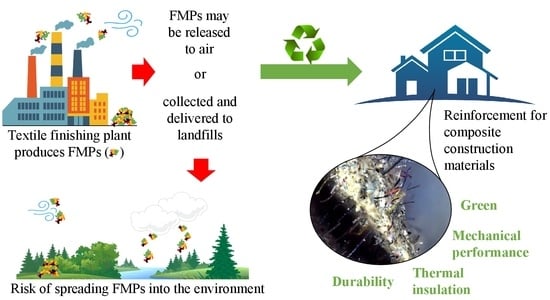

A Practical Valorization Approach for Mitigating Textile Fibrous Microplastics in the Environment: Collection of Textile-Processing Waste Microfibers and Direct Reuse in Green Thermal-Insulating and Mechanical-Performing Composite Construction Materials

Abstract

:1. Introduction

2. Materials and Methods

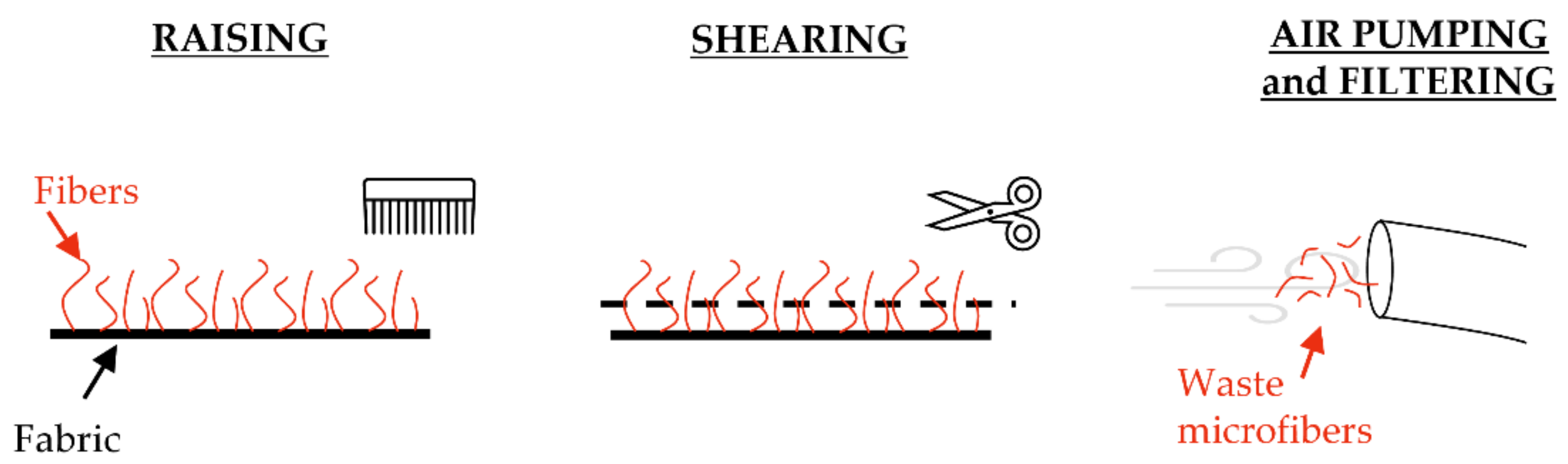

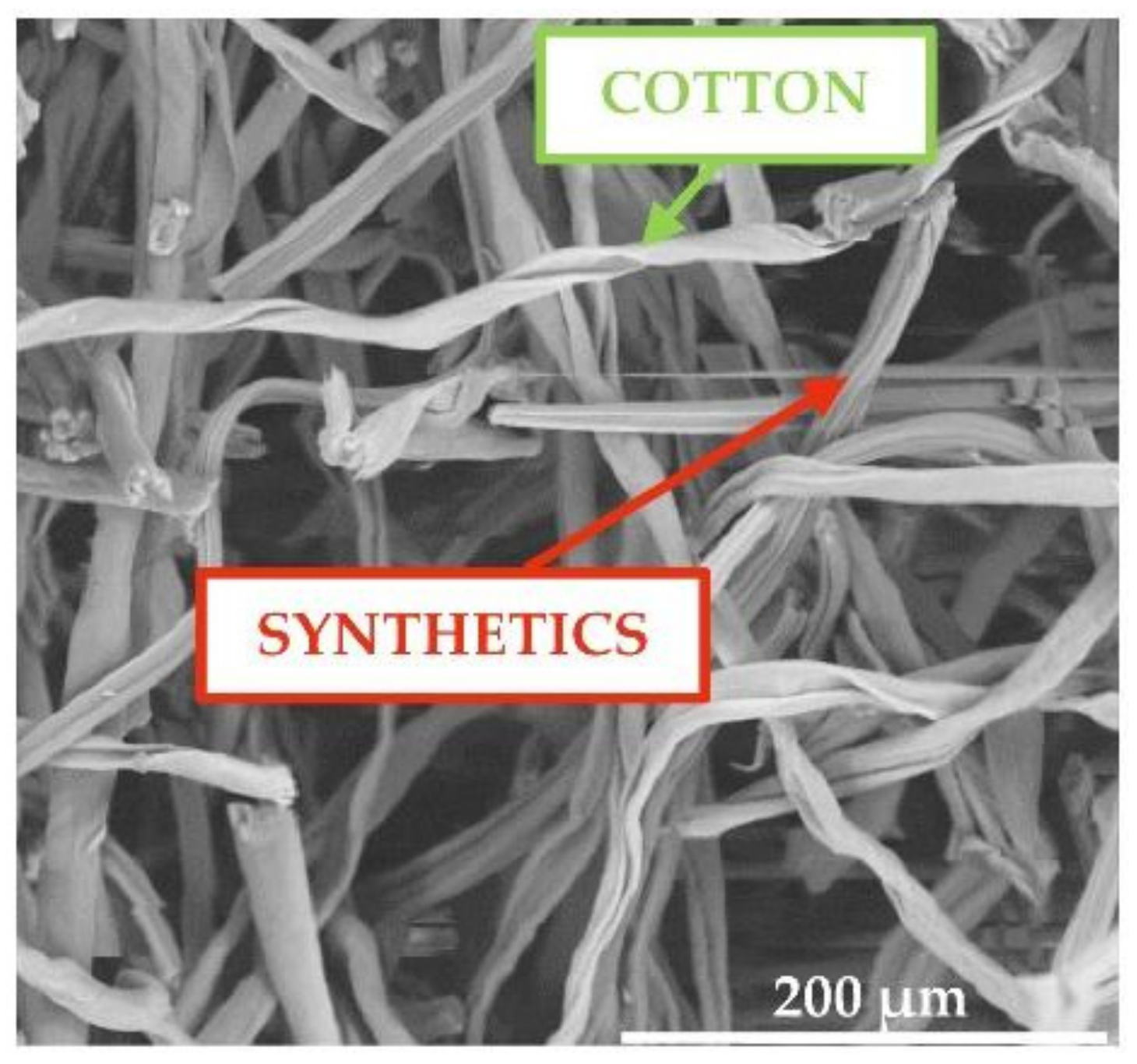

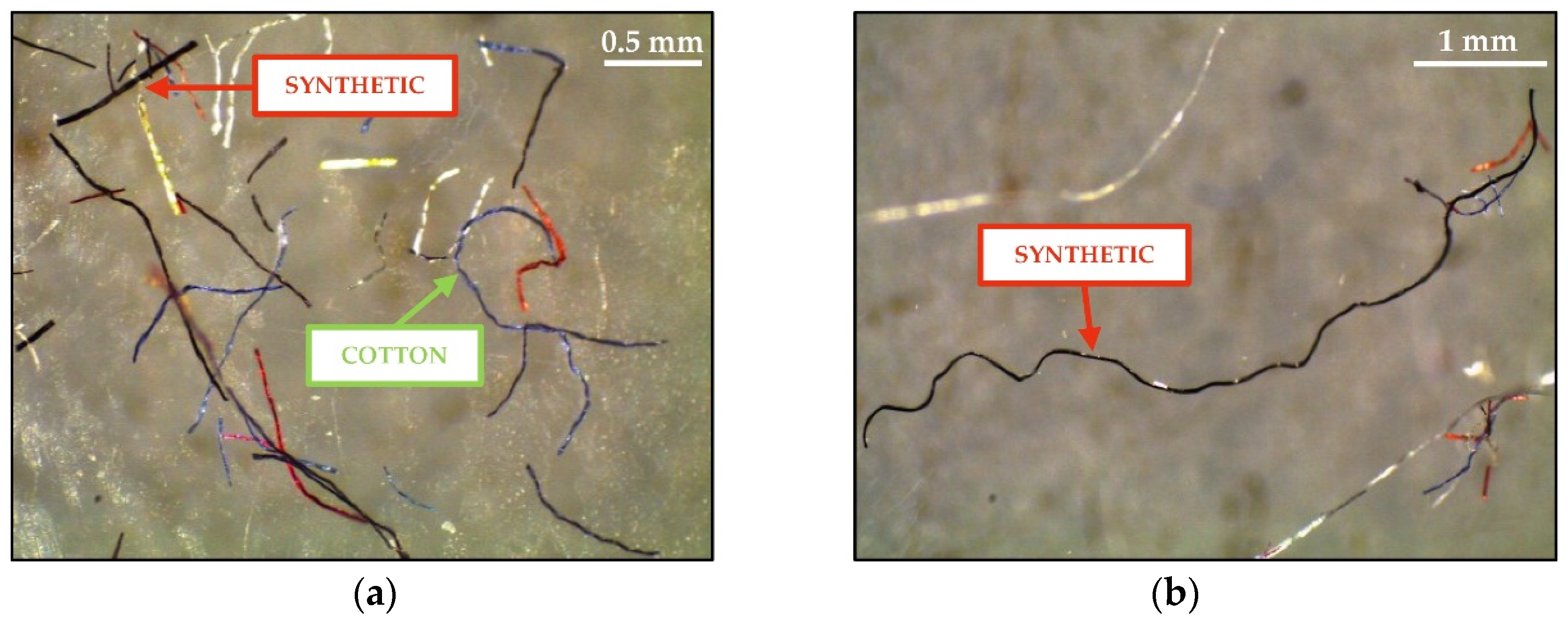

2.1. Textile Waste Microfibers

2.2. Treatments of the Textile Waste Microfibers

2.3. Cement-Based Composites Reinforced by Textile Waste Microfibers (FRCs)

