Abstract

This study investigates a parametric architectural design methodology that arises from the relationship between humans, architecture, and nature and utilizes modern technological means and sustainable construction materials. Specifically, it concerns a structure of mycelium bio-composite, produced at the lowest possible environmental cost. The design uses an optimal structural form to maximize the material’s efficiency. The development of the structure is initially modular, using two different types of geometric blocks. At the same time, the whole structure gradually becomes monolithic with the help of the plant part of the fungi, the mycelium. The basic 2D arch structure is initially assembled using two different geometric blocks. More complex configurations can be derived from this foundational module to meet various requirements for applications and structures. The structure will be constructed entirely of load-bearing mycelium blocks, with its geometry specifically designed to emphasize compression forms, enhancing the structural performance of the inherently weak material. This approach reflects an innovative vision for construction materials grounded in the principles of cultivation and growth from natural, earth-derived resources.

1. Introduction

The rapid advancements in the field of biomaterials have opened up new prospects for the construction industry, particularly in the realm of sustainable and eco-friendly building practices. The use of mycelium-based bio-composites has emerged as a promising alternative to traditional construction materials, offering a unique blend of structural integrity, environmental friendliness, and design flexibility [1,2,3,4]. The literature emphasizes the critical requirement for new sustainable, environmentally friendly, durable materials suitable for structural and architectural applications [5].

Mycelium-based materials provide substantial ecological benefits compared to conventional engineered materials. However, they typically exhibit low structural strength, particularly in tension and bending. To effectively create using these materials and overcome their structural limitations, it is crucial to utilize optimal geometry. This ensures stability primarily through compression, relying on contact equilibrium rather than material strength. This approach allows for the use of weaker materials by achieving stability through geometric design principles [6]. Mycelium bio-composites are environmentally friendly materials created by utilizing the natural growth process of fungal mycelium on organic waste substrates. Mycelium acts as a natural adhesive, binding the organic material into a solid composite. These bio-composites are adaptable and can be customized for various applications. The resulting materials can have a wide range of properties, including elasticity, stiffness, porosity, and water resistance, making them suitable for construction, textiles, packaging, and more. Additionally, mycelium-based materials are biodegradable, cost-effective, and require minimal energy for production, making them a sustainable alternative to traditional building materials. Recently, mycelium bio-composite blocks have been increasingly incorporated into architectural projects, showcasing their potential as a sustainable and innovative building material [1,2].

Prototypological research in architecture involves developing full-scale prototypes as tools for systematic investigation within a broader research framework [7]. Despite their inherent weakness, mycelium-based composite materials can be enhanced with natural fibers to improve their density, structural integrity, and load-bearing capacity for optimized use in large-scale architectural applications [4,8]. In the real-world applications cited in this work, the structures are primarily designed to withstand compression loads, with the mycelium components supporting both their own weight and the weight of the grid. The average values of density are obtained from the literature [9] (2024 Voutetaki)—222 Kg/m3, 1105 kPa compression strength, and 505 kPa flexural strength. Furthermore, reinforcements can be strategically developed to create efficient or multifunctional composites, such as designing the primary substrate for thermal performance while adding structural reinforcement particles [10,11]. The integration of mycelium bio-composites into architectural parametric design has the potential to revolutionize the way we approach building design and construction [12,13,14].

Parametric design, a computational design approach that leverages algorithmic processes to generate and manipulate complex geometries, can be seamlessly combined with the unique properties of mycelium bio-composites. This synergy allows architects and designers to explore novel architectural forms and spatial configurations that are not only visually striking, but also environmentally responsible [12,15,16].

The use of mycelium bio-composites in parametric design can offer several advantages. For instance, the material’s ability to be molded into complex shapes aligns well with the intricate geometries generated in parametric design. Moreover, the material’s inherent structural properties can be optimized through parametric modeling, allowing for the creation of efficient and resilient building components [17].

Significant advancements related to the use of mycelium biomaterials in architecture have been recorded during the past decade [18]. Almpani-Lekka et al. [19] have highlighted six architectural projects that present various design strategies, fabrication techniques, and post-processing methods and have made notable technical contributions.

