From Fabric to Fallout: A Systematic Review of the Impact of Textile Parameters on Fibre Fragment Release

Abstract

:1. Introduction

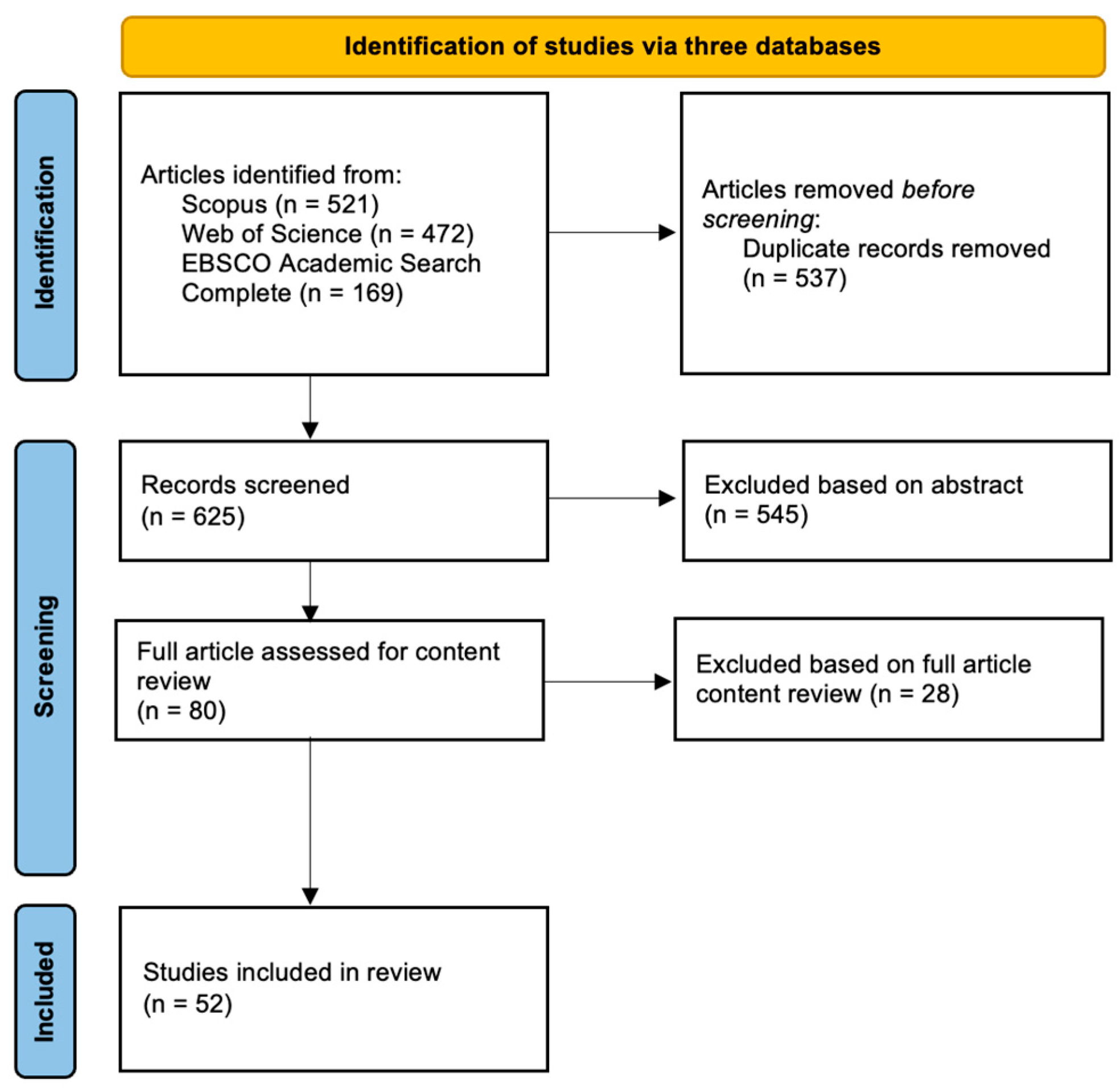

2. Methods

3. Results

| Ref. | Year | Samples Tested | Textile Parameter Studied | Findings | ||||

|---|---|---|---|---|---|---|---|---|

| Fibre | Yarn | Fabric | Finish | Garment | ||||

| [38] | 2016 |

| Y | - | - | - | - |

|

| [72] | 2017 |

| Y | Y | Y | - | - |

|

| [12] | 2017 |

| Y | - | Y | - | - |

|

| [21] | 2018 |

| Y | Y | Y | Y | - |

|

| [62] | 2018 |

| - | - | - | Y* | - |

|

| [50] | 2018 |

| Y* | - | Y* | - | Y* |

|

| [34] | 2019 |

| Y | - | Y | - | - |

|

| [63] | 2019 |

| - | - | - | Y* | - |

|

| [41] | 2019 |

| Y | Y | Y | - | - |

|

| [45] | 2019 |

| Y | Y | Y | - | - |

|

| [24] | 2019 |

| Y | Y | - | - | - |

|

| [39] | 2020 |

| - | Y | Y | Y | Y* |

|

| [64] | 2020 |

| - | Y | Y | Y | Y* |

|

| [35] | 2020 |

| Y | Y | Y | - | - |

|

| [9] | 2020 |

| Y | Y | Y | - | - |

|

| [69] | 2020 |

| Y | - | Y | - | - |

|

| [54] | 2021 |

| - | - | - | Y* | - |

|

| [47] | 2021 |

| - | - | Y* | - | - |

|

| [40] | 2021 |

| - | Y | - | - | - |

|

| [48] | 2021 |

| - | - | Y | - | - |

|

| [65] | 2021 |

| - | Y | - | - | Y |

|

| [13] | 2021 |

| Y | - | Y | Y | - |

|

| [44] | 2021 |

| Y* | Y* | - | - | - |

|

| [67] | 2021 |

| Y | Y | Y | Y | - | |

|

| |||||||

| ||||||||

| [10] | 2022 |

| Y | Y | Y | - | - |

|

| [49] | 2022 |

| - | - | Y | - | - |

|

| [73] | 2022 |

| Y | - | - | - | - |

|

| [11] | 2022 |

| Y | Y | Y | Y | - |

|

| [52] | 2022 |

| - | - | Y | Y* | - |

|

| [70] | 2022 |

| Y | Y | - | - | - |

|

| [71] | 2022 |

| - | Y* | - | - | - |

|

| [46] | 2022 |

| Y | - | Y | - | - |

|

| [58] | 2022 |

| - | - | Y | Y* | - |

|

| [42] | 2023 |

| - | Y* | - | - | - |

|

| [43] | 2023 |

| - | Y* | - | - | - |

|

| [59] | 2023 |

| - | - | Y | Y* | - |

|

| [74] | 2023 |

| - | Y | Y | Y | - |

|

| [75] | 2023 |

| Y* | - | - | - | - |

|

| [57] | 2023 |

| - | - | - | Y* | - |

|

| [76] | 2023 |

| Y | Y | Y | - | - |

|

| [77] | 2023 |

| - | - | Y | Y* | - |

|

| [55] | 2023 |

| - | - | Y | Y* | - |

|

| [66] | 2023 |

| - | - | - | - | Y* |

|

| [53] | 2023 |

| Y | - | Y | - | - |

