Hemp: From Field to Fiber—A Review

Abstract

:1. Introduction

2. Discussion

2.1. Industrial Hemp

2.2. Growing Industrial Hemp

2.3. Retting Process

2.4. Fiber Extraction

2.5. Properties of Hemp Fiber

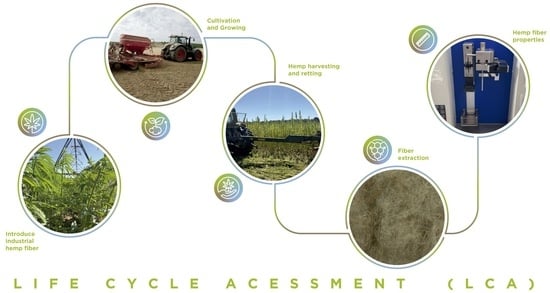

2.6. Hemp’s Lyfe Cicle Assessment

3. Conclusions

4. Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Exchange, T. Preferred Fiber & Materials Market Report 2021; Textile Exchange: Lamesa, TX, USA, 2022. [Google Scholar]

- European Parliament News. The Impact of Textile Production and Waste on the Environment (Infographic). 2022. Available online: https://www.europarl.europa.eu/news/en/headlines/society/20201208STO93327/the-impact-of-textile-production-and-waste-on-the-environment-infographics (accessed on 30 October 2022).

- Bick, R.; Halsey, E.; Ekenga, C.C. The global environmental injustice of fast fashion. Environ. Health 2018, 17, 92. [Google Scholar] [CrossRef]

- Niinimäki, K.; Peters, G.; Dahlbo, H.; Perry, P.; Rissanen, T.; Gwilt, A. The environmental price of fast fashion. Nat. Rev. Earth Environ. 2020, 1, 189–200. [Google Scholar] [CrossRef]

- Karthik, T.; Rathinamoorthy, R. Sustainable synthetic fibre production. In Sustainable Fibres and Textiles; Woodhead Publishing: Sawston, UK, 2017; pp. 191–240. [Google Scholar] [CrossRef]

- Ranasinghe, L.; Jayasooriya, V. Ecolabelling in textile industry: A review. Resour. Environ. Sustain. 2021, 6, 100037. [Google Scholar] [CrossRef]

- Chen, H.-L.; Burns, L.D. Environmental Analysis of Textile Products. Cloth. Text. Res. J. 2006, 24, 248–261. [Google Scholar] [CrossRef]

- Kamaruddin, Z.H.; Jumaidin, R.; Rushdan, A.I.; Selamat, M.Z.; Alamjuri, R.H. Characterization of natural cellulosic fiber isolated from Malaysian Cymbopogan citratus leaves. BioResources 2021, 16, 7728–7749. [Google Scholar] [CrossRef]

- Sachelaru, A.G. Isolation of Cellulose Fibers from Hemp for Textile Industry. Master’s Thesis, Groningen University, Groningen, The Netherlands, 2019. [Google Scholar]

- Rani, K.; Ahirwar, M.; Behera, B.K. Comparative Analysis of Alkaline and Enzymatic Degumming Process of Hemp Fibers. J. Inst. Eng. Ser. E 2020, 101, 1–10. [Google Scholar] [CrossRef]

- Rupasinghe, H.V.; Davis, A.; Kumar, S.K.; Murray, B.; Zheljazkov, V.D. Industrial hemp (Cannabis sativa subsp. sativa) as an emerging source for value-added functional food ingredients and nutraceuticals. Molecules 2020, 25, 4078. [Google Scholar] [CrossRef]

- Exchange, T. Growing Hemp for the Future; Textile Exchange: Lamesa, TX, USA, 2023. [Google Scholar]

- Tancig, M.; Kelly-Begazo, C.; Kaur, N.; Sharma, L.; Brym, Z. Industrial Hemp in the United States: Definition and History: SS-AGR-457/AG458, 9/2021. EDIS 2021, 2021. [Google Scholar] [CrossRef]

- European Union. Commission Regulation (EU) 2022/1393 of 11 August 2022 amending Regulation (EC) No 1881/2006 as regards maximum levels of delta-9-tetrahydrocannabinol (Δ9-THC) in hemp seeds and products derived therefrom (Text with EEA relevance). Off. J. Eur. Union 2022, 211, 83–85. Available online: http://data.europa.eu/eli/reg/2022/1393/oj (accessed on 30 October 2023).

