An Assessment of Energy and Groundwater Consumption of Textile Dyeing Mills in Bangladesh and Minimization of Environmental Impacts via Long-Term Key Performance Indicators (KPI) Baseline

Abstract

:1. Introduction

1.1. Water and Energy Consumption in Textile Dyeing Mills

1.2. Impact of Discharged Wastewater on the Environment

1.3. Groundwater Level Depletion

2. Materials and Methods

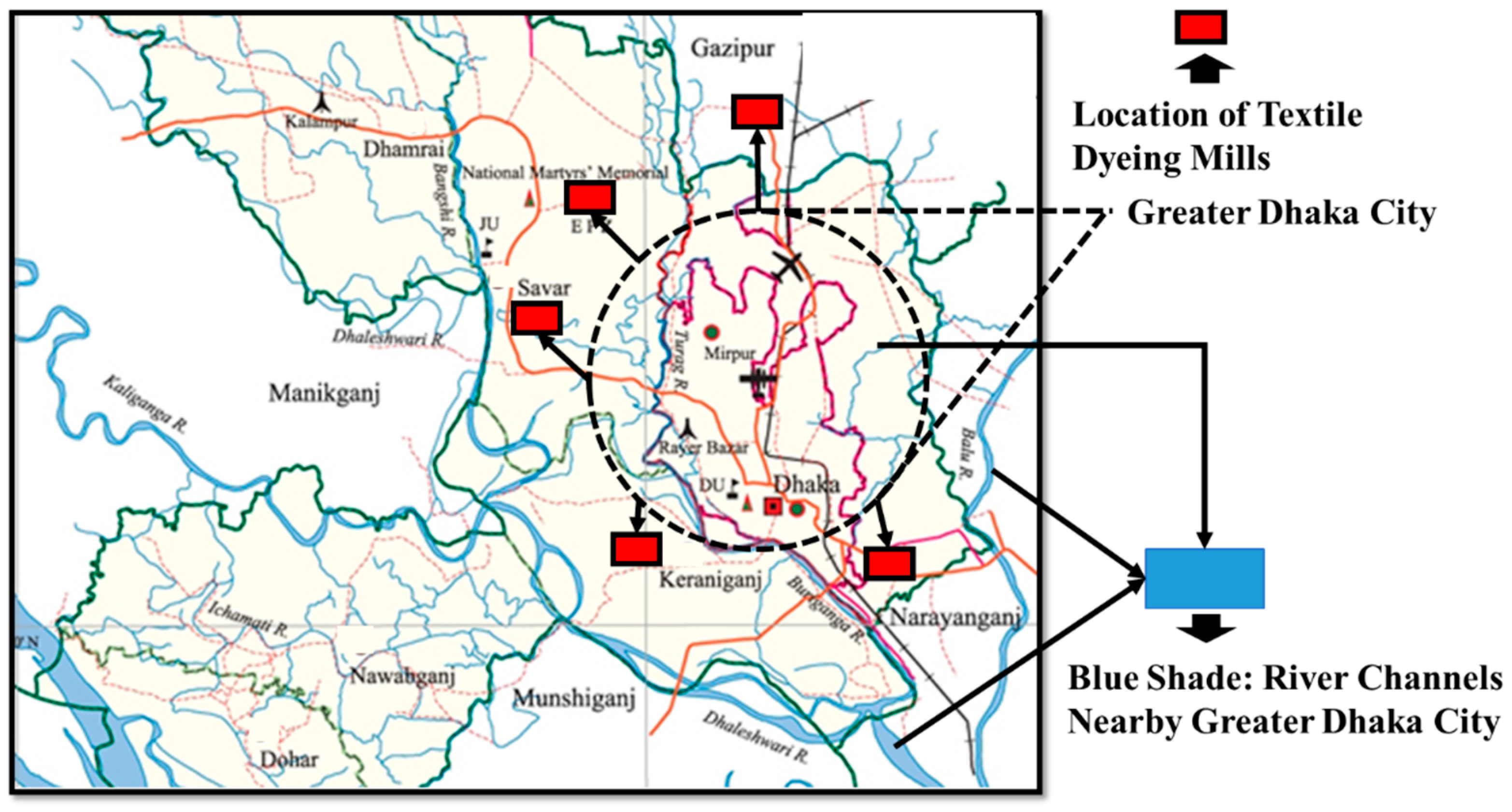

2.1. Study Approach

2.2. Data Collection

Groundwater Demand and Wastewater Discharge into the Environment

2.3. Data Collected from Selected Dyeing Mills

Energy Consumption and Carbon Footprint

3. Results

3.1. Production vs. Energy Consumption

3.2. Carbon Footprint Contribution to kWh Electricity and Dyed Fabric

3.3. Groundwater vs. Discharged Wastewater Comparison

3.4. Heavy Metal Discharge with Treated Wastewater

3.5. COD and BOD Amount in Effluent Discharged Wastewater

4. Discussion

4.1. Yearly Basis KPI% Reduction Approach and Potential Saving

4.2. Recommendations

4.2.1. Best Available Techniques for Potential Water-saving Approaches

- Process-wise and machine-wise water consumption should be monitored for individual dyeing machine water consumption and take initiatives where water consumption is comparatively high;

- Use water-efficient machinery and equipment, for instance, substituting a high liquor ratio dyeing machine with a low liquor ratio [13];

- Ensure optimum condensate recovery from all sections by installing steam traps and condensate transfer pump to reuse as boiler feedwater;

- Reuse of effluent-treated wastewater in cleaning the empty chemical drums, printing screens and production floor, car washing and toilet flushing [14];

- Rainwater is much purer than groundwater and can be used in the production process without passing through the WTP (Water Treatment Plant), which is economically suitable and environmentally friendly;

- Prevent all leakages in the waterline and use a trigger nozzle in hose pipes to avoid the excessive flow of water;

- For fabric washing purposes, counter-current rinsing should be followed. Pretreatment washing of the dyed fabric should be conducted according to the requirement to avoid excess washing. Additionally, avoiding the excessive washing of machines;

- Adopting digital printing instead of a standard printing system where chemical wastage is minimal and requires less water;

- Provision of recovering salt from used liquor, which is ultimately drained to ETP, increasing treatment cost and using acid to neutralize the high amount of alkaline effluent.

