The New Italian Standard on the Life Assessment of Martensitic Steels—First Results of the Experimental Validation Activity of XRD by Testing P91 and P92 Samples from Interrupted Uniaxial Creep Tests

Abstract

:1. Introduction

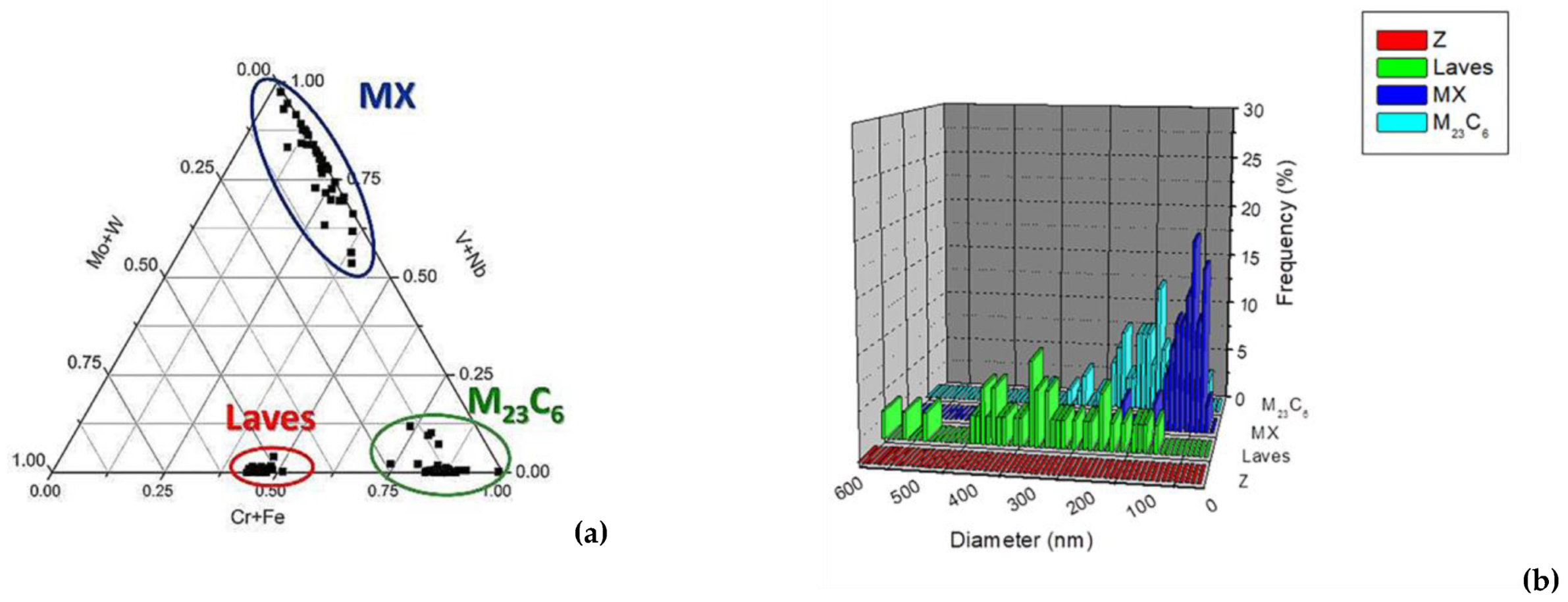

- Fine-grain MX particles together with M23C6 in the first period;

- A change in the number and size of these particles, together with the formation of different phases, such as the Laves phase and Z phase, in a subsequent period [10].

- A study on the evolution of the microstructure and analyses of the precipitates of Grade 91 steel, artificially aged in a furnace, from 40,000 to 65,000 h at 550 °C and from 50,000 to 75,000 at 600 and 650 °C;

- A study on the effect of mechanical stress on the evolution of the microstructure and of the state of Grade 91 steel precipitation at 550 °C, 600 °C, and 650 °C, with a creep test for each temperature and value of the load corresponding to the failure for creep at 50,000 h (according to ECCC datasheets) [13];

- A study on the microstructural evolution of Grade 91 in the thermally altered zone (HAZ) of welded joints subjected to creep failure tests at temperatures of 550 °C, 600 °C, and 650 °C (with failure times of the order of 10,000, 20,000 and 50,000 h);

- Setting up an isotherm for Grade 92 steel at a temperature between 600 and 650 °C, with five load conditions corresponding to creep failure at 20,000, 40,000, 60,000, 80,000, and 100,000 h (according to an ECCC datasheet);

- A study on the evolution of the microstructure and of the precipitation state of Grade 92 steel at temperatures of 600 and 650 °C with load and in the absence of load, for times of 5000, 10,000, and 20,000 h; in regard to the tests with load, interrupted creep tests at 5000, 10,000 and 20,000 h, with load corresponding to creep failure at 50,000 h (according to an ECCC datasheet);

- A study on the microstructural evolution in the HAZ of Grade 92 steel artificially aged in a furnace at 600 and 650 °C for 5000, 10,000, and 20,000 h;

- A comparison of the microstructural evolution of the two Grade 91 and 92 steels for aging times from 3000 to 75,000 h.

2. Materials and Methods

- Chemical composition of the steel;

- Technological process of manufacturing;

- Heat treatments;

- Any welding qualifications;

- Anything else useful for defining the initial delivering conditions before it begins its operational life;

- A detailed description of the operating conditions and all kinds of event, with a particular attention to the data related to incidents and accidents.

- No material removal, as the precipitates are extracted by stripping to an amorphous film; it is not necessary to cut a component sample;

- The higher resolution of a TEM compared to an SEM;

- It provides, for each category of precipitates, the chemical composition and size.

- The main disadvantages are as follows:

- Typical problems related to the development of the extraction replica process and the potential risk of pollution during sampling;

- Further processes on replicas for TEM management (from acetate support to support for TEM use);

- Very localized TEM survey area;

- The analysis is usually performed on a few particles (<200);

- A slow and expensive analysis is required for each position;

- Limited availability of TEM equipment.

- The applicability in situ (applies only to the portable instrument);

- The technique allows for the recognition and quantitative study of sample phases;

- It detects local plastic deformation and texture.

- The main disadvantages are as follows:

- Safety settings required for ionizing radiation (X-rays);

- The measurement takes from a few to a few tens of minutes per point, during which neither the component nor the equipment must move or vibrate;

- The preparation for the measurement depends on the accuracy required;

- Very complex analysis of diffraction profiles (patterns), which requires highly specific training;

- In cases of massive samples, routine software reveals 5–10% of the concentration of phases only for a few seconds; for higher sensitivities, more time and specific applications are required;

- The measuring point has a variable extension;

- It is necessary to operate in several steps if you want to study the second phases.

- Laboratory testing (thermal ageing in furnaces, creep tests);

- Metallographic characterization;

- OM, SEM, and TEM analyses;

- XRD analysis;

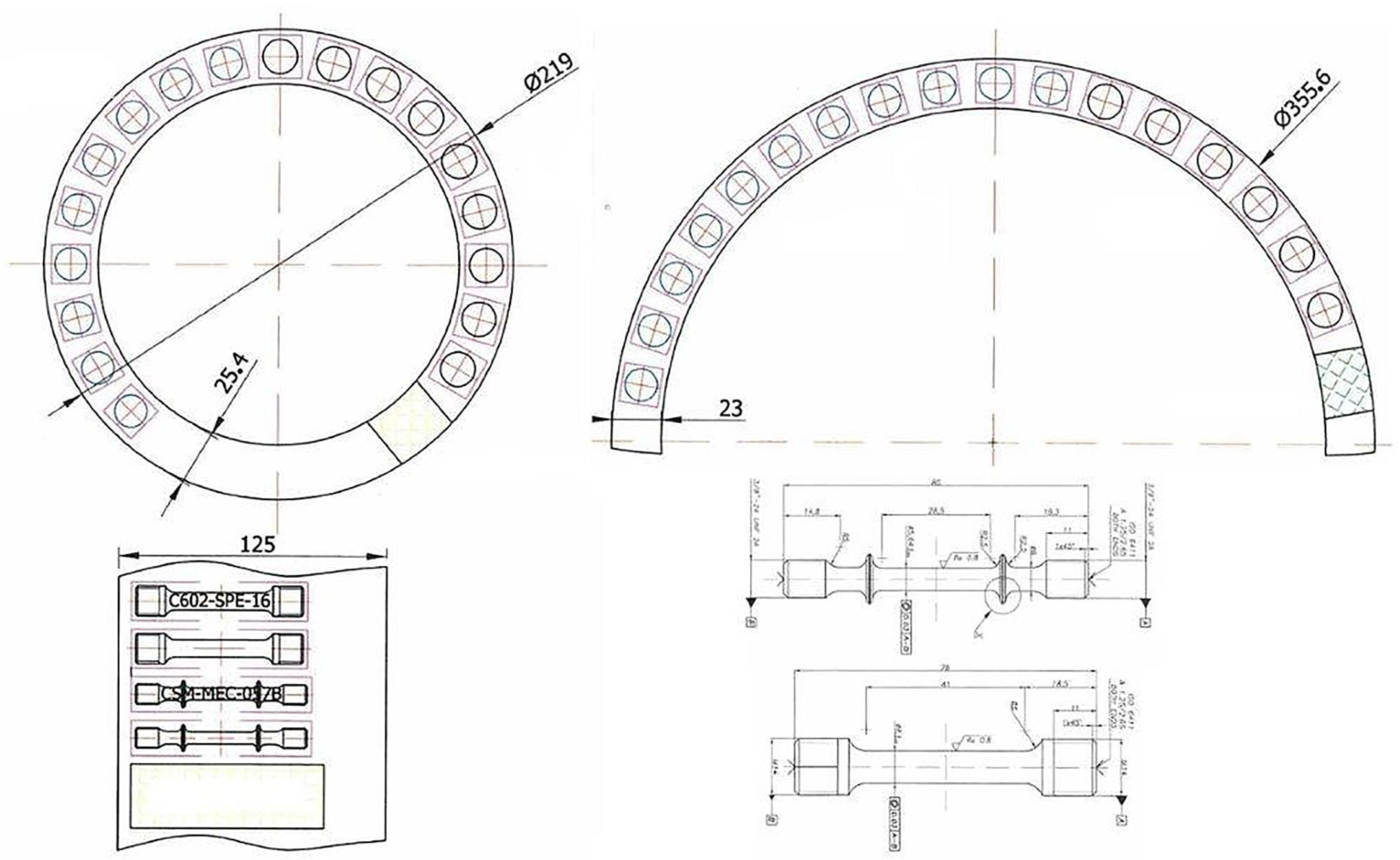

- Sample preparation for the small punch test (SPT);

- Design of the final output.

