Additively Manufactured Alnico Permanent Magnet Materials—A Review

Abstract

:1. Introduction

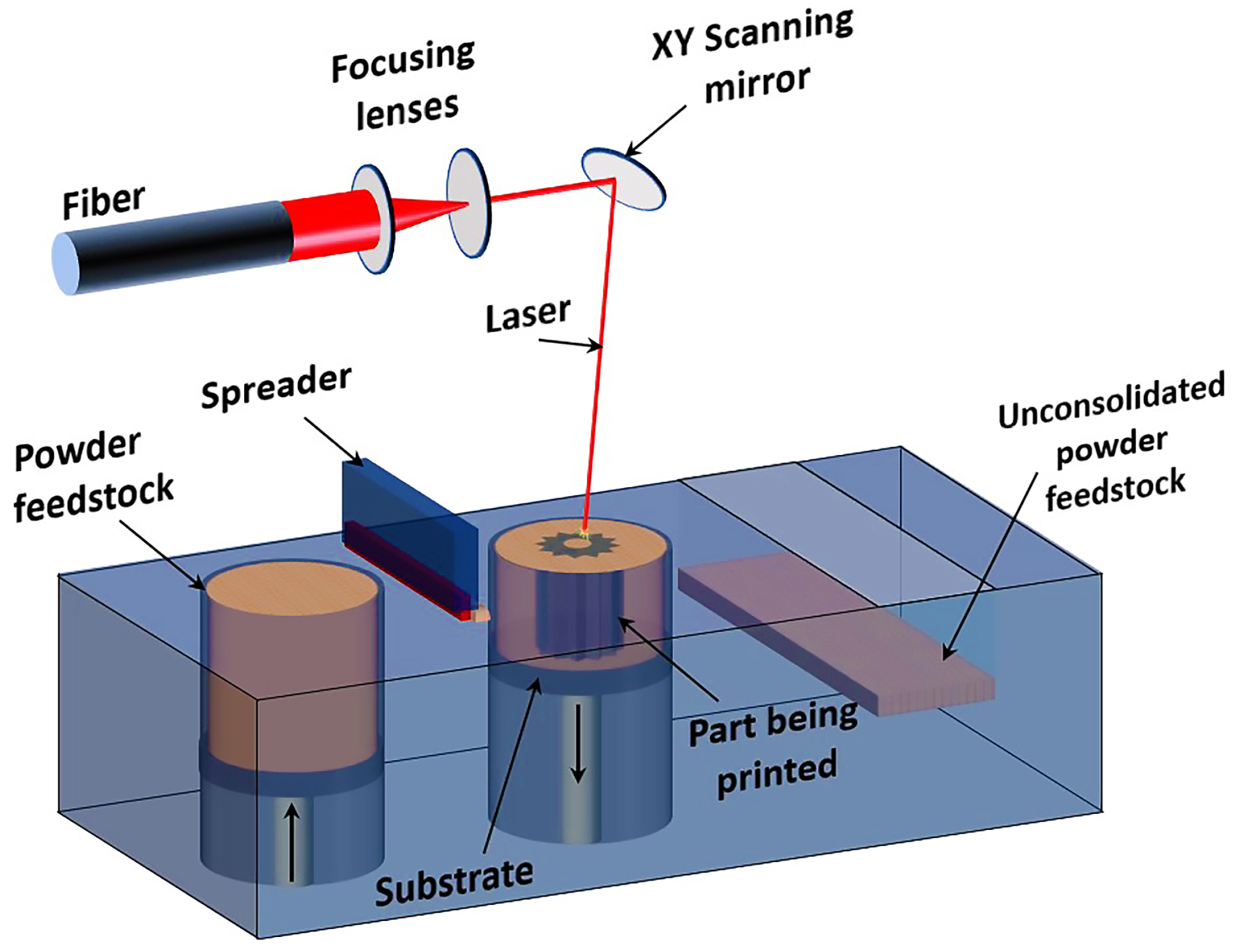

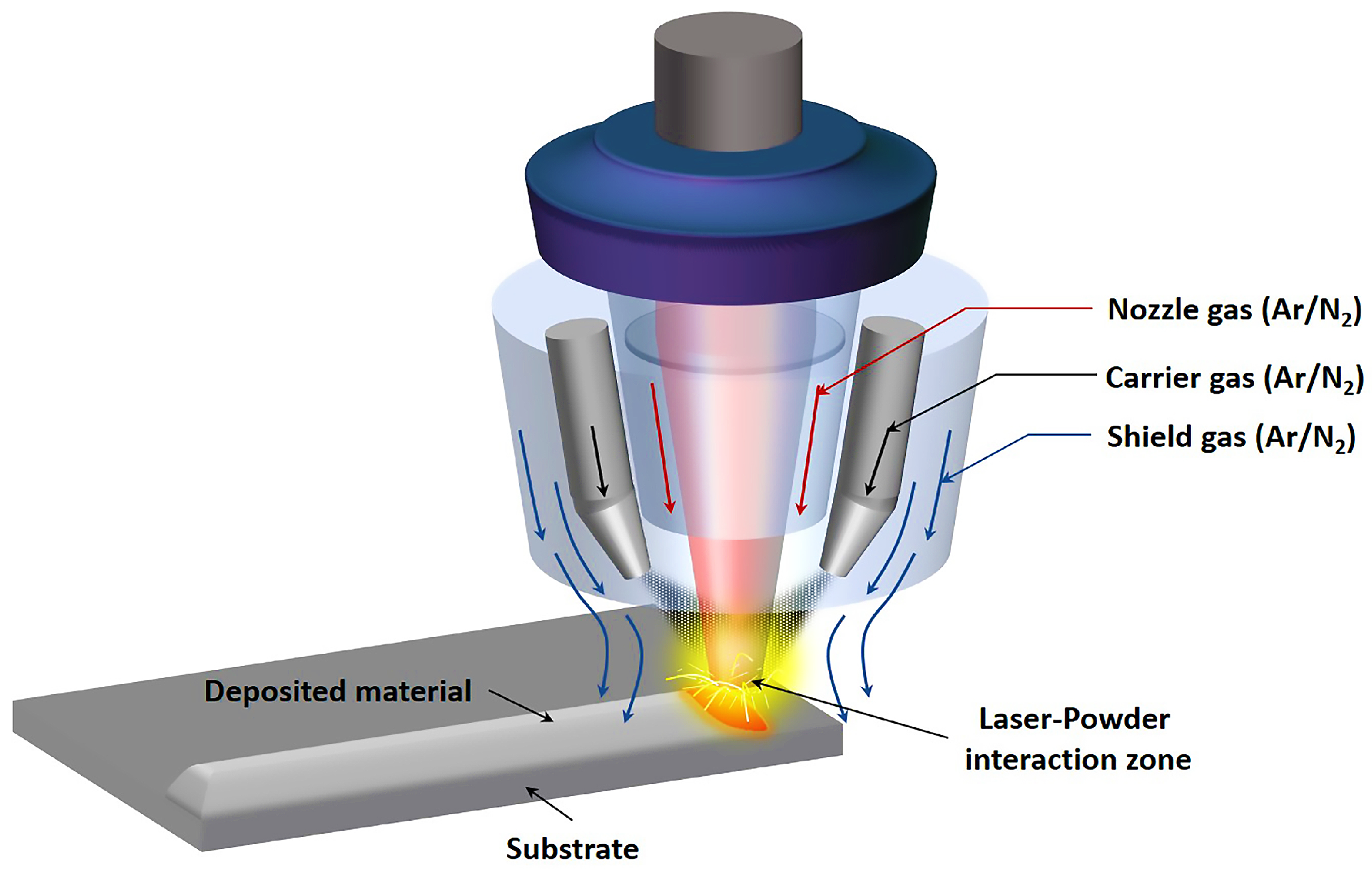

2. Additive Manufacturing

2.1. Additive Manufacturing of Alnico

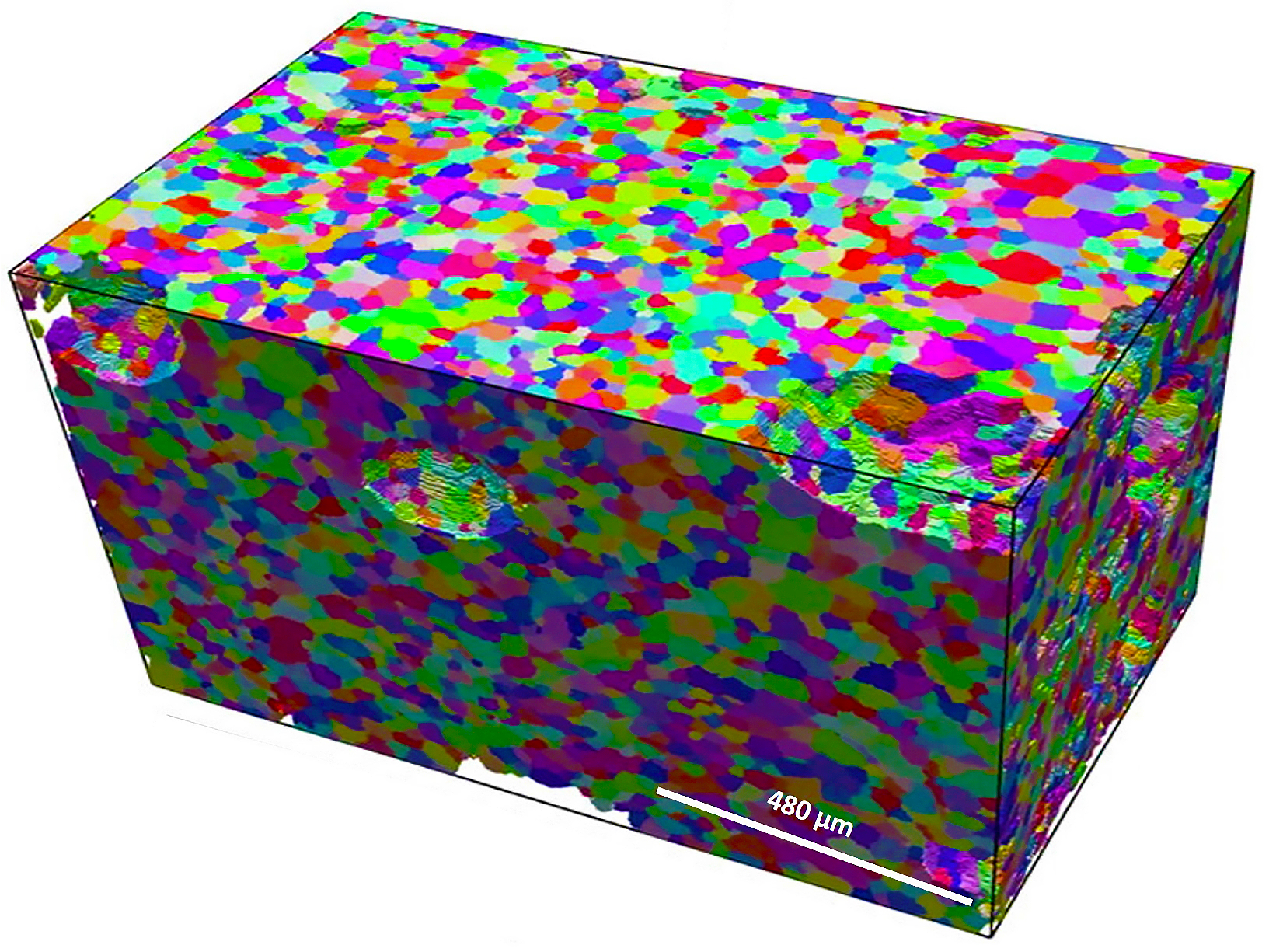

2.2. Microstructure of Additively Manufactured Alnico

2.3. Effects of Grain Size and Morphological and Crystallographic Texture on Magnetic Properties

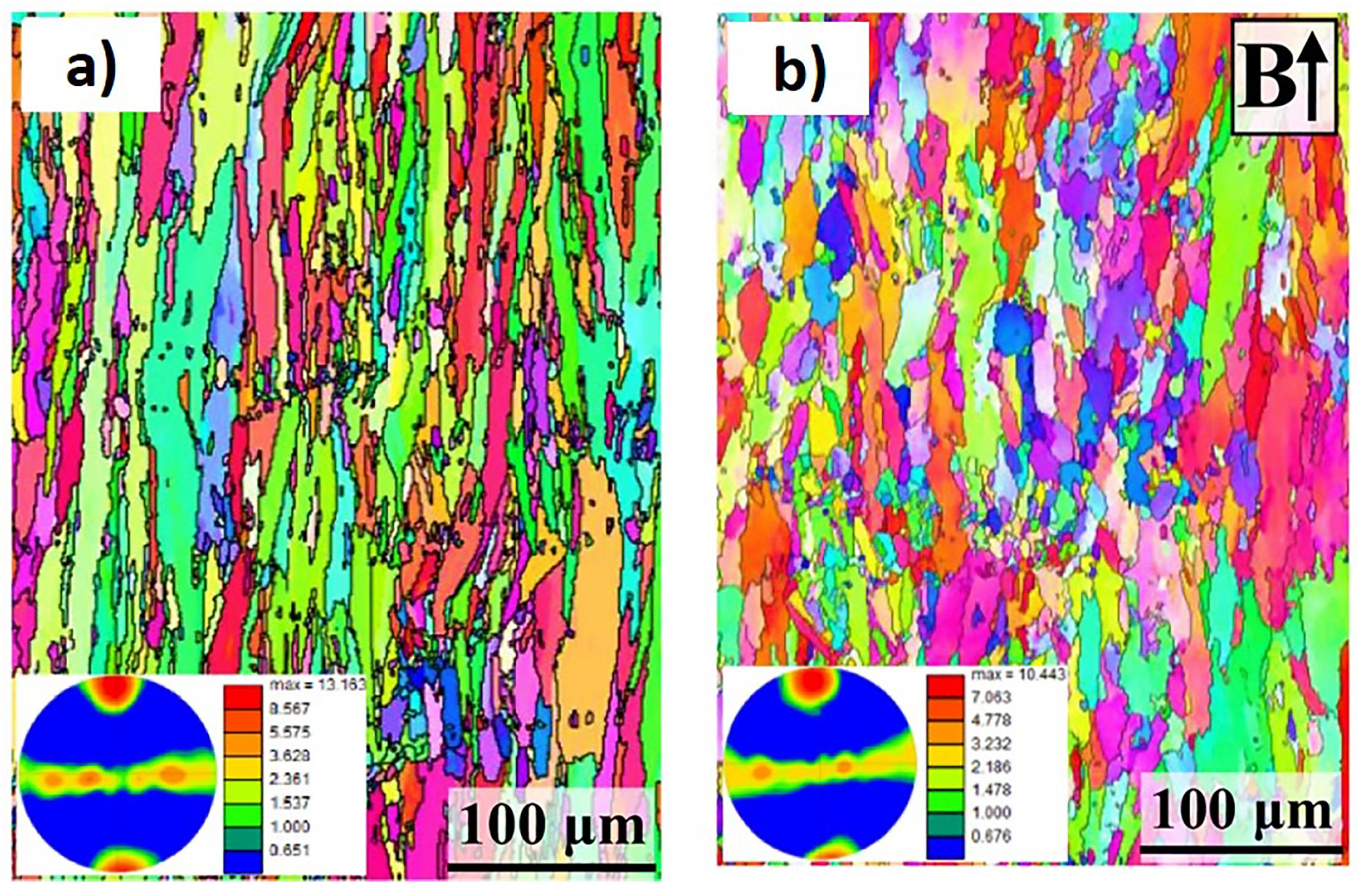

2.4. Additive Manufacturing Process-Driven Morphological and Crystallographic Textures of Grain in Alnico

