High Impact Biomass Valorization for Second Generation Biorefineries in India: Recent Developments and Future Strategies for Sustainable Circular Economy

Abstract

1. Introduction

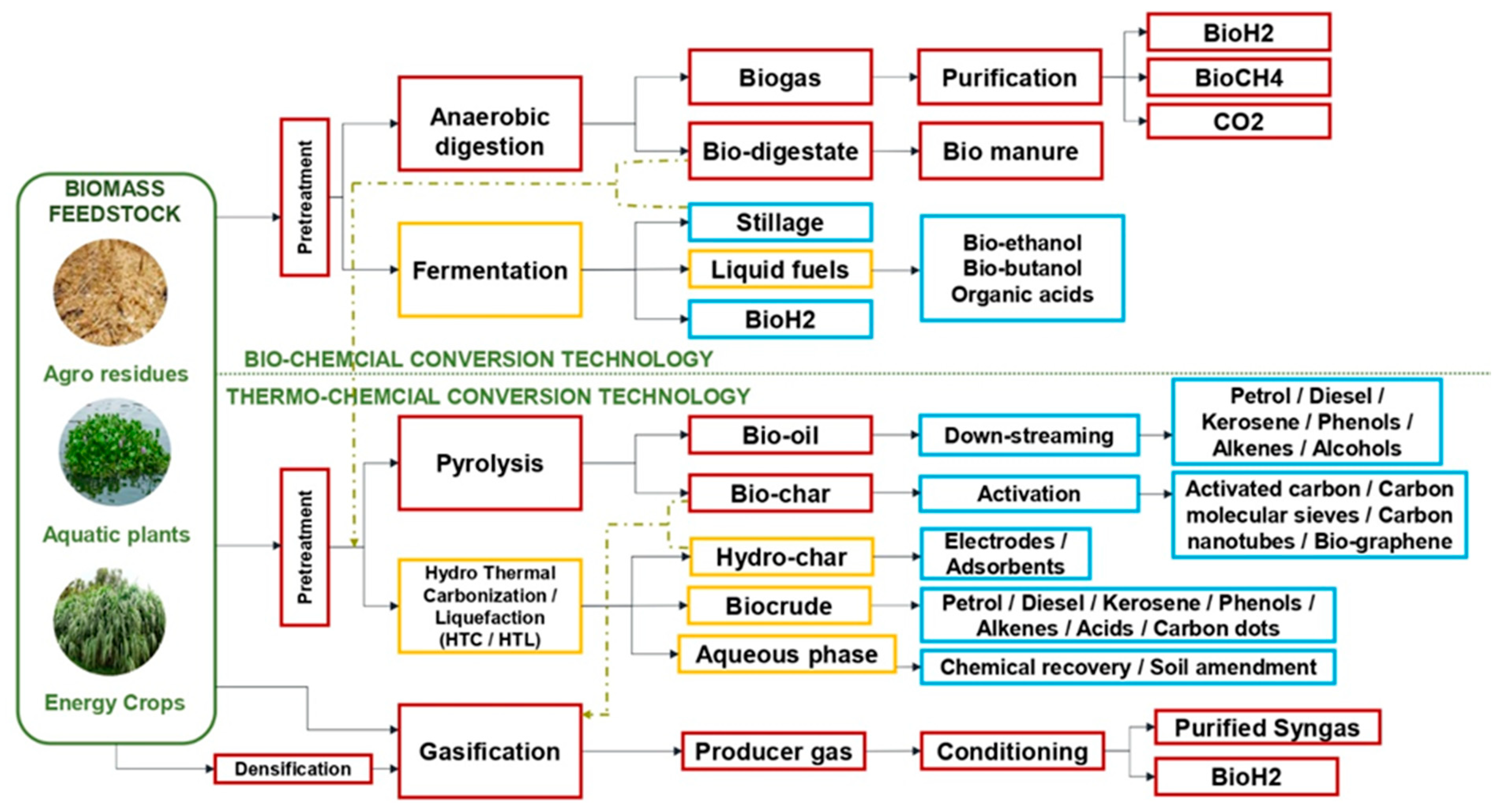

2. Biorefinery Technologies Involved in Biomass Valorization

2.1. Biochemical Conversion Technology

2.2. Thermochemical Conversion Technology

| Primary Feedstock | Secondary Feedstock | Technology | Products | Co-Products | Reference |

|---|---|---|---|---|---|

| Corn Stover | Food waste, crop residues | Fermentation | Bioethanol, Bio-based chemicals | CO2, Furfural, Lignin | [29,30,31,32] |

| Sugarcane Bagasse | Rice husk, coconut shell | Fermentation | Bioethanol, Biobutanol | Lignin, Xylitol, Acetic acid | [1,33,34] |

| Paddy Straw | Wheat straw, maize stalks | Fermentation | Bioethanol, Biomethane | Lignin, Animal Feed | [35,36] |

| Poplar | Willow, Eucalyptus | Fermentation | Bioethanol, Acetic acid | Lignin, Biochar | [37,38,39] |

| Cocoa Pods | Coffee husks, banana stems | Fermentation | Biochemical, Organic acids | Liquor | [40,41] |

| Food Waste | Kitchen waste | Fermentation, Anaerobic Digestion | Bioethanol, organic acids | Biogas, Organic Fertilizer | [42,43,44] |

| Coconut Shell | Kernel shells, paddy husk | Pyrolysis | Biochar, Bio-oil, Activated carbon | Pyrogas | [45] |

| Water Hyacinth | Duckweed, algae | Pyrolysis | Bio-oil, Biochar | Pyrogas, Bio-fertilizer | [46,47,48] |

| Willow | Miscanthus, Poplar | Pyrolysis, gasification | Syngas, Biochar, Bio-oil | Heat, Power | [49,50,51,52] |

| Wood | Agricultural residues, sawdust, bark | Pyrolysis, Gasification | Bio-oil, Biochar, Syngas | Biochar, Heat, Power | [53,54,55,56] |

| Switchgrass | Wood chips, wheat straw | Pyrolysis, Gasification | Bio-oil, Syngas | Biochar, Electricity | [57,58,59,60,61,62] |

| Microalgae | Seaweed, wastewater | Algae-based Biorefinery | Biodiesel, Bioethanol | Animal Feed, Biochar | [63,64,65,66] |

2.3. Synergistic Approach

3. Pros and Cons of Biorefinery Approaches

| Technology | Pros | Cons | Technology Ready Level | Reference |

|---|---|---|---|---|

| Anaerobic Digestion |

|

| 7–9 | [76,77] |

| Fermentation |

|

| 5–7 | [78,79] |

| Pyrolysis |

|

| 5 | [80] |

| Gasification |

|

| 6–7 | [80] |

| Hydrothermal Carbonization (HTC) |

|

| 5–7 | [81,82] |

| Hydrothermal Liquefaction (HTL) |

|

| 4–6 | [80,83] |

| Algae-Based Biorefinery |

|

| 6–7 | [84,85,86] |

| Integrated Biorefineries |

|

| 5–6 | [81,87] |

4. Assessment of Energy and Bioproducts from Biomass

5. Policy Framework for Supporting Biorefinery Development

- Ministry of New and Renewable Energy (MNRE): Formulates overarching policies and provides research support.

- Ministry of Petroleum and Natural Gas (MoPNG): Oversees marketing, pricing, and procurement.

- Ministry of Agriculture (MoA): Conducts feedstock research.

- Ministry of Rural Development (MoRD) and Ministry of Panchayati Raj (MoPR): Promote Jatropha and other plantation initiatives on wastelands.

- Ministry of Science and Technology (MoS&T): Focuses on non-edible oil feedstocks.

- Ministry of Environment and Forests (MoEF): Monitors environmental impacts.

- Ministry of Finance (MoF): Provides financial incentives.

- Punjab’s 2012 Energy Policy targeted 600 MW of biomass power by 2022 but achieved only 62.5 MW by 2020.

- Haryana’s 2018 Bioenergy Policy aimed for 150 MW but showed limited progress.

6. State-Level Bioenergy Development Initiatives

| State/Union Territory | Key Activities and Initiatives | Remarks | Source |

|---|---|---|---|

| Punjab | Biogas from agro-waste, gasification, co-generation in sugar mills. | Proactive state with remarkable agro-waste energy production. | [101] |

| Haryana | Biofuels, bioenergy, and biogas programs, along with both grid-connected and off-grid initiatives. | Programs are well-directed and regularly upgraded. | [102] |

| Uttar Pradesh | Bioenergy Development Board; biogas, biodiesel, and bioethanol missions. | Effective grassroots-level programs. | [103] |

| Rajasthan | Biomass power, biogas, forest department involvement. | Policies need updating but cumulative efforts are reliable. | [104] |

| Gujarat | Waste-to-Energy Policy, biomass power, co-generation projects. | Proactive state; innovative waste-to-energy policy. | [105] |

| Madhya Pradesh | Grid-connected and off-grid biomass projects. | Significant private-sector involvement. | [106] |

| Jharkhand | Biogas and biomass power programs. | Limited diversification in bioenergy projects. | [107] |

| Chhattisgarh | Policy-based incentives for bioenergy. | Information on bioenergy options is limited. | [108] |

| Telangana | Biomass and biogas programs, spanning from cooking applications to megawatt-scale power generation. | Appreciable efforts for rural and urban regions. | [109] |

| Andhra Pradesh | Biomass-based captive power in sugar mills. | Active in bioenergy development. | [110] |

| Karnataka | Biogas, combustion, and co-generation schemes. | Well-planned bioenergy development direction. | [111] |

| Tamil Nadu | Waste-to-energy, biogas, and gasification projects. | Effective grid-connected urban initiatives. | [112] |

| Maharashtra | Incentives for biomass briquettes and waste-to-energy projects. | Comprehensive decentralized bioenergy policy. | [113] |

| Odisha | Improved cook stoves, biomass gasification. | Cumulative incentive-based schemes. | [114] |

| West Bengal | Biogas production, village energy security programs. | Significant urban MSW-to-energy efforts. | [115] |

| Tripura | Biogas plants and improved cook stoves (Unnat Chulha). | Ground-level initiatives are commendable. | [116] |

| Sikkim | Renewable energy nodal agency. | Limited information on bioenergy activities. | [117] |

| Nagaland | Financial support for Unnat Chulha and NBMMP. | Focused on grassroots-level clean energy. | [118] |

| Meghalaya | Subsidies for Unnat Chulha and NBMMP. | Basic bioenergy initiatives. | [119] |

| Kerala | Biogas plant setups under NBMMP. | Well-organized renewable energy programs. | [120] |

| Assam | Biogas and biomass gasification programs. | High potential for bioenergy. | [121] |

| Chandigarh | MSW-to-energy projects. | Efficient urban waste management for energy. | [122] |