2.1. Thermal Ageing, Creep Testing, OM, SEM, TEM, and XRD Analyses for the Atlas Project

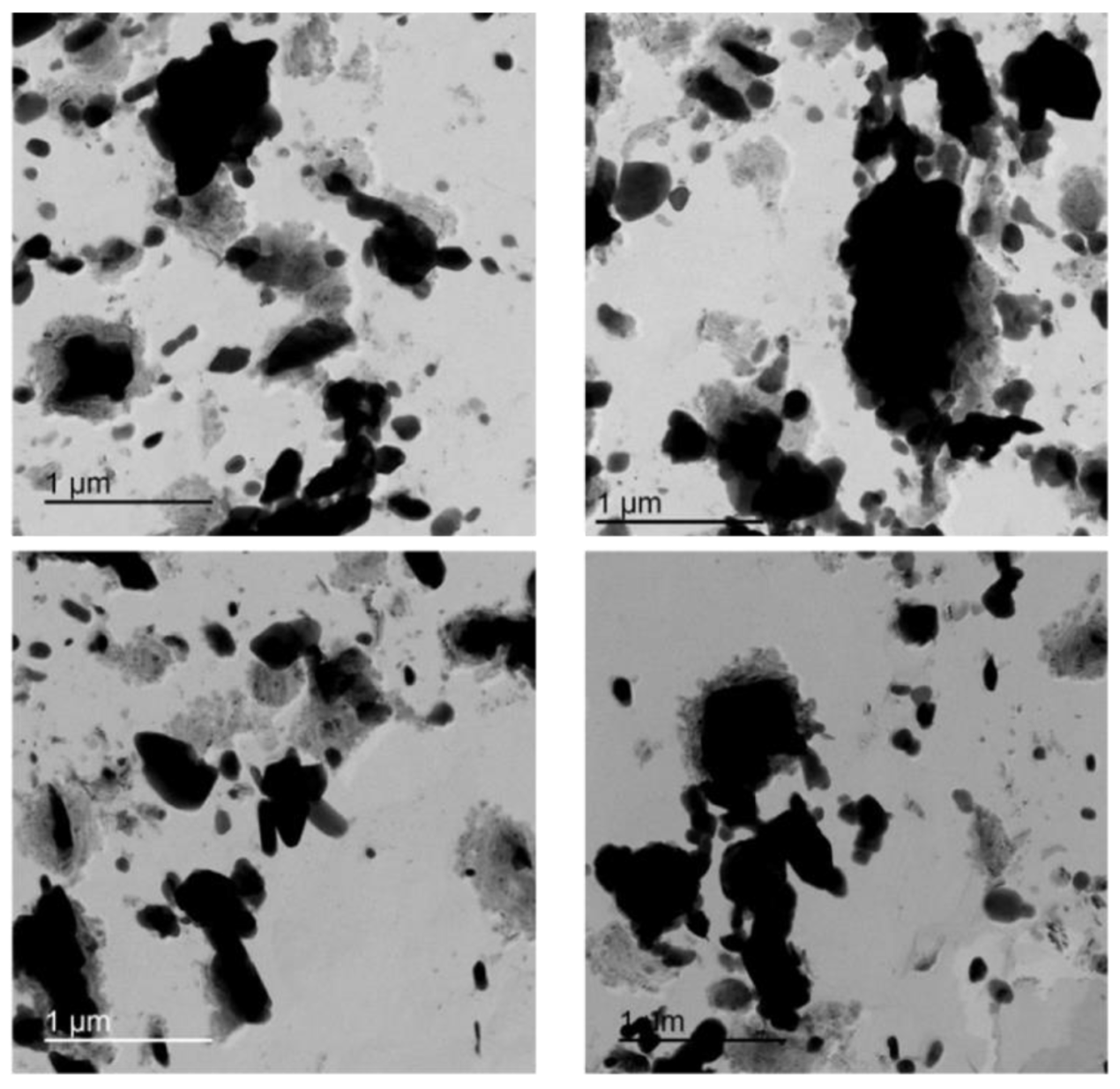

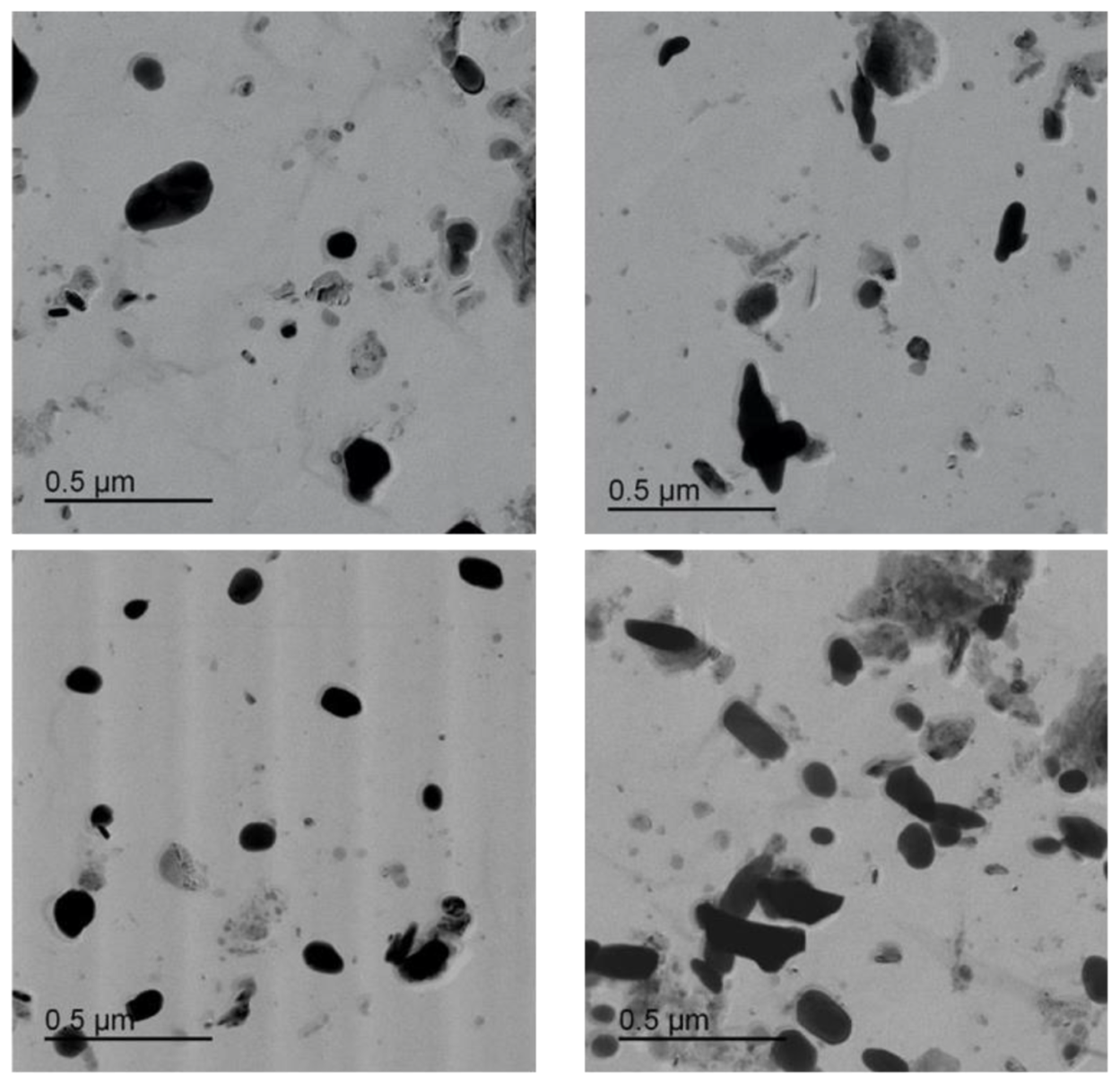

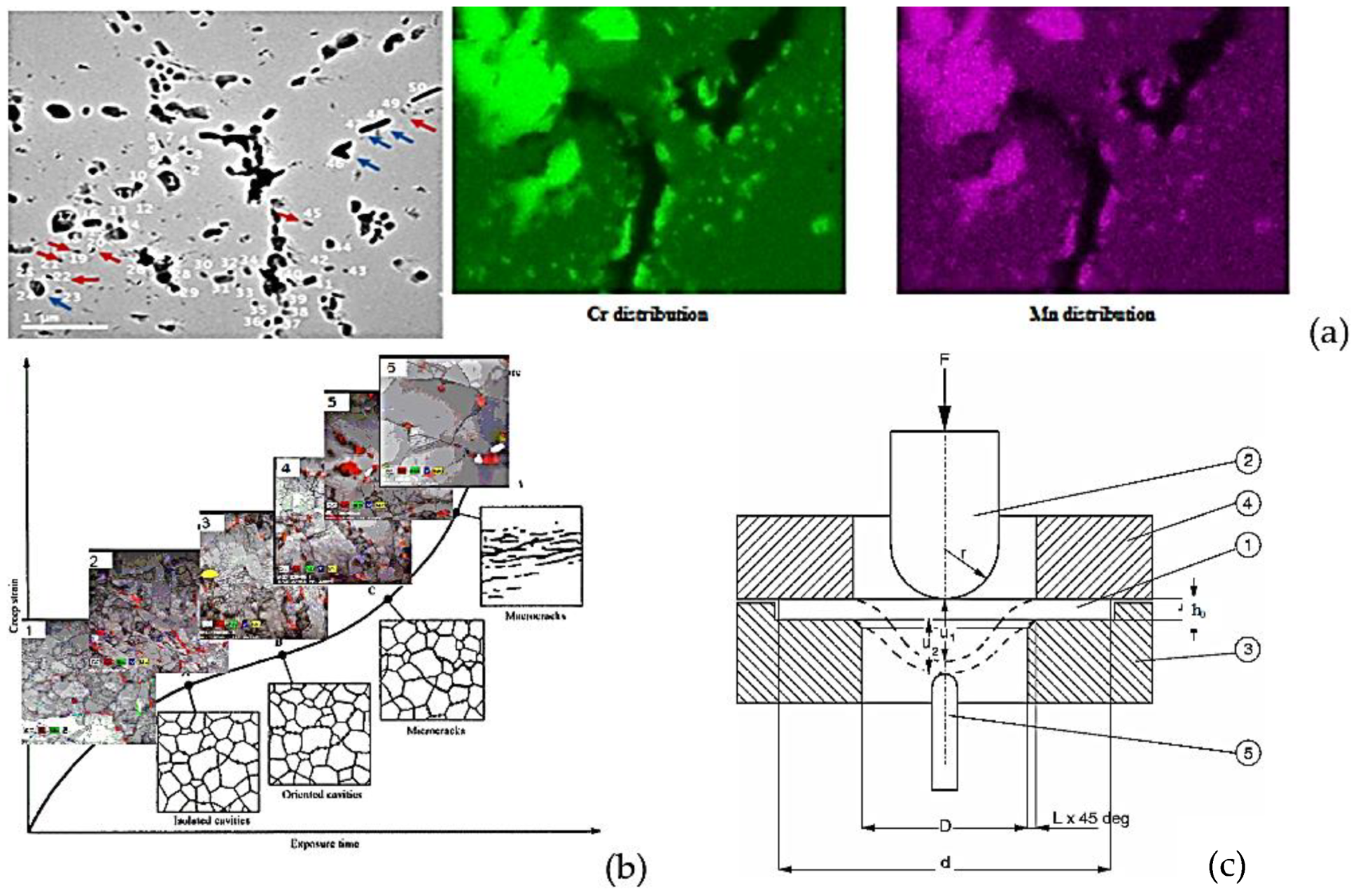

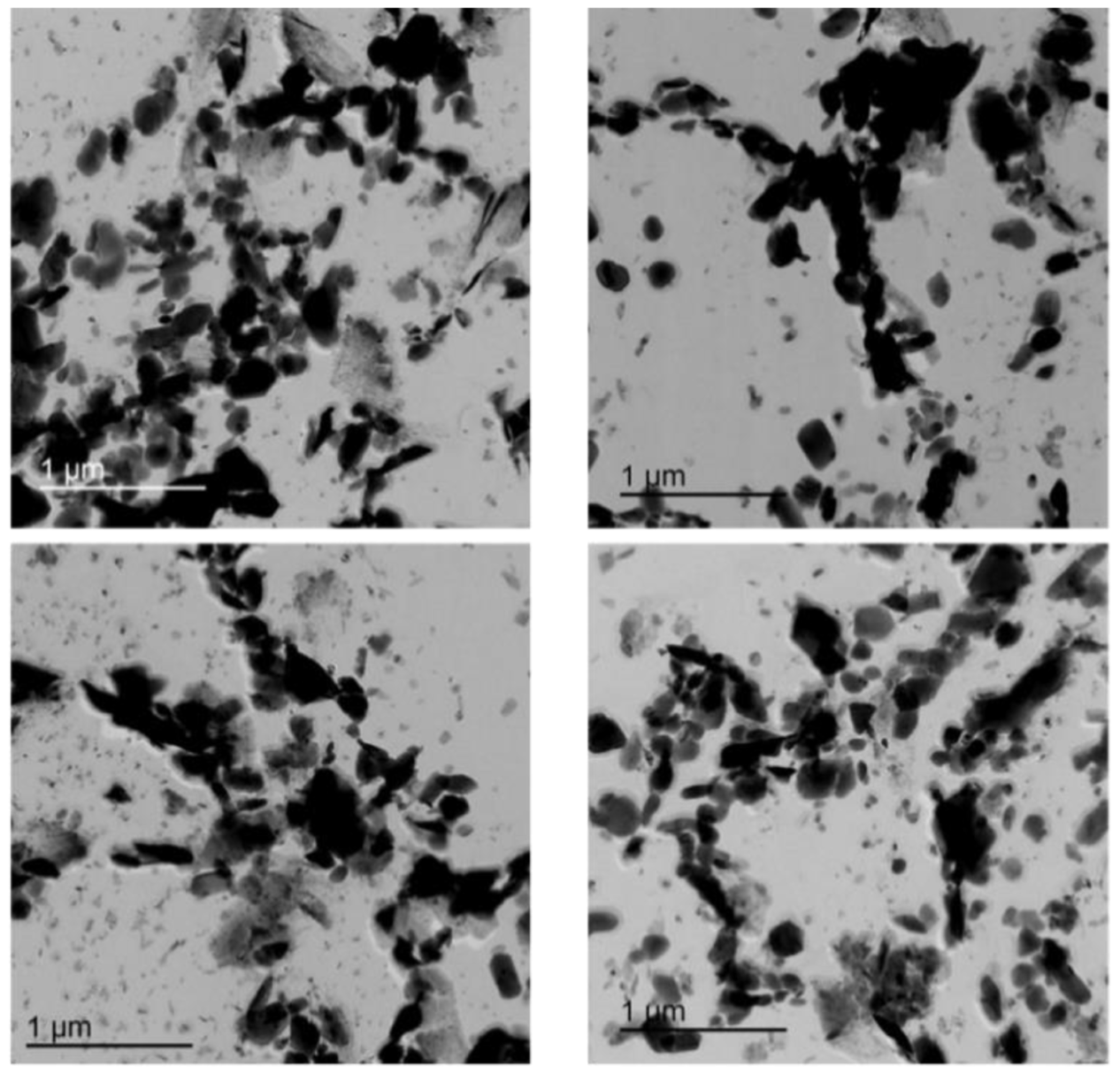

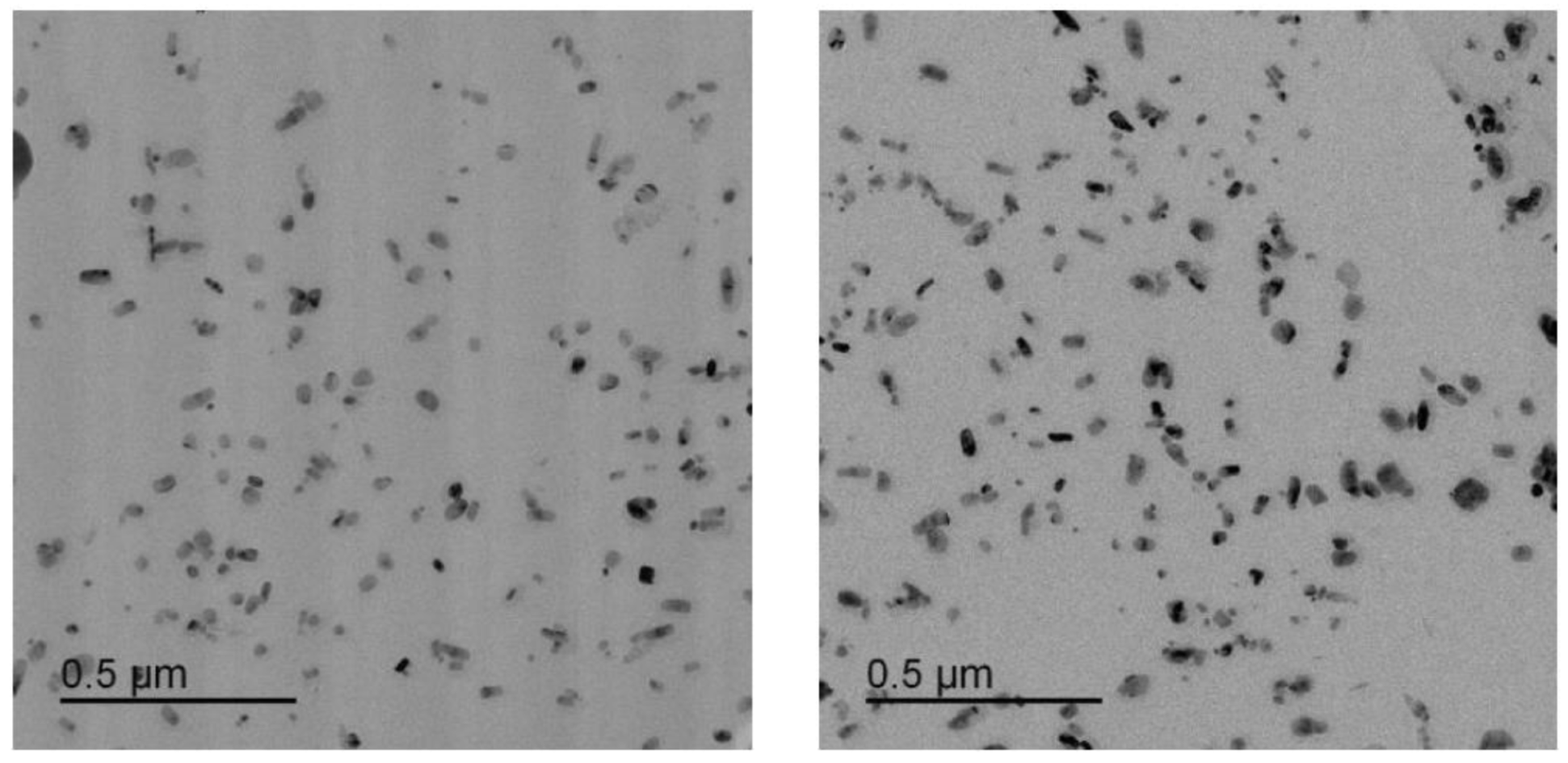

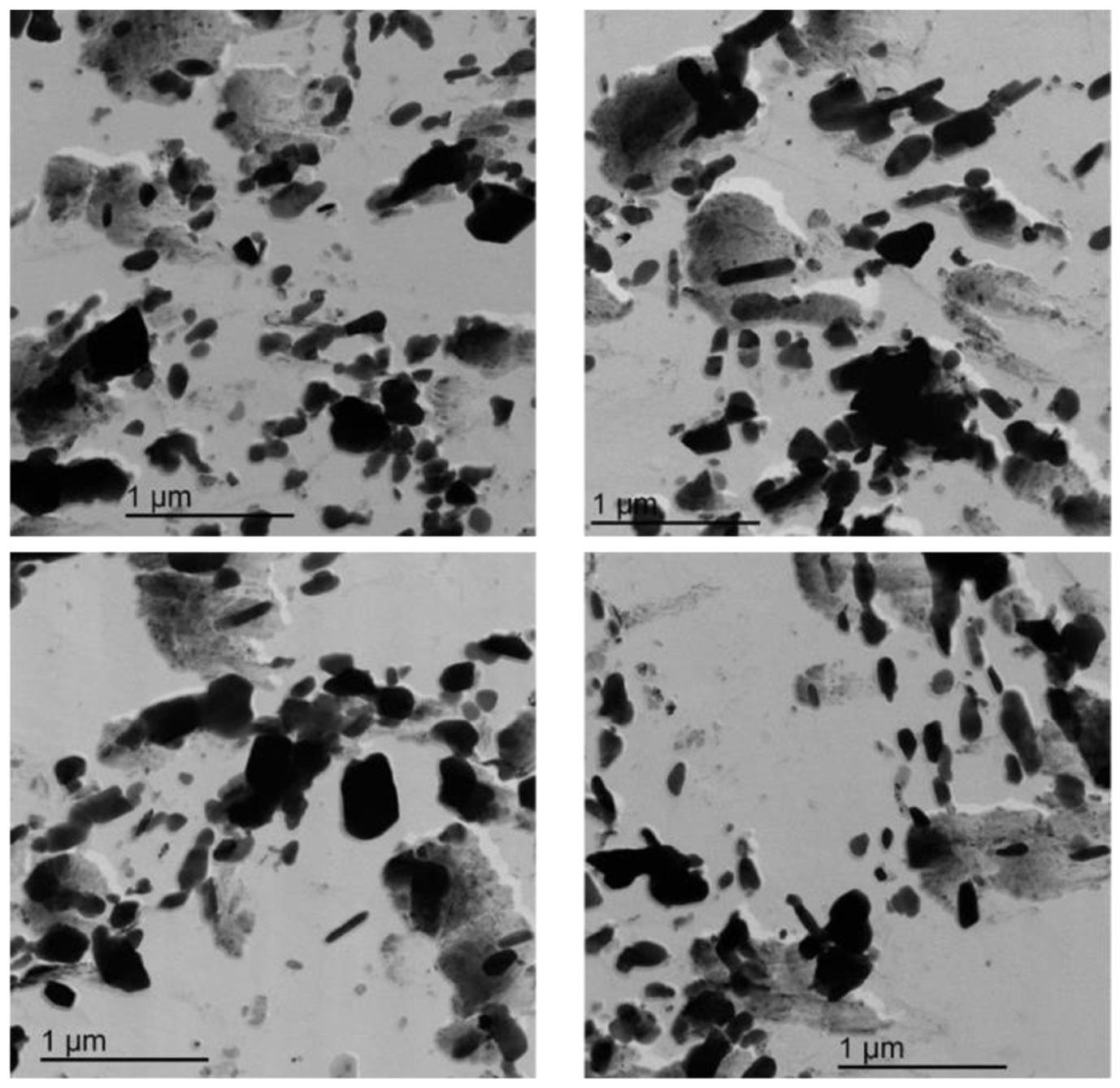

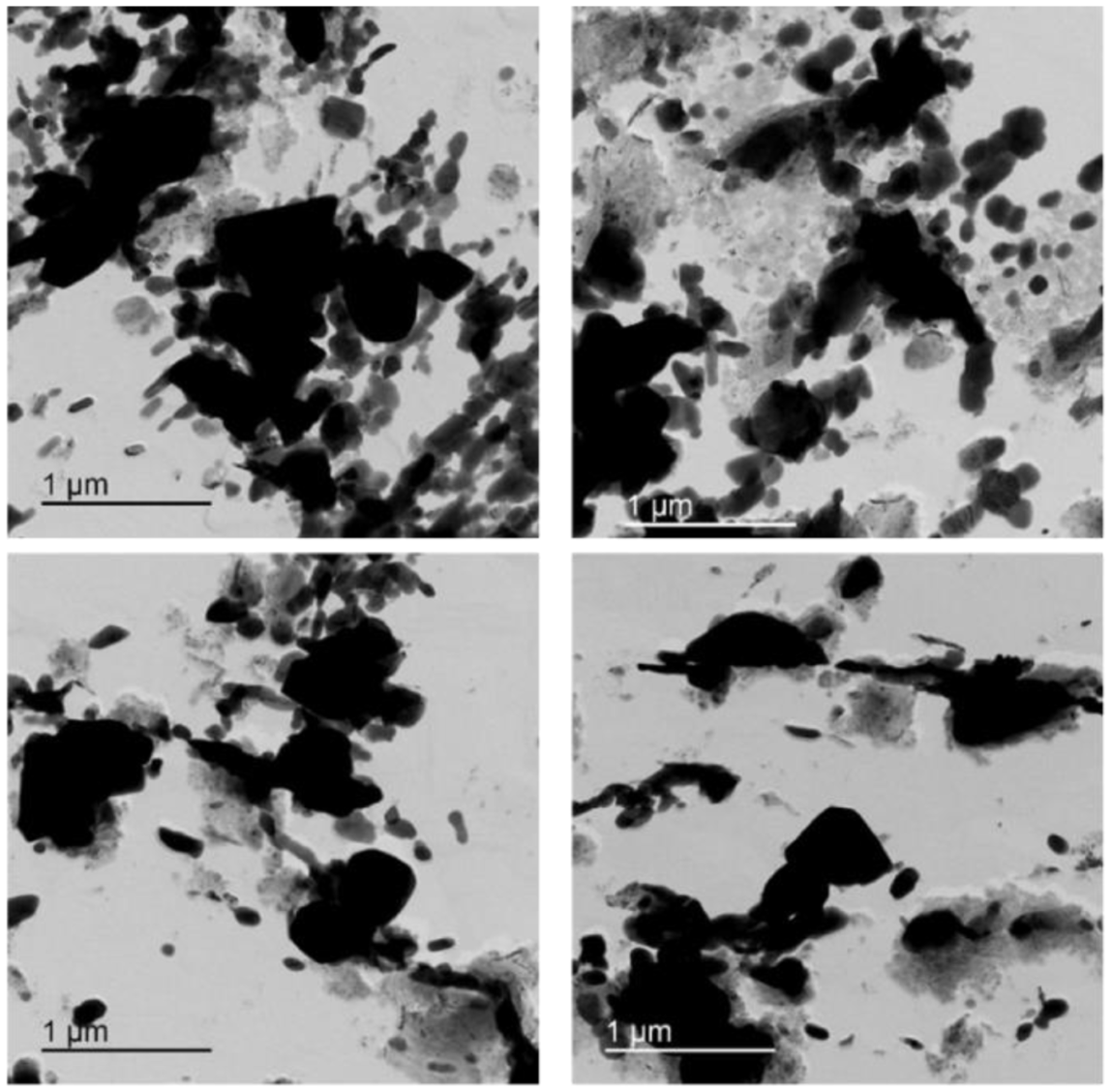

- Grain and subgrain (polygonal ferrite) coarse M23C6 (Cr-, Fe-, and Mo-rich carbides) and Laves-phase Fe- as well as Mo-rich particles with sizes in the range of 0.5 to 1.0 μm;

- M23C6 carbides and Laves-phase particles with sizes in the range of 0.5 to 1.0 μm positioned on prior austenite grain boundaries, polygonal subgrain boundaries, martensite lath boundaries, and within recovered martensite laths.