3. Post-Additive Manufacturing Thermal Treatments and Magnetic Properties of Alnico

3.1. Solutionization

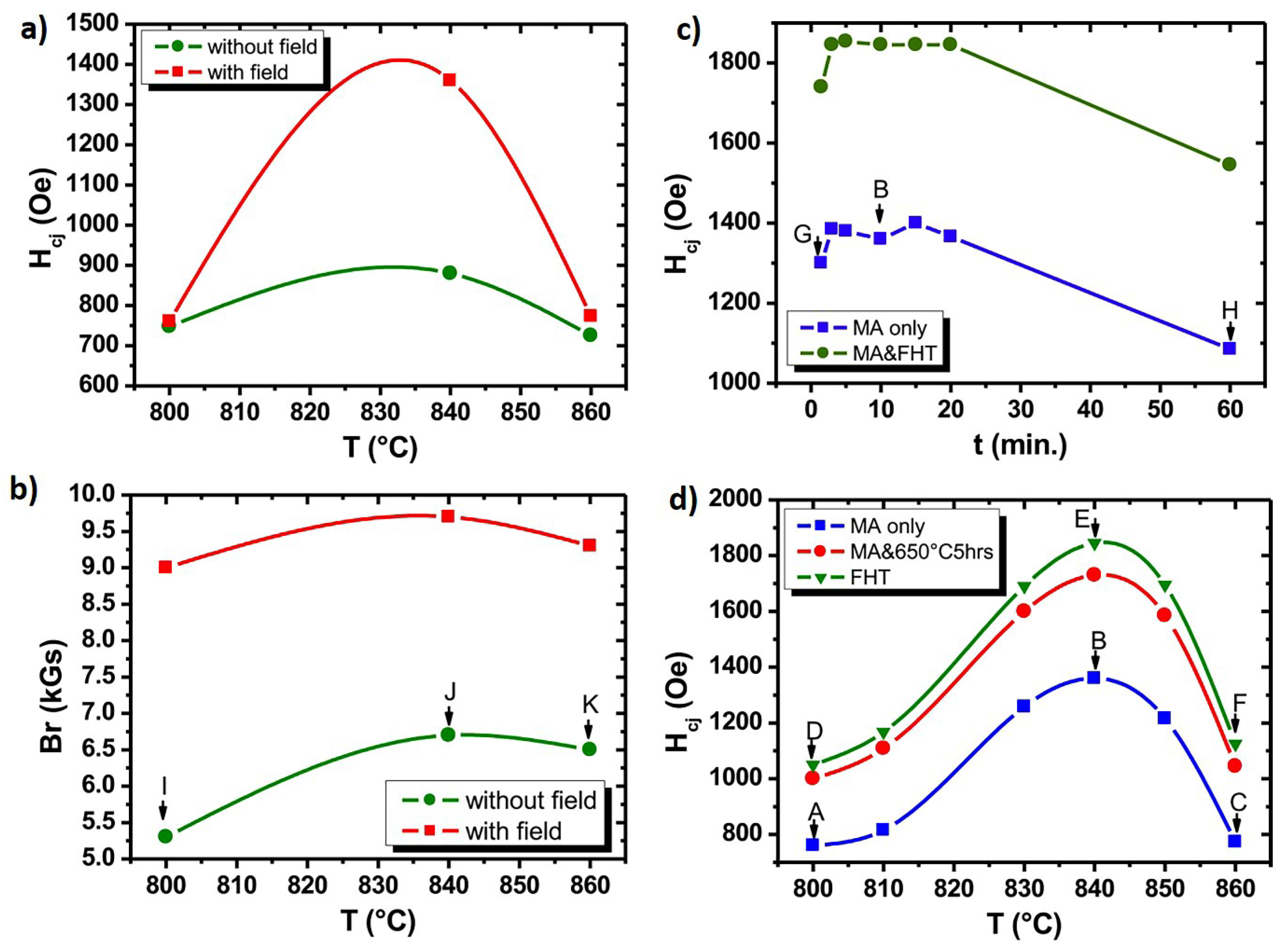

3.2. Magnetic Annealing

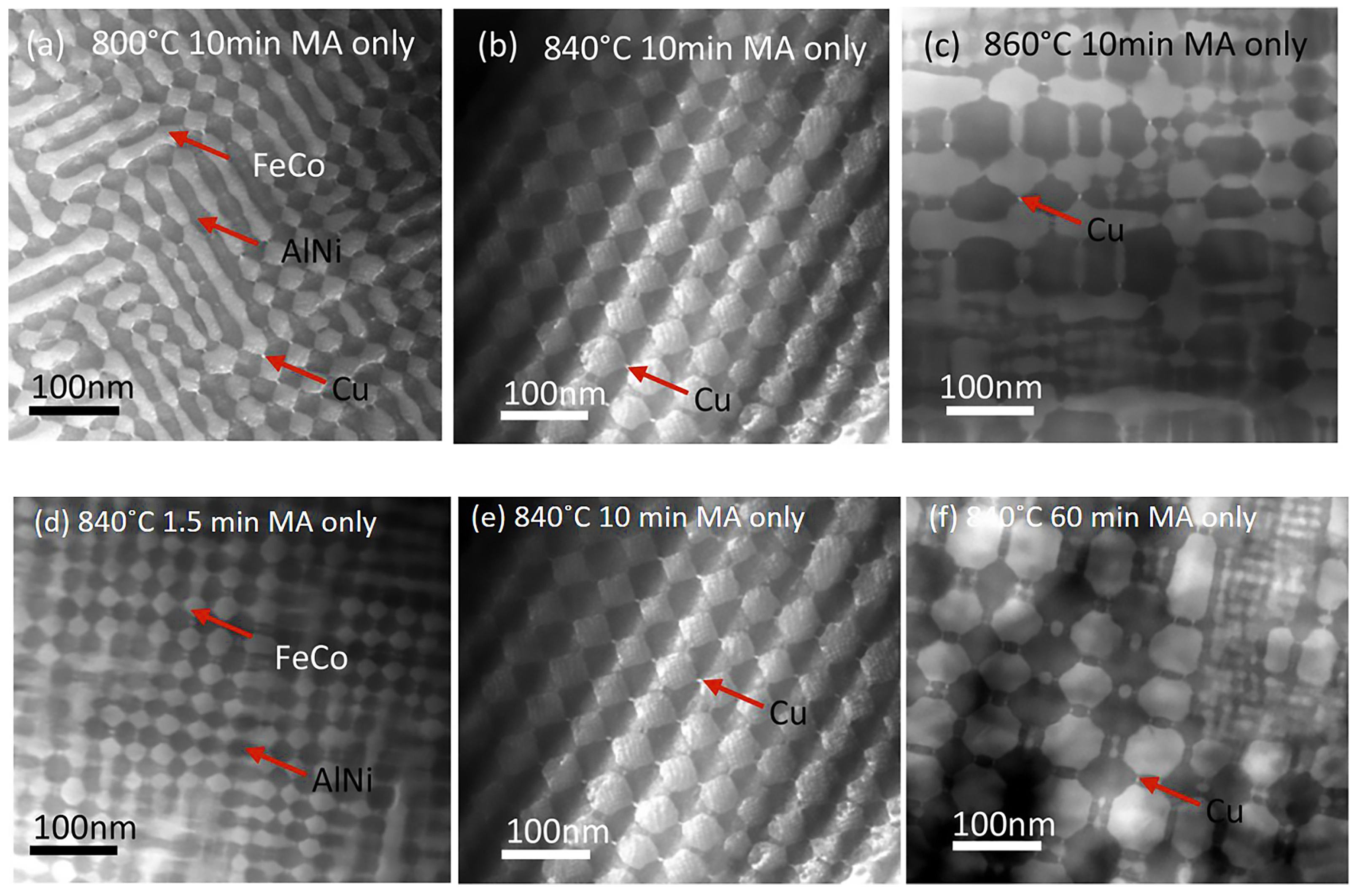

Effect of Annealing-Derived Phases on Magnetic Properties

3.3. Tempering

4. Potential Additive Manufacturing Techniques for the Fabrication of Alnico

4.1. Binder Jet Printing and Extrusion-Based Additive Manufacturing

4.2. Magnetic Field-Assisted Additive Manufacturing

5. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fan, M.; Liu, Y.; Jha, R.; Dulikravich, G.S.; Schwartz, J.; Koch, C. On the evolution of Cu-Ni-rich bridges of Alnico alloys with tempering. J. Magn. Magn. Mater. 2016, 420, 296–302. [Google Scholar] [CrossRef]

- Rehman, S.U.; Jiang, Q.; He, L.; Ghazanfar, M.; Lei, W.; Hu, X.; Awan, S.U.; Ma, S.; Zhong, Z. Synthesis, microstructures, magnetic properties and thermal stabilities of isotropic alnico ribbons. J. Magn. Magn. Mater. 2018, 466, 277–282. [Google Scholar] [CrossRef]