4.2.2. Best Available Techniques for Potential Energy-Saving Approaches

- Substitute manual blowdown of boilers with an auto blowdown system to save energy;

- The concept of smart lighting involves utilizing natural light from the sun. Smart lighting is also a good initiative that minimizes and saves light by allowing the proper place lighting;

- Proper insulation of all steam valves & flanges to avoid heat loss

- Maintain proper air and fuel ration in boiler through oxygen tuning/oxygen analyzer to reduce excessive natural gas consumption;

- Installation of exhaust gas boiler and heat recovery from flue gas by installing an economizer;

- Performing regular leakage tests and monitoring the leakage level of compressed air lines.

4.2.3. Factory Management Initiatives

- Employee and worker training on water usage also plays a significant role [14]. Conveying the environmental impact and the growing consciousness of illiterate or less-educated workers is very important. The feasibility of waterless dyeing with CO2 or plasma processing should be investigated as a pilot project basis in Bangladesh as soon as possible. With modern techniques and solid economic background, some countries are introducing absolute recycling of water through the zero liquid discharge (ZLD) plant, which could be the ultimate solution for toxic wastewater. As Dhaka’s groundwater level is significantly declining, some researchers have suggested recharging the groundwater artificially [11].

- These approaches could be taken to minimize water and energy without significant investment. However, this study has analyzed the energy and groundwater consumption trend based on 15 textile dyeing mills in Bangladesh in 2019. The article was set up as a critical review of the failure criteria that guide the selection of the most suitable criterion for the chosen case study. Long-term key performance indicator (KPI) reduction is set to a baseline by reducing energy and groundwater consumption in textile dyeing mills. The overall calculation can vary by location of textile dyeing mills worldwide, the number of textile dyeing mills, and the timelines. This case study was limited to energy and groundwater consumption trends in textile dyeing mills in Bangladesh. Future recommendations of this study could be expanded to other textile regions in Bangladesh.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Niinimäki, K.; Peters, G.; Dahlbo, H.; Perry, P.; Rissanen, T.; Gwilt, A. The environmental price of fast fashion. Nat. Rev. Earth Environ. 2020, 1, 189–200. [Google Scholar] [CrossRef]

