Investigating the Physicochemical Property Changes of Plastic Packaging Exposed to UV Irradiation and Different Aqueous Environments

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

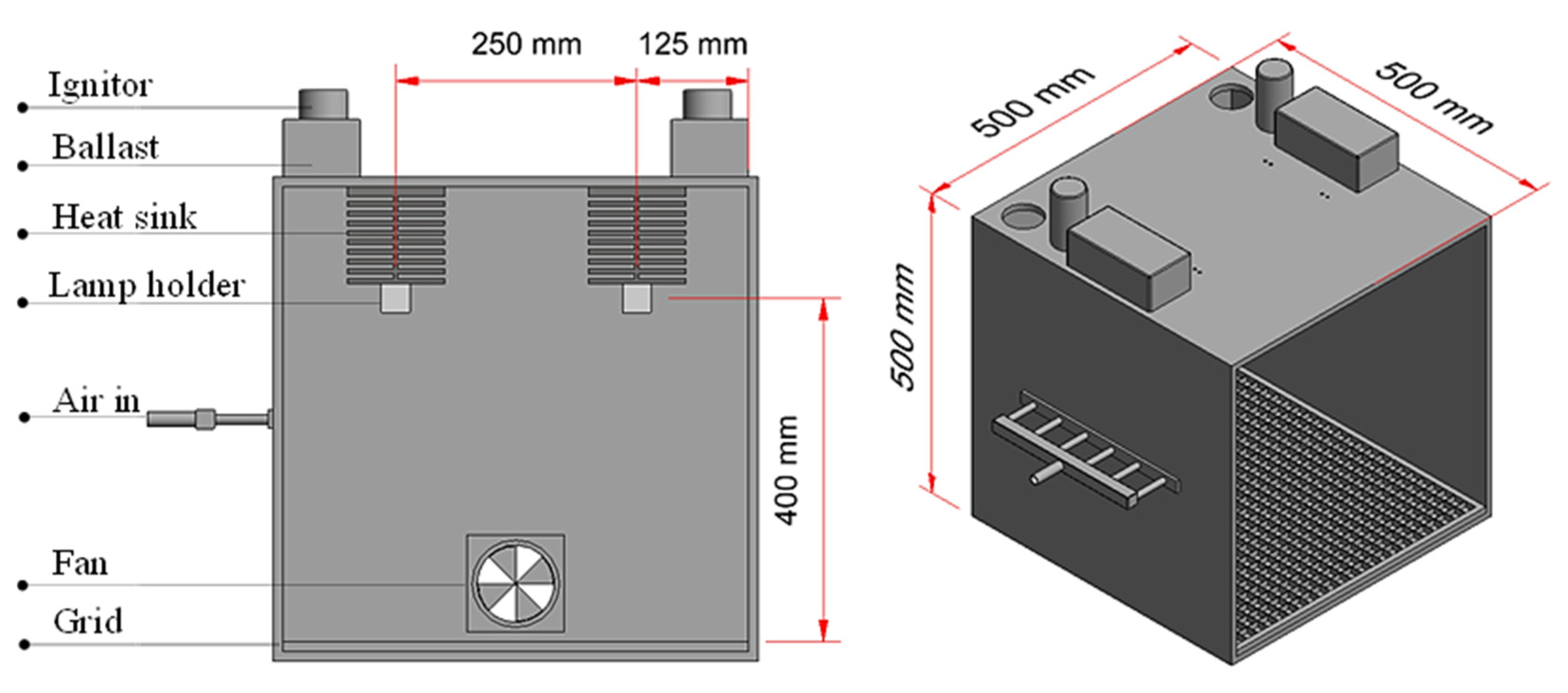

2.2. UV Exposure Chamber