7. Impact on the Environment, Economy, and Energy Sectors

7.1. Environment

7.2. Economy

7.3. Energy

7.4. Life Cycle Analysis (LCA)

- Carbon Footprint Reduction: Bio-derived products consistently demonstrate lower GHG emissions compared to fossil-based alternatives. For example, bio-derived polyethylene reduces emissions by 0.75 kg CO2-eq/kg compared to conventional petrochemical processes [137].

- Process Optimization: Advances in production methods have significantly decreased environmental impacts. Optimized charcoal value chains, for instance, reduced emissions from 2.15 CO2-eq to 0.50 CO2-eq through improved processes and better resource utilization [138].

- Holistic Impact Assessment: LCA studies assess environmental impacts beyond carbon emissions, including water quality, land use, biodiversity, and human health.

- Technology Comparison: LCA facilitates comparisons between different conversion pathways. Biochemical routes often show advantages in water-related impacts, while thermochemical pathways may excel in energy efficiency.

7.5. Circular Economy

- Resource Efficiency: Circular biorefinery models have demonstrated significant improvements in resource use, with some systems achieving near-zero waste through cascading biomass components [140].

- Environmental Performance: Circular approaches have been shown to reduce GHG emissions by 39–86% and decrease non-renewable energy usage by 65% compared to linear production models [137].

- Economic Value Creation: The circular bioeconomy creates new revenue streams by revalorizing materials previously considered waste. For example, lignin valorization has applications in polymers, bio-composites, and nanomaterials, with global markets projected to reach USD 1.2 billion by 2025 [139].

- Rural Development: Circular biorefinery models stimulate rural economies by establishing collection centers, preprocessing facilities, and local value-addition activities.

- Social Inclusion: These models also promote social inclusion by incorporating traditional knowledge and providing marginalized communities with opportunities to participate in biorefinery value chains.

8. Roadmap to Implement Biorefinery Approach

- Process Development and Optimization: This stage focuses on improving biorefinery efficiency and sustainability by optimizing feedstock cultivation, processing, and product recovery to reduce GHG emissions and non-renewable energy use [142]. Optimization of the entire value chain is essential to achieving cost-effectiveness and economic viability.

- Supply Chain Development: Effective supply chain management ensures the smooth delivery of biomass to the biorefinery. Selecting strategic locations minimizes transportation costs, while optimizing biomass production and developing efficient logistics systems improve the overall operational efficiency of the supply chain [135].

- Integration with Existing Infrastructure: Biorefineries can enhance their capabilities by integrating with existing petrochemical plants, creating hybrid systems. Utilizing advanced biotechnology enables the seamless adaptation of current infrastructure, bridging gaps and maximizing resource utilization [143].

- Economic Viability and Revenue Diversification: To achieve financial sustainability, biorefineries must diversify their revenue streams. Producing high-value biochemicals alongside biofuels, generating energy for self-sustaining operations, and exploring additional revenue opportunities are critical to their long-term success [144].

- Policy and Regulatory Support: A robust and stable policy framework is essential for fostering growth in biorefinery projects. Clear subsidies, legal guidelines, and mandates are needed to inspire confidence among investors and ensure compliance with environmental and economic objectives [96].

- Environmental Monitoring and Circular Economy: Monitoring and reducing the environmental impact of biorefineries is a cornerstone of their development. Implementing life cycle assessments and adopting circular economy principles, such as resource recovery and closed-loop systems, ensures sustainability and minimizes waste [145].

Step-by-Step Roadmap for Biorefinery Development and Optimization

- Identify Objectives and Goals: Define the primary objectives, such as reducing GHG emissions, improving sustainability, and achieving economic viability. Align goals with global and regional sustainability [96].

- Conduct Feasibility Studies: Evaluate the availability of biomass feedstocks and their environmental impact. Assess market demand for bio-based products and energy [135].

- Develop Process Design and Optimization: Design efficient processes for feedstock cultivation, processing, and product recovery. Incorporate advanced technologies to maximize energy efficiency and minimize waste [141].

- Build an Efficient Supply Chain: Choose strategic locations to reduce transportation costs. Optimize biomass production and logistics for collection, transport, and preprocessing [135].

- Integrate with Existing Infrastructure: Develop hybrid systems that combine biorefineries with petrochemical plants. Utilize biotechnology to bridge gaps and enhance operational efficiency [143].

- Establish Economic Models: Create a financial plan that includes high-value biochemicals, biofuels, and self-sustaining energy generation. Diversify revenue streams to ensure long-term viability [144].

- Engage Policy and Regulatory Stakeholders: Work with policymakers to establish subsidies, mandates, and guidelines. Foster investor confidence by ensuring regulatory compliance [96].

- Implement Environmental Monitoring and Sustainability Practices: Conduct life cycle assessments to track environmental impact. Apply circular economy principles like resource recovery and closed-loop systems [145].

- Pilot and Scale-Up: Launch pilot projects to validate designs and processes. Scale up operations based on pilot results, ensuring efficiency and sustainability.

- Continuous Improvement and Innovation: Regularly review and refine processes to incorporate technological advancements. Monitor market trends to adapt products and services accordingly.

9. Challenges

10. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| LCA | Life Cycle Analysis |

| GDP | Gross domestic product |

| GHG | Greenhouse Gas |

| HTC | Hydrothermal Carbonization |

| HTL | Hydrothermal Liquefaction |

| CHP | Combined Heat and Power |

| MNRE | Ministry of New and Renewable Energy |

| MoPNG | Ministry of Petroleum and Natural Gas |

| MoA | Ministry of Agriculture |

| MoRD | Ministry of Rural Development |

| MoPR | Ministry of Panchayati Raj |

| MoS&T | Ministry of Science and Technology |

| MoEF | Ministry of Environment and Forests |

| MoF | Ministry of Finance |

| NPMCR | The National Policy for Management of Crop Residue |

| CAGR | Compound Annual Growth Rate |

| BAU | Business-As-Usual |

| NPB | National Policy on Biofuels |

| BTL | Biomass-To-Liquid |

References

- Ajala, E.O.; Ighalo, J.O.; Ajala, M.A.; Adeniyi, A.G.; Ayanshola, A.M. Sugarcane Bagasse: A Biomass Sufficiently Applied for Improving Global Energy, Environment and Economic Sustainability. Bioresour. Bioprocess. 2021, 8, 87. [Google Scholar] [CrossRef]

- Sudha, P.; Ravindranath, N.H. Land Availability and Biomass Production Potential in India. Biomass Bioenergy 1999, 16, 207–221. [Google Scholar] [CrossRef]

- Koul, B.; Yakoob, M.; Shah, M.P. Agricultural Waste Management Strategies for Environmental Sustainability. Environ. Res. 2022, 206, 112285. [Google Scholar] [CrossRef]

- Central Pollution Control Board (CPCB); Delhi. 2021. Available online: https://cpcb.nic.in/openpdffile.php?id=UmVwb3J0RmlsZXMvMTQwM18xNjU1MzU0NzkxX21lZGlhcGhvdG8xNjQ3MS5wZGY= (accessed on 8 February 2025).

- MOEFCC. 2021. Available online: https://fsi.nic.in/isfr-2021/chapter-9.pdf (accessed on 8 February 2025).