- Zhou, L.; Miller, M.K.; Lu, P.; Ke, L.; Skomski, R.; Dillon, H.; Xing, Q.; Palasyuk, A.; McCartney, M.; Smith, D.; et al. Architecture and magnetism of alnico. Acta Mater. 2014, 74, 224–233. [Google Scholar] [CrossRef]

- White, E.; Rinko, E.; Prost, T.; Horn, T.; Ledford, C.; Rock, C.; Anderson, I. Processing of alnico magnets by additive manufacturing. Appl. Sci. 2019, 9, 4843. [Google Scholar] [CrossRef]

- Zhou, L.; Tang, W.; Ke, L.; Guo, W.; Poplawsky, J.D.; Anderson, I.E.; Kramer, M.J. Microstructural and magnetic property evolution with different heat-treatment conditions in an alnico alloy. Acta Mater. 2017, 133, 73–80. [Google Scholar] [CrossRef]

- Coey, J. Permanent magnet applications. J. Magn. Magn. Mater. 2002, 248, 441–456. [Google Scholar] [CrossRef]

- Rehman, S.U.; Ahmad, Z.; ul Haq, A.; Akhtar, S. Effects of Zr alloying on the microstructure and magnetic properties of Alnico permanent magnets. J. Magn. Magn. Mater. 2017, 442, 136–140. [Google Scholar] [CrossRef]

- Chukwuchekwa, N. Investigation of Magnetic Properties and Barkhausen Noise of Electrical Steel. Ph.D. Thesis, Cardiff University, Cardiff, UK, 2011. [Google Scholar]

- Périgo, E.; Jacimovic, J.; Ferré, F.G.; Scherf, L. Additive manufacturing of magnetic materials. Addit. Manuf. 2019, 30, 100870. [Google Scholar] [CrossRef]

- Chaudhary, V.; Mantri, S.; Ramanujan, R.; Banerjee, R. Additive manufacturing of magnetic materials. Prog. Mater. Sci. 2020, 114, 100688. [Google Scholar] [CrossRef]

- Kontos, S.; Ibrayeva, A.; Leijon, J.; Mörée, G.; Frost, A.E.; Schönström, L.; Gunnarsson, K.; Svedlindh, P.; Leijon, M.; Eriksson, S. An overview of MnAl permanent magnets with a study on their potential in electrical machines. Energies 2020, 13, 5549. [Google Scholar] [CrossRef]

- Rao, A.S. Alnico permanent magnets an overview. In Proceedings of the Electrical/Electronics Insulation Conference, Chicago, IL, USA, 4–7 October 1993; pp. 373–383. [Google Scholar]

- Zhou, L.; Tang, W.; Guo, W.; Poplawsky, J.D.; Anderson, I.; Kramer, M. Spinodal decomposition in an alnico alloy. Microsc. Microanal. 2016, 22, 670–671. [Google Scholar] [CrossRef]

- Rehman, S.U.; Jiang, Q.; Lei, W.; He, L.; Tan, Q.; Quan, Q.; Wang, L.; Zhong, M.; Ma, S.; ul Haq, A.; et al. Improved microstructure and magnetic properties of Alnico 8 Alloys by B-doping. IEEE Trans. Magn. 2018, 54, 1–6. [Google Scholar] [CrossRef]

- Shao, B.; Li, B.B.; Li, C.H.; Ma, Y.L.; Zheng, Q.; Guo, D.L.; Chen, D.M.; Sun, J.C. Microstructure and Distribution of Low Content Elements in AlNiCo 9. Mater. Sci. Forum 2017, 898, 1669–1674. [Google Scholar] [CrossRef]

- Zhou, L.; White, E.; Ke, L.; Cullen, D.A.; Lu, P.; Constantinides, S.; McCallum, R.; Anderson, I.; Kramer, M.J. Microstructure and coercivity in alnico 9. J. Magn. Magn. Mater. 2019, 471, 142–147. [Google Scholar] [CrossRef]

- Löwe, K.; Dürrschnabel, M.; Molina-Luna, L.; Madugundo, R.; Frincu, B.; Kleebe, H.J.; Gutfleisch, O.; Hadjipanayis, G.C. Microstructure and magnetic properties of melt-spun Alnico-5 alloys. J. Magn. Magn. Mater. 2016, 407, 230–234. [Google Scholar] [CrossRef]

- Kramer, M.; McCallum, R.; Anderson, I.; Constantinides, S. Prospects for non-rare earth permanent magnets for traction motors and generators. JOM 2012, 64, 752–763. [Google Scholar] [CrossRef]

- Gutfleisch, O.; Willard, M.A.; Brück, E.; Chen, C.H.; Sankar, S.; Liu, J.P. Magnetic materials and devices for the 21st century: Stronger, lighter, and more energy efficient. Adv. Mater. 2011, 23, 821–842. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Kramer, M.; Zhou, L.; Liu, F.; Gabay, A.; Hadjipanayis, G.; Balasubramanian, B.; Sellmyer, D. Current progress and future challenges in rare-earth-free permanent magnets. Acta Mater. 2018, 158, 118–137. [Google Scholar] [CrossRef]

- Sun, Y.; Zhao, J.; Liu, Z.; Xia, W.; Zhu, S.; Lee, D.; Yan, A. The phase and microstructure analysis of Alnico magnets with high coercivity. J. Magn. Magn. Mater. 2015, 379, 58–62. [Google Scholar] [CrossRef]

- Stanek, M.; Leonowicz, M. Investigations of thermo-magnetic treatment of Alnico 8 alloy. Arch. Metall. Mater. 2010, 55, 571–577. [Google Scholar]

- McCurrie, R. The structure and properties of alnico permanent magnet alloys. Handb. Ferromagn. Mater. 1982, 3, 107–188. [Google Scholar]

- Betteridge, W. Nickel-Iron-Aluminum Permanent Magnet Alloys. Iron Steel Inst. Lond. 1939, 139, 187–208. [Google Scholar]

- Begin, G.; Dube, A. On the magnetizations of the phase in alnico alloys. IEEE Trans. Magn. 1972, 8, 42–45. [Google Scholar] [CrossRef]

- Zhou, L.; Guo, W.; Poplawsky, J.D.; Ke, L.; Tang, W.; Anderson, I.E.; Kramer, M.J. On spinodal decomposition in alnico-A transmission electron microscopy and atom probe tomography study. Acta Mater. 2018, 153, 15–22. [Google Scholar] [CrossRef]

- Iwama, Y.; Inagaki, M.; Miyamoto, T. Effects of Titanium in Alnico 8-Type Magnet Alloys. Trans. Jpn. Inst. Met. 1970, 11, 268–274. [Google Scholar] [CrossRef]

- Takeuchi, M.; Iwama, Y. Effects of Titanium upon Magnetic Anisotropy and Coercivity in Alnico Magnet Alloys. Trans. Jpn. Inst. Met. 1976, 17, 489–496. [Google Scholar] [CrossRef]

- Fan, M.; Liu, Y.; Jha, R.; Dulikravich, G.S.; Schwartz, J.; Koch, C. On the formation and evolution of Cu–Ni-rich bridges of alnico alloys with thermomagnetic treatment. IEEE Trans. Magn. 2016, 52, 1–10. [Google Scholar] [CrossRef]

- Ahmad, Z.; Liu, Z.; Ul Haq, A. Synthesis, magnetic and microstructural properties of Alnico magnets with additives. J. Magn. Magn. Mater. 2017, 428, 125–131. [Google Scholar] [CrossRef]

- Kassen, A.G. Exploration of Alnico Permanent Magnet Microstructure and Processing for Near Final Shape Magnets with Solid-State Grain Alignment for Improved Properties. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2018. [Google Scholar]

- Cui, J.; Ormerod, J.; Parker, D.; Ott, R.; Palasyuk, A.; Mccall, S.; Paranthaman, M.P.; Kesler, M.S.; McGuire, M.A.; Nlebedim, I.C.; et al. Manufacturing processes for permanent magnets: Part I—sintering and casting. JOM 2022, 74, 1279–1295. [Google Scholar] [CrossRef]

- Wang, C.; Zhong, W.; Ping, W.; Lin, Z.; Wang, R.; Dai, J.; Guo, M.; Xiong, W.; Zhao, J.C.; Hu, L. Rapid synthesis and sintering of metals from powders. Adv. Sci. 2021, 8, 2004229. [Google Scholar] [CrossRef]

