Sorghum Biomass as an Alternative Source for Bioenergy

Abstract

1. Introduction

2. Materials and Methods

2.1. Sorghum, Eucalyptus, and Bio-Oil Production

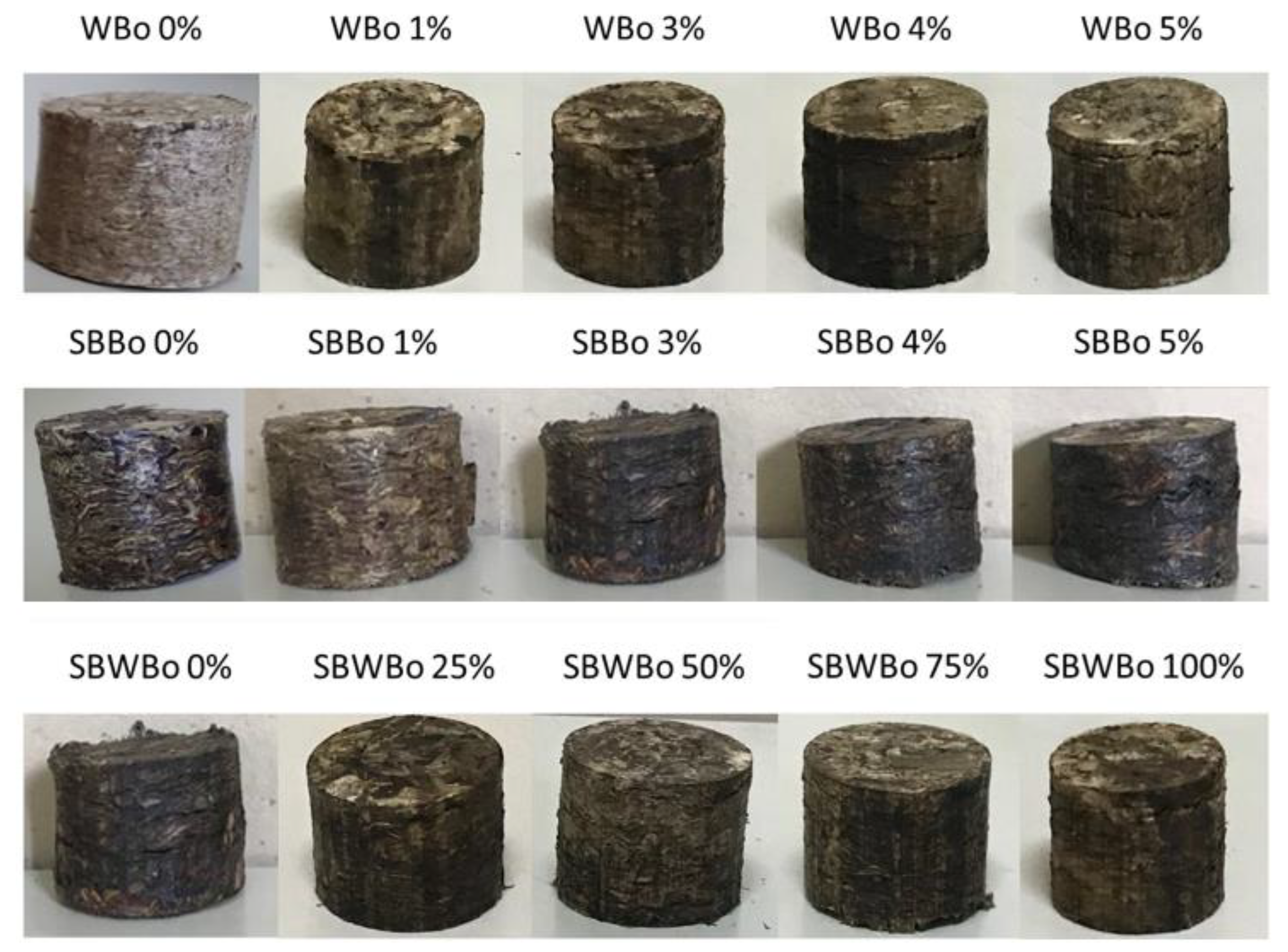

2.2. Biomass Densification into Briquettes

2.3. Biomass Characterization

2.4. Statistical Analyses

3. Results

3.1. Biomass Yields

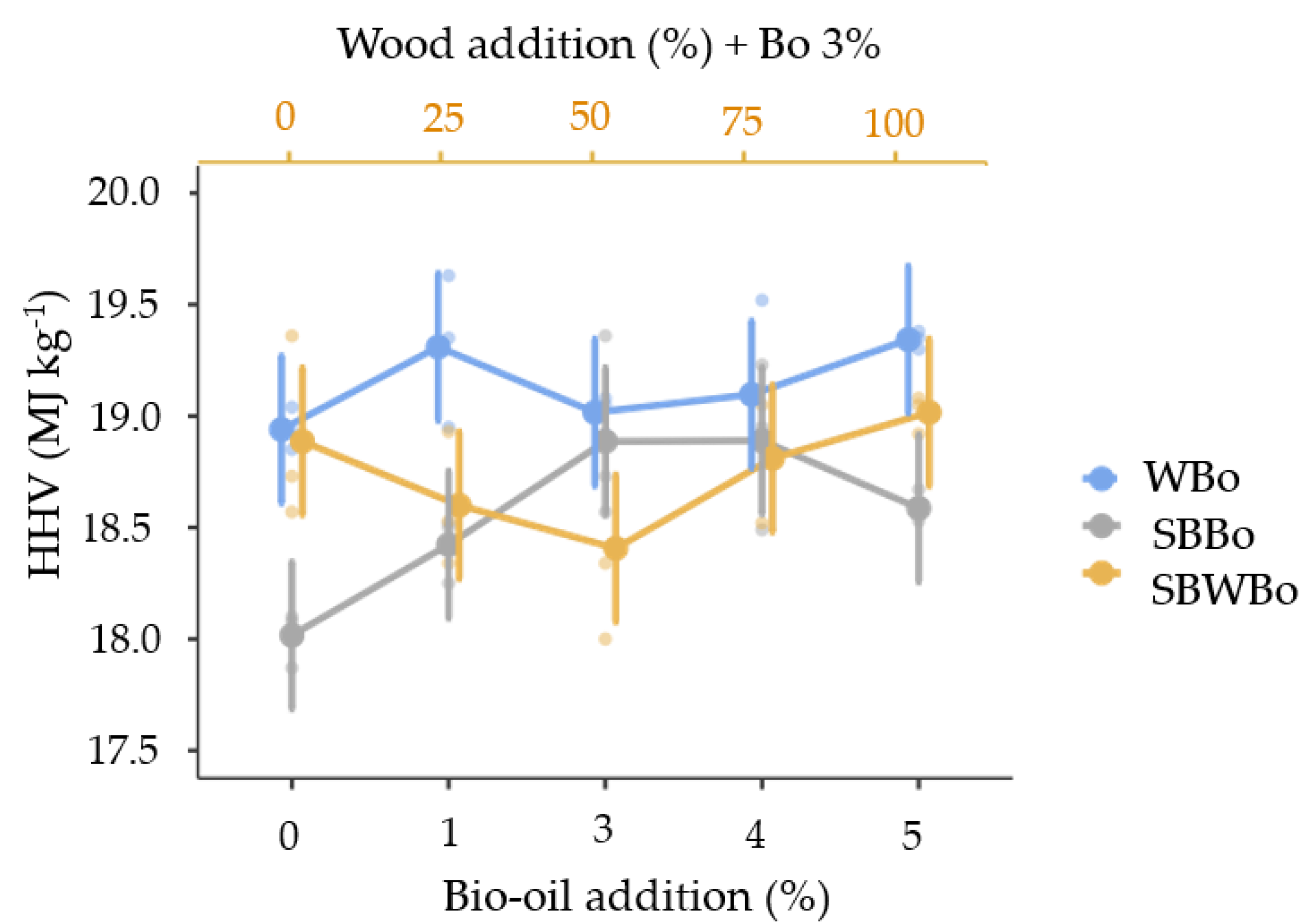

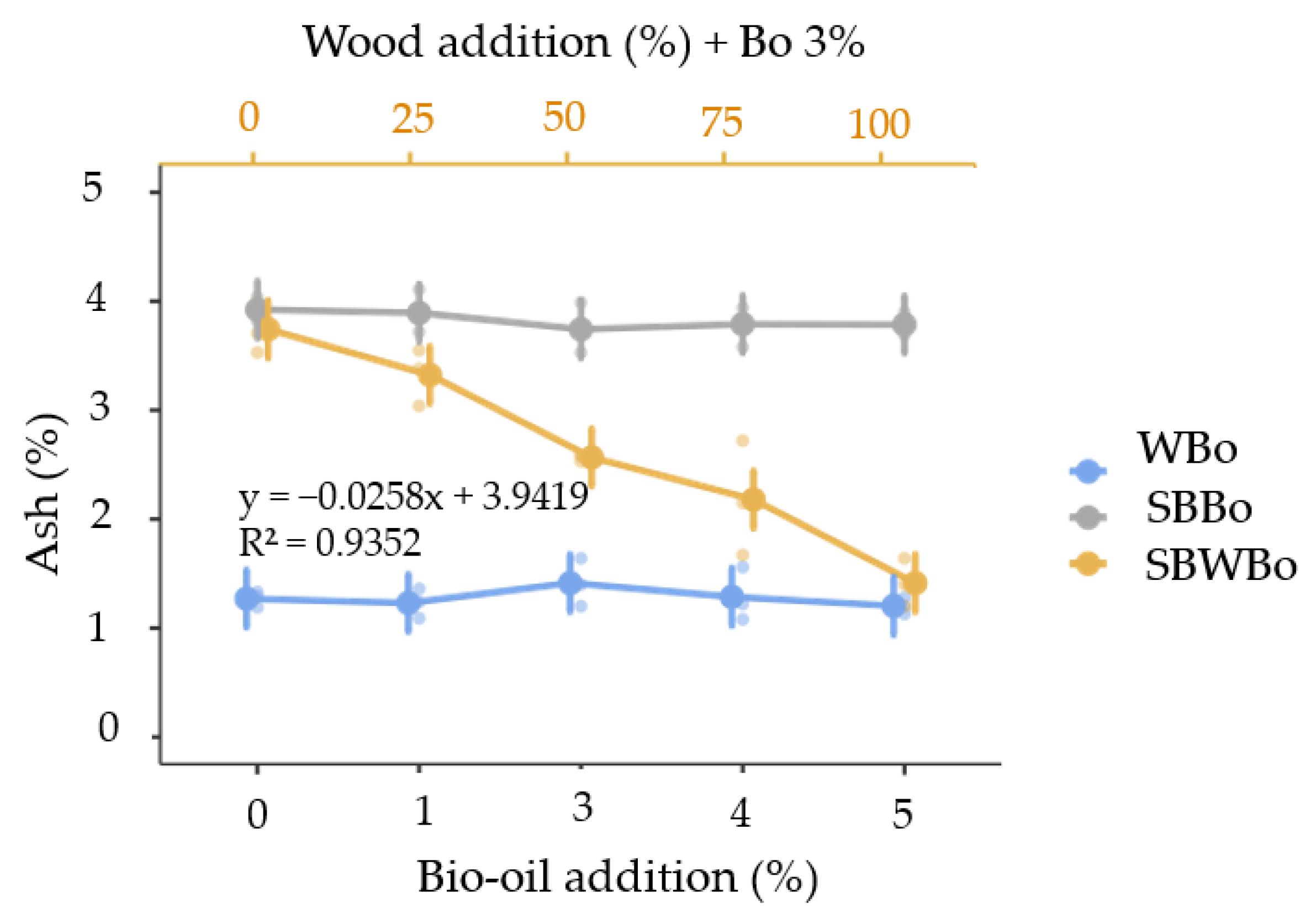

3.2. Energy Properties of Biomass and Bio-Oil

4. Discussion

4.1. Comparing Results to Past Research

4.2. Agro-Forestry Alternative for Energy and Other Uses

4.3. Sustainability Implications of Sorghum Biomass

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alidrisi, H.; Demirbas, A. Enhanced electricity generation using biomass materials. Energy Sources Part A Recovery Util. Environ. Eff. 2016, 38, 1419–1427. [Google Scholar] [CrossRef]

- Akhmat, G.; Zaman, K.; Shukui, T.; Sajjad, F. Does energy consumption contribute to climate change? Evidence from major regions of the world. Renew. Sustain. Energy Rev. 2014, 36, 123–134. [Google Scholar] [CrossRef]

- Riti, J.S.; Shu, Y.; Song, D.; Kamah, M. The contribution of energy use and financial development by source in climate change mitigation process: A global empirical perspective. J. Clean. Prod. 2017, 148, 882–894. [Google Scholar] [CrossRef]