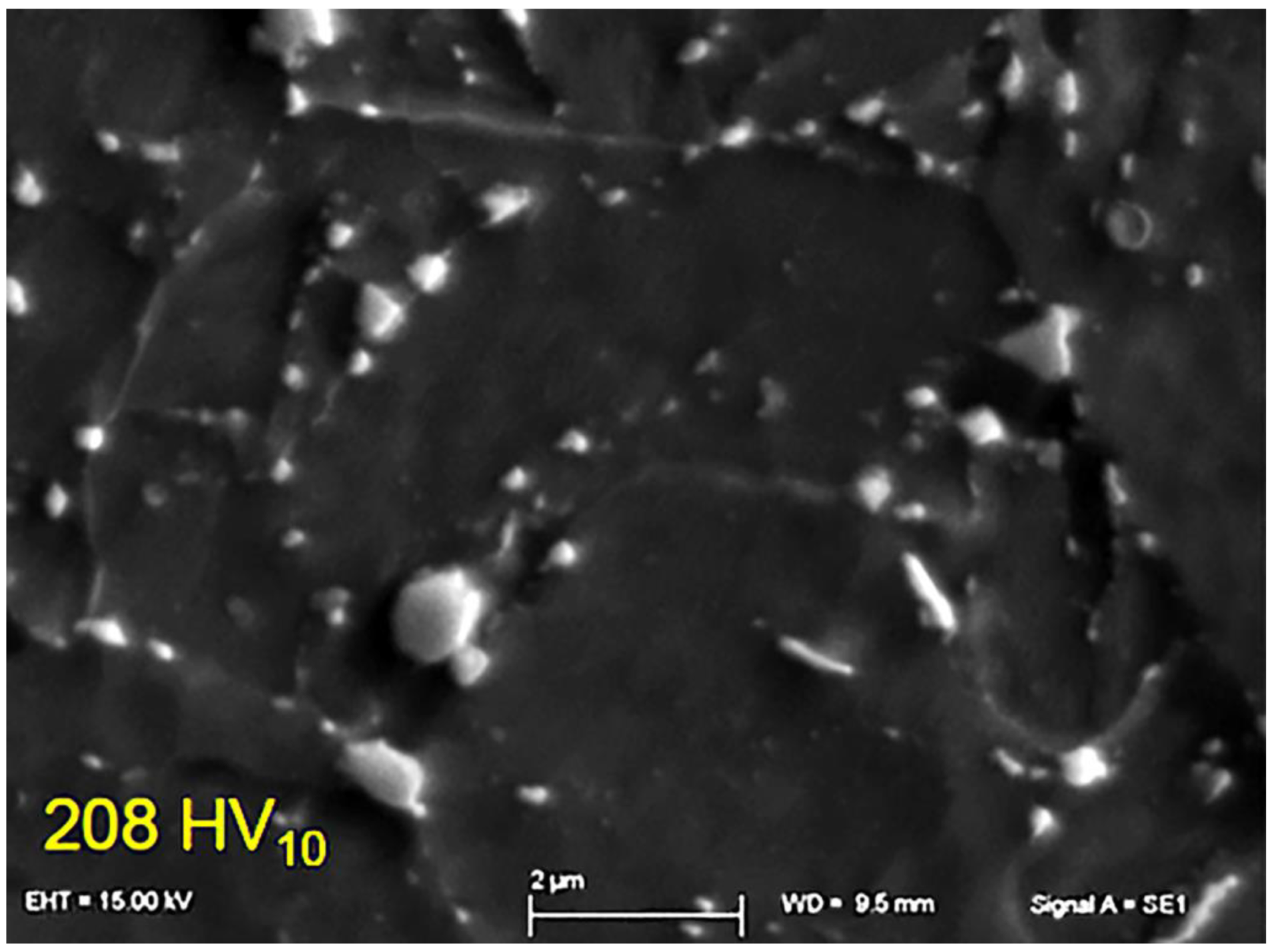

- An analysis of the microstructure with an optical microscope and image acquisition of micrographs at X100, X200, X500, and X1000 to integrate the atlas of the P91 and P92 microstructures;

- Hardness take-over (HV10);

- SEM and FEG-SEM microstructure analyses and digital image acquisition at X1000, X3000, X5000, and X10,000 zooms to integrate the atlas of the P91 and P92 microstructures;

- A qualitative analysis of the precipitation state through an SEM and FEG-SEM, size, and position, and of the chemical composition of the precipitates through an EDS analysis;