2.3. UV Exposure in Air for Pretreatment

2.4. Aqueous UV Degradation Studies

2.5. Analyses and Data Interpretation

2.5.1. Mass Loss

2.5.2. Differential Scanning Calorimetry (DSC)

2.5.3. Fourier-Transform Infrared Spectroscopy (FTIR)

2.5.4. Microhardness

2.5.5. Analysis of Variance (ANOVA)

3. Results and Discussion

3.1. UV Pretreatment in Air

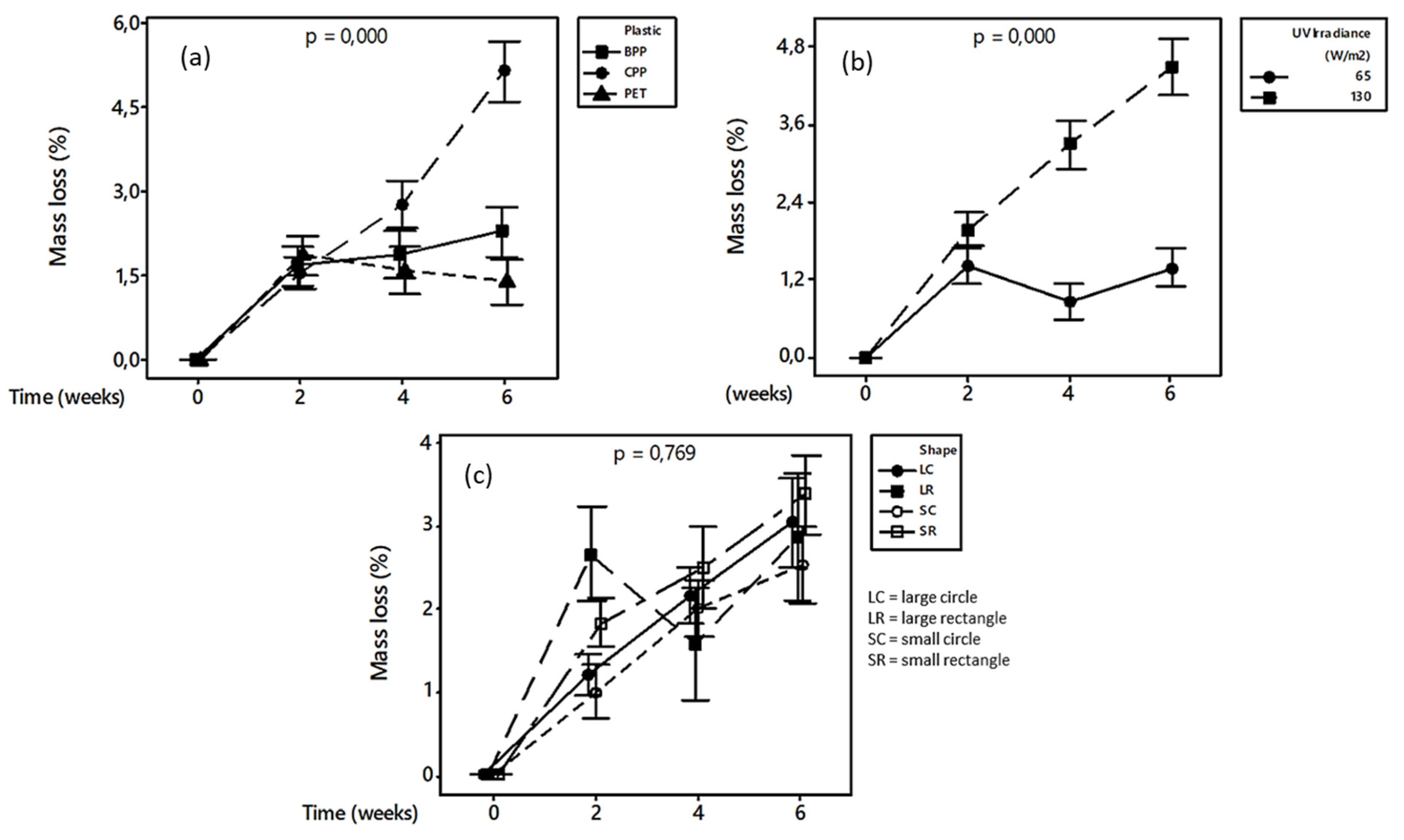

3.1.1. Mass Loss

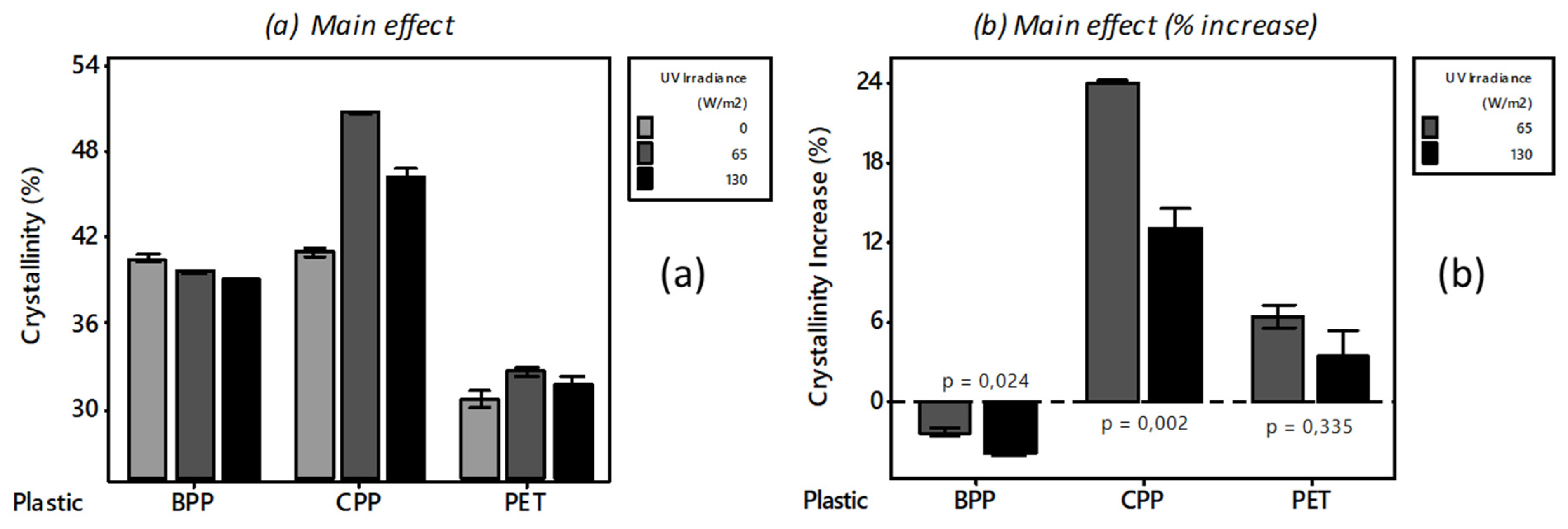

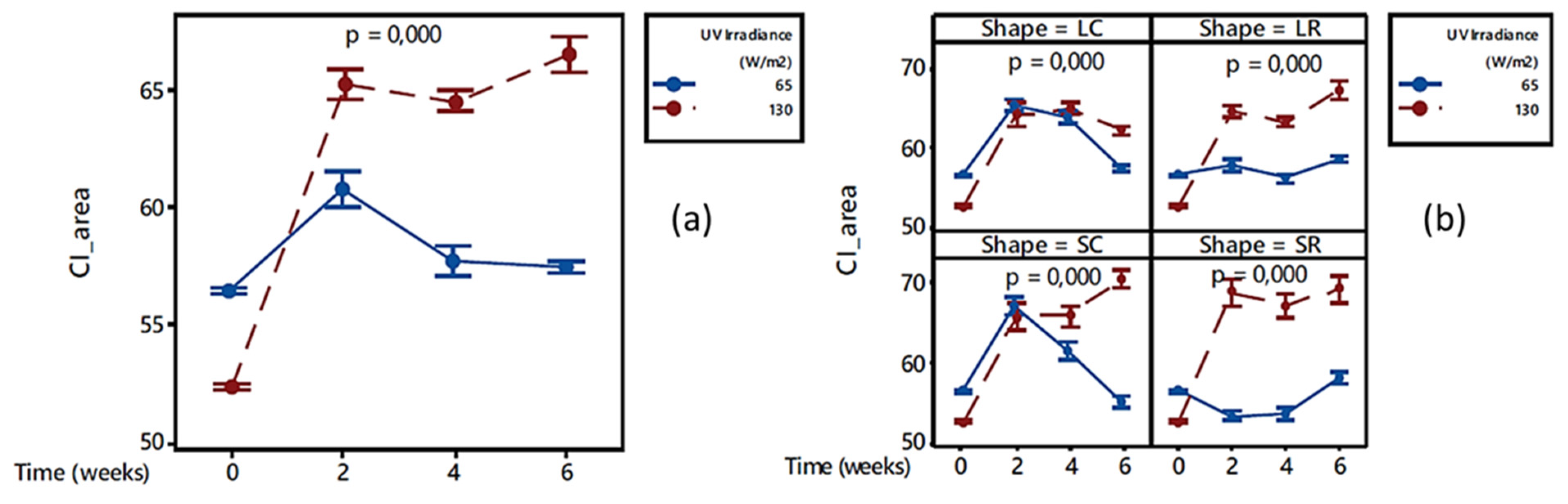

