Impact of Freeze–Thaw Cycling on the Mechanical and Durability Properties of Rapid Repair-Based Overlay Systems

Abstract

1. Introduction

1.1. Initiation of Damage in Freeze–Thaw-Affected Concrete Structures

1.2. Partial Depth Repairs

1.3. Frost Durability of Rehabilitated Structures

2. Materials

2.1. Cementitious Binders

2.2. Aggregates

2.3. Mix Design of Concrete Substrate

2.4. Mix Design of Overlay Systems

3. Experimental Program

3.1. Preparation of Substrate Specimens

3.2. Rapid Repair Overlay Placement

3.3. Curing and Conditioning of Composite Substrate-Overlay Specimen

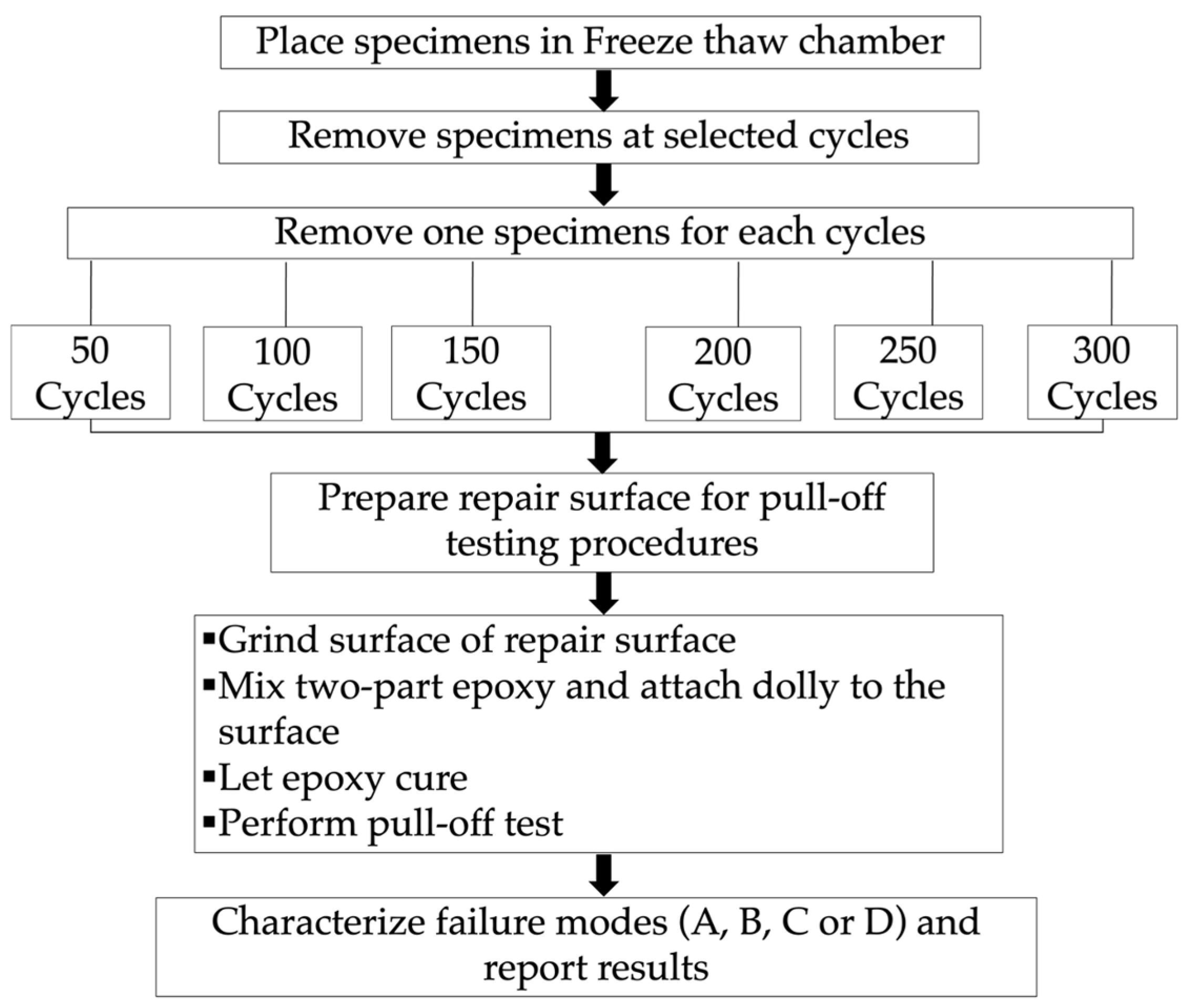

3.4. Freeze–Thaw Conditioning

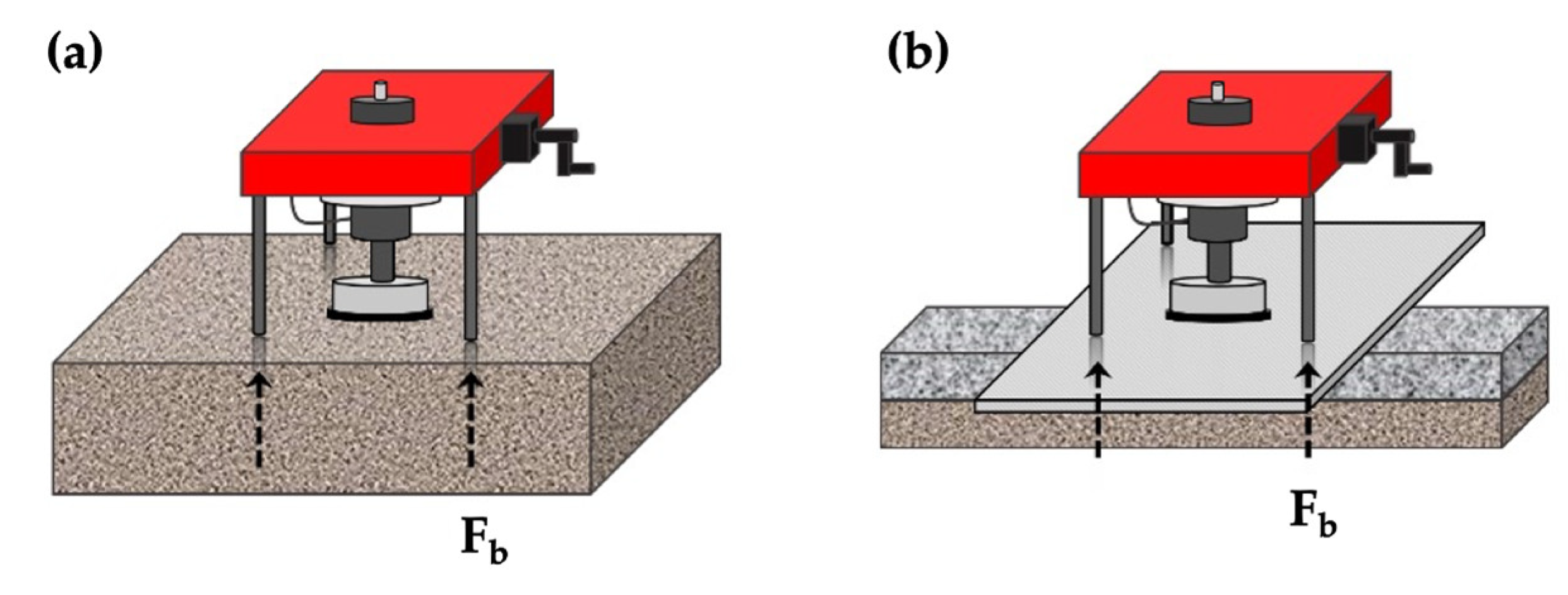

3.5. Pull-Off Testing

4. Results

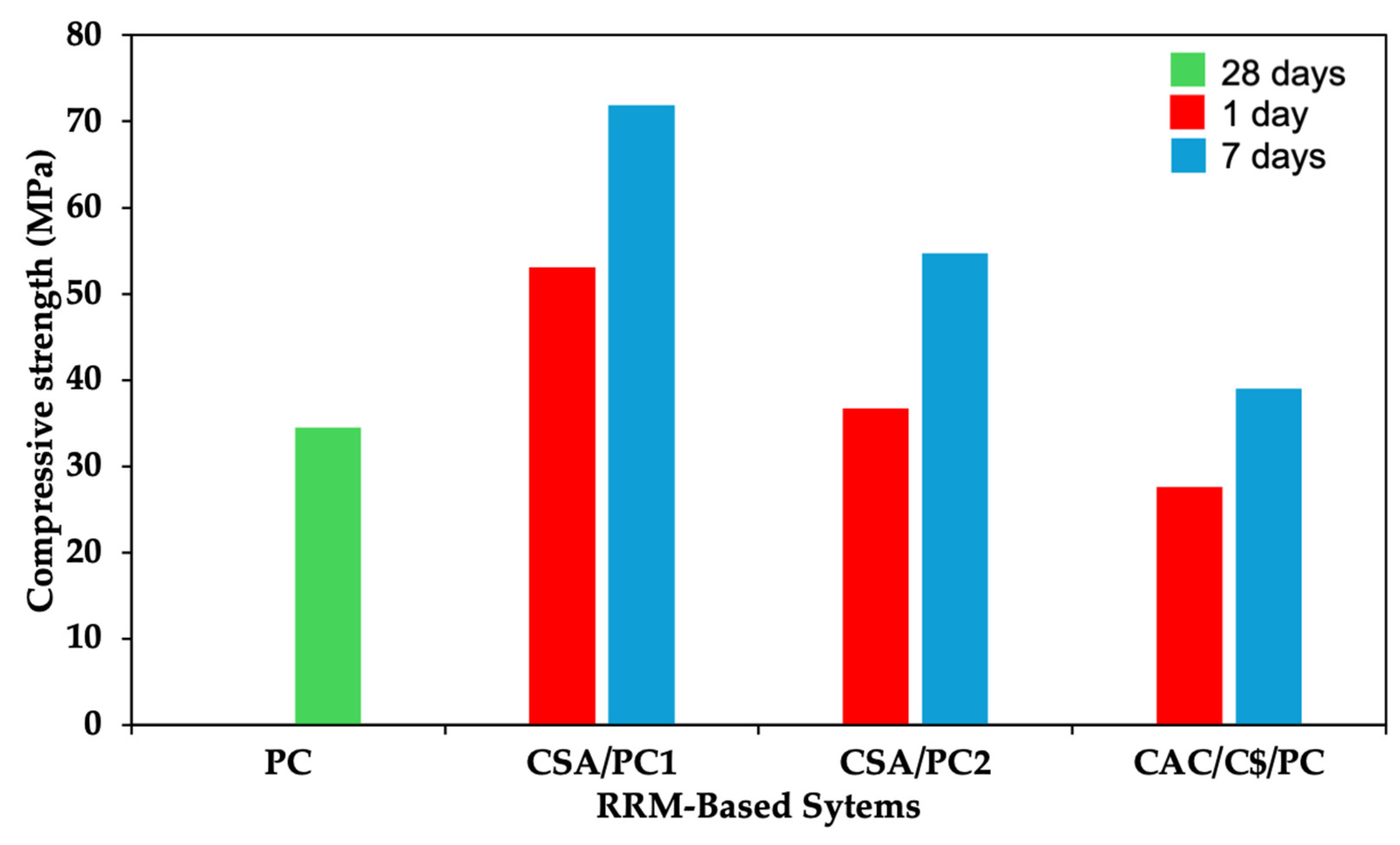