- Choudhury, A.K.R. Environmental impacts of the textile industry and its assessment through life cycle assessment. In Roadmap to Sustainable Textiles and Clothing; Muthu, S.S., Ed.; Springer: Singapore, 2014; pp. 1–39. [Google Scholar] [CrossRef]

- Palamutcu, S. Energy footprints in the textile industry. In Handbook of Life Cycle Assessment (LCA) of Textiles and Clothing; Elsevier: Amsterdam, The Netherlands, 2015; pp. 31–61. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L. A technical review of emerging technologies for energy and water efficiency and pollution reduction in the textile industry. J. Clean. Prod. 2015, 95, 30–44. [Google Scholar] [CrossRef]

- Lehmann, M.; Arici, G.; Martinez-pardo, C. Pulse of the Fashion, Global Fashion Agenda & Boston Consulting Group & Sustainable Apparel Coalition. 2019. Available online: http://media-publications.bcg.com/france/Pulse-of-the-Fashion-Industry2019.pdf (accessed on 28 August 2022).

- Rather, L.J.; Jameel, S.; Dar, O.A.; Ganie, S.A.; Bhat, K.A.; Mohammad, F. Advances in the sustainable technologies for water conservation in textile industries. In Water in Textiles and Fashion; Elsevier: Amsterdam, The Netherlands, 2019; pp. 175–194. [Google Scholar] [CrossRef]

- BGMEA. Export Performance. 2022. Available online: https://www.bgmea.com.bd/page/Export_Performance (accessed on 28 August 2022).

- Agoncillo, J. “Rapid Assessment of Greater Dhaka Groundwater Sustainability”, 2030 Water Resources Group, 11 November 2019. Available online: https://2030wrg.org/rapid-assessment-of-greater-dhaka-groundwater-sustainability/ (accessed on 28 August 2022).

- Mathews, B. Water issues could harm Bangladesh textile sector. Ecotextile News, 1 February 2016. [Google Scholar]

- Ashraf, A. Zero Liquid Discharge: A Success Story of Tirupur Textile Cluster; Partnership for Cleaner Textile (PaCT): Dhaka, Bangladesh, 2015; pp. 41–43. [Google Scholar]

- Islam, D.S.; Islam, F.F. Spatial Disparity of Groundwater Depletion in Dhaka City. In Proceedings of the 15th International Conference on Environmental Science and Technology, Rhodes, Greece, 31 August–2 September 2017; Volume 31, p. 7. [Google Scholar]

- Hoque, M.A.; Hoque, M.M.; Ahmed, K.M. Declining groundwater level and aquifer dewatering in Dhaka metropolitan area, Bangladesh: Causes and quantification. Hydrogeol. J. 2007, 15, 1523–1534. [Google Scholar] [CrossRef]

- Hussain, T.; Wahab, A. A critical review of the current water conservation practices in textile wet processing. J. Clean. Prod. 2018, 198, 806–819. [Google Scholar] [CrossRef]

- Ozturk, E.; Koseoglu, H.; Karaboyacı, M.; Yigit, N.O.; Yetis, U.; Kitis, M. Minimization of water and chemical use in a cotton/polyester fabric dyeing textile mill. J. Clean. Prod. 2016, 130, 92–102. [Google Scholar] [CrossRef]

- Amar, N.B.; Kechaou, N.; Palmeri, J.; Deratani, A.; Sghaier, A. Comparison of tertiary treatment by nanofiltration and reverse osmosis for water reuse in denim textile industry. J. Hazard. Mater. 2009, 170, 111–117. [Google Scholar] [CrossRef] [PubMed]

- Brik, M.; Schoeberl, P.; Chamam, B.; Braun, R.; Fuchs, W. Advanced treatment of textile wastewater towards reuse using a membrane bioreactor. Process Biochem. 2006, 41, 1751–1757. [Google Scholar] [CrossRef]

- Dasgupta, J.; Sikder, J.; Chakraborty, S.; Curcio, S.; Drioli, E. Remediation of textile effluents by membrane based treatment techniques: A state of the art review. J. Environ. Manag. 2015, 147, 55–72. [Google Scholar] [CrossRef]