|

| [68] | 2023 |

| Y | Y | Y | - | - |

|

| [78] | 2023 |

| - | Y | Y | Y | - |

|

| [37] | 2024 |

| Y* | - | - | Y | - |

|

| [36] | 2024 |

| Y* | Y* | Y* | - | - |

|

| [51] | 2024 |

| Y | - | Y | - | - |

|

| [61] | 2024 |

| Y | - | Y | Y | - |

|

| [60] | 2024 |

| - | Y | Y* | - |

| |

| [56] | 2024 |

| - | - | Y | - |

| |

4. Discussion

4.1. Fibre Properties

4.1.1. Fibre Tenacity

4.1.2. Fibre Type

4.1.3. Fibre Length

4.1.4. Fibre Interactions with Water

4.2. Yarn Properties

4.2.1. Staple vs. Filament Yarns

4.2.2. Yarn Count

4.2.3. Blended Yarns

4.2.4. Yarn Hairiness and Twist

4.2.5. Yarn Production Process

4.3. Fabric Properties

4.3.1. Knit vs. Woven Fabrics

4.3.2. Fabric Weight

4.3.3. Abrasion Resistance

4.4. Finishes and Treatments

4.4.1. Mechanical Processes

4.4.2. Chemical Finishes

4.4.3. Eco-Friendly Finishes

4.5. Garment Construction

4.5.1. Cutting Method

4.5.2. Sewing Method

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ReportLinker. Textile Global Market Report 2022. Available online: https://www.globenewswire.com/news-release/2022/04/06/2417253/0/en/Textile-Global-Market-Report-2022.html (accessed on 18 November 2023).

- Remy, N.; Speelman, E.; Swartz, S. Style That’s Sustainable: A New Fast-Fashion Formula. Available online: https://www.mckinsey.com/capabilities/sustainability/our-insights/style-thats-sustainable-a-new-fast-fashion-formula#/ (accessed on 8 October 2024).

- Niinimäki, K.; Peters, G.; Dahlbo, H.; Perry, P.; Rissanen, T.; Gwilt, A. The Environmental Price of Fast Fashion. Nat. Rev. Earth Environ. 2020, 1, 189–200. [Google Scholar] [CrossRef]

- Bick, R.; Halsey, E.; Ekenga, C.C. The Global Environmental Injustice of Fast Fashion. Environ. Health 2018, 17, 92. [Google Scholar] [CrossRef]

- Sarwar, T.; Khan, S. Textile Industry: Pollution Health Risks and Toxicity. In Textile Wastewater Treatment: Sustainable Bio-nano Materials and Macromolecules, Volume 1; Muthu, S.S., Khadir, A., Eds.; Sustainable Textiles: Production, Processing, Manufacturing & Chemistry; Springer Nature: Singapore, 2022; pp. 1–28. ISBN 978-981-19283-2-1. [Google Scholar]

- AATCC TM212-2021; Test Method for Fiber Fragment Release during Home Laundering. AATCC: Research Triangle Park, NC, USA, 2021.

