Hybrid Small Modular Nuclear Reactor with Concentrated Solar Power: Towards 4+ Reactors?

Abstract

1. Introduction

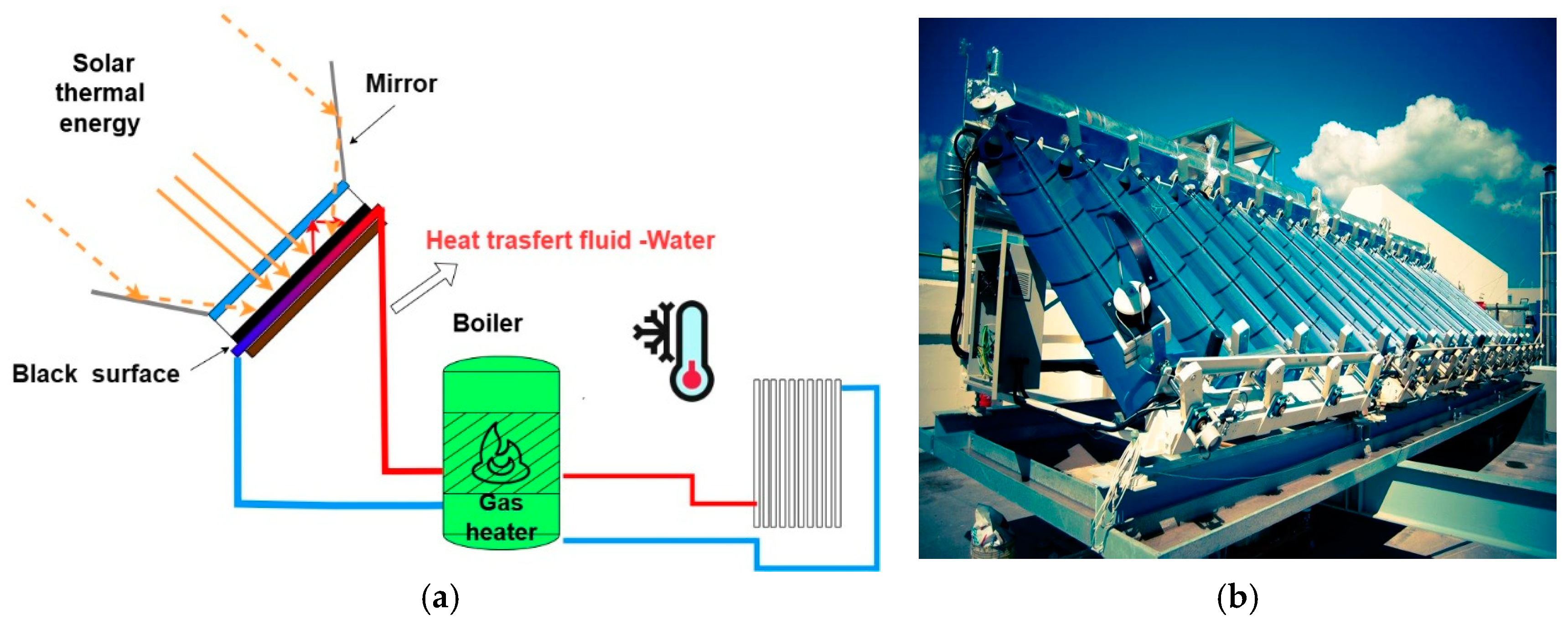

2. Solar Thermal Energy Technologies

3. Small Modular Reactors

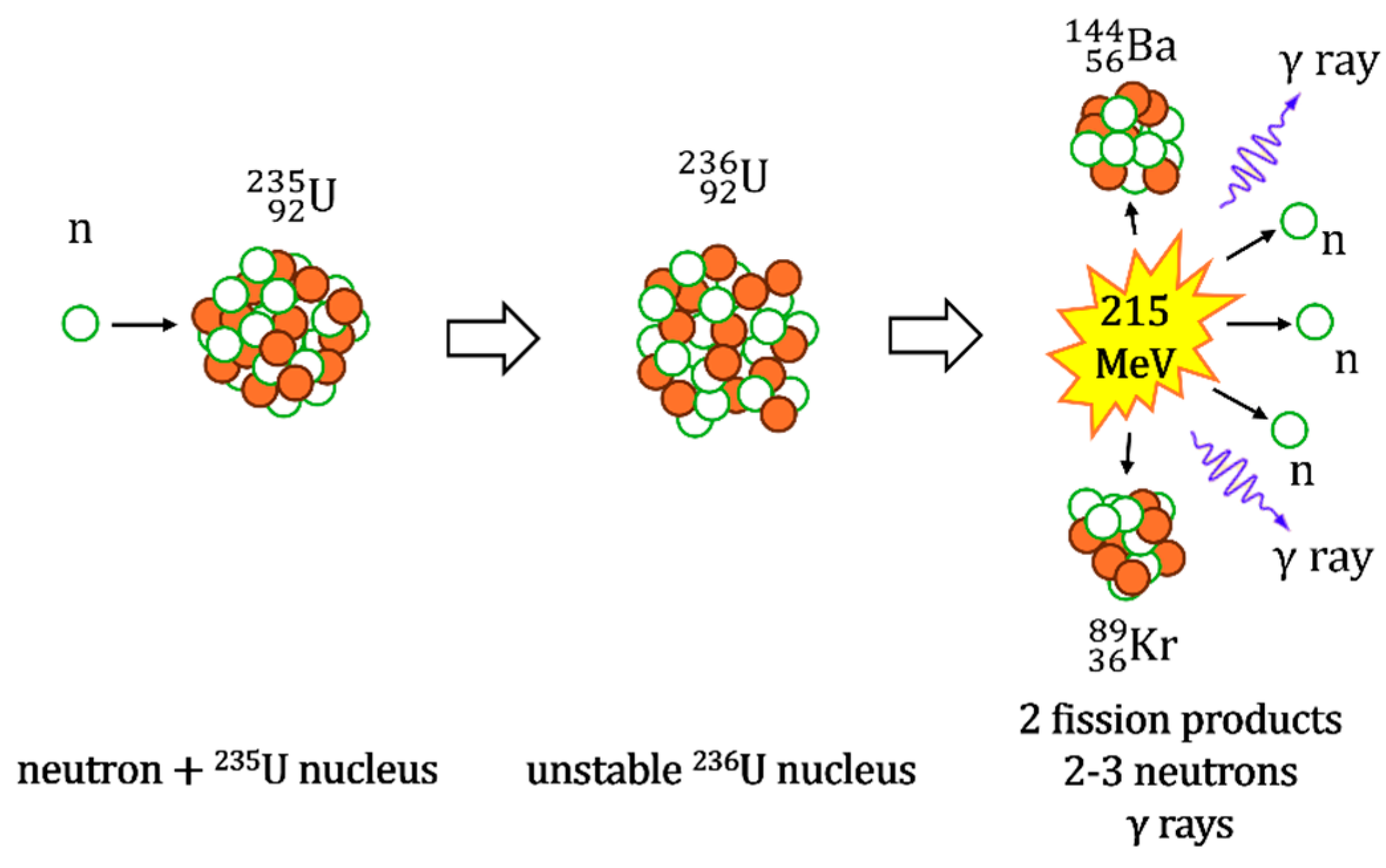

3.1. Nuclear Reactors and Nuclear Fuel

- I generation: Early exploratory research prototypes.

- II generation: Most of the currently operational nuclear plants (upscaled versions of gen. I, mostly LWRs).

- III and III+ generation: How most nuclear plants are currently being built (evolutionary designs improving II generation reactors in terms of safety and reliability).

- IV generation: Future reactors (revolutionary designs aimed to improve safety, sustainability, efficiency, and cost), including some MSRs, LMFRs, and GFRs (and more) [88].

3.2. Small Modular Reactors

- -

- In addition, smaller reactors imply more efficient passive safety systems, as the operating power and pressure are significantly lower than in conventional reactors. Reaction times for operators to counter accident situations are also largely extended due to the decreased operational power [97].

- -

- Most SMRs (including MSRs; LMFR; and high-temperature gas-cooled reactors, HTGRs) have negative void and/or temperature coefficients of reactivity. This implies that in case of loss-of-coolant accidents (LOCAs), the chain reaction self-extinguishes, meaning they are intrinsically safer than the already existing LWRs (whose chain reactions must be shut down by the operators).

- -

- -

- Less consumed fuel also means a lower radioactive inventory inside spent fuel, meaning lower radioactivity, lower worker exposure, and smaller emergency planning zones (EPZs). SMR SNF is less radioactive when discharged and remains radioactive for less time after discharge.