4.1. Fresh and Mechanical Properties

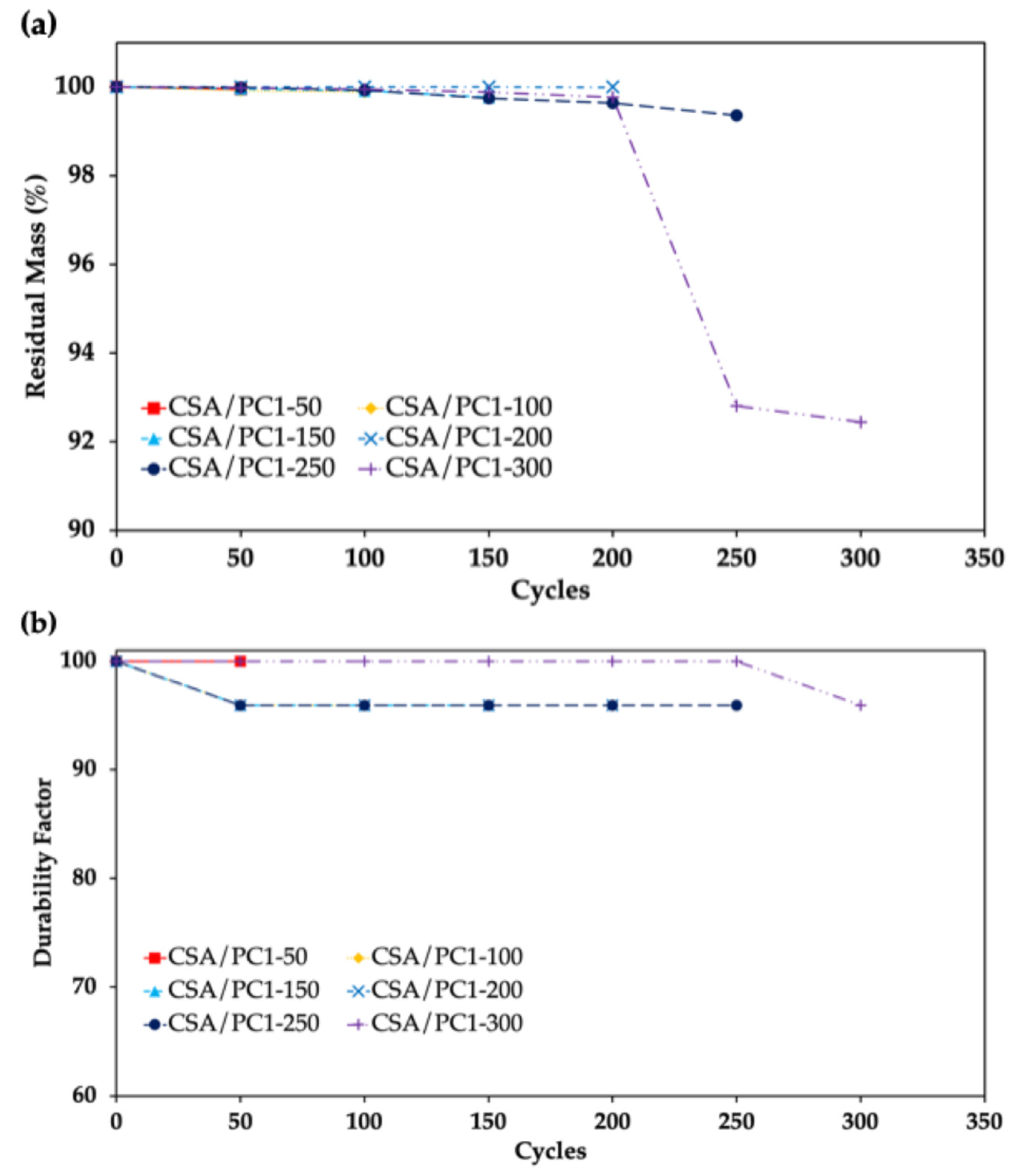

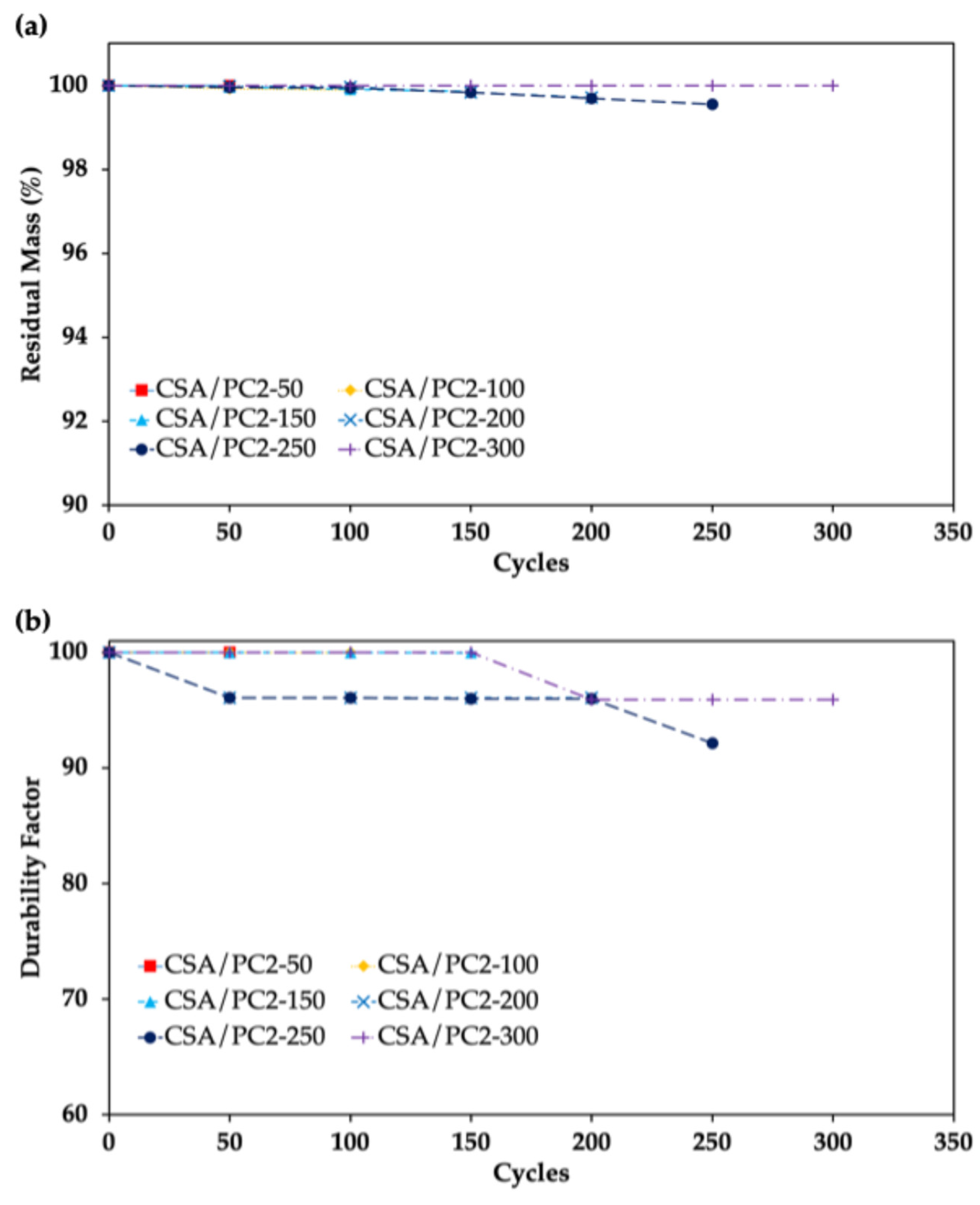

4.2. Freeze–Thaw Deterioration and Performance

Graphical Representation of Specimens After Freeze–Thaw Cycle

4.3. Tensile Pull-Off Strength

5. Discussion

5.1. Relative Performance of Rapid Repair Overlays

5.1.1. Freeze–Thaw Performance

5.1.2. Compressive Strength and Tensile Bond Strength

5.1.3. Evaluation of Combined Testing Measures and Modifications

5.1.4. Availability of Dataset and Accuracy Measures

5.1.5. Specimen Handling and Mass Change Parameters

5.1.6. Relationship Between Tensile Pull-Off Data and Transverse Frequency Response

5.1.7. Edynamic and Relative Edynamic

5.2. Validity of Proposed Test Method

6. Conclusions

- ▪