- Weis, J.S.; De Falco, F. Microfibers: Environmental Problems and Textile Solutions. Microplastics 2022, 1, 626–639. [Google Scholar] [CrossRef]

- Galvão, A.; Aleixo, M.; De Pablo, H.; Lopes, C.; Raimundo, J. Microplastics in Wastewater: Microfiber Emissions from Common Household Laundry. Environ. Sci. Pollut. Res. 2020, 27, 26643–26649. [Google Scholar] [CrossRef]

- De Falco, F.; Cocca, M.; Avella, M.; Thompson, R.C. Microfiber Release to Water, via Laundering, and to Air, via Everyday Use: A Comparison between Polyester Clothing with Differing Textile Parameters. Environ. Sci. Technol. 2020, 54, 3288–3296. [Google Scholar] [CrossRef]

- Choi, S.; Kim, J.; Kwon, M. The Effect of the Physical and Chemical Properties of Synthetic Fabrics on the Release of Microplastics during Washing and Drying. Polymers 2022, 14, 3384. [Google Scholar] [CrossRef] [PubMed]

- Dreillard, M.; Barros, C.D.F.; Rouchon, V.; Emonnot, C.; Lefebvre, V.; Moreaud, M.; Guillaume, D.; Rimbault, F.; Pagerey, F. Quantification and Morphological Characterization of Microfibers Emitted from Textile Washing. Sci. Total Environ. 2022, 832, 154973. [Google Scholar] [CrossRef] [PubMed]

- Sillanpää, M.; Sainio, P. Release of Polyester and Cotton Fibers from Textiles in Machine Washings. Environ. Sci. Pollut. Res. 2017, 24, 19313–19321. [Google Scholar] [CrossRef]

- Kärkkäinen, N.; Sillanpää, M. Quantification of Different Microplastic Fibres Discharged from Textiles in Machine Wash and Tumble Drying. Environ. Sci. Pollut. Res. 2021, 28, 16253–16263. [Google Scholar] [CrossRef]

- Athey, S.N.; Adams, J.K.; Erdle, L.M.; Jantunen, L.M.; Helm, P.A.; Finkelstein, S.A.; Diamond, M.L. The Widespread Environmental Footprint of Indigo Denim Microfibers from Blue Jeans. Environ. Sci. Technol. Lett. 2020, 7, 840–847. [Google Scholar] [CrossRef]

- Adams, J.K.; Dean, B.Y.; Athey, S.N.; Jantunen, L.M.; Bernstein, S.; Stern, G.; Diamond, M.L.; Finkelstein, S.A. Anthropogenic Particles (Including Microfibers and Microplastics) in Marine Sediments of the Canadian Arctic. Sci. Total Environ. 2021, 784, 147155. [Google Scholar] [CrossRef] [PubMed]

- Textile Exchange. Materials Market Report 2023; Textile Exchange: Lamesa, TX, USA, 2023. [Google Scholar]

- Stanton, T.; James, A.; Prendergast-Miller, M.T.; Peirson-Smith, A.; KeChi-Okafor, C.; Gallidabino, M.D.; Namdeo, A.; Sheridan, K.J. Natural Fibers: Why Are They Still the Missing Thread in the Textile Fiber Pollution Story? Environ. Sci. Technol. 2024, 58, 12763–12766. [Google Scholar] [CrossRef]

- Li, L.; Frey, M.; Browning, K.J. Biodegradability Study on Cotton and Polyester Fabrics. J. Eng. Fibers Fabr. 2010, 5, 155892501000500406. [Google Scholar] [CrossRef]

- Royer, S.-J.; Wiggin, K.; Kogler, M.; Deheyn, D.D. Degradation of Synthetic and Wood-Based Cellulose Fabrics in the Marine Environment: Comparative Assessment of Field, Aquarium, and Bioreactor Experiments. Sci. Total Environ. 2021, 791, 148060. [Google Scholar] [CrossRef] [PubMed]

- Trunk, U.; Harding-Rolls, G.; Banegas, X.; Urbancic, N.; Rautner, M.; Holkar, V. Trashion: The Stealth Export of Waste Plastic Clothes to Kenya. Available online: https://changingmarkets.org/wp-content/uploads/2023/02/CM-Trashion-online-reports-layout.pdf (accessed on 8 October 2024).

- Carney Almroth, B.M.; Åström, L.; Roslund, S.; Petersson, H.; Johansson, M.; Persson, N.-K. Quantifying Shedding of Synthetic Fibers from Textiles; a Source of Microplastics Released into the Environment. Environ. Sci. Pollut. Res. 2018, 25, 1191–1199. [Google Scholar] [CrossRef]

- Browne, M.A.; Crump, P.; Niven, S.J.; Teuten, E.; Tonkin, A.; Galloway, T.; Thompson, R. Accumulation of Microplastic on Shorelines Worldwide: Sources and Sinks. Environ. Sci. Technol. 2011, 45, 9175–9179. [Google Scholar] [CrossRef]

- Periyasamy, A.P.; Tehrani-Bagha, A. A Review on Microplastic Emission from Textile Materials and Its Reduction Techniques. Polym. Degrad. Stab. 2022, 199, 109901. [Google Scholar] [CrossRef]