- Yoro, K.O.; Daramola, M.O. Chapter 1-CO2 emission sources, greenhouse gases, and the global warming effect. In Advances in Carbon Capture: Methods, Technologies and Applications, 1st ed.; Rahimpour, M.R., Farsi, M., Makarem, M.A., Eds.; Elsevier Science: Amsterdam, The Netherlands, 2020; pp. 3–28 (570 pp.). ISBN 0128196572. [Google Scholar] [CrossRef]

- Lamb, W.F.; Wiedmann, T.; Pongratz, J.; Andrew, R.; Crippa, M.; Olivier, J.G.J.; Wiedenhofer, D.; Mattioli, G.; Khourdajie, A.A.; House, J.; et al. A review of trends and drivers of greenhouse gas emissions by sector from 1990 to 2018. Environ. Res. Lett. 2021, 16, 073005. [Google Scholar] [CrossRef]

- Evans, A.; Strezov, V.; Evans, T.J. Sustainability considerations for electricity generation from biomass. Renew. Sustain. Energy Rev. 2010, 14, 1419–1427. [Google Scholar] [CrossRef]

- Raymer, A.K.P. A comparison of avoided greenhouse gas emissions when using different kinds of wood energy. Biomass Bioenergy 2006, 30, 605–617. [Google Scholar] [CrossRef]

- Timmons, D.; Harris, J.M.; Roach, B. The Economics of Renewable Energy; An ECI Teaching Module on Social and Environmental Issues in Economics; Global Development Policy Center, Boston University: Boston, MA, USA, 2024; Available online: https://www.bu.edu/eci/files/2024/03/renewable-energy-econ-module-final.pdf (accessed on 4 June 2024).

- Kaygusuz, K. Climate Change and Biomass Energy for Sustainability. Energy Sources Part B Econ. Plan. Policy 2010, 5, 133–146. [Google Scholar] [CrossRef]

- Frankowski, J.; Wawro, A.; Batog, J.; Szambelan, K.; Łacka, A. Bioethanol Production Efficiency from Sorghum Waste Biomass. Energies 2022, 15, 3132. [Google Scholar] [CrossRef]

- Srivastav, A.L.; Bhardwaj, A.K.; Kumar, M. (Eds.) Valorization of Biomass Wastes for Environmental Sustainability: Green Practices for the Rural Circular Economy, 1st ed.; Springer: Cham, Switzerland, 2024; pp. 1–337. ISBN 978-3-031-52484-4/978-3-031-52485-1. [Google Scholar] [CrossRef]

- Primadita, D.S.; Kumara, I.N.S.; Ariastina, W.G. A Review on Biomass for Electricity Generation in Indonesia. J. Electr. Electron. Inform. 2020, 4, 1–9. [Google Scholar] [CrossRef]

- Vijay, V.; Kapoor, R.; Singh, P.; Hiloidhari, M.; Ghosh, P. Sustainable utilization of biomass resources for decentralized energy generation and climate change mitigation: A regional case study in India. Environ. Res. 2022, 212 Pt B, 113257. [Google Scholar] [CrossRef]

- Ahamer, G. How to Compute Whether Biomass Fuels Are Carbon Neutral. C 2024, 10, 48. [Google Scholar] [CrossRef]

- Azar, C. Biomass for energy: A dream come true…or a nightmare? Wiley Interdiscip. Rev. Clim. Chang. 2011, 2, 309–323. [Google Scholar] [CrossRef]

- Gutsch, M.; Lasch-Born, P.; Lüttger, A.B.; Suckow, F.; Murawski, A.; Pilz, T. Uncertainty of biomass contributions from agriculture and forestry to renewable energy resources under climate change. Meteorol. Z. 2015, 24, 213–223. [Google Scholar] [CrossRef]

- Winchester, N.; Reilly, J.M. The feasibility, costs, and environmental implications of large-scale biomass energy. Energy Econ. 2015, 51, 188–203. [Google Scholar] [CrossRef]

- De Freitas, E.N.; Salgado, J.C.S.; Alnoch, R.C.; Contato, A.G.; Habermann, E.; Michelin, M.; Martinez, C.A.; Polizeli, M.d.L.T.M. Challenges of Biomass Utilization for Bioenergy in a Climate Change Scenario. Biology 2021, 10, 1277. [Google Scholar] [CrossRef]

- Kinefuchi, E. Burning forests: The wood pellet industry’s framing of sustainability and its shadow places. Front. Commun. 2024, 9, 1237141. [Google Scholar] [CrossRef]

