Comprehensive Review of Compressed Air Energy Storage (CAES) Technologies

Abstract

:1. Introduction

2. CAES History and Basic Principles

- A motor or generator with clutches for alternate engagement with the compressor or turbine train.

- An air compressor with two or more stages, inter-coolers and after-coolers, to achieve compression efficiency and reduce compressed air moisture content.

- The turbine train that includes both high-pressure and low-pressure turbines.

- Controls for the combustion turbine, compressor, and auxiliaries, as well as for the regulation and control of the changeover from generation to storage mode.

- Auxiliary equipment for the facility’s operation, including fuel storage and handling, as well as mechanical and electrical systems for various heat exchangers.

- The underground component mainly consisting of a cavity for compressed air storage.

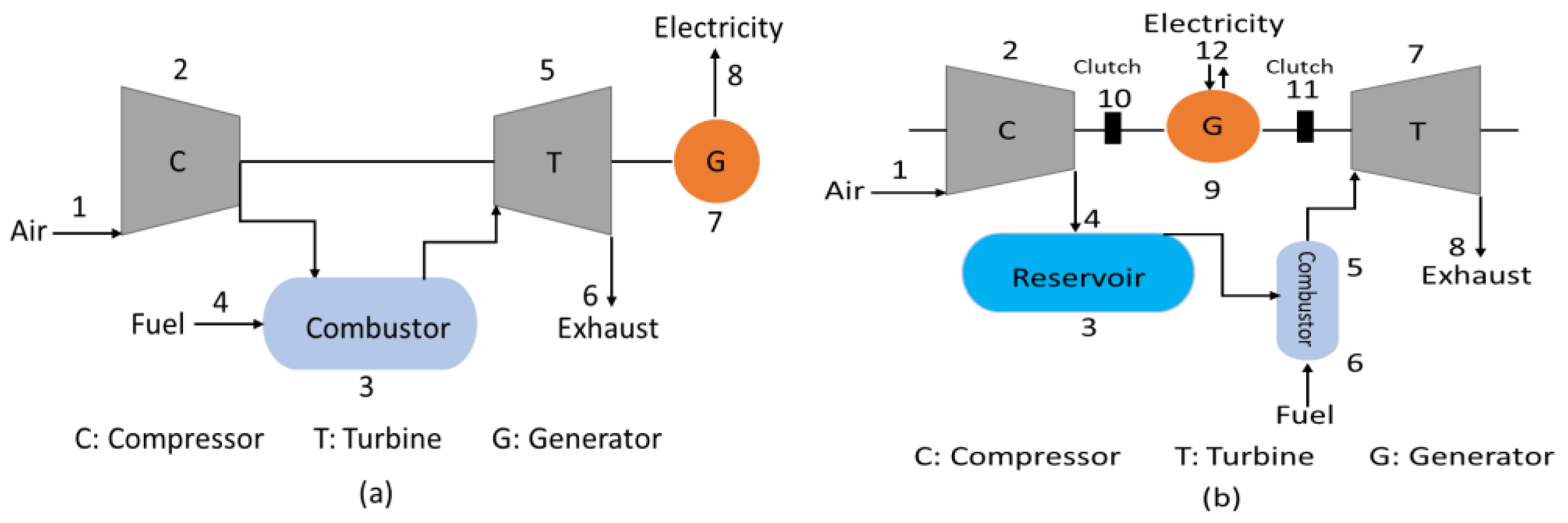

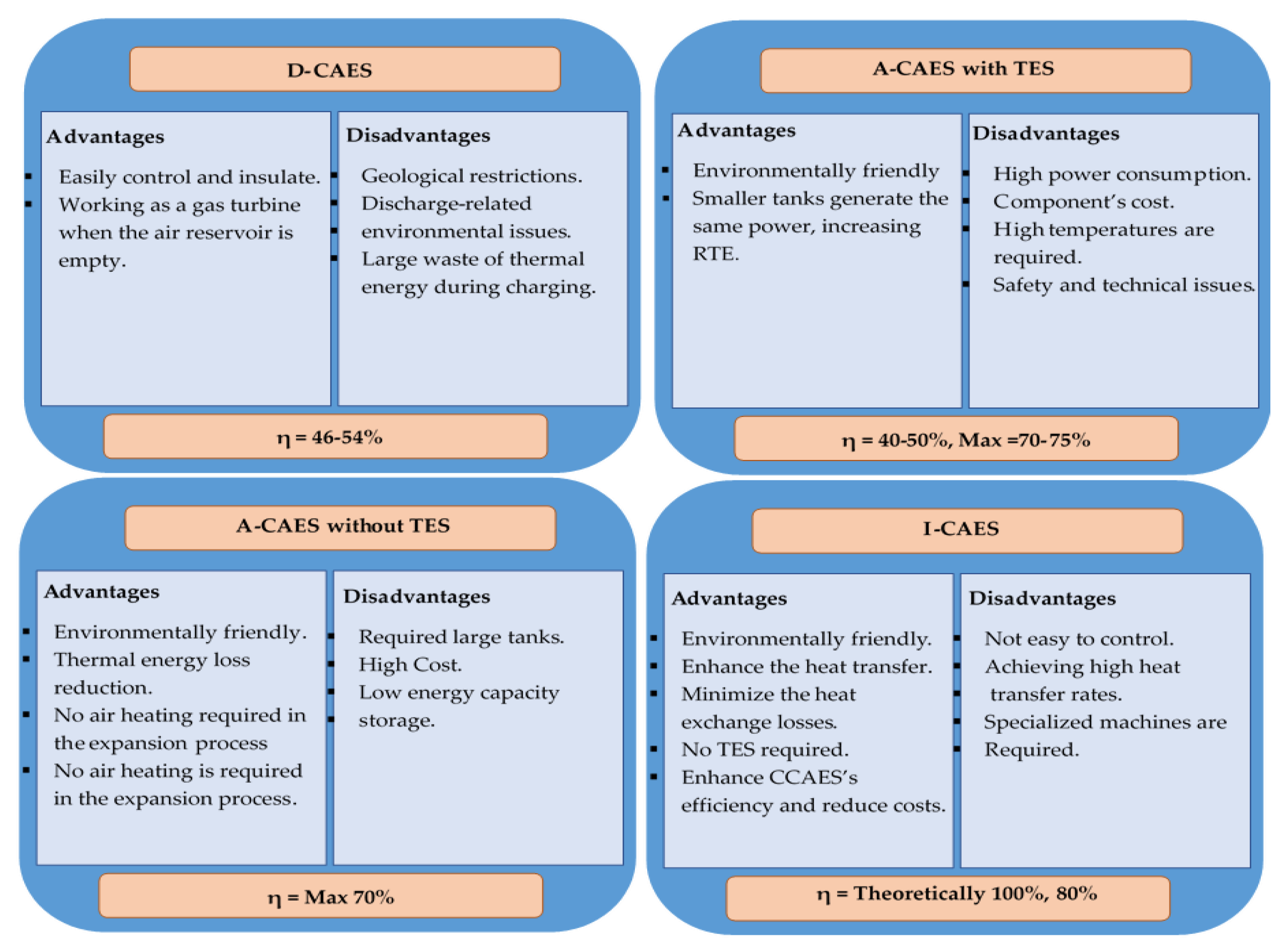

2.1. Diabatic CAES Systems (D-CAS)

2.2. Adiabatic/Advanced Adiabatic Compressed Air Energy Storage (A-CAES)/(AA-CAES)

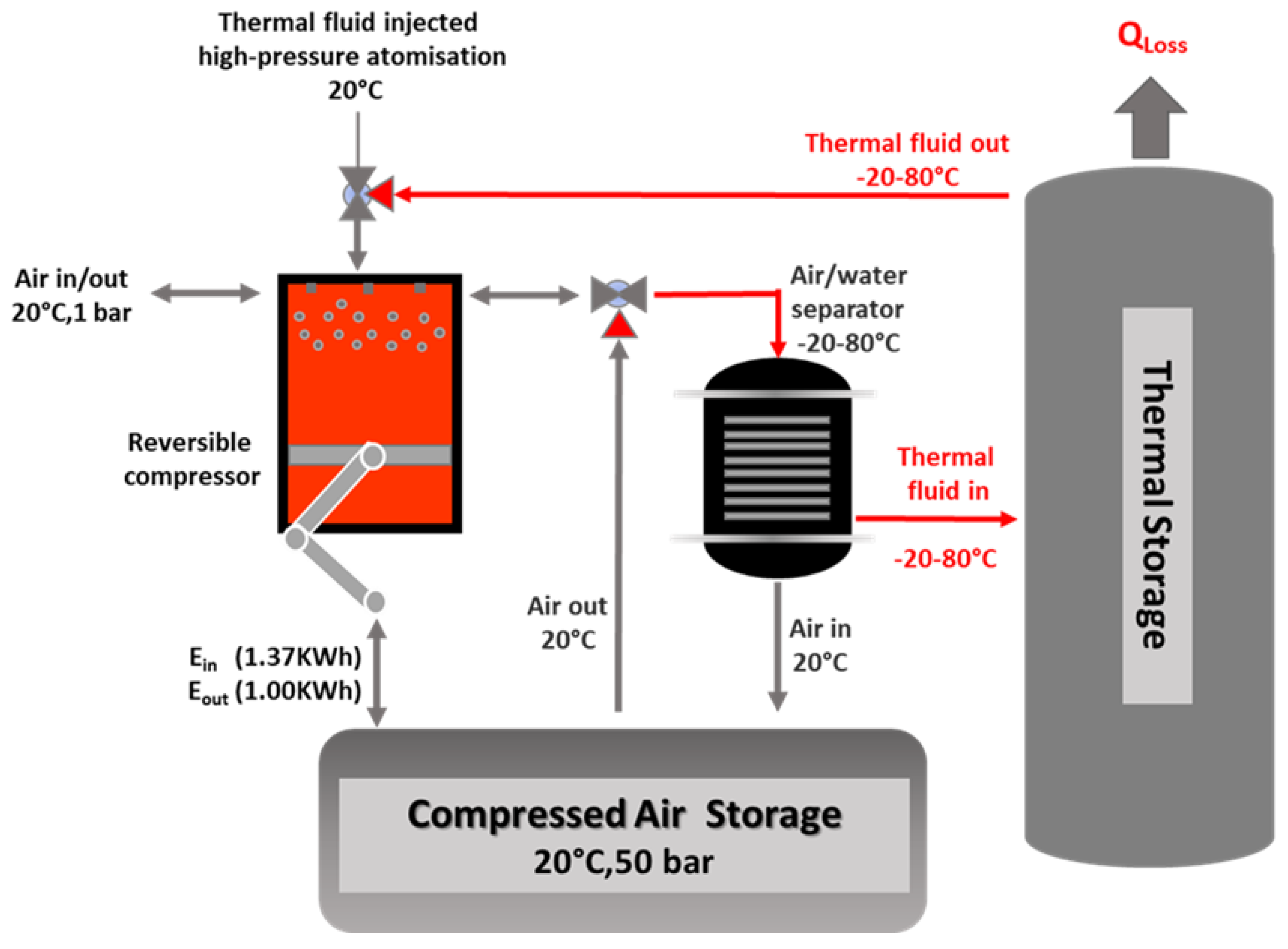

2.3. Isothermal Compressed Air Energy Storage (I-CAES)

2.4. Droplet-Based I-CAES

2.5. Liquid Piston Air Compressor/Expander (LP-CAES)

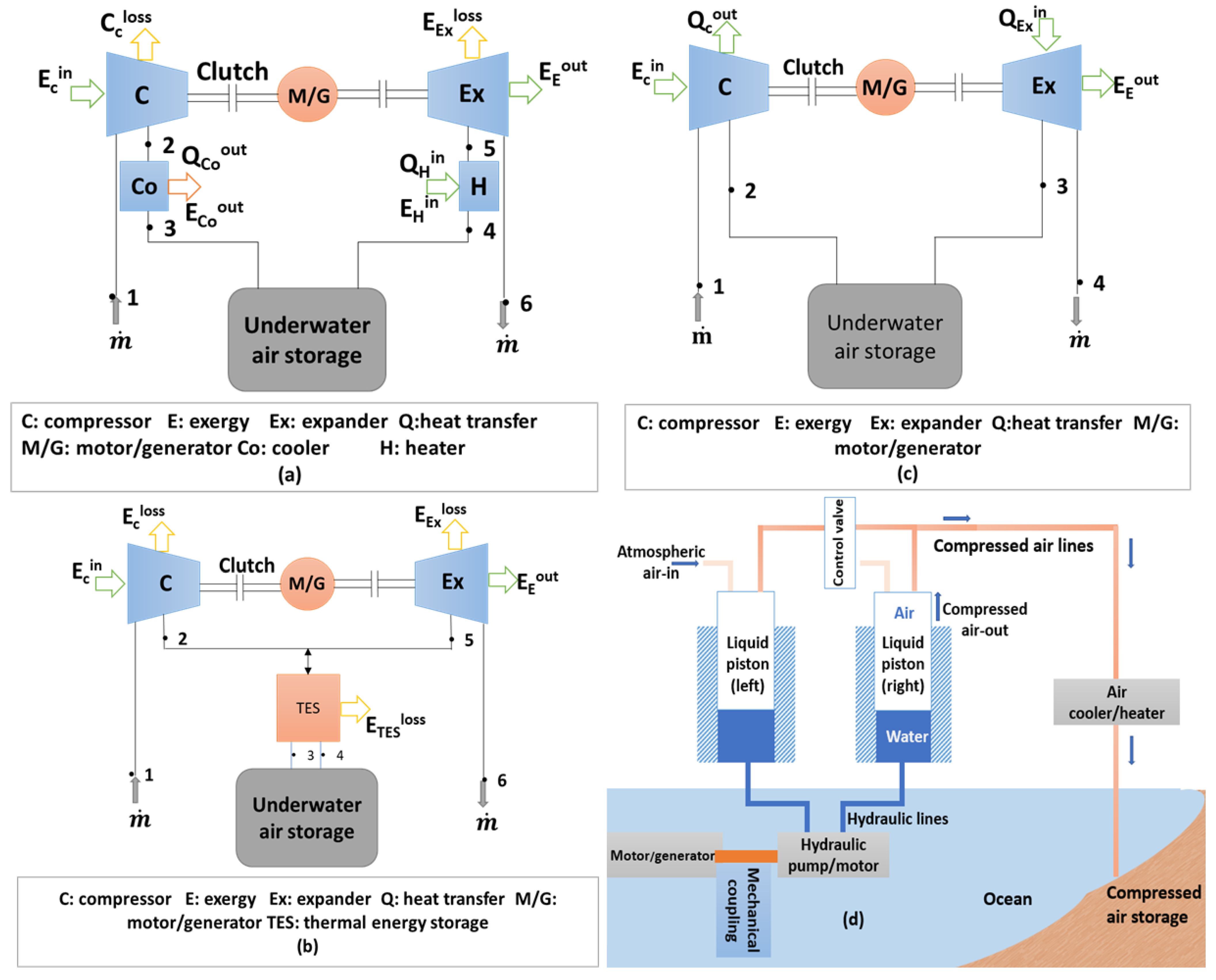

2.6. Ocean CAES (OCAES)

3. Performance and Operating Conditions of D-CAES, A-CAES and I-CAES

4. CAES Variants and Integrating of CAES Systems with the Renewable Energy Storage Technologies

5. Conclusions

- CAES systems’ high energy capacity, high power rating, and long life span of around 40 years make it suitable for stationary and large-scale applications.