Structural efficiency is crucial in architectural construction, as it focuses on reducing material consumption while maximizing load-bearing capacity. The use of tetrahedral units in architectural applications presents significant advantages due to their inherent stability. An innovative modular structural system for tall buildings utilizes tetrahedral units to explore architectural implications, mechanical performance, and economical design optimization. It also includes guidelines and analytical formulas for preliminary member sizing based on stiffness requirements [20]. The incorporation of tetrahedral units in architectural design offers a compelling and complex field of study, addressing both aesthetic impacts and the detailed considerations of mechanical performance and cost efficiency. Researchers are investigating strategies like optimizing spatial structure shapes and using curved geometries to align with internal stress flows. A notable approach is the application of chain models, which can significantly decrease bending moments and enhance overall structural performance. The optimal utilization of mycelium in construction maximizes its inherent structural performance, enabling more ambitious architectural applications despite its natural compressive strength limitations. Inspired by the principle of the inverted catenary arch, which aims to reduce the bending moment—as in the Chapel of the Holy Shroud, designed by Italian architect Guarino Guarini—catenary frames can create architectural pavilions [21]. Another paper [22] examines the minimization of bending moments in arches using a multi-body rope approach. This method focuses on dynamic numerical simulations of hanging nets, which helps in identifying optimal arch forms that minimize internal stresses [23].

The present work aims to investigate the structural potential of an arch structure by exploring various assembly configurations, from simple to complex structures, utilizing basic modules made from mycelium composites. Despite the inherent weaknesses of mycelium composite materials, specific morphological configurations can effectively enhance their load-bearing capacity. The arch shape eliminates tension by converting it into compression, taking advantage of its higher compressive strength. The structural form of a tetrahedron utilizing the catenary arch model is combined to create a joint block, optimizing the use of mycelium material in a parametric arch structure. Additionally, it can serve as an invaluable educational resource in architectural studies, providing students with deep insights into innovative materials and cutting-edge design methodologies. This comprehensive procedure enriches their understanding of structural efficiency and also inspires architects to explore and implement advanced design principles in their projects. In conclusion, the final section provides a summary of the work and the process.

2. Materials and Methods

The general approach of the present study is to design a structure that grows organically, just like the material made from mycelium, with the goals of enhancing sustainability and minimizing environmental impact. Since this material is relatively new, particularly in the field of architecture, there have been limited comprehensive life cycle assessment studies conducted so far. However, based on some recent findings, mycelium bio-composite materials hold significant potential for sustainable architecture due to their use of industrial byproducts. These composites are fully biodegradable, which greatly reduces their environmental impact. Their production is energy efficient, requiring less energy than traditional building materials, and they offer a substantially lower carbon footprint in the construction industry. Additionally, mycelium bio-composites can be composted at the end of their life cycle, allowing them to be repurposed as agricultural fertilizer. Upon disposal, MBCs naturally decompose and reintegrate into the environment. Furthermore, mycelium bio-composites are non-flammable and offer excellent thermal and sound insulation properties [24,25,26].

Creating a scalable and adaptable structure requires understanding of the fundamental human needs and the guarantee of flexibility for future growth and changes. While mycelium composite materials offer significant ecological benefits over established engineered materials, they may have comparatively lower structural strength.

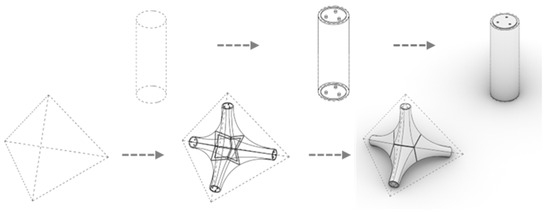

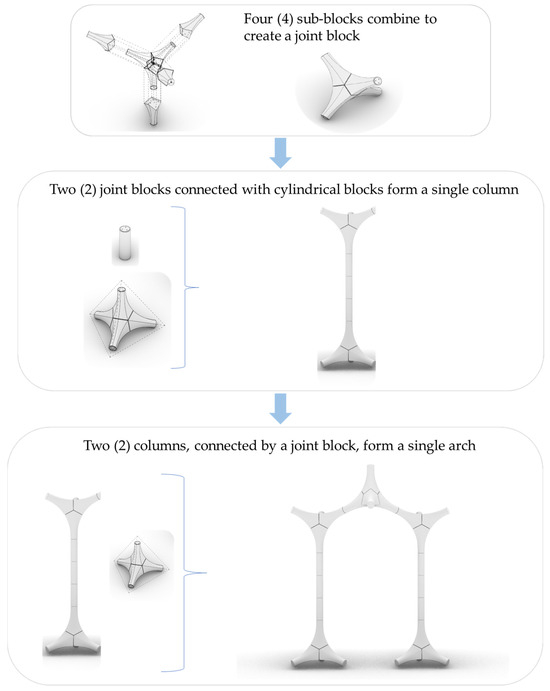

Two types of geometric blocks define the structure’s form, as depicted in Figure 1. New innovative technologies, such as parametric design programs and 3D printing fabrication, are employed to achieve greater morphological freedom, aiming primarily for more efficient use of materials and their properties. The geometry of the pieces is based on the basic shapes of the tetrahedron and the cylinder.

Figure 1.

Types of geometric blocks—tetrahedrons, cylinders—and their modification.