- Abbasi, T.; Abbasi, S.A. Biomass energy and the environmental impacts associated with its production and utilization. Renew. Sustain. Energy Rev. 2010, 14, 919–937. [Google Scholar] [CrossRef]

- Prakasham, R.S.; Nagaiah, D.; Vinutha, K.S.; Uma, A.; Chiranjeevi, T.; Umakanth, A.V.; Rao, P.S.; Yan, N. Sorghum biomass: A novel renewable carbon source for industrial bioproducts. Biofuels 2014, 5, 159–174. [Google Scholar] [CrossRef]

- Ahmad, T.; Buneen, U.; Sajid, S.N.; Almas, H.I.; Haseeb, A.; Rubab, A.; Kanwal, M.; Arsh, Q.E.; Asghar, H. Morphological and molecular diversity analyses of high biomass sorghum (Sorghum bicolor L. Moench). Int. J. Biosci. 2020, 16, 253–273, ISSN 2220-665 (Print), 2222-5234 (Online). [Google Scholar]

- Staggenborg, S. Forage and Renewable Sorghum End Uses. In Sorghum: A State of the Art and Future Perspectives; Ciampitti, I.A., Prasad, P.V., Eds.; American Society of Agronomy Crop Science Society of America Soil Science Society of America: Madison, WI, USA, 2019; Volume 58, Chapter 20; pp. 441–461. [Google Scholar] [CrossRef]

- Umakanth, A.V.; Paroha, S.; Kumar, A.; Ranganathan, A.; Swain, D. Sweet Sorghum for Biofuel Production in Sub-Tropical India. J. Sci. Res. Rep. 2024, 30, 1–9. [Google Scholar] [CrossRef]

- Da Costa Parrella, R.A.; Schaffert, R.E.; de Menezes, C.B.; Rodrigues, J.A.S.; Magalhães, J.V.; Damasceno, C.M.B.; da Silva, D.D.; Mendes, S.M. Improving sorghum cultivation in South America. In Achieving Sustainable Cultivation of Sorghum Volume 2, 1st ed.; Rooney, B., Ed.; Burleigh Dodds Science Publishing: Cambridge, UK, 2017; Chapter 7; 34p, ISBN 9781351114394. [Google Scholar] [CrossRef]

- Pavinato, P.S.; Cherubin, M.R.; Soltangheisi, A.; Rocha, G.C.; Chadwick, D.R.; Jones, D.L. Revealing soil legacy phosphorus to promote sustainable agriculture in Brazil. Sci. Rep. 2020, 10, 15615. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Zhou, Q.; Sheng, X.; Chen, X.; Hua, Y.; Lin, S.; Luo, Q.; Yu, B.; Shao, T.; Wu, Y.; et al. Harnessing the Genetic Basis of Sorghum Biomass-Related Traits to Facilitate Bioenergy Applications. Int. J. Mol. Sci. 2023, 24, 14549. [Google Scholar] [CrossRef] [PubMed]

- Castro, F.M.R.; Bruzi, A.T.; Nunes, J.A.R.; Parrella, R.A.C.; Lombardi, G.M.R.; Albuquerque, C.J.B.; Lopes, M. Agronomic and Energetic Potential of Biomass Sorghum Genotypes. Am. J. Plant Sci. 2015, 6, 1862–1873. [Google Scholar] [CrossRef]

- Suyatno, H.; Prayoga, M.Z.E.; Sugiyono, A.; Maulana, I.; Ruhiyat, A.S.; Hidayat, Y. Investigation on Potential of Slagging Fouling and Corrosion in Co-firing Bituminous Coal and Sorghum Waste Pellet. Int. J. Appl. Sci. Technol. Eng. 2023, 1, 197–203, ISSN 2987-2499. [Google Scholar] [CrossRef]

- Pannacci, E.; Bartolini, S. Effect of nitrogen fertilization on sorghum for biomass production. Agron. Res. 2018, 16, 2146–2155. [Google Scholar] [CrossRef]

- Picchio, R.; Di Marzio, N.; Cozzolino, L.; Venanzi, R.; Stefanoni, W.; Bianchini, L.; Pari, L.; Latterini, F. Pellet Production from Pruning and Alternative Forest Biomass: A Review of the Most Recent Research Findings. Materials 2023, 16, 4689. [Google Scholar] [CrossRef] [PubMed]

- Kwapong, N.A. Biomass Pelletisation: Influence of Biomass Characteristics on Pellet Quality. Technical Article, Biomass Connect. March 2023. Available online: https://www.biomassconnect.org/technical-articles/biomass-pelletisation-influence-of-biomass-characteristics-on-pellet-quality/ (accessed on 28 May 2024).