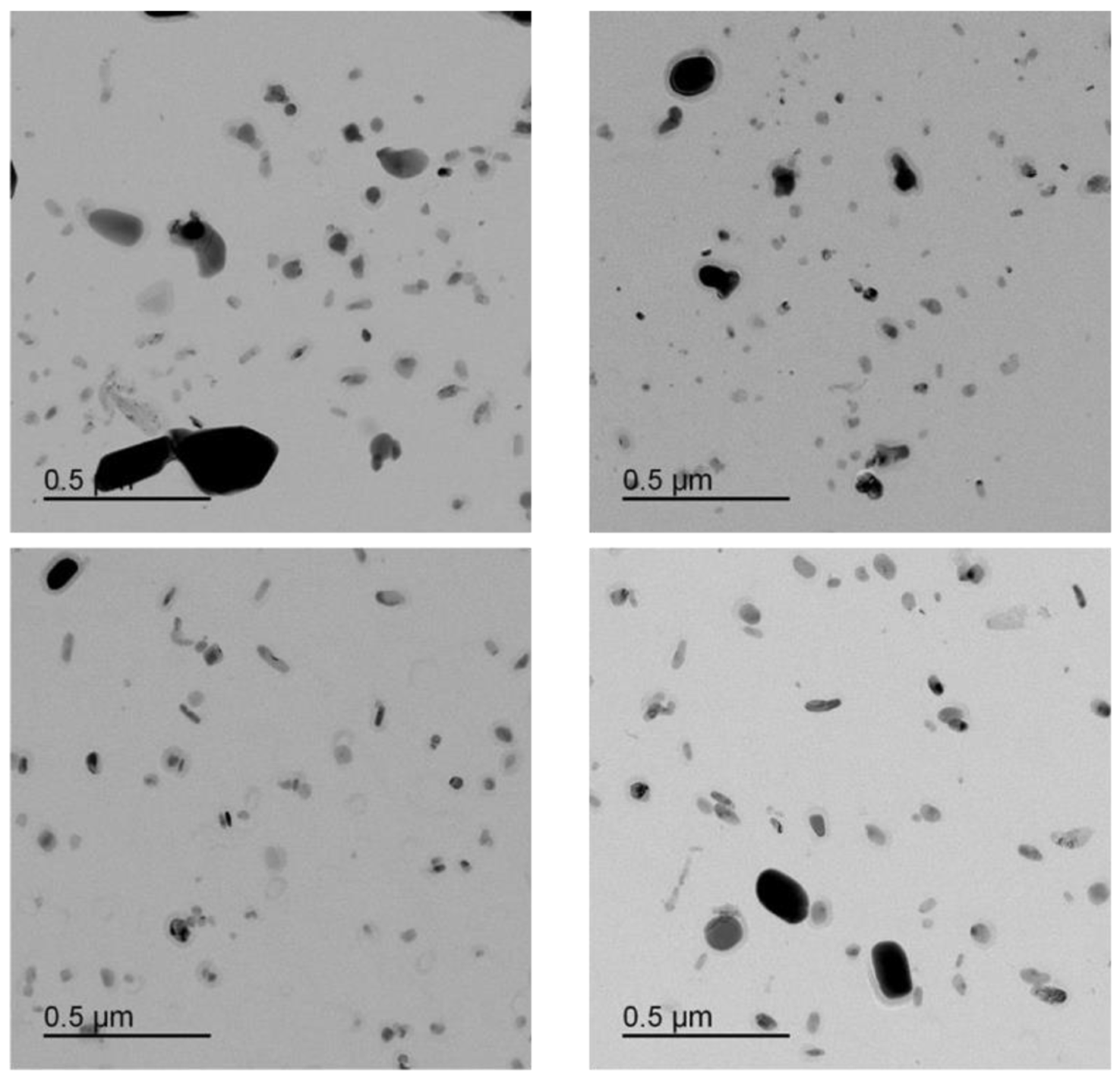

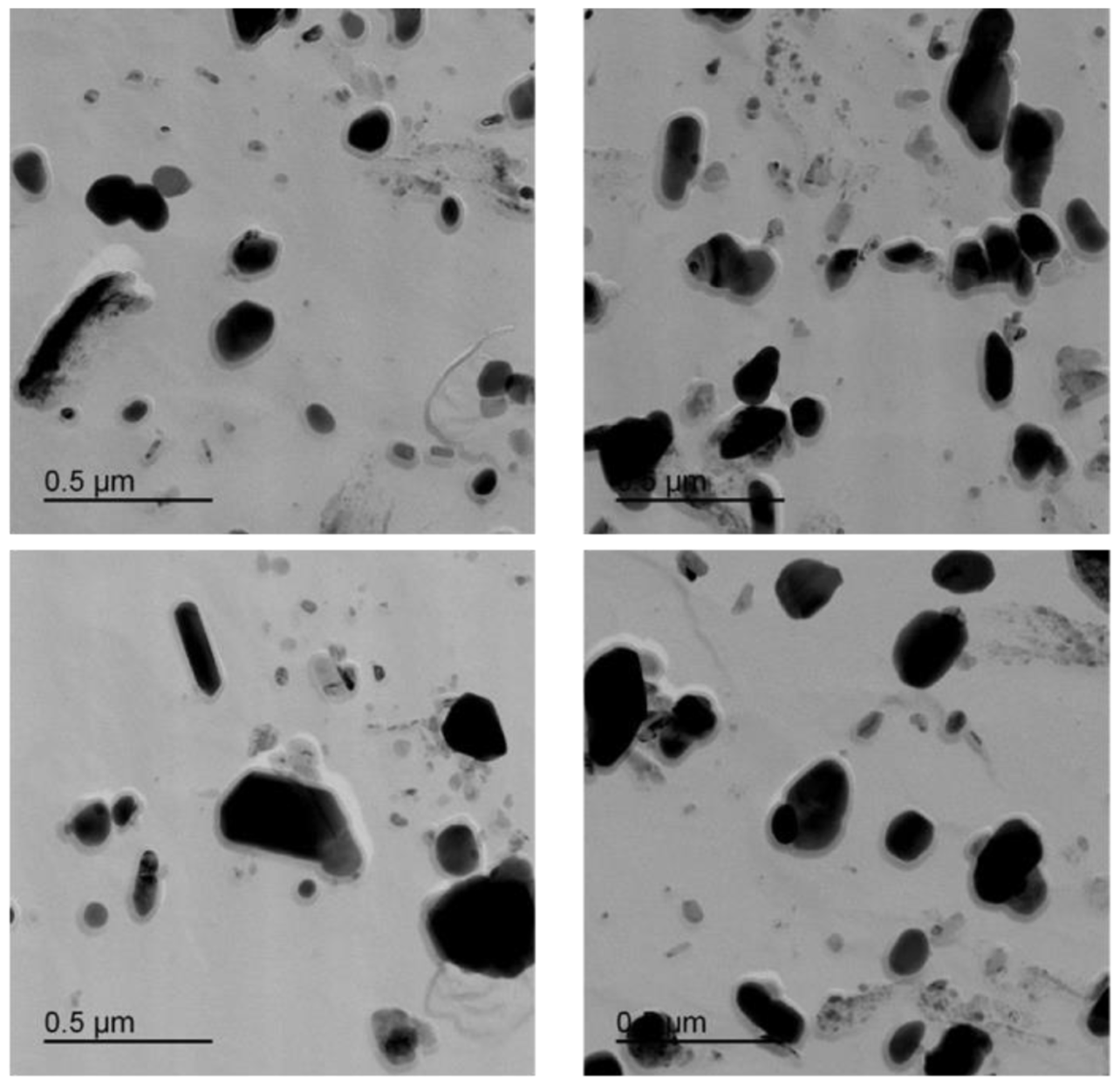

- An evaluation of the morphology and chemical composition of submicrometric precipitates by a TEM on an extraction replica (RE), the identification of precipitates by a chemical analysis (EDS), and X-ray diffraction of the crystal lattice (e.g., MX, M2X, M23C6, ...); image acquisition for P91 and P92 atlas integration;

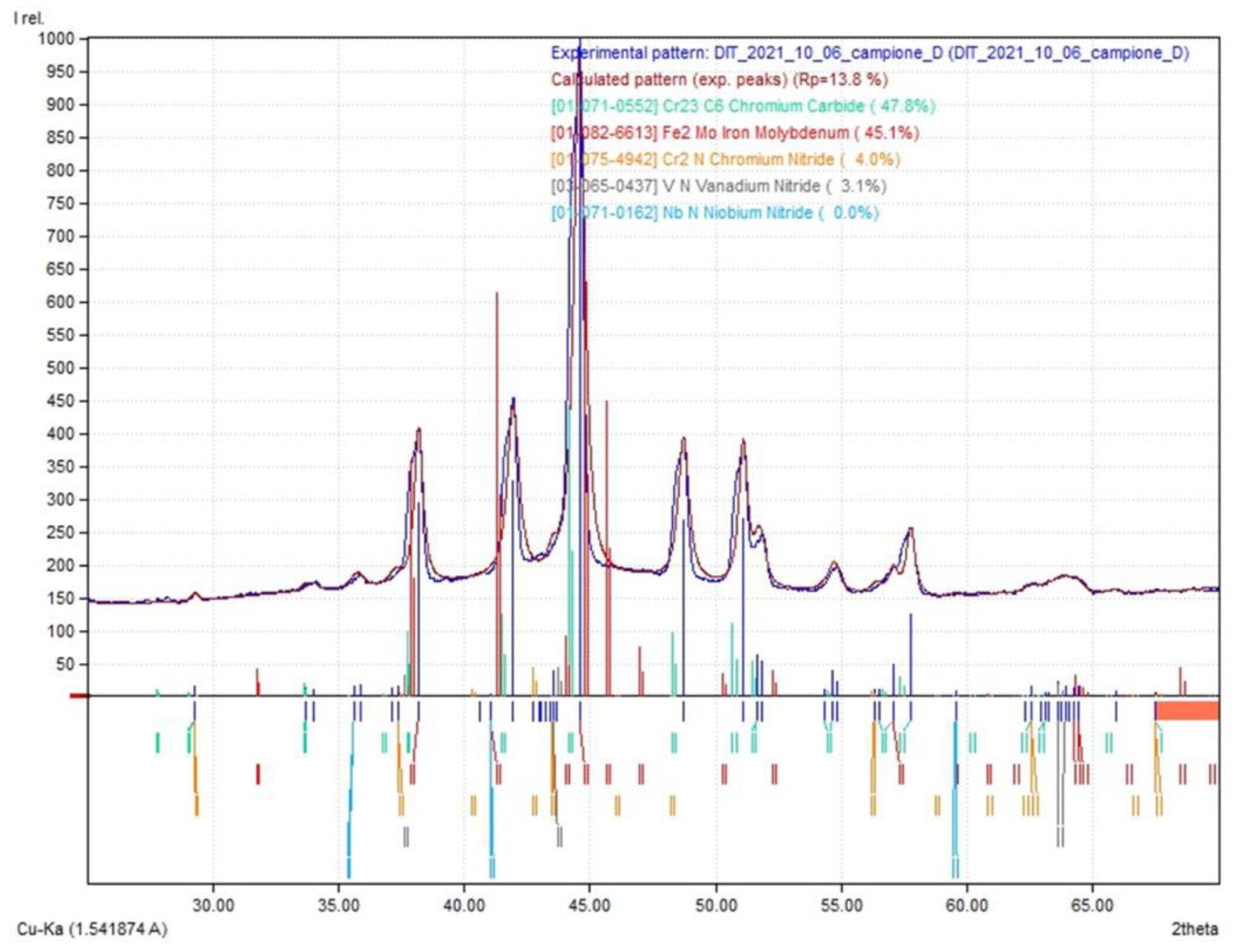

- Precipitate extraction from the massive sample by the electrolytic dissolution and collection of the extracted powders, analyses of the powders, and the realization of the diffraction spectrum; the interpretation of the diffraction spectra is also on the basis of the investigation results described above;

- The preparation after the test, for each sample, of two discs, with a 8 mm diameter and a 0.5 mm thickness, to perform small punch tests according to CEN EN10371:2021.

2.2. Original Material for Subprojects N. 3 and N. 6: Specimen Geometries, Compositions, Mechanical Properties, Welding Specifications, and Grain Sizes

2.3. Creep Testing in Subprojects N. 3 and N. 6

2.4. OM and SEM Analyses for Subprojects N. 3 and N. 6

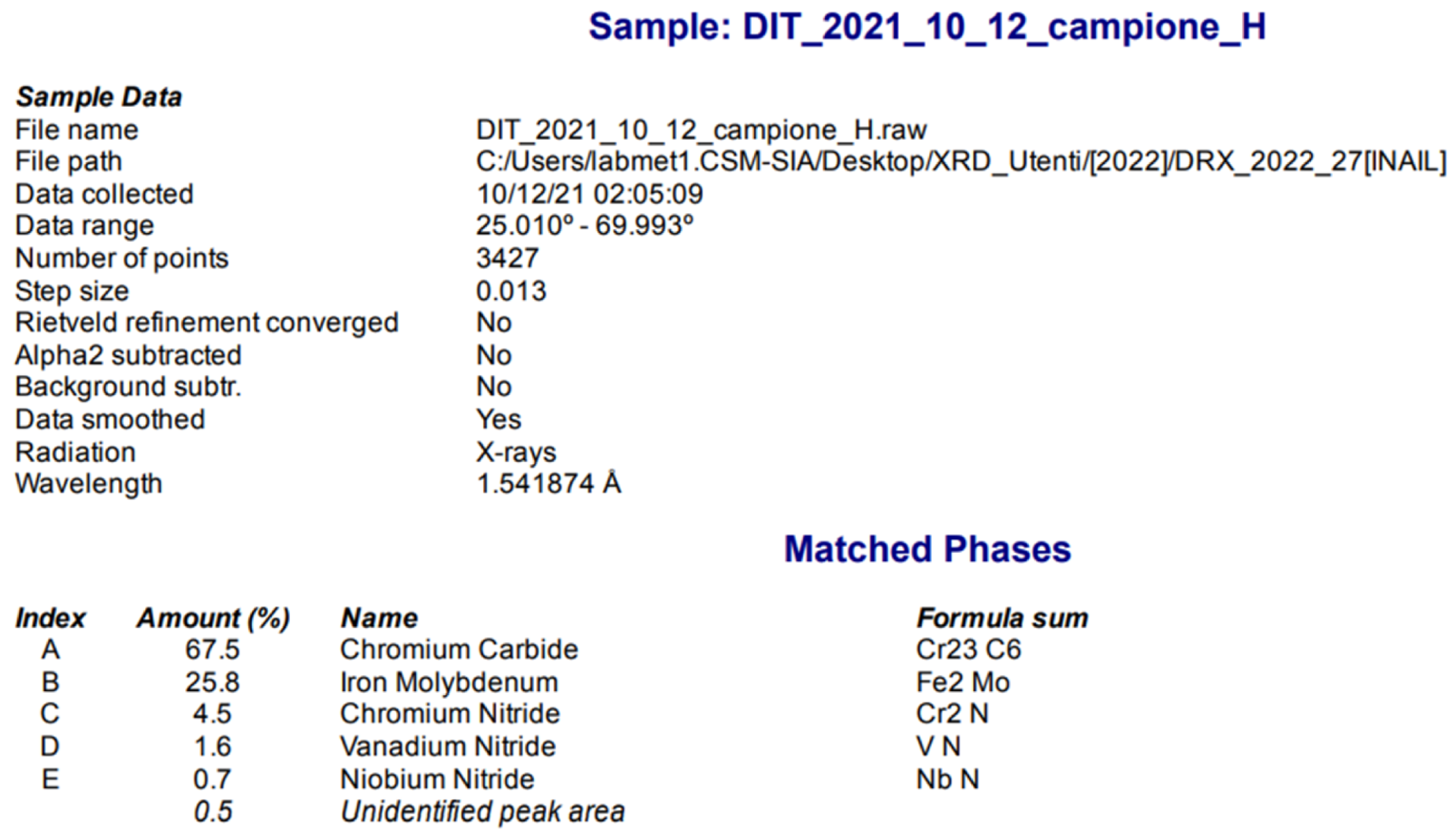

2.5. The XRD Analysis for Subprojects N. 3 and N. 6

- Dissolution of the steel matrix—the anodic dissolution of the steel matrix is carried out in an acidic solution of 5% HCl in 95% ethanol through an electrolytic cell equipped with a dc power supply unit (HP 6261B) at room temperature at a potential of 15 V. For each sample, 10 g of steel is dissolved in 0.5 l of electrolytic solution;

- Filtering of second phases—second-phase particles are extracted from the solution by filtering through a Millipore Isopore VMTP (0.05 µm mesh size) polycarbonate filter. Thereafter, the precipitates are carefully washed with ethanol to clear from possible contaminations due to the original solution containing iron and chlorides. Finally, the filter is dried and the powder is collected.

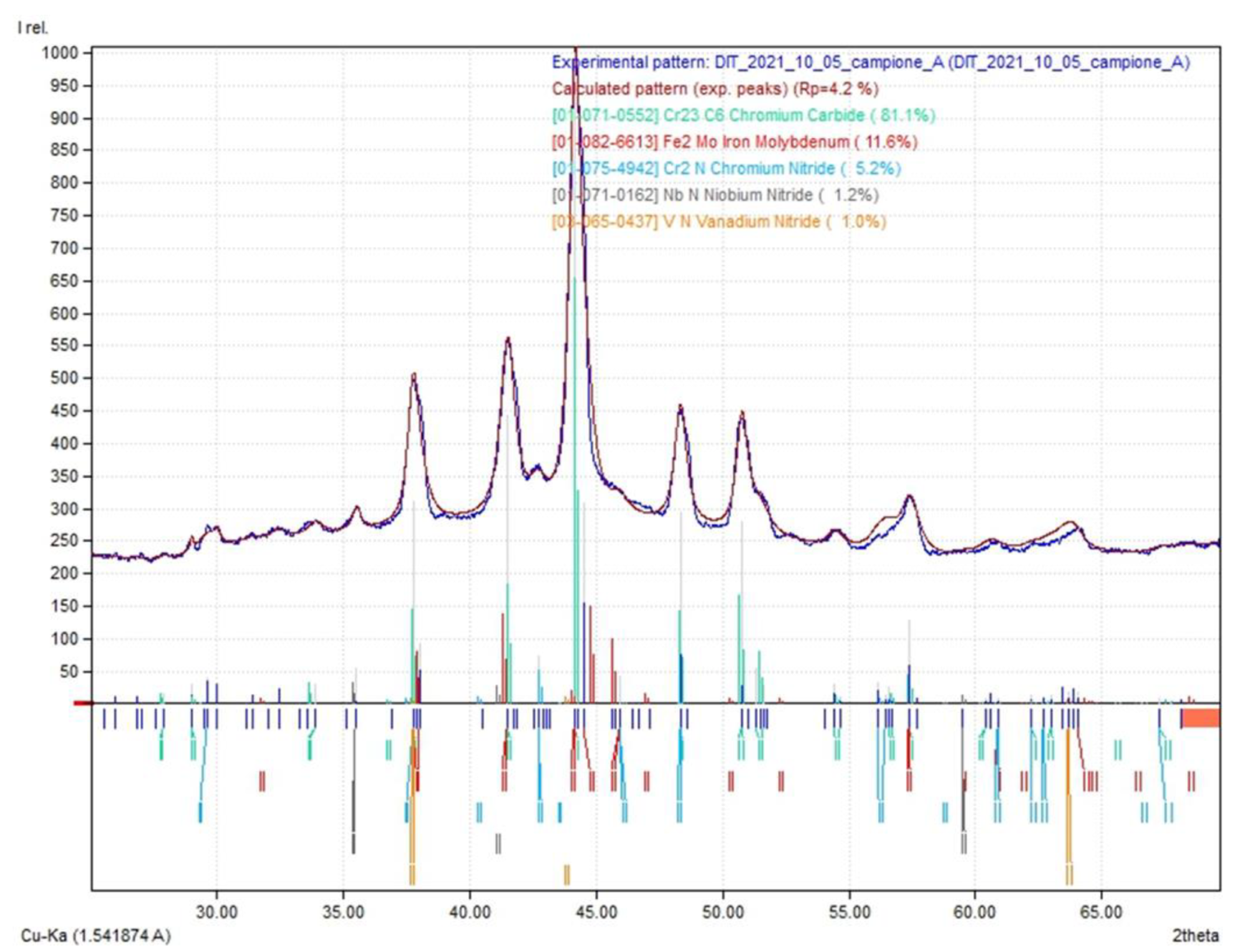

- Number of points: 3427;

- Step size: 0.013;

- 2ndeta correction: 0.34°;

- Radiation X-rays;

- Wavelength 1.541874 Å.