- Rottmann, P.F.; Polonsky, A.T.; Francis, T.; Emigh, M.G.; Krispin, M.; Rieger, G.; Echlin, M.P.; Levi, C.G.; Pollock, T.M. TriBeam tomography and microstructure evolution in additively manufactured Alnico magnets. Mater. Today 2021, 49, 23–34. [Google Scholar] [CrossRef]

- Mukherjee, T.; DebRoy, T. Theory and Practice of Additive Manufacturing; John Wiley & Sons: Hoboken, NJ, USA, 2023. [Google Scholar]

- Lynch, P.; Hasbrouck, C.; Wilck, J.; Kay, M.; Manogharan, G. Challenges and opportunities to integrate the oldest and newest manufacturing processes: Metal casting and additive manufacturing. Rapid Prototyp. J. 2020, 26, 1145–1154. [Google Scholar] [CrossRef]

- Gao, M.; Li, L.; Wang, Q.; Ma, Z.; Li, X.; Liu, Z. Integration of additive manufacturing in casting: Advances, challenges, and prospects. Int. J. Precis. Eng. Manuf.-Green Technol. 2022, 9, 305–322. [Google Scholar] [CrossRef]

- Abedi, M.; Sovizi, S.; Azarniya, A.; Giuntini, D.; Seraji, M.E.; Hosseini, H.R.M.; Amutha, C.; Ramakrishna, S.; Mukasyan, A. An analytical review on Spark Plasma Sintering of metals and alloys: From processing window, phase transformation, and property perspective. Crit. Rev. Solid State Mater. Sci. 2023, 48, 169–214. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Dehoff, R.R.; Kirka, M.; Sames, W.; Bilheux, H.; Tremsin, A.; Lowe, L.; Babu, S. Site specific control of crystallographic grain orientation through electron beam additive manufacturing. Mater. Sci. Technol. 2015, 31, 931–938. [Google Scholar] [CrossRef]

- Makino, N.; Kimura, Y. Techniques to achieve texture in permanent magnet alloy systems. J. Appl. Phys. 1965, 36, 1185–1190. [Google Scholar] [CrossRef]

- Sharma, S.; Joshi, S.S.; Pantawane, M.V.; Radhakrishnan, M.; Mazumder, S.; Dahotre, N.B. Multiphysics multi-scale computational framework for linking process–structure–property relationships in metal additive manufacturing: A critical review. Int. Mater. Rev. 2023, 68, 943–1009. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.; Zuback, J.; Mukherjee, T.; Elmer, J.; Milewski, J.; Beese, A.M.; Wilson-Heid, A.d.; De, A.; Zhang, W. Additive manufacturing of metallic components–process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Milewski, J. Additive Manufacturing of Metals; Springer Series in Materials Science; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Utela, B.; Storti, D.; Anderson, R.; Ganter, M. A review of process development steps for new material systems in three dimensional printing (3DP). J. Manuf. Process. 2008, 10, 96–104. [Google Scholar] [CrossRef]

- Dahotre, N.B.; Pantawane, M.V.; Sharma, S. Laser-Based Additive Manufacturing: Modeling, Simulation, and Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2022. [Google Scholar]

- Sharma, S.; Krishna, K.M.; Joshi, S.S.; Radhakrishnan, M.; Palaniappan, S.; Dussa, S.; Banerjee, R.; Dahotre, N.B. Laser based additive manufacturing of tungsten: Multi-scale thermo-kinetic and thermo-mechanical computational model and experiments. Acta Mater. 2023, 259, 119244. [Google Scholar] [CrossRef]

- Heidenreich, R.; Nesbitt, E. Physical structure and magnetic anisotropy of alnico 5. Part I. J. Appl. Phys. 1952, 23, 352–365. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.P.; Van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.P.; Van Humbeeck, J. Microstructure and mechanical properties of a novel β titanium metallic composite by selective laser melting. Acta Mater. 2014, 68, 150–158. [Google Scholar] [CrossRef]

- Liu, F.; Lin, X.; Huang, C.; Song, M.; Yang, G.; Chen, J.; Huang, W. The effect of laser scanning path on microstructures and mechanical properties of laser solid formed nickel-base superalloy Inconel 718. J. Alloys Compd. 2011, 509, 4505–4509. [Google Scholar] [CrossRef]

- Hagihara, K.; Nakano, T. Control of anisotropic crystallographic texture in powder bed fusion additive manufacturing of metals and ceramics—A review. JOM 2022, 74, 1760–1773. [Google Scholar] [CrossRef]

- White, E.M.H.; Kassen, A.G.; Simsek, E.; Tang, W.; Ott, R.T.; Anderson, I.E. Net shape processing of alnico magnets by additive manufacturing. IEEE Trans. Magn. 2017, 53, 1–6. [Google Scholar] [CrossRef]

- Li, F.; Meng, X.; Fang, Y.; He, K. Magnetic properties and optimization of AlNiCo fabricated by additive manufacturing. In Proceedings of the 2022 IEEE 17th Conference on Industrial Electronics and Applications (ICIEA), Chengdu, China, 16–19 December 2022; pp. 354–358. [Google Scholar]

- Li, F.; Meng, X.; Fang, Y.; He, K. Mechanical properties and optimization of AlNiCo magnetic materials fabricated by selective laser melting. In Proceedings of the 2022 IEEE 17th Conference on Industrial Electronics and Applications (ICIEA), Chengdu, China, 16–19 December 2022; pp. 1283–1288. [Google Scholar]

- Shakirov, I.; Zhukov, A.; Perevislov, S.; Olisov, A. The Effect of Selective Laser Melting Conditions on the Structure of an Alnico Alloy. Phys. Met. Metallogr. 2022, 123, 227–237. [Google Scholar] [CrossRef]

- Zhukov, A.S.; Shakirov, I.; Olisov, A.V.; Barakhtin, B.; Perevislov, S. Structural and mechanical state of AlNiCO35 alloy produced by selective laser melting. Metallurgist 2022, 65, 1149–1156. [Google Scholar] [CrossRef]

- Kuznetsov, P.; Shakirov, I.; Mozhayko, A.; Zhukov, A.; Bobyr, V. Comparison of sequential and circular scanning thermal fields and their influence on microstructure of Alnico alloy produced by laser powder bed fusion. J. Phys. Conf. Ser. 2021, 1967, 012064. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Zhou, M.J.; Sun, J.B.; Li, B.; Wang, S.; Wang, Z.; Wang, S.; Zhang, Z.Y.; Zhang, Y. High-performance Alnico magnets prepared by powder bed fusion. J. Alloys Compd. 2024, 976, 173380. [Google Scholar] [CrossRef]

- Herzer, G. Soft magnetic nanocrystalline materials. Scr. Metall. Mater. 1995, 33, 1741–1756. [Google Scholar] [CrossRef]

- Herzer, G. Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets. IEEE Trans. Magn. 1990, 26, 1397–1402. [Google Scholar] [CrossRef]

- Bance, S.; Seebacher, B.; Schrefl, T.; Exl, L.; Winklhofer, M.; Hrkac, G.; Zimanyi, G.; Shoji, T.; Yano, M.; Sakuma, N.; et al. Grain-size dependent demagnetizing factors in permanent magnets. J. Appl. Phys. 2014, 116. [Google Scholar] [CrossRef]

- Dong, B. Development of Nanostructured Soft Magnetic Composite Materials Using the Field Assisted Sintering Technique; Case Western Reserve University: Cleveland, OH, USA, 2021. [Google Scholar]

- Shao, J.; Yu, G.; He, X.; Li, S.; Chen, R.; Zhao, Y. Grain size evolution under different cooling rate in laser additive manufacturing of superalloy. Opt. Laser Technol. 2019, 119, 105662. [Google Scholar] [CrossRef]

- Kou, S. Welding metallurgy. New Jersey USA 2003, 431, 223–225. [Google Scholar]

- Flemings, M.C. Solidification processing. Metall. Mater. Trans. B 1974, 5, 2121–2134. [Google Scholar] [CrossRef]

- Herzer, G. Modern soft magnets: Amorphous and nanocrystalline materials. Acta Mater. 2013, 61, 718–734. [Google Scholar] [CrossRef]