- Schluttenhofer, C.; Yuan, L. Challenges towards Revitalizing Hemp: A Multifaceted Crop. Trends Plant Sci. 2017, 22, 917–929. [Google Scholar] [CrossRef]

- Mańkowski, J.; Kołodziej, J.; Pudełko, K.; Kozłowski, R.M. Bast fibres: The role of hemp (Cannabis sativa L.) in remediation of degraded lands. In Handbook of Natural Fibres; Woodhead Publishing: Sawston, UK, 2020; pp. 393–417. [Google Scholar] [CrossRef]

- Thümmler, K.; Fischer, J.; Fischer, S.; Kosan, B.; Meister, F. Lyohemp™ Fibres from Hemp Shive Dissolving Pulp. Lenzing. Berichte 2022, 97, 25–31. [Google Scholar]

- Gusovius, H.J.; Hoffmann, T.; Budde, J.; Lühr, C. Still special? Harvesting procedures for industrial hemp. Landtechnik 2016, 71, 14–24. [Google Scholar] [CrossRef]

- Zimniewska, M. Hemp Fibre Properties and Processing Target Textile: A Review. Materials 2022, 15, 1901. [Google Scholar] [CrossRef] [PubMed]

- European Commission; Directorate-General for Communication. European Green Deal: Delivering on Our Targets; Publications Office of the European Union: Luxembourg, 2021. [Google Scholar]

- Food and Agriculture Organization of the United Nations. FAOSTAT. 2023. Available online: https://www.fao.org/faostat/en/#data/QCL/visualize (accessed on 2 November 2023).

- United States Department of Agriculture. Econnomics, Statistics and Market Information System. USDA. 2023. Available online: https://usda.library.cornell.edu/concern/publications/gf06h2430?locale=en (accessed on 2 November 2023).

- European Commision. Hemp Production in the EU. 2023. Available online: https://agriculture.ec.europa.eu/farming/crop-productions-and-plant-based-products/hemp_en (accessed on 2 November 2023).

- Clarke, R.C. Traditional Fiber Hemp (Cannabis) Production, Processing, Yarn Making, and Weaving Strategies—Functional Constraints and Regional Responses. Part 1. J. Nat. Fibers 2010, 7, 118–153. [Google Scholar] [CrossRef]

- Gill, A.R.; Loveys, B.R.; Cavagnaro, T.R.; Burton, R.A. The potential of industrial hemp (Cannabis sativa L.) as an emerging drought resistant fibre crop. Plant Soil 2023, 493, 7–16. [Google Scholar] [CrossRef]

- Muzyczek, M. The use of flax and hemp for textile applications. In Handbook of Natural Fibres; Woodhead Publishing: Sawston, UK, 2020; pp. 147–167. [Google Scholar] [CrossRef]

- Amaducci, S.; Scordia, D.; Liu, F.; Zhang, Q.; Guo, H.; Testa, G.; Cosentino, S. Key cultivation techniques for hemp in Europe and China. Ind. Crop. Prod. 2015, 68, 2–16. [Google Scholar] [CrossRef]

- Assirelli, A.; Re, L.D.; Esposito, S.; Cocchi, A.; Santangelo, E. The Mechanical Harvesting of Hemp Using In-Field Stand-Retting: A Simpler Approach Converted to the Production of Fibers for Industrial Use. Sustainability 2020, 12, 8795. [Google Scholar] [CrossRef]

- Tilkat, E.; Hoşer, A.; Tilkat, E.A.; Süzerer, V.; Çiftçi, Y.Ö. Production of Industrial Hemp: Breeding Strategies, Limitations, Economic Expectations, and Potential Applications. Türk Bilimsel Derlemeler Derg. 2023, 16, 54–74. [Google Scholar]

- HEMPFLAX. Double Cut Combine. GROENOORD. 2023. Available online: https://www.hempflax.com/wp-content/uploads/HempFlax-Groenoord-Double-Cut-Combine-Prospectus.pdf (accessed on 2 November 2023).