- Zambrano, M.C.; Pawlak, J.J.; Daystar, J.; Ankeny, M.; Cheng, J.J.; Venditti, R.A. Microfibers Generated from the Laundering of Cotton, Rayon and Polyester Based Fabrics and Their Aquatic Biodegradation. Mar. Pollut. Bull. 2019, 142, 394–407. [Google Scholar] [CrossRef]

- Seltenrich, N. New Link in the Food Chain? Marine Plastic Pollution and Seafood Safety. Environ. Health Perspect. 2015, 123, A34–A41. [Google Scholar] [CrossRef]

- Siddiqui, S.; Hutton, S.J.; Dickens, J.M.; Pedersen, E.I.; Harper, S.L.; Brander, S.M. Natural and Synthetic Microfibers Alter Growth and Behavior in Early Life Stages of Estuarine Organisms. Front. Mar. Sci. 2023, 9, 991650. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Q.; An, L.; Wang, M.; Yang, Q.; Zhu, B.; Ding, J.; Ye, C.; Xu, Y. Microfiber Pollution in the Earth System. Rev. Environ. Contam. Toxicol. 2022, 260, 13. [Google Scholar] [CrossRef]

- Periyasamy, A.P. Microfiber Emissions from Functionalized Textiles: Potential Threat for Human Health and Environmental Risks. Toxics 2023, 11, 406. [Google Scholar] [CrossRef] [PubMed]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations: New York City, NY, USA, 2015. [Google Scholar]

- Selonen, S.; Dolar, A.; Jemec Kokalj, A.; Skalar, T.; Parramon Dolcet, L.; Hurley, R.; van Gestel, C.A.M. Exploring the Impacts of Plastics in Soil—The Effects of Polyester Textile Fibers on Soil Invertebrates. Sci. Total Environ. 2020, 700, 134451. [Google Scholar] [CrossRef]

- Herweyers, L.; Catarci Carteny, C.; Scheelen, L.; Watts, R.; Du Bois, E. Consumers’ Perceptions and Attitudes toward Products Preventing Microfiber Pollution in Aquatic Environments as a Result of the Domestic Washing of Synthetic Clothes. Sustainability 2020, 12, 2244. [Google Scholar] [CrossRef]

- Grant, M.J.; Booth, A. A Typology of Reviews: An Analysis of 14 Review Types and Associated Methodologies. Health Inf. Libr. J. 2009, 26, 91–108. [Google Scholar] [CrossRef] [PubMed]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Belzagui, F.; Crespi, M.; Álvarez, A.; Gutiérrez-Bouzán, C.; Vilaseca, M. Microplastics’ Emissions: Microfibers’ Detachment from Textile Garments. Environ. Pollut. 2019, 248, 1028–1035. [Google Scholar] [CrossRef] [PubMed]

- Cesa, F.S.; Turra, A.; Checon, H.H.; Leonardi, B.; Baruque-Ramos, J. Laundering and Textile Parameters Influence Fibers Release in Household Washings. Environ. Pollut. 2020, 257, 113553. [Google Scholar] [CrossRef]

- Hazlehurst, A.; Sumner, M.; Taylor, M. Investigating the Influence of Yarn Characteristics on Microfibre Release from Knitted Fabrics during Laundering. Front. Environ. Sci. 2024, 12, 1340229. [Google Scholar] [CrossRef]

- Gao, M.; Yang, T.; Som, C.; Nowack, B. Differences in the Release of Microplastic Fibers and Fibrils from Virgin and Recycled Polyester Textiles. Resour. Conserv. Recycl. 2024, 207, 107659. [Google Scholar] [CrossRef]

- Napper, I.E.; Thompson, R.C. Release of Synthetic Microplastic Plastic Fibres from Domestic Washing Machines: Effects of Fabric Type and Washing Conditions. Mar. Pollut. Bull. 2016, 112, 39–45. [Google Scholar] [CrossRef] [PubMed]

- Cai, Y.; Mitrano, D.M.; Heuberger, M.; Hufenus, R.; Nowack, B. The Origin of Microplastic Fiber in Polyester Textiles: The Textile Production Process Matters. J. Clean. Prod. 2020, 267, 121970. [Google Scholar] [CrossRef]

- Choi, S.; Kwon, M.; Park, M.-J.; Kim, J. Analysis of Microplastics Released from Plain Woven Classified by Yarn Types during Washing and Drying. Polymers 2021, 13, 2988. [Google Scholar] [CrossRef]

- De Falco, F.; Di Pace, E.; Cocca, M.; Avella, M. The Contribution of Washing Processes of Synthetic Clothes to Microplastic Pollution. Sci. Rep. 2019, 9, 6633. [Google Scholar] [CrossRef] [PubMed]

- Jabbar, A.; Tausif, M. Investigation of Ring, Airjet and Rotor Spun Yarn Structures on the Fragmented Fibers (Microplastics) Released from Polyester Textiles during Laundering. Text. Res. J. 2023, 93, 5017–5028. [Google Scholar] [CrossRef]