- Solomon, S.; Swapna, M. Indian Sugar Industry: Towards Self-Reliance for Sustainability. Sugar Tech. 2022, 24, 630–650. [Google Scholar] [CrossRef] [PubMed]

- Saravanan, A.; Senthil Kumar, P.; Badawi, M.; Mohanakrishna, G.; Aminabhavi, T.M. Valorization of Micro-Algae Biomass for the Development of Green Biorefinery: Perspectives on Techno-Economic Analysis and the Way towards Sustainability. Chem. Eng. J. 2023, 453, 139754. [Google Scholar] [CrossRef]

- Bassoli, S.C.; da Fonseca, Y.A.; Wandurraga, H.J.L.; Baeta, B.E.L.; de Souza Amaral, M. Research Progress, Trends, and Future Prospects on Hydrothermal Liquefaction of Algae for Biocrude Production: A Bibliometric Analysis. Biomass Convers. Biorefinery 2024, 14, 28781–28796. [Google Scholar] [CrossRef]

- Ning, P.; Yang, G.; Hu, L.; Sun, J.; Shi, L.; Zhou, Y.; Wang, Z.; Yang, J. Recent Advances in the Valorization of Plant Biomass. Biotechnol. Biofuels 2021, 14, 102. [Google Scholar] [CrossRef]

- Song, B.; Lin, R.; Lam, C.H.; Wu, H.; Tsui, T.-H.; Yu, Y. Recent Advances and Challenges of Inter-Disciplinary Biomass Valorization by Integrating Hydrothermal and Biological Techniques. Renew. Sustain. Energy Rev. 2021, 135, 110370. [Google Scholar] [CrossRef]

- Ghamari, M.; Suvish; Hwang See, C.; Yu, H.; Anitha, T.; Balamurugan, V.T.; Velusamy, S.; Hughes, D.; Sundaram, S. Nanocellulose Extraction from Biomass Waste: Unlocking Sustainable Pathways for Biomedical Applications. Chem. Rec. 2025, Online ahead of print, e202400249. [Google Scholar] [CrossRef]

- Liakakou, E.T.; Vreugdenhil, B.J.; Cerone, N.; Zimbardi, F.; Pinto, F.; André, R.; Marques, P.; Mata, R.; Girio, F. Gasification of Lignin-Rich Residues for the Production of Biofuels via Syngas Fermentation: Comparison of Gasification Technologies. Fuel 2019, 251, 580–592. [Google Scholar] [CrossRef]

- Quinn, J.C.; Yates, T.; Douglas, N.; Weyer, K.; Butler, J.; Bradley, T.H.; Lammers, P.J. Nannochloropsis Production Metrics in a Scalable Outdoor Photobioreactor for Commercial Applications. Bioresour. Technol. 2012, 117, 164–171. [Google Scholar] [CrossRef]

- Schmidt, K.N.; Zou, C.B.; Kakani, V.G.; Zhong, Y.; Will, R.E. Improved Productivity, Water Yield, and Water Use Efficiency by Incorporating Switchgrass Cultivation and Native Ecosystems in an Integrated Biofuel Feedstock System. GCB Bioenergy 2021, 13, 369–381. [Google Scholar] [CrossRef]

- Kolarić, L.; Popović, V.; Ikanović, J.; Živanović, L.; Janković, S.; Rakašćan, N.; Stevanović, P. Productivity of Soybean and the Possibility of Using It as Energy. Sel. I Semen. 2023, 29, 51–59. [Google Scholar] [CrossRef]

- Booth, T.H.; Raison, R.J.; Crawford, D.F.; Jovanovic, T.; O’Connor, M.H.; Raisbeck-Brown, N.; O’Connell, D.A.; Hogg, B.W.; Lee, D.J. Biomass for Aviation Fuel Production in the Fitzroy Basin, Queensland: A Preliminary Assessment of Native and Plantation Forest Potential. Aust. For. 2014, 77, 1–8. [Google Scholar] [CrossRef]

- Yancey, N.A.; Tumuluru, J.S.; Wright, C.T. Drying, Grinding and Pelletization Studies on Raw and Formulated Biomass Feedstock’s for Bioenergy Applications. J. Biobased Mater. Bioenergy 2013, 7, 549–558. [Google Scholar] [CrossRef]

- Börjesson, P.; Hansson, J.; Berndes, G. Future Demand for Forest-Based Biomass for Energy Purposes in Sweden. For. Ecol. Manag. 2017, 383, 17–26. [Google Scholar] [CrossRef]

- Mignogna, D.; Szabó, M.; Ceci, P.; Avino, P. Biomass Energy and Biofuels: Perspective, Potentials, and Challenges in the Energy Transition. Sustainability 2024, 16, 7036. [Google Scholar] [CrossRef]

- Natarajan, K.; Latva-Käyrä, P.; Zyadin, A.; Chauhan, S.; Singh, H.; Pappinen, A.; Pelkonen, P. Biomass Resource Assessment and Existing Biomass Use in the Madhya Pradesh, Maharashtra, and Tamil Nadu States of India. Challenges 2015, 6, 158–172. [Google Scholar] [CrossRef]

- Cvetković, S.M.; Radoičić, T.K.; Kijevčanin, M.; Novaković, J.G. Life Cycle Energy Assessment of Biohydrogen Production via Biogas Steam Reforming: Case Study of Biogas Plant on a Farm in Serbia. Int. J. Hydrogen Energy 2021, 46, 14130–14137. [Google Scholar] [CrossRef]

- Suhartini, S.; Pangestuti, M.B.; Elviliana; Rohma, N.A.; Junaidi, M.A.; Paul, R.; Nurika, I.; Rahmah, N.L.; Melville, L. Valorisation of Macroalgae for Biofuels in Indonesia: An Integrated Biorefinery Approach. Environ. Technol. Rev. 2024, 13, 269–304. [Google Scholar] [CrossRef]

- Gupta, A.; Thengane, S.K.; Mahajani, S. Kinetics of Pyrolysis and Gasification of Cotton Stalk in the Central Parts of India. Fuel 2020, 263, 116752. [Google Scholar] [CrossRef]

- Jafri, N.; Wong, W.Y.; Doshi, V.; Yoon, L.W.; Cheah, K.H. A Review on Production and Characterization of Biochars for Application in Direct Carbon Fuel Cells. Process Saf. Environ. Prot. 2018, 118, 152–166. [Google Scholar] [CrossRef]

- Legonda, I.A. Biomass Gasification Using a Horizontal Entrained-Flow Gasifier and Catalytic Processing of the Product Gas. Ph.D. Thesis, Cardiff University, Cardiff, UK, 2012. [Google Scholar]

- Liu, Z.; Quek, A.; Balasubramanian, R. Preparation and Characterization of Fuel Pellets from Woody Biomass, Agro-Residues and Their Corresponding Hydrochars. Appl. Energy 2014, 113, 1315–1322. [Google Scholar] [CrossRef]

- Rajagopal, J.; Gopinath, K.P.; Neha, R.; Aakriti, K.; Jayaraman, R.S.; Arun, J.; Pugazhendhi, A. Processing of Household Waste via Hydrothermal Gasification and Hydrothermal Liquefaction for Bio-Oil and Bio-Hydrogen Production: Comparison with RSM Studies. J. Environ. Chem. Eng. 2022, 10, 107218. [Google Scholar] [CrossRef]

- Güleç, F.; Parthiban, A.; Umenweke, G.C.; Musa, U.; Williams, O.; Mortezaei, Y.; Suk-Oh, H.; Lester, E.; Ogbaga, C.C.; Gunes, B.; et al. Progress in Lignocellulosic Biomass Valorization for Biofuels and Value-Added Chemical Production in the EU: A Focus on Thermochemical Conversion Processes. Biofuels Bioprod. Biorefining 2024, 18, 755–781. [Google Scholar] [CrossRef]

- Alavijeh, R.S.; Shahvandi, A.; Okoro, O.V.; Denayer, J.F.M.; Karimi, K. Biorefining of Corn Stover for Efficient Production of Bioethanol, Biodiesel, Biomethane, and Value-Added Byproducts. Energy Convers. Manag. 2023, 283, 116877. [Google Scholar] [CrossRef]

- Zhao, Y.; Damgaard, A.; Christensen, T.H. Bioethanol from Corn Stover—A Review and Technical Assessment of Alternative Biotechnologies. Prog. Energy Combust. Sci. 2018, 67, 275–291. [Google Scholar] [CrossRef]

- Yong, K.J.; Wu, T.Y.; Lee, C.B.T.L.; Lee, Z.J.; Liu, Q.; Jahim, J.M.; Zhou, Q.; Zhang, L. Furfural Production from Biomass Residues: Current Technologies, Challenges and Future Prospects. Biomass Bioenergy 2022, 161, 106458. [Google Scholar] [CrossRef]

- Isah, S.; Ozbay, G. Valorization of Food Loss and Wastes: Feedstocks for Biofuels and Valuable Chemicals. Front. Sustain. Food Syst. 2020, 4, 82. [Google Scholar] [CrossRef]

- Chen, S.-J.; Chen, X.; Zhu, M.-J. Xylose Recovery and Bioethanol Production from Sugarcane Bagasse Pretreated by Mild Two-Stage Ultrasonic Assisted Dilute Acid. Bioresour. Technol. 2022, 345, 126463. [Google Scholar] [CrossRef]

- Bolivar-Telleria, M.; Turbay, C.; Favarato, L.; Carneiro, T.; de Biasi, R.S.; Fernandes, A.A.R.; Santos, A.M.C.; Fernandes, P.M.B. Second-Generation Bioethanol from Coconut Husk. Biomed. Res. Int. 2018, 2018, 4916497. [Google Scholar] [CrossRef] [PubMed]

- Geetha Thanuja, K.; Marimuthu, S.; Ramesh, D.; Karthikeyan, S. Paddy Straw-Based Circular Economy for Sustainable Waste Management. In Handbook of Solid Waste Management; Springer Nature: Singapore, 2022; pp. 683–710. [Google Scholar]

- Swain, M.R.; Singh, A.; Sharma, A.K.; Tuli, D.K. Bioethanol Production from Rice-And Wheat Straw: An Overview. In Bioethanol Production from Food Crops; Elsevier: Amsterdam, The Netherlands, 2019; pp. 213–231. [Google Scholar]