- CAES suffers from relatively low energy efficiency (between 40 and 70%), and there is much interest in its integration with different cycles to recover waste heat and to reducing exergy destruction.

- It is also necessary to integrate CAES with renewable energy sources in order to increase renewable penetration and system reliability.

- It is necessary to improve the performance of CAES technologies in order to extend their competitiveness, affordability, and efficiency for large-scale applications.

- To avoid under-sizing, over-sizing, decreased profitability, or decreased reliability, optimum capacity for a given pressure range of the air reservoir is required.

- Figure 12 below provides a comprehensive summary of the main advantages and disadvantages of the CAES classifications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cantarero, M.M.V. Of renewable energy, energy democracy, and sustainable development: A roadmap to accelerate the energy transition in developing countries. Energy Res. Soc. Sci. 2020, 70, 101716. [Google Scholar] [CrossRef]

- Dreißigacker, V.; Belik, S. High temperature solid media thermal energy storage system with high effective storage densities for flexible heat supply in electric vehicles. Appl. Therm. Eng. 2019, 149, 173–179. [Google Scholar] [CrossRef]

- Hemmati, M.; Mohammadi-Ivatloo, B.; Abapour, M.; Shafiee, M. Thermodynamic modeling of compressed air energy storage for energy and reserve markets. Appl. Therm. Eng. 2021, 193, 116948. [Google Scholar] [CrossRef]

- He, W.; Wang, J. Optimal selection of air expansion machine in Compressed Air Energy Storage: A review. Renew. Sustain. Energy Rev. 2018, 87, 77–95. [Google Scholar] [CrossRef]

- McTigue, J. Analysis & Optimization of Thermal Energy Storage. Ph.D. Dissertation, St. Catharine’s College, Cambridge University, Cambridge, UK, 2016; pp. 1–265. [Google Scholar]

- Chen, H.; Cong, T.N.; Yang, W.; Tan, C.; Li, Y.; Ding, Y. Progress in electrical energy storage system: A critical review. Prog. Nat. Sci. 2009, 19, 291–312. [Google Scholar] [CrossRef]

- White, A.J.; McTigue, J.D.; Markides, C.N. Analysis and optimisation of packed-bed thermal reservoirs for electricity storage applications. SAGE J. 2016, 230, 739–754. [Google Scholar] [CrossRef]

- Abbaspour, M.; Satkin, M.; Mohammadi-Ivatloo, B.; Lotfi, F.H.; Noorollahi, Y. Optimal operation scheduling of wind power integrated with compressed air energy storage (CAES). Renew. Energy 2013, 51, 53–59. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Simone, A. Modelling, Design and Analysis Of Innovative Thermal Energy Storage Systems Using PCM for Industrial Processes, Heat and Power. Ph.D. Thesis, University of Cagliari, Cagliari, Italy, 2015; p. 117. [Google Scholar]

- Kalhammer, F.R.; Schneider, T.R. Energy Storage. Annu. Rev. Energy 1976, 1, 311–343. [Google Scholar] [CrossRef]

- Ibrahim, H.; Ilinca, A.; Perron, J. Energy storage systems—Characteristics and comparisons. Renew. Sustain. Energy Rev. 2008, 12, 1221–1250. [Google Scholar] [CrossRef]

- Budt, M.; Wolf, D.; Span, R.; Yan, J. A review on compressed air energy storage: Basic principles, past milestones and recent developments. Appl. Energy 2016, 170, 250–268. [Google Scholar] [CrossRef]

- Hadjipaschalis, I.; Poullikkas, A.; Efthimiou, V. Overview of current and future energy storage technologies for electric power applications. Renew. Sustain. Energy Rev. 2009, 13, 1513–1522. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, X.; Liu, J.T.C. Compressed Air Energy Storage. Energy Storage-Technologies and Applications. Available online: http://dx.doi.org/10.5772/ (accessed on 15 January 2013).

- Alsagri, A.S.; Arabkoohsar, A.; Alrobaian, A.A. Combination of subcooled compressed air energy storage system with an Organic Rankine Cycle for better electricity efficiency, a thermodynamic analysis. J. Clean. Prod. 2019, 239, 118119. [Google Scholar] [CrossRef]

- Luo, X.; Wang, J.; Dooner, M.; Clarke, J.; Krupke, C. Overview of Current Development in Compressed Air Energy Storage Technology. Energy Procedia 2014, 62, 603–611. [Google Scholar] [CrossRef] [Green Version]

- Bouman, E.A.; Øberg, M.M.; Hertwich, E.G. Life cycle assessment of compressed air energy storage (CAES). In Proceedings of the 6th International Conference on Life Cycle Management, Gothenburg, Sweden, 25–28 August 2013. [Google Scholar]

- King, M.; Jain, A.; Bhakar, R.; Mathur, J.; Wang, J. Overview of current compressed air energy storage projects and analysis of the potential underground storage capacity in India and the UK. Renew. Sustain. Energy Rev. 2021, 139, 110705. [Google Scholar] [CrossRef]

- Zhang, C. CFD Simulations and Thermal Design for Application to Compressed Air Energy Storage. Ph.D. Thesis, University of Minnesota, Minneapolis, MN, USA, June 2015. [Google Scholar]

- Zhang, Y.; Xu, Y.; Zhou, X.; Guo, H.; Zhang, X.; Chen, H. Compressed air energy storage system with variable configuration for accommodating large-amplitude wind power fluctuation. Appl. Energy 2019, 239, 957–968. [Google Scholar] [CrossRef]

- Yin, J.; Wang, D.; Kim, Y.T.; Lee, Y.H. A hybrid energy storage system using pump compressed air and micro-hydro turbine. Renew. Energy 2014, 65, 117–122. [Google Scholar] [CrossRef]

- Raju, M.; Khaitan, S.K. Modeling and simulation of compressed air storage in caverns: A case study of the Huntorf plant. Appl. Energy 2012, 89, 474–481. [Google Scholar] [CrossRef]

- Liu, W.; Liu, L.; Zhou, L.; Huang, J.; Zhang, Y.; Xu, G.; Yang, Y. Analysis and Optimization of a Compressed Air Energy Storage—Combined Cycle System. Entropy 2014, 16, 3103–3120. [Google Scholar] [CrossRef]

- Sun, H.; Luo, X.; Wang, J. Feasibility study of a hybrid wind turbine system—Integration with compressed air energy storage. Appl. Energy 2015, 137, 617–628. [Google Scholar] [CrossRef]

- Quoilin, S.; Van Den Broek, M.; Declaye, S.; Dewallef, P.; Lemort, V. Techno-economic survey of organic Rankine cycle (ORC) systems. Renew. Sustain. Energy Rev. 2013, 22, 168–186. [Google Scholar] [CrossRef] [Green Version]

- Mozayeni, H. Development of a Combined Pumped Hydro and Compressed Air Energy Storage System. Ph.D. Dissertation, University of Tasmania, Tasmania, Australia, August 2019. [Google Scholar]