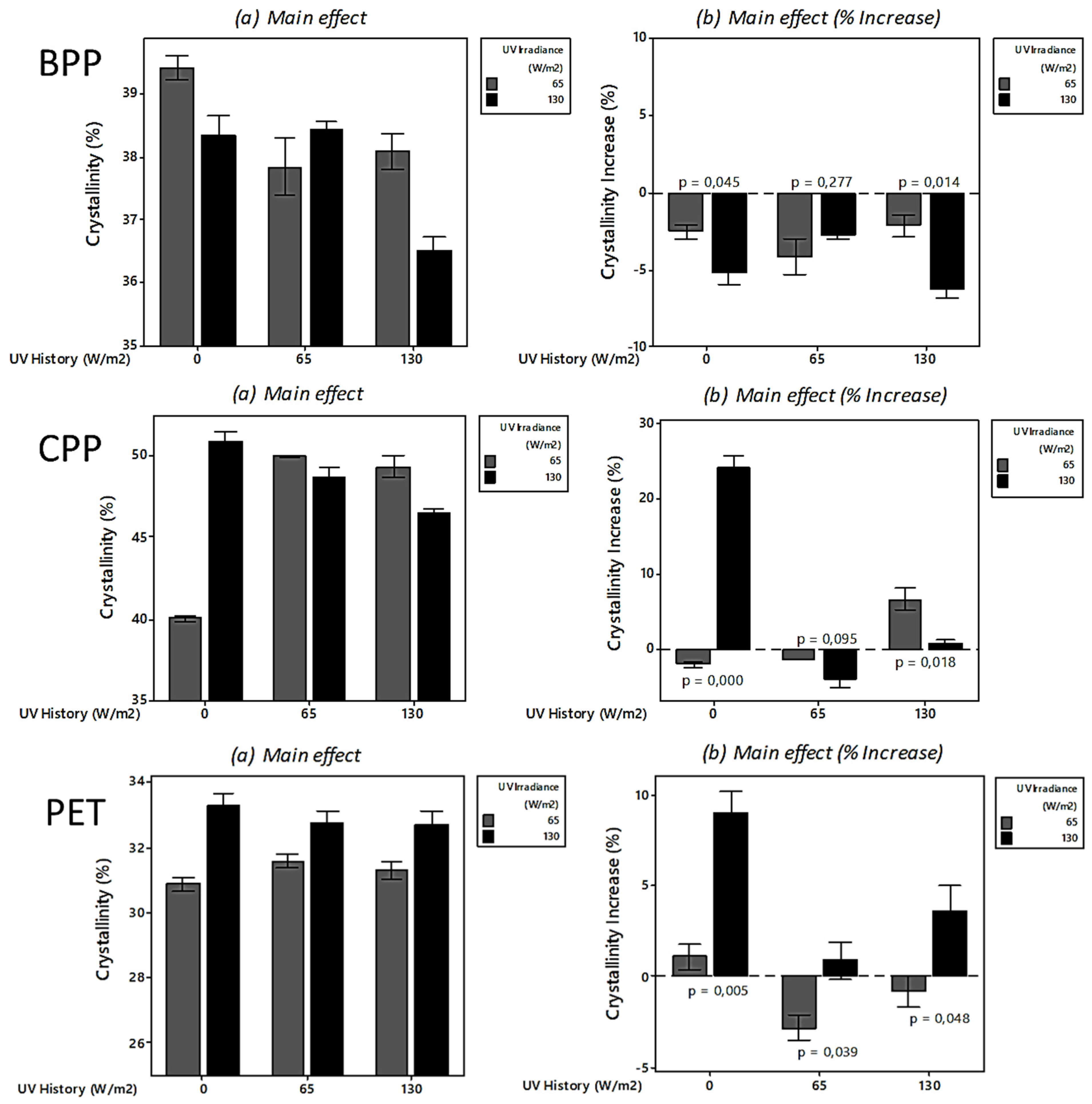

3.1.2. Crystallinity

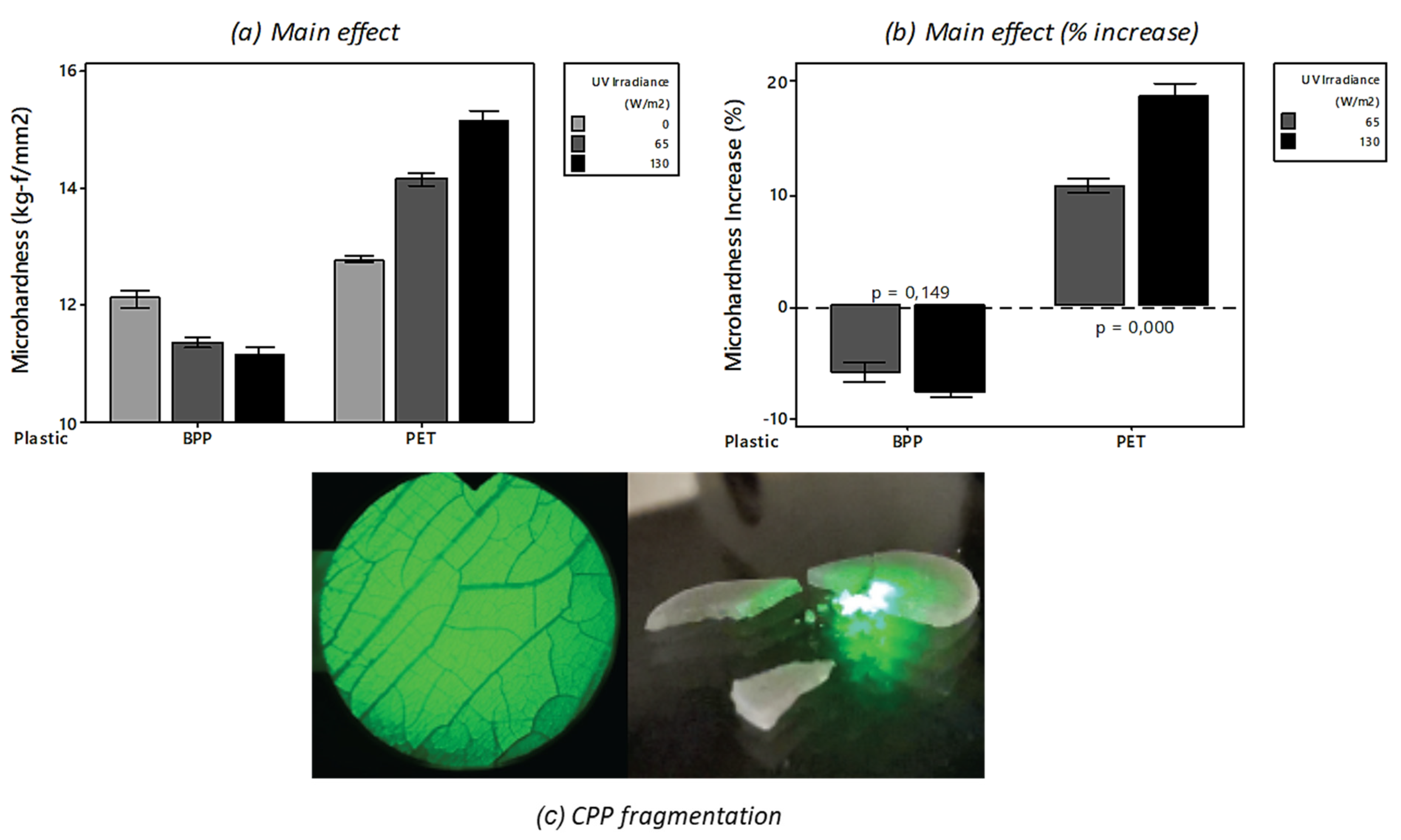

3.1.3. Microhardness

3.1.4. Carbonyl Indices

3.2. UV Tests in Aqueous Environment

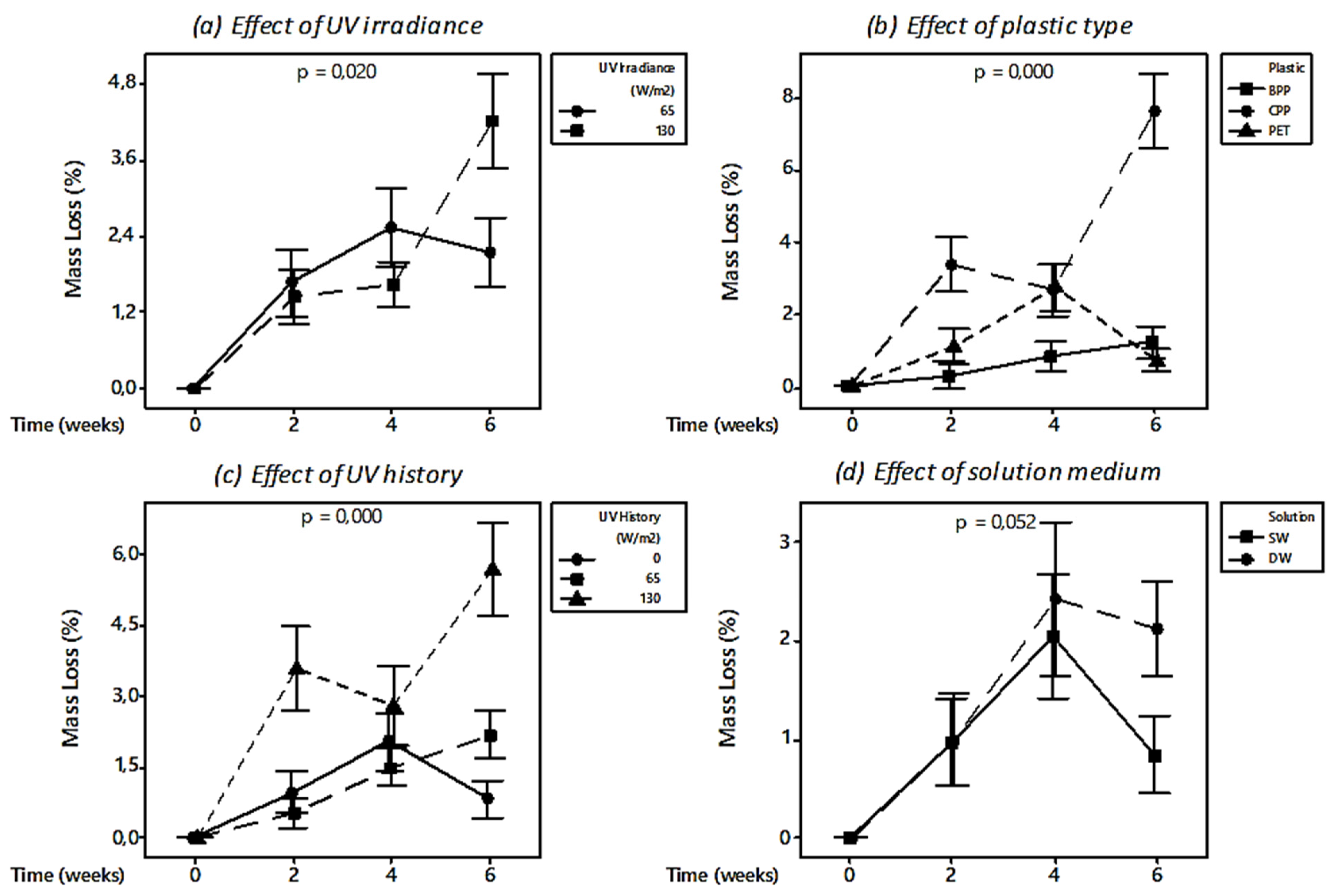