- the overlay thickness must meet the manufacturer’s minimum specification;

- ▪

- the aggregate size should be one-third of the substrate depth;

- ▪

- the sample depth must be at least 3 inches perpendicular to the drilling face;

- ▪

- drilling should extend at least ½ inch beyond the bond zone;

- ▪

- testing must use a bearing plate to ensure full engagement of the dolly.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pang, B.; Yang, C.; Wang, P.; Tian, L.; Mei, B.; Song, X. Cement-Based Ductile Rapid Repair Material Modified with Self-Emulsifying Waterborne Epoxy. J. Build. Eng. 2023, 79, 107864. [Google Scholar] [CrossRef]

- Liu, Z.; Jiang, J.; Jin, X.; Wang, Y.; Zhang, Y. Experimental and Numerical Investigations on the Inhibition of Freeze–Thaw Damage of Cement-Based Materials by a Methyl Laurate/Diatomite Microcapsule Phase Change Material. J. Energy Storage 2023, 68, 107665. [Google Scholar] [CrossRef]

- Liu, Z.; Qian, R.; Gao, S.; Wang, Y.; Jiang, J.; Zhang, Y. Modelling of Damage Spatiotemporal Distribution in Saturated Cementitious Materials and Its Chloride Transport Evolution. J. Adv. Concr. Technol. 2023, 21, 248–261. [Google Scholar] [CrossRef]

- Weisbrod, G.; Vary, D.; Treyz, G. Measuring Economic Costs of Urban Traffic Congestion to Business. Transp. Res. Rec. 2003, 1839, 98–106. [Google Scholar] [CrossRef]

- Weisbrod, G.; Vary, D.; Treyz, G.I. Economic Implications of Congestion; NCHRP Report; TRID: Washington, DC, USA, 2001. [Google Scholar]

- FHWA. Concrete Pavement Preservation Guide, 2nd ed.; 7th Floor: Washington, DC, USA, 2014.