4. Hybrid SMR + CSP

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AEM | Anion Exchange Membrane |

| BWR | boiling water reactor |

| CPC | compound parabolic collector |

| CSP | concentrated solar power |

| DNI | direct normal irradiation |

| EPZ | emergency planning zone |

| ETC | evacuated tube collector |

| FHR | fluoride salt-cooled reactor |

| EPZ | emergency planning zone |

| FPC | flat plate collector |

| FVC | Flat Vacuum Collector |

| GCR | gas-cooled reactor |

| GFR | gas-cooled fast reactor |

| HTF | heat transfer fluid |

| HTGR | high-temperature gas-cooled reactor |

| LBE | lead–bismuth eutectic |

| LCOE | levelized cost of electricity |

| LFR | linear Fresnel reflector |

| LMR | liquid metal-cooled reactor |

| LMFR | liquid metal-cooled fast reactor |

| LOCA | loss of coolant accident |

| LWR | light water reactor |

| MMR | micro modular reactor |

| MSR | molten salt reactor |

| PEM | Proton Exchange Membrane |

| PHWR | pressurized heavy water reactor |

| PTC | parabolic trough collector |

| PWR | pressurized water reactor |

| sCO2 | supercritical CO2 |

| SOEC | Solid Oxide Electrolysis Cell |

| SHIP | solar heat for industrial processes |

| SmAHTR | small modular advanced high-temperature rector |

| SMR | small modular reactor |

| SNF | spent nuclear fuel |

| TES | thermal energy storage |

| TRISO | TRi-structural ISO-tropic particle fuel |

References

- Hayashi, H. Drying Technologies of Foods-Their History and Future. Dry. Technol. 1989, 7, 315–369. [Google Scholar] [CrossRef]