- Jabbar, A.; Palacios-Marín, A.V.; Ghanbarzadeh, A.; Yang, D.; Tausif, M. Impact of Conventional and Modified Ring-Spun Yarn Structures on the Generation and Release of Fragmented Fibers (Microfibers) during Abrasive Wear and Laundering. Text. Res. J. 2023, 93, 1099–1112. [Google Scholar] [CrossRef]

- Özkan, İ.; Gündoğdu, S. Investigation on the Microfiber Release under Controlled Washings from the Knitted Fabrics Produced by Recycled and Virgin Polyester Yarns. J. Text. Inst. 2021, 112, 264–272. [Google Scholar] [CrossRef]

- Yang, L.; Qiao, F.; Lei, K.; Li, H.; Kang, Y.; Cui, S.; An, L. Microfiber Release from Different Fabrics during Washing. Environ. Pollut. 2019, 249, 136–143. [Google Scholar] [CrossRef]

- Raja Balasaraswathi, S.; Rathinamoorthy, R. Effect of Fabric Properties on Microfiber Shedding from Synthetic Textiles. J. Text. Inst. 2022, 113, 789–809. [Google Scholar] [CrossRef]

- Berruezo, M.; Bonet-Aracil, M.; Montava, I.; Bou-Belda, E.; Díaz-García, P.; Gisbert-Payá, J. Preliminary Study of Weave Pattern Influence on Microplastics from Fabric Laundering. Text. Res. J. 2021, 91, 1037–1045. [Google Scholar] [CrossRef]

- Choi, S.; Kwon, M.; Park, M.-J.; Kim, J. Characterization of Microplastics Released Based on Polyester Fabric Construction during Washing and Drying. Polymers 2021, 13, 4277. [Google Scholar] [CrossRef] [PubMed]

- Cui, H.; Xu, C. Study on the Relationship between Textile Microplastics Shedding and Fabric Structure. Polymers 2022, 14, 5309. [Google Scholar] [CrossRef] [PubMed]

- Jönsson, C.; Levenstam Arturin, O.; Hanning, A.-C.; Landin, R.; Holmström, E.; Roos, S. Microplastics Shedding from Textiles —Developing Analytical Method for Measurement of Shed Material Representing Release during Domestic Washing. Sustainability 2018, 10, 2457. [Google Scholar] [CrossRef]

- Julapong, P.; Srichonphaisarn, P.; Meekoch, T.; Tabelin, C.B.; Juntarasakul, O.; Phengsaart, T. The Influence of Textile Type, Textile Weight, and Detergent Dosage on Microfiber Emissions from Top-Loading Washing Machines. Toxics 2024, 12, 210. [Google Scholar] [CrossRef]

- Nyssanbek, M.; Mukhametov, A.; Azimov, A. Isolation of Microfibers in the Processing of Polyamide Fabrics. Mater. Technol. 2022, 56, 623–627. [Google Scholar] [CrossRef]

- Stanton, T.; Stanes, E.; Gwinnett, C.; Lei, X.; Cauilan-Cureg, M.; Ramos, M.; Sallach, J.B.; Harrison, E.; Osborne, A.; Sanders, C.H.; et al. Shedding Off-the-Grid: The Role of Garment Manufacturing and Textile Care in Global Microfibre Pollution. J. Clean. Prod. 2023, 428, 139391. [Google Scholar] [CrossRef]

- Zambrano, M.C.; Pawlak, J.J.; Daystar, J.; Ankeny, M.; Venditti, R.A. Impact of Dyes and Finishes on the Microfibers Released on the Laundering of Cotton Knitted Fabrics. Environ. Pollut. 2021, 272, 115998. [Google Scholar] [CrossRef] [PubMed]

- Rathinamoorthy, R.; Raja Balasaraswathi, S. Effect of Surface Modification of Polyester Fabric on Microfiber Shedding from Household Laundry. Int. J. Cloth. Sci. Technol. 2023, 35, 13–31. [Google Scholar] [CrossRef]

- Rathinamoorthy, R.; Nivruthi, K.; Puvisha, R.; Suganthini, S.; Raja Balasaraswathi, S. A Novel Approach to Combat Microfiber Release from Polyester Textiles through Surface Treatment. Fibers Polym. 2024, 25, 961–976. [Google Scholar] [CrossRef]

- Ramasamy, R.; Subramanian, R.B. Microfiber Mitigation from Synthetic Textiles—Impact of Combined Surface Modification and Finishing Process. Environ. Sci. Pollut. Res. 2023, 30, 49136–49149. [Google Scholar] [CrossRef]

- Ramasamy, R.; Subramanian, R.B. Enzyme Hydrolysis of Polyester Knitted Fabric: A Method to Control the Microfiber Shedding from Synthetic Textile. Environ. Sci. Pollut. Res. 2022, 29, 81265–81278. [Google Scholar] [CrossRef] [PubMed]

- Lahiri, S.K.; Azimi Dijvejin, Z.; Golovin, K. Polydimethylsiloxane-Coated Textiles with Minimized Microplastic Pollution. Nat. Sustain. 2023, 6, 559–567. [Google Scholar] [CrossRef]