- Tumuluru, J.S. Effect of pellet die diameter on density and durability of pellets made from high moisture woody and herbaceous biomass. Carbon Resour. Convers. 2018, 1, 44–54. [Google Scholar] [CrossRef]

- Garcia, D.P.; Caraschi, J.C.; Ventorim, G.; Vieira, F.H.A.; de Paula Protásio, T. Assessment of plant biomass for pellet production using multivariate statistics (PCA and HCA). Renew. Energy 2019, 139, 796–805. [Google Scholar] [CrossRef]

- Theerarattananoon, K.; Xu, F.; Wilson, J.; Ballard, R.; Mckinney, L.; Staggenborg, S.; Vadlani, P.; Pei, Z.J.; Wang, D. Physical properties of pellets made from sorghum stalk, corn stover, wheat straw, and big bluestem. Ind. Crops Prod. 2011, 33, 325–332. [Google Scholar] [CrossRef]

- Rupasinghe, R.L.; Perera, P.; Bandara, R.; Amarasekera, H.; Vlosky, R. Insights into Properties of Biomass Energy Pellets Made from Mixtures of Woody and Non-Woody Biomass: A Meta-Analysis. Energies 2024, 17, 54. [Google Scholar] [CrossRef]

- Ferreira, I.R.; dos Santos, R.; Castro, R.; de Cássia Oliveira Carneiro, A.; Castro, A.F.; de Sousa Santos, C.P.; de Lima Costa, S.E.; Mairinck, K. Sorghum (Sorghum biocolor) Pellet Production and Characterization. Floresta e Ambient. 2019, 26, e20171001. [Google Scholar] [CrossRef]

- NBR 8112: EN 14961-2:2012 & EN 14961-2:2011; Solid Biofuels: Fuel Specification and Classes. Part 2: Wood Pellets for Non-Industrial Use. European Committee for Standardization (CEN): Brussels, Belgium, 2011. Available online: https://standards.globalspec.com/std/1381909/en-14961-2 (accessed on 28 May 2024).

- Tannús, C.M.; Santos, A.C.; Pereira, G.S.J.; Alves, M.G.; Corrêa, L.V.T.; da Costa Parrella, R.; Sette, C.R. Technical Feasibility of Sorghum Biomass for Briquettes Production. TreeDimensional J. 2023, 1, e2023023. [Google Scholar] [CrossRef]

- Carvalho, L.; Wopienka, E.; Pointner, C.; Lundgren, J.; Verma, V.K.; Haslinger, W.; Schmidl, C. Performance of a pellet boiler fired with agricultural fuels. Appl. Energy 2013, 104, 286–296. [Google Scholar] [CrossRef]

- NBR 8112; Carvão Vegetal: Análise Imediata. Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 1986. Available online: https://www.normas.com.br/visualizar/abnt-nbr-nm/3314/abnt-nbr8112-carvao-vegetal-analise-imediata (accessed on 28 May 2024).

- D5868 2013; Standard Test Method for Gross Calorific Value of Coal and Coke. American Society for Testing and Material (ASTM): West Conshohocken, PA, USA, 2013. Available online: https://standards.globalspec.com/std/3852823/astm-d5865-13 (accessed on 28 May 2024).

- Brito, J.O. Expressão da produção florestal em unidades energéticas. In Congresso Florestal Panamericano, Congresso Forestal Brazileiro, Curitiba, Floresta para o Desenvolvimento: Política, Ambiente, Tecnologia e Mercado; SBS, SBEF: Anais, São Paulo, Brazil, 1993; Volume 3, pp. 280–282. Available online: https://repositorio.usp.br/item/000859490 (accessed on 6 August 2024).

- Purohit, A.N.; Nautiyal, A.R. Fuelwood Value Index of Indian mountain tree species. Int. Tree Crops J. 1987, 4, 177–182. [Google Scholar] [CrossRef]

- Jamovi. Open Statistical Software for the Desktop and Cloud. 2023. Available online: https://www.jamovi.org/ (accessed on 6 July 2023).