- Zhou, Q.; Du, D.; Lu, C.; He, Q.; Liu, W. A review of thermal energy storage in compressed air energy storage system. Energy 2019, 188, 115993. [Google Scholar] [CrossRef]

- El-Ela, A.A.A.; Allam, S.M.; Shehata, N.K. Optimal Allocation of a Hybrid Wind Energy-Fuel Cell System Using Different Optimization Techniques in the Egyptian Distribution Network. Energy Power Eng. 2021, 13, 17–40. [Google Scholar] [CrossRef]

- Succar, S.; Williams, R.H. Compressed Air Energy Storage: Theory, Resources, and Applications for Wind Power; Report by Energy Systems Analysis Group; Princeton Environmental Institute, Princeton University: Princeton, NJ, USA, 2008. [Google Scholar]

- Barnes, F.S.; Levine, J.G. Large Energy Storage Systems Handbook; Taylor & Francis Group: New York, NY, USA, 2011. [Google Scholar]

- Greenblatt, J.B.; Succar, S.; Denkenberger, D.C.; Williams, R.H.; Socolow, R.H. Baseload wind energy: Modeling the competition between gas turbines and compressed air energy storage for supplemental generation. Energy Policy 2007, 35, 1474–1492. [Google Scholar] [CrossRef]

- Qin, C.; Loth, E. Liquid piston compression efficiency with droplet heat transfer. Appl. Energy 2014, 114, 539–550. [Google Scholar] [CrossRef]

- Kim, Y.M.; Favrat, D. Energy and exergy analysis of a micro-compressed air energy storage and air cycle heating and cooling system. Energy 2010, 35, 213–220. [Google Scholar] [CrossRef] [Green Version]

- Réveillère, A.; Londe, L. Compressed Air Energy Storage: A new beginning ? Paper Compressed Air Energy Storage: A new beginning? In Proceedings of the Solution Mining Research Institute Fall 2017 Technical Conference, Munster, Germany, 25–26 September 2017. [Google Scholar]

- Sciacovelli, A.; Li, Y.; Chen, H.; Wu, Y.; Wang, J.; Garvey, S.; Ding, Y. Dynamic simulation of Adiabatic Compressed Air Energy Storage (A-CAES) plant with integrated thermal storage—Link between components performance and plant performance. Appl. Energy 2017, 185, 16–28. [Google Scholar] [CrossRef] [Green Version]

- Parfomak, P.W. Energy Storage for Power grids and Electric Transportation: A Technological Assessment, Report no. R42455, Congressional Research Services, USA. 2012. Available online: https://crsreports.congress.gov/product/pdf/R/R42455 (accessed on 15 January 2023).

- Guo, J.; Ma, R.; Zou, H. Compressed Air Energy Storage and Future Development. J. Phys. Conf. Ser. 2021, 2108, 012037. [Google Scholar] [CrossRef]

- Wang, J.; Lu, K.; Ma, L.; Wang, J.; Dooner, M.; Miao, S.; Li, J.; Wang, D. Overview of Compressed Air Energy Storage and Technology Development. Energies 2017, 10, 991. [Google Scholar] [CrossRef] [Green Version]

- Schoenung, S.M.; Eyer, J.M.; Iannucci, J.J.; Horgan, S.A. Energy storage for a competitive power market. Annu. Rev. Energy Env. 1996, 21, 347–370. [Google Scholar] [CrossRef]

- Barbour, E.; Mignard, D.; Ding, Y.; Li, Y. Adiabatic Compressed Air Energy Storage with packed bed thermal energy storage. Appl. Energy 2015, 155, 804–815. [Google Scholar] [CrossRef] [Green Version]

- Grazzini, G.; Milazzo, A. Thermodynamic analysis of CAES/TES systems for renewable energy plants. Renew. Energy 2008, 33, 1998–2006. [Google Scholar] [CrossRef]

- Roos, P.; Haselbacher, A. Analytical modeling of advanced adiabatic compressed air energy storage: Literature review and new models. Renew. Sustain. Energy Rev. 2021, 163, 112464. [Google Scholar] [CrossRef]

- Garrison, J.B.; Webber, M.E. An integrated energy storage scheme for a dispatchable solar and wind powered energy systema. J. Renew. Sustain. Energy 2011, 3, 043101. [Google Scholar] [CrossRef] [Green Version]

- Guo, H.; Xu, Y.; Chen, H.; Zhou, X. Thermodynamic characteristics of a novel supercritical compressed air energy storage system. Energy Convers. Manag. 2016, 115, 167–177. [Google Scholar] [CrossRef]

- Minutillo, M.; Lavadera, A.L.; Jannelli, E. Assessment of design and operating parameters for a small compressed air energy storage system integrated with a stand-alone renewable power plant. J. Energy Storage 2015, 4, 135–144. [Google Scholar] [CrossRef]

- Li, R.; Zhang, Y.; Chen, H.; Zhang, H.; Yang, Z.; Yao, E.; Wang, H. Exploring thermodynamic potential of multiple phase change thermal energy storage for adiabatic compressed air energy storage system. J. Energy Storage 2021, 33, 102054. [Google Scholar] [CrossRef]

- ADELE-Adiabatic Compressed-Air Energy Storage for Electricity Supply-RWE Power. (n.d.). Available online: https://www.readkong.com/page/adele-adiabatic-compressed-air-energy-storage-for-2887816 (accessed on 15 January 2023).

- Yang, K.; Zhang, Y.; Li, X.; Xu, J. Theoretical evaluation on the impact of heat exchanger in Advanced Adiabatic Compressed Air Energy Storage system. Energy Convers. Manag. 2014, 86, 1031–1044. [Google Scholar] [CrossRef]

- Hartmann, N.; Vöhringer, O.; Kruck, C.; Eltrop, L. Simulation and analysis of different adiabatic Compressed Air Energy Storage plant configurations. Appl. Energy 2012, 93, 541–548. [Google Scholar] [CrossRef]

- Wolf, D.; Budt, M. LTA-CAES—A low-temperature approach to Adiabatic Compressed Air Energy Storage. Appl. Energy 2014, 125, 158–164. [Google Scholar] [CrossRef]

- Luo, X.; Wang, J.; Krupke, C.; Wang, Y.; Sheng, Y.; Li, J.; Xu, Y.; Wang, D.; Miao, S.; Chen, H. Modelling study, efficiency analysis and optimisation of large-scale Adiabatic Compressed Air Energy Storage systems with low-temperature thermal storage. Appl. Energy 2016, 162, 589–600. [Google Scholar] [CrossRef]

- Chen, L.X.; Hu, P.; Zhao, P.P.; Xie, M.N.; Wang, D.X.; Wang, F.X. A novel throttling strategy for adiabatic compressed air energy storage system based on an ejector. Energy Convers. Manag. 2018, 158, 50–59. [Google Scholar] [CrossRef]

- Mousavi, S.B.; Adib, M.; Soltani, M.; Razmi, A.R.; Nathwani, J. Transient thermodynamic modeling and economic analysis of an adiabatic compressed air energy storage (A-CAES) based on cascade packed bed thermal energy storage with encapsulated phase change materials. Energy Convers. Manag. 2021, 243, 114379. [Google Scholar] [CrossRef]

- Li, R.; Zhang, H.; Chen, H.; Zhang, Y.; Li, Z.; Zhao, J.; Wang, X.; Wang, H. Hybrid techno-economic and environmental assessment of adiabatic compressed air energy storage system in China-Situation. Appl. Therm. Eng. 2021, 186, 116443. [Google Scholar] [CrossRef]