- Phipps, B.; Schluttenhofer, C. Perspectives of industrial hemp cultivation. In Industrial Hemp; Academic Press: Cambridge, MA, USA, 2022; pp. 1–36. [Google Scholar] [CrossRef]

- Vandepitte, K.; Vasile, S.; Vermeire, S.; Vanderhoeven, M.; Van der Borght, W.; Latré, J.; De Raeve, A.; Troch, V. Hemp (Cannabis sativa L.) for high-value textile applications: The effective long fiber yield and quality of different hemp varieties, processed using industrial flax equipment. Ind. Crop. Prod. 2020, 158, 112969. [Google Scholar] [CrossRef]

- Réquilé, S.; Mazian, B.; Grégoire, M.; Musio, S.; Gautreau, M.; Nuez, L.; Day, A.; Thiébeau, P.; Philippe, F.; Chabbert, B.; et al. Exploring the dew retting feasibility of hemp in very contrasting European environments: Influence on the tensile mechanical properties of fibres and composites. Ind. Crops Prod. 2021, 164, 113337. [Google Scholar] [CrossRef]

- Thygesen, A.; Lui, M.; Meyer, A.S.; Daniel, G. Hemp fibres: Enzymatic effect of microbial processing on fibre bundle structure. Proc. Risø Int. Symp. Mater. Sci. 2013, 34, 373–380. [Google Scholar]

- Manian, A.P.; Cordin, M.; Pham, T. Extraction of cellulose fibers from flax and hemp: A review. Cellulose 2021, 28, 8275–8294. [Google Scholar] [CrossRef]

- Zhang, X.; Guo, J.; Ma, Y.; Lyu, L.; Ji, Y.; Guo, Y.; Hao, X. Green Degumming Technology of Hemp and a Comparison between Chemical and Biological Degumming. ACS Omega 2021, 6, 35067–35075. [Google Scholar] [CrossRef] [PubMed]

- Lyu, P.; Zhang, Y.; Wang, X.; Hurren, C. Degumming methods for bast fibers—A mini review. Ind. Crop. Prod. 2021, 174, 114158. [Google Scholar] [CrossRef]

- Mazian, B.; Bergeret, A.; Benezet, J.-C.; Malhautier, L. A Comparative Study of the Effect of Field Retting Time on the Properties of Hemp Fibres Harvested at Different Growth Stages. Fibers 2019, 7, 108. [Google Scholar] [CrossRef]

- Majumdar, B.; Saha, A.R.; Sarkar, S.; Datta, S.; Mazumdar, S.P.; Saha, D.; Chattopadhyay, L.; Barai, S.; Kar, G. Improved microbial retting and quality jute (Corchorus spp.) fibre production in India—A review. Indian J. Agric. Sci. 2022, 92, 1415–1422. [Google Scholar] [CrossRef]

- Yadav, S.; Yadav, P.K.; Dubey, A.K.; Anand, G.; Tanveer, A.; Dwivedi, R.; Yadav, D. Molecular biology, genomics and bioinformatics insights into fungal pectin lyase: An overview. In Applications of Biotechnology for Sustainable Development; Springer: Singapore, 2017; pp. 51–64. [Google Scholar] [CrossRef]

- Ahmed, A.T.M.F.; Islam, Z.; Mahmud, S.; Sarker, E.; Islam, R. Hemp as a potential raw material toward a sustainable world: A review. Heliyon 2022, 8, e08753. [Google Scholar] [CrossRef] [PubMed]

- Jönsson, L.J.; Martín, C. Pretreatment of lignocellulose: Formation of inhibitory by-products and strategies for minimizing their effects. Bioresour. Technol. 2016, 199, 103–112. [Google Scholar] [CrossRef] [PubMed]

- Madhav, S.; Ahamad, A.; Singh, P.; Mishra, P.K. A review of textile industry: Wet processing, environmental impacts, and effluent treatment methods. Environ. Qual. Manag. 2018, 27, 31–41. [Google Scholar] [CrossRef]