3.2.1. Mass Loss

3.2.2. Crystallinity

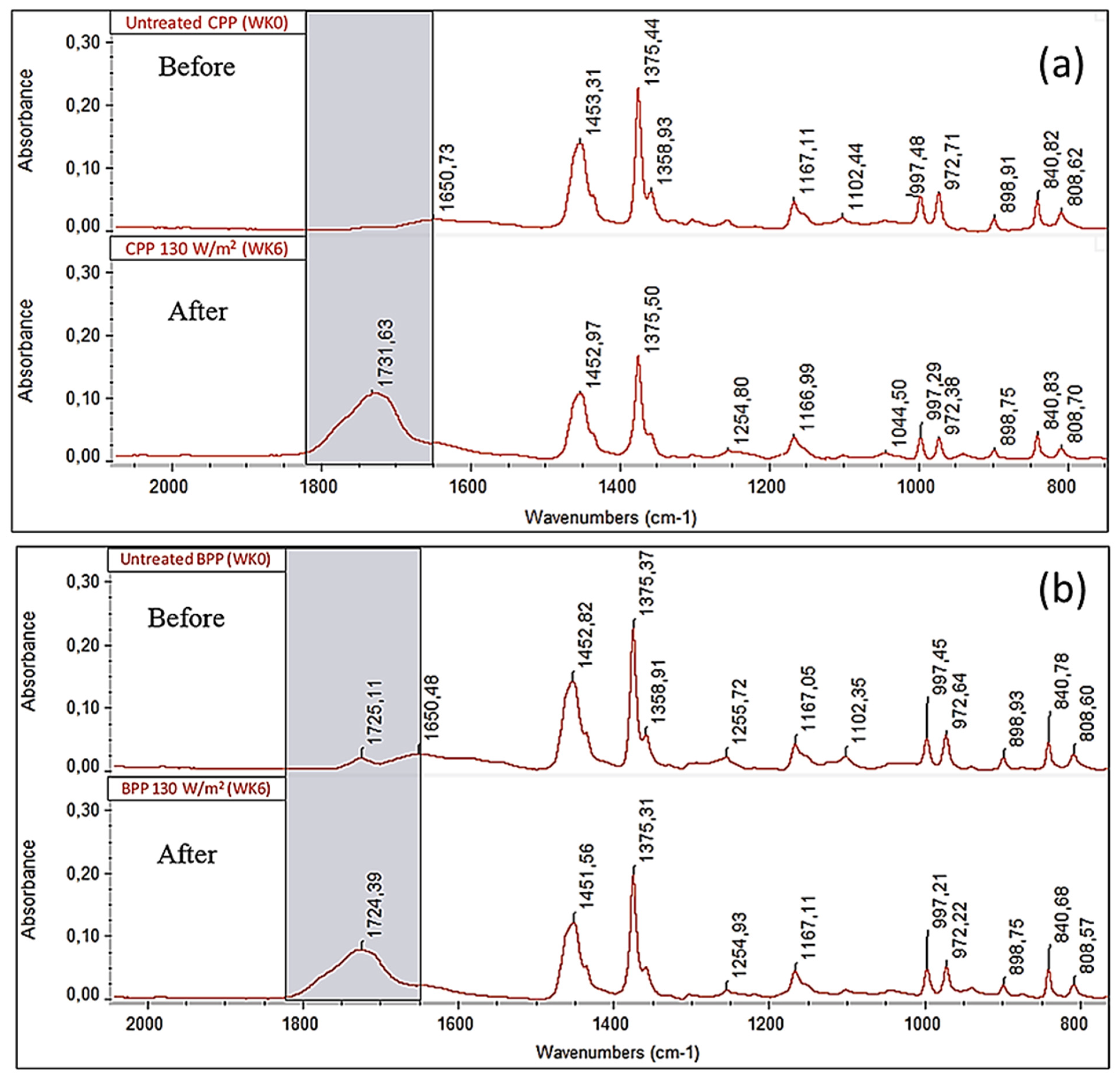

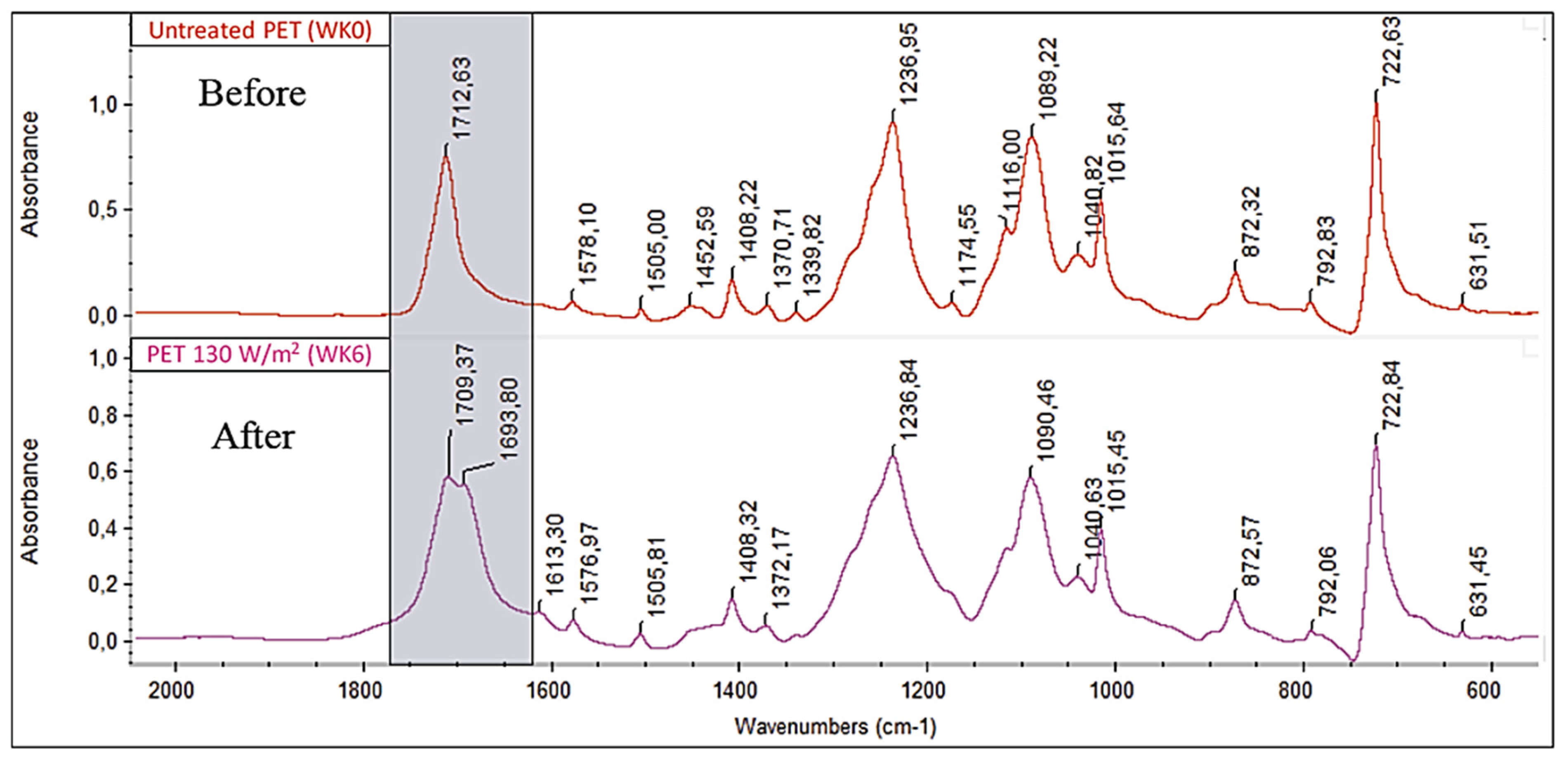

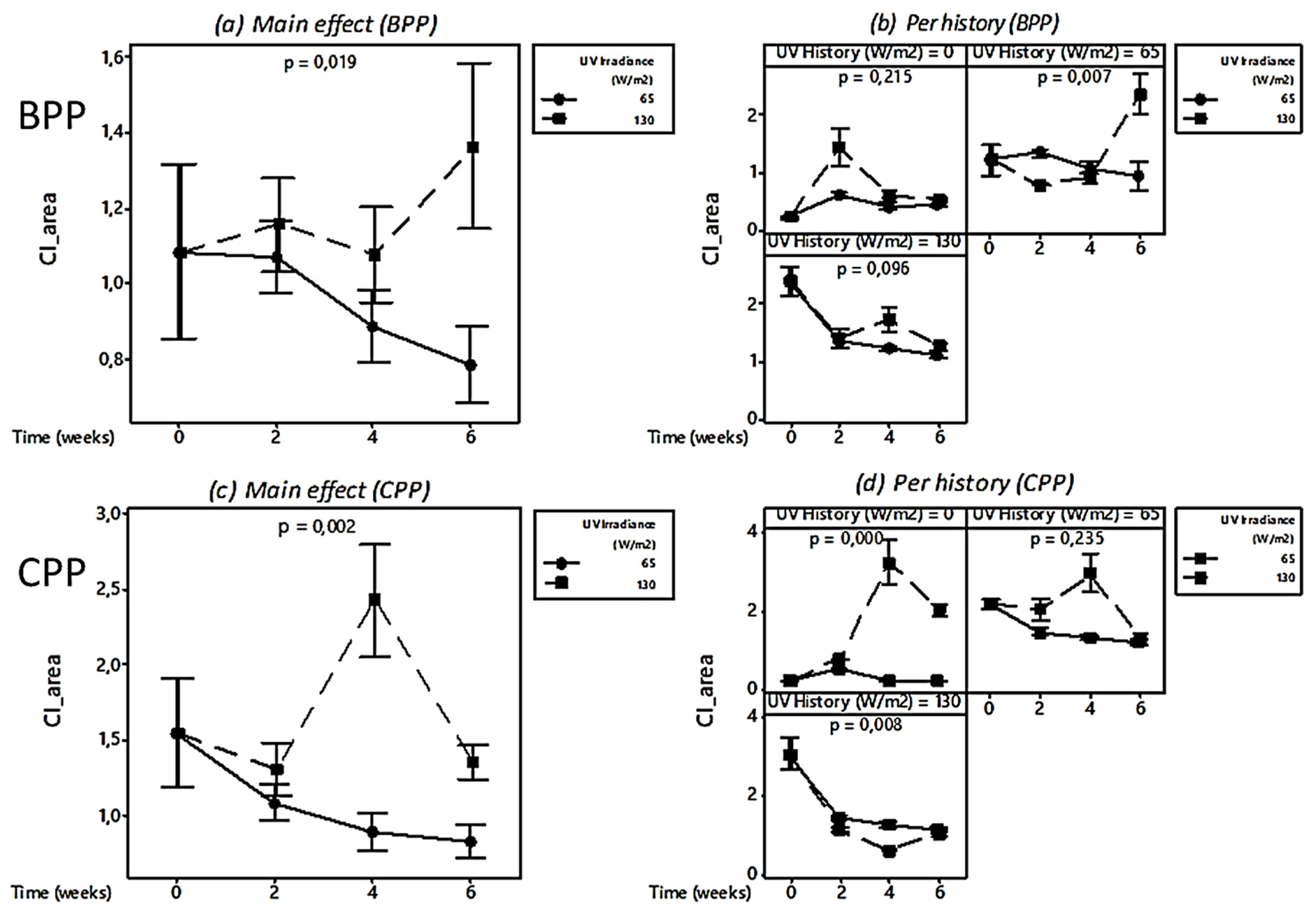

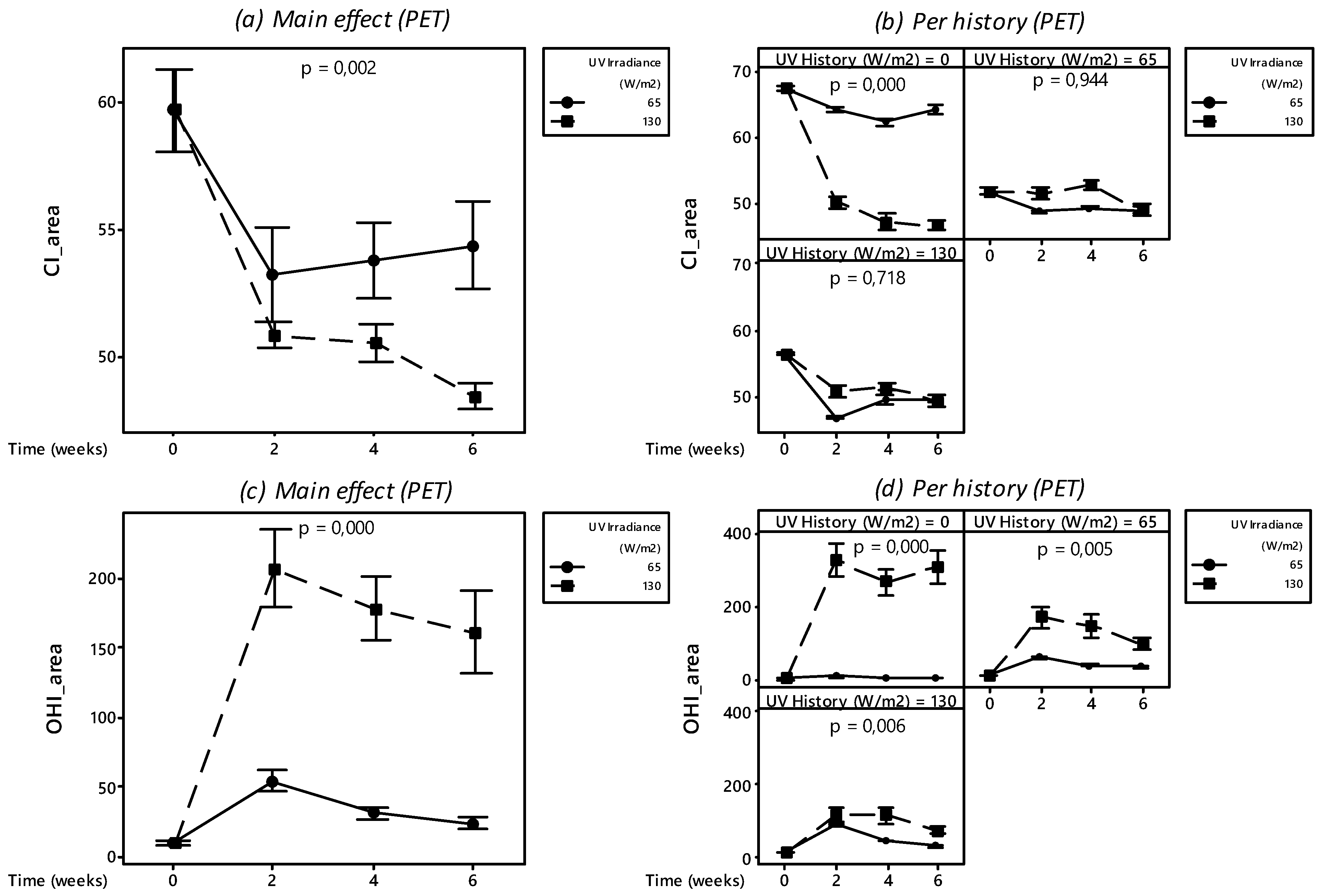

3.2.3. FTIR Indices

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Plastics Europe, Plastics—The Facts 2019: An Analysis of European Plastics Production, Demand and Waste Data. 2019. Available online: https://www.plasticseurope.org/en/resources/market-data (accessed on 18 May 2022).

