Analyzing the Synchronous Acoustic and Electric Response of Coal Burst Failure: Validation through the On-Site Application

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Specimens

2.2. Experimental Set-Up

3. Experimental Results and Analysis

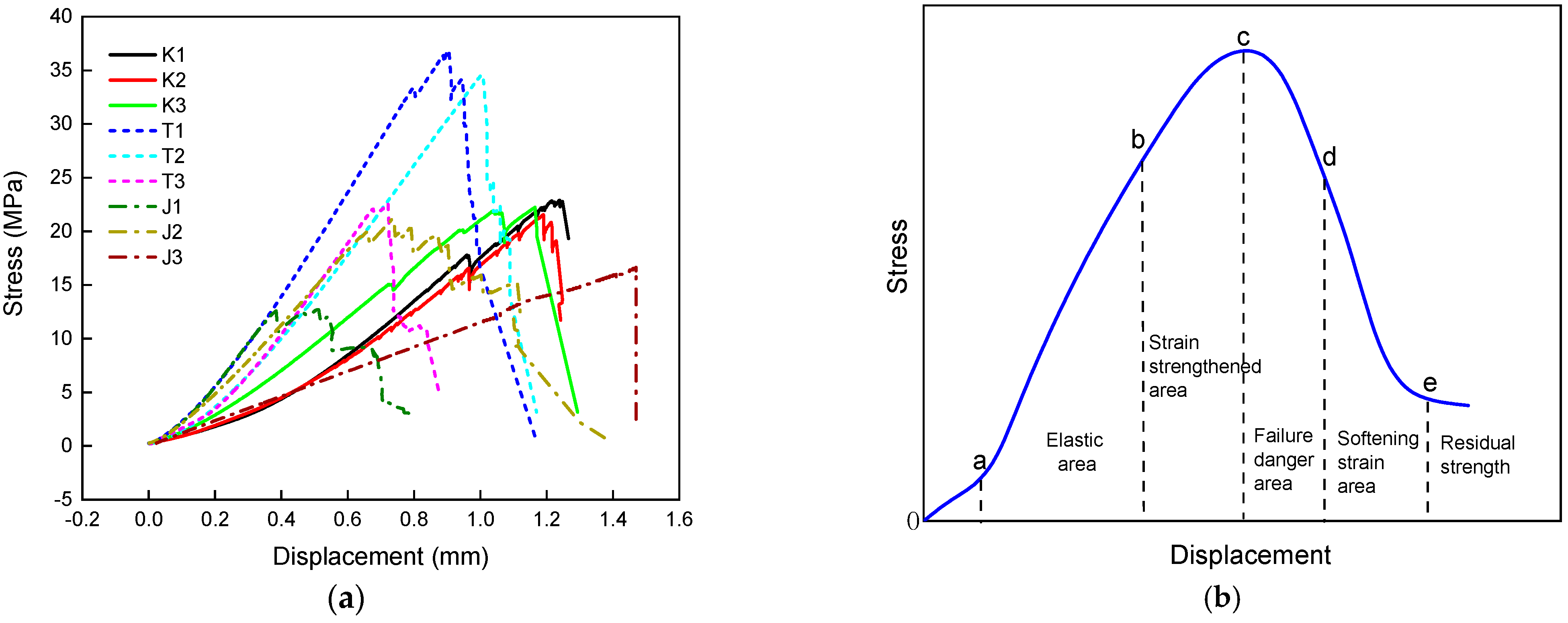

3.1. Stress-Deformation Characteristics of the Uniaxial Compression Damage Process of Coal Samples

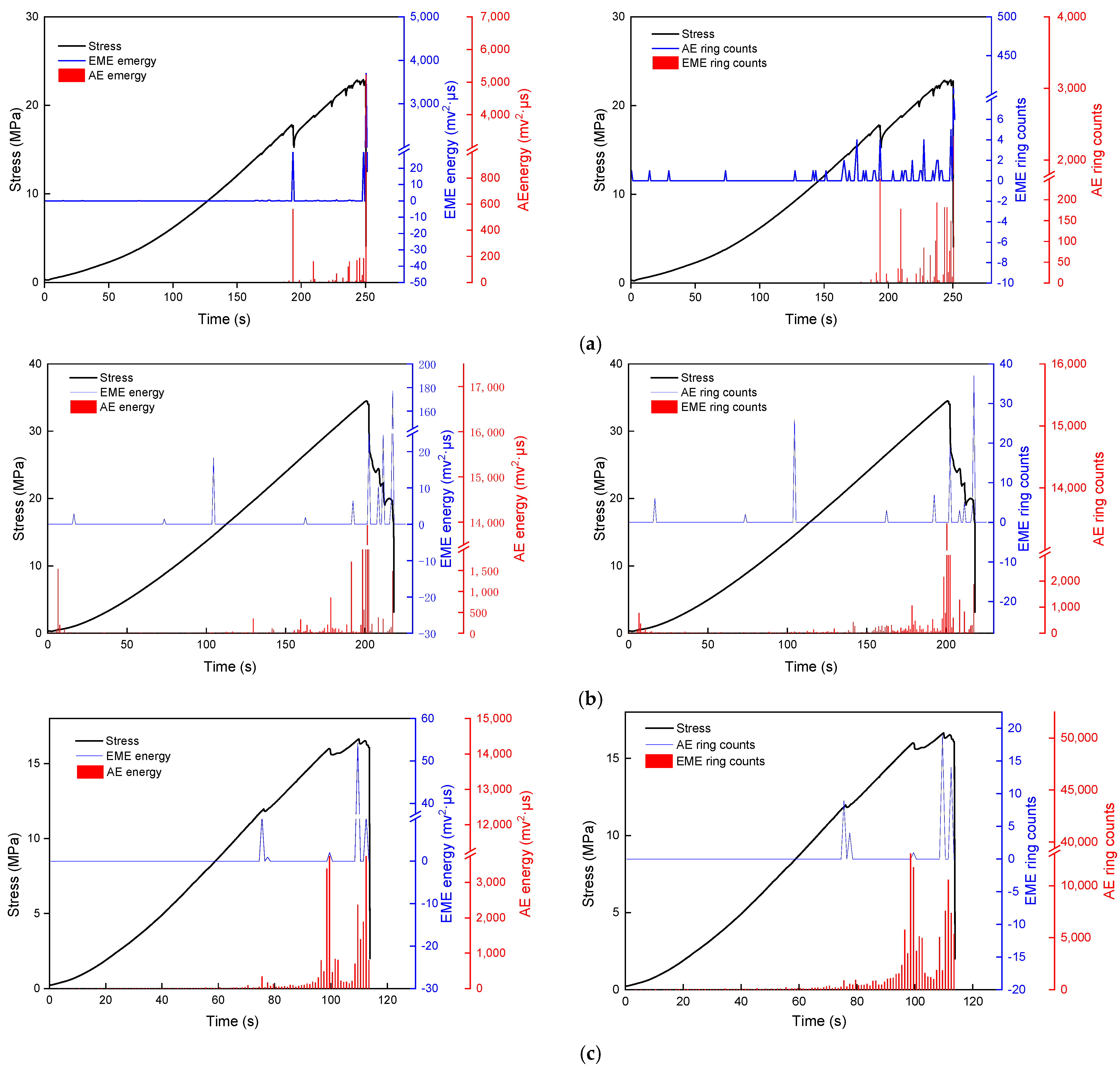

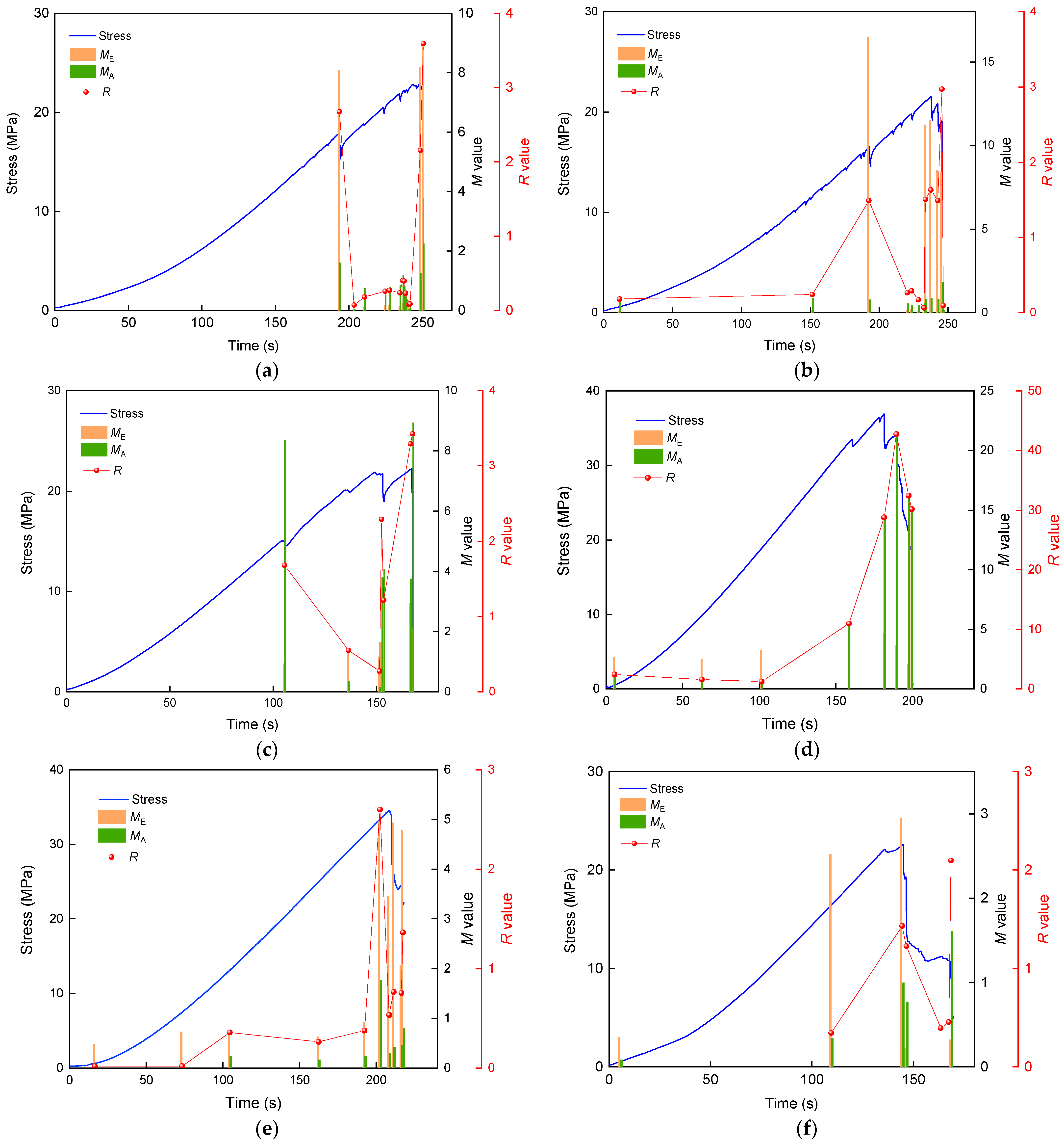

3.2. AE and EME Response of Coal Samples during Uniaxial Compression Failure

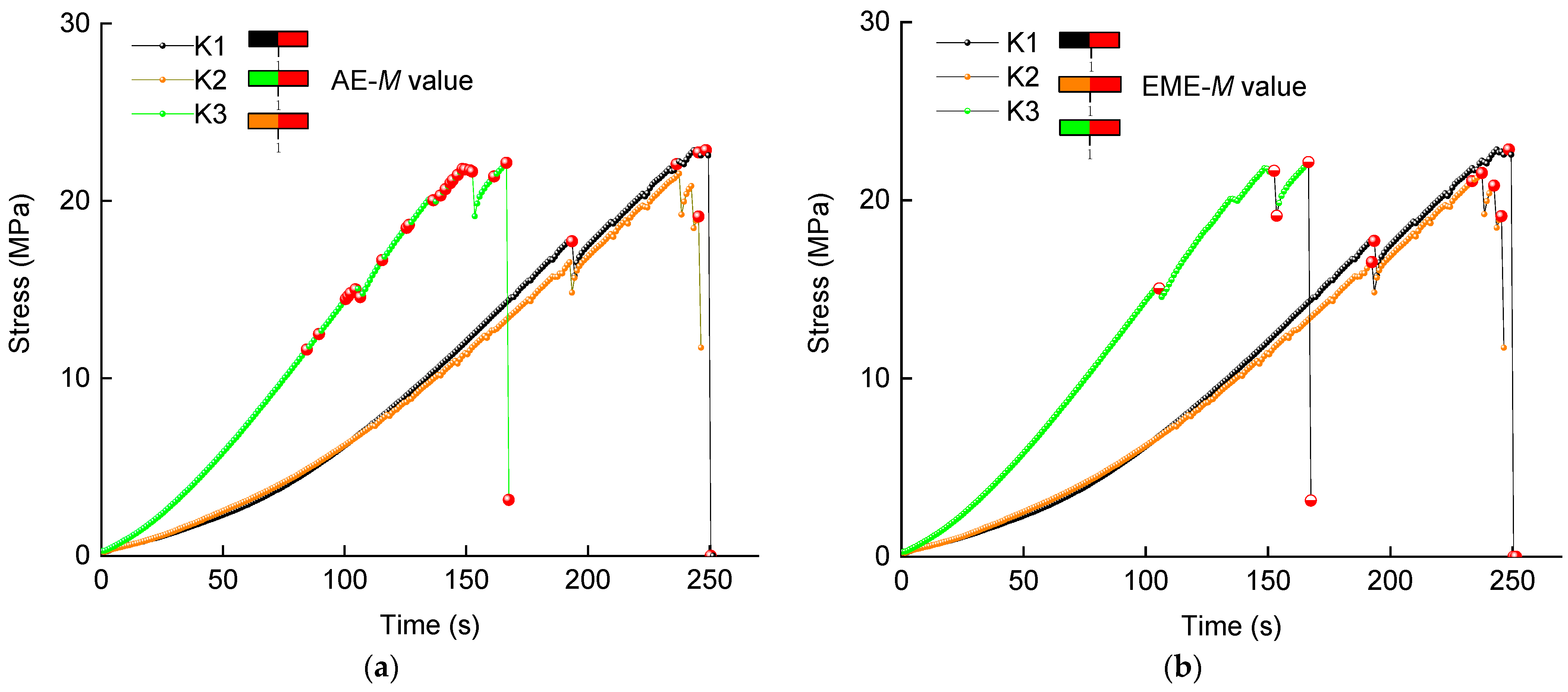

3.3. Relationship between Coal Rock Body Failure and M Value

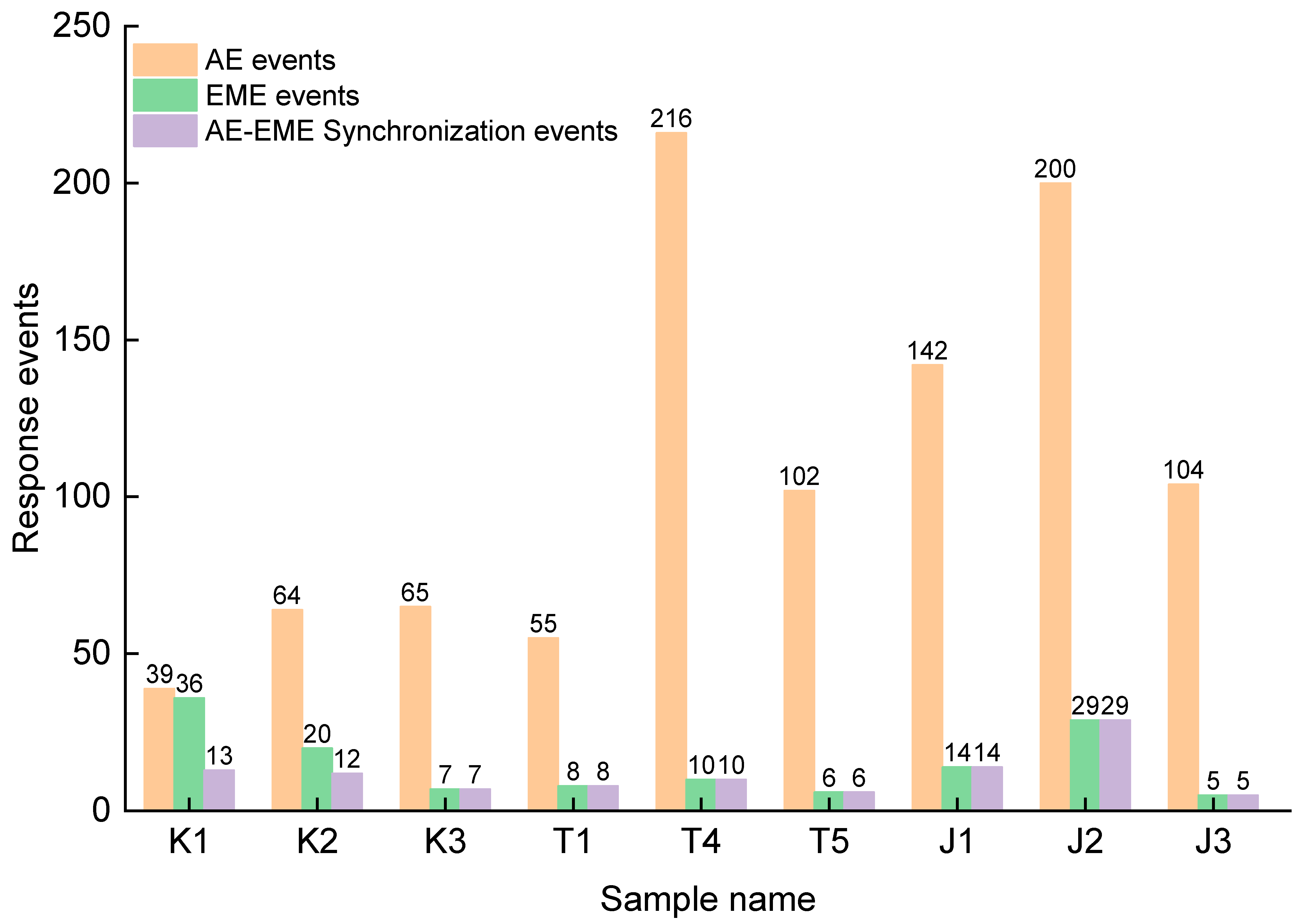

3.4. AE and EME Synchronous Response Analysis and Early Warning R Index

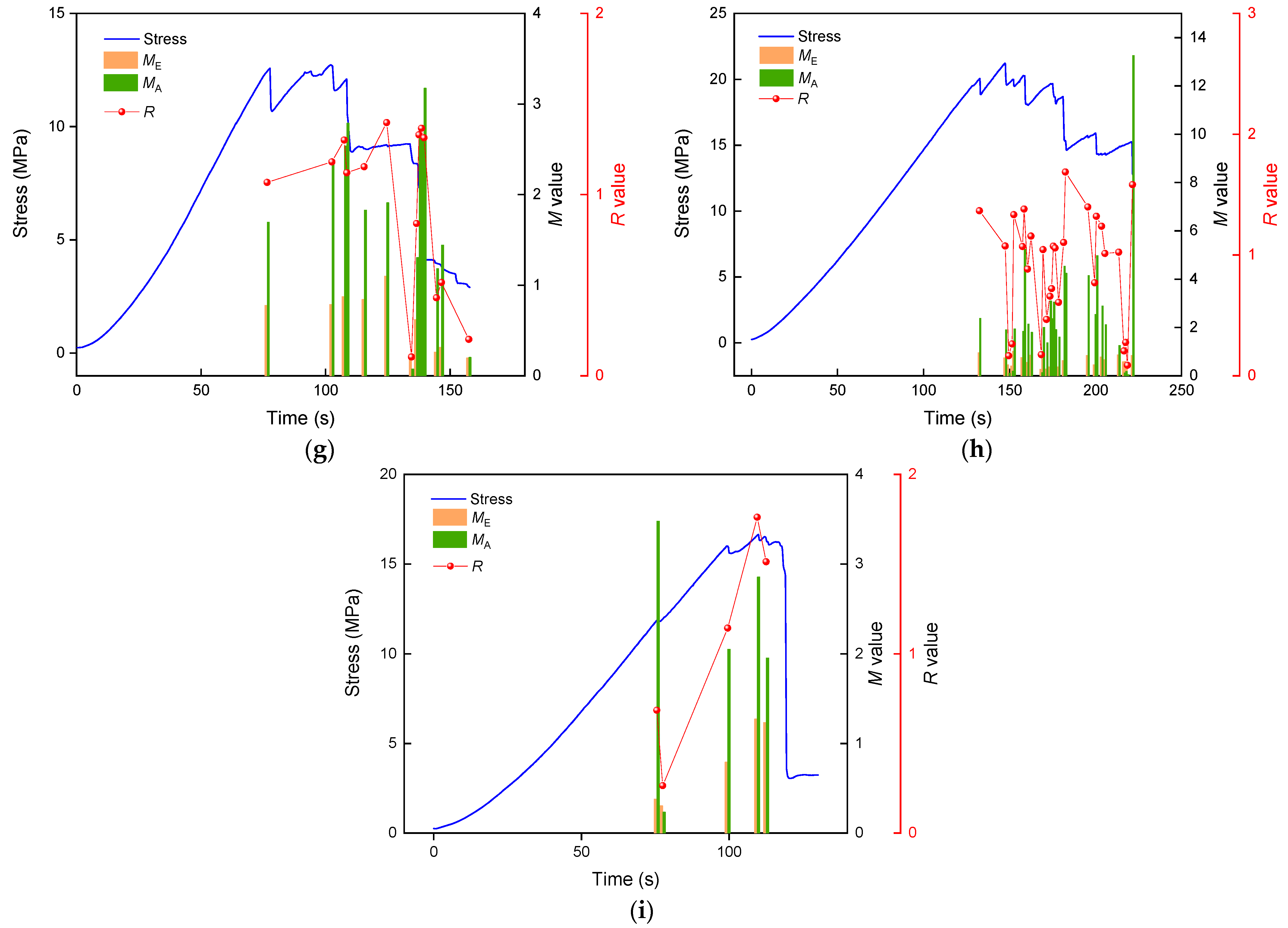

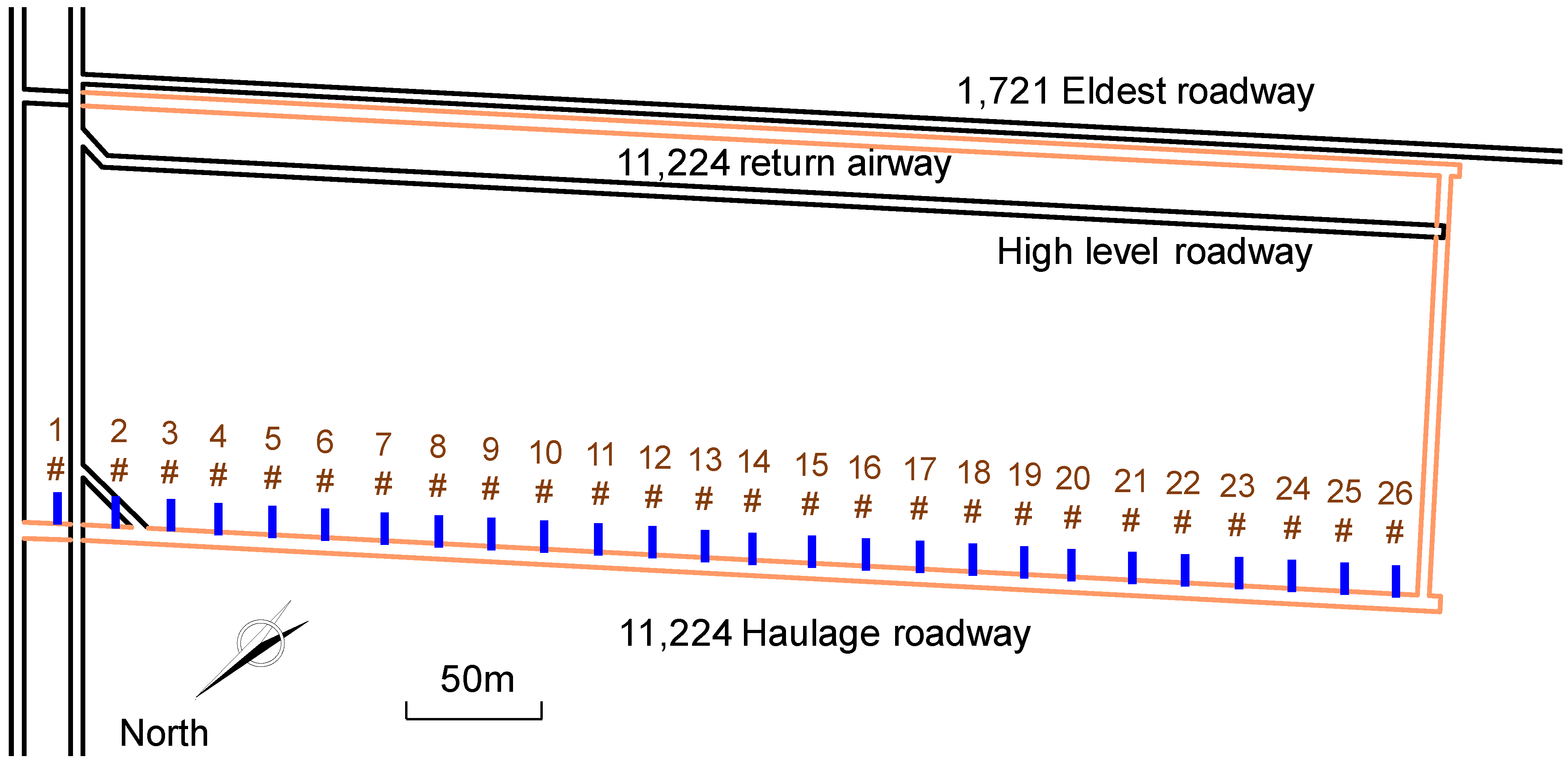