2.1. Construction

2.1.1. Material

The available local agricultural waste allows the selection of substrate and molds and, consequently, the construction morphology to make the mycelium composite biomaterial. This method reduces landfill waste, stimulates a circular economy, and creates renewable and biodegradable mycelium composites, contributing to environmental sustainability. The development of the hemp fiber-reinforced biomaterial progresses gradually through three phases [19,27,28,29]:

Phase I: the mycelium seeds are initially placed in the substrate, where they grow by attaching to and replacing the substrate with fungal biomass.

Phase II: Upon completion of the previous phase, the mycelium parasitizes the potato starch mold, forming a monolithic structure. The outer layer of the fungal cell wall contains hydrophobins, a type of protein with hydrophobic properties. Consequently, a dense mycelial network develops on the exterior of the molds, providing the construction with the necessary water resistance [30,31].

Phase III: Finally, the mycelium fills the gaps between neighboring pieces, repeating the same process. This is possible because the mycelium can bridge gaps of up to 6 mm [32].

Mycelium-based binders in composite materials provide an environmentally friendly alternative to synthetic adhesives, reducing harmful emissions and enhancing mechanical strength [33].

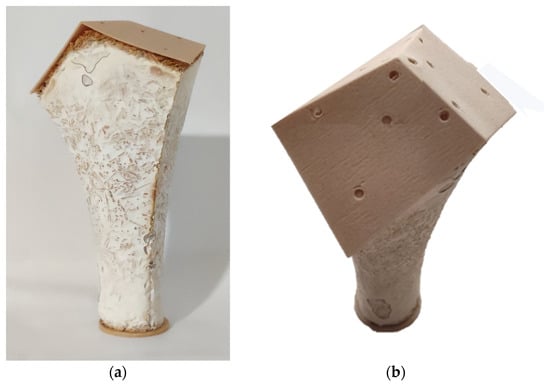

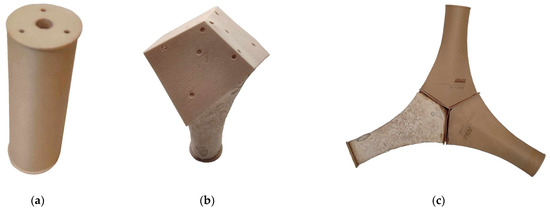

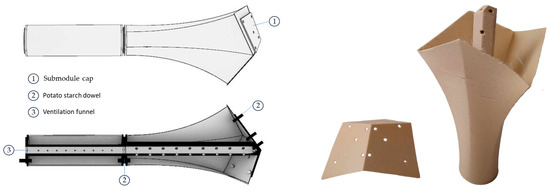

In general, due to the demanding process of mycelium development and the biomaterial’s inability to withstand mechanical stresses, especially bending loads, developing it in small pieces is preferred. Consequently, the maximum size chosen for the individual parts making up the pieces is 20 cm. This limitation also stems from the maximum size that can be printed by a conventional 3D printer. Figure 2 shows the geometric sub-block, made from Ganoderma lucidum mycelium cultivated in a hemp fiber substrate, used in the present work.

Figure 2.

The geometric sub-block made from Ganoderma lucidum mycelium cultivated in a hemp fiber substrate (GIY kit, Ecovative). One of three types of geometric building elements with different geometry produced in the context of a Diploma Thesis in the Department of Architectural Engineering, and used in the present study. (a) Front view, (b) top view.

2.1.2. Geometric Blocks

In order to achieve the maximum material strength of the blocks, they were designed based on a Platonic solid: the tetrahedron. Due to its geometric properties, the tetrahedron is considered one of the most highly stable Platonic solids. Each of the four faces of a tetrahedron is a triangle, which is inherently rigid, contributing to its overall stability and ability to distribute stress evenly across its structure. This stability makes it an excellent choice for designs requiring maximum compressive strength [34]. The edges have been replaced by circular surface connection points, and the shell features a double-curved chain-curve profile. The main advantages of using a catenary curve in the design include optimal load distribution, reduced tensile and stretching stresses, material efficiency, and aesthetic appeal. These benefits led to the selection of this curve for shaping the molds and the final blocks. Consequently, the arrangement of the modules could simulate the crystalline structure of diamonds.

The ratio of compressive strength to weight in mycelium bio-composites is comparable to that of concrete. The substrate’s granulometry significantly influences its density, which correlates with compressive strength. Typically, mycelium bio-composites exhibit compressive strength approximately three times greater than their tensile strength [4,35].