- Morales-Vera, R.; Vásquez-Ibarra, L.; Scott, F.; Puettmann, M.; Gustafson, R. Life Cycle Assessment of Bioethanol Production: A Case Study from Poplar Biomass Growth in the U.S. Pacific Northwest. Fermentation 2022, 8, 734. [Google Scholar] [CrossRef]

- Xu, F.; Sun, D.; Wang, Z.; Li, M.; Yin, X.; Li, H.; Xu, L.; Zhao, J.; Bao, X. Highly Efficient Production of Cellulosic Ethanol from Poplar Using an Optimal C6/C5 Co-Fermentation Strain of Saccharomyces Cerevisiae. Microorganisms 2024, 12, 1174. [Google Scholar] [CrossRef]

- Ligero, P.; Villaverde, J.J.; de Vega, A.; Bao, M. Delignification of Eucalyptus Globulus Saplings in Two Organosolv Systems (Formic and Acetic Acid). Ind. Crops Prod. 2008, 27, 110–117. [Google Scholar] [CrossRef]

- Hozman-Manrique, A.S.; Garcia-Brand, A.J.; Hernández-Carrión, M.; Porras, A. Isolation and Characterization of Cellulose Microfibers from Colombian Cocoa Pod Husk via Chemical Treatment with Pressure Effects. Polymers 2023, 15, 664. [Google Scholar] [CrossRef]

- Ingale, S.; Joshi, S.J.; Gupte, A. Production of Bioethanol Using Agricultural Waste: Banana Pseudo Stem. Braz. J. Microbiol. 2014, 45, 885–892. [Google Scholar] [CrossRef] [PubMed]

- Singh, P.K.; Mohanty, P.; Mishra, S.; Adhya, T.K. Food Waste Valorisation for Biogas-Based Bioenergy Production in Circular Bioeconomy: Opportunities, Challenges, and Future Developments. Front. Energy Res. 2022, 10, 903775. [Google Scholar] [CrossRef]

- Mahish, P.K.; Verma, D.K.; Ghritlahare, A.; Arora, C.; Otero, P. Microbial Bioconversion of Food Waste to Bio-Fertilizers. Sustain. Food Technol. 2024, 2, 689–708. [Google Scholar] [CrossRef]

- Bibra, M.; Samanta, D.; Sharma, N.K.; Singh, G.; Johnson, G.R.; Sani, R.K. Food Waste to Bioethanol: Opportunities and Challenges. Fermentation 2022, 9, 8. [Google Scholar] [CrossRef]

- Igliński, B.; Kujawski, W.; Kiełkowska, U. Pyrolysis of Waste Biomass: Technical and Process Achievements, and Future Development—A Review. Energies 2023, 16, 1829. [Google Scholar] [CrossRef]

- Matamba, T.; Tahmasebi, A.; Yu, J.; Keshavarz, A.; Abid, H.R.; Iglauer, S. A Review on Biomass as a Substitute Energy Source: Polygeneration Influence and Hydrogen Rich Gas Formation via Pyrolysis. J. Anal. Appl. Pyrolysis 2023, 175, 106221. [Google Scholar] [CrossRef]

- Muradov, N.; Fidalgo, B.; Gujar, A.C.; T-Raissi, A. Pyrolysis of Fast-Growing Aquatic Biomass—Lemna Minor (Duckweed): Characterization of Pyrolysis Products. Bioresour. Technol. 2010, 101, 8424–8428. [Google Scholar] [CrossRef]

- Wauton, I.; Ogbeide, S.E. Characterization of Pyrolytic Bio-Oil from Water Hyacinth (Eichhornia crassipes) Pyrolysis in a Fixed Bed Reactor. Biofuels 2021, 12, 899–904. [Google Scholar] [CrossRef]

- Mitu, M.; Razus, D.; Boldor, D.; Marculescu, C. Flammability Properties of the Pyrolysis Gas Generated from Willow Wood. Processes 2023, 11, 2103. [Google Scholar] [CrossRef]

- Kukharets, S.; Jasinskas, A.; Golub, G.; Sukmaniuk, O.; Hutsol, T.; Mudryk, K.; Čėsna, J.; Glowacki, S.; Horetska, I. The Experimental Study of the Efficiency of the Gasification Process of the Fast-Growing Willow Biomass in a Downdraft Gasifier. Energies 2023, 16, 578. [Google Scholar] [CrossRef]

- Chen, D.; Li, Y.; Cen, K.; Luo, M.; Li, H.; Lu, B. Pyrolysis Polygeneration of Poplar Wood: Effect of Heating Rate and Pyrolysis Temperature. Bioresour. Technol. 2016, 218, 780–788. [Google Scholar] [CrossRef]

- Lakshman, V.; Brassard, P.; Hamelin, L.; Raghavan, V.; Godbout, S. Pyrolysis of Miscanthus: Developing the Mass Balance of a Biorefinery through Experimental Tests in an Auger Reactor. Bioresour. Technol. Rep. 2021, 14, 100687. [Google Scholar] [CrossRef]

- Azeta, O.; Ayeni, A.O.; Agboola, O.; Elehinafe, F.B. A Review on the Sustainable Energy Generation from the Pyrolysis of Coconut Biomass. Sci. Afr. 2021, 13, e00909. [Google Scholar] [CrossRef]

- Mohan, D.; Pittman, C.U.; Steele, P.H. Pyrolysis of Wood/Biomass for Bio-Oil: A Critical Review. Energy Fuels 2006, 20, 848–889. [Google Scholar] [CrossRef]

- Volpi, M.P.C.; Silva, J.C.G.; Hornung, A.; Ouadi, M. Review of the Current State of Pyrolysis and Biochar Utilization in Europe: A Scientific Perspective. Clean. Technol. 2024, 6, 152–175. [Google Scholar] [CrossRef]

- Ahmed, A.; Abu Bakar, M.S.; Sukri, R.S.; Hussain, M.; Farooq, A.; Moogi, S.; Park, Y.-K. Sawdust Pyrolysis from the Furniture Industry in an Auger Pyrolysis Reactor System for Biochar and Bio-Oil Production. Energy Convers. Manag. 2020, 226, 113502. [Google Scholar] [CrossRef]

- Irfan, M.; Chen, Q.; Yue, Y.; Pang, R.; Lin, Q.; Zhao, X.; Chen, H. Co-Production of Biochar, Bio-Oil and Syngas from Halophyte Grass (Achnatherum splendens L.) under Three Different Pyrolysis Temperatures. Bioresour. Technol. 2016, 211, 457–463. [Google Scholar] [CrossRef] [PubMed]

- Imam, T.; Capareda, S. Characterization of Bio-Oil, Syn-Gas and Bio-Char from Switchgrass Pyrolysis at Various Temperatures. J. Anal. Appl. Pyrolysis 2012, 93, 170–177. [Google Scholar] [CrossRef]

- Mahinpey, N.; Murugan, P.; Mani, T.; Raina, R. Analysis of Bio-Oil, Biogas, and Biochar from Pressurized Pyrolysis of Wheat Straw Using a Tubular Reactor. Energy Fuels 2009, 23, 2736–2742. [Google Scholar] [CrossRef]

- Chen, T.; Liu, R.; Scott, N.R. Characterization of Energy Carriers Obtained from the Pyrolysis of White Ash, Switchgrass and Corn Stover—Biochar, Syngas and Bio-Oil. Fuel Process. Technol. 2016, 142, 124–134. [Google Scholar] [CrossRef]

- Chojnacki, J.; Kielar, J.; Kukiełka, L.; Najser, T.; Pachuta, A.; Berner, B.; Zdanowicz, A.; Frantík, J.; Najser, J.; Peer, V. Batch Pyrolysis and Co-Pyrolysis of Beet Pulp and Wheat Straw. Materials 2022, 15, 1230. [Google Scholar] [CrossRef]

- Mishra, R.K.; Misra, Y.; Prasanna Kumar, D.J.; Sankannavar, R.; Kumar, P. Environmental Impacts on Second-Generation Biofuel Production from Lignocellulosic Biomass. In Biofuels Production from Lignocellulosic Materials; Elsevier: Amsterdam, The Netherlands, 2025; pp. 101–123. [Google Scholar]

- Salami, R.; Kordi, M.; Bolouri, P.; Delangiz, N.; Asgari Lajayer, B. Algae-Based Biorefinery as a Sustainable Renewable Resource. Circ. Econ. Sustain. 2021, 1, 1349–1365. [Google Scholar] [CrossRef]

- da Rosa, M.D.H.; Alves, C.J.; dos Santos, F.N.; de Souza, A.O.; da Rosa Zavareze, E.; Pinto, E.; Noseda, M.D.; Ramos, D.; de Pereira, C.M.P. Macroalgae and Microalgae Biomass as Feedstock for Products Applied to Bioenergy and Food Industry: A Brief Review. Energies 2023, 16, 1820. [Google Scholar] [CrossRef]

- De Bhowmick, G.; Sarmah, A.K.; Sen, R. Zero-Waste Algal Biorefinery for Bioenergy and Biochar: A Green Leap towards Achieving Energy and Environmental Sustainability. Sci. Total Environ. 2019, 650, 2467–2482. [Google Scholar] [CrossRef]

- Narayanan, M. Biorefinery Products from Algal Biomass by Advanced Biotechnological and Hydrothermal Liquefaction Approaches. Discov. Appl. Sci. 2024, 6, 146. [Google Scholar] [CrossRef]