2.6. The TEM Analysis for Subprojects N. 3 and N. 6

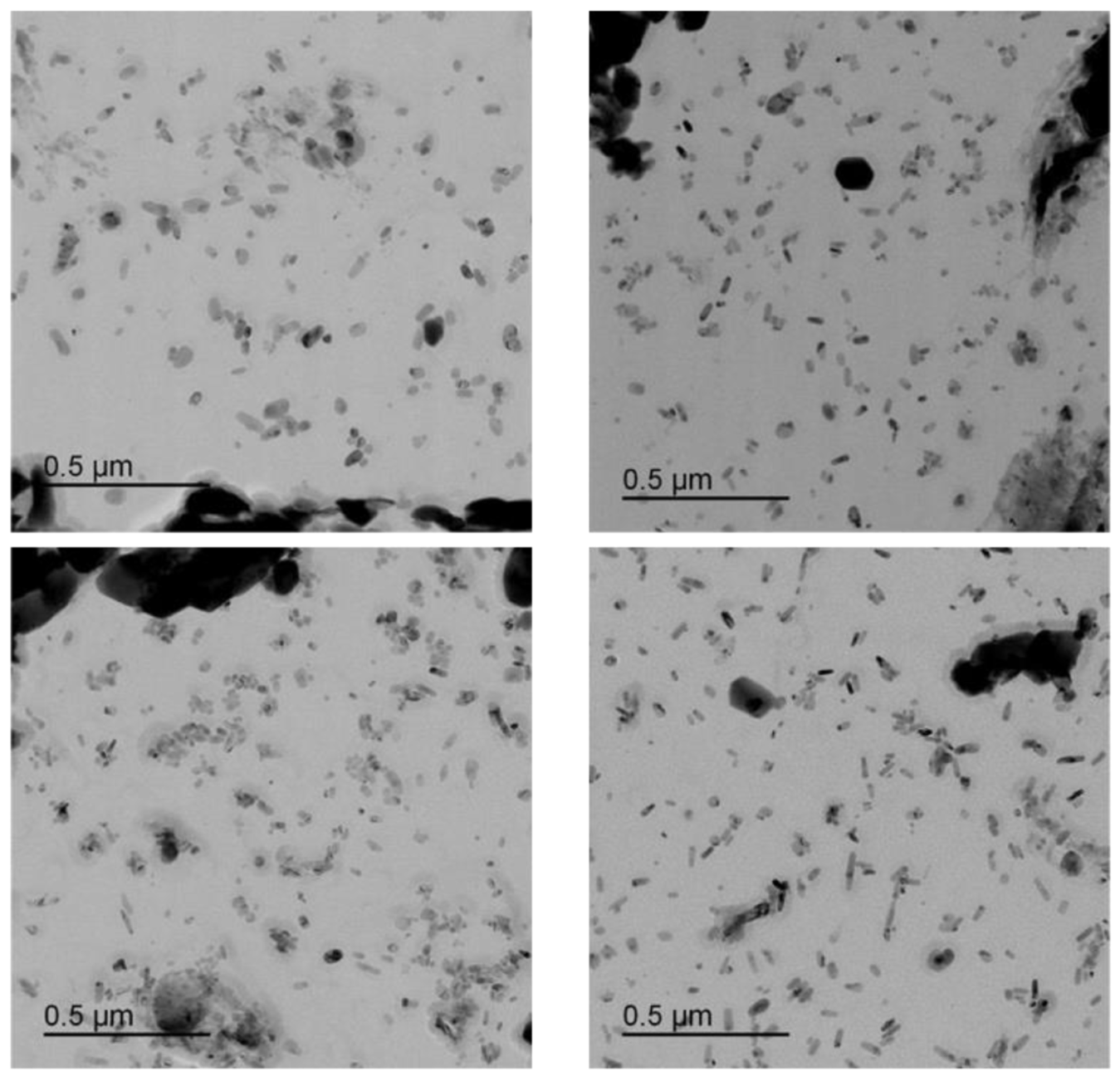

- TEM images: Diffraction contrast technique. Two beam conditions in the selected area diffraction (SAD) pattern are selected for generating dark- and bright-field diffraction contrast images in order to highlight microstructural component constituents. A high-contrast, bright-field, and low-magnification image at 1000X is first acquired in order to highlight a general view of several prior austenite grains of the extraction and identify the representative area to be investigated. Then, TEM bright-field images are acquired in the selected area at different magnifications (12,000X, 50,000X, and 100,000X). In some regions of the selected area, information may be given concerning the precipitate position on the microstructural features, such as prior austenitic grain boundaries, recovered martensite lath boundaries, subgrain boundaries, and within recovered martensite laths.

- Automatic image analysis: AIA applied on bright-field images. The assessment of morphology, size (diameter), size distribution, mean value, and the standard deviation of the overall precipitate population is performed on bright-field images by using automatic image analysis (AIA).