3. Results and Discussion

3.1. Characterization of Textile Waste Microfibers

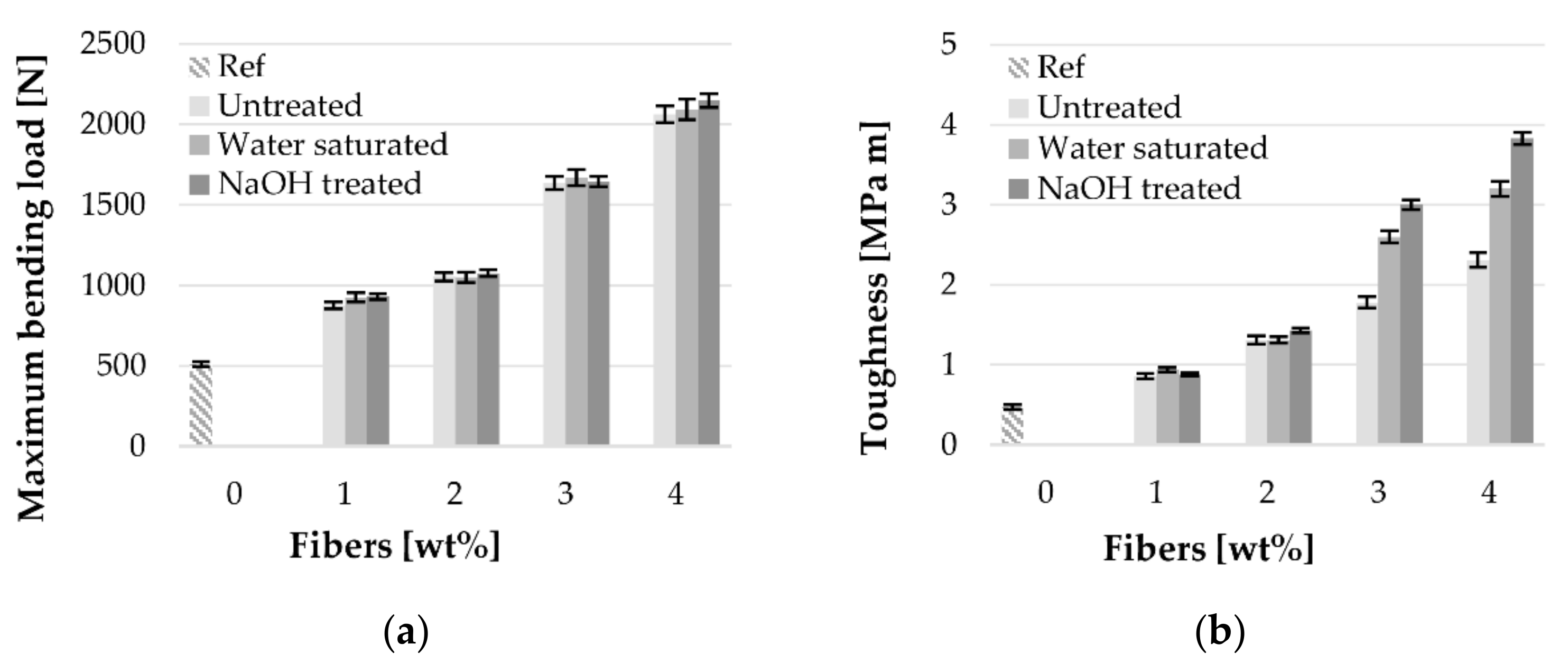

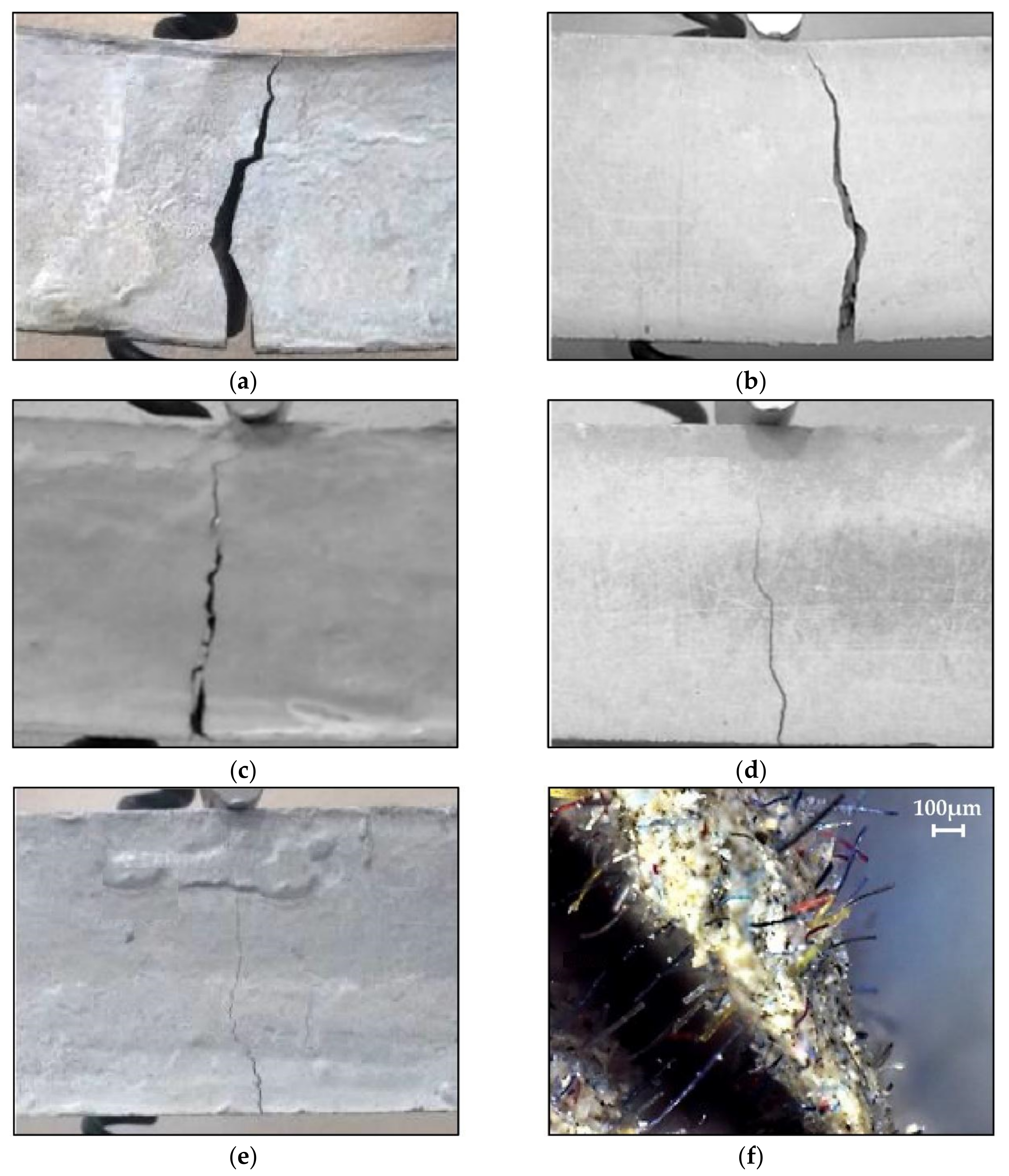

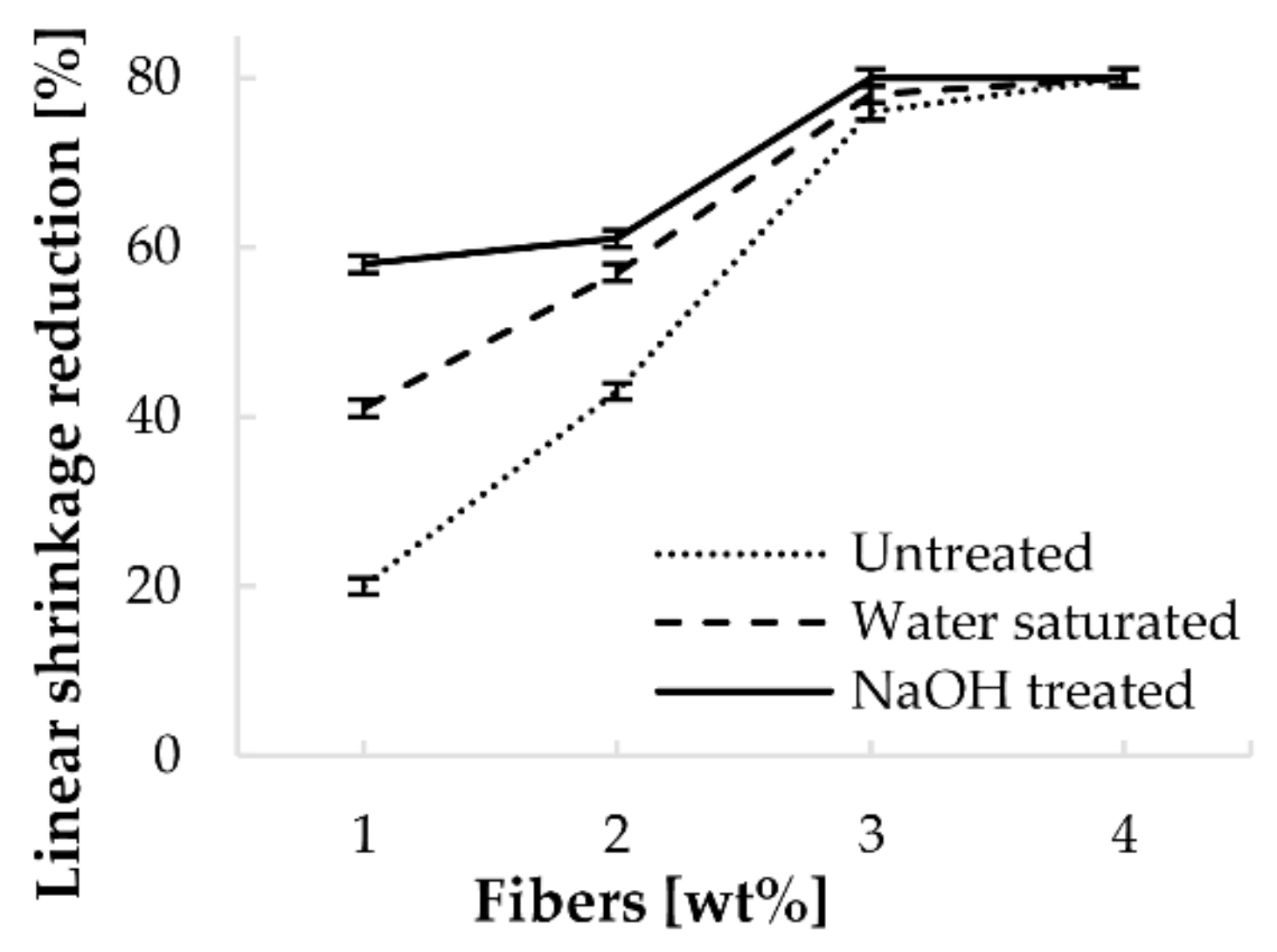

3.2. Characterization of Composite Construction Materials Containing Textile Waste Microfibers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Committee for Risk Assessment (RAC); Committee for Socio-economic Analysis (SEAC). Background Document to the Opinion on the Annex XV Report Proposing Restrictions on Intentionally Added Microplastics; European Chemicals Agency (ECHA): Helsinki, Finland, 2000. [Google Scholar]

- Zhang, Y.-Q.; Lykaki, M.; Markiewicz, M.; Alrajoula, M.T.; Kraas, C.; Stolte, S. Environmental Contamination by Microplastics Originating from Textiles: Emission, Transport, Fate and Toxicity. J. Hazard. Mater. 2022, 430, 128453. [Google Scholar] [CrossRef]