- Lahiri, S.K.; Azimi Dijvejin, Z.; Gholamreza, F.; Shabanian, S.; Khatir, B.; Wotherspoon, L.; Golovin, K. Liquidlike, Low-Friction Polymer Brushes for Microfibre Release Prevention from Textiles. Small 2024, 20, 2400580. [Google Scholar] [CrossRef]

- Klinkhammer, K.; Kolbe, S.; Brandt, S.; Meyer, J.; Ratovo, K.; Bendt, E.; Rabe, M. Release of Fibrous Microplastics from Functional Polyester Garments through Household Washing. Front. Environ. Sci. 2024, 12, 1330922. [Google Scholar] [CrossRef]

- De Falco, F.; Gentile, G.; Avolio, R.; Errico, M.E.; Di Pace, E.; Ambrogi, V.; Avella, M.; Cocca, M. Pectin Based Finishing to Mitigate the Impact of Microplastics Released by Polyamide Fabrics. Carbohydr. Polym. 2018, 198, 175–180. [Google Scholar] [CrossRef] [PubMed]

- De Falco, F.; Cocca, M.; Guarino, V.; Gentile, G.; Ambrogi, V.; Ambrosio, L.; Avella, M. Novel Finishing Treatments of Polyamide Fabrics by Electrofluidodynamic Process to Reduce Microplastic Release during Washings. Polym. Degrad. Stab. 2019, 165, 110–116. [Google Scholar] [CrossRef]

- Cai, Y.; Yang, T.; Mitrano, D.M.; Heuberger, M.; Hufenus, R.; Nowack, B. Systematic Study of Microplastic Fiber Release from 12 Different Polyester Textiles during Washing. Environ. Sci. Technol. 2020, 54, 4847–4855. [Google Scholar] [CrossRef]

- Dalla Fontana, G.; Mossotti, R.; Montarsolo, A. Influence of Sewing on Microplastic Release from Textiles during Washing. Water Air Soil Pollut. 2021, 232, 50. [Google Scholar] [CrossRef]

- Rathinamoorthy, R.; Raja Balasaraswathi, S. Impact of Sewing on Microfiber Release from Polyester Fabric during Laundry. Sci. Total Environ. 2023, 903, 166247. [Google Scholar] [CrossRef]

- Vassilenko, E.; Watkins, M.; Chastain, S.; Mertens, J.; Posacka, A.M.; Patankar, S.; Ross, P.S. Domestic Laundry and Microfiber Pollution: Exploring Fiber Shedding from Consumer Apparel Textiles. PLoS ONE 2021, 16, e0250346. [Google Scholar] [CrossRef]

- Wang, M.; Yang, J.; Zheng, S.; Jia, L.; Yong, Z.Y.; Yong, E.L.; See, H.H.; Li, J.; Lv, Y.; Fei, X.; et al. Unveiling the Microfiber Release Footprint: Guiding Control Strategies in the Textile Production Industry. Environ. Sci. Technol. 2023, 57, 21038–21049. [Google Scholar] [CrossRef] [PubMed]

- Frost, H.; Zambrano, M.C.; Leonas, K.; Pawlak, J.J.; Venditti, R.A. Do Recycled Cotton or Polyester Fibers Influence the Shedding Propensity of Fabrics during Laundering? AATCC J. Res. 2020, 7, 32–41. [Google Scholar] [CrossRef]

- Palacios-Marín, A.V.; Jabbar, A.; Tausif, M. Fragmented Fiber Pollution from Common Textile Materials and Structures during Laundry. Text. Res. J. 2022, 92, 2265–2275. [Google Scholar] [CrossRef]

- Pinlova, B.; Hufenus, R.; Nowack, B. Systematic Study of the Presence of Microplastic Fibers during Polyester Yarn Production. J. Clean. Prod. 2022, 363, 132247. [Google Scholar] [CrossRef]

- Hernandez, E.; Nowack, B.; Mitrano, D.M. Polyester Textiles as a Source of Microplastics from Households: A Mechanistic Study to Understand Microfiber Release during Washing. Environ. Sci. Technol. 2017, 51, 7036–7046. [Google Scholar] [CrossRef]

- De Felice, B.; Antenucci, S.; Ortenzi, M.A.; Parolini, M. Laundering of Face Masks Represents an Additional Source of Synthetic and Natural Microfibers to Aquatic Ecosystems. Sci. Total Environ. 2022, 806, 150495. [Google Scholar] [CrossRef] [PubMed]

- Pinlova, B.; Nowack, B. Characterization of Fiber Fragments Released from Polyester Textiles during UV Weathering. Environ. Pollut. 2023, 322, 121012. [Google Scholar] [CrossRef]

- Qian, Y.; Cui, P.; Zhang, J.; Wang, S.; Duan, X.; Li, G. Modified Polyamide Fibers with Low Surface Friction Coefficient to Reduce Microplastics Emission during Domestic Laundry. Environ. Pollut. 2023, 335, 122356. [Google Scholar] [CrossRef] [PubMed]

- Rathinamoorthy, R.; Raja Balasaraswathi, S.; Madhubashini, S.; Prakalya, A.; Rakshana, J.B.; Shathvika, S. Investigation on Microfiber Release from Elastane Blended Fabrics and Its Environmental Significance. Sci. Total Environ. 2023, 903, 166553. [Google Scholar] [CrossRef]