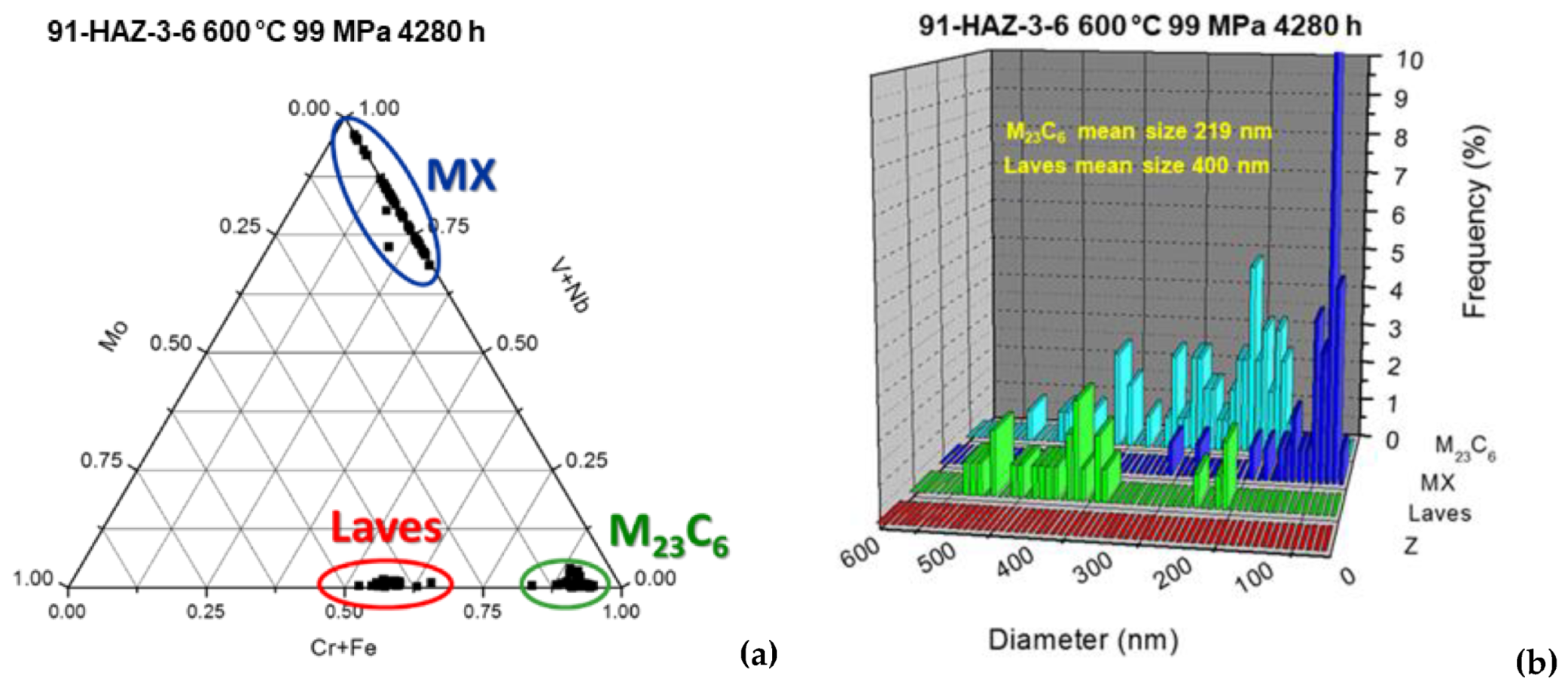

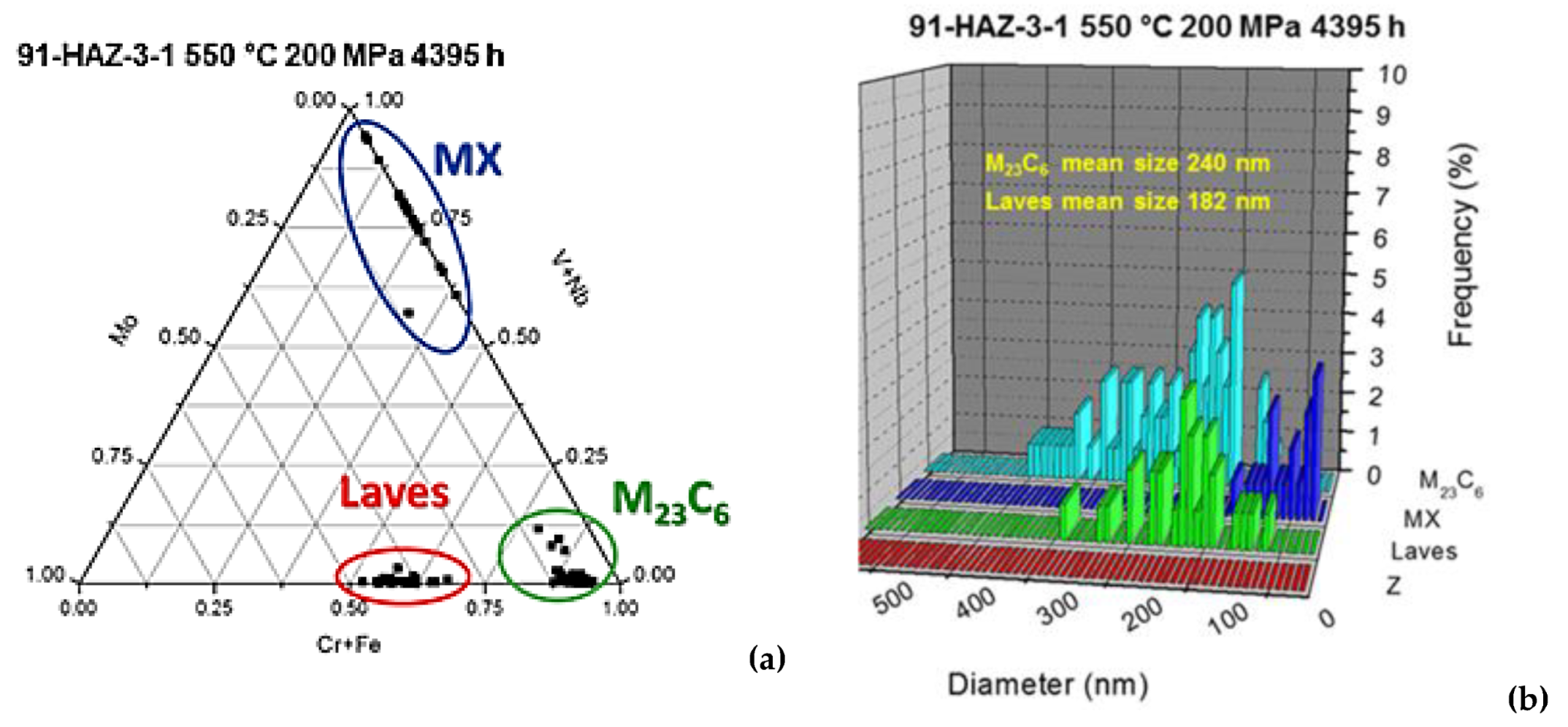

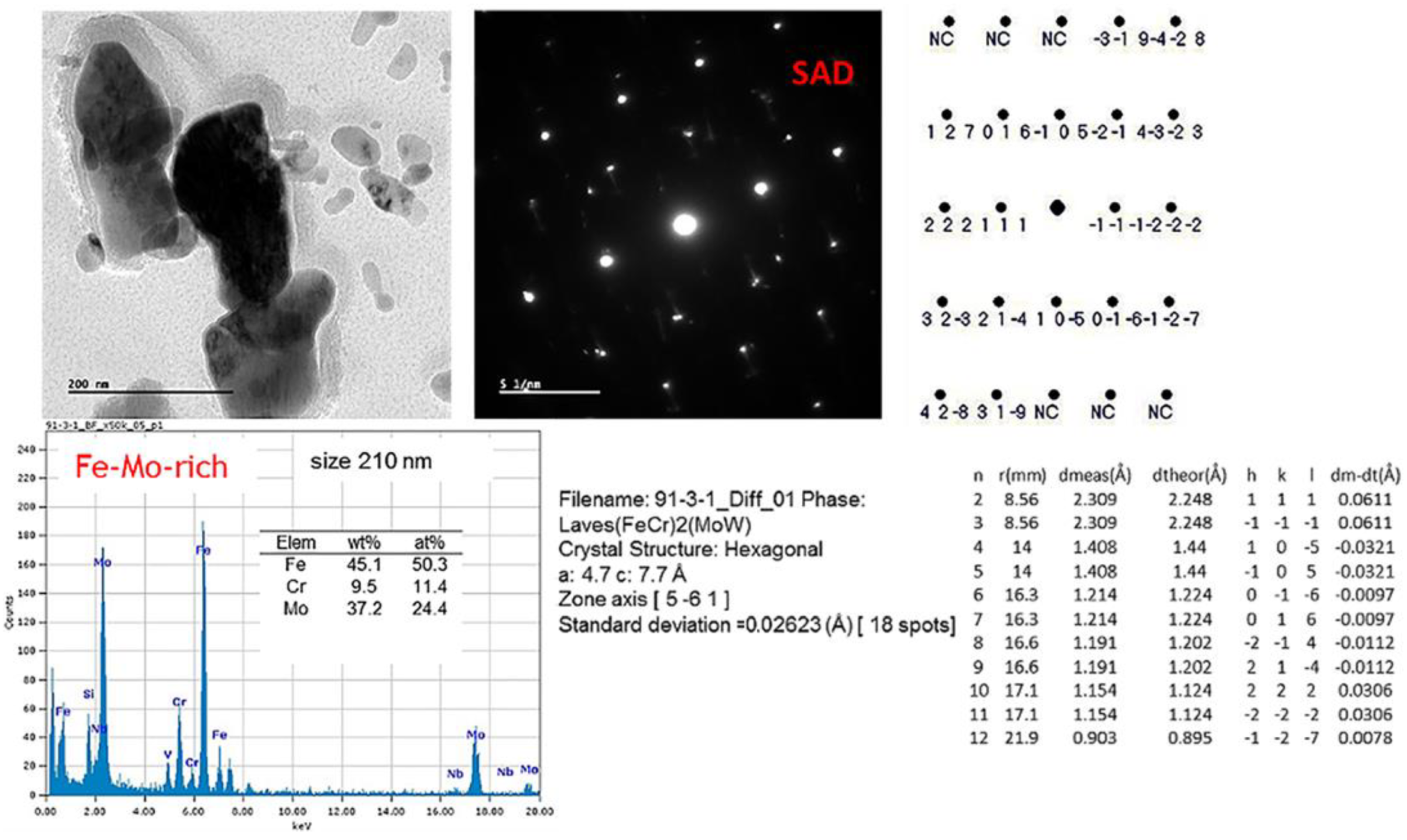

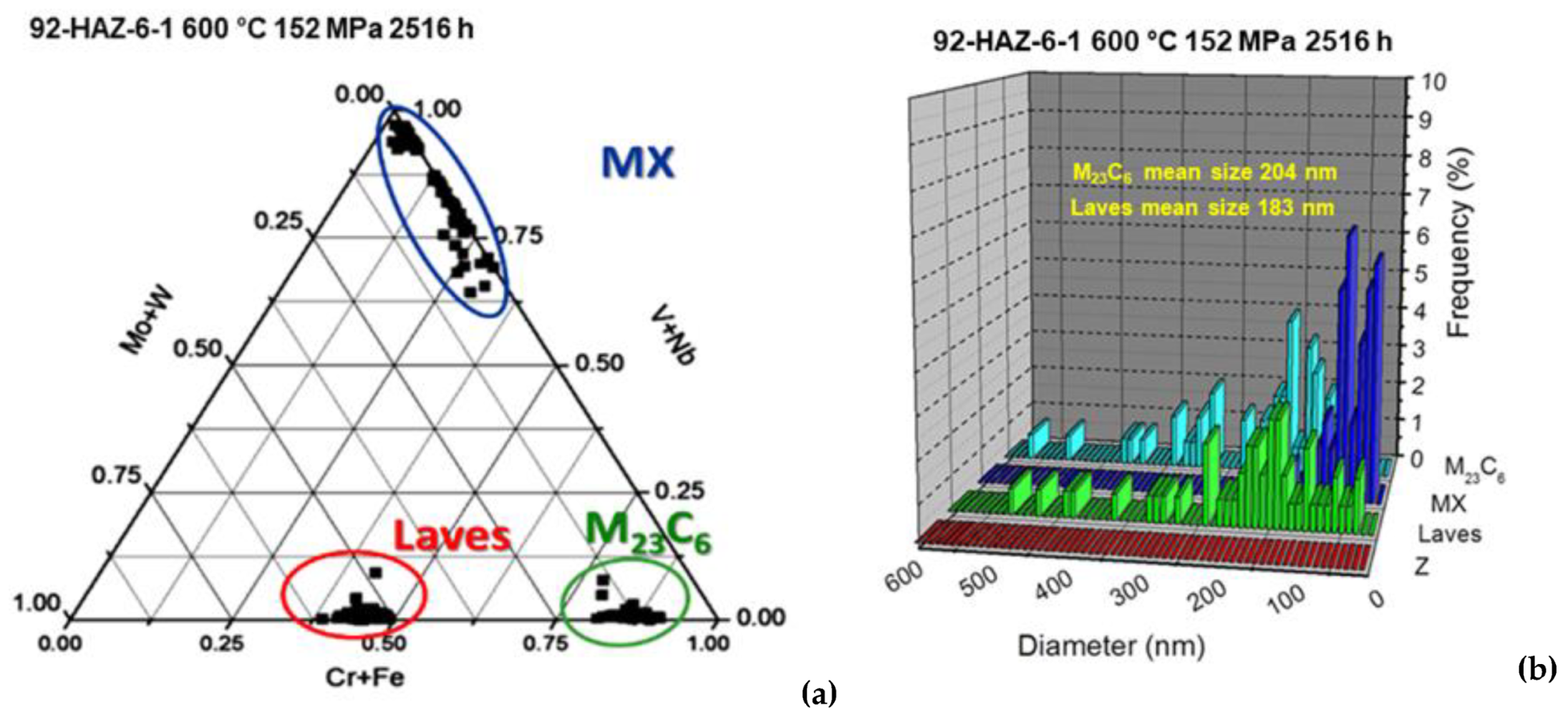

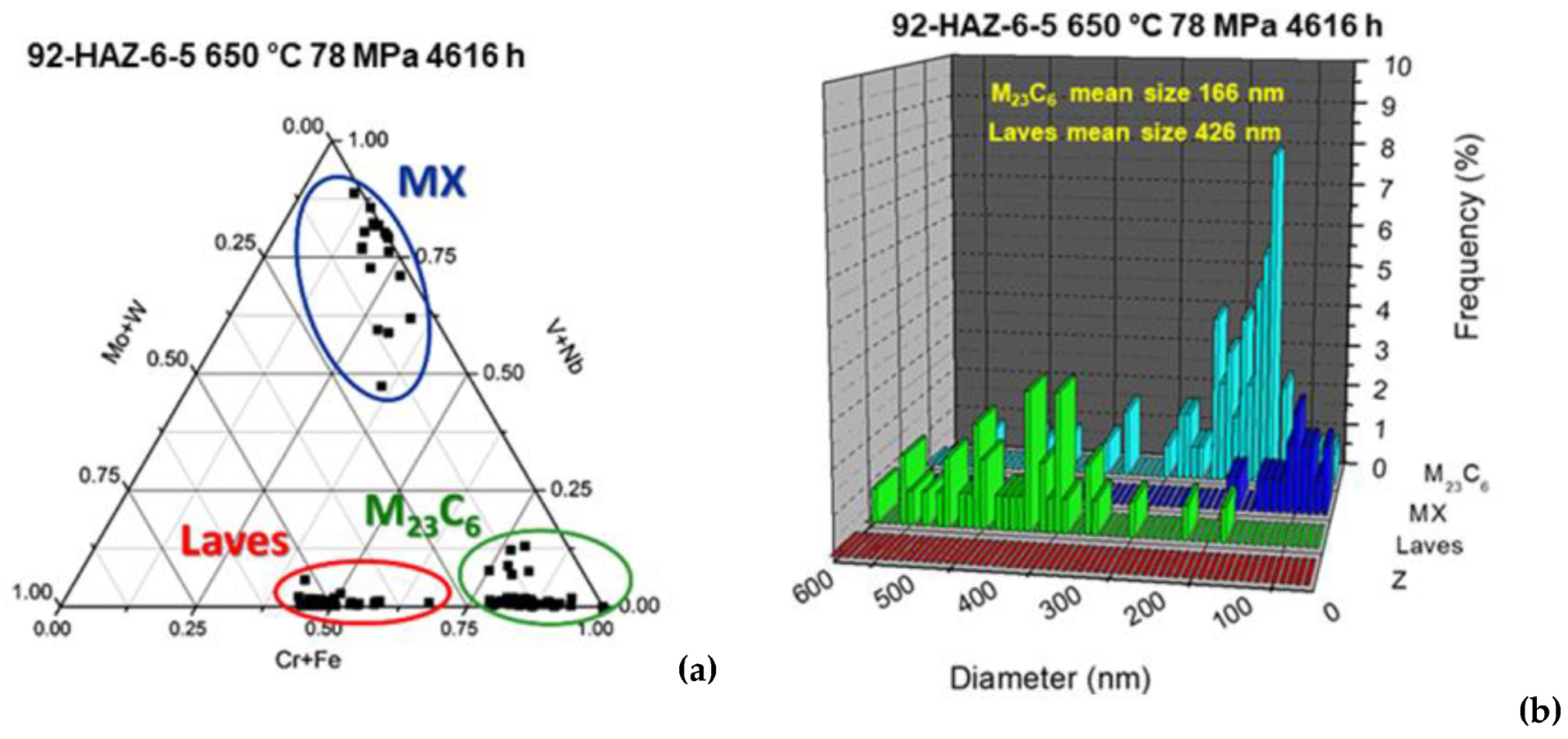

- High-spatial-resolution microanalysis: The chemical composition of about 100 precipitates positioned on prior austenite grain boundaries, subgrain boundaries, recovered martensite lath boundaries, and within recovered martensite laths as well as subgrains is assessed by using high-spatial-resolution microanalysis (EDS). On the basis of element repartition, such as Cr, Fe, Mo, W, V, and Nb, different classes of precipitates are distinguished: M23C6, (Cr,Fe,W,Mo)-rich carbides; MX, V-rich, Nb-rich carbonitrides; Laves, Fe2 (W,Mo) phase (W,Mo)-rich; and Z nitride, (Cr,Nb,V)N phase (Cr,V,Nb)-rich.

3. Results

- The XRD spectrum, calculated diffraction pattern, and matched phases associated with each peak intensity;

- The Match Phase Analysis Report;

- The evaluation of the partition of matched phases (amount %) given in the Match Phase Analysis Report;

- The comparison with data obtained by extraction replicas and TEM analyses.

3.1. Results of the Tests Performed on Grade 91 HAZ

- Chromium carbide, Cr23C6 (81.1%);

- Iron molybdenum, Fe2Mo (11.6%);

- Chromium nitride, Cr2N (5.2%);

- Niobium nitride, NbN (1.2%);

- Vanadium nitride, VN (1.0%);

- Unidentified peaks (0.6%).

- By XRD: more than 81% of M23C6, around 2% MX, and 12% Laves phases;

- By the TEM: 60% M23C6, around 23% Laves phases, and 17% MX.

- Chromium carbide, Cr23C6 (47.8%);

- Iron molybdenum, Fe2Mo (45.1%);

- Chromium nitride, Cr2N (4.0%);

- Vanadium nitride, VN (3.1%);

- Unidentified peaks (3.4%).

3.2. Results of the Tests Performed on Ex-Service Grade 92

- Chromium carbide, Cr23C6 (85.6%);

- Iron molybdenum, Fe2Mo (8.0%);

- Vanadium nitride, VN (6.0%);

- Niobium nitride, NbN (0.4%);

- Unidentified peaks (3.5%).

- By XRD: more than 80% M23C6, few MX and Laves phases;

- By the TEM: 46% M23C6, around 25% Laves phases and MX.

3.3. Results of the Tests Performed on Grade 92 HAZ

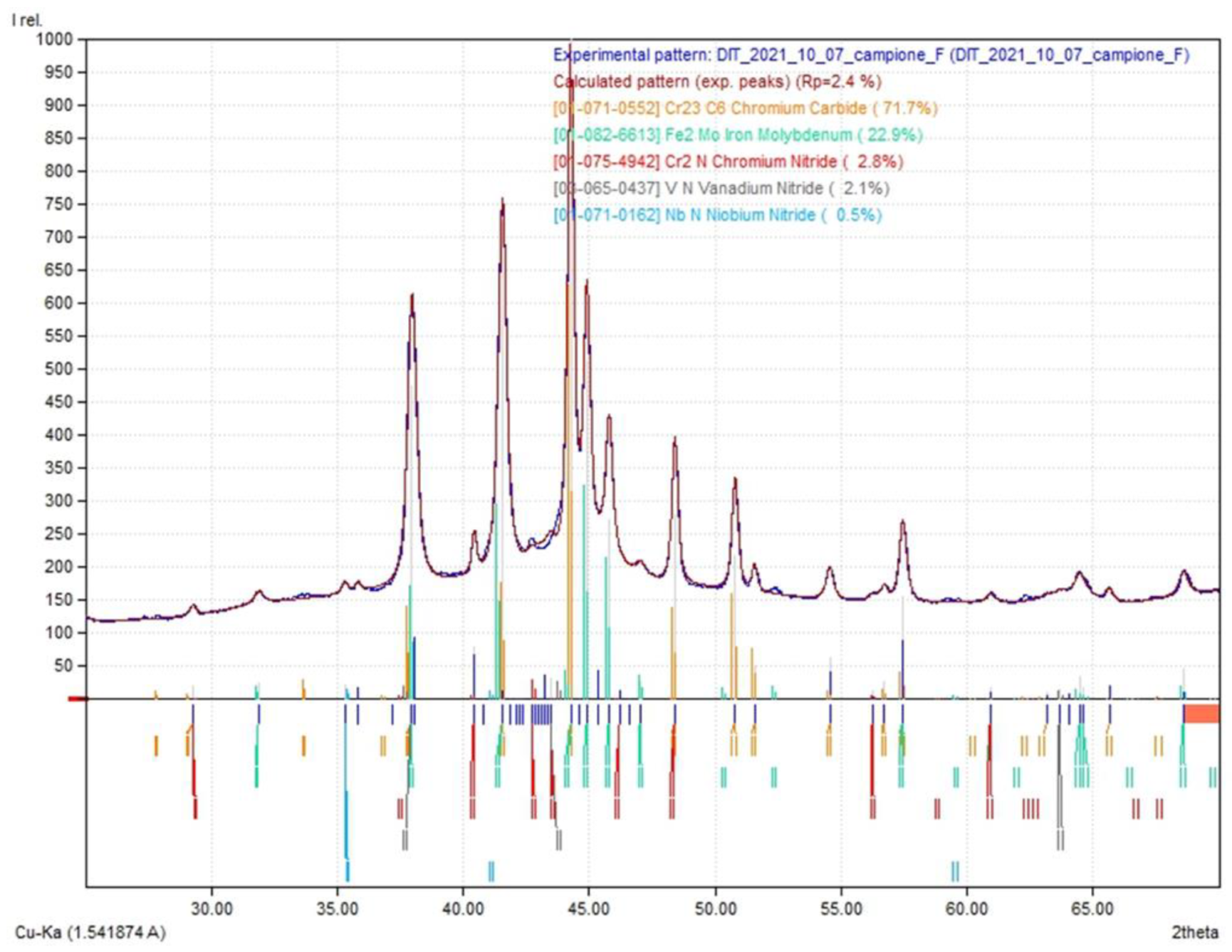

- Chromium carbide, Cr23C6 (71.7%);

- Iron molybdenum, Fe2Mo (22.9%);

- Chromium nitride, Cr2N (2.8%);

- Vanadium nitride, VN (2.1%);

- Niobium nitride, NbN (0.5%);

- Unidentified peaks (3.2%).