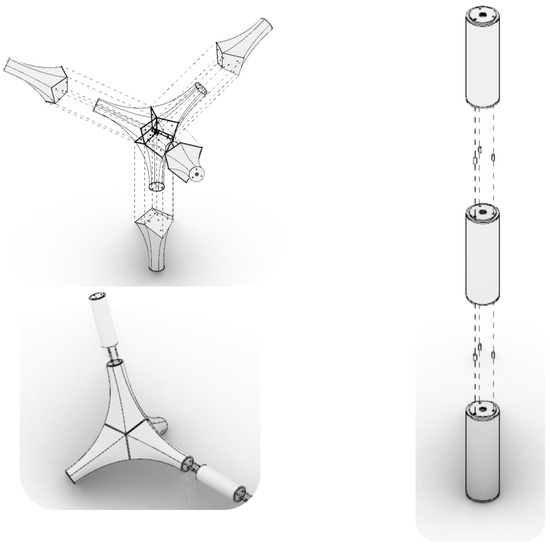

The approach to organizing the hemp sub-blocks is depicted in Figure 3.

Figure 3.

Assembling the geometric blocks.

2.1.3. Parametric Design

Parametric design refers to a design methodology derived from algorithmic relationships among specific construction parameters. This approach fosters a dynamic relationship between design intent and the final outcome. While this design method does not inherently rely on computer systems, technological advancements enable the creation of increasingly intricate forms. Coupled with digital manufacturing techniques like 3D printing, these advancements allow for the realization of forms and spaces that were previously impossible to achieve. This design method was chosen for its organic character, mirroring the developmental processes of living organisms. Moreover, the goal of the project is to foster collaboration among humans, nature, and technology.

The structure’s geometry was designed using double-curvature geometries, hanging chain models, and the segmentation of pieces into individual units. This aims to maximize the material’s compressive capacity, minimize flexural loads, and allow for greater flexibility in scaling.

2.1.4. Molds and 3D Printing

In this study, 3D printing was utilized to create molds for the fiber-reinforced mycelium substrate. Figure 4 illustrates the molds created through 3D printing for the two basic geometrical blocks.

Figure 4.

The molds created from 3D printing for the two basic geometrical blocks (PLA, Prusa Research); (a) cylinder geometric block; (b) one from the four sub-blocks of the joint geometric block; (c) joint geometric block.

The primary advantage of this method is the digital production of intricately shaped pieces with complex geometry and the ability to connect them. Specifically, the 3D printing technique employed is Fused Filament Fabrication (FFF) [36]. In this method, solid filaments, typically made from recycled plastic, are melted at high temperatures and deposited layer by layer as they solidify, forming the desired final shape. However, despite the prevalence of recycled plastic filaments, their use was not preferred for this study. Instead, the requirement was to utilize molds crafted solely from natural organic materials.

The filament proposed in this study falls under bioplastics, which are derived from biodegradable materials and renewable sources like potato starch, coffee beans, and biowaste [27]. This category represents an experimental stage, and the existing literature on it is still relatively limited. As a result, the molds have multiple roles. Apart from defining the shapes of the pieces, they also provide the fungus with the substances necessary for its growth, are integrated into the construction, and enhance the resistance of the final material to mechanical stress.

Figure 5 illustrates a flowchart of the production of the geometrical blocks and the basic 2D arch structure.

Figure 5.

Flowchart of production of geometrical blocks and basic 2D arch structure.

2.1.5. Assembly Method of Geometric Sub-Blocks

The construction software and corresponding molds were created using Rhinoceros 8.9.24194.18121, the Grasshopper plug-in visual programming language, and the WASP extension. The molds were created using the Prusa MK4 3D printer and PrusaSlicer 2.8.0 software. The filaments used include PLA, which is used for convenience due to the unavailability of potato starch from PRUSA RESEARCH and Woodfill from ColorFabb.

The geometric sub-blocks were designed using cylinders and Platonic solids, such as tetrahedrons, chosen for their specific properties. Incorporating double-curvature geometries and chain-curve profiles, as well as dividing the pieces into individual units, was intended to enhance the material’s compressive strength, reduce bending stresses, and maximize scalability.

Each mold needed to be perforated to allow the fungus to breathe. However, to prevent the growth of fruiting bodies (mushrooms), these perforations had to be kept small. Each piece contained integrated perforated channels, which added strength and provided air, ensuring more homogeneous growth of the organism. Figure 6 shows the ventilation funnel in number 3.

Figure 6.

Details of the geometric sub-blocks’ assembly.

The FFF technique explored in the present paper allows for morphological freedom, making it possible to create complex geometries. The printing filament was created using potato starch, which encourages fungal growth and provides elasticity and support to individual pieces. The surface connection cover played a crucial role in enhancing the distribution of the load across the individual pieces. When combined with the interior conductors, it enabled the seamless connection of each piece to the neighboring pieces, providing a reliable and efficient means of joining the components (Figure 6, number 1). Additionally, the openings in these covers promoted the spread of the mycelium. The different components of the structure were joined using wedges (Figure 6, number 2).