- Ozturk, E.; Yetis, U.; Dilek, F.B.; Demirer, G.N. A chemical substitution study for a wet processing textile mill in Turkey. J. Clean. Prod. 2009, 17, 239–247. [Google Scholar] [CrossRef]

- Çay, A. Energy consumption and energy saving potential in clothing industry. Energy 2018, 159, 74–85. [Google Scholar] [CrossRef]

- Brander, M.; Sood, A.; Wylie, C.; Haughton, A.; Lovell, J. Electricity-specific emission factors for grid electricity. Ecometrica 2011, 1–22. [Google Scholar]

- Ozturk, E.; Karaboyacı, M.; Yetis, U.; Yigit, N.O.; Kitis, M. Evaluation of integrated pollution prevention control in a textile fiber production and dyeing mill. J. Clean. Prod. 2015, 88, 116–124. [Google Scholar] [CrossRef]

- Samanta, K.K.; Pandit, P.; Samanta, P.; Basak, S. Water consumption in textile processing and sustainable approaches for its conservation. In Water in Textiles and Fashion; Elsevier: Amsterdam, The Netherlands, 2019; pp. 41–59. [Google Scholar] [CrossRef]

- Asghar, A.; Raman, A.A.A.; Daud, W.M.A.W. Advanced oxidation processes for in-situ production of hydrogen peroxide/hydroxyl radical for textile wastewater treatment: A review. J. Clean. Prod. 2015, 87, 826–838. [Google Scholar] [CrossRef]

- Hossain, L.; Sarker, S.K.; Khan, M.S. Evaluation of present and future wastewater impacts of textile dyeing industries in Bangladesh. Environ. Dev. 2018, 26, 23–33. [Google Scholar] [CrossRef]

- Islam, M.; Chowdhury, M.; Billah, M.; Tusher, T.; Sultana, N. Investigation of effluent quality discharged from the textile industry of purbani group, Gazipur, Bangladesh and It’s textile industry of purbani group, Gazipur, Bangladesh and It’s management. Bangladesh J. Environ. Sci. 2012, 23, 123–130. [Google Scholar]

- Sultana, M.S.; Islam, M.S.; Saha, R.; Al-Mansur, M. Impact of the effluents of textile dyeing industries on the surface water quality inside D.N.D embankment, Narayanganj. Bangladesh J. Sci. Ind. Res. 1970, 44, 65–80. [Google Scholar] [CrossRef]

- Bhuiyan, M.A.H.; Suruvi, N.I.; Dampare, S.B.; Islam, M.A.; Quraishi, S.B.; Ganyaglo, S.; Suzuki, S. Investigation of the possible sources of heavy metal contamination in lagoon and canal water in the tannery industrial area in Dhaka, Bangladesh. Environ. Monit. Assess. 2011, 175, 633–649. [Google Scholar] [CrossRef]

- Banglapedia. Dhaka District. 2022. Available online: https://en.banglapedia.org/index.php/Dhaka_District (accessed on 28 August 2022).

- Ali, T. Waste of Water, Way to Disaster, the Daily Star. 2019. Available online: https://www.thedailystar.net/supplements/news/waste-water-way-disaster-1718767 (accessed on 28 August 2022).

- Khan, M.R.; Koneshloo, M.; Knappett, P.S.K.; Ahmed, K.M.; Bostick, B.; Mailloux, B.J.; Mozumder, R.; Zahid, A.; Harvey, C.; Van Geen, A.; et al. Megacity pumping and preferential flow threaten groundwater quality. Nat. Commun. 2016, 7, 12833. [Google Scholar] [CrossRef] [Green Version]

- Akan, A.E.; Akan, A.P. Potential of reduction in carbon dioxide equivalent emissions via energy efficiency for a textile factory. J. Energy Syst. 2018, 2, 57–69. [Google Scholar] [CrossRef]

- Laurent, A.; Olsen, S.I.; Hauschild, M.Z. Carbon footprint as environmental performance indicator for the manufacturing industry. CIRP Ann. 2010, 59, 37–40. [Google Scholar] [CrossRef]