- Kershaw, P. Sources, Fate and Effects of Microplastics in the Marine Environment: Part Two of a Global Assessment; IMO/FAO/UNESCO IOC/UNIDO/WMO/IAEA/UN/UNEP/UNDP Joint Group of Experts on the Scientific Aspects of Marine Environmental Protection; International Maritime Organization: London, UK, 2016; Volume 93, p. 220. [Google Scholar]

- Gewert, B.; Plassmann, M.M.; MacLeod, M. Pathways for degradation of plastic polymers floating in the marine environment. Environ. Sci. Processes Impacts 2015, 17, 1513–1521. [Google Scholar] [CrossRef]

- Zambrano, M.C.; Pawlak, J.J.; Daystar, J.; Ankeny, M.; Cheng, J.J.; Venditti, R.A. Microfibers generated from the laundering of cotton, rayon and polyester based fabrics and their aquatic biodegradation. Mar. Pollut. Bull. 2019, 142, 394–407. [Google Scholar] [CrossRef]

- Da Costa, J.P.; Nunes, A.R.; Santos, P.S.M.; Girao, A.V.; Duarte, A.C.; Rocha-Santos, T. Degradation of polyethylene microplastics in seawater: Insights into the environmental degradation of polymers. J. Environ. Sci. Health Part A Tox. Hazard. Subst. Environ. Eng. 2018, 53, 866–875. [Google Scholar] [CrossRef]

- Andrady, A.L. Microplastics in the marine environment. Mar. Pollut. Bull. 2011, 62, 1596–1605. [Google Scholar] [CrossRef]

- Sait, S.T.L.; Sørensen, L.; Kubowicz, S.; Vike-Jonas, K.; Gonzalez, S.V.; Asimakopoulos, A.G.; Booth, A.M. Microplastic fibres from synthetic textiles: Environmental degradation and additive chemical content. Environ. Pollut. 2021, 268, 115745. [Google Scholar] [CrossRef]

- Sørensen, L.; Groven, A.S.; Hovsbakken, I.A.; Del Puerto, O.; Krause, D.F.; Sarno, A.; Booth, A.M. UV degradation of natural and synthetic microfibers causes fragmentation and release of polymer degradation products and chemical additives. Sci. Total Environ. 2021, 755, 143170. [Google Scholar] [CrossRef]

- Ter Halle, A.; Ladirat, L.; Martignac, M.; Mingotaud, A.F.; Boyron, O.; Perez, E. To what extent are microplastics from the open ocean weathered? Environ. Pollut. 2017, 227, 167–174. [Google Scholar] [CrossRef]

- Cai, L.; Wang, J.; Peng, J.; Wu, Z.; Tan, X. Observation of the degradation of three types of plastic pellets exposed to UV irradiation in three different environments. Sci. Total Environ. 2018, 628−629, 740–747. [Google Scholar] [CrossRef]

- Kumar, A.; Ganesh Anjana, K.; Hinduja, M.; Sujitha, K.; Dharani, G. Review on Plastic Wastes in Marine Environment–Biodegradation and Biotechnological Solutions. Mar. Pollut. Bulletin. 2019, 150, 110733. [Google Scholar]

- Carneiro, P.A.; Nogueira, R.F.P.; Zanoni, M.V.B. Homogeneous photodegradation of C.I. Reactive Blue 4 using a photo-Fenton process under artificial and solar irradiation. Dye. Pigment. 2007, 74, 127–132. [Google Scholar] [CrossRef]

- Asimakopoulos, A.G.; Thomaidis, N.S.; Kannan, K. Widespread occurrence of bisphenol A diglycidyl ethers, p-hydroxybenzoic acid esters (parabens), benzophenone type-UV filters, triclosan, and triclocarban in human urine from Athens, Greece. Sci. Total Environ. 2014, 470–471, 1243–1249. [Google Scholar] [CrossRef]

- Organisation for Economic Co-operation and Development (OECD). Emission Scenario Document on Plastic Additives; Series on Emission Scenario; Documents No. 3; OECD: Paris, France, 2009. [Google Scholar]

- Organisation for Economic Co-operation and Development (OECD). Complementing Document to the Emission Scenario; Document on Plastic Additives: Plastic Additives during the Use of End Products; OECD: Paris, France, 2019. [Google Scholar]

- Andrade, H.; Glüge, J.; Herzke, D.; Ashta, N.M.; Nayagar, S.M.; Scheringer, M. Oceanic long-range transport of organic additives present in plastic products: An overview. Environ. Sci. Eur. 2021, 85, 33. [Google Scholar] [CrossRef]

- Hermabessiere, L.; Dehaut, A.; Paul-Pont, I.; Lacroix, C.; Jezequel, R.; Soudant, P.; Duflos, G. Occurrence and effects of plastic additives on marine environments and organisms: A review. Chemosphere 2017, 182, 781–793. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, M.; Zhang, L.; Wang, K.; Yu, X.; Zheng, Z.; Zheng, R. Sorption behaviors of phenanthrene on the microplastics identified in a mariculture farm in Xiangshan Bay, southeastern China. Sci. Total Environ. 2018, 628, 1617–1626. [Google Scholar] [CrossRef]

- Ziccardi, L.M.; Edgington, A.; Hentz, K.; Kulacki, K.J.; Kane Driscoll, S. Microplastics as vectors for bioaccumulation of hydrophobic organic chemicals in the marine environment: A state-of-the-science review. Environ. Toxicol. Chem. 2016, 35, 1667–1676. [Google Scholar] [CrossRef]

- Sørensen, L.; Rogers, E.; Altin, D.; Salaberria, I.; Booth, A.M. Sorption of PAHs to microplastic and their bioavailability and toxicity to marine copepods under co-exposure conditions. Environ. Pollut. 2020, 258, 113844. [Google Scholar] [CrossRef]

- Halsband, C.; Booth, A.M. Ecological Impacts of Particulate Plastics in Marine Ecosystems. In Particulate Plastics in Terrestrial and Aquatic Environments; Bolan, N.S., Kirkham, M.B., Halsband, C., Nugegoda, D., Ok, Y.S., Eds.; Taylor & Francis Group: Abingdon-on-Thames, UK, 2020; pp. 233–248. [Google Scholar]

- Booth, A.M.; Sørensen, L. Microplastic Fate and Impacts in the Environment. In Handbook of Microplastics in the Environment; Rocha-Santos, T., Costa, M., Mouneyrac, C., Eds.; Springer: Cham, Switzerland, 2020; pp. 1–24. [Google Scholar]

- Vroom, R.J.E.; Koelmans, A.A.; Besseling, E.; Halsband, C. Aging of microplastics promotes their ingestion by marine zooplankton. Environ. Pollut. 2017, 231, 987–996. [Google Scholar] [CrossRef]

- Xia, B.; Sui, Q.; Du, Y.; Wang, L.; Jing, J.; Zhu, L.; Zhao, X.; Sun, X.; Booth, A.M.; Chen, B.; et al. Secondary PVC microplastics are more toxic than primary PVC microplastics to Oryzias melastigma embryos. J. Hazard. Mater. 2022, 424, 127421. [Google Scholar] [CrossRef]

- Primpke, S.; Gerdts, G.; Strand, J.; Scholz-Böttcher, B.; Aliani, S.; Patankar, S.; Lusher, A.; Booth, A.M.; Gomiero, A.; Kögel, T.; et al. Monitoring of microplastic pollution in the Arctic: Recent developments in polymer identification, quality assurance and control (QA/QC), and data reporting. Arct. Sci. 2022, in press. [CrossRef]

- Allen, N.S.; Edge, M.; Mohammadian, M. Hydrolytic degradation of Poly(ethylene terephthalate): Importance of chain scission versus crystallinity. Eur. Polym. J. 1991, 27, 1373–1378. [Google Scholar] [CrossRef]

- Osram GmbH. More Than Just Light—Solutions in Ultraviolet Light; Osram GmbH: Munich, Germany, 2013; Available online: https://docs.rs-online.com/45d7/0900766b81506d14.pdf (accessed on 20 August 2019).