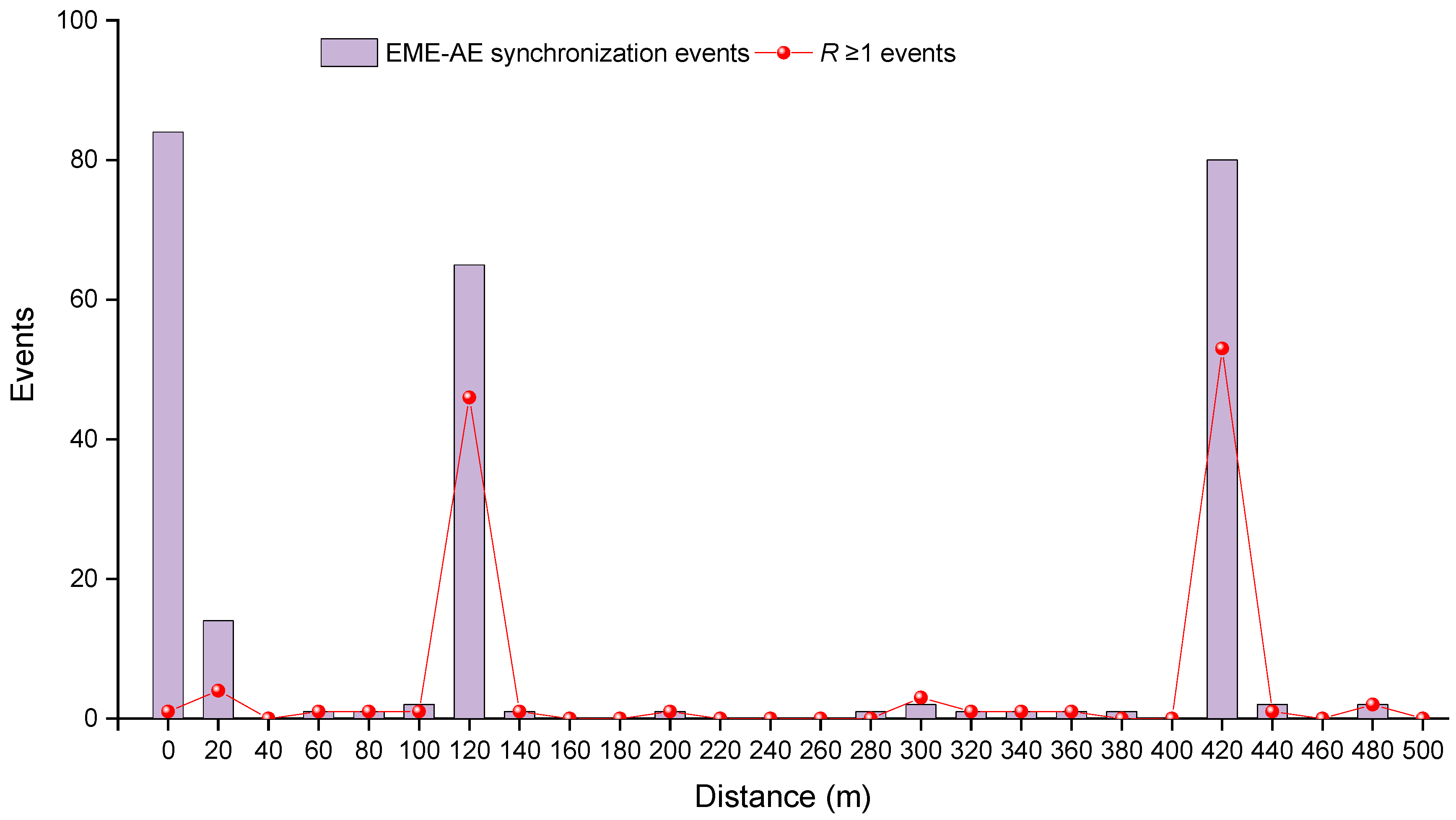

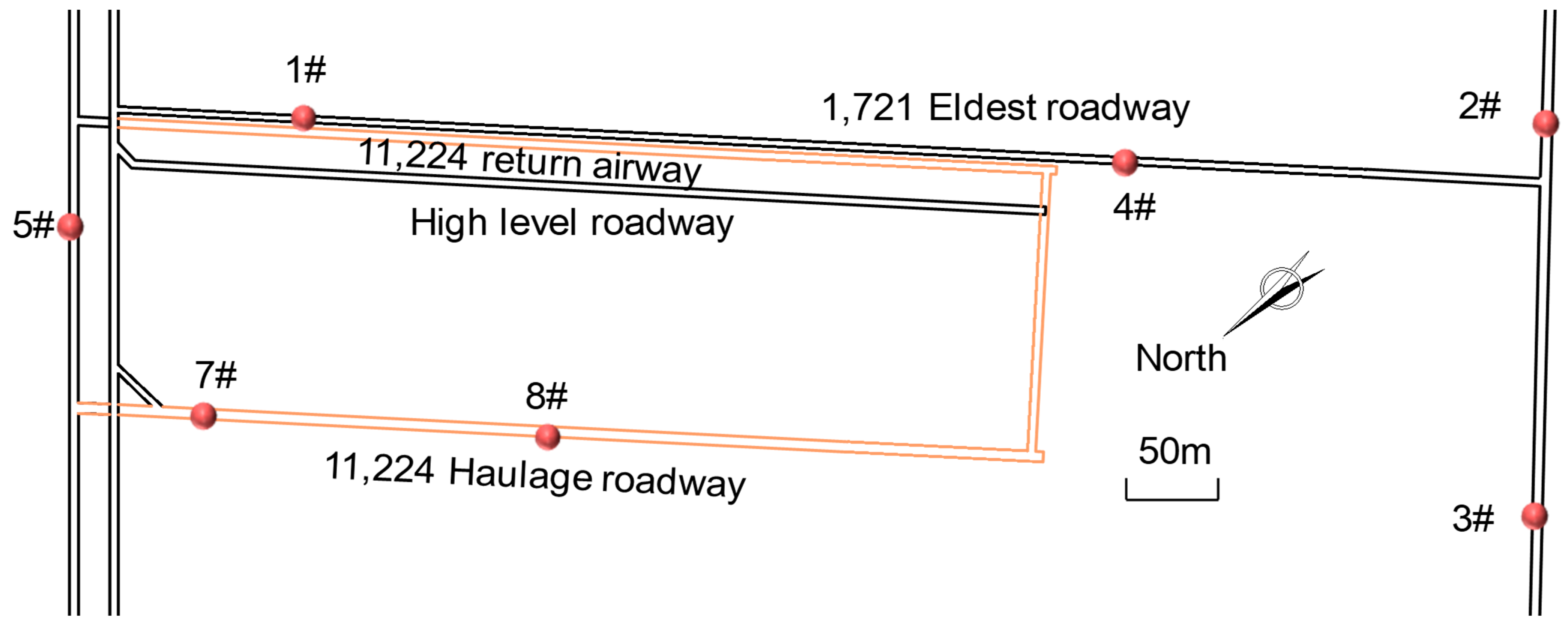

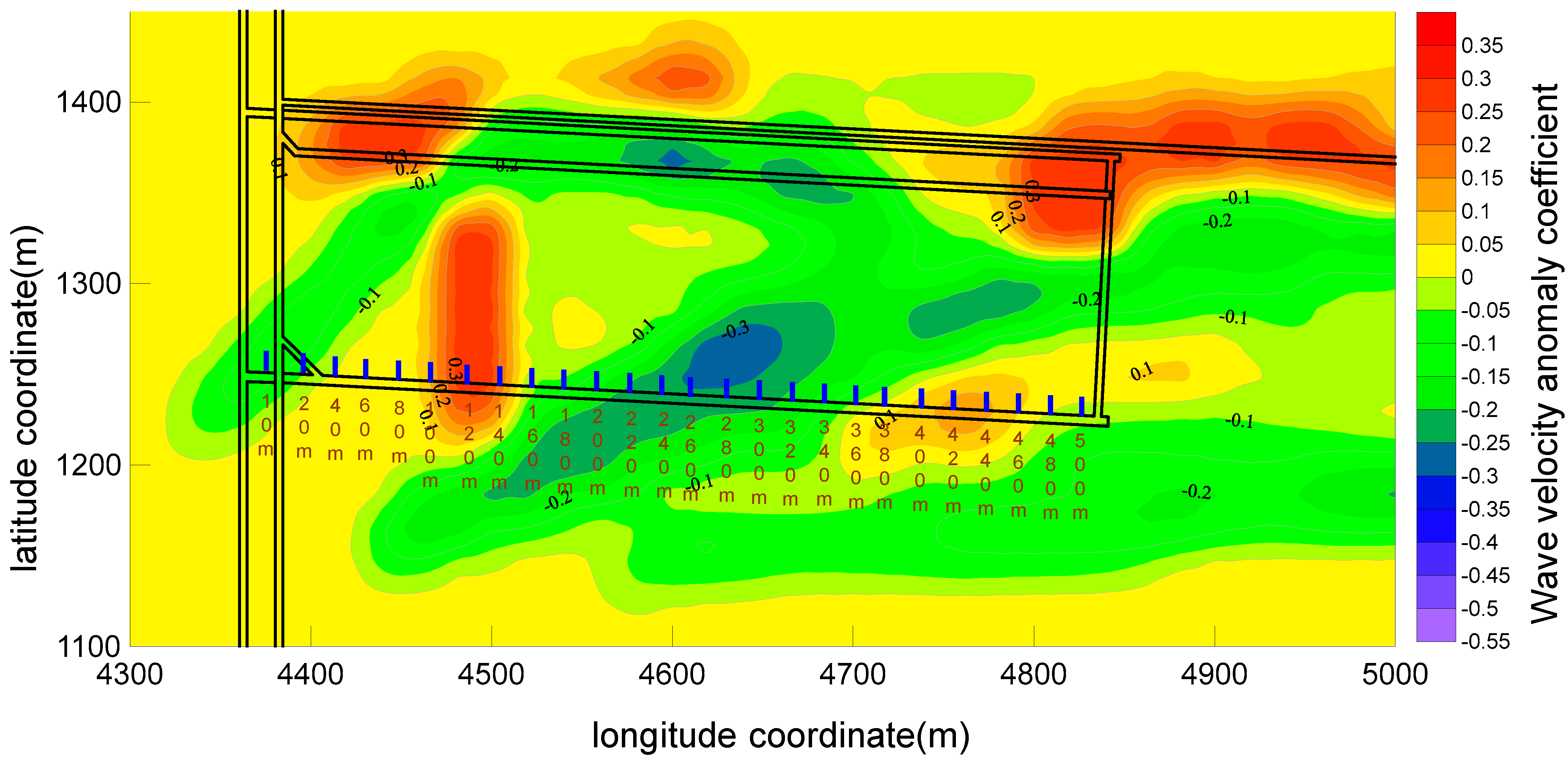

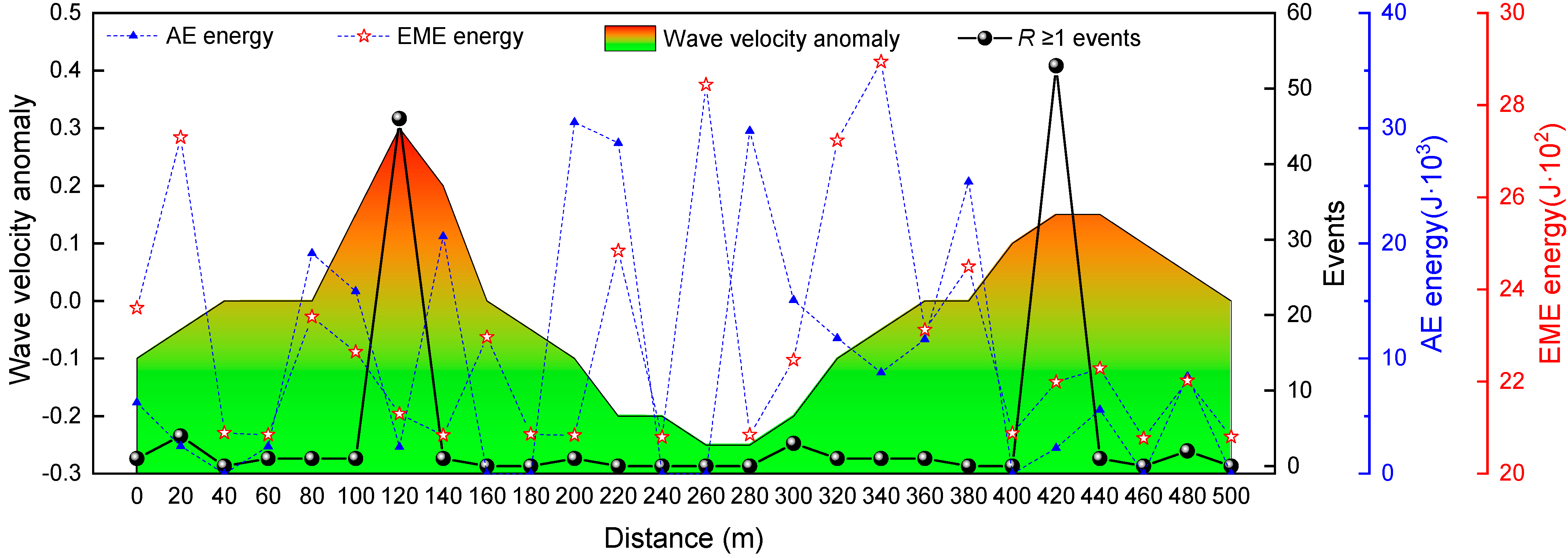

4. Field Application and Validation

5. Conclusions

- (1)

- During uniaxial loading, the AE and EME signals increase significantly and appear strongly synchronized after entering strain strengthening area. With a significant reduction in the load in the strain-reinforced zone and before and after entering the damaged zone, the synchronization of the AE and EME signal is the strongest. At this stage, it can accurately reflect the coal mass entering the damage danger zone.

- (2)

- The R value, the fusion unified dimensionless index of AE and EME, can well reflect whether the coal mass entered the damage danger zone and can be regarded as one