- Brahney, J.; Mahowald, N.; Prank, M.; Cornwell, G.; Klimont, Z.; Matsui, H.; Prather, K.A. Constraining the Atmospheric Limb of the Plastic Cycle. Proc. Natl. Acad. Sci. USA 2021, 118, e2020719118. [Google Scholar] [CrossRef] [PubMed]

- Thompson, R.C.; Olsen, Y.; Mitchell, R.P.; Davis, A.; Rowland, S.J.; John, A.W.G.; McGonigle, D.; Russell, A.E. Lost at Sea: Where Is All the Plastic? Science 2004, 304, 838. [Google Scholar] [CrossRef] [PubMed]

- Tadsuwan, K.; Babel, S. Microplastic Abundance and Removal via an Ultrafiltration System Coupled to a Conventional Municipal Wastewater Treatment Plant in Thailand. J. Environ. Chem. Eng. 2022, 10, 107142. [Google Scholar] [CrossRef]

- Ahmed, R.; Hamid, A.K.; Krebsbach, S.A.; He, J.; Wang, D. Critical Review of Microplastics Removal from the Environment. Chemosphere 2022, 293, 133557. [Google Scholar] [CrossRef] [PubMed]

- Vital-Grappin, A.D.; Ariza-Tarazona, M.C.; Luna-Hernández, V.M.; Villarreal-Chiu, J.F.; Hernández-López, J.M.; Siligardi, C.; Cedillo-González, E.I. The Role of the Reactive Species Involved in the Photocatalytic Degradation of HDPE Microplastics Using C,N-TiO2 Powders. Polymers 2021, 13, 999. [Google Scholar] [CrossRef]

- Domínguez-Jaimes, L.P.; Cedillo-González, E.I.; Luévano-Hipólito, E.; Acuña-Bedoya, J.D.; Hernández-López, J.M. Degradation of Primary Nanoplastics by Photocatalysis Using Different Anodized TiO2 Structures. J. Hazard. Mater. 2021, 413, 125452. [Google Scholar] [CrossRef]

- Acuña-Bedoya, J.D.; Luévano-Hipólito, E.; Cedillo-González, E.I.; Domínguez-Jaimes, L.P.; Hurtado, A.M.; Hernández-López, J.M. Boosting Visible-Light Photocatalytic Degradation of Polystyrene Nanoplastics with Immobilized CuxO Obtained by Anodization. J. Environ. Chem. Eng. 2021, 9, 106208. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, S.; Su, Y.; Wu, D.; Zhao, Y.; Xie, B. Removal of Microplastics from Aqueous Solutions by Magnetic Carbon Nanotubes. Chem. Eng. J. 2021, 406, 126804. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, J.; Kang, Z.; Wu, X.; Tang, L.; Qiang, Z.; Zhang, D.; Pan, X. Removal of Micron-Scale Microplastic Particles from Different Waters with Efficient Tool of Surface-Functionalized Microbubbles. J. Hazard. Mater. 2021, 404, 124095. [Google Scholar] [CrossRef]

- Kumari, A.; Rajput, V.D.; Mandzhieva, S.S.; Rajput, S.; Minkina, T.; Kaur, R.; Sushkova, S.; Kumari, P.; Ranjan, A.; Kalinitchenko, V.P.; et al. Microplastic Pollution: An Emerging Threat to Terrestrial Plants and Insights into Its Remediation Strategies. Plants 2022, 11, 340. [Google Scholar] [CrossRef]

- Dris, R.; Gasperi, J.; Rocher, V.; Saad, M.; Renault, N.; Tassin, B.; Dris, R.; Gasperi, J.; Rocher, V.; Saad, M.; et al. Microplastic Contamination in an Urban Area: A Case Study in Greater Paris. Environ. Chem. 2015, 12, 592–599. [Google Scholar] [CrossRef]

- Dris, R.; Gasperi, J.; Saad, M.; Mirande, C.; Tassin, B. Synthetic Fibers in Atmospheric Fallout: A Source of Microplastics in the Environment? Mar. Pollut. Bull. 2016, 104, 290–293. [Google Scholar] [CrossRef] [PubMed]

- Boucher, J.; Friot, D. Primary Microplastics in the Oceans: A Global Evaluation of Spurces; International Union for Conservation of Nature and Natural Resources (IUCN): Gland, Switzerland, 2017. [Google Scholar]

- Zhao, T.; Lozano, Y.M.; Rillig, M.C. Microplastics Increase Soil PH and Decrease Microbial Activities as a Function of Microplastic Shape, Polymer Type, and Exposure Time. Front. Environ. Sci. 2021, 9, 675803. [Google Scholar] [CrossRef]