- Ozgener, L.; Ozgener, O. Exergy Analysis of Drying Process: An Experimental Study in Solar Greenhousetle. Dry. Technol. Int. J. 2009, 27, 580–586. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Nontracking Solar Collection Technologies for Solar Heating and Cooling Systems. In Advances in Solar Heating and Cooling; Elsevier: Amsterdam, The Netherlands, 2016; pp. 63–80. [Google Scholar]

- Bennamoun, L. Reviewing the Experience of Solar Drying in Algeria with Presentation of the Different Design Aspects of Solar Dryers. Renew. Sustain. Energy Rev. 2011, 15, 3371–3379. [Google Scholar] [CrossRef]

- Pratticò, L.; Bartali, R.; Crema, L.; Sciubba, E. Analysis of Radiation Propagation inside a Hierarchical Solar Volumetric Absorber. Proceedings 2020, 58, 27. [Google Scholar] [CrossRef]

- Gao, M.; Zhu, L.; Peh, C.K.; Ho, G.W. Solar Absorber Material and System Designs for Photothermal Water Vaporization towards Clean Water and Energy Production. Energy Environ. Sci. 2018, 12, 841–864. [Google Scholar] [CrossRef]

- Tian, Z.; Zhang, S.; Deng, J.; Fan, J.; Huang, J.; Kong, W.; Perers, B.; Furbo, S. Large-Scale Solar District Heating Plants in Danish Smart Thermal Grid: Developments and Recent Trends. Energy Convers. Manag. 2018, 198, 67–80. [Google Scholar] [CrossRef]

- Perers, B.; Furbo, S.; Tian, Z.; Bava, F.; Sallaberry, F. A CSP Plant Combined with Biomass CHP Using ORC-Technology in Brønderslev Denmark. In Proceedings of the EuroSun, Palma de Mallorca, Spain, 11–14 October 2016. [Google Scholar]

- Osuna, R.; Olavarría, R.; Morillo, R.; Sánchez, M.; Cantero, F.; Fernández-Quero, V.; Robles, P.; Cerro, T.; Esteban, A.; Cerón, F.; et al. PS10, Construction of a 11MW Solar Thermal Tower Plant in Seville, Spain. In Proceedings of the SolarPACES Conference, Seville, Spain, 20–23 June 2006; pp. 20–23. [Google Scholar]

- Romov, E.; Teschner, N.A. A Place under the Sun: Planning, Landscape and Participation in a Case of a Solar Powerplant in the Israeli Desert. Sustainability 2022, 14, 7666. [Google Scholar] [CrossRef]

- IRENA. Innovation Outlook: Thermal Energy Storage; IRENA: Masdar City, United Arab Emirates, 2020; ISBN 978-92-9260-279-6. [Google Scholar]

- Roni, M.M.; Hoque, I.U.; Ahmed, T. Comparative Study of Levelized Cost of Electricity (LCOE) for Concentrating Solar Power (CSP) and Photovoltaic (PV) Plant in the Southeastern Region of Bangladesh. In Proceedings of the 2019 International Conference on Electrical, Computer and Communication Engineering (ECCE), Cox’s Bazar, Bangladesh, 7–9 February 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Aqachmar, Z.; Allouhi, A.; Jamil, A.; Gagouch, B.; Kousksou, T. Parabolic Trough Solar Thermal Power Plant Noor I in Morocco. Energy 2019, 178, 572–584. [Google Scholar] [CrossRef]

- Zurita, A.; Mata-Torres, C.; Cardemil, J.M.; Escobar, R.A. Assessment of Time Resolution Impact on the Modeling of a Hybrid CSP-PV Plant: A Case of Study in Chile. Sol. Energy 2020, 202, 553–570. [Google Scholar] [CrossRef]

- Tharp, J.; Anderson, K.R. Simulation and Lessons Learned from the Ivanpah Solar Plant Project. In Proceedings of the SOLAR 2018 Conference, Bouder, CO, USA, 5–8 August 2018; pp. 1–10. [Google Scholar]

- Glatzmaier, G.C.; Turchi, C.S. Supercritical CO2 as a Heat Transfer and Power Cycle Fluid for CSP Systems. In Proceedings of the ASME 2009 3rd International Conference on Energy Sustainability, San Francisco, CA, USA, 19–23 July 2009; Volume 2, pp. 673–676. [Google Scholar]

- Van, D.; Gerardo, D. Carbon Dioxide as Working Fluid for Medium and High-Temperature Concentrated Solar Thermal Systems. AIMS Energy 2014, 2, 99–115. [Google Scholar] [CrossRef]