of the precursors of the imminent failure of coal and rock. When R > 1, it indicates that the specimen is about to enter or has entered the failure danger zone, and the more concentrated the R > 1 event, the greater the danger.

- (3)

- On-site verification shows that the stress distribution of the roadway has a good correspondence with the number of the R > 1 events. In areas with abnormally increased roadway stress, the number of the R > 1 events in 90 s is greater than 40. In areas with normal or reduced roadway stress, the number of the R > 1 events in 90 s is between zero and two. Compared with the index of AE or EME energy signal, the unified R value index of AE and EME fusion can better reduce the influence of interference factors and can reflect the danger of localized coal and rock dynamic disaster clearly and accurately.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dou, L.; He, X. Theory and Technology of Rock Burst Prevention; China University of Mining and Technology Press: Xuzhou, China, 2001. [Google Scholar]

- Lu, C.; Liu, Y.; Liu, G.; Zhao, T. Stress evolution caused by hard roof fracturing and associated multi-parameter precursors. Tunn. Undergr. Space Technol. 2019, 84, 295–305. [Google Scholar] [CrossRef]

- Qiu, L.; Wang, E.; Song, D.; Liu, Z.; Shen, R.; Lv, G.; Xu, Z. Measurement of the stress field of a tunnel through its rock EMR. J. Geophys. Eng. 2017, 14, 949–959. [Google Scholar] [CrossRef]

- Liu, X.; Wang, E. Study on characteristics of EMR signals induced from fracture of rock samples and their application in rockburst prediction in copper mine. J. Geophys. Eng. 2018, 15, 909–920. [Google Scholar] [CrossRef]