- Rathinamoorthy, R.; Raja Balasaraswathi, S. Characterization of Microfibers Released from Chemically Modified Polyester Fabrics—A Step towards Mitigation. Sci. Total Environ. 2023, 866, 161317. [Google Scholar] [CrossRef]

- Yang, T.; Gao, M.; Nowack, B. Formation of Microplastic Fibers and Fibrils during Abrasion of a Representative Set of 12 Polyester Textiles. Sci. Total Environ. 2023, 862, 160758. [Google Scholar] [CrossRef] [PubMed]

- Salvador Cesa, F.; Turra, A.; Baruque-Ramos, J. Synthetic Fibers as Microplastics in the Marine Environment: A Review from Textile Perspective with a Focus on Domestic Washings. Sci. Total Environ. 2017, 598, 1116–1129. [Google Scholar] [CrossRef]

- Cai, Y.; Mitrano, D.M.; Hufenus, R.; Nowack, B. Formation of Fiber Fragments during Abrasion of Polyester Textiles. Environ. Sci. Technol. 2021, 55, 8001–8009. [Google Scholar] [CrossRef] [PubMed]

- Periyasamy, A.P.; Militky, J. LCA (Life Cycle Assessment) on Recycled Polyester. In Environmental Footprints of Recycled Polyester; Muthu, S.S., Ed.; Textile Science and Clothing Technology; Springer: Singapore, 2020; pp. 1–30. ISBN 9789811395789. [Google Scholar]

- Radhakrishnan, S.; Vetrivel, P.; Vinodkumar, A.; Palanisamy, H. Recycled Polyester—Tool for Savings in the Use of Virgin Raw Material. In Environmental Footprints of Recycled Polyester; Muthu, S.S., Ed.; Textile Science and Clothing Technology; Springer: Singapore, 2020; pp. 49–83. ISBN 9789811395789. [Google Scholar]

- Laitala, K.; Klepp, I.G.; Henry, B. Does Use Matter? Comparison of Environmental Impacts of Clothing Based on Fiber Type. Sustainability 2018, 10, 2524. [Google Scholar] [CrossRef]

- Kadolph, S.J.; Marcketti, S. Textiles, 12th ed.; Pearson: London, UK, 2017. [Google Scholar]

- Raja Balasaraswathi, S.; Rathinamoorthy, R. Effect of Textile Parameters on Microfiber Shedding Properties of Textiles. In Microplastic Pollution; Muthu, S.S., Ed.; Sustainable Textiles: Production, Processing, Manufacturing & Chemistry; Springer: Singapore, 2021; pp. 1–25. ISBN 9789811602979. [Google Scholar]

- Celik, S. Microplastic Release from Domestic Washing. Avrupa Bilim ve Teknoloji Dergisi 2021, 25, 790–795. [Google Scholar] [CrossRef]

- Mather, R.R. Synthetic Textile Fibres: Polyolefin, Elastomeric and Acrylic Fibres. In Textiles and Fashion; Sinclair, R., Ed.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2015; pp. 115–138. ISBN 978-1-84569-931-4. [Google Scholar]

- Šaravanja, A.; Pušić, T.; Dekanić, T. Microplastics in Wastewater by Washing Polyester Fabrics. Materials 2022, 15, 2683. [Google Scholar] [CrossRef]

- Rejali, M.; Hasani, H.; Ajeli, S.; Shanbeh, M. Optimization and Prediction of the Pilling Performance of Weft Knitted Fabrics Produced from Wool/Acrylic Blended Yarns. Indian J. Fibre Text. Res. 2014, 39, 83–88. [Google Scholar]

- Lawrence, C. Fibre to Yarn: Filament Yarn Spinning. In Textiles and Fashion; Sinclair, R., Ed.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2015; pp. 213–253. ISBN 978-1-84569-931-4. [Google Scholar]

- Tyagi, G.K. Yarn Structure and Properties from Different Spinning Techniques. In Advances in Yarn Spinning Technology; Lawrence, C.A., Ed.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2010; pp. 119–154. ISBN 978-1-84569-444-9. [Google Scholar]

- Elhawary, I.A. Fibre to Yarn: Staple-Yarn Spinning. In Textiles and Fashion; Sinclair, R., Ed.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2015; pp. 191–212. ISBN 978-1-84569-931-4. [Google Scholar]

- Harmsen, P.; Scheffer, M.; Bos, H. Textiles for Circular Fashion: The Logic behind Recycling Options. Sustainability 2021, 13, 9714. [Google Scholar] [CrossRef]

- Deopura, B.L.; Padaki, N.V. Synthetic Textile Fibres: Polyamide, Polyester and Aramid Fibres. In Textiles and Fashion; Sinclair, R., Ed.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2015; pp. 97–114. ISBN 978-1-84569-931-4. [Google Scholar]

- Haeggblom, J.; Budde, I. Circular Design as a Key Driver for Sustainability in Fashion and Textiles. In Sustainable Textile and Fashion Value Chains: Drivers, Concepts, Theories and Solutions; Matthes, A., Beyer, K., Cebulla, H., Arnold, M.G., Schumann, A., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 35–45. ISBN 978-3-030-22018-1. [Google Scholar]