- Barboza, L.G.A.; Lopes, C.; Oliveira, P.; Bessa, F.; Otero, V.; Henriques, B.; Raimundo, J.; Caetano, M.; Vale, C.; Guilhermino, L. Microplastics in Wild Fish from North East Atlantic Ocean and Its Potential for Causing Neurotoxic Effects, Lipid Oxidative Damage, and Human Health Risks Associated with Ingestion Exposure. Sci. Total Environ. 2020, 717, 134625. [Google Scholar] [CrossRef]

- Schwabl, P.; Köppel, S.; Königshofer, P.; Bucsics, T.; Trauner, M.; Reiberger, T.; Liebmann, B. Detection of Various Microplastics in Human Stool: A Prospective Case Series. Ann. Intern. Med. 2019, 171, 453–457. [Google Scholar] [CrossRef]

- Jenner, L.C.; Rotchell, J.M.; Bennett, R.T.; Cowen, M.; Tentzeris, V.; Sadofsky, L.R. Detection of Microplastics in Human Lung Tissue Using ΜFTIR Spectroscopy. Sci. Total Environ. 2022, 831, 154907. [Google Scholar] [CrossRef]

- Grand View Research. Synthetic Fibers Market Growth Analysis Report, 2021–2028; Grand View Research: San Francisco, CA, USA, 2021; p. 145. [Google Scholar]

- Istituto Superiore per la Protezione e la Ricerca Ambientale. Rapporto Rifiuti Speciali, Edizione 2020; ISPRA—Istituto Superiore per la Protezione e la Ricerca Ambientale: Rome, Italy, 2020; p. 611.

- Brandt, A.M. Fibre Reinforced Cement-Based (FRC) Composites after over 40 Years of Development in Building and Civil Engineering. Compos. Struct. 2008, 86, 3–9. [Google Scholar] [CrossRef]

- Signorini, C.; Sola, A.; Malchiodi, B.; Nobili, A. Highly Dissipative Fiber-Reinforced Concrete for Structural Screeds. J. Mater. Civ. Eng. 2022, 34, 04022022. [Google Scholar] [CrossRef]

- Verma, D.; Goh, K.L. Effect of Mercerization/Alkali Surface Treatment of Natural Fibres and Their Utilization in Polymer Composites: Mechanical and Morphological Studies. J. Compos. Sci. 2021, 5, 175. [Google Scholar] [CrossRef]

- Giraldo, L.J.Q.; Cruz, L.J.; García, J.A.; Alcaraz, A.; González, E.; Osorio, J.A. Incidence of Mercerization Treatment in the Mechanical Properties of Bamboo Fibre Bundles “Guadua Angustifolia Kunth” from Colombian Origin. DYNA 2019, 86, 156–163. [Google Scholar] [CrossRef] [Green Version]

- Rizal, S.; Olaiya, F.G.; Saharudin, N.I.; Abdullah, C.K.; Olaiya, N.G.; Mohamad Haafiz, M.K.; Yahya, E.B.; Sabaruddin, F.A.; Ikramullah; Abdul Khalil, H.P.S. Isolation of Textile Waste Cellulose Nanofibrillated Fibre Reinforced in Polylactic Acid-Chitin Biodegradable Composite for Green Packaging Application. Polymers 2021, 13, 325. [Google Scholar] [CrossRef]

- Hanoğlu, A.; Çay, A.; Yanık, J. Production of Biochars from Textile Fibres through Torrefaction and Their Characterisation. Energy 2019, 166, 664–673. [Google Scholar] [CrossRef]

- Yousef, S.; Tatariants, M.; Tichonovas, M.; Kliucininkas, L.; Lukošiūtė, S.-I.; Yan, L. Sustainable Green Technology for Recovery of Cotton Fibers and Polyester from Textile Waste. J. Clean. Prod. 2020, 254, 120078. [Google Scholar] [CrossRef]

- Rafikov, A.S.; Khakimova, M.S.; qizi Fayzullayeva, D.A.; Reyimov, A.F. Microstructure, Morphology and Strength of Cotton Yarns Sized by Collagen Solution. Cellulose 2020, 27, 10369–10384. [Google Scholar] [CrossRef]

- National Research Council. Guide for the Design and Construction of Fiber-Reinforced Concrete Structures 2007; National Research Council: Rome, Italy, 2007. [Google Scholar]

- Payrow, P.; Nokken, M.R.; Banu, D.; Feldman, D. Effect of Surface Treatment on the Post-Peak Residual Strength and Toughness of Polypropylene/Polyethylene-Blended Fiber-Reinforced Concrete. J. Compos. Mater. 2011, 45, 2047–2054. [Google Scholar] [CrossRef]