- Contoyiannis, Y.; Potirakis, S. Signatures of the symmetry breaking phenomenon in pre-seismic electromagnetic emissions. J. Stat. Mech. 2018, 2018, 083208. [Google Scholar] [CrossRef]

- Carpinteri, A.; Borla, O. Acoustic, electromagnetic, and neutron emissions as seismic precursors: The lunar periodicity of low-magnitude seismic swarms. Eng. Fract. Mech. 2019, 210, 29–41. [Google Scholar] [CrossRef]

- Frid, V.; Rabinovitch, A.; Bahat, D. Seismic moment estimation based on fracture induced electromagnetic radiation. Eng. Geol. 2020, 274, 105692. [Google Scholar] [CrossRef]

- Potirakis, S.M.; Contoyiannis, Y.; Schekotov, A.; Eftaxias, K.; Hayakawa, M. Evidence of critical dynamics in various electromagnetic precursors. Eur. Phys. J. Spec. Top. 2021, 230, 151–177. [Google Scholar] [CrossRef]

- Tsutsumi, A.; Shirai, N. Electromagnetic signals associated with stick–slip of quartz-free rocks. Tectonophysics 2008, 450, 79–84. [Google Scholar] [CrossRef]

- Nitsan, U. Electromagnetic emission accompanying fracture of quartz-bearing rocks. Geophys. Res. Lett. 1977, 4, 333–336. [Google Scholar] [CrossRef]

- Alekseev, D.V.; Egorov, P.V.; Ivanov, V.V. Mechanisms of electrification of cracks and electromagnetic precursors of rock fracture. J. Min. Sci. 1993, 28, 515–519. [Google Scholar] [CrossRef]

- O’Keefe, S.G.; Thiel, D.V. A mechanism for the production of electromagnetic radiation during fracture of brittle materials. Phys. Earth Planet. Inter. 1995, 89, 127–135. [Google Scholar] [CrossRef]

- Frid, V.; Rabinovitch, A.; Bahat, D. Fracture induced electromagnetic radiation. J. Phys. D Appl. Phys. 2003, 36, 1620. [Google Scholar] [CrossRef]

- Rabinovitch, A.; Frid, V.; Bahat, D. Surface oscillations—A possible source of fracture induced electromagnetic radiation. Tectonophysics 2007, 431, 15–21. [Google Scholar] [CrossRef]

- Rabinovitch, A.; Frid, V.; Bahat, D. Directionality of electromagnetic radiation from fractures. Int. J. Fract. 2017, 204, 239–244. [Google Scholar] [CrossRef]

- Wang, E.Y.; He, X.Q. An experimental study of the electromagnetic emission during the deformation and fracture of coal or rock. Chin. J. Geophys. 2000, 43, 134–140. [Google Scholar] [CrossRef]

- Frid, V. Rockburst hazard forecast by electromagnetic radiation excited by rock fracture. Rock Mech. Rock Eng. 1997, 30, 229–236. [Google Scholar] [CrossRef]

- Frid, V. Electromagnetic radiation method for rock and gas outburst forecast. J. Appl. Geophys. 1997, 38, 97–104. [Google Scholar] [CrossRef]