- Durand-Charre, M.; Bronner, C.; Lagarde, J.P. Relation between magnetic properties and crystallographic texture of columnar Alnico 8 permanent magnets. IEEE Trans. Magn. 1978, 14, 797–799. [Google Scholar] [CrossRef]

- Jia, Y.; Wu, Y.; Zhao, S.; Wang, J.; Jiang, C. Relation between solidification microstructure and coercivity in MnAl permanent-magnet alloys. Intermetallics 2018, 96, 41–48. [Google Scholar] [CrossRef]

- Kim, T.S.; Madavali, B.; Jo, S.J.; Lee, J.G.; Song, G.; Hong, S.J. Enhancement of magnetic properties in spark plasma sintered Nd-Fe-B magnets via controlled microstructure of melt-spun ribbons. J. Magn. Magn. Mater. 2023, 582, 170991. [Google Scholar]

- Peng, B.; Jin, J.; Liu, Y.; Zhang, Z.; Yan, M. Effects of (Nd, Pr)-Hx addition on the coercivity of Nd-Ce-Y-Fe-B sintered magnet. J. Alloys Compd. 2019, 772, 656–662. [Google Scholar] [CrossRef]

- Selcuk, C. Laser metal deposition for powder metallurgy parts. Powder Metall. 2011, 54, 94–99. [Google Scholar] [CrossRef]

- Li, H.; Huang, Y.; Jiang, S.; Lu, Y.; Gao, X.; Lu, X.; Ning, Z.; Sun, J. Columnar to equiaxed transition in additively manufactured CoCrFeMnNi high entropy alloy. Mater. Des. 2021, 197, 109262. [Google Scholar] [CrossRef]

- Hunt, J.D. Steady state columnar and equiaxed growth of dendrites and eutectic. Mater. Sci. Eng. 1984, 65, 75–83. [Google Scholar] [CrossRef]

- Nartu, M.S.; Welk, B.A.; Mantri, S.A.; Taylor, N.L.; Viswanathan, G.B.; Dahotre, N.B.; Banerjee, R.; Fraser, H.L. Underlying factors determining grain morphologies in high-strength titanium alloys processed by additive manufacturing. Nat. Commun. 2023, 14, 3288. [Google Scholar] [CrossRef] [PubMed]

- Guan, S.; Solberg, K.; Wan, D.; Berto, F.; Welo, T.; Yue, T.; Chan, K. Formation of fully equiaxed grain microstructure in additively manufactured AlCoCrFeNiTi0.5 high entropy alloy. Mater. Des. 2019, 184, 108202. [Google Scholar] [CrossRef]

- Kurz, W.; Bezençon, C.; Gäumann, M. Columnar to equiaxed transition in solidification processing. Sci. Technol. Adv. Mater. 2001, 2, 185. [Google Scholar] [CrossRef]

- Gäumann, M.; Bezencon, C.; Canalis, P.; Kurz, W. Single-crystal laser deposition of superalloys: Processing–microstructure maps. Acta Mater. 2001, 49, 1051–1062. [Google Scholar] [CrossRef]

- Gäumann, M.; Trivedi, R.; Kurz, W. Nucleation ahead of the advancing interface in directional solidification. Mater. Sci. Eng. A 1997, 226, 763–769. [Google Scholar] [CrossRef]

- Yang, K.V.; Shi, Y.; Palm, F.; Wu, X.; Rometsch, P. Columnar to equiaxed transition in Al-Mg (-Sc)-Zr alloys produced by selective laser melting. Scr. Mater. 2018, 145, 113–117. [Google Scholar] [CrossRef]

- Ishimoto, T.; Hagihara, K.; Hisamoto, K.; Sun, S.H.; Nakano, T. Crystallographic texture control of beta-type Ti–15Mo–5Zr–3Al alloy by selective laser melting for the development of novel implants with a biocompatible low Young’s modulus. Scr. Mater. 2017, 132, 34–38. [Google Scholar] [CrossRef]

- Ishimoto, T.; Hagihara, K.; Hisamoto, K.; Nakano, T. Stability of crystallographic texture in laser powder bed fusion: Understanding the competition of crystal growth using a single crystalline seed. Addit. Manuf. 2021, 43, 102004. [Google Scholar] [CrossRef]

- Geiger, F.; Kunze, K.; Etter, T. Tailoring the texture of IN738LC processed by selective laser melting (SLM) by specific scanning strategies. Mater. Sci. Eng. A 2016, 661, 240–246. [Google Scholar] [CrossRef]

- Sun, S.H.; Hagihara, K.; Nakano, T. Effect of scanning strategy on texture formation in Ni-25 at.% Mo alloys fabricated by selective laser melting. Mater. Des. 2018, 140, 307–316. [Google Scholar] [CrossRef]

- Wan, H.Y.; Zhou, Z.J.; Li, C.P.; Chen, G.; Zhang, G. Effect of scanning strategy on grain structure and crystallographic texture of Inconel 718 processed by selective laser melting. J. Mater. Sci. Technol. 2018, 34, 1799–1804. [Google Scholar] [CrossRef]

- Rehman, S.U.; Jiang, Q.; Tan, Q.; Liu, K.; Haq, A.U.; Zhong, Z. Evolution of Microstructure, Magnetic Properties, and Thermal Stabilities of Isotropic Alnico Ribbons. IEEE Trans. Magn. 2020, 56, 1–5. [Google Scholar] [CrossRef]

- King, W.E.; Anderson, A.T.; Ferencz, R.M.; Hodge, N.E.; Kamath, C.; Khairallah, S.A.; Rubenchik, A.M. Laser powder bed fusion additive manufacturing of metals; physics, computational, and materials challenges. Appl. Phys. Rev. 2015, 2, 041304. [Google Scholar] [CrossRef]

- Cahn, J.W. Magnetic aging of spinodal alloys. J. Appl. Phys. 1963, 34, 3581–3586. [Google Scholar] [CrossRef]

- Guo, W.; Sneed, B.T.; Zhou, L.; Tang, W.; Kramer, M.J.; Cullen, D.A.; Poplawsky, J.D. Correlative energy-dispersive X-ray spectroscopic tomography and atom probe tomography of the phase separation in an alnico 8 alloy. Microsc. Microanal. 2016, 22, 1251–1260. [Google Scholar] [CrossRef] [PubMed]

- Rehman, S.U.; Jiang, Q.; Ge, Q.; Lei, W.; Zhang, L.; Zeng, Q.; Ul Haq, A.; Liu, R.; Zhong, Z. Microstructure and magnetic properties of alnico permanent magnetic alloys with Zr-B additives. J. Magn. Magn. Mater. 2018, 451, 243–247. [Google Scholar] [CrossRef]

- Hao, S.M.; Ishida, K.; Nishizawa, T. Role of alloying elements in phase decomposition in alnico magnet alloys. Metall. Trans. A 1985, 16, 179–185. [Google Scholar] [CrossRef]

- Gleiter, H.; Christian, J.; Haasen, P.; Massalski, T. Progress in Materials Science, Chalmers Anniversary Volume; Pergamon Press: Oxford, UK, 1981. [Google Scholar]

- Campbell, I.; Fert, A.; Wohlfarth, E. Ferromagnetic Materials; EP Wolfarth: North Holland, The Amsterdam, 1982. [Google Scholar]

- Zhou, L.; Miller, M.; Cullen, D.A.; Lu, P.; McCallum, R.; Anderson, I.; Constantinides, S.; Kramer, M. Microstractural characterization of Alnico 9 alloy. Microsc. Microanal. 2015, 21, 1343–1344. [Google Scholar] [CrossRef]

- Vasin, G.; Povolotskii, E. Tempering of high-coercivity Alnico alloys. Met. Sci. Heat Treat. 1970, 12, 679–682. [Google Scholar] [CrossRef]

- Mostafaei, A.; Kimes, K.A.; Stevens, E.L.; Toman, J.; Krimer, Y.L.; Ullakko, K.; Chmielus, M. Microstructural evolution and magnetic properties of binder jet additive manufactured Ni-Mn-Ga magnetic shape memory alloy foam. Acta Mater. 2017, 131, 482–490. [Google Scholar] [CrossRef]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Prog. Mater. Sci. 2021, 119, 100707. [Google Scholar] [CrossRef]