- Morales, M.M.; Tardin, F.D.; Behling, M.; de Abreu, D.C.; Martins, A.R.R.; André, V.L.S.; Porto, F.L. Eucalipto e sorgo biomassa para geração de energia em Mato Grosso. In 3.a Vitrine Tecnológica Agrícola: Atualidades na Cultura do Milho em Sistema Soja e Milho-safrinha; de Abreu, D.C., de Lima Dias, M.P., Boscoli, D.Z., da Silva, W.M., de Paula Alberto, F., Martins, A.R.R., Pinheiro, D.T., Eds.; UNISELVA: Cuiabá, Mato Grosso, Brazil, 2022; Chapter 8; pp. 121–144. ISBN 978-65-86743-50-0. [Google Scholar]

- Perazzo, A.F.; de Carvalho, G.G.P.; Santos, E.M.; Pinho, R.M.A.; Campos, F.S.; Macedo, C.H.O.; Azevêdo, J.A.G.; Tabosa, J.N. Agronomic evaluation of 32 sorghum cultivars in the Brazilian semi-arid region. Rev. Bras. Zootec. 2014, 43, 232–237. [Google Scholar] [CrossRef]

- Cunha, A.P.M.A.; Zeri, M.; Leal, K.D.; Costa, L.; Cuartas, L.A.; Marengo, J.A.; Tomasella, J.; Vieira, R.M.; Barbosa, A.A.; Cunningham, C.; et al. Extreme Drought Events over Brazil from 2011 to 2019. Atmosphere 2019, 10, 642. [Google Scholar] [CrossRef]

- Sharma, S.; Sharma, M.; Mudgal, D.; Bhowmick, H. Adoption of strategies for clean combustion of biomass in boilers. Corros. Rev. 2021, 39, 387–408. [Google Scholar] [CrossRef]

- ISO 17225-2; Solid Biofuels: Fuel Specifications and Classes. Part 2, Graded Wood Pellets, 2nd Edition, Vernier. International Organization for Standardization: Geneva, Switzerland, 2021. Available online: https://www.iso.org/standard/76088.html (accessed on 3 July 2024).

- ISO 17225-6; International Organization for Standardization. Solid biofuels: Fuel Specifications and Classes. Part 6, Graded Non-Woody Pellets. Lithuanian Standards Board: Vilnius, Lithuania, 2021. Available online: https://www.iso.org/standard/76093.html (accessed on 3 July 2024).

- Brand, M.A. Energia da Biomassa Florestal; Interciência: Rio de Janeiro, Brazil, 2010; pp. 1–114. ISBN 8571932441. [Google Scholar]

- Engebretsen, S.E. Toxicity and Genotoxicity of five pyrolytic Bio-Oils produced from Wood, measured as Root Growth Inhibition and DNA Double-Strand Breaks in Allium cepa. Master’s Project, Department of Biology, Norwegian University of Science and Technology. 30 May 2014. Available online: https://ntnuopen.ntnu.no/ntnu-xmlui/bitstream/handle/11250/245485/733671_FULLTEXT01.pdf?sequence=1 (accessed on 4 July 2024).

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G.; Morgan, T.J. An overview of the organic and inorganic phase composition of biomass. Fuel 2012, 94, 1–33. [Google Scholar] [CrossRef]

- Jardim, A.M.d.R.F.; da Silva, G.I.N.; Biesdorf, E.M.; Pinheiro, A.G.; da Silva, M.V.; do Nascimento Araújo Júnior, G.; dos Santos, A.; Alves, H.K.M.N.; de Sá Souza, M.; de Morais, J.E.F.; et al. Production potential of Sorghum bicolor (L.) Moench crop in the Brazilian semiarid: Review. Pubvet 2020, 14, 141. [Google Scholar] [CrossRef]

- Pinho, R.V.; Silva, E.V.V.; de Oliveira, T.L.; de Souza, V.F.; de Menezes, C.B. Breeding Sorghum for Grain, Forage and Bioenergy in Brazil. Rev. Bras. Milho Sorgo 2022, 21, e1275. [Google Scholar] [CrossRef]

- Tonapi, V.A.; Talwar, H.S.; Are, A.K.; Bhat, B.V.; Reddy, C.R.; Dalton, T.J. (Eds.) Sorghum in the 21st Century: Food–Fodder–Feed–Fuel for a Rapidly Changing World, 1st ed.; Springer Nature Singapore Pte Ltd.: Singapore, 2020; pp. 1–940. ISBN 978-981-15-8248-6/978-981-15-8249-3. [Google Scholar] [CrossRef]