- Yeping, X.; Jianyong, Y.; Liu, L.; Ruiyun, Z.; Yongshuai, Q.; Miaolei, J. The chemo-enzymatic modification and degumming of hemp fiber by the laccase-2,2,6,6-tetramethylpiperidine-1-oxyl radical-hemicellulase system and physico-chemical properties of the products. Text. Res. J. 2019, 89, 2433–2443. [Google Scholar] [CrossRef]

- Liu, M.; Meyer, A.S.; Fernando, D.; Silva, D.A.S.; Daniel, G.; Thygesen, A. Effect of pectin and hemicellulose removal from hemp fibres on the mechanical properties of unidirectional hemp/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 724–735. [Google Scholar] [CrossRef]

- Wang, H.; Postle, R.; Kessler, R.; Kessler, W. Removing Pectin and Lignin During Chemical Processing of Hemp for Textile Applications. Text. Res. J. 2003, 73, 664–669. [Google Scholar] [CrossRef]

- Miao, Q.; Zhang, X.; Wang, Y.; Li, X.; Wang, Z.; Tian, L.; Qu, L.; Wei, Y. Characterization of Novel Pectinolytic Enzymes Derived from the Efficient Lignocellulose Degradation Microbiota. Biomolecules 2022, 12, 1388. [Google Scholar] [CrossRef]

- Fadiji, A.E.; Babalola, O.O. Metagenomics methods for the study of plant-associated microbial communities: A review. J. Microbiol. Methods 2020, 170, 105860. [Google Scholar] [CrossRef]

- Nazir, A. Review on metagenomics and its applications. Imp. J. Intersd. Res. 2016, 2, 277–286. [Google Scholar]

- Duan, S.W.; Cheng, L.F.; Feng, X.Y.; Yang, Q.; Liu, Z.Y.; Zheng, K.; De Peng, Y. Insights on bio-degumming of kenaf bast based on metagenomic and proteomics. BMC Genom. 2020, 21, 121. [Google Scholar] [CrossRef]

- Hossain, M.; Siddiquee, S.; Kumar, V. Isolation of Alkalophilic Pectinolytic Bacteria and their Bio Retting Effect on Kenaf Fiber Compositions. Alinteri J. Agric. Sci. 2021, 36, 156–165. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, Q.; Wang, P. Bioprocessing of bast fibers. In Advances in Textile Biotechnology; Woodhead Publishing: Sawston, UK, 2019; pp. 1–19. [Google Scholar] [CrossRef]

- Aktar, N.; Mannan, E.; Kabir, S.M.T.; Hasan, R.; Hossain, S.; Ahmed, R.; Ahmed, B.; Islam, S. Comparative metagenomics and microbial dynamics of jute retting environment. Int. Microbiol. 2023, 27, 113–126. [Google Scholar] [CrossRef]

- Law, A.D.; McNees, C.R.; Moe, L.A. The Microbiology of Hemp Retting in a Controlled Environment: Steering the Hemp Microbiome towards More Consistent Fiber Production. Agronomy 2020, 10, 492. [Google Scholar] [CrossRef]

- Djemiel, C.; Grec, S.; Hawkins, S. Characterization of Bacterial and Fungal Community Dynamics by High-Throughput Sequencing (HTS) Metabarcoding during Flax Dew-Retting. Front. Microbiol. 2017, 8, 2052. [Google Scholar] [CrossRef]

- Horne, M.R. Bast fibres: Hemp cultivation and production. In Handbook of Natural Fibres; Woodhead Publishing: Sawston, UK, 2020; pp. 163–196. [Google Scholar] [CrossRef]

- Grégoire, M.; Bar, M.; De Luycker, E.; Musio, S.; Amaducci, S.; Gabrion, X.; Placet, V.; Ouagne, P. Comparing flax and hemp fibres yield and mechanical properties after scutching/hackling processing. Ind. Crop. Prod. 2021, 172, 114045. [Google Scholar] [CrossRef]

- Grégoire, M.; Barthod-Malat, B.; Labonne, L.; Evon, P.; De Luycker, E.; Ouagne, P. Investigation of the potential of hemp fibre straws harvested using a combine machine for the production of technical load-bearing textiles. Ind. Crop. Prod. 2020, 145, 111988. [Google Scholar] [CrossRef]