- Paranthaman, M.P.; Shafer, C.S.; Elliott, A.M.; Siddel, D.H.; McGuire, M.A.; Springfield, R.M.; Martin, J.; Fredette, R.; Ormerod, J. Binder jetting: A novel NdFeB bonded magnet fabrication process. JOM 2016, 68, 1978–1982. [Google Scholar] [CrossRef]

- Cramer, C.L.; Nandwana, P.; Yan, J.; Evans, S.F.; Elliott, A.M.; Chinnasamy, C.; Paranthaman, M.P. Binder jet additive manufacturing method to fabricate near net shape crack-free highly dense Fe-6.5 wt.% Si soft magnets. Heliyon 2019, 5, e02804. [Google Scholar] [CrossRef]

- Li, L.; Jones, K.; Sales, B.; Pries, J.L.; Nlebedim, I.; Jin, K.; Bei, H.; Post, B.K.; Kesler, M.S.; Rios, O.; et al. Fabrication of highly dense isotropic Nd-Fe-B nylon bonded magnets via extrusion-based additive manufacturing. Addit. Manuf. 2018, 21, 495–500. [Google Scholar] [CrossRef]

- Li, L.; Tirado, A.; Nlebedim, I.; Rios, O.; Post, B.; Kunc, V.; Lowden, R.; Lara-Curzio, E.; Fredette, R.; Ormerod, J.; et al. Big area additive manufacturing of high performance bonded NdFeB magnets. Sci. Rep. 2016, 6, 36212. [Google Scholar] [CrossRef] [PubMed]

- Paranthaman, M.P.; Yildirim, V.; Lamichhane, T.N.; Begley, B.A.; Post, B.K.; Hassen, A.A.; Sales, B.C.; Gandha, K.; Nlebedim, I.C. Additive manufacturing of isotropic NdFeB PPS bonded permanent magnets. Materials 2020, 13, 3319. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Wang, Y.; Hou, Y.; Wang, Y.; Wu, Y.; Ma, S.; Liu, Z.; Zeng, D.; Tian, Y.; Xia, W.; et al. Magnetic microstructure and magnetic properties of spark plasma sintered NdFeB magnets. J. Magn. Magn. Mater. 2016, 399, 175–178. [Google Scholar] [CrossRef]

- Du, D.; Haley, J.C.; Dong, A.; Fautrelle, Y.; Shu, D.; Zhu, G.; Li, X.; Sun, B.; Lavernia, E.J. Influence of static magnetic field on microstructure and mechanical behavior of selective laser melted AlSi10Mg alloy. Mater. Des. 2019, 181, 107923. [Google Scholar] [CrossRef]

- Filimonov, A.M.; Rogozin, O.A.; Dubinin, O.N.; Kuzminova, Y.O.; Shibalova, A.A.; Okulov, I.V.; Akhatov, I.S.; Evlashin, S.A. Modification of mechanical properties in directed energy deposition by a static magnetic field: Experimental and theoretical analysis. Materials 2021, 14, 5190. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Song, C.; Yang, Y.; Han, C.; Wang, M.; Xiao, Y.; Liu, Z. The microstructure and properties evolution of SS316L fabricated by magnetic field-assisted laser powder bed fusion. Mater. Sci. Eng. A 2022, 845, 143216. [Google Scholar] [CrossRef]

- Sarkar, A.; Somashekara, M.; Paranthaman, M.P.; Kramer, M.; Haase, C.; Nlebedim, I.C. Functionalizing magnet additive manufacturing with in-situ magnetic field source. Addit. Manuf. 2020, 34, 101289. [Google Scholar] [CrossRef]

- Seidel, A.; Degener, L.; Schneider, J.; Brueckner, F.; Beyer, E.; Leyens, C. Novel Approach for Suppressing of Hot Cracking Via Magneto-fluid Dynamic Modification of the Laser-Induced Marangoni Convection. In Superalloys 2020: Proceedings of the 14th International Symposium on Superalloys; Springer: Cham, Switzerland, 2020; pp. 972–981. [Google Scholar]

- Tan, C.; Li, R.; Su, J.; Du, D.; Du, Y.; Attard, B.; Chew, Y.; Zhang, H.; Lavernia, E.J.; Fautrelle, Y.; et al. Review on field assisted metal additive manufacturing. Int. J. Mach. Tools Manuf. 2023, 189, 104032. [Google Scholar] [CrossRef]

- Du, D.; Wang, L.; Dong, A.; Yan, W.; Zhu, G.; Sun, B. Promoting the densification and grain refinement with assistance of static magnetic field in laser powder bed fusion. Int. J. Mach. Tools Manuf. 2022, 183, 103965. [Google Scholar] [CrossRef]

- Katakam, S.; Dahotre, N. Laser patterning of Fe–Si–B amorphous ribbons in magnetic field. Appl. Phys. A 2014, 117, 1241–1247. [Google Scholar] [CrossRef]

- Lu, K. Nanocrystalline metals crystallized from amorphous solids: Nanocrystallization, structure, and properties. Mater. Sci. Eng. R Rep. 1996, 16, 161–221. [Google Scholar] [CrossRef]

- Wang, X.D.; Qi, M.; Yi, S. Crystallization behavior of bulk amorphous alloy Zr62Al8Ni13Cu17 under high magnetic field. Scr. Mater. 2004, 51, 1047–1050. [Google Scholar] [CrossRef]

- Huan, P.C.; Wei, X.; Wang, X.N.; Di, H.S.; Chen, Y.; Zhang, Q.Y.; Chen, X.M.; Shen, X.J. Comparative study on the microstructure, mechanical properties and fracture mechanism of wire arc additive manufactured Inconel 718 alloy under the assistance of alternating magnetic field. Mater. Sci. Eng. A 2022, 854, 143845. [Google Scholar] [CrossRef]

| Permanent Magnetic Alloy Family | Br (T) | Hc (kOe) | BHmax (MGOe) | Curie Temperature () (°C) |

|---|---|---|---|---|

| Alnico | 0.70–1.30 | 0.50–1.89 | 1.25–9.40 | 820–860 |

| Ferrite | 0.20–0.46 | 2.4–4.5 | 0.75–5.66 | 450 |

| SmCo | 0.70–1.20 | 12.5–35.0 | 15.08–32.67 | 700 |

| Nd-Fe-B | 0.70–1.50 | 11.30–34.00 | 15.08–54.04 | 310–370 |

| Alloy (Cast) | Al (wt%) | Ni (wt%) | Co (wt%) | Ti (wt%) | Cu (wt%) | BHmax (MGOe) | Br (T) | Hc (kOe) | (Solidification Range) (°C) |

|---|---|---|---|---|---|---|---|---|---|

| Alnico-1 | 12 | 21 | 5 | - | 3 | 1.4 | 0.72 | 0.47 | 24 |

| Alnico-2 | 10 | 19 | 13 | - | 3 | 1.7 | 0.75 | 0.56 | 27 |

| Alnico-3 | 12 | 25 | - | - | 3 | 1.35 | 0.70 | 0.48 | 35 |

| Alnico-5 | 8 | 14 | 24 | - | 3 | 5.5 | 1.28 | 0.64 | 24 |

| Alnico-6 | 8 | 16 | 24 | - | 3 | 3.9 | 1.05 | 0.78 | 26 |

| Alnico-8 | 7 | 15 | 35 | 5 | 4 | 5.3 | 0.82 | 1.65 | 220 |

| Alnico-8H | 8 | 14 | 38 | 8 | 3 | 5.0 | 0.72 | 1.90 | 283 |

| Alnico-9 | 7 | 15 | 35 | 5 | 4 | 9.0 | 1.06 | 1.50 | 220 |

| Alloying Element | Effect on Alnico Alloy |

|---|---|

| Ti | 1. Increases the volume fraction of the phase. 2. Avoids the formation of the gamma phase. 3. Supports the formation of Cu-Ni bridges between the phase. |

| Co | 1. Coercivity and remanence increased with the increase in Co of up to 35 wt% beyond which it decreases. 2. Increases volume fraction of the phase. |

| Nb | 1. Coercivity increased with increase in Nb up to 2 wt% beyond which it decreases. 2. Remanence and BHmax highest at 1.5 wt%. 3. Increase in the phase. 4. Reduces chipping and brittleness. |