- Riley, J.; Skirrow, G. Chemical Oceanography, 2nd ed.; Academic Press: London, UK, 1975; Volume 2. [Google Scholar]

- Laird, M.; Write, A.; Massie, V.; Clark, B. Marine Environmental Impact Assessment for the Proposed Desalination Plants around the Cape Peninsula, South Africa; Anchor Environmental Consultants Report No. 1768/322; WorleyParsons Group: Cape Town, South Africa, 2017; Available online: https://sahris.sahra.org.za/sites/default/files/heritagereports/Marine%20Environmental%20Impact%20Assessment%20-%20CoCT%20Desalination%20Plants%20-%20Draft%203%20copy.pdf (accessed on 18 May 2022).

- Chamas, A.; Moon, H.; Zheng, J.; Qiu, Y.; Tabassum, T.; Jang, J.H.; Abu-Omar, M.; Scott, S.L.; Suh, S. Degradation Rates of Plastics in the Environment. ACS Sustain. Chem. Eng. 2020, 8, 3494–3511. [Google Scholar] [CrossRef]

- Moore, G.F.; Saunders, S.M. Advances in Biodegradable Polymers, 1st ed.; CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Karger-Kocsis, J. Structure and morphology. In Polypropylene: Structure, Blends and Composites; Chapman & Hall: London, UK, 1995. [Google Scholar]

- Wunderlich, B. Macromolecular Physics V1, 1st ed.; Elsevier Inc.: New York, NY, USA, 1973. [Google Scholar]

- Francois-Heude, A.; Richaud, E.; Desnoux, E.; Colin, X. A general kinetic model for the photothermal oxidation of polypropylene. J. Photochem. Photobiol. A Chem. 2015, 296, 48–65. [Google Scholar] [CrossRef]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering, 9th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015. [Google Scholar]

- Pilař, J.; Michálková, D.; Šlouf, M.; Vacková, T. Long-term accelerated weathering of HAS stabilized PE and PP plaques: Compliance of ESRI, IR, and microhardness data characterizing heterogeneity of photooxidation. Polym. Degrad. Stab. 2015, 120, 114–121. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; Wiley: New York, NY, USA, 1976; ISBN 9780471614210. [Google Scholar]

- Singh, B.; Sharma, N. Mechanistic implications of plastic degradation. Polym. Degrad. Stab. 2008, 93, 561–584. [Google Scholar] [CrossRef]

- McKeen, L.W. The Effect of UV Light and Weather on Plastics and Elastomers, 3rd ed.; Elsevier: Waltham, MA, USA, 2013. [Google Scholar]

- Edge, M.; Hayes, M.; Mohammadian, M.; Allen, N.S.; Jewitt, T.S.; Brems, K.; Jones, K. Aspects of poly(ethylene terephthalate) degradation for archival life and environmental degradation. Polym. Degrad. Stab. 1991, 32, 131–153. [Google Scholar] [CrossRef]

- Nagai, Y.; Ogawa, T.; Zhen, L.Y.; Nishimoto, Y.; Ohishi, F. Analysis of weathering of thermoplastic polyester elastomers—I. Polyether-polyester elastomers. Polym. Degrad. Stab. 1997, 56, 115–121. [Google Scholar] [CrossRef]

- Ehrenstein, G.W.; Richard, P. Theriault. Polymeric Materials: Structure, Properties, Applications; Hanser Verlag: Munich, Germany, 2001; pp. 67–78. [Google Scholar]

- Quan, X.; Fry, E.S. Empirical equation for the index of refraction of seawater. Appl. Opt. 1995, 34, 3477–3480. [Google Scholar] [CrossRef]

- Alimi, O.S.; Claveau-Mallet, D.; Kurusu, R.S.; Lapointe, M.; Bayen, S.; Tufenkji, N. Weathering pathways and protocols for environmentally relevant microplastics and nanoplastics: What are we missing? J. Hazard. Mater. 2022, 423, 126955. [Google Scholar] [CrossRef]

- Lee, Y.K.; Murphy, K.R.; Hur, J. Fluorescence Signatures of Dissolved Organic Matter Leached from Microplastics: Polymers and Additives. Environ. Sci. Technol. 2020, 54, 11905–11914. [Google Scholar] [CrossRef]

- Rabello, M.S.; White, J.R. Photodegradation of polypropylene containing a nucleating agent. Appl. Polym. Sci. 1966, 64, 2505–2517. [Google Scholar] [CrossRef]

- Brandon, J.; Goldstein, M.; Ohman, M.D. Long-term aging and degradation of microplastic particles: Comparing in situ oceanic and experimental weathering patterns. Mar. Pollut. Bull. 2016, 110, 299–308. [Google Scholar] [CrossRef] [PubMed]

- Canopoli, L.; Coulon, F.; Wagland, S.T. Degradation of excavated polyethylene and polypropylene waste from landfill. Sci. Total Environ. 2020, 2020, 698. [Google Scholar] [CrossRef] [PubMed]

- Gok, A. Degradation Pathway Models of Poly(Ethylene-Terephthalate) under Accelerated Weathering Exposures. Ph.D. Thesis, Case Western Reserve University, Cleveland, OH, USA, 2016. [Google Scholar]

- Awaja, F.; Pavel, D. Recycling of PET. Eur. Polym. J. 2005, 41, 1453–1477. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Conradie, W.; Dorfling, C.; Chimphango, A.; Booth, A.M.; Sørensen, L.; Akdogan, G. Investigating the Physicochemical Property Changes of Plastic Packaging Exposed to UV Irradiation and Different Aqueous Environments. Microplastics 2022, 1, 456-476. https://doi.org/10.3390/microplastics1030033

Conradie W, Dorfling C, Chimphango A, Booth AM, Sørensen L, Akdogan G. Investigating the Physicochemical Property Changes of Plastic Packaging Exposed to UV Irradiation and Different Aqueous Environments. Microplastics. 2022; 1(3):456-476. https://doi.org/10.3390/microplastics1030033

Chicago/Turabian StyleConradie, Wihann, Christie Dorfling, Annie Chimphango, Andy M. Booth, Lisbet Sørensen, and Guven Akdogan. 2022. "Investigating the Physicochemical Property Changes of Plastic Packaging Exposed to UV Irradiation and Different Aqueous Environments" Microplastics 1, no. 3: 456-476. https://doi.org/10.3390/microplastics1030033

APA StyleConradie, W., Dorfling, C., Chimphango, A., Booth, A. M., Sørensen, L., & Akdogan, G. (2022). Investigating the Physicochemical Property Changes of Plastic Packaging Exposed to UV Irradiation and Different Aqueous Environments. Microplastics, 1(3), 456-476. https://doi.org/10.3390/microplastics1030033