- Muñoz-Antón, J.; Rubbia, C.; Rovira, A.; Martínez-Val, J.M. Performance Study of Solar Power Plants with CO2 as Working Fluid. A Promising Design Window. Energy Convers. Manag. 2015, 92, 36–46. [Google Scholar] [CrossRef]

- Agyekum, E.B.; Adebayo, T.S.; Bekun, F.V.; Kumar, N.M.; Panjwani, M.K. Effect of Two Different Heat Transfer Fluids on the Performance of Solar Tower CSP by Comparing Recompression Supercritical CO2 and Rankine Power Cycles, China. Energies 2021, 14, 3426. [Google Scholar] [CrossRef]

- Cheng, P.; Wang, D.; Schaaf, P. A Review on Photothermal Conversion of Solar Energy with Nanomaterials and Nanostructures: From Fundamentals to Applications. Adv. Sustain. Syst. 2022, 6, 2200115. [Google Scholar] [CrossRef]

- Atkinson, C.; Sansom, C.L.; Almond, H.J.; Shaw, C.P. Coatings for Concentrating Solar Systems—A Review. Renew. Sustain. Energy Rev. 2015, 45, 113–122. [Google Scholar] [CrossRef]

- Crema, L. Final Report Summary—DIGESPO (Distributed CHP Generation from Small Size Concentrated Solar Power); Fondazione Bruno Kessler: Trento, Italy, 2014. [Google Scholar]

- Kalogirou, S.A. Solar Energy Engineering, Processes and Systems; Press, A., Ed.; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Bartali, R.; Crema, L. Study on Carnauba Wax as Phase-Change Material Integrated in Evacuated-Tube Collector for Solar-Thermal Heat Production. Clean Energy 2023, 7, 547–554. [Google Scholar] [CrossRef]

- Tasmin, N.; Farjana, S.H.; Hossain, M.R.; Golder, S.; Mahmud, M.A.P. Integration of Solar Process Heat in Industries: A Review. Clean Technol. 2022, 4, 97–131. [Google Scholar] [CrossRef]

- Rockenbaugh, C.; Dean, J.; Lovullo, D.; Liesell, L.; Barker, G.; Hanckock, E.; Norton, P. High Performance Flat Plate Solar Thermal Collector Evaluation; NREL/TP-7A40-66215; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2016. [Google Scholar]

- Ikmal, N.; Azha, S.; Hussin, H.; Nasif, M.S. Thermal Performance Enhancement in Flat Plate Solar Collector Solar Water Heater A Review. Processes 2020, 8, 756. [Google Scholar] [CrossRef]

- Greco, A.; Gundabattini, E.; Gnanaraj, D.S.; Masselli, C. A Comparative Study on the Performances of Flat Plate and Evacuated Tube Collectors Deployable in Domestic Solar Water Heating Systems in Different Climate Areas. Climate 2020, 8, 78. [Google Scholar] [CrossRef]

- Desai, N.B.; Bandyopadhyay, S. Comparison of Parabolic Trough and Linear Fresnel Collectors Based Concentrating Solar Power Plants Using Organic Rankine Cycle. Chem. Eng. Trans. 2015, 45, 1597–1602. [Google Scholar] [CrossRef]

- Maghsoudizadeh, M.; Ameri, M.; Javaran, E.J. Comparative Study of Parabolic Trough and Linear Fresnel Collectors from Advanced Exergy Point of View. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 372. [Google Scholar] [CrossRef]

- Shokrnia, M.; Cagnoli, M.; Grena, R.; D’Angelo, A.; Lanchi, M.; Zanino, R. Comparative Techno-Economic Analysis of Parabolic Trough and Linear Fresnel Collectors with Evacuated and Non-Evacuated Receiver Tubes in Different Geographical Regions. Processes 2024, 12, 2376. [Google Scholar] [CrossRef]

- Milani, D.; Abbas, A. Multiscale Modeling and Performance Analysis of Evacuated Tube Collectors for Solar Water Heaters Using Diffuse Flat Reflector. Renew Energy 2016, 86, 360–374. [Google Scholar] [CrossRef]

- Elarem, R.; Alqahtani, T.; Mellouli, S.; Aich, W.; Ben Khedher, N.; Kolsi, L.; Jemni, A. Numerical Study of an Evacuated Tube Solar Collector Incorporating a Nano-PCM as a Latent Heat Storage System. Case Stud. Therm. Eng. 2021, 24, 100859. [Google Scholar] [CrossRef]

- Guillermo Martínez-Rodríguez Amanda, L.F.S.; Picón-Núñez, M. Solar Thermal Networks Operating with Evacuated-Tube Collectors. Energy 2018, 146, 26–83. [Google Scholar]

- Horta, P.; March, J. One-Sun CPC-Type Solar Collectors with Evacuated Tubular Receivers. Renew. Energy 2019, 134, 247–257. [Google Scholar] [CrossRef]