3. Results

The structure’s form and function are flexible and depend on the specific availability and requirements. The structure can be utilized as a pavilion or as a complementary backdrop for theater sets, offering opportunities for creative expression and adaptation to the specific requirements of each project. The design is constrained by the shapes of the structural components, the potential spatial relationships they could form, and the methods of their connections. The primary factors that influence the design are:

- The environment and the space to be covered;

- The available local agricultural waste in the area;

- The nature of the bio-composite and its development process;

- The molds and their manufacturing and connection method.

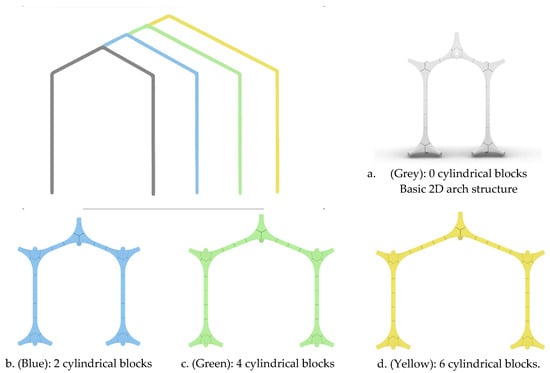

3.1. Progressing from Simple to Extended Construction

3.1.1. The Basic 2D Arch Structure

This section aims to propose an arch structural system by exploring various examples of potential assemblies, ranging from simple to more extended structures, using basic modules. The basic 2D arch structure and the modifications needed in order to extend its span are illustrated in Figure 7 (a flowchart of the production of the geometrical blocks and the basic structure). As shown, the arch is assembled by connecting geometric joint blocks with cylindrical blocks. To adjust the dimensions, additional cylindrical blocks can be added, allowing for an increase in the opening and, possibly, the height of the arch.

Figure 7.

The basic 2D arch structure and its modifications. (a) The assembly of a joint block represents the beam between two columns to make an arch. (b) Assembling a joint and two additional cylindrical blocks to extend the span between the two columns of the arch. (c) The same as b, but instead of two, four additional cylindrical blocks. (d) The same as (b), but instead of two, six additional cylindrical blocks.

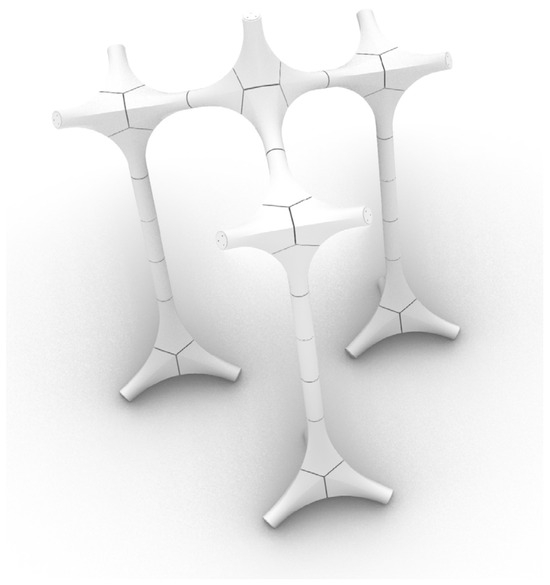

3.1.2. Modifying Structure from 2D to 3D

The application of this assembling method can be expanded into the realm of three-dimensional design, allowing for a more comprehensive and multifaceted approach to building and developing a structure. Figure 8 illustrates the basic 3D structure of arches. As shown in Figure 8, an additional column is assembled into the basic 2D arch structure to create a 3D structure. This expansion allows for greater complexity and innovation in structural design, enhancing architectural possibilities.

Figure 8.

The basic 3D arch structure.