| Alloy | Composition (wt%) | AM Process | Laser Power | Scan Speed | Notes |

|---|---|---|---|---|---|

| Alnico-8 | 33Fe-7Al-13Ni- 38Co-7Ti-3Cu | L-DED | 50–200 W | 0.203 mm/s (motion only along Z-axis) | 1. Melt pool size is kept constant by varying the laser power. 2. Stainless steel is used as a substrate. 3. Pre-alloyed powders were used for printing. |

| Alnico-8 | 30Fe-7Al-14Ni- 38.5Co-7.5Ti-3Cu | L-DED | 50–200 W | 0.203 mm/s (motion only along Z-axis) | 1. Melt pool size is kept constant by varying the laser power. 2. Samples are printed on Alnico-9, and stainless steel is used as a substrate. 3. Pre-alloyed powders were used for printing. |

| Alnico-8H (Co lean) | 32Fe-7.5Al-17Ni- 33Co-8Ti-3Cu | EBM/PBF | 3.5–14 mA | 200–800 mm/s | 1. Pre-alloyed powders were used for printing. 2. Cobalt content is reduced from 38 to 29 wt.% when compared with Alnico-8H. 3. Geometrical density of 7.27 g/cc. 4. Equiaxed microstructure is observed throughout the sample. |

| Alnico-8H | 28Fe-7.5Al-15Ni- 38Co-8Ti-3.8Cu | L-DED | 100 W | 1500 steps/s | 1. Pre-alloyed powders were used for printing. 2. Melt pool size is kept constant by varying the laser power between 70 and 200 W. 3. Geometrical density of 7.25 g/cc. 4. Equiaxed microstructure is observed throughout the sample. |

| Alnico-8H (Co lean) | 32Fe-7.5Al-17Ni- 33Co-8Ti-3Cu | L-DED | 100 W | 1600 steps/s | 1. Pre-alloyed powders were used for printing. 2. Cobalt content is reduced from 38 to 29 wt.% when compared with Alnico-8H. 3. Geometrical density of 7.25 g/cc. |

| Alnico-35 | 55Fe-12Ni-25Co- 2Mo-3Cu | LPBF | 190 W | 600–800 mm/s | 1. Pre-alloyed powders were used for printing. |

| Alnico-5 | 50.4Fe-24Co-13Ni- 7Al-3Cu | LPBF | 110–190 W | 600–800 mm/s | 1. Pre-alloyed powders were used for printing. 2. Sound sample is obtained at 190 W and 800 mm/s. |

| Alnico-8 | 29Fe-38.5Co-7.5Al- 14.5Ni-7.5Ti-3Cu | LPBF | 170 W | 600 mm/s (hatch distance of 0.06 mm) | 1. Pre-alloyed powders were used for printing. 2. Printing is performed on a heated stage at a temperature of around 800 °C. 3. Precipitation of the gamma phase is observed along the grain boundaries. |

| Alnico-5 | 48Fe-24Co-12Ni- 14Al-2Cu | LPBF | 150–190 W | 400–1200 mm/s | 1. Pre-alloyed powders were used for printing. 2. Defects like holes and cracks were observed. 3. Maximum density is achieved at 170 W and 800 mm/s. |

| Alnico-8 Alloy | Intrinsic Coercivity (kOe) | Remanence (Tesla) | BHmax (MGOe) |

|---|---|---|---|

| Columnar grains with <100> crystallographic orientation | 1.63 | 1.08 | 9.75 |

| Equiaxed microstructure | 1.55 | 0.910 | 5.5 |

| Processing | As Processed (Microstructure) | Solutionization (Microstructure) | Magnetic Annealing (at 830 °C) (Microstructure) |

|---|---|---|---|

| Conventional process (Sintering/Casting) | phase + phase | phase | phase + phase |

| Additive manufacturing (LPBF/L-DED) | phase | phase | phase + phase |

| LPBF with heated stage | phase + phase + | - | - |

| Alloy | Composition (wt%) | AM Process | Solutionization (°C) | Magnetic Annealing (°C) | Tempering (°C) | Hcj (kOe) | BHmax (MGOe) | Notes |

|---|---|---|---|---|---|---|---|---|

| Alnico-8 | 33Fe-7Al- 13Ni-38Co- 7Ti-3Cu | L-DED | 1250 30 min | 840 10 min, 1T | 650–5 h 580–5 h | 1.83 | 6 | L-DED-processed samples have shown Hc comparable with the sintered AlNiCo-8H and BHmax higher than the sintered Alnico-8H. |

| Alnico-8 | 30Fe-7Al- 14Ni-38.5Co- 7.5Ti-3Cu | L-DED | 1250 30 min | 840 9 min,1T | 670–1.5 h 650, 620, 580, 550, 520, at each temperature for 4 h | 2.03 | 4.8 | Samples printed on stainless steel substrate has shown high coercivity and BHmax when compared with samples printed on AlNiCo-9 substrate. |

| Alnico-8H (Co lean) | 32Fe-7.5Al- 17Ni-33Co- 8Ti-3Cu | EBM/PBF | 1210 10 min | 830–870 1–8 min, 1 T | 650–5 h 580–5 h | 1.6 | - | When compared with L-DED samples, EBM/PBF samples have lower magnetic properties. |

| Alnico-8H | 28Fe-7.5Al- 15Ni-38Co- 8Ti-3.8Cu | L-DED | 1210 10 min | 830–870 1–8 min,1 T | 650–5 h 580–5 h | 2.1 | 4.9 | The magnetic properties of printed samples are similar to those of sintered and cast Alnico magnets. |

| Alnico-8H (Co lean) | 32Fe-7.5Al- 17Ni-33Co- 8Ti-3Cu | L-DED | 1210 10 min | 830–870 1–8 min, 1 T | 650–5 h 580–5 h | 2.1 | 4.2 | The magnetic properties of printed samples are similar to those of sintered and higher than the cast Alnico magnets. |

| Alnico-5 | 50.4Fe-24Co- 13Ni-7Al-3Cu | LPBF | From 1290 °C cooling at a rate of 14.5/min | 20 min cooling in electromagnet to 400 °C | 610–3 h 590–8 h 570–15 h 550–20 h | 0.49 | 4.5 | Hc, Br and BHmax increased with increasing laser power and scan speed. |

| Alnico-8 | 29Fe-38.5Co- 7.5Al-7.5Ti- 14.5Ni-3Cu | LPBF (Heated Stage) | - | - | - | 0.6 | - | The magnetic properties of printed samples are similar to those of sintered Alnico magnets. |

| Alnico-5 | 48Fe-24Co- 14Al-12Ni-2Cu | LPBF | 1250 15 min | - | 800–10 min 650–3 h 600–8 h 550–10 h | 0.48 | 1.46 | BHmax is increased with the increase in laser power and scan speed. |

| NdFeB+SmFeN | Coercivity (kOe) |

|---|---|

| Fabricated without magnetic field (isotropic sample) | 12.2 |

| Fabricated with magnetic field in perpendicular direction (anisotropic sample) | 13.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dussa, S.; Joshi, S.S.; Sharma, S.; Krishna, K.V.M.; Radhakrishnan, M.; Dahotre, N.B. Additively Manufactured Alnico Permanent Magnet Materials—A Review. Magnetism 2024, 4, 125-156. https://doi.org/10.3390/magnetism4020010

Dussa S, Joshi SS, Sharma S, Krishna KVM, Radhakrishnan M, Dahotre NB. Additively Manufactured Alnico Permanent Magnet Materials—A Review. Magnetism. 2024; 4(2):125-156. https://doi.org/10.3390/magnetism4020010

Chicago/Turabian StyleDussa, Saikumar, Sameehan S. Joshi, Shashank Sharma, Karri Venkata Mani Krishna, Madhavan Radhakrishnan, and Narendra B. Dahotre. 2024. "Additively Manufactured Alnico Permanent Magnet Materials—A Review" Magnetism 4, no. 2: 125-156. https://doi.org/10.3390/magnetism4020010

APA StyleDussa, S., Joshi, S. S., Sharma, S., Krishna, K. V. M., Radhakrishnan, M., & Dahotre, N. B. (2024). Additively Manufactured Alnico Permanent Magnet Materials—A Review. Magnetism, 4(2), 125-156. https://doi.org/10.3390/magnetism4020010