- Wang, J.; Yu, L.; Jiang, C.; Yang, S.; Liu, T. Optical Analysis of Solar Collector with New V-Shaped CPC. Sol. Energy 2016, 135, 780–785. [Google Scholar] [CrossRef]

- Antonelli, M.; Francesconi, M.; Di Marco, P.; Desideri, U. Analysis of Heat Transfer in Different CPC Solar Collectors: A CFD Approach. Appl. Therm. Eng. 2016, 101, 476–489. [Google Scholar] [CrossRef]

- Buttinger, F.; Beikircher, T.; Pröll, M.; Schölkopf, W. Development of a New Flat Stationary Evacuated CPC-Collector for Process Heat Applications. Sol. Energy 2010, 84, 1166–1174. [Google Scholar] [CrossRef]

- Rabl, A. Optical and Thermal Properties of Compound Parabolic Concentrators. Sol. Energy 1976, 18, 497–511. [Google Scholar] [CrossRef]

- Jung, C.; Senholdt, M.; Spenke, C.; Schmidt, T.; Ulmer, S. Hydrogen Monitoring in the Heat Transfer Fluid of Parabolic Trough Plants. AIP Conf. Proc. 2019, 2126, 080004. [Google Scholar]

- Cortés, F.; Ibarra, M.; Moser, F.; Muñoz, I.; Crespo, A.; Murray, C. Techno-Economical Evaluation of Parabolic Trough Collectors Systems for Steam Processes in the Chilean Industry. AIP Conf. Proc. 2018, 2033, 150003. [Google Scholar] [CrossRef]

- Dieckmann, S.; Dersch, J.; Giuliano, S.; Puppe, M.; Lüpfert, E.; Hennecke, K.; Pitz-Paal, R.; Taylor, M.; Ralon, P. LCOE Reduction Potential of Parabolic Trough and Solar Tower CSP Technology until 2025. AIP Conf. Proc. 2017, 1850, 160004. [Google Scholar] [CrossRef]

- Di Fraia, S.; Figaj, R.D.; Massarotti, N.; Vanoli, L. An Integrated System for Sewage Sludge Drying through Solar Energy and a Combined Heat and Power Unit Fuelled by Biogas. Energy Convers. Manag. 2018, 171, 587–603. [Google Scholar] [CrossRef]

- Vidal, A.; Díaz, A.I. High-Performance, Low-Cost Solar Collectors for Disinfection of Contaminated Water. Water Environ. Res. 2000, 72, 271–276. [Google Scholar] [CrossRef]

- Mortazavi, S.M.; Maleki, A. A Review of Solar Compound Parabolic Collectors in Water Desalination Systems. Int. J. Model. Simul. 2019, 40, 339–354. [Google Scholar] [CrossRef]

- Bolognese, M.; Crema, L.; Luca, P.; Viesi, D.; Bartali, R. Solar Thermal Technologies for Low-Carbon Industrial Processes: Dynamic Modelling, Techno-Economic Analysis and Environmental Impact. Proceedings 2020, 58, 14. [Google Scholar] [CrossRef]

- Suyanto; Hantoro, R.; Suharto, A.; Saleh, R.; Reynaldi, T.D. A Review of Linear Fresnel Reflector Technology for Heating Sulphur Liquid in Nickel Processing Industry. AIP Conf. Proc. 2019, 2088, 020034. [Google Scholar]

- Feuermann, D.; Gordon, J.M. Analysis of a Two-Stage Linear Fresnel Reflector Solar Concentrator. J. Sol. Energy Eng. 1991, 113, 272–279. [Google Scholar] [CrossRef]

- Buscemi, A.; Panno, D.; Ciulla, G.; Beccali, M.; LoBrano, V. Concrete Thermal Energy Storage for Linear Fresnel Collectors; Exploiting the South Mediterranean’s Solar Potential for Agrifood Processes. Energy Conver Manag 2018, 166, 719–734. [Google Scholar] [CrossRef]

- Bolognese, M.; Viesi, D.; Bartali, R.; Crema, L. Modeling Study for Low-Carbon Industrial Processes Integrating Solar Thermal Technologies. A Case Study in the Italian Alps: The Felicetti Pasta Factory. Sol. Energy 2020, 208, 548–558. [Google Scholar] [CrossRef]

- Renewable Energies Chair of the University of Évora; German Aerospace Center Évora Molten Salt Platform (EMSP). Available online: http://www.emsp.uevora.pt/index.html (accessed on 6 February 2025).