- Latif, R.; Wakeel, S.; Zaman Khan, N.; Noor Siddiquee, A.; Lal Verma, S.; Akhtar Khan, Z. Surface Treatments of Plant Fibers and Their Effects on Mechanical Properties of Fiber-Reinforced Composites: A Review. J. Reinf. Plast. Compos. 2019, 38, 15–30. [Google Scholar] [CrossRef]

- Signorini, C.; Sola, A.; Malchiodi, B.; Nobili, A.; Gatto, A. Failure Mechanism of Silica Coated Polypropylene Fibres for Fibre Reinforced Concrete (FRC). Constr. Build. Mater. 2020, 236, 117549. [Google Scholar] [CrossRef]

- Shafei, B.; Kazemian, M.; Dopko, M.; Najimi, M. State-of-the-Art Review of Capabilities and Limitations of Polymer and Glass Fibers Used for Fiber-Reinforced Concrete. Materials 2021, 14, 409. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, M. Experimental Study on Engineering Properties of Concrete Reinforced with Hybrid Recycled Tyre Steel and Polypropylene Fibres. J. Clean. Prod. 2020, 259, 120914. [Google Scholar] [CrossRef]

- Rostami, R.; Zarrebini, M.; Sanginabadi, K.; Mostofinejad, D.; Abtahi, S.M.; Fashandi, H. The Effect of Specific Surface Area of Macro Fibers on Energy Absorption Capacity of Concrete. J. Text. Inst. 2019, 110, 707–714. [Google Scholar] [CrossRef]

- Arienzo, M.; Ferrara, L.; Trifuoggi, M. The Dual Role of Microplastics in Marine Environment: Sink and Vectors of Pollutants. J. Mar. Sci. Eng. 2021, 9, 642. [Google Scholar] [CrossRef]

- Rodrigues, J.P.; Duarte, A.C.; Santos-Echeandía, J.; Rocha-Santos, T. Significance of Interactions between Microplastics and POPs in the Marine Environment: A Critical Overview. TrAC Trends Anal. Chem. 2019, 111, 252–260. [Google Scholar] [CrossRef]

- Luan, X.; Kou, X.; Zhang, L.; Chen, L.; Liu, W.; Cui, Z. Estimation and Prediction of Plastic Losses to the Environment in China from 1950 to 2050. Resour. Conserv. Recycl. 2022, 184, 106386. [Google Scholar] [CrossRef]

- Siddiqui, M.O.R.; Sun, D. Development of Experimental Setup for Measuring the Thermal Conductivity of Textiles. Cloth. Text. Res. J. 2018, 36, 215–230. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malchiodi, B.; Cedillo-González, E.I.; Siligardi, C.; Pozzi, P. A Practical Valorization Approach for Mitigating Textile Fibrous Microplastics in the Environment: Collection of Textile-Processing Waste Microfibers and Direct Reuse in Green Thermal-Insulating and Mechanical-Performing Composite Construction Materials. Microplastics 2022, 1, 393-405. https://doi.org/10.3390/microplastics1030029

Malchiodi B, Cedillo-González EI, Siligardi C, Pozzi P. A Practical Valorization Approach for Mitigating Textile Fibrous Microplastics in the Environment: Collection of Textile-Processing Waste Microfibers and Direct Reuse in Green Thermal-Insulating and Mechanical-Performing Composite Construction Materials. Microplastics. 2022; 1(3):393-405. https://doi.org/10.3390/microplastics1030029

Chicago/Turabian StyleMalchiodi, Beatrice, Erika Iveth Cedillo-González, Cristina Siligardi, and Paolo Pozzi. 2022. "A Practical Valorization Approach for Mitigating Textile Fibrous Microplastics in the Environment: Collection of Textile-Processing Waste Microfibers and Direct Reuse in Green Thermal-Insulating and Mechanical-Performing Composite Construction Materials" Microplastics 1, no. 3: 393-405. https://doi.org/10.3390/microplastics1030029

APA StyleMalchiodi, B., Cedillo-González, E. I., Siligardi, C., & Pozzi, P. (2022). A Practical Valorization Approach for Mitigating Textile Fibrous Microplastics in the Environment: Collection of Textile-Processing Waste Microfibers and Direct Reuse in Green Thermal-Insulating and Mechanical-Performing Composite Construction Materials. Microplastics, 1(3), 393-405. https://doi.org/10.3390/microplastics1030029