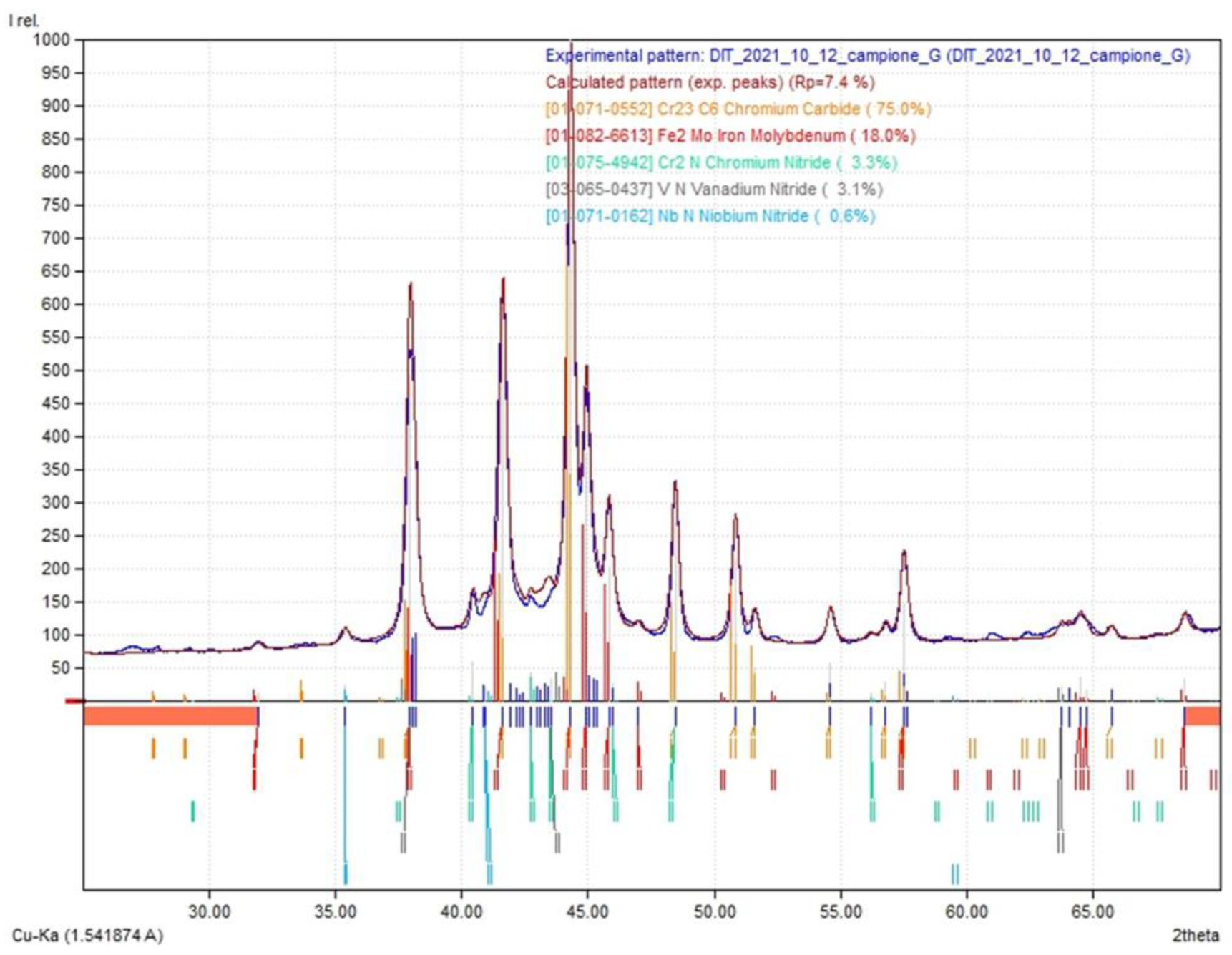

- Chromium carbide, Cr23C6 (75.0%);

- Iron molybdenum, Fe2Mo (18.0%);

- Chromium nitride, Cr2N (3.3%);

- Vanadium nitride, VN (3.1%);

- Niobium nitride, NbN (0.6%);

- Unidentified peaks (7.0%).

4. Discussion

5. Conclusions

- Eight HAZ failed crept specimens were submitted to XRD examinations;

- Eight XRD diagrams were produced and subsequently compared with twelve replicas for each specimen; that is, ninety-six extraction replicas were produced for this work;

- Around 5000 precipitates were analyzed for each specimen, and an average of 120 precipitates were characterized with TEM-EDS analyses;

- The possibility to perform a correct quantitative analysis was demonstrated by a comparison with extraction replicas, showing the same precipitates found by XRD as well as the same microstructure evolution: the decreasing in MX, the little decreasing in M23C6, and the increasing in Laves phases were noted after the conclusion of the creep tests and for the ex-service specimen exposed to 600 °C, 40 MPa, and 74,000 h;

- The results obtained (the XRD diagrams) will be included in the P91 and P92 microstructure atlas, the final aim of this research activity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix A.1. Subproject N°3: GR 91 HAZ CREEP

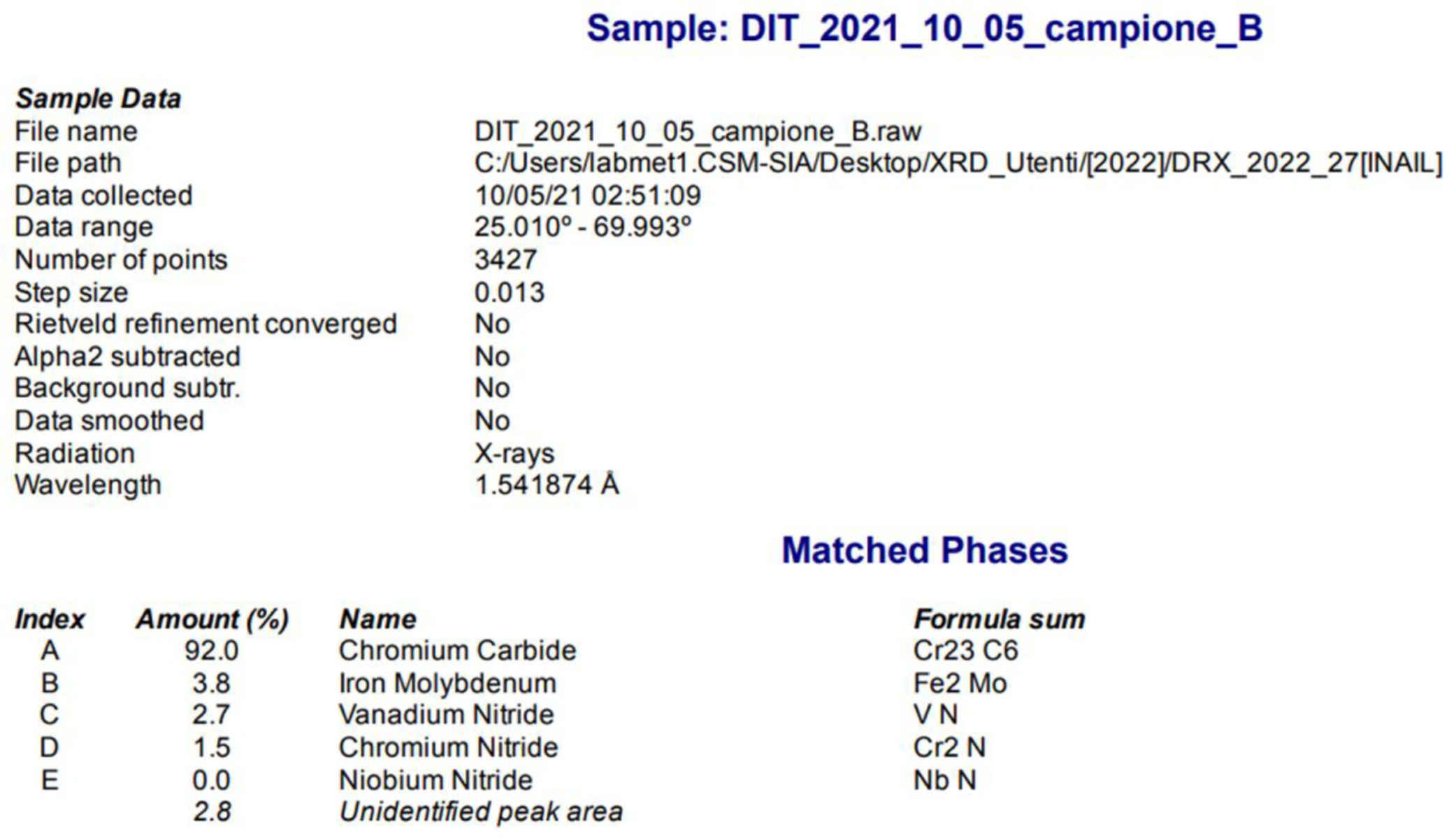

Appendix A.1.1. The Figure A1 Provide the Results of XRD on Failed Crept Cross-Weld Specimen 91-HAZ-3-5 600 °C 112 MPa 3216 h (Sample B)

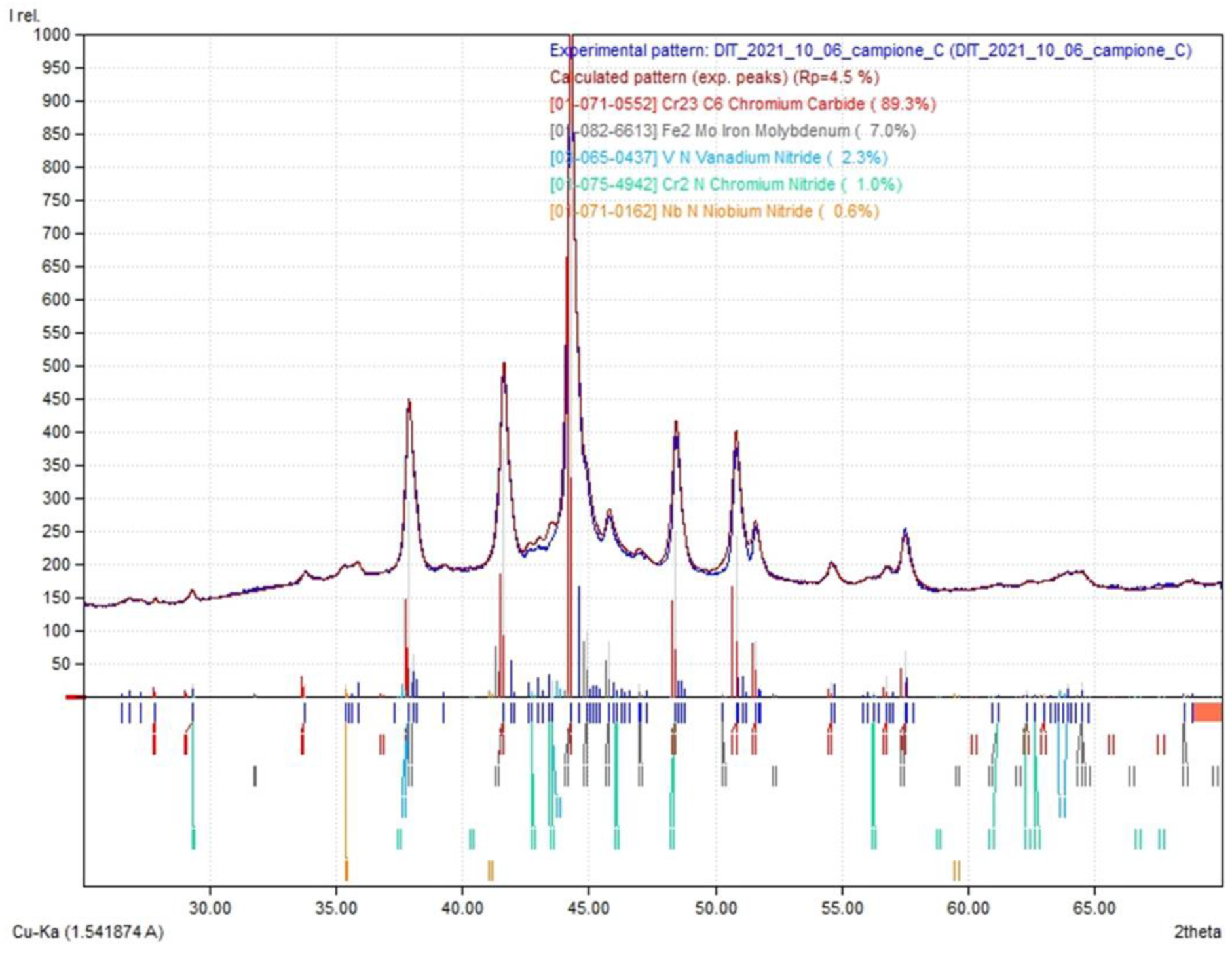

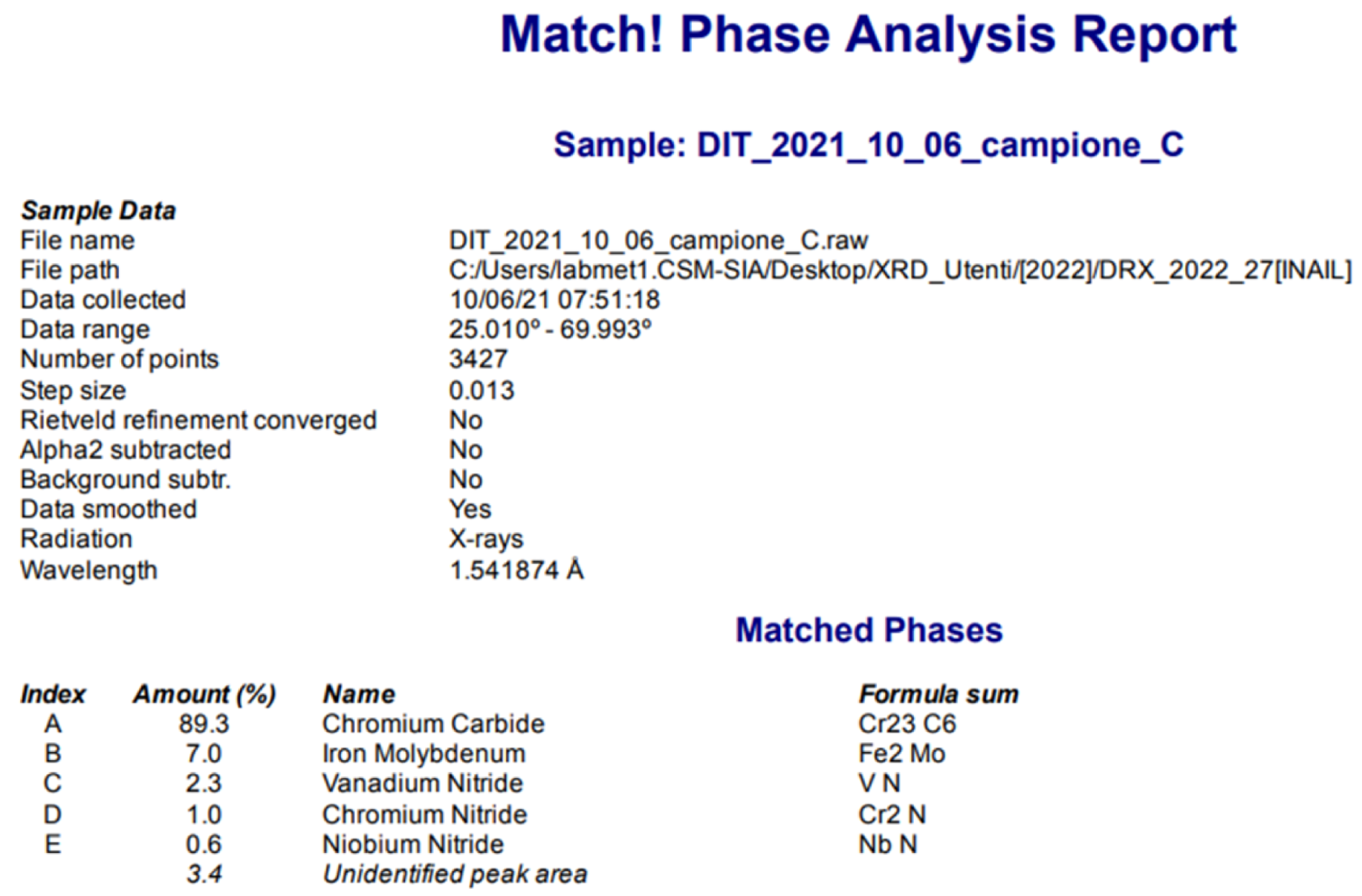

Appendix A.1.2. The Figure A6 Provide the Results of XRD on Failed Crept Cross-Weld Specimen 91-HAZ-3-6 600 °C 99 MPa 4280 h (Sample C)