- Dicke, N.; Meyer-Grünefeldt, M.; Wittmann, M.; Stengler, J.; Horta, P.; Martins, P.; Torabzadegan, M.; Schmitz, K.; Schmitz, M.; Gathmann, N.; et al. Demonstration of 3.5 MWth Parabolic Trough with Ternary Molten Salt at the Évora Molten Salt Platform. In Proceedings of the SolarPACES Conference Proceedings, Rome, Italy, 8–11 October 2024; Volume 1. [Google Scholar] [CrossRef]

- Gavagnin, G.; Sánchez, D.; Martínez, G.S.; Rodríguez, J.M.; Muñoz, A. Cost Analysis of Solar Thermal Power Generators Based on Parabolic Dish and Micro Gas Turbine: Manufacturing, Transportation and Installation. Appl. Energy 2017, 194, 108–122. [Google Scholar] [CrossRef]

- Reinalter, W.; Ulmer, S.; Heller, P.; Rauch, T.; Gineste, J.M.; Ferrière, A.; Nepveu, F. Detailed Performance Analysis of the 10-Kw CNRS-PROMES Dish/Stirling System. In Proceedings of the Concentrated Solar Power and Chemical Energy Tecnologies, Seville, Spain, 20–23 June 2006. [Google Scholar]

- Javier, F.; Granados, G.; Silva, M.A.; García, F.J.; Pérez, M.A.S. Thermal Model of the EuroDish Solar Stirling. J. Sol. Energy Eng. 2008, 130, 011014. [Google Scholar] [CrossRef]

- Boujjat, H.; Rodat, S.; Abanades, S. Techno-Economic Assessment of Solar-Driven Steam Gasification of Biomass for Large-Scale Hydrogen Production. Processes 2021, 9, 462. [Google Scholar] [CrossRef]

- Murat Cekirge, H.; Eser Erturan, S.; Stanley Thorsen, R. CSP (Concentrated Solar Power)—Tower Solar Thermal Desalination Plant. Am. J. Mod. Energy 2020, 6, 51–58. [Google Scholar] [CrossRef]

- Sanz-Bermejo, J.; Muñoz-Antón, J.; Gonzalez-Aguilar, J.; Romero, M. Optimal Integration of a Solid-Oxide Electrolyser Cell into a Direct Steam Generation Solar Tower Plant for Zero-Emission Hydrogen Production. Appl. Energy 2014, 131, 238–247. [Google Scholar] [CrossRef]

- Hussaini, Z.A.; King, P.; Sansom, C. Numerical Simulation and Design of Multi-Tower Concentrated Solar Power Fields. Sustainability 2020, 12, 2402. [Google Scholar] [CrossRef]

- Cabrera, F.J.; Fernández-García, A.; Silva, R.M.P.; Pérez-García, M. Use of Parabolic Trough Solar Collectors for Solar Refrigeration and Air-Conditioning Applications. Renew. Sustain. Energy Rev. 2013, 20, 103–118. [Google Scholar] [CrossRef]

- Roccabruna, M.; Menna, F.; Remondino, F.; Crema, L. Solar Flux Map Distribution of a Parabolic-Spheric Dish Based on Photographic Method. In Proceedings of the ISES EuroSun 2018 Conference Proceedings, Rapperswil, Switzerland, 10–13 September 2018; pp. 1–14. Available online: http://proceedings.ises.org (accessed on 6 February 2025).

- Karabulut, H.; Yucesu, H.S.; Cinar, C.; Aksoy, F. Construction and Testing of a Dish/Stirling Solar Energy Unit. J. Energy Inst. 2009, 82, 228–232. [Google Scholar] [CrossRef]

- Soomro, M.I.; Mengal, A.; Memon, Y.A.; Khan, M.W.A.; Shafiq, Q.N.; Mirjat, N.H. Performance and Economic Analysis of Concentrated Solar Power Generation for Pakistan. Processes 2019, 7, 575. [Google Scholar] [CrossRef]

- Gu, Z. History Review of Nuclear Reactor Safety. Ann. Nucl. Energy 2018, 120, 682–690. [Google Scholar] [CrossRef]

- COMMISSARIAT À L’ÉNERGIE ATOMIQUE ET AUX ÉNERGIES ALTERNATIVES. Les Centrales Nucléaires Dans Le Monde/Nuclear Power Plants in the World—ÉDITION 2019; CEA-Commissariat a l’energie atomique et aux energies alternatives: Gif sur Yvette, France, 2018; ISBN 1280-9039. [Google Scholar]

- International Atomic Energy Agency. IAEA Annual Report 2023; IAEA Annual Report; International Atomic Energy Agency: Vienna, Austria, 2023; p. 133. [Google Scholar]

- International Energy Agency. World Energy Outlook 2023; International Energy Agency: Paris, France, 2023; p. 355. [Google Scholar]

- International Atomic Energy Agency. Operating Experience with Nuclear Power Stations in Member States; IAEA: Vienna, Austria, 2024; p. 1518. [Google Scholar]

- World Nuclear Association. World Nuclear Performance Report 2023; World Nuclear Association: London, UK, 2023; p. 64. [Google Scholar]

- International Atomic Energy Agency. Nuclear Power Reactors in the World, 2024th ed.; International Atomic Energy Agency: Vienna, Austria, 2024; ISBN 978-92-0-122224-4. [Google Scholar]

- Kok, K.D. (Ed.) Nuclear Engineering Handbook, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2016; ISBN 978-1-315-37382-9. [Google Scholar]