- Cheayb, M.; Gallego, M.M.; Tazerout, M.; Poncet, S. Modelling and experimental validation of a small-scale trigenerative compressed air energy storage system. Appl. Energy 2019, 239, 1371–1384. [Google Scholar] [CrossRef] [Green Version]

- Facci, A.L.; Sánchez, D.; Jannelli, E.; Ubertin, S. Trigenerative micro compressed air energy storage: Concept and thermodynamic assessment. Appl. Energy 2015, 158, 243–254. [Google Scholar] [CrossRef]

- Venkataramani, G.; Vijayamithran, P.; Li, Y.; Ding, Y.; Chen, H.; Ramalingam, V. Thermodynamic analysis on compressed air energy storage augmenting power/polygeneration for roundtrip efficiency enhancement. Energy 2019, 180, 107–120. [Google Scholar] [CrossRef]

- Razmi, A.R.; Afshar, H.H.; Pourahmadiyan, A.; Torabi, M. Investigation of a combined heat and power (CHP) system based on biomass and compressed air energy storage (CAES). Sustain. Energy Technol. Assess. 2021, 46, 101253. [Google Scholar] [CrossRef]

- Alirahmi, S.M.; Mousavi, S.B.; Razmi, A.R.; Ahmadi, P. A comprehensive techno-economic analysis and multi-criteria optimization of a compressed air energy storage (CAES) hybridized with solar and desalination units. Energy Convers. Manag. 2021, 236, 114053. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, X.; Yang, L.; Zhou, Y.; Wang, J. Experimental study of compressed air energy storage system with thermal energy storage. Energy 2016, 103, 182–191. [Google Scholar] [CrossRef]

- Becattini, V.; Geissbühler, L.; Zanganeh, G.; Haselbacher, A.; Steinfeld, A. Pilot-scale demonstration of advanced adiabatic compressed air energy storage, Part 2: Tests with combined sensible/latent thermal-energy storage. J. Energy Storage 2018, 17, 140–152. [Google Scholar] [CrossRef]

- Geissbühler, L.; Becattini, V.; Zanganeh, G.; Zavattoni, S.; Barbato, M.; Haselbacher, A.; Steinfeld, A. Pilot-scale demonstration of advanced adiabatic compressed air energy storage, Part 1: Plant description and tests with sensible thermal-energy storage. J. Energy Storage 2018, 17, 129–139. [Google Scholar] [CrossRef]

- Guo, C.; Xu, Y.; Zhang, X.; Guo, H.; Zhou, X.; Liu, C.; Qin, W.; Li, W.; Dou, B.; Chen, H. Performance analysis of compressed air energy storage systems considering dynamic characteristics of compressed air storage. Energy 2017, 135, 876–888. [Google Scholar] [CrossRef]

- Tola, V.; Meloni, V.; Spadaccini, F.; Cau, G. Performance assessment of Adiabatic Compressed Air Energy Storage (A-CAES) power plants integrated with packed-bed thermocline storage systems. Energy Convers. Manag. 2017, 151, 343–356. [Google Scholar] [CrossRef]

- Mozayeni, H.; Negnevitsky, M.; Wang, X.; Cao, F.; Peng, X. Performance Study of an Advanced Adiabatic Compressed Air Energy Storage System. Energy Procedia 2017, 110, 71–76. [Google Scholar] [CrossRef]

- Li, Y.; Miao, S.; Zhang, S.; Yin, B.; Luo, X.; Dooner, M.; Wang, J. A reserve capacity model of AA-CAES for power system optimal joint energy and reserve scheduling. Int. J. Electr. Power Energy Syst. 2019, 104, 279–290. [Google Scholar] [CrossRef]

- Renaldi, R. Modelling and Optimisation of Energy Systems with Thermal Energy Storage. Ph.D. Thesis, The University of Edinburgh, Edinburgh, UK, 2018. [Google Scholar]

- Ennil, A.B. Optimization of Small-Scale Axial Turbine for Distributed Compressed Air Energy Storage System. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 2016. [Google Scholar]

- Yu, Q.; Li, X.; Geng, Y.; Tan, X. Study on quasi-isothermal expansion process of compressed air based on spray heat transfer. Energy Rep. 2022, 8, 1995–2007. [Google Scholar] [CrossRef]

- Li, P.Y.; Loth, E.; Simon, T.W.; Van de Ven, J.D.; Crane, S.E. Compressed air energy storage for offshore wind turbines. Proc. Int. Fluid Power Exhib. 2020, 2011, 1039–1046. [Google Scholar]

- Bollinger, B.R. System and Method for Rapid Isothermal Gas Expansion and Compression for Energy Storage. U.S. Patent 7,802,426, 28 September 2010. [Google Scholar]

- Bell, I.H.; Lemort, V.; Groll, E.A.; Braun, J.E.; King, G.B.; Horton, W.T. Liquid-flooded compression and expansion in scroll machines—Part I: Model development. Int. J. Refrig. 2012, 35, 1878–1889. [Google Scholar] [CrossRef] [Green Version]

- Bell, I.; Lemort, V.; Groll, E.A.; Braun, J.E.; King, G.; Travis, W.; Ian Bell, A.; Travis Horton, W.; Bell, I.H.; Groll, E.A.; et al. Liquid flooded compression and expansion in scroll machines-Part II: Experimental testing and model validation. Int. J. Refrig. 2012, 35, 1890–1900. [Google Scholar] [CrossRef] [Green Version]

- Van de Ven, J.D.; Li, P.Y. Liquid piston gas compression. Appl. Energy 2009, 86, 2183–2191. [Google Scholar] [CrossRef]

- Ro, P.I.; He, X.; Mazzoleni, A.P.; Park, J.K. Analysis and proof-of-concept experiment of liquid-piston compression for ocean compressed air energy storage (ocaes) system. In Proceedings of the 2nd Marine Energy Technology Symposium, Seattle, WA, USA, 15–18 April 2014. [Google Scholar]

- Saadat, M.; Shirazi, F.A.; Li, P.Y. Modeling and control of an open accumulator Compressed Air Energy Storage (CAES) system for wind turbines. Appl. Energy 2015, 137, 603–616. [Google Scholar] [CrossRef]

- Yan, B.; Wieberdink, J.; Shirazi, F.; Li, P.Y.; Simon, T.W.; Van de Ven, J.D. Experimental study of heat transfer enhancement in a liquid piston compressor/expander using porous media inserts. Appl. Energy 2015, 154, 40–50. [Google Scholar] [CrossRef]

- Shen, J.; Xing, Z.; Zhang, K.; He, Z.; Wang, X. Development of a water-injected twin-screw compressor for mechanical vapor compression desalination systems. Appl. Therm. Eng. 2016, 95, 125–135. [Google Scholar] [CrossRef]

- James, N.A.; Braun, J.E.; Groll, E.A.; Horton, W.T. Semi-empirical modeling and analysis of oil flooded R410A scroll compressors with liquid injection for use in vapor compression systems. Int. J. Refrig. 2016, 66, 50–63. [Google Scholar] [CrossRef]

- Rizos, D. Compressed Air Energy Storage for Offshore Wind Turbine. Bachelor’s Thesis, University of Sussex, Brighton, UK, 2020. [Google Scholar]

- Chen, H.; Wang, H.; Li, R.; Sun, H.; Ge, G.; Ling, L. Experimental and analytical investigation of near-isothermal pumped hydro-compressed air energy storage system. Energy 2022, 249, 123607. [Google Scholar] [CrossRef]