- Pereira, C.H.; Patino, H.O.; Hoshide, A.K.; Abreu, D.C.D.; Rotz, C.A.; Nabinger, C. Grazing supplementation and crop diversification benefits for southern Brazil beef: A case study. Agric. Syst. 2018, 162, 1–9. [Google Scholar] [CrossRef]

- Pedrosa, L.M.; Hoshide, A.K.; Abreu, D.C.; Molossi, L.; Couto, E.G. Financial transition and costs of sustainable agricultural intensification practices on a beef cattle and crop farm in Brazil’s Amazon. Renew. Agric. Food Syst. 2019, 36, 26–37. [Google Scholar] [CrossRef]

- Morales, M.M.; Tonini, H.; Behling, M.; Hoshide, A.K. The role of forest carbon stock in an integrated livestock-forestry system. Sustainability 2023, 15, 7750. [Google Scholar] [CrossRef]

- Jagtap, A.; Kalbande, S. Pelletization Process for the Production of Fuel Pellets from Various Surplus Biomass: A Review. Int. J. Environ. Clim. Chang. 2023, 13, 200–208, ISSN 2581-8627. [Google Scholar] [CrossRef]

| Country | Study | Year(s) | Location | Planting Date/ Harvest Date | Green Matter Yield (metric tons ha−1) | Dry Matter Yield (metric tons ha−1) |

|---|---|---|---|---|---|---|

| Brazil | Current | 2022–2023 | Sete Lagoas, Minas Gerais | 1 November to 23 March 1 | 84.1 | 30.6 |

| Morales et al., 2023 [46] | 2013–2020 | Sinop, Mato Grosso | Various 1 | 89.5 | 34.5 | |

| 2014, 2019 | Sinop, MT | Various 2 | 56.2 | 20.5 | ||

| Castro et al., 2015 [28] * | 2013–2014 | Lavras, MG | 29 November to 20 May 1 | 88.9 | - | |

| 2013–2014 | Sete Lagoas, MG | 21 November to 11 March 1 | 41.6 | - | ||

| 2014 | Uberlândia, MG | 13 March to 26 June 2 | 39.0 | - | ||

| Perazzo et al., 2014 [47] | 2011 | Soledade, Paraíba | 5 March to 28 May/7 June 2 | 55.0 | 14.9 | |

| Italy | Pannacci and Bartolini 2018 [30] | 2005 2006 | Perugia, Umbria Perugia, Umbria | 17 May to 13 October 15 May to 25 September | 66.5 63.7 | 21.0 29.2 |

| Biomass Processing | Biomass Type | Higher Heating Value (MJ kg−1) | Moisture Content (%) | Net Calorific Value (MJ kg−1) | Ash Content (%) | Fixed Carbon (%) |

|---|---|---|---|---|---|---|

| Raw product | Eucalyptus sawdust 1 | 18.8 | 60 | 4.9 | 3.9 | 21.2 |

| Sorghum biomass | 18.0 | 55 | 5.4 | 3.9 | 16.3 | |

| Compressed | Sorghum biomass | 18.0 | 7.5 | 13.8 | 3.9 | 16.3 |

| Eucalyptus sawdust 1 | 18.8 | 5.7 | 15.2 | 1.3 | 21.2 | |

| Bio-oil (pyrolysis) | Eucalyptus | 29.8 | 30 | 14.0 | 0.04 | 17.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morales, M.M.; Hoshide, A.K.; Carvalho, L.M.P.; Tardin, F.D. Sorghum Biomass as an Alternative Source for Bioenergy. Biomass 2024, 4, 1017-1030. https://doi.org/10.3390/biomass4030057

Morales MM, Hoshide AK, Carvalho LMP, Tardin FD. Sorghum Biomass as an Alternative Source for Bioenergy. Biomass. 2024; 4(3):1017-1030. https://doi.org/10.3390/biomass4030057

Chicago/Turabian StyleMorales, Marina Moura, Aaron Kinyu Hoshide, Leticia Maria Pavesi Carvalho, and Flavio Dessaune Tardin. 2024. "Sorghum Biomass as an Alternative Source for Bioenergy" Biomass 4, no. 3: 1017-1030. https://doi.org/10.3390/biomass4030057

APA StyleMorales, M. M., Hoshide, A. K., Carvalho, L. M. P., & Tardin, F. D. (2024). Sorghum Biomass as an Alternative Source for Bioenergy. Biomass, 4(3), 1017-1030. https://doi.org/10.3390/biomass4030057