- Moncada, J.; Tamayo, J.A.; Cardona, C.A. Integrating First, Second, and Third Generation Biorefineries: Incorporating Microalgae into the Sugarcane Biorefinery. Chem. Eng. Sci. 2014, 118, 126–140. [Google Scholar] [CrossRef]

- Moncada, J.; Cardona, C.A.; Rincón, L.E. Design and Analysis of a Second and Third Generation Biorefinery: The Case of Castorbean and Microalgae. Bioresour. Technol. 2015, 198, 836–843. [Google Scholar] [CrossRef]

- Gheewala, S.H. Life Cycle Assessment for Sustainability Assessment of Biofuels and Bioproducts. Biofuel Res. J. 2023, 10, 1810–1815. [Google Scholar] [CrossRef]

- Ayisha Naziba, T.; Praveen Kumar, D.; Karthikeyan, S.; Sriramajayam, S.; Djanaguiraman, M.; Sundaram, S.; Ghamari, M.; Prasada Rao, R.; Ramakrishna, S.; Ramesh, D. Biomass Derived Biofluorescent Carbon Dots for Energy Applications: Current Progress and Prospects. Chem. Rec. 2024, 24, e202400030. [Google Scholar] [CrossRef]

- Dhanya, M.S. Perspectives of Agro-Waste Biorefineries for Sustainable Biofuels. In Zero Waste Biorefinery; Springer Nature: Singapore, 2022; pp. 207–232. [Google Scholar]

- Ahmed, S.F.; Kabir, M.; Mehjabin, A.; Oishi, F.T.Z.; Ahmed, S.; Mannan, S.; Mofijur, M.; Almomani, F.; Badruddin, I.A.; Kamangar, S. Waste Biorefinery to Produce Renewable Energy: Bioconversion Process and Circular Bioeconomy. Energy Rep. 2023, 10, 3073–3091. [Google Scholar] [CrossRef]

- Ogwu, M.C.; Kosoe, E.A.; Osawaru, M.E. Raw Materials for Sustainable Bioeconomy Development in the Global South. In Sustainable Bioeconomy Development in the Global South; Springer Nature: Singapore, 2025; pp. 37–63. [Google Scholar]

- Makepa, D.C.; Chihobo, C.H. Barriers to Commercial Deployment of Biorefineries: A Multi-Faceted Review of Obstacles across the Innovation Chain. Heliyon 2024, 10, e32649. [Google Scholar] [CrossRef] [PubMed]

- Guajardo, N.; Schrebler, R.A. Upstream and Downstream Bioprocessing in Enzyme Technology. Pharmaceutics 2023, 16, 38. [Google Scholar] [CrossRef]

- Nleya, Y.; Young, B.; Nooraee, E.; Baroutian, S. Opportunities and Challenges for Anaerobic Digestion of Farm Dairy Effluent. ChemBioEng Rev. 2023, 10, 924–940. [Google Scholar] [CrossRef]

- Elsayed, A.; Laqa Kakar, F.; Mustafa Abdelrahman, A.; Ahmed, N.; AlSayed, A.; Sherif Zagloul, M.; Muller, C.; Bell, K.Y.; Santoro, D.; Norton, J.; et al. Enhancing Anaerobic Digestion Efficiency: A Comprehensive Review on Innovative Intensification Technologies. Energy Convers. Manag. 2024, 320, 118979. [Google Scholar] [CrossRef]

- Müller-Langer, F.; Majer, S.; O’Keeffe, S. Benchmarking Biofuels—A Comparison of Technical, Economic and Environmental Indicators. Energy Sustain. Soc. 2014, 4, 20. [Google Scholar] [CrossRef]

- Mazzanti, G.; Demichelis, F.; Fino, D.; Tommasi, T. A Closed-Loop Valorization of the Waste Biomass through Two-Stage Anaerobic Digestion and Digestate Exploitation. Renew. Sustain. Energy Rev. 2025, 207, 114938. [Google Scholar] [CrossRef]

- Decker, S.R.; Milbrandt, A. Anaerobic Digestion of Food Waste: Products and Their Uses. Available online: https://www.nrel.gov/docs/fy22osti/81676.pdf (accessed on 8 February 2025).

- Okolie, J.A.; Epelle, E.I.; Tabat, M.E.; Orivri, U.; Amenaghawon, A.N.; Okoye, P.U.; Gunes, B. Waste Biomass Valorization for the Production of Biofuels and Value-Added Products: A Comprehensive Review of Thermochemical, Biological and Integrated Processes. Process Saf. Environ. Prot. 2022, 159, 323–344. [Google Scholar] [CrossRef]

- Munir, M.T.; Mansouri, S.S.; Udugama, I.A.; Baroutian, S.; Gernaey, K.V.; Young, B.R. Resource Recovery from Organic Solid Waste Using Hydrothermal Processing: Opportunities and Challenges. Renew. Sustain. Energy Rev. 2018, 96, 64–75. [Google Scholar] [CrossRef]

- Kargbo, H.; Harris, J.S.; Phan, A.N. “Drop-in” Fuel Production from Biomass: Critical Review on Techno-Economic Feasibility and Sustainability. Renew. Sustain. Energy Rev. 2021, 135, 110168. [Google Scholar] [CrossRef]

- Brutyan, M.M. Foresight of Microalgae Usage for the Production of Third-Generation Biofuel. Indian. J. Sci. Technol. 2017, 10, 1–10. [Google Scholar] [CrossRef]

- Dębowski, M.; Świca, I.; Kazimierowicz, J.; Zieliński, M. Large Scale Microalgae Biofuel Technology—Development Perspectives in Light of the Barriers and Limitations. Energies 2022, 16, 81. [Google Scholar] [CrossRef]

- Al-Jabri, H.; Das, P.; Khan, S.; Thaher, M.; AbdulQuadir, M. Treatment of Wastewaters by Microalgae and the Potential Applications of the Produced Biomass—A Review. Water 2020, 13, 27. [Google Scholar] [CrossRef]

- Brown, A.; Ebadian, M.; Saddler, J.; Nylund, N.-O.; Aakko-Saksa, P.; Waldheim, L.; Bacovsky, D. The Role of Renewable Transport Fuels in Decarbonizing Road Transport. Available online: https://www.ieabioenergy.com/wp-content/uploads/2020/11/Production-Technologies-and-Costs.pdf (accessed on 8 February 2025).

- Srivastava, N.; Singh, R.; Singh, P.; Ahmad, I.; Singh, R.P.; Rai, A.K.; Asiri, M.; Gupta, V.K. Recent Advances on Lignocellulosic Bioresources and Their Valorization in Biofuels Production: Challenges and Viability Assessment. Environ. Technol. Innov. 2023, 29, 103037. [Google Scholar] [CrossRef]

- Ghamari, M.; Sun, D.; Dai, Y.; See, C.H.; Yu, H.; Edirisinghe, M.; Sundaram, S. Valorization of Diverse Waste-Derived Nanocellulose for Multifaceted Applications: A Review. Int. J. Biol. Macromol. 2024, 280, 136130. [Google Scholar] [CrossRef]

- El-Araby, R. Biofuel Production: Exploring Renewable Energy Solutions for a Greener Future. Biotechnol. Biofuels Bioprod. 2024, 17, 129. [Google Scholar] [CrossRef]

- Sventzouri, E.; Manthos, G.; Tsigkou, K.; Mastropetros, S.G.; Pispas, K.; Zagklis, D.; Ali, S.S.; Kornaros, M. Municipal Effluents: Generation, Characteristics, Impacts, and Applications for Bio-Based Product Recovery in a Biorefinery. In Biorefinery of Industrial Effluents for a Sustainable Circular Economy; Elsevier: Amsterdam, The Netherlands, 2025; pp. 95–110. [Google Scholar]

- Gitanjali, J.; Kalpana, M.; Ramesh, D.; Karthikeyan, S.; Venkatesa Palanichamy, N. Biofuel Potential Assignment Tool. Available online: https://drive.google.com/file/d/1qzHrWCJw4iqi3dhqy0AzwyU_wMsdo4kP/view (accessed on 8 February 2025).

- Guo, M.; Song, W.; Buhain, J. Bioenergy and Biofuels: History, Status, and Perspective. Renew. Sustain. Energy Rev. 2015, 42, 712–725. [Google Scholar] [CrossRef]

- Paul, S.; Panja, A.; Jha, P. Hindrances and Drawbacks of the Existing Policies and Roadmap for Sustainable Production of Biofuels: An Indian Scenario. In Biofuels and Sustainability; Elsevier: Amsterdam, The Netherlands, 2025; pp. 237–252. [Google Scholar]

- Patel, A.; Shah, A.R. Integrated Lignocellulosic Biorefinery: Gateway for Production of Second Generation Ethanol and Value Added Products. J. Bioresour. Bioprod. 2021, 6, 108–128. [Google Scholar] [CrossRef]

- Saravanan, A.P.; Mathimani, T.; Deviram, G.; Rajendran, K.; Pugazhendhi, A. Biofuel Policy in India: A Review of Policy Barriers in Sustainable Marketing of Biofuel. J. Clean. Prod. 2018, 193, 734–747. [Google Scholar] [CrossRef]

- Usmani, Z.; Sharma, M.; Awasthi, A.K.; Lukk, T.; Tuohy, M.G.; Gong, L.; Nguyen-Tri, P.; Goddard, A.D.; Bill, R.M.; Nayak, S.C.; et al. Lignocellulosic Biorefineries: The Current State of Challenges and Strategies for Efficient Commercialization. Renew. Sustain. Energy Rev. 2021, 148, 111258. [Google Scholar] [CrossRef]

- Kumar Biswas, P.; Pohit, S. What Ails India’s Biodiesel Programme? Energy Policy 2013, 52, 789–796. [Google Scholar] [CrossRef]

- Dutta, A.; Patra, A.; Hazra, K.K.; Nath, C.P.; Kumar, N.; Rakshit, A. A State of the Art Review in Crop Residue Burning in India: Previous Knowledge, Present Circumstances and Future Strategies. Environ. Chall. 2022, 8, 100581. [Google Scholar] [CrossRef]

- Kothari, R.; Vashishtha, A.; Singh, H.M.; Pathak, V.V.; Tyagi, V.V.; Yadav, B.C.; Ashokkumar, V.; Singh, D.P. Assessment of Indian Bioenergy Policy for Sustainable Environment and Its Impact for Rural India: Strategic Implementation and Challenges. Environ. Technol. Innov. 2020, 20, 101078. [Google Scholar] [CrossRef]

- Biogas: Converting Waste to the Best Renewable Energy Resource. Available online: https://www.peda.gov.in/waste-to-energy-projects (accessed on 25 February 2025).