- Sureshkumar, R.; Kale, S.R.; Dhar, P.L. Heat and mass transfer processes between a water spray and ambient air-II. Simulations. Appl. Therm. Eng. 2008, 28, 361–371. [Google Scholar] [CrossRef]

- Ibrahim, H.; Belmokhtar, K.; Ghandour, M. Investigation of usage of compressed air energy storage for power generation system improving-Application in a microgrid integrating wind energy. Energy Procedia 2015, 73, 305–316. [Google Scholar] [CrossRef] [Green Version]

- Coney, M.W.; Stephenson, P.; Malmgren, A.; Linnemann, C.; Morgan, R.E.; Richards, R.A.; Huxley, R.; Abdallah, H. Development of A Reciprocating Compressor Using Water Injection To Achieve Quasi-Isothermal Compression. In Proceedings of the International Compressor Engineering Conference, West Lafayette, IN, USA, 16–19 July 2002. [Google Scholar]

- Mohan, A.; Chidambaram, P.K.; Suryan, A.; Kim, H.D. Energy efficiency analysis of wet compression systems through thermo-fluid dynamic considerations. J. Clean. Prod. 2019, 214, 132–144. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Y.; Zhou, X.; Zhang, Y.; Li, W.; Zuo, Z.; Guo, H.; Huang, Y.; Chen, H. A near-isothermal expander for isothermal compressed air energy storage system. Appl. Energy 2018, 225, 955–964. [Google Scholar] [CrossRef]

- Gouda, E.M. Investigation of a Compressed Air Energy Storage System: Flow and Heat Transfer Numerical Modeling in a Liquid Piston. Ph.D. Thesis, Université de Nantes, Nantes, France, 2021. [Google Scholar]

- Saadat, M.; Li, P.Y. Modeling and Control of a Novel Compressed Air Energy Storage System for Offshore Wind Turbine. In Proceedings of the 2012 American Control Conference, Montreal, QC, Canada, 27–29 June 2012; Volume 2015, pp. 3032–3037. [Google Scholar]

- Wieberdink, J.; Li, P.Y.; Simon, T.W.; Van de Ven, J.D. Effects of porous media insert on the efficiency and power density of a high pressure (210 bar) liquid piston air compressor/expander—An experimental study. Appl. Energy 2018, 212, 1025–1037. [Google Scholar] [CrossRef]

- Cazzaniga, R.; Cicu, M.; Marrana, T.; Rosa-Clot, M.; Rosa-Clot, P.; Tina, G.M. DOGES: Deep ocean gravitational energy storage. J. Energy Storage 2017, 14, 264–270. [Google Scholar] [CrossRef]

- Moradi, J.; Shahinzadeh, H.; Khandan, A.; Moazzami, M. A profitability investigation into the collaborative operation of wind and underwater compressed air energy storage units in the spot market. Energy 2017, 141, 1779–1794. [Google Scholar] [CrossRef]

- Puchta, M.; Bard, J.; Dick, C.; Hau, D.; Krautkremer, B.; Thalemann, F.; Hahn, H. Development and testing of a novel offshore pumped storage concept for storing energy at sea—Stensea. J. Energy Storage 2017, 14, 271–275. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Z.; Liang, C.; Carriveau, R.; Ting, D.S.K.; Li, P.; Xiong, W. Underwater Compressed Gas Energy Storage (UWCGES): Current Status, Challenges, and Future Perspectives. Appl. Sci. 2022, 12, 961. [Google Scholar] [CrossRef]

- Hunt, J.D.; Zakeri, B.; de Barros, A.G.; Leal Filho, W.; Marques, A.D.; Barbosa PS, F.; Schneider, P.S.; Farenzena, M. Buoyancy Energy Storage Technology: An energy storage solution for islands, coastal regions, offshore wind power and hydrogen compression. J. Energy Storage 2021, 40, 102746. [Google Scholar] [CrossRef]

- Lim, S.D.; Mazzoleni, A.P.; Park, J.-K.; Ro, P.I.; Quinlan, B. Conceptual Design of Ocean Compressed Air Energy Storage System. In 2012 Oceans; IEEE: New York, NY, USA, 2012; pp. 1–8. [Google Scholar]

- Patil, V.C.; Ro, P.I. Energy and Exergy Analysis of Ocean Compressed Air Energy Storage Concepts. J. Eng. 2018, 2018, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Seymour, R. Ocean energy on-demand using underocean compressed air storage. In Proceedings of the ASME 2007 26th International Conference on Offshore Mechanics and Arctic Engineering, American Society of Mechanical Engineers, San Diego, CA, USA, 10–15 June 2007; pp. 527–531. [Google Scholar]

- Spalding, M.J. California and the World Ocean’97. Taking a Look at California’s Ocean Resources: An Agenda for the Future. J. Environ. Dev. 2022, 6, 453–455. [Google Scholar] [CrossRef]

- Park, J.K.; Ro, P.I.; Lim, S.D.; Mazzoleni, A.P.; Quinlan, B. Analysis and optimization of a quasi-isothermal compression and expansion cycle for ocean compressed air energy storage (OCAES). In Proceedings of the 2012 Oceans MTS/IEEE Harnessing Power Ocean, Virginia Beach, VA, USA, 14–19 October 2012. [Google Scholar]

- Patil, V.C.; Kishore, R.R.; Ro, P. Efficiency Improvement Techniques For Liquid Piston based Ocean Compressed Air Energy Storage. In Proceedings of the TechConnect World Innovation Conference & Expo, Washington, DC, USA, 15–16 May 2017. [Google Scholar]

- Sheng, L.; Zhou, Z.; Charpentier, J.F.; Benbouzid, M.E.H. Stand-alone island daily power management using a tidal turbine farm and an ocean compressed air energy storage system. Renew. Energy 2017, 103, 286–294. [Google Scholar]

- Hunt, J.D.; Zakeri, B.; Nascimento, A.; Barbosa, P.S.F.; Tomé, F.M.C.; Castro, N.J.; Leal Filho, W.; Riahi, K. Isothermal Deep Ocean Compressed Air Energy Storage: An Affordable Solution for Long-Term Energy Storage. SSRN Electron. J. 2022, 1–20. [Google Scholar] [CrossRef]

- AirBattery Energy Storage System—YouTube. Available online: https://www.youtube.com/watch?v=VeI1OHMAAus (accessed on 13 June 2022).

- Augwind’s AirBattery-Harnessing the Elements for a Cleaner Future—YouTube. Available online: https://www.youtube.com/watch?v=nbUN2j5HeYs (accessed on 13 June 2022).