- Sanjar, T.; Baxramovna, K.D.; Parpiyev, H.; Erkinov, Z. Influence of Short Fibers on the Quality Characteristics of the Product, Yield of Yarn and Waste of Cotton Fiber. Int. J. Innov. Sci. Res. 2014, 6, 44–49. [Google Scholar]

- Tojimirzaev, S.; Sadikov, M.; Rasulov, S.; Mirzaahmedov, J.; Plekhanov, A.F. Observation of Damage of Cotton Fiber in the Processes of Blowing, Cleaning and Carding. E3S Web Conf. 2021, 320, 03009. [Google Scholar] [CrossRef]

- Alagirusamy, R.; Das, A. Conversion of Fibre to Yarn: An Overview. In Textiles and Fashion; Sinclair, R., Ed.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2015; pp. 159–189. ISBN 978-1-84569-931-4. [Google Scholar]

- Mishuk, A.I.; Saha, T.; Sina, A.S.; Mostafa, G. Carded and Combed Yarn Effect on Finished Fabric Quality. Eur. Sci. J. 2015, 11, 276–287. [Google Scholar]

- Niinimäki, K.; Hassi, L. Emerging Design Strategies in Sustainable Production and Consumption of Textiles and Clothing. J. Clean. Prod. 2011, 19, 1876–1883. [Google Scholar] [CrossRef]

- Cooper, T.; Claxton, S. Garment Failure Causes and Solutions: Slowing the Cycles for Circular Fashion. J. Clean. Prod. 2022, 351, 131394. [Google Scholar] [CrossRef]

- Kang, H.; Park, S.; Lee, B.; Ahn, J.; Kim, S. Impact of Chitosan Pretreatment to Reduce Microfibers Released from Synthetic Garments during Laundering. Water 2021, 13, 2480. [Google Scholar] [CrossRef]

- Gaylarde, C.; Baptista-Neto, J.A.; da Fonseca, E.M. Plastic Microfibre Pollution: How Important Is Clothes’ Laundering? Heliyon 2021, 7, e07105. [Google Scholar] [CrossRef]

- Tiffin, L.; Hazlehurst, A.; Sumner, M.; Taylor, M. Reliable Quantification of Microplastic Release from the Domestic Laundry of Textile Fabrics. J. Text. Inst. 2022, 113, 558–566. [Google Scholar] [CrossRef]

- Brannigan, M. Is the Fleece Trend-Bubble about to Burst? Available online: https://fashionista.com/2020/01/fleece-jacket-trend-market (accessed on 18 November 2023).

| Inclusion Criteria | Exclusion Criteria |

|---|---|

| Empirical research study | Textile parameters included in the study are confounding |

| Article explores the topic of FF release from textiles via laundering | Conference proceedings, reviews, working papers, commentaries |

| One or more textile parameter has been manipulated in the study | Articles that could not be accessed in full |

| Published in a peer-reviewed journal | |

| Publication is in English | |

| Published between 2011 and June 2024 |

| Level | Parameter | Direction | References |

|---|---|---|---|

| Fibre | Fibre tenacity | Increase | [24,36,44,72,79] |

| Fibre length | Increase | [24,40,72] | |

| Yarn | Yarn Type | Filament | [40,44,62,72] |

| Yarn Hairiness | Decrease | [24,39,41,42,44,70] | |

| Yarn Twist | Increase (to an optimal point) | [10,21,24,39,40,43,68,70] | |

| Fabric | Fabric structure | Tighter (to an optimal point) | [9,13,21,39,41,45,47,48,49,51,77] |

| Abrasion resistance | Increase | [24,55,78,80] | |

| Treatments/Finishes | Mechanical finishes | Finishes/treatments that reduce protruding fibre ends | [39,58,64,67] |

| Chemical finishes | Finishes/treatments that increase the abrasion resistance of the fabric | [52,55,57,59,60,63] | |

| Garment construction | Sewing and cutting method | Enclosure or sealing of fabric edges | [39,50,64,65,66] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, J.; McQueen, R.H.; Batcheller, J.C. From Fabric to Fallout: A Systematic Review of the Impact of Textile Parameters on Fibre Fragment Release. Textiles 2024, 4, 459-492. https://doi.org/10.3390/textiles4040027

Han J, McQueen RH, Batcheller JC. From Fabric to Fallout: A Systematic Review of the Impact of Textile Parameters on Fibre Fragment Release. Textiles. 2024; 4(4):459-492. https://doi.org/10.3390/textiles4040027

Chicago/Turabian StyleHan, Jacqueline, Rachel H. McQueen, and Jane C. Batcheller. 2024. "From Fabric to Fallout: A Systematic Review of the Impact of Textile Parameters on Fibre Fragment Release" Textiles 4, no. 4: 459-492. https://doi.org/10.3390/textiles4040027

APA StyleHan, J., McQueen, R. H., & Batcheller, J. C. (2024). From Fabric to Fallout: A Systematic Review of the Impact of Textile Parameters on Fibre Fragment Release. Textiles, 4(4), 459-492. https://doi.org/10.3390/textiles4040027