- Haryana Bio-Energy Policy. 2018. Available online: https://hareda.gov.in/document/haryana-bio-energy-policy-2018 (accessed on 25 February 2025).

- Bio Energy Program. Available online: https://upneda.org.in/bio-energy-program.aspx (accessed on 25 February 2025).

- Rajasthan Integrated Clean Energy Policy. 2024. Available online: https://www.eqmagpro.com/wp-content/uploads/2024/12/Final-Draft_Itegrated-Clean-Energy-Policy2024-Nov24-VER1-1-final-1_compressed-1-28.pdf (accessed on 25 February 2025).

- Determination of Generic Tariff and Other Terms and Conditions for Procurement of Power by Distribution Licensees from Municipal Solid Waste to Energy Projects in the State of Gujarat. MSW Discussion Paper 2023. 2016. Available online: https://www.eqmagpro.com/determination-of-generic-tariff-and-other-terms-and-conditions-for-procurement-of-power-by-distributionlicensees-from-municipal-solid-wasteto-energy-projects-in-the-state-of-gujarat-eq/ (accessed on 25 February 2025).

- Madhya Pradesh Renewable Energy Policy—202. Available online: https://www.nsefi.in/assets/policies/Madhya_pradesh_renewable_enrgy_policy_2022.pdf (accessed on 25 February 2025).

- Study of Opportunities Associated with Biogas Energy in Jharkhand. Available online: https://www.researchgate.net/publication/352367485_Study_of_Opportunities_Associated_with_Biogas_Energy_in_Jharkhand (accessed on 25 February 2025).

- Sori, S.K.; Sushila, K.; Ekka, A. Economic Analysis of Biofuel Policy of Chhattisgarh. Available online: https://www.researchgate.net/publication/276252837_Economic_analysis_of_Biofuel_policy_of_Chhattisgarh (accessed on 25 February 2025).

- Biomass Energy. Available online: https://tgredco.telangana.gov.in/Biomass.aspx (accessed on 25 February 2025).

- Bio Energy and Solar Energy Programmes/Schemes. Available online: https://nredcap.in/BioEnergy_Solar_Programs.aspx (accessed on 25 February 2025).

- Kavya Koonampilli Policy and Market Briefing. 2024. Available online: https://www.worldbiogasassociation.org/wp-content/uploads/2024/10/WBA-India-Policy-and-Market-Briefing-2024.pdf (accessed on 13 March 2025).

- Ethanol Blending Policy. Available online: https://cms.tn.gov.in/cms_migrated/document/GO/ind_e_71_2023.pdf (accessed on 13 March 2025).

- Biomass (Agro-Waste) Based Power Project. Available online: https://www.mahaurja.com/meda/en/grid_connected_power/biomass (accessed on 25 February 2025).

- RE Programs. Available online: https://oredaodisha.com/re-programs/ (accessed on 25 February 2025).

- Bio Energy Programme. Available online: http://www.wbreda.org/bio-energy-programme/ (accessed on 25 February 2025).

- Unnat Chullha Abhiyan Programme. Available online: https://krishijagran.com/agriculture-world/tripura-s-bio-villages-aim-to-offer-sustainable-livelihood-opportunities-deputy-cm/ (accessed on 25 February 2025).

- Biogas. Available online: https://sikkimsreda.in/BioGas.html (accessed on 25 February 2025).

- Projects & Activities. Available online: https://nre.nagaland.gov.in/ (accessed on 25 February 2025).

- Meghalaya Power Policy. Available online: https://www.mnreda.gov.in/index.htm (accessed on 25 February 2025).

- National Biogas Development Project. Available online: https://keralaagriculture.gov.in/en/2021/09/14/national-biogas-development-project (accessed on 25 February 2025).

- Biomass Gasification. Available online: https://aeda.assam.gov.in/frontimpotentdata/biomass-gasification (accessed on 25 February 2025).

- State of Environment Report for Chandigarh UT-2021. Available online: https://chandigarhenvis.gov.in/sites/default/files/pdffiles/SoER_Chandigrah%202021-5.pdf (accessed on 25 February 2025).

- Purohit, P.; Dhar, S. Lignocellulosic Biofuels in India: Current Perspectives, Potential Issues and Future Prospects. AIMS Energy 2018, 6, 453–486. [Google Scholar] [CrossRef]

- Grangeia, C.; Santos, L.; Lazaro, L.L.B. The Brazilian Biofuel Policy (RenovaBio) and Its Uncertainties: An Assessment of Technical, Socioeconomic and Institutional Aspects. Energy Convers. Manag. X 2022, 13, 100156. [Google Scholar] [CrossRef]

- Goswami, L.; Kayalvizhi, R.; Dikshit, P.K.; Sherpa, K.C.; Roy, S.; Kushwaha, A.; Kim, B.S.; Banerjee, R.; Jacob, S.; Rajak, R.C. A Critical Review on Prospects of Bio-Refinery Products from Second and Third Generation Biomasses. Chem. Eng. J. 2022, 448, 137677. [Google Scholar] [CrossRef]

- Singh Yadav, A.; Singh, P.; Sahu, R.; Thangamuthu, P.; Shyam Narain, R.; Anupam Rao, Y.; Balu, A.; Prasad Panda, B.; Sharma, A. Potential Utilization of Turpentine Oil as an Alternative Fuel. Mater. Today Proc. 2022, 63, A1–A8. [Google Scholar] [CrossRef]

- Chauhan, A.; Upadhyay, S.; Saini, G.; Senthilkumar, N. Agricultural Crop Residue Based Biomass in India: Potential Assessment, Methodology and Key Issues. Sustain. Energy Technol. Assess. 2022, 53, 102552. [Google Scholar] [CrossRef]

- Pattnaik, F.; Patra, B.R.; Nanda, S.; Mohanty, M.K.; Dalai, A.K.; Rawat, J. Drivers and Barriers in the Production and Utilization of Second-Generation Bioethanol in India. Recycling 2024, 9, 19. [Google Scholar] [CrossRef]

- Chatterjee, E. India’s Oligarchic State Capitalism. Curr. Hist. 2023, 122, 123–130. [Google Scholar] [CrossRef]

- Sukumaran, R.K.; Mathew, A.K.; Kiran Kumar, M.; Abraham, A.; Chistopher, M.; Sankar, M. First- and Second-Generation Ethanol in India: A Comprehensive Overview on Feedstock Availability, Composition, and Potential Conversion Yields. In Sustainable Biofuels Development in India; Springer International Publishing: Cham, Switzerland, 2017; pp. 223–246. [Google Scholar]

- Duarah, P.; Haldar, D.; Patel, A.K.; Dong, C.-D.; Singhania, R.R.; Purkait, M.K. A Review on Global Perspectives of Sustainable Development in Bioenergy Generation. Bioresour. Technol. 2022, 348, 126791. [Google Scholar] [CrossRef]

- Purohit, P.; Dhar, S. Biofuel Roadmap for India; UNEP DTU Partnership: New Delhi, India, 2015. [Google Scholar]

- Singal, S.K. Review of Augmentation of Energy Needs Using Renewable Energy Sources in India. Renew. Sustain. Energy Rev. 2007, 11, 1607–1615. [Google Scholar] [CrossRef]

- Murphy, F.; Sosa, A.; McDonnell, K.; Devlin, G. Life Cycle Assessment of Biomass-to-Energy Systems in Ireland Modelled with Biomass Supply Chain Optimisation Based on Greenhouse Gas Emission Reduction. Energy 2016, 109, 1040–1055. [Google Scholar] [CrossRef]

- Yu, S.; Tao, J. Economic, Energy and Environmental Evaluations of Biomass-Based Fuel Ethanol Projects Based on Life Cycle Assessment and Simulation. Appl. Energy 2009, 86, S178–S188. [Google Scholar] [CrossRef]

- Giarola, S.; Zamboni, A.; Bezzo, F. Spatially Explicit Multi-Objective Optimisation for Design and Planning of Hybrid First and Second Generation Biorefineries. Comput. Chem. Eng. 2011, 35, 1782–1797. [Google Scholar] [CrossRef]

- Tsiropoulos, I.; Faaij, A.P.C.; Lundquist, L.; Schenker, U.; Briois, J.F.; Patel, M.K. Life Cycle Impact Assessment of Bio-Based Plastics from Sugarcane Ethanol. J. Clean. Prod. 2015, 90, 114–127. [Google Scholar] [CrossRef]