- Luo, X.; Wang, J.; Dooner, M.; Clarke, J. Overview of current development in electrical energy storage technologies and the application potential in power system operation. Appl. Energy 2015, 137, 511–536. [Google Scholar] [CrossRef] [Green Version]

- Knowlen, C.; Williams, J.; Mattick, A.T.; Deparis, H.; Hertzberg, A. Quasi-Isothermal Expansion Engines for Liquid Nitrogen Automotive Propulsion. In Proceedings of the SAE Future Transportation Technology Conference and Exposition 1997, San Diego, CA, USA, 6–8 August 1997; p. 972649. [Google Scholar]

- Zavattoni, S.; Barbato, M.; Geissbühler, L.; Haselbacher, A.; Zanganeh, G.; Steinfeld, A. CFD modeling and experimental validation of the TES unit integrated into the world’s first underground AA-CAES pilot plant. In AIP Conference Proceedings; AIP Publishing LLC: Manno, Switzerland, 2019. [Google Scholar] [CrossRef]

- Zhao, P.; Gao, L.; Wang, J.; Dai, Y. Energy efficiency analysis and off-design analysis of two different discharge modes for compressed air energy storage system using axial turbines. Renew. Energy 2016, 85, 1164–1177. [Google Scholar] [CrossRef]

- Kim, M.J.; Kim, T.S. Integration of compressed air energy storage and gas turbine to improve the ramp rate. Appl. Energy 2019, 247, 363–373. [Google Scholar] [CrossRef]

- Giuseppe, G.; Milazzo, A. A thermodynamic analysis of multistage adiabatic CAES. In Proceedings of the IEEE, Beijing, China, 23–25 March 2012; Volume 100, pp. 461–472. [Google Scholar]

- Kim, Y.M.; Lee, J.H.; Kim, S.J.; Favrat, D. Potential and evolution of compressed air energy storage: Energy and exergy analyses. Entropy 2012, 14, 1501–1521. [Google Scholar] [CrossRef]

- Wojcik, J.D.; Wang, J. Feasibility study of Combined Cycle Gas Turbine (CCGT) power plant integration with Adiabatic Compressed Air Energy Storage (ACAES). Appl. Energy 2018, 221, 477–489. [Google Scholar] [CrossRef]

- Johnson, P.; Dhamshala, P.; Kazemersky, P. Assessment of compressed air energy storage system (CAES). Master’s Thesis, University of Tennessee at Chattanooga, Chattanooga, TN, USA, 2014. [Google Scholar]

- Yang, Z.; Wang, Z.; Ran, P.; Li, Z.; Ni, W. Thermodynamic analysis of a hybrid thermal-compressed air energy storage system for the integration of wind power. Appl. Therm. Eng. 2014, 66, 519–527. [Google Scholar] [CrossRef]

- Donnellan, B.J.; Vowles, D.J.; Soong, W.L. A review of energy storage and its application in power systems. In Proceedings of the 2015 Australasian Universities Power Engineering Conference, Wollongong, Australia, 27–30 September 2015. [Google Scholar]

- Foley, A.; Lobera, I.D. Impacts of compressed air energy storage plant on an electricity market with a large renewable energy portfolio. Energy 2013, 57, 85–94. [Google Scholar] [CrossRef]

- Kere, A.; Sadiki, N.; Py, X.; Goetz, V. Applicability of thermal energy storage recycled ceramics to high temperature and compressed air operating conditions. Energy Convers. Manag. 2014, 88, 113–119. [Google Scholar] [CrossRef]

- Liu, J.L.; Wang, J.H. A comparative research of two adiabatic compressed air energy storage systems. Energy Convers. Manag. 2016, 108, 566–578. [Google Scholar] [CrossRef]

- Dinter, F.; Geyer, M.A.; Tamme, R. Thermal Energy Storage for Commercial Applications: A Feasibility Study on Economic Storage Systems, 1st ed.; Springer: Berlin/Heidelberg, Germany, 1991; p. 401. [Google Scholar]

- Peng, H.; Li, R.; Ling, X.; Dong, H. Modeling on heat storage performance of compressed air in a packed bed system. Appl. Energy 2015, 160, 1–9. [Google Scholar] [CrossRef]

- Peng, H.; Dong, H.; Ling, X. Thermal investigation of PCM-based high temperature thermal energy storage in packed bed. Energy Convers. Manag. 2014, 81, 420–427. [Google Scholar] [CrossRef]

- Nie, B.; Palacios, A.; Zou, B.; Liu, J.; Zhang, T.; Li, Y. Review on phase change materials for cold thermal energy storage applications. Renew. Renew. Sustain. Energy Rev. 2020, 134, 110340. [Google Scholar] [CrossRef]

- Oró, E.; de Gracia, A.; Castell, A.; Farid, M.M.; Cabeza, L.F. Review on phase change materials (PCMs) for cold thermal energy storage applications. Appl. Energy 2012, 99, 513–533. [Google Scholar] [CrossRef] [Green Version]

- Kenisarin, M.; Mahkamov, K. Passive thermal control in residential buildings using phase change materials. Renew. Sustain. Energy Rev. 2016, 55, 371–398. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, Z.; Zuo, J.; Huang, K.; Zhang, L. Phase change materials for solar thermal energy storage in residential buildings in cold climate. Renew. Renew. Sustain. Energy Rev. 2015, 48, 692–703. [Google Scholar] [CrossRef]

- Tian, Y.; Zhao, C.Y. A review of solar collectors and thermal energy storage in solar thermal applications. Appl. Energy 2013, 104, 538–553. [Google Scholar] [CrossRef] [Green Version]

- Gil, A.; Medrano, M.; Martorell, I.; Lázaro, A.; Dolado, P.; Zalba, B.; Cabeza, L.F. State of the art on high temperature thermal energy storage for power generation. Part 1—Concepts, materials and modellization. Renew. Sustain. Energy Rev. 2010, 14, 31–55. [Google Scholar] [CrossRef]

- Tessier, M.J.; Floros, M.C.; Bouzidi, L.; Narine, S.S. Exergy analysis of an adiabatic compressed air energy storage system using a cascade of phase change materials. Energy 2016, 106, 528–534. [Google Scholar] [CrossRef]

- Zhang, C.; Yan, B.; Wieberdink, J.; Li, P.; Van de Ven, J.; Loth, E.; Simon, T. Thermal analysis of a compressor for application to Compressed Air Energy Storage. Appl. Therm. Eng. 2014, 73, 1402–1411. [Google Scholar] [CrossRef]

- Chen, L.; Zheng, T.; Mei, S.; Xue, X.; Liu, B.; Lu, Q. Review and prospect of compressed air energy storage system. J. Mod. Power Syst. Clean Energy 2016, 4, 529–541. [Google Scholar] [CrossRef] [Green Version]

- Arabkoohsar, A.; Machado, L.; Farzaneh-Gord, M.; Koury, R.N.N. Thermo-economic analysis and sizing of a PV plant equipped with a compressed air energy storage system. Renew. Energy 2015, 83, 491–509. [Google Scholar] [CrossRef]

- Arabkoohsar, A.; Machado, L.; Koury, R.N.N. Operation analysis of a photovoltaic plant integrated with a compressed air energy storage system and a city gate station. Energy 2016, 98, 78–91. [Google Scholar] [CrossRef]

- Jin, H.; Liu, P.; Li, Z. Dynamic modeling and design of a hybrid compressed air energy storage and wind turbine system for wind power fluctuation reduction. Comput. Chem. Eng. 2019, 122, 59–65. [Google Scholar] [CrossRef]

- Wang, X.; Yang, C.; Huang, M.; Ma, X. Multi-objective optimization of a gas turbine-based CCHP combined with solar and compressed air energy storage system. Energy Convers. Manag. 2018, 164, 93–101. [Google Scholar] [CrossRef]

- Wang, X.; Yang, C.; Huang, M.; Ma, X. Off-design performances of gas turbine-based CCHP combined with solar and compressed air energy storage with organic Rankine cycle. Energy Convers. Manag. 2018, 156, 626–638. [Google Scholar] [CrossRef]

- Razmi, A.; Soltani, M.; Tayefeh, M.; Torabi, M.; Dusseault, M.B. Thermodynamic analysis of compressed air energy storage (CAES) hybridized with a multi-effect desalination (MED) system. Energy Convers. Manag. 2019, 199, 112047. [Google Scholar] [CrossRef]