- He, X.; Nie, B.; Chen, W.; Wang, E.; Dou, L.; Wang, Y.; Liu, M.; Hani, M. Research progress on electromagnetic radiation in gas-containing coal and rock fracture and its applications. Saf. Sci. 2012, 50, 728–735. [Google Scholar] [CrossRef]

- He, X.; Dou, L.; Mu, Z.; Gong, S.; Cao, A.; He, J. Continuous monitoring and warning theory and technology of rock burst dynamic disaster of coal. J. China Coal Soc. 2014, 39, 1485–1491. [Google Scholar]

- He, X.; Chen, W.; Nie, B.; Mitri, H. Electromagnetic emission theory and its application to dynamic phenomena in coal-rock. Int. J. Rock Mech. Min. 2011, 48, 1352–1358. [Google Scholar] [CrossRef]

- Song, D.; Wang, E.; Song, X.; Jin, P.; Qiu, L. Changes in frequency of electromagnetic radiation from loaded coal rock. Rock Mech. Rock Eng. 2016, 49, 291–302. [Google Scholar] [CrossRef]

- Song, D.; Wang, E.; He, X.; Jia, H.; Qiu, L.; Chen, P.; Wang, S. Use of electromagnetic radiation from fractures for mining-induced stress field assessment. J. Geophys. Eng. 2018, 15, 1093–1103. [Google Scholar] [CrossRef]

- Wang, C.L.; Chen, Z.; Liao, Z.F.; Hou, X.L.; Li, H.T.; Wang, A.W.; Li, C.Z.; Qian, P.F.; Li, G.S.; Lu, H. Experimental investigation on predicting precursory changes in entropy for dominant frequency of rockburst. J. Cent. South Univ. 2020, 27, 2834–2848. [Google Scholar] [CrossRef]

- Lacidogna, G.; Carpinteri, A.; Manuello, A.; Durin, G.; Schiavi, A.; Niccolini, G.; Agosto, A. Acoustic and electromagnetic emissions as precursor phenomena in failure processes. Strain 2011, 47, 144–152. [Google Scholar] [CrossRef]

- Lou, Q.; Song, D.; He, X.; Li, Z.; Qiu, L.; Wei, M.; He, S. Correlations between acoustic and electromagnetic emissions and stress drop induced by burst-prone coal and rock fracture. Saf. Sci. 2019, 115, 310–319. [Google Scholar] [CrossRef]

- Wei, M.; Song, D.; He, X.; Li, Z.; Qiu, L.; Lou, Q. Effect of rock properties on electromagnetic radiation characteristics generated by rock fracture during uniaxial compression. Rock Mech. Rock Eng. 2020, 53, 5223–5238. [Google Scholar] [CrossRef]

- Wang, E.Y.; Liu, X.F.; He, X.Q.; Li, Z.L. Acoustic emission and electromagnetic radiation synchronized monitoring technology and early-warning application for coal and rock dynamic disaster. J. China Univ. Min. Technol. 2018, 47, 942–948. [Google Scholar]

- Hall, S.A.; Sanctis, F.; Viggiani, G. Monitoring fracture propagation in a soft rock (Neapolitan Tuff) using acoustic emissions and digital images. Pure Appl. Geophys. 2006, 163, 2171–2204. [Google Scholar] [CrossRef]

- Byun, Y.S.; Sagong, M.; Kim, S.C.; Chun, B.S.; Park, S.Y.; Jung, H.S. A study on using acoustic emission in rock slope with difficult ground—Focused on rainfall. Geosci. J. 2012, 16, 435–445. [Google Scholar] [CrossRef]

- Zhao, Y.; Song, D.; Qiu, L.; Wang, A. Research on seismic wave CT technology application in stress field detection of outburst coal seam. J. Chin. Sci. Pap. 2021, 16, 82–90. [Google Scholar]

- Dou, L.; Cai, W.; Gong, S.; Han, R.; Liu, J. Dynamic risk assessment of rock burst based on the technology of seismic computed tomography detection. J. Coal 2014, 39, 238–244. [Google Scholar]

| Sample | Sample Number | Density/g∙cm−1 | Peak Load/kN | Elastic Modulus /GPa | Compressive Strength/MPa |

|---|---|---|---|---|---|

| Kuangou mine sample | K1 | 1.34 | 44.96 | 1.85 | 22.91 |

| K2 | 1.33 | 42.08 | 1.81 | 21.55 | |

| K3 | 1.33 | 43.58 | 1.92 | 22.34 | |

| Mean value | 1.33 | 43.54 | 1.86 | 22.67 | |

| Tashan mine sample | T1 | 1.27 | 72.41 | 2.89 | 24.89 |

| T2 | 1.28 | 67.72 | 3.42 | 34.51 | |

| T3 | 1.27 | 44.27 | 3.14 | 22.56 | |

| Mean value | 1.27 | 61.5 | 3.15 | 27.32 | |

| Jinjia mine sample | J1 | 1.44 | 24.98 | 1.78 | 9.24 |

| J2 | 1.44 | 41.64 | 2.74 | 20.28 | |

| J3 | 1.45 | 32.66 | 0.96 | 14.08 | |

| Mean value | 1.44 | 33.09 | 1.82 | 14.53 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Song, D.; Wei, M.; Khan, M.; Li, Z.; Qiu, L.; Yin, S. Analyzing the Synchronous Acoustic and Electric Response of Coal Burst Failure: Validation through the On-Site Application. Foundations 2022, 2, 746-762. https://doi.org/10.3390/foundations2030051

Zhao Y, Song D, Wei M, Khan M, Li Z, Qiu L, Yin S. Analyzing the Synchronous Acoustic and Electric Response of Coal Burst Failure: Validation through the On-Site Application. Foundations. 2022; 2(3):746-762. https://doi.org/10.3390/foundations2030051

Chicago/Turabian StyleZhao, Yingjie, Dazhao Song, Menghan Wei, Majid Khan, Zhenlei Li, Liming Qiu, and Shan Yin. 2022. "Analyzing the Synchronous Acoustic and Electric Response of Coal Burst Failure: Validation through the On-Site Application" Foundations 2, no. 3: 746-762. https://doi.org/10.3390/foundations2030051

APA StyleZhao, Y., Song, D., Wei, M., Khan, M., Li, Z., Qiu, L., & Yin, S. (2022). Analyzing the Synchronous Acoustic and Electric Response of Coal Burst Failure: Validation through the On-Site Application. Foundations, 2(3), 746-762. https://doi.org/10.3390/foundations2030051