Appendix A.2. Subproject N°6: GR 92 HAZ CREEP

References

- Neubauer, B.; Arens-Fisher, F. Restfile Estimation of Power Plant Component under Creep Load. In Proceedings of the VGB Congress Power Plants 1982, Mannheim, Germany, 14–17 September 1982. [Google Scholar]

- Honda, T.; Fukahori, T.; Tokiyoshi, T.; Igari, T.; Tominaga, K.; Cocks, A.C.F. Type IV creep crack initiation and propagation in mod.9Cr-1Mo steel welds. Mater. High Temp. 2022, 39, 603–612. [Google Scholar] [CrossRef]

- Saini, A.; Pollock, T. High-temperature materials increase efficiency of gas power plants. MRS Bull. 2012, 37, 550–551. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.Y.; Lee, J. Issues and solutions for integrity of pressure vessels and piping subjected to long-term creep exposure in supercritical thermal plants. Mater. High Temp. 2022, 39, 436–445. [Google Scholar] [CrossRef]

- Krein, R.; Schubert, J.; Klenk, A. Weld strength reduction in modern tempered martensitic 9% Chromium creep resistant steels. In Proceedings of the 4th International ECCC Creep & Fracture Conference, Dusseldorf, Germany, 10–14 September 2017. [Google Scholar]

- Zhang, S.; Tokunaga, H.; Kanai, M.; Lin, S.; Yaguchi, M.; Tamura, K.; Minami, Y. Effect of abnormal structure on creep strength of long-term used 9Cr steel welded joint. Mater. High Temp. 2022, 39, 578–589. [Google Scholar] [CrossRef]

- Maddi, L.; Ballal, A.R.; Peshwe, D.R.; Mathew, M.D. Influence of normalizing and tempering temperatures on the creep properties of P92 steel. High Temp. Mater. Process. 2020, 39, 178–188. [Google Scholar] [CrossRef]

- Gotti, A.; Di Gianfrancesco, A.; Ferrara, A.; Gariboldi, E.; Merckling, G.; Navone, S.; Parodi, S.; Poggio, E.; Ripamonti, D.; Verdino, S. Creep properties of ASTM A335 P92 pipe parent material and erection welded joint simulation: Effect of 1 or 3 PWHT. Mater. High Temp. 2022, 39, 647–654. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Ferrara, A. Evolution of precipitation particles with respect to grain boundary energy in Grade 91 steel during creep exposure. Mater. High Temp. 2022, 39, 480–486. [Google Scholar] [CrossRef]

- Hasegawa, Y.; Ishii, N.; Kodama, M.; Kunieda, A.; Shimizu, K.; Kamada, Y. Possible microstructural resistant factors in P91 steel to the magnetic domain wall motion of electro-magnetic inspection method. In Proceedings of the High Temperature Plant Materials, Inspection, Monitoring & Assessment—MIMA 2 Conference, London, UK, 11–13 October 2022. [Google Scholar]

- Tamura, M.; Abe, F. Analysis of the Degradation in the Creep Strength of High-Cr Martensitic Steels. J. Mater. Sci. Res. 2021, 10, 1. [Google Scholar] [CrossRef]

- Di Nunzio, P.E.; Cipolla, L.; Tiberi Vipraio, S.; Martelli, S.; Somers MA, J. Quantitative X-ray diffraction analysis of development of Z phase in 12%Cr–Nb–V–N steel. Mater. Sci. Technol. 2010, 26, 1423–1428. [Google Scholar] [CrossRef]

- ECCC Recommendation Volumes. Available online: https://www.eccc-creep.com/eccc-recommendations-volumes (accessed on 9 February 2023).

- API Recommended Practice 580, 3rd ed.; Risk-based Inspection; American Petroleum Institute: Washington DC, USA, 2016.

- Merckling, G.; Benini, D.; Casiraghi, L.; Corsi, A.; Staffolani, A. Metallic replica technique for residual life assessment for components serviced in creep regime. Mater. High Temp. 2022, 39, 622–633. [Google Scholar] [CrossRef]

- Shibli, A. Remaining life assessment issues in high Cr martensitic steels and development of new innovative tools for damage monitoring and integrity assessment. Trans. Indian Inst. Met. 2010, 63, 339–348. [Google Scholar] [CrossRef]

- Wilson, J.W.; Allen, D.; Peyton, A.J.; Shibli, A.; Davis, C. Detection of creep degradation during pressure vessel testing using electromagnetic sensor technology. Mater. High Temp. 2017, 34, 448–457. [Google Scholar] [CrossRef] [Green Version]

- Wojcik, A.; Waitt, M.; Santos, A.; Shibli, A. A review of factors affecting the use of electrical potential drop (EPD) for creep life monitoring. Mater. High Temp. 2022. accepted. [Google Scholar] [CrossRef]

- EN 10371:2021; Metallic Materials—Small Punch Test Method. CEN-CENELEC: Brussels, Belgium, 2021.

- Peng, Z.; Liu, S.; Yang, C.; Yang, H. Correlation of hardness with maximum allowable stresses of Grade 91 steel. Mater. High Temp. 2022, 39, 472–479. [Google Scholar] [CrossRef]

- Yaguchi, M.; Hamaguchi, T.; Miki, K.; Yamamoto, Y.; Nomura, K.; Murakami, E.; Komai, N.; Inukai, T. Effects of chemical composition and heat treatment on creep properties of Grade 91 steel base metal and welded joint. Mater. High Temp. 2022, 39, 689–701. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Z.; Papadaki, C.; Korsunsky, A.M. The Creep Deformation of a New Nickel-Base Alloy-by-Design Studied Using Synchrotron X-ray Diffraction. 2022. Available online: https://arxiv.org/abs/2210.16840 (accessed on 16 December 2022).

- Cipolla, L. Conversion of MX Nitrides to Modified Z-Phase in 9–12%Cr Ferritic Steels. Ph.D. Thesis, Technical University of Denmark, Kongens Lyngby, Denmark, March 2010. [Google Scholar]

- Danielsen, H.K. Review of Z phase precipitation in 9–12 wt-%Cr steels. Mater. Sci. Technol. 2016, 32, 126–137. [Google Scholar] [CrossRef] [Green Version]

- Alviz-Meza, A.; Duong, A.; Orozco-Agamez, J.; Kafarov, V.; Cardenas-Escorcia, Y.; Carrillo-Caballero, G.; Pena-Ballesteros, D. Study of Early P91 Dual Corrosion in Steam and Simulated Combustion Gases from a Gas-Fired Boiler. J. Mater. Res. Technol. 2021, 13, 271–282. [Google Scholar] [CrossRef]

| C | Mn | Si | P | S | Cr | Mo | Ni | V | Al | Cu | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.09 | 0.46 | 0.31 | 0.016 | 0.003 | 8.49 | 0.87 | 0.14 | 0.19 | 0.004 | 0.04 | 0.002 |

| Nb | W | As | Sn | Co | Pb | B | Sb | Zr | Bi | Ca | N |

| 0.068 | 0.0046 | 0.002 | 0.004 | 0.0117 | 0.0019 | 0.0002 | 0.0005 | 0.0001 | 0.0011 | 0.0004 | 0.055 |

| C | Mn | Si | P | S | Cr | Mo | Ni | V | Al | Ti | Nb | W | B | Zr | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.09 | 0.48 | 0.34 | 0.011 | 0.006 | 8.99 | 0.37 | 0.12 | 0.17 | <0.01 | <0.01 | 0.06 | 1.86 | 0.005 | <0.01 | 0.049 |

| T (°C) | YS (MPa) | UTS (MPa) | A (%) | H (HB) | Flattening Test (Result) |

|---|---|---|---|---|---|

| +20 | 525 | 585 | 26.3 | 223 | Passed |

| T (°C) | YS (MPa) | UTS (MPa) | A (%) | H (HB) | Flattening Test (Result) |

|---|---|---|---|---|---|

| +20 | 491 | 676 | 20.7 | 217 | Passed |

| Creep Specimen Identification Code | Temp. °C | Stress Level (MPa) | Expected Time to Rupture (Hours) | Time to NDEs if the Specimen Does Not Break Before |

|---|---|---|---|---|

| 91-HAZ-3-1 | 550 | 200 | 10,000 | 10,000 1 |

| 91-HAZ-3-2 | 550 | 189 | 20,000 | 20,000 1 |

| 91-HAZ-3-3 | 550 | 175 | 50,000 | 25,000 2 |

| 91-HAZ-3-4 | 600 | 122 | 10,000 | 10,000 1 |

| 91-HAZ-3-5 | 600 | 112 | 20,000 | 20,000 1 |

| 91-HAZ-3-6 | 600 | 99 | 50,000 | 25,000 2 |

| 91-HAZ-3-7 | 650 | 68 | 10,000 | 10,000 1 |

| 91-HAZ-3-8 | 650 | 61 | 20,000 | 20,000 1 |

| 91-HAZ-3-9 | 650 | 54 | 50,000 | 25,000 2 |

| Creep Specimen Identification Code | Temp. °C | Stress Level (MPa) | Expected Time to Rupture (Hours) | Time to NDEs if the Specimen Does Not Break Before |

|---|---|---|---|---|

| 92-HAZ-6-1 | 600 | 152 | 10,000 | 10,000 1 |

| 92-HAZ-6-2 | 600 | 141 | 20,000 | 20,000 1 |

| 92-HAZ-6-3 | 600 | 125 | 50,000 | 25,000 2 |

| 92-HAZ-6-4 | 650 | 88 | 10,000 | 10,000 1 |

| 92-HAZ-6-5 | 650 | 78 | 20,000 | 20,000 1 |

| 92-HAZ-6-6 | 650 | 65 | 50,000 | 25,000 2 |

| Steel Grades 91 and 92 Microstructure and Precipitate Evolution Atlas Identification Code (Grade 91) | Identif. Code XRD Analysis | Steel Grades 91 and 92 Microstructure and Precipitate Evolution Atlas Identification Code (Grade 92) | Identif. Code XRD Analysis |

|---|---|---|---|

| 91-HAZ-3-1 550 °C 200 MPa 4395 h | A | 92-EX-1-2 (92 BM 604 °C 43 MPa 74,001 h) | E |

| 91-HAZ-3-5 600 °C 112 MPa 3216 h | B | 92-HAZ-6-1 600 °C 152 MPa 2516 h | F |

| 91-HAZ-3-6 600 °C 99 MPa 4280 h | C | 92-HAZ-6-5 650 °C 78 MPa 4616 h | G |

| 91-HAZ-3-8 650 °C 61 MPa 2072 h | D | 92-HAZ-6-6 650 °C 65 MPa 3877 h | H |

| Identified Phases by XRD in Steel Grade 91 and 92 | ||

|---|---|---|

| Name | Formula Sum | Classification |

| Chromium Carbide | Cr23C6 | M23C6 carbide |

| Iron Molybdenum | Fe2Mo | Laves phase |

| Chromium Nitride | Cr2N | M2N nitride |

| Niobium Nitride | NbN | MX carbonitride |

| Vanadium Nitride | VN | |

| C | Mn | Si | P | S | Cr | Mo | Ni | V | Al | Sn | Nb | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.092 | 0.43 | 0.38 | 0.012 | 0.002 | 8.88 | 0.93 | 0.28 | 0.24 | 0.014 | 0.006 | 0.072 | 0.047 |

| T (°C) | YS (MPa) | UTS (MPa) | A (%) | H (HB) | Flattening Test (Result) |

|---|---|---|---|---|---|

| +20 | 556 | 704 | 41 | 217 | Passed |

| Failed Crept Cross Weld Specimen GR 91 | Identif. Code XRD Analysis | Evaluation of Partition of Second Phases by XRD Analysis | ||||

|---|---|---|---|---|---|---|

| M23C6 | MX | Laves | M2N | |||

| Cr23C6 | Nb N | VN | Fe2Mo | |||

| Amount % | Amount % | Amount % | Amount % | Amount % | ||

| 91-HAZ-3-1 550 °C 200 MPa 4395 h | A | 81 | 1 | 1 | 12 | 5 |

| 91-HAZ-3-5 600 °C 112 MPa 3216 h | B | 92 | 3 | 4 | 1 | |

| 91-HAZ-3-6 600 °C 99 MPa 4280 h | C | 89 | 1 | 2 | 7 | 1 |

| 91-HAZ-3-8 650 °C 61 MPa 2072 h * | D | 48 | 3 | 45 | 4 | |

| Specimen GR 92 | Identif. Code XRD Analysis | Evaluation of Partition of Second Phases by XRD Analysis | ||||

|---|---|---|---|---|---|---|

| M23C6 | MX | Laves | M2N | |||

| C23C6 | NbN | VN | Fe2Mo | |||

| Amount % | Amount % | Amount % | Amount % | Amount % | ||

| 92-EX-1-2 (92 BM 604 °C 43 MPa 74,001 h) | E | 86 | 0.4 | 6 | 8 | |

| 92-HAZ-6-1 600 °C 152 MPa 2516 h | F | 72 | 0.5 | 2 | 23 | 3 |

| 92-HAZ-6-5 650 °C 78 MPa 4616 h | G | 75 | 0.6 | 3 | 18 | 3 |

| 92-HAZ-6-6 650 °C 65 MPa 3877 h | H | 67 | 0.7 | 2 | 26 | 5 |

| Failed Crept Cross Weld Specimen | Precipitate Description | TEM EDS Analysis of Type of Precipitates | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Classification | Category | Mean Size nm | N | F% | Average Element (wt%) | |||||

| V | Cr | Fe | Nb | Mo | ||||||

| M23C6 carbide | (Cr,Fe,Mo)-rich | 240 | 73 | 60 | 0.6 | 68.0 | 24.4 | 0.0 | 6.7 | |

| (Cr,Fe,Mo)23C6 | ||||||||||

| MX carbo-nitride | Nb-rich | 51 | 2 | 2 | 10.5 | 4.0 | 2.0 | 82.2 | 0.0 | |

| 91-HAZ-3-1 | (Nb,V)(N,C) | |||||||||

| 550 °C 200 MPa 4395 h | V-rich | 65 | 18 | 15 | 66.6 | 19.6 | 4.9 | 5.6 | 0.6 | |

| (V,Nb)(C,N) | ||||||||||

| Laves phase | (Fe,Mo)-rich | 182 | 27 | 23 | 0.4 | 12.4 | 44.3 | 0.2 | 38.7 | |

| Fe2Mo | ||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tonti, A.; De Blasi, P. The New Italian Standard on the Life Assessment of Martensitic Steels—First Results of the Experimental Validation Activity of XRD by Testing P91 and P92 Samples from Interrupted Uniaxial Creep Tests. Micro 2023, 3, 274-307. https://doi.org/10.3390/micro3010020

Tonti A, De Blasi P. The New Italian Standard on the Life Assessment of Martensitic Steels—First Results of the Experimental Validation Activity of XRD by Testing P91 and P92 Samples from Interrupted Uniaxial Creep Tests. Micro. 2023; 3(1):274-307. https://doi.org/10.3390/micro3010020

Chicago/Turabian StyleTonti, Andrea, and Pietro De Blasi. 2023. "The New Italian Standard on the Life Assessment of Martensitic Steels—First Results of the Experimental Validation Activity of XRD by Testing P91 and P92 Samples from Interrupted Uniaxial Creep Tests" Micro 3, no. 1: 274-307. https://doi.org/10.3390/micro3010020

APA StyleTonti, A., & De Blasi, P. (2023). The New Italian Standard on the Life Assessment of Martensitic Steels—First Results of the Experimental Validation Activity of XRD by Testing P91 and P92 Samples from Interrupted Uniaxial Creep Tests. Micro, 3(1), 274-307. https://doi.org/10.3390/micro3010020