- Guo, H.; Xu, Y.; Zhang, X.; Liang, Q.; Wang, S.; Chen, H. Dynamic characteristics and control of supercritical compressed air energy storage systems. Appl. Energy 2021, 283, 116294. [Google Scholar] [CrossRef]

| Specifications | Unit | Huntorf Plant | McIntosh Plant |

|---|---|---|---|

| Operation year | - | 1978 | 1991 |

| Capacity | [MW] | 290 | 110 |

| Charging period | [h] | 8 | 40 |

| Discharging period | [h] | 2 | 26 |

| Start-up time | [min] | 14 | 12 |

| Charging time | [h] | 8 | 40 |

| Discharging time | [h] | 2 | 26 |

| Efficiency of plant | [%] | 42 | 53 |

| Efficiency of compressor | [%] | 80 | 80 |

| Minimum/Maximum energy | [MWh] | Min. 0, Max. 480 | Min. 200, Max. 2000 |

| Number of caverns | - | 2 | 1 |

| Pressure range of cavern | [bar] | 46–72 | 46–75 |

| Cavern volume | [m3] | 310,000 | 538,000 |

| Air mass flow of compression | [kg/s] | 107 | 93 |

| Air mass flow expansion | [kg/s] | 455 | 154 |

| Temperature of exhaust gas | [°C] | 480 | 370 1 |

| Reference | System Evaluated | Outcome |

|---|---|---|

| [49] | A-CAES: Effectiveness and pressure loss of heat exchangers in A-CAES systems | Improved heat exchanger efficiency during charging or discharging significantly improved system efficiency |

| [50] | CAES: Configurations | High-temperature thermal storage (>600 °C) with temperature-resistant compressor materials improved efficiency |

| [51] | A-CAES: Multi-stage compressors and expanders and TES at 95–200 °C | Low round-trip efficiency (52–60%), fast start-up, and a wide range of partial load capability |

| [52] | A-CES: Low-temperature TES | Cycle efficiency (68%) and heat energy cycle efficiency (60%), |

| [25,50,51,52,53,54,55] | A-CAES | Developed advanced adiabatic compressed air energy storage options |

| [56,57] | T-CAES: trigeneration compressed air energy storage | Developed advanced CAES system |

| [21] | A-CAES: variable configuration system | System for variable fluctuations, e.g., from wind power |

| [58] | CAES, A-CAES: Thermodynamics analysis | Efficient compressed heat utilization contributed significantly to energy conversion efficiency during charge/discharge. Electrical efficiency of 71.8% |

| [38,59,60] | CAES: Integration with various renewable energy sources | Specific system for renewable sources |

| [61] | AA-CAES: Above-ground pilot with air storage (100 m3 tanks) and TES (pressurized water) | Efficiency of 22.6% |

| [62,63] | AA-CAES: Underground Swiss pilot with 1942 m3 rock cavern | Sensible and latent TES at temperatures as high as 550 °C |

| [36,41,50,52,64,65] | AA_CAES: Theoretical modelling | Incorporated phenomena such as real gas effects, variable turbomachinery efficiency, and temperature-dependent thermophysical properties |

| [54] | A-CAES: Environmentally friendly system. Examined thermodynamic and economic aspects as well as transient models of the TES tanks. | Using low-cost, off-peak electricity for charging and generating during peak demand gave round trip energy efficiency (61.5%) and exergy efficiency (68.2%) with a payback period of 3.5 years |

| Method of Enhancing Heat Transfer | Impact |

|---|---|

| A process of injecting small liquid droplets into the air at a high mass flow rate while being compressed. | The compression efficiency can be increased by up to 98%. |

| Compressing air using Pareto’s optimal trajectory in a liquid piston. | An increase of 10–40% in power density. |

| Inserting porous inserts into a liquid piston at low pressures. | Increased power density by 39 times and increased efficiency by 18%. |

| Inserting porous inserts into a liquid piston under high pressure. | 20 times increase in power density and a 23% increase in efficiency. |

| Utilization of hollow spheres. | The peak air temperature of the system was reduced by 32 °C and the end-to-end efficiency of OCAES was increased by 9%. |

| The OCAES uses spray cooling and porous media. | End-to-end efficiency improved by 17%. |

| System | Temperature [°C] | Pressure in Cavern/Tank [MPa] | Round-Trip Efficiency [%] | Ref(s) |

|---|---|---|---|---|

| D-CAES | Inlet temperature for LP 1 ≥ 850. Inlet temperature for HP 2 ≥ 550 | Pmax,cavern = 7.2 P operation = 4.8–6.6 | η = 42 | [17,113] |

| D-CAES (With recuperator) | Inlet temperature for LP ≈ 870 Inlet temperature for HP ≈ 540 | P operation = 4.5–7.4 | η = 54 | [113,114] |

| D-CAES | The maximum temperature is 1050. Outlet temperature of LT is 583. Exhaust temperature from HRSC 95 | P = 6 | η = 51.1 (CAES-CC) η = 53.4 (Recuperated CAES) | [24] |

| D-CAES | Inlet temperature of HP is 550 Inlet temperature of LP is 827 Temperature of exhaust gas is 204, Air temperature in cavern is 25 | P operation,min =4.2 P operation,max = 7.2 | η ≈ 45 | [109] |

| A-CAES | Operating temperature range is 90–200 | Two configurations were considered: one is 7.2 and the other is 15 | η = 56 | [51] |

| A-CAES & I-CAES | Max. temperatures for A-CAES are 623 and 239 For single-stage and two-stage compression, respectively. Maximum temperature is 80 for I-CAES systems for both configurations | Two pressure ratios: for single-stage compression/expansion the ratio is 50 & (~5); for two-stage compression/expansion the ratio is 7.1 and 7.1 (~5) | A-CAES (Single-stage) η = 23.6 A-CAES (Two-stage) η = 48.6 I-CAES (Single-stage) η = 70.6 I-CAES (Two-stage) η = 73.9 | [34] |

| A-CAES | Max. temperature is 400 | Pmax,cavern = 6.6 Pmin,cavern = 4.6 | “Hypothetically” 79.2 if heat exchanger efficiency is 0.7 | [115] |

| A-CAES | Exhaust temperature is 3 Air temperature at compressor outlet is 159. Air temperature at air turbine inlet 130. | Pmax,tank = 3.5 Pmin,tank = 2.5 | ηstorage = 57 | [69] |

| A-CAES | Max. temperature is ≈150. Exhaust temperature is 15. | Pressure ratio 90 | η= 50–75 3 | [116] |

| I-CAES | Ideal isothermal constant temperature | Pmax = 1 | η ≥ 90 | [33] |

| I-CAES | Isothermal constant temperature. Temperature difference ≤ 5. | P operation = 20–35 | η= 74.8 4 | [77] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rabi, A.M.; Radulovic, J.; Buick, J.M. Comprehensive Review of Compressed Air Energy Storage (CAES) Technologies. Thermo 2023, 3, 104-126. https://doi.org/10.3390/thermo3010008

Rabi AM, Radulovic J, Buick JM. Comprehensive Review of Compressed Air Energy Storage (CAES) Technologies. Thermo. 2023; 3(1):104-126. https://doi.org/10.3390/thermo3010008

Chicago/Turabian StyleRabi, Ayah Marwan, Jovana Radulovic, and James M. Buick. 2023. "Comprehensive Review of Compressed Air Energy Storage (CAES) Technologies" Thermo 3, no. 1: 104-126. https://doi.org/10.3390/thermo3010008

APA StyleRabi, A. M., Radulovic, J., & Buick, J. M. (2023). Comprehensive Review of Compressed Air Energy Storage (CAES) Technologies. Thermo, 3(1), 104-126. https://doi.org/10.3390/thermo3010008