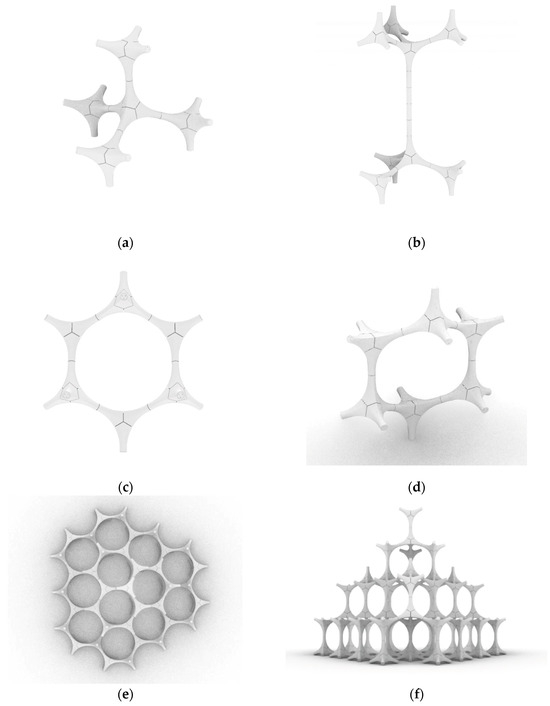

3.1.3. Different Approaches to Utilizing Geometric Blocks

There are many different perspectives on assembling geometric blocks to create various forms and fulfil different purposes. These include decorative objects, furniture, scenery for cultural events, exhibition pavilions, and a wide range of architectural elements or objects, each offering unique design possibilities and functional benefits. Figure 9a,b illustrate assemblies that can serve as bases for objects such as chairs or floor lamps, respectively. Figure 9c,d show an assembly of six joint blocks forming a circular structure. Figure 9e illustrates a combination of cycles, while Figure 9f presents a diamond crystal form structure. Joint blocks are generally used to create curved forms, whereas cylindrical objects are employed as extensions.

Figure 9.

Assembling geometric blocks in different ways: (a) joint; (b) column; (c) circle; (d) circle, 3D version; (e) combination of circles; (f) diamond crystal structure.

In addition, exploring different approaches to utilizing geometric blocks, such as tetrahedral or cylindrical units, can significantly enrich architectural studies by offering students a deeper understanding of structural efficiency and innovative design methodologies. These geometric blocks serve as a practical tool for exploring the fundamental principles of stability, load distribution, and modular construction. By experimenting with various configurations and applications of geometric blocks, students gain hands-on experience with cutting-edge materials and techniques. This exposure enhances their technical skills and also promotes creativity, encouraging future architects to introduce advanced design principles into their projects.

4. Discussion and Conclusions

Mycelium-based composites have the potential to replace conventional materials in architectural applications. This study employs modern technological methods and parametric design to explore the use of tetrahedral joint blocks in creating arch structures. These technological methods aim to optimize production processes, enhance material properties, and increase scalability. Initially, the focus was on simple assemblies, and it progressed to the use of various configurations of base modules to construct structures using sustainable mycelium bio-composite material, bearing in mind its inherent weaknesses. The emphasis is on effective material use to create large-scale structures. By maximizing material usage and minimizing bending moments and internal stresses, it is possible to design large-scale structures that efficiently distribute loads and maintain stability. Mycelium composite materials offer lightweight, regenerative properties, addressing the challenges associated with architectural bio-applications.

The proposal of the present work uses fundamental modules to explore an arch structure by examining various potential assemblies, from simple to more complex. The material properties of the mycelium bio-composite can influence the span of the basic 2D arch structure and its modifications. Geometric objects offer unlimited possibilities and can be arranged in various ways to create diverse architectural structures tailored to meet a wide range of needs in both 2D and 3D, for large- or small-scale projects.

This paper outlines the early stages of a broader investigation into the potential of mycelium-based composites as an alternative construction material. Future research could examine the impacts of various fungal species and substrates on mechanical properties and explore the potential for maximum span configurations. Additionally, efforts should focus on optimizing environmental conditions and cultivation processes. Future challenges include scaling up the manufacturing process for mycelium composites and developing creative geometries using this innovative bio-based material.

Author Contributions

Conceptualization, E.T.G.; Methodology, E.T.G., M.E.V. and D.G.G.; Software, E.T.G.; Validation, M.E.V. and D.G.G.; Formal Analysis, M.E.V.; Investigation, E.T.G., M.E.V. and D.G.G.; Resources, E.T.G., M.E.V. and D.G.G.; Data Curation, E.T.G., M.E.V. and D.G.G.; Writing—Original Draft Preparation, M.E.V.; Writing—Review & Editing, M.E.V.; Visualization, E.T.G. and D.G.G.; Supervision, M.E.V., E.T.G. and D.G.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data is contained within the article.

Acknowledgments

The authors would like to acknowledge the assistance from Panagiotis Kozokos, of the Architectural Engineering Department, School of Engineering, Democritus University of Thrace, for his insightful feedback and suggestions throughout the research process.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sharma, M.; Verma, S.; Chauhan, G.; Arya, M.; Kumari, A. Mycelium-Based Biocomposites: Synthesis and Applications. Environ. Sustain. 2024. [Google Scholar] [CrossRef]

- Ghazvinian, A.; Farrokhsiar, P.; Vieira, F.; Pecchia, J.; Gursoy, B. Mycelium-Based Bio-Composites for Architecture: Assessing the Effects of Cultivation Factors on Compressive Strength. In Proceedings of the Blucher Design Proceedings, Porto, Portugal, 11–13 September 2019; pp. 505–514. [Google Scholar]

- Dessi-Olive, J. Strategies for Growing Large-Scale Mycelium Structures. Biomimetics 2022, 7, 129. [Google Scholar] [CrossRef] [PubMed]