- Pinsard, L.; Revol, N.; Pomikal, H.; De Luycker, E.; Ouagne, P. Production of Long Hemp Fibers Using the Flax Value Chain. Fibers 2023, 11, 38. [Google Scholar] [CrossRef]

- Musio, S.; Müssig, J.; Amaducci, S. Optimizing Hemp Fiber Production for High Performance Composite Applications. Front. Plant Sci. 2018, 9, 1702. [Google Scholar] [CrossRef] [PubMed]

- Wardiningsih, W.; Sopyan, M.; Pradana, S.; Pudjiati, P.; Rudy, R. Characterization of Natural Fiber Extracted from Etlingera elatior Stalk for Textile Applications. J. Nat. Fibers 2021, 19, 9384–9395. [Google Scholar] [CrossRef]

- Smole, M.; Hribernik, S.; Stana Kleinschek, K.; Kreže, T. Plant fibres for textile and technical applications. In Advances in Agrophysical Research; IntechOpen: London, UK, 2013; pp. 369–398. [Google Scholar]

- Mahir, F.I.; Keya, K.N.; Sarker, B.; Nahiun, K.M.; Khan, R.A. A brief review on natural fiber used as a replacement of synthetic fiber in polymer composites. Mater. Eng. Res. 2019, 1, 88–99. [Google Scholar] [CrossRef]

- Wardiningsih, W.; Efendi, S.; Mulyani, R.W.; Totong, T.; Rudy, R.; Pradana, S. Extraction and characterization of curcuma zedoaria pseudo-stems fibers for textile application. Res. J. Text. Appar. [CrossRef]

- Stevulova, N.; Cigasova, J.; Estokova, A.; Terpakova, E.; Geffert, A.; Kacik, F.; Singovszka, E.; Holub, M. Properties Characterization of Chemically Modified Hemp Hurds. Materials 2014, 7, 8131–8150. [Google Scholar] [CrossRef]

- Nacci, T.; Sabatini, F.; Cirrincione, C.; Degano, I.; Colombini, M.P. Characterization of textile fibers by means of EGA-MS and Py-GC/MS. J. Anal. Appl. Pyrolysis 2022, 165, 105570. [Google Scholar] [CrossRef]

- Wang, J.; Ramaswamy, G.N. Effects of Chemical Processing on Hemp and Kenaf Dyeing Properties. AATCC Rev. 2005, 5, 21–24. [Google Scholar]

- Koh, J. Dyeing of cellulosic fibres. In Handbook of Textile and Industrial Dyeing; Clark, M., Ed.; Woodhead Publishing: Sawston, UK, 2011. [Google Scholar] [CrossRef]

- Özomay, M.; Akalın, M. Optimization of Fastness Properties with Gray Relational Analysis Method in Dyeing of Hemp Fabric with Natural and Classic Mordant. J. Nat. Fibers 2022, 19, 2914–2928. [Google Scholar] [CrossRef]

- Araújo, P.L.D.S.D. Modelos de Padrões de Qualidade Para Produção do fio de Algodão, Utilizando Recursos da Tecnologia da Computação. Ph.D. Dissertation, University of Minho, Braga, Portugal, 2019. [Google Scholar]

- Tahir, P.M.; Ahmed, A.B.; SaifulAzry, S.O.A.; Ahmed, Z. Retting process of some bast plant fibers and its effect on fibre quality: A review. BioResources 2011, 6, 5260–5281. [Google Scholar] [CrossRef]

- Jayaprakash, K.; Osama, A.; Rajagopal, R.; Goyette, B.; Karthikeyan, O.P. Agriculture Waste Biomass Repurposed into Natural Fibers: A Circular Bioeconomy Perspective. Bioengineering 2022, 9, 296. [Google Scholar] [CrossRef]

- Samanta, K.K.; Roy, A.N.; Baite, H.; Debnath, S.; Ammayappan, L.; Nayak, L.K.; Singha, A.; Kundu, T.K. Applications of Nettle Fibre in Textile: A Brief Review. Int. J. Bioresouce Sci. 2021, 8, 39–45. [Google Scholar] [CrossRef]