- Muthu, S.S.; Li, Y.; Hu, J.Y.; Ze, L. Carbon footprint reduction in the textile process chain: Recycling of textile materials. Fibers Polym. 2012, 13, 1065–1070. [Google Scholar] [CrossRef]

| Factory | Total Production (kg) | Total Electricity Use (kWh) | Extracted Groundwater (in Million Liters) | Discharged Wastewater (in Million Liters) |

|---|---|---|---|---|

| F1 | 4,330,515.00 | 15,125,711.00 | 744.05 | 624.19 |

| F2 | 9,088,174.00 | 20,034,081.00 | 1455.87 | 865.66 |

| F3 | 4,413,619.00 | 6,673,371.00 | 687.66 | 340.77 |

| F4 | 3,639,554.00 | 7,566,789.00 | 533.58 | 501.68 |

| F5 | 2,409,076.00 | 8,099,029.00 | 477.45 | 372.53 |

| F6 | 4,083,918.00 | 13,265,449.00 | 703.73 | 481.55 |

| F7 | 11,193,569.00 | 21,806,157.00 | 1297.86 | 922.51 |

| F8 | 4,355,228.00 | 6,595,024.00 | 470.36 | 270.21 |

| F9 | 4,049,474.00 | 6,992,793.00 | 401.49 | 350.37 |

| F10 | 10,702,135.00 | 6,5546454.00 | 1302.71 | 851.50 |

| F11 | 5,223,919.00 | 9,699,231.00 | 652.66 | 358.01 |

| F12 | 41,530,362.00 | 57,402,492.00 | 4526.32 | 2815.04 |

| F13 | 2,553,747.00 | 4,194,361.00 | 356.67 | 260.12 |

| F14 | 2,895,710.00 | 4,574,060.00 | 371.86 | 281.81 |

| F15 | 3,574,246.00 | 17,766,474.00 | 436.65 | 307.67 |

| Country | kgCO2/kWh | kgCH4/kWh | kgN2O/kWh |

|---|---|---|---|

| Bangladesh | 0.6371 | 0.00001236 | 0.00000191 |

| China | 0.9746 | 0.00001047 | 0.00001521 |

| Cambodia | 1.1708 | 0.00004638 | 0.00000928 |

| India | 1.3332 | 0.00001552 | 0.00002011 |

| Pakistan | 0.4734 | 0.00001384 | 0.00000243 |

| Vietnam | 0.4668 | 0.00000705 | 0.00000420 |

| Sri Lanka | 0.4172 | 0.00001644 | 0.00000329 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mamun, A.A.; Bormon, K.K.; Rasu, M.N.S.; Talukder, A.; Freeman, C.; Burch, R.; Chander, H. An Assessment of Energy and Groundwater Consumption of Textile Dyeing Mills in Bangladesh and Minimization of Environmental Impacts via Long-Term Key Performance Indicators (KPI) Baseline. Textiles 2022, 2, 511-523. https://doi.org/10.3390/textiles2040029

Mamun AA, Bormon KK, Rasu MNS, Talukder A, Freeman C, Burch R, Chander H. An Assessment of Energy and Groundwater Consumption of Textile Dyeing Mills in Bangladesh and Minimization of Environmental Impacts via Long-Term Key Performance Indicators (KPI) Baseline. Textiles. 2022; 2(4):511-523. https://doi.org/10.3390/textiles2040029

Chicago/Turabian StyleMamun, Abdullah Al, Koushik Kumar Bormon, Mst Nigar Sultana Rasu, Amit Talukder, Charles Freeman, Reuben Burch, and Harish Chander. 2022. "An Assessment of Energy and Groundwater Consumption of Textile Dyeing Mills in Bangladesh and Minimization of Environmental Impacts via Long-Term Key Performance Indicators (KPI) Baseline" Textiles 2, no. 4: 511-523. https://doi.org/10.3390/textiles2040029

APA StyleMamun, A. A., Bormon, K. K., Rasu, M. N. S., Talukder, A., Freeman, C., Burch, R., & Chander, H. (2022). An Assessment of Energy and Groundwater Consumption of Textile Dyeing Mills in Bangladesh and Minimization of Environmental Impacts via Long-Term Key Performance Indicators (KPI) Baseline. Textiles, 2(4), 511-523. https://doi.org/10.3390/textiles2040029