- Alaneme, K.K.; Anaele, J.U.; Oke, T.M.; Kareem, S.A.; Adediran, M.; Ajibuwa, O.A.; Anabaranze, Y.O. Mycelium Based Composites: A Review of Their Bio-Fabrication Procedures, Material Properties and Potential for Green Building and Construction Applications. Alex. Eng. J. 2023, 83, 234–250. [Google Scholar] [CrossRef]

- Thomoglou, A.K.; Voutetaki, M.E.; Fantidis, J.G.; Chalioris, C.E. Novel Natural Bee Brick with a Low Energy Footprint for “Green” Masonry Walls: Mechanical Properties. Eng. Proc. 2024, 60, 9. [Google Scholar] [CrossRef]

- Heisel, F. Design of a Load-Bearing Mycelium Structure through Informed Structural Engineering: The MycoTree at the 2017 Seoul Biennale of Architecture and Urbanism. In Proceedings of the World Congress on Sustainable Technologies (WCST-2017), Cambridge, UK, 4–6 November 2017. [Google Scholar]

- Heisel, F.; Hebel, D.E. Pioneering Construction Materials through Prototypological Research. Biomimetics 2019, 4, 56. [Google Scholar] [CrossRef]

- Karana, E.; Blauwhoff, D.; Hultink, E.-J.; Camere, S. When the material grows: A case study on designing (with) mycelium-based materials. Int. J. Des. 2018, 12, 119–136. [Google Scholar]

- Voutetaki, M.E.; Mpalaskas, A.C. Natural Fiber-Reinforced Mycelium Composite for Innovative and Sustainable Construction Materials. Fibers 2024, 12, 57. [Google Scholar] [CrossRef]

- Rigobello, A.; Colmo, C.; Ayres, P. Effect of Composition Strategies on Mycelium-Based Composites Flexural Behaviour. Biomimetics 2022, 7, 53. [Google Scholar] [CrossRef] [PubMed]

- Elsacker, E.; De Laet, L.; Peeters, E. Functional Grading of Mycelium Materials with Inorganic Particles: The Effect of Nanoclay on the Biological, Chemical and Mechanical Properties. Biomimetics 2022, 7, 57. [Google Scholar] [CrossRef]

- Attias, N.; Danai, O.; Abitbol, T.; Tarazi, E.; Ezov, N.; Pereman, I.; Grobman, Y.J. Mycelium Bio-Composites in Industrial Design and Architecture: Comparative Review and Experimental Analysis. J. Clean. Prod. 2020, 246, 119037. [Google Scholar] [CrossRef]

- Modanloo, B.; Ghazvinian, A.; Matini, M.; Andaroodi, E. Tilted Arch; Implementation of Additive Manufacturing and Bio-Welding of Mycelium-Based Composites. Biomimetics 2021, 6, 68. [Google Scholar] [CrossRef] [PubMed]

- Rigobello, A.; Ayres, P. Design Strategies for Mycelium-Based Composites. In Fungi and Fungal Products in Human Welfare and Biotechnology; Satyanarayana, T., Deshmukh, S.K., Eds.; Springer Nature: Singapore, 2023; pp. 605–635. ISBN 978-981-19885-2-3. [Google Scholar]

- Sydor, M.; Bonenberg, A.; Doczekalska, B.; Cofta, G. Mycelium-Based Composites in Art, Architecture, and Interior Design: A Review. Polymers 2021, 14, 145. [Google Scholar] [CrossRef] [PubMed]

- Beghini, L.L.; Carrion, J.; Beghini, A.; Mazurek, A.; Baker, W.F. Structural Optimization Using Graphic Statics. Struct. Multidisc. Optim. 2014, 49, 351–366. [Google Scholar] [CrossRef]

- Javadian, A.; Le Ferrand, H.; Hebel, D.E.; Saeidi, N. Application of Mycelium-Bound Composite Materials in Construction Industry: A Short Review. SOJMSE 2020, 7, 1–9. [Google Scholar] [CrossRef]

- Sanches Previti, I.; Sachs, H. Mycelion: A Wood-Mycelium Composite-Based, Experimental Pavilion with Multiple Growth Phases. In Proceedings of the SIGraDi 2023 Accelerated Landscapes XXVII International Conference of the Ibero-American Society of Digital Graphics, Maldonado, Uruguay, 29 November–1 December 2024; pp. 410–421. [Google Scholar] [CrossRef]

- Almpani-Lekka, D.; Pfeiffer, S.; Schmidts, C.; Seo, S.-I. A Review on Architecture with Fungal Biomaterials: The Desired and the Feasible. Fungal Biol. Biotechnol. 2021, 8, 17. [Google Scholar] [CrossRef]