- Frentress, D.P.; Harrington, D.S. Guide for Partial Depth Repair of Concrete Pavements; Institute for Transportation-Iowa State University: Ames, IA, USA, 2012. [Google Scholar]

- Broomfield, J. Corrosion of Steel in Concrete: Understanding. Investig. Repair/EFN 1997, 1–15. [Google Scholar]

- Roberge, P.R. Corrosion Engineering: Principles and Practice; McGraw Hill: New York, NY, USA, 2008; Volume 232. [Google Scholar]

- Amini, K. Laboratory Testing of High Performance Repair Materials for Pavements and Bridge Decks. Ph.D. Thesis, Cleveland State University, Cleveland, OH, USA, 2015. [Google Scholar]

- Thomas, J.G. The Electrochemistry of Corrosion. Hinds, G., Ed.; The National Physical Laboratory: Teddington, UK, 2004. [Google Scholar]

- Adams, M.P.; Lute, R.D.; Moffatt, E.G.; Ideker, J.H. Evaluation of a Procedure for Determining the Converted Strength of Calcium Aluminate Cement Concrete. J. Test. Eval. 2018, 46, 1659–1672. [Google Scholar] [CrossRef]

- Yu, H.; Ma, H.; Yan, K. An Equation for Determining Freeze-Thaw Fatigue Damage in Concrete and a Model for Predicting the Service Life. Constr. Build. Mater. 2017, 137, 104–116. [Google Scholar] [CrossRef]

- Guo, J.; Sun, W.; Xu, Y.; Lin, W.; Jing, W. Damage Mechanism and Modeling of Concrete in Freeze–Thaw Cycles: A Review. Buildings 2022, 12, 1317. [Google Scholar] [CrossRef]

- De Kock, T.; Boone, M.A.; De Schryver, T.; Van Stappen, J.; Derluyn, H.; Masschaele, B.; De Schutter, G.; Cnudde, V. A Pore-Scale Study of Fracture Dynamics in Rock Using X-Ray Micro-CT under Ambient Freeze–Thaw Cycling. Environ. Sci. Technol. 2015, 49, 2867–2874. [Google Scholar] [CrossRef]

- American Concrete Institute. ACI Committee 201 201.2R-16 Guide to Durable Concrete; Technical Documents; American Concrete Institute: Farmington Hills, MI, USA, 2016. [Google Scholar]

- ASTM C666/C666M; Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing. ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- Qiu, J.; Zhou, Y.; Vatin, N.I.; Guan, X.; Sultanov, S.; Khemarak, K. Damage Constitutive Model of Coal Gangue Concrete under Freeze-Thaw Cycles. Constr. Build. Mater. 2020, 264, 120720. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, Q.; Li, Y. Deterioration of Concrete under the Coupling Effects of Freeze–Thaw Cycles and Other Actions: A Review. Constr. Build. Mater. 2022, 319, 126045. [Google Scholar] [CrossRef]

- Shang, H.-S.; Yi, T.-H. Freeze-thaw Durability of Air-entrained Concrete. Sci. World J. 2013, 2013, 650791. [Google Scholar] [CrossRef] [PubMed]

- Peng, G.-F.; Ma, Q.; Hu, H.-M.; Gao, R.; Yao, Q.-F.; Liu, Y.-F. The Effects of Air Entrainment and Pozzolans on Frost Resistance of 50–60 MPa Grade Concrete. Constr. Build. Mater. 2007, 21, 1034–1039. [Google Scholar] [CrossRef]

- Zhao, Z.; Guan, X.; Xiao, F.; Xie, Z.; Xia, P.; Zhou, Q. Applications of Asphalt Concrete Overlay on Portland Cement Concrete Pavement. Constr. Build. Mater. 2020, 264, 120045. [Google Scholar] [CrossRef]

- Wang, B.; Gupta, R. Analyzing Bond-Deterioration during Freeze-Thaw Exposure in Cement-Based Repairs Using Non-Destructive Methods. Cem. Concr. Compos. 2021, 115, 103830. [Google Scholar] [CrossRef]

- Harrington, D.; Fick, G.; Bordelon, A.; Cable, J.; DeGraaf, D.; Parkes, N.; Riley, R.; Rodden, R.; Roesler, J.; Vandenbossche, J. Guide to Concrete Overlays: Sustainable Solutions for Resurfacing and Rehabilitating Existing Pavements, 3rd ed.; American Concrete Pavement Association: Washington, DC, USA, 2014. [Google Scholar] [CrossRef]

- Guan, Y.; Gao, Y.; Sun, R.; Won, M.C.; Ge, Z. Experimental Study and Field Application of Calcium Sulfoaluminate Cement for Rapid Repair of Concrete Pavements. Front. Struct. Civ. Eng. 2017, 11, 338–345. [Google Scholar] [CrossRef]

- Darter, M. Concrete Repair Best Practices: A Series of Case Studies; Missouri Department of Transportation, Construction & Materials Division: Jefferson City, MO, USA, 2017. [Google Scholar]

- Chen, D.-H.; Lin, H.-H.; Sun, R. Field Performance Evaluations of Partial-Depth Repairs. Constr. Build. Mater. 2011, 25, 1369–1378. [Google Scholar] [CrossRef]

- Moffatt, E. Durability of Rapid-Set (Ettringite-Based) Concrete. Doctoral Dissertation, University of New Brunswick, Fredricton, NB, Canada, 2016. [Google Scholar]

- Zaman, J. Concrete Mix Design for TxDOT CRCP Repair: Utilizing Rapid Set Cement (RSC) with Nano Calcium Carbonate. Ph.D Thesis, Texas Tech University, Lubbock, TX, USA, 2024. [Google Scholar]