- Wiss, T.; Konings, R.J.M.; Staicu, D.; Benedetti, A.; Colle, J.-Y.; Rondinella, V.V.; Maugeri, E.; Talip, Z.; Janssen, A.; Dieste, O.; et al. Impact of Alpha-Damage and Helium Production on the Heat Capacity of Actinide Oxides. Front. Nucl. Eng. 2025, 4, 1495360. [Google Scholar] [CrossRef]

- Vălu, S.-O.; De Bona, E.; Popa, K.; Griveau, J.-C.; Colineau, E.; Konings, R.J.M. The Effect of Lattice Disorder on the Low-Temperature Heat Capacity of (U1−yThy)O2 and 238Pu-Doped UO2. Sci. Rep. 2019, 9, 15082. [Google Scholar] [CrossRef] [PubMed]

- Wiss, T.; Hiernaut, J.-P.; Roudil, D.; Colle, J.-Y.; Maugeri, E.; Talip, Z.; Janssen, A.; Rondinella, V.; Konings, R.J.M.; Matzke, H.-J.; et al. Evolution of Spent Nuclear Fuel in Dry Storage Conditions for Millennia and Beyond. J. Nucl. Mater. 2014, 451, 198–206. [Google Scholar] [CrossRef]

- Carbol, P.; Wegen, D.H.; Wiss, T.; Fors, P.; Jegou, C.; Spahiu, K. Spent Nuclear Fuel as Waste Material. In Comprehensive Nuclear Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 347–386. ISBN 978-0-08-102866-7. [Google Scholar]

- Wiss, T.; Benedetti, A.; De Bona, E. Radiation Effects in UO2. In Comprehensive Nuclear Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 125–148. ISBN 978-0-08-102866-7. [Google Scholar]

- Wiss, T.; Dieste, O.; De Bona, E.; Benedetti, A.; Rondinella, V.; Konings, R. SUPERFACT: A Model Fuel for Studying the Evolution of the Microstructure of Spent Nuclear Fuel during Storage/Disposal. Materials 2021, 14, 6538. [Google Scholar] [CrossRef] [PubMed]

- Beynon, T.D. The Nuclear Physics of Fast Reactors. Rep. Prog. Phys. 1974, 37, 951–1034. [Google Scholar] [CrossRef]

- Koch, L.J.; Paxton, H.C. Fast Reactors. Annu. Rev. Nucl. Sci. 1959, 9, 437–472. [Google Scholar] [CrossRef]

- Mathew, M.D. Nuclear Energy: A Pathway towards Mitigation of Global Warming. Prog. Nucl. Energy 2022, 143, 104080. [Google Scholar] [CrossRef]

- Cochran, T.B.; Feiveson, H.A.; Patterson, W.; Pshakin, G.; Ramana, M.V.; Schneider, M.; Suzuki, T.; von Hippel, F. Fast Breeder Reactor Programs: History and Status; International Panel on Fissile Materials: Princeton, NJ, USA, 2010; ISBN 978-0-9819275-6-5. [Google Scholar]

- Simnad, M. Overview of Fast Breeder Reactors. Energy 1998, 23, 523–531. [Google Scholar] [CrossRef]

- Lopez-Solis, R.; François, J.-L. The Breed and Burn Nuclear Reactor: A Chronological, Conceptual, and Technological Review. Int. J. Energy Res. 2018, 42, 953–965. [Google Scholar] [CrossRef]

- Liu, B.; Han, J.; Liu, F.; Sheng, J.; Li, Z. Minor Actinide Transmutation in the Lead-Cooled Fast Reactor. Prog. Nucl. Energy 2020, 119, 103148. [Google Scholar] [CrossRef]

- Koch, L. Minor Actinide Transmutation—A Waste Management Option. J. Common Met. 1986, 122, 371–382. [Google Scholar] [CrossRef]

- Krall, L.M.; Macfarlane, A.M.; Ewing, R.C. Nuclear Waste from Small Modular Reactors. Proc. Natl. Acad. Sci. USA 2022, 119, e2111833119. [Google Scholar] [CrossRef]

- Demkowicz, P.A.; Liu, B.; Hunn, J.D. Coated Particle Fuel: Historical Perspectives and Current Progress. J. Nucl. Mater. 2019, 515, 434–450. [Google Scholar] [CrossRef]

- Locatelli, G.; Mancini, M.; Todeschini, N. Generation IV Nuclear Reactors: Current Status and Future Prospects. Energy Policy 2013, 61, 1503–1520. [Google Scholar] [CrossRef]

- Ingersoll, D.T. Deliberately Small Reactors and the Second Nuclear Era. Prog. Nucl. Energy 2009, 51, 589–603. [Google Scholar] [CrossRef]

- Zohuri, B. Generation IV Nuclear Reactors. In Nuclear Reactor Technology Development and Utilization; Elsevier: Amsterdam, The Netherlands, 2020; pp. 213–246. ISBN 978-0-12-818483-7. [Google Scholar]

- International Atomic Energy Agency; OECD Nuclear Energy Agency. Small and Medium Power Reactors: Project Initiation Study Phase I; International Atomic Energy Agency: Vienna, Austria, 1985; p. 168. [Google Scholar]