- Bhardwaj, S.; Sood, S.; Kavita. Morphology and Proprieties of the Stinging Nettle fibre (Bisshu Ghass) in Himalayan Foot Hills. Int. J. Text. Fash. 2020, 10, 2319–4510. [Google Scholar]

- Bogard, F.; Bach, T.; Abbes, B.; Bliard, C.; Maalouf, C.; Bogard, V.; Beaumont, F.; Polidori, G. A comparative review of Nettle and Ramie fiber and their use in biocomposites, particularly with a PLA matrix. J. Nat. Fibers 2022, 19, 8205–8229. [Google Scholar] [CrossRef]

- Martin, N.; Mouret, N.; Davies, P.; Baley, C. Influence of the degree of retting of flax fibers on the tensile properties of single fibers and short fiber/polypropylene composites. Ind. Crop. Prod. 2013, 49, 755–767. [Google Scholar] [CrossRef]

- Dai, D.X. Fibers. In Biomechanical Engineering of Textiles and Clothing, 1st ed.; Li, Y., Dai, D.X., Eds.; Woodhead Publishing: Cambridge, UK, 2006. [Google Scholar] [CrossRef]

- Awais, H.; Nawab, Y.; Anjang, A.; Akil, H.M.; Abidin, M.S.Z. Mechanical Properties of Continuous Natural Fibres (Jute, Hemp, Flax) Reinforced Polypropylene Composites Modified with Hollow Glass Microspheres. Fibers Polym. 2020, 21, 2076–2083. [Google Scholar] [CrossRef]

- Silva, A.P.V. Industrialização Têxtil da Fibra Curauá. Master’s Thesis, University of Minho, Braga, Portugal, 2019. [Google Scholar]

- Summerscales, J.; Dissanayake, N.P.; Virk, A.S.; Hall, W. A review of bast fibres and their composites. Part 1—Fibres as reinforcements. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1329–1335. [Google Scholar] [CrossRef]

- Manaia, J.P.; Manaia, A.T.; Rodriges, L. Industrial Hemp Fibers: An Overview. Fibers 2019, 7, 106. [Google Scholar] [CrossRef]

- Ribeiro, J.; Bueno, G.; Martín, M.R.; Rocha, J. Experimental Study on Mechanical Properties of Hemp Fibers Influenced by Various Parameters. Sustainability 2023, 15, 9610. [Google Scholar] [CrossRef]

- Gieparda, W.; Rojewski, S.; Różańska, W. Effectiveness of Silanization and Plasma Treatment in the Improvement of Selected Flax Fibers’ Properties. Materials 2021, 14, 3564. [Google Scholar] [CrossRef] [PubMed]

- Konczewicz, W.; Wojtysiak, J. The effect of physical factors on the process of physical-mechanical degumming of flax fibers. Text. Res. J. 2015, 85, 391–403. [Google Scholar] [CrossRef]

- Heller, K.; Byczyńska, M. The Impact of Environmental Factors and Applied Agronomy on Quantitative and Qualitative Traits of Flax Fiber. J. Nat. Fibers 2015, 12, 26–38. [Google Scholar] [CrossRef]

- Kozłowski, R.; Czaplicki, Z.; Zaręba, S.; Mańkowski, J. OE Cotton Yarns with a High Content of Enzyme-Modified Flax Fibers. J. Nat. Fibers 2012, 9, 137–149. [Google Scholar] [CrossRef]

- Harzallah, O.; Benzina, H.; Drean, J.-Y. Physical and Mechanical Properties of Cotton Fibers: Single-fiber Failure. Text. Res. J. 2010, 80, 1093–1102. [Google Scholar] [CrossRef]

- Gordon, S.; Hsieh, Y.L. (Eds.) Cotton: Science and Technolog; Woodhead Publishing: Sawston, UK, 2006. [Google Scholar]

- Davies, G.; Bruce, D. Effect of Environmental Relative Humidity and Damage on the Tensile Properties of Flax and Nettle Fibers. Text. Res. J. 1998, 68, 623–629. [Google Scholar] [CrossRef]

- Kaynak, H.K.; Babaarslan, O. Breaking Strength and Elongation Properties of Polyester Woven Fabrics on the Basis of Filament Fineness. J. Eng. Fibers Fabr. 2015, 10, 155892501501000416. [Google Scholar] [CrossRef]