- Nehring, J.; Neubauer, J.; Berger, S.; Goetz-Neunhoeffer, F. Acceleration of OPC by CAC in Binary and Ternary Systems: The Role of Pore Solution Chemistry. Cem. Concr. Res. 2018, 107, 264–274. [Google Scholar] [CrossRef]

- Qoku, E.; Bier, T.A.; Schmidt, G.; Skibsted, J. Impact of Sulphate Source on the Hydration of Ternary Pastes of Portland Cement, Calcium Aluminate Cement and Calcium Sulphate. Cem. Concr. Compos. 2022, 131, 104502. [Google Scholar] [CrossRef]

- Qoku, E.; Bier, T.A.; Westphal, T. Phase Assemblage in Ettringite-Forming Cement Pastes: A X-Ray Diffraction and Thermal Analysis Characterization. J. Build. Eng. 2017, 12, 37–50. [Google Scholar] [CrossRef]

- Du, F.; Zhu, W.; Yang, R.; Zhang, Y.; Wang, J.; Li, W.; Zuo, W.; Zhang, L.; Chen, L.; She, W. Bioinspired Super Thermal Insulating, Strong and Low Carbon Cement Aerogel for Building Envelope. Adv. Sci. 2023, 10, 2300340. [Google Scholar] [CrossRef]

- Ojovan, M.I.; Lee, W.E.; Kalmykov, S.N. Chapter 17—Immobilisation of Radioactive Waste in Cement. In An Introduction to Nuclear Waste Immobilisation, 3rd ed.; Ojovan, M.I., Lee, W.E., Kalmykov, S.N., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 271–303. ISBN 978-0-08-102702-8. [Google Scholar]

- Sanfelix, S.G.; Zea-García, J.D.; Londono-Zuluaga, D.; Santacruz, I.; la Torre, A.G.D.; Kjøniksen, A.-L. Hydration Development and Thermal Performance of Calcium Sulphoaluminate Cements Containing Microencapsulated Phase Change Materials. Cem. Concr. Res. 2020, 132, 106039. [Google Scholar] [CrossRef]

- Péra, J.; Ambroise, J. New Applications of Calcium Sulfoaluminate Cement. Cem. Concr. Res. 2004, 34, 671–676. [Google Scholar] [CrossRef]

- Glasser, F.P.; Zhang, L. High-Performance Cement Matrices Based on Calcium Sulfoaluminate–Belite Compositions. Cem. Concr. Res. 2001, 31, 1881–1886. [Google Scholar] [CrossRef]

- Zuniga, J.R. Development of Rapid, Cement-Based Repair Materials for Transportation Structures. Master’s Thesis, University of Texas at Austin, Austin, TX, USA, 2013. [Google Scholar]

- Al-Basha, A.J.; Toledo, W.K.; Newtson, C.M.; Weldon, B.D. Ultra-High Performance Concrete Overlays for Concrete Bridge Decks; IOP Publishing: Bristol, UK, 2019; Volume 471, p. 032007. [Google Scholar]

- Ma, Z.; Zhu, F.; Ba, G. Effects of Freeze-Thaw Damage on the Bond Behavior of Concrete and Enhancing Measures. Constr. Build. Mater. 2019, 196, 375–385. [Google Scholar] [CrossRef]

- Santos, P.M.D.; Júlio, E.N.B.S. Factors Affecting Bond between New and Old Concrete. ACI Mater. J. 2011, 108, 449. [Google Scholar]

- Talbot, C.; Pigeon, M.; Beaupre, D.; Morgan, D. Influence of Surface Preparation on Long-Term Bonding of Shotcrete. Mater. J. 1995, 91, 560–566. [Google Scholar]

- Santos, P.M.; Júlio, E.N. A State-of-the-Art Review on Roughness Quantification Methods for Concrete Surfaces. Constr. Build. Mater. 2013, 38, 912–923. [Google Scholar] [CrossRef]

- Zhao, Y.-R.; Wang, L.; Lei, Z.-K.; Han, X.-F.; Shi, J.-N. Study on Bending Damage and Failure of Basalt Fiber Reinforced Concrete under Freeze-Thaw Cycles. Constr. Build. Mater. 2018, 163, 460–470. [Google Scholar] [CrossRef]

- Chen, J.; Wang, H.; Xie, P. Finite Element Modeling of Mechanical Responses of Concrete Pavement with Partial Depth Repair. Constr. Build. Mater. 2020, 240, 117960. [Google Scholar] [CrossRef]

- ASTM C150/C150M; Standard Specification for Portland Cement1. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- Adams, M.P.; Ideker, J.H. Influence of Aggregate Type on Conversion and Strength in Calcium Aluminate Cement Concrete. Cem. Concr. Res. 2017, 100, 284–296. [Google Scholar] [CrossRef]

- ASTM C33/C33M; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- ASTM C127; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- ACI 211.1-91; Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. 38800 Country Club Drive: Farmington Hills, MI, USA, 1991.