- Okoko, A.; Reinhard, J.; von Dach, S.W.; Zah, R.; Kiteme, B.; Owuor, S.; Ehrensperger, A. The Carbon Footprints of Alternative Value Chains for Biomass Energy for Cooking in Kenya and Tanzania. Sustain. Energy Technol. Assess. 2017, 22, 124–133. [Google Scholar] [CrossRef]

- Rajesh Banu, J.; Kavitha, S.; Yukesh Kannah, R.; Poornima Devi, T.; Gunasekaran, M.; Kim, S.-H.; Kumar, G. A Review on Biopolymer Production via Lignin Valorization. Bioresour. Technol. 2019, 290, 121790. [Google Scholar] [CrossRef]

- Özdenkçi, K.; De Blasio, C.; Muddassar, H.R.; Melin, K.; Oinas, P.; Koskinen, J.; Sarwar, G.; Järvinen, M. A Novel Biorefinery Integration Concept for Lignocellulosic Biomass. Energy Convers. Manag. 2017, 149, 974–987. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Sarsaiya, S.; Patel, A.; Juneja, A.; Singh, R.P.; Yan, B.; Awasthi, S.K.; Jain, A.; Liu, T.; Duan, Y.; et al. Refining Biomass Residues for Sustainable Energy and Bio-Products: An Assessment of Technology, Its Importance, and Strategic Applications in Circular Bio-Economy. Renew. Sustain. Energy Rev. 2020, 127, 109876. [Google Scholar] [CrossRef]

- Adom, F.; Dunn, J.B.; Han, J.; Sather, N. Life-Cycle Fossil Energy Consumption and Greenhouse Gas Emissions of Bioderived Chemicals and Their Conventional Counterparts. Environ. Sci. Technol. 2014, 48, 14624–14631. [Google Scholar] [CrossRef]

- Singh, N.; Singhania, R.R.; Nigam, P.S.; Dong, C.-D.; Patel, A.K.; Puri, M. Global Status of Lignocellulosic Biorefinery: Challenges and Perspectives. Bioresour. Technol. 2022, 344, 126415. [Google Scholar] [CrossRef] [PubMed]

- Luo, L.; van der Voet, E.; Huppes, G. Biorefining of Lignocellulosic Feedstock—Technical, Economic and Environmental Considerations. Bioresour. Technol. 2010, 101, 5023–5032. [Google Scholar] [CrossRef] [PubMed]

- Kapoor, R.; Ghosh, P.; Kumar, M.; Sengupta, S.; Gupta, A.; Kumar, S.S.; Vijay, V.; Kumar, V.; Kumar Vijay, V.; Pant, D. Valorization of Agricultural Waste for Biogas Based Circular Economy in India: A Research Outlook. Bioresour. Technol. 2020, 304, 123036. [Google Scholar] [CrossRef] [PubMed]

- Cazzola, P.; Morrison, G.; Kaneko, H.; Cuenot, F.; Ghandi, A.; Fulton, L. Production Costs of Alternative Transport Fuels: Influence of Crude Oil Price and Technology Maturity; IEA: Paris, France, 2013. [Google Scholar]

| Biomass | Properties | Technology | Estimated Energy Generation Potential | Bioproducts | |

|---|---|---|---|---|---|

| Crop residues | Crop straws (Paddy straw, wheat straw, barley straw) | Cellulose, %: 30–45 Hemicellulose, %: 20–25 Lignin, %: 10–20 Ash content, %: 4–20 Moisture, %: 8–12 Energy value, MJ/kg: 10–16 Bulk density, kg/m3: 50–120 | Anaerobic digestion | Biogas: 0.3–0.6 m3 per kg volatile solids | Bio-digestate slurry |

| Fermentation | Bioethanol: 0.3–0.5 L per kg dry biomass | Biocompost, animal feed, biochemicals | |||

| Pyrolysis | Biooil: 0.2–0.3 L per kg dry biomass Biochar: 0.2–0.25 kg per kg dry biomass | Pyrogas | |||

| Gasification | Syngas: 1–1.5 m3 per kg dry biomass | Biochar | |||

| HTC/HTL | Biocrude: 0.3–0.5 L per kg dry biomass Hydrochar: 0.3–0.4 kg per kg dry biomass | Aqueous phase | |||

| Crop stalks (cotton stalk, millet stalk, corn stalk, pea stalk) | Cellulose, %: 30–45 Hemicellulose, %: 15–30 Lignin, %: 10–25 Ash content, %: 3–8 Moisture, %: 8–14 Energy value, MJ/kg: 14–18 Bulk density, kg/m3: 50–150 | Anaerobic digestion | Biogas: 0.3–0.7 m3 per kg volatile solids | Bio-digestate slurry | |

| Fermentation | Bioethanol: 0.25–0.45 L per kg dry biomass | Animal feed, organic acids, biochemicals | |||

| Pyrolysis | Biooil: 0.2–0.35 L per kg dry biomass Biochar: 0.25–0.3 kg per kg dry biomass | Pyrogas | |||

| Gasification | Syngas: 1–1.5 m3 per kg dry biomass | Biochar | |||

| HTC/HTL | Biocrude: 0.3–0.5 L per kg dry biomass Hydrochar: 0.3–0.5 kg per kg dry biomass | Aqueous phase | |||

| Agro Processing Residues | Husks and Shells (Coconut, sunflower, coffee, paddy husks and nut shell) | Cellulose, %: 25–45 Hemicellulose, %: 15–25 Lignin, %: 15–45 Ash content, %: 0.5–5 Moisture, %: 5–15 Energy value, MJ/kg: 13–20 Bulk density, kg/m3: 80–400 | Anaerobic digestion | Biogas: 0.2–0.4 m3 per kg volatile solids | Bio-digestate slurry |

| Fermentation | Bioethanol: 0.1–0.25 L per kg dry biomass | Stillage, animal feed | |||

| Pyrolysis | Biooil: 0.3–0.5 L per kg dry biomass Biochar: 0.25–0.35 kg per kg dry biomass | Pyrogas | |||

| Gasification | Syngas: 1–1.5 m3 per kg dry biomass | Biochar | |||

| HTC/HTL | Biocrude: 0.4–0.6 L per kg dry biomass Hydrochar: 0.3–0.5 kg per kg dry biomass | Aqueous phase | |||

| Fruit and Vegetable Waste (Peels, pomace, seeds) | Carbohydrates, %: 20–40 Lipids, %: 2–40 Ash content, %: 2–8 Moisture, %: 10–90 Energy value, MJ/kg: 10–25 Bulk density, kg/m3: 250–800 | Anaerobic digestion | Biogas: 0.2–0.4 m3 per kg volatile solids | Bio-digestate | |

| Fermentation | Bioethanol: 0.1–0.25 L per kg dry biomass | Bio-composites, biopolymers | |||

| Pyrolysis | Biooil: 0.3–0.5 L per kg dry biomass Biochar: 0.25–0.35 kg per kg dry biomass | Pyrogas | |||

| Gasification | Syngas: 1–1.5 m3 per kg dry biomass | Biochar | |||

| HTC/HTL | Biocrude: 0.3–0.5 L per kg dry biomass Hydrochar: 0.4–0.6 kg per kg dry biomass | Bioactive compounds | |||

| Oil industry (Fruit bunches, fronds, oil cake) | Lignin, %: 5–25 Ash content, %: 4–20 Moisture, %: 12–60 Energy value, MJ/kg: 14–20 Bulk density, kg/m3: 100–600 | Anaerobic digestion | Biogas: 0.3–0.5 m3 per kg volatile solids | bio-compost, bio-digestate | |

| Fermentation | Bioethanol: 0.1–0.25 L per kg dry biomass | Bioplastic, animal feed | |||

| Pyrolysis | Biooil: 0.3–0.6 L per kg dry biomass Biochar: 0.2–0.35 kg per kg dry biomass | Pyrogas | |||

| Gasification | Syngas: 1–1.5 m3 per kg dry biomass | Biochar | |||

| HTC/HTL | Biocrude: 0.3–0.5 L per kg dry biomass Hydrochar: 0.3–0.6 kg per kg dry biomass | Phenols, biochemicals | |||

| Brewery and Distillery Waste (Spent grain, distiller’s dried grains) | Cellulose, %: 17–30 Hemicellulose, %: 15–35 Lignin, %: 10–18 Lipids, %: 5–12 Moisture, %db: 8–12 Moisture, %wb: 70–80 Energy value, MJ/kg: 10–12 Bulk density, kg/m3: 200–300 | Anaerobic digestion | Biogas: 0.3–0.5 m3 per kg volatile solids | Bio-digestate | |

| Fermentation | Bioethanol: 0.1–0.25 L per kg dry biomass | Biocompost | |||

| Pyrolysis | Biooil: 0.3–0.5 L per kg dry biomass Biochar: 0.2–0.4 kg per kg dry biomass | Animal feed | |||

| Gasification | Syngas: 1–1.5 m3 per kg dry biomass | Biochar | |||

| HTC/HTL | Biocrude: 0.3–0.5 L per kg dry biomass Hydrochar: 0.3–0.5 kg per kg dry biomass | Biochemicals, phenols | |||

| Energy Crops | Perennial Grasses (Switchgrass, miscanthus, Napier grass) | Cellulose, %: 30–50 Hemicellulose, %: 20–30 Lignin, %: 10–25 Ash content, %: 1–8 Moisture, %: 10–20 Energy value, MJ/kg: 15–19 Bulk density, kg/m3: 50–150 | Anaerobic digestion | Biogas: 0.3–0.5 m3 per kg volatile solids | Organic acids, Bio-digestate |