- Angelucci, G.; Mollaioli, F.; Tardocchi, R. A New Modular Structural System for Tall Buildings Based on Tetrahedral Configuration. Buildings 2020, 10, 240. [Google Scholar] [CrossRef]

- Fallacara, G.; Cavaliere, I.; Melchiorre, J.; Marano, G.C.; Manuello, A. Reinterpretation of Catenary Vaulted Spaces: Construction of a Prototype and Structural Evaluation through Multibody Rope Approach. Structures 2024, 66, 106746. [Google Scholar] [CrossRef]

- Manuello, A. Multi-Body Rope Approach for Grid Shells: Form-Finding and Imperfection Sensitivity. Eng. Struct. 2020, 221, 111029. [Google Scholar] [CrossRef]

- Heyman, J. The Stone Skeleton; Cambridge University Press: Cambridge, UK, 1995. [Google Scholar]

- Lewandowska, A.; Bonenberg, A.; Sydor, M. Mycelium-Based Composites: Surveying Their Acceptance by Professional Architects. Biomimetics 2024, 9, 333. [Google Scholar] [CrossRef]

- Bagheriehnajjar, G.; Yousefpour, H.; Rahimnejad, M. Environmental Impacts of Mycelium-Based Bio-Composite Construction Materials. Int. J. Environ. Sci. Technol. 2024, 21, 5437–5458. [Google Scholar] [CrossRef]

- Akromah, S.; Chandarana, N.; Rowlandson, J.L.; Eichhorn, S.J. Potential Environmental Impact of Mycelium Composites on African Communities. Sci. Rep. 2024, 14, 11867. [Google Scholar] [CrossRef] [PubMed]

- Bitting, S.; Derme, T.; Lee, J.; Van Mele, T.; Dillenburger, B.; Block, P. Challenges and Opportunities in Scaling up Architectural Applications of Mycelium-Based Materials with Digital Fabrication. Biomimetics 2022, 7, 44. [Google Scholar] [CrossRef]

- Walter, N.; Gürsoy, B. A Study on the Sound Absorption Properties of Mycelium-Based Composites Cultivated on Waste Paper-Based Substrates. Biomimetics 2022, 7, 100. [Google Scholar] [CrossRef]

- Girometta, C.; Picco, A.M.; Baiguera, R.M.; Dondi, D.; Babbini, S.; Cartabia, M.; Pellegrini, M.; Savino, E. Physico-Mechanical and Thermodynamic Properties of Mycelium-Based Biocomposites: A Review. Sustainability 2019, 11, 281. [Google Scholar] [CrossRef]

- Fungus: The Plastic of the Future|Microbros. Available online: https://www.youtube.com/watch?v=htdwl30b_Zs (accessed on 22 October 2020).

- Verma, N.; Jujjavarapu, S.E.; Mahapatra, C. Green Sustainable Biocomposites: Substitute to Plastics with Innovative Fungal Mycelium Based Biomaterial. J. Environ. Chem. Eng. 2023, 11, 110396. [Google Scholar] [CrossRef]

- Gantenbein, S.; Colucci, E.; Käch, J.; Trachsel, E.; Coulter, F.B.; Rühs, P.A.; Masania, K.; Studart, A.R. Three-Dimensional Printing of Mycelium Hydrogels into Living Complex Materials. Nat. Mater. 2023, 22, 128–134. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Chen, C.; Zhang, H.; Xia, L.; Huang, Y.; Huang, H.; Wang, Y.; Qian, D.; Wang, J.; Wang, X.; et al. Eco-Friendly Fiberboard Production without Binder Using Poplar Wood Shavings Bio-Pretreated by White Rot Fungi Coriolus Versicolor. Constr. Build. Mater. 2020, 236, 117620. [Google Scholar] [CrossRef]

- Zhang, L.-Y.; Jiang, J.-H.; Wei, K.; Yin, X.; Xu, G.-K.; Zhang, J. Self-Equilibrium and Super-Stability of Rhombic Truncated Regular Tetrahedral and Cubic Tensegrities Using Symmetry-Adapted Force-Density Matrix Method. Int. J. Solids Struct. 2021, 233, 111215. [Google Scholar] [CrossRef]

- Jones, M.; Huynh, T.; Dekiwadia, C.; Daver, F.; John, S. Mycelium Composites: A Review of Engineering Characteristics and Growth Kinetics. J. Bionanosci. 2017, 11, 241–257. [Google Scholar] [CrossRef]

- Haryńska, A.; Janik, H.; Sienkiewicz, M.; Mikolaszek, B.; Kucińska-Lipka, J. PLA–Potato Thermoplastic Starch Filament as a Sustainable Alternative to the Conventional PLA Filament: Processing, Characterization, and FFF 3D Printing. ACS Sustain. Chem. Eng. 2021, 9, 6923–6938. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).