- ASTM C928/C928M; Standard Specification for Packaged, Dry, Rapid-Hardening Cementitious Materials for Concrete Repairs. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM C109/C109M; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- ASTM C1583/C1583M; Standard Test Method for Tensile Strength of Concrete Surfaces and the Bond Strength or Tensile Strength of Concrete Repair and Overlay Materials by Direct Tension (Pull-Off Method). ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C511; Standard Specification for Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in the Testing of Hydraulic Cements and Concretes. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ICRI Committee 310. Guideline No. 310.2R–2013: Selecting and Specifying Concrete Surface Preparation for Sealers, Coatings, Polymer Overlays, and Concrete Repair; International Concrete Repair Institute: Minneapolis, MN, USA, 2013. [Google Scholar]

- ASTM C215; Standard Test Method for Fundamental Transverse, Longitudinal, and Torsional Resonant Frequencies of Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- ASTM C143/C143M; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM C138/C138M; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- ASTM C39/C39M; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- Lamond, J.F.; Pielert, J.H. Significance of Tests and and Concrete-Making STP 169D; ASTM International: West Conshohocken, PA, USA, 2012; p. 664. [Google Scholar]

- FHWA. Partial-Depth Repairs; FHWA: Washington, DC, USA, 2017.

- Feng, S.; Lyu, J. The Method of Slant Shear Test with Various Slant Shear Angles Decouple Cohesion and Friction of Substrate-Overlays Interface. Constr. Build. Mater. 2024, 456, 139238. [Google Scholar] [CrossRef]

- Diab, A.M.; Abd Elmoaty, M.; Eldin, M.R.T. Slant Shear Bond Strength between Self Compacting Concrete and Old Concrete. Constr. Build. Mater. 2017, 130, 73–82. [Google Scholar] [CrossRef]

- Feng, S.; Xiao, H.; Li, Y. Influence of Interfacial Parameters and Testing Methods on UHPC–NSC Bond Strength: Slant Shear vs. Direct Tensile Testing. Cem. Concr. Compos. 2022, 131, 104568. [Google Scholar] [CrossRef]

- He, S.; Huang, X.; Zhong, H.; Wan, Z.; Liu, G.; Xin, H.; Zhang, Y. Experimental Study on Bond Performance of UHPC-to-NC Interfaces: Constitutive Model and Size Effect. Eng. Struct. 2024, 317, 118681. [Google Scholar] [CrossRef]

- Doitrand, A.; Henry, R.; Lube, T.; Meille, S. Size Effect Assessment by Weibull’s Approach and the Coupled Criterion. Eng. Fract. Mech. 2021, 256, 107979. [Google Scholar] [CrossRef]

- Zhao, H.; Hu, Y.; Tang, Z.; Wang, K.; Li, Y.; Li, W. Deterioration of Concrete under Coupled Aggressive Actions Associated with Load, Temperature and Chemical Attacks: A Comprehensive Review. Constr. Build. Mater. 2022, 322. [Google Scholar] [CrossRef]

- Vicente, M.A.; González, D.C.; Mínguez, J.; Tarifa, M.A.; Ruiz, G.; Hindi, R. Influence of the Pore Morphology of High Strength Concrete on Its Fatigue Life. Int. J. Fatigue 2018, 112, 106–116. [Google Scholar] [CrossRef]

- Silva, A.; Jiang, Y.; Castro, J.; Silvestre, N.; Monteiro, R. Monotonic and Cyclic Flexural Behaviour of Square/Rectangular Rubberized Concrete-Filled Steel Tubes. J. Constr. Steel Res. 2017, 139, 385–396. [Google Scholar] [CrossRef]

- Bao, J.; Xue, S.; Zhang, P.; Dai, Z.; Cui, Y. Coupled Effects of Sustained Compressive Loading and Freeze–Thaw Cycles on Water Penetration into Concrete. Struct. Concr. 2021, 22, E944–E954. [Google Scholar] [CrossRef]

- Hao, L.; Liu, Y.; Xiao, J. Durability of Recycled Aggregate Thermal Insulation Concrete under Combined Flexural Loading and Freeze–Thaw Cycles. Constr. Build. Mater. 2021, 272, 121652. [Google Scholar] [CrossRef]

- Shen, Y.; Liu, J.; Zhou, S.; Li, G. Experimental Investigation on the Freeze–Thaw Durability of Concrete under Compressive Load and with Joints. Constr. Build. Mater. 2019, 229, 116893. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Y.; Zhang, P.; Ma, Y.; Zhao, T.; Wang, H.; Zhang, Z. Water Absorption and Chloride Diffusivity of Concrete under the Coupling Effect of Uniaxial Compressive Load and Freeze–Thaw Cycles. Constr. Build. Mater. 2019, 209, 566–576. [Google Scholar] [CrossRef]

| Portland Cement | Rapid-Set CSA Cement | CAC Cement [47] | |

|---|---|---|---|

| Oxide | Amount (%) | ||

| Na2O | 0.21 | 0.18 | 0.03 |

| MgO | 2.75 | 2.89 | 0.71 |

| Al2O3 | 3.73 | 10.01 | 38.23 |

| SiO2 | 20.5 | 16.58 | 4.98 |

| P2O5 | 0.22 | 0.18 | 0.13 |

| SO3 | 2.9 | 7.65 | 0.06 |

| Cl | 0.05 | * | |

| K2O | 0.77 | 1 | 0.23 |

| CaO | 62.43 | 57.1 | 37.53 |

| TiO2 | 0.19 | 0.56 | 1.8 |

| Cr2O3 | 0.06 | 0.05 | |

| MnO | 0.23 | 0.11 | * |

| Mn2O3 | * | * | 0.23 |

| Fe2O3 | 3.34 | 2.01 | 15.4 |

| ZnO | 0.14 | 0.05 | * |

| SrO | 0.22 | 0.23 | 0.02 |

| LOI ** | * | 1.41 | 0.65 |

| Total | 100 | ||

| Aggregate Specification | Dry-Rodded Unit Weight kg/m3 | Relative Density (SG) | Absorption Capacity (%) |