| Fermentation | Bioethanol: 0.2–0.35 L per kg dry biomass | Biocompost | |||

| Pyrolysis | Biooil: 0.2–0.4 L per kg dry biomass Biochar: 0.2–0.3 kg per kg dry biomass | Pyrogas | |||

| Gasification | Syngas: 1–1.5 m3 per kg dry biomass | Biochar | |||

| HTC/HTL | Biocrude: 0.2–0.4 L per kg dry biomass Hydrochar: 0.4–0.6 kg per kg dry biomass | Biochemicals, nutrients | |||

| Woody Crops (Willow, Casuarina, eucalyptus) | Cellulose, %: 40–50 Hemicellulose, %: 25–30 Lignin, %: 20–30 Ash content, %: 0.5–3 Moisture, %: 10–15 Energy value, MJ/kg: 17–20 Bulk density, kg/m3: 180–350 | Anaerobic digestion | Biogas: 0.2–0.4 m3 per kg volatile solids | Bio-digestate | |

| Fermentation | Bioethanol: 0.15–0.25 L per kg dry biomass | Pharmaceuticals | |||

| Pyrolysis | Biooil: 0.2–0.4 L per kg dry biomass Biochar: 0.3–0.4 kg per kg dry biomass | Aromatic oils, pyrogas | |||

| Gasification | Syngas: 1–1.5 m3 per kg dry biomass | Biochar | |||

| HTC/HTL | Biocrude: 0.2–0.4 L per kg dry biomass Hydrochar: 0.4–0.6 kg per kg dry biomass | Liquid fertilizer | |||

| Non-edible plant (jatropha) | Cellulose, %: 35–45 Hemicellulose, %: 20–30 Lignin, %: 25–35 Ash content, %: 4–10 Moisture, %: 8–14 Energy value, MJ/kg: 18–22 Bulk density, kg/m3: 200–300 | Anaerobic digestion | Biogas: 0.3–0.5 m3 per kg volatile solids | Bio-digestate | |

| Fermentation | Bioethanol: 0.12–0.20 L per kg dry biomass | Bioplastics | |||

| Pyrolysis | Biooil: 0.2–0.4 L per kg dry biomass Biochar: 0.3–0.4 kg per kg dry biomass | Pyrogas | |||

| Gasification | Syngas: 1–1.5 m3 per kg dry biomass | Biochar | |||

| HTC/HTL | Biocrude: 0.2–0.4 L per kg dry biomass Hydrochar: 0.4–0.5 kg per kg dry biomass | Nutraceuticals, biochemicals | |||

| Aquatic biomass | Algae (microalgae and macroalgae) | Cellulose, %: 10–20 Hemicellulose, %: 5–15 Lignin, %: <1 Ash content, %: 10–40 Moisture, %wb: 80–90 Moisture, %db: 10–20 Energy value, MJ/kg: 10–25 Bulk density, kg/m3: 100–300 | Anaerobic digestion | Biogas: 0.2–0.4 m3 per kg of biomass | Bio-digestate |

| Fermentation | Bioethanol: 0.1–0.2 L per kg biomass | bioplastics | |||

| Pyrolysis | Biooil: 0.1–0.3 L per kg biomass Biochar: 0.2–0.3 kg per kg biomass | Nutraceuticals | |||

| Gasification | Syngas: 1–1.5 m3 per kg biomass | Biochar | |||

| HTC/HTL | Biocrude: 0.3–0.5 L per kg biomass Hydrochar: 0.3–0.5 kg per kg biomass | Nutrient recover, chemicals | |||

| Water hyacinth and duckweed (aquatic plants) | Cellulose, %: 15–40 Hemicellulose, %: 10–30 Lignin, %: 1–20 Ash content, %: 10–25 Moisture, %wb: 80–95 Moisture, %db: 5–20 Energy value, MJ/kg: 10–18 Bulk density, kg/m3: 80–250 | Anaerobic digestion | Biogas: 0.2–0.4 m3 per kg of biomass | Bio-digestate | |

| Fermentation | Bioethanol: 0.1–0.2 L per kg biomass | Organic acids | |||

| Pyrolysis | Biooil: 0.1–0.3 L per kg biomass Biochar: 0.2–0.3 kg per kg biomass | Pyrogas, biochemicals | |||

| Gasification | Syngas: 1–1.5 m3 per kg biomass | Biochar | |||

| HTC/HTL | Biocrude: 0.3–0.6 L per kg biomass Hydrochar: 0.3–0.5 kg per kg biomass | Biochemicals, nutrients | |||

| Environmental Impact | Description |

|---|---|

| Reduction in GHG Emissions | Lignocellulosic biofuels approach carbon neutrality, offsetting CO2 emissions through plant sequestration. |

| Waste Valorization | Utilization of agricultural residues prevents open field burning, mitigating air pollution. |

| Biodiversity Conservation | Sustainable biomass sourcing reduces the need for agricultural land expansion, limiting deforestation. |

| Water Conservation | Advanced biorefineries consume 30–70% less water compared to first-generation biofuels; water recycling systems improve efficiency. |

| Soil Health Improvement | By-products such as biochar and bio-digestate enhance soil carbon content and microbial activity, improving agricultural sustainability. |

| Economy Impact | Description |

|---|---|

| Reduced Fossil Fuel Dependency | Domestic biofuel production reduces crude oil imports, strengthening trade balance and energy security. |

| Market Growth | India‘s bioethanol market is projected to grow at a CAGR of 8.7%, potentially doubling by 2030. |

| Investment Attraction | Major corporations like Reliance and Adani Group have committed substantial investments in bioenergy. |

| Value-Added Products | Biorefineries produce high-value chemicals such as xylitol, furfural, and organic acids, enhancing profitability. |

| Rural Development | Increased demand for agricultural residues boosts rural incomes and stimulates local supply chains. |

| Economy Impact | Description |

|---|---|

| Energy Demand Growth | Energy demand rose from 6101 Mtoe (1973) to 13,699 Mtoe (2016). |

| GHG Emissions Reduction | Potential 2.7% reduction in GDP by 2030 from second-generation biorefineries. |

| Solar Energy Potential | India’s annual solar potential exceeds 5000 trillion kWh. |

| CHP Efficiency | CHP systems in biorefineries achieve 80–90% efficiency, compared to 30–40% for conventional systems. |

| Renewable Energy Contribution | Increased demand for agricultural residues boosts rural incomes and stimulates local supply chains. |

| Energy Diversification | Biomass diversifies India’s energy portfolio, reducing reliance on fossil fuels. |

| Decentralized Energy Production | Biorefineries contribute to rural electrification by reducing transmission losses. |

| Integration with Other Renewables | Combines solar with biomass to address intermittency and optimize solar potential. |

| Grid Stability | Biogas and biomethane enhance grid stability, supporting renewable energy integration. |

| Transportation Costs | Transportation can reduce biorefinery operational expenses. |

| Parameter | Details |

|---|---|

| Carbon Footprint Reduction | Bio-derived polyethylene reduces emissions by 0.75 kg CO2-eq/kg compared to fossil-based polyethylene. |

| Process Optimization | Charcoal value chain emissions reduced from 2.15 CO2-eq to 0.50 CO2-eq through process improvements. |

| Circular Economy Resource Efficiency | Circular biorefineries demonstrate near-zero waste and enhanced resource use through cascading biomass. |

| Environmental Performance of Circular Economy | Circular approaches reduce GHG emissions by 39–86% and non-renewable energy by 65% compared to linear models. |

| Economic Value Creation | Lignin valorization for polymers, bio-composites, and nanomaterials, with a market projected at USD 1.2 billion by 2025. |

| Sustainability Alignment | Circular economy principles support environmental, economic, and social sustainability goals, aligned with the UN SDGs. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thaha, A.N.; Ghamari, M.; Jothiprakash, G.; Velusamy, S.; Karthikeyan, S.; Ramesh, D.; Sundaram, S. High Impact Biomass Valorization for Second Generation Biorefineries in India: Recent Developments and Future Strategies for Sustainable Circular Economy. Biomass 2025, 5, 16. https://doi.org/10.3390/biomass5010016

Thaha AN, Ghamari M, Jothiprakash G, Velusamy S, Karthikeyan S, Ramesh D, Sundaram S. High Impact Biomass Valorization for Second Generation Biorefineries in India: Recent Developments and Future Strategies for Sustainable Circular Economy. Biomass. 2025; 5(1):16. https://doi.org/10.3390/biomass5010016

Chicago/Turabian StyleThaha, Ayisha Naziba, Mehrdad Ghamari, Gitanjali Jothiprakash, Sasireka Velusamy, Subburamu Karthikeyan, Desikan Ramesh, and Senthilarasu Sundaram. 2025. "High Impact Biomass Valorization for Second Generation Biorefineries in India: Recent Developments and Future Strategies for Sustainable Circular Economy" Biomass 5, no. 1: 16. https://doi.org/10.3390/biomass5010016

APA StyleThaha, A. N., Ghamari, M., Jothiprakash, G., Velusamy, S., Karthikeyan, S., Ramesh, D., & Sundaram, S. (2025). High Impact Biomass Valorization for Second Generation Biorefineries in India: Recent Developments and Future Strategies for Sustainable Circular Economy. Biomass, 5(1), 16. https://doi.org/10.3390/biomass5010016