + 0.3 wt.% paraffin | 3100 |

| OLEIC | HE + 0.1 wt.% oleic acid | 3080 |

| CONTROL | AKD | AKD + PAR | OLEIC | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Age (w) | D10 | D50 | D90 | D10 | D50 | D90 | D10 | D50 | D90 | D10 | D50 | D90 |

| (μm) | (μm) | (μm) | (μm) | |||||||||

| 0 | 2.3 | 5.0 | 8.9 | 1.5 | 3.4 | 6.0 | 1.7 | 4.1 | 7.7 | 1.1 | 5.7 | 12 |

| 1 | 3.5 | 9.2 | 16 | 3.5 | 7.5 | 13 | 2.8 | 8.4 | 16 | 2.8 | 6.8 | 12 |

| 2 | 4.0 | 9.5 | 17 | 3.2 | 9.3 | 18 | 2.9 | 7.8 | 14 | 3.5 | 8.0 | 14 |

| 4 | 4.1 | 10 | 19 | 3.7 | 10 | 20 | 3.6 | 11 | 23 | 3.3 | 9.1 | 19 |

| 8 | 4.1 | 11 | 22 | 3.6 | 10 | 22 | 2.9 | 9.1 | 21 | 3.1 | 10 | 35 |

| 12 | 5.0 | 14 | 41 | 3.7 | 10 | 19 | 3.4 | 9.5 | 18 | 3.4 | 9.4 | 18 |

| Control | AKD | AKD + PAR | OLEIC | GRIND AID | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D10 | D50 | D90 | D10 | D50 | D90 | D10 | D50 | D90 | D10 | D50 | D90 | D10 | D50 | D90 |

| (μm) | (μm) | (μm) | (μm) | (μm) | ||||||||||

| 3.4 | 13 | 41 | 2.7 | 11 | 33 | 2.9 | 11 | 22 | 3.2 | 13 | 39 | 2.4 | 11 | 29 |

| Clinker ID | Materials | Surface Area (m2/kg) |

|---|---|---|

| CONTROL | clinker | 226 |

| AKD | clinker + 0.15 wt.% AKD wax | 237 |

| AKD + PAR | clinker + 0.15 wt.% AKD + 0.3 wt.% paraffin | 215 |

| OLEIC | clinker + 0.1 wt.% oleic acid | 214 |

| GRIND AID | clinker + 0.1 wt.% MAPEI BXR | 270 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ozersky, A.; Khomyakov, A.; Zhao, P.; Herzog Bromerchenkel, L.; Chernoloz, O.; Peterson, K. New Mitigation Strategies for Cement Prehydration. Constr. Mater. 2024, 4, 444-467. https://doi.org/10.3390/constrmater4020024

Ozersky A, Khomyakov A, Zhao P, Herzog Bromerchenkel L, Chernoloz O, Peterson K. New Mitigation Strategies for Cement Prehydration. Construction Materials. 2024; 4(2):444-467. https://doi.org/10.3390/constrmater4020024

Chicago/Turabian StyleOzersky, Alexander, Alexander Khomyakov, Pengfei Zhao, Lucas Herzog Bromerchenkel, Oleksiy Chernoloz, and Karl Peterson. 2024. "New Mitigation Strategies for Cement Prehydration" Construction Materials 4, no. 2: 444-467. https://doi.org/10.3390/constrmater4020024

APA StyleOzersky, A., Khomyakov, A., Zhao, P., Herzog Bromerchenkel, L., Chernoloz, O., & Peterson, K. (2024). New Mitigation Strategies for Cement Prehydration. Construction Materials, 4(2), 444-467. https://doi.org/10.3390/constrmater4020024