|---|---|---|---|

| Coarse Aggregate (CA) | 1511 | 2.69 | 0.66 |

| Fine Aggregate (FA) | - | 2.75 | 0.57 |

| Property | PC-S1 | PC-S2 | PC-S3 |

|---|---|---|---|

| Compressive Strength [MPa] | 36 | 34 | 32.5 |

| Unit Weight [kg/m3] | 2306 | 2291 | 2306 |

| Slump [mm] | 8.9 | 12.7 | 12.7 |

| Air Content | 7.50% | 8% | 6.50% |

| Repair System Used on Substrate | CSA/PC1 | CSA/PC2 | CAC/C$/PC |

| CSA/PC1-50 | CSA/PC1-100 | CSA/PC1-150 | CSA/PC1-200 | CSA/PC1-250 | CSA/PC1-300 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cycle | RM (%) | DF | RM (%) | DF | RM (%) | DF | RM (%) | DF | RM (%) | DF | RM (%) | DF |

| 0 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| 50 | 99.9 | 100 | 99.9 | 95.9 | 99.9 | 95.9 | 99.9 | 95.9 | 99.9 | 95.9 | 99.9 | 100 |

| 100 | 99.9 | 95.9 | 99.9 | 95.9 | 99.9 | 95.9 | 99.9 | 95.9 | 99.9 | 100 | ||

| 150 | 99.8 | 95.9 | 99.9 | 95.9 | 99.7 | 95.9 | 99.9 | 100 | ||||

| 200 | 99.9 | 95.9 | 99.6 | 95.9 | 99.8 | 100 | ||||||

| 250 | 99.4 | 95.9 | 92.8 | 100 | ||||||||

| 300 | 92.4 | 95.9 | ||||||||||

| CSA/PC2-50 | CSA/PC2-100 | CSA/PC2-150 | CSA/PC2-200 | CSA/PC2-250 | CSA/PC2-300 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cycle | RM (%) | DF | RM (%) | DF | RM (%) | DF | RM (%) | DF | RM (%) | DF | RM (%) | DF |

| 0 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| 50 | 100 | 100 | 99.9 | 100 | 99.9 | 100 | 99.9 | 96.1 | 99.9 | 96.1 | 100 | 100 |

| 100 | 99.9 | 99.9 | 99.9 | 100 | 99.9 | 96.1 | 99.9 | 96.1 | 100 | 100 | ||

| 150 | 99.9 | 99.9 | 99.8 | 96.1 | 99.8 | 95.9 | 100 | 100 | ||||

| 200 | 99.7 | 96.1 | 99.7 | 95.9 | 100 | 95.9 | ||||||

| 250 | 99.5 | 92.1 | 100 | 95.9 | ||||||||

| 300 | 100 | 95.9 | ||||||||||

| CAC/C$/ PC-50 | CAC/C$/ PC-100 | CAC/C$/ PC-150 | CAC/C$/ PC-200 | CAC/C$/ PC-250 | CAC/C$/ PC-300 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cycle | RM (%) | DF | RM (%) | DF | RM (%) | DF | RM (%) | DF | RM (%) | DF | RM (%) | DF |

| 0 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| 50 | 99.9 | 100 | 99.6 | 100 | 99.8 | 100 | 99.6 | 100 | 99.5 | 100 | 96.1 | 100 |

| 100 | 99.5 | 100 | 99.8 | 100 | 99.1 | 100 | 99.1 | 100 | 96.1 | 100 | ||

| 150 | 99.3 | 95.9 | 98.8 | 95.9 | 98.6 | 95.9 | 95.2 | 95.9 | ||||

| 200 | 98.3 | 95.9 | 97.9 | 95.9 | 94.5 | 95.9 | ||||||

| 250 | 97.2 | 95.9 | 93.6 | 84.3 | ||||||||

| 300 | 92.9 | 84.3 | ||||||||||

| Overlay System | Initial Pull-Off Strength (MPa) | 300-Cycle Pull-Off Strength (MPa) | 300-Cycle Decrease (%) | Avg. Decrease per Cycle (kPa/c) |

|---|---|---|---|---|

| CSA/PC1 | 2.5 | 2.1 | 14.9 | 1.2 |

| CSA/PC2 | 2 | 1.9 | 7.1 | 0.5 |

| CAC/C$/PC | 1.8 | 0.6 | 66.2 | 4.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thibodeaux, N.A.; Hasan, M.M.; Bandelt, M.J.; Adams, M.P. Impact of Freeze–Thaw Cycling on the Mechanical and Durability Properties of Rapid Repair-Based Overlay Systems. Constr. Mater. 2025, 5, 3. https://doi.org/10.3390/constrmater5010003

Thibodeaux NA, Hasan MM, Bandelt MJ, Adams MP. Impact of Freeze–Thaw Cycling on the Mechanical and Durability Properties of Rapid Repair-Based Overlay Systems. Construction Materials. 2025; 5(1):3. https://doi.org/10.3390/constrmater5010003

Chicago/Turabian StyleThibodeaux, Noah A., Md Maruf Hasan, Matthew J. Bandelt, and Matthew P. Adams. 2025. "Impact of Freeze–Thaw Cycling on the Mechanical and Durability Properties of Rapid Repair-Based Overlay Systems" Construction Materials 5, no. 1: 3. https://doi.org/10.3390/constrmater5010003

APA StyleThibodeaux, N. A., Hasan, M. M., Bandelt, M. J., & Adams, M. P. (2025). Impact of Freeze–Thaw Cycling on the Mechanical and Durability Properties of Rapid Repair-Based Overlay Systems. Construction Materials, 5(1), 3. https://doi.org/10.3390/constrmater5010003