- de Beus, N.; Carus, M.; Barth, M. Carbon footprint and sustainability of different natural fibres for biocomposites and insulation material. Study Provid. Data Automot. Insul. Ind. 2019, 2019, 16–39. [Google Scholar]

- Shahzad, A. Hemp fiber and its composites—A review. J. Compos. Mater. 2012, 46, 973–986. [Google Scholar] [CrossRef]

- Zampori, L.; Dotelli, G.; Vernelli, V. Life Cycle Assessment of Hemp Cultivation and Use of Hemp-Based Thermal Insulator Materials in Buildings. Environ. Sci. Technol. 2013, 47, 7413–7420. [Google Scholar] [CrossRef]

- Wötzel, K.; Wirth, R.; Flake, M. Life cycle studies on hemp fibre reinforced components and ABS for automotive parts. Die Angew. Makromol. Chem. 1999, 272, 121–127. [Google Scholar] [CrossRef]

- Van Eynde, H. Comparative Life Cycle Assessment of Hemp and Cotton Fibres Used in Chinese Textile Manufacturing. Master Thesis, KU Leuven, Leuven, Belgium, 2015. [Google Scholar]

- van der Werf, H.M.; Turunen, L. The environmental impacts of the production of hemp and flax textile yarn. Ind. Crop. Prod. 2008, 27, 1–10. [Google Scholar] [CrossRef]

- van der Werf, H.M.G. Life Cycle Analysis of field production of fibre hemp, the effect of production practices on environmental impacts. Euphytica 2004, 140, 13–23. [Google Scholar] [CrossRef]

- González-García, S.; Hospido, A.; Feijoo, G.; Moreira, M. Life cycle assessment of raw materials for non-wood pulp mills: Hemp and flax. Resour. Conserv. Recycl. 2010, 54, 923–930. [Google Scholar] [CrossRef]

| Properties | Cotton | Hemp | Flax | Nettle | References |

|---|---|---|---|---|---|

| Fiber Length (mm) | 10–60 | 2–500 | 5–1000 | 16–171 | [9,32,41,59,62,63,64,65,66,67,68,69,70,71,72,73,74] |

| Diameter (µm) | 12–45 | 16–50 | 5–38 | 19–72 | [62,73,74,75,76,77,78] |

| Density (g/cm3) | 1.5–1.6 | 1.4–1.8 | 1.5 | 0.7–1.5 | [41,73,74,78,79,80,81,82,83] |

| Linear Mass (dTex) | 1–3.2 | 3.3–30 | 6–40 | 18–27 | [19,75,76,83,84,85,86,87,88] |

| Tensile Strength (Mpa) | 287–800 | 550–1110 | 88–1500 | 300–1500 | [9,19,65,73,79,89] |

| Tenacity (cN/dTex) | 3.6–8.2 | 2.5–8 | 2.3–11 | 2.4–6.0 | [19,73,74,79,89] |

| Elongation (%) | 3–10 | 1.6–3.3 | 1.3–3.3 | 1.6–2.9 | [41,61,63,73,77,89] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mariz, J.; Guise, C.; Silva, T.L.; Rodrigues, L.; Silva, C.J. Hemp: From Field to Fiber—A Review. Textiles 2024, 4, 165-182. https://doi.org/10.3390/textiles4020011

Mariz J, Guise C, Silva TL, Rodrigues L, Silva CJ. Hemp: From Field to Fiber—A Review. Textiles. 2024; 4(2):165-182. https://doi.org/10.3390/textiles4020011

Chicago/Turabian StyleMariz, João, Catarina Guise, Teresa Luísa Silva, Lúcia Rodrigues, and Carla Joana Silva. 2024. "Hemp: From Field to Fiber—A Review" Textiles 4, no. 2: 165-182. https://doi.org/10.3390/textiles4020011

APA StyleMariz, J., Guise, C., Silva, T. L., Rodrigues, L., & Silva, C. J. (2024). Hemp: From Field to Fiber—A Review. Textiles, 4(2), 165-182. https://doi.org/10.3390/textiles4020011