- OECD Nuclear Energy Agency. Small and Medium Reactors Volume 1; Nuclear Energy Agency: Paris, France, 1991; p. 134. [Google Scholar]

- Schlegel, J.P.; Bhowmik, P.K. Small Modular Reactors. In Nuclear Power Reactor Designs; Elsevier: Amsterdam, The Netherlands, 2024; pp. 283–308. ISBN 978-0-323-99880-2. [Google Scholar]

- OECD Nuclear Energy Agency. Small Modular Reactors: Challenges and Opportunities; Nuclear Energy Agency: Paris, France, 2021; p. 56. [Google Scholar]

- Vujić, J.; Bergmann, R.M.; Škoda, R.; Miletić, M. Small Modular Reactors: Simpler, Safer, Cheaper? Energy 2012, 45, 288–295. [Google Scholar] [CrossRef]

- Hussein, E.M.A. Emerging Small Modular Nuclear Power Reactors: A Critical Review. Phys. Open 2020, 5, 100038. [Google Scholar] [CrossRef]

- Hidayatullah, H.; Susyadi, S.; Subki, M.H. Design and Technology Development for Small Modular Reactors—Safety Expectations, Prospects and Impediments of Their Deployment. Prog. Nucl. Energy 2015, 79, 127–135. [Google Scholar] [CrossRef]

- Mignacca, B.; Locatelli, G. Economics and Finance of Small Modular Reactors: A Systematic Review and Research Agenda. Renew. Sustain. Energy Rev. 2020, 118, 109519. [Google Scholar] [CrossRef]

- Sainati, T.; Locatelli, G.; Brookes, N. Small Modular Reactors: Licensing Constraints and the Way Forward. Energy 2015, 82, 1092–1095. [Google Scholar] [CrossRef]

- International Atomic Energy Agency. Advances in Small Modular Reactor Technology Developments; International Atomic Energy Agency: Vienna, Austria, 2022. [Google Scholar]

- Giaconia, A.; Montagnino, F.; Paredes, F.; Donato, F.; Caputo, G.; Mazzei, D. Co-Generation and Innovative Heat Storage Systems in Small-Medium CSP Plants for Distributed Energy Production. AIP Conf. Proc. 2017, 1850, 110002. [Google Scholar] [CrossRef]

- Guedez, R.; Guccione, S.; Trevisan, S.; Horta, P.; Stengler, J.; Martins, P.; Meyer-Grünefeldt, M.; López-Román, A.; Barberis, S.; Xhani, I. Demonstration of the SOLARSCO2OL sCO2 Power Cycle for Future Hybrid CSP-PV Plants at the Évora Molten Salt Platform. In Proceedings of the 28th International Conference on Concentrating Solar Power and Chemical Systems, SolarPACES 2022, Albuquerque, NM, USA, 27–30 September 2022. [Google Scholar]

- Migliari, L.; Cocco, D.; Puddu, P. Influence of Solar Field Recirculation on Medium-Size CSP Performance. Sol. Energy 2018, 159, 10–19. [Google Scholar] [CrossRef]

- Ruth, M.F.; Zinaman, O.R.; Antkowiak, M.; Boardman, R.D.; Cherry, R.S.; Bazilian, M.D. Nuclear-Renewable Hybrid Energy Systems: Opportunities, Interconnections, and Needs. Energy Convers. Manag. 2014, 78, 684–694. [Google Scholar] [CrossRef]

- Petrovic, B. Role of High-Temperature Reactors in Sustainable Development and Synergy with Renewable Energy Sources; Nuclear and Radiological Engineering, Georgia Tech: Atlanta, GA, USA, 2014. [Google Scholar]

- Popov, D.; Borissova, A. Innovative Configuration of a Hybrid Nuclear-Solar Tower Power Plant. Energy 2017, 125, 736–746. [Google Scholar] [CrossRef]

- Zhao, B.; Cheng, M.; Liu, C.; Dai, Z. Conceptual Design and Preliminary Performance Analysis of a Hybrid Nuclear-Solar Power System with Molten-Salt Packed-Bed Thermal Energy Storage for on-Demand Power Supply. Energy Convers. Manag. 2018, 166, 174–186. [Google Scholar] [CrossRef]

- Soto, G.J.; Wagner, M.J.; Neises, T.W.; Lindley, B.A. Performance Analysis of Integrated Nuclear-Solar Energy System Sharing Same Molten Salt Thermal Energy Storage. Prog. Nucl. Energy 2024, 17, 105166. [Google Scholar] [CrossRef]

- Son, I.W.; Jeong, Y.H.; Choi, Y.J.; Lee, J.I. Feasibility Study of Solar-Nuclear Hybrid System for Distributed Power Source. Energy Convers. Manag. 2021, 230, 113808. [Google Scholar] [CrossRef]

- Al Kindi, A.; Marco Pantaleo, A.; Wang, K.; Al Kindi, A.A.; Pantaleo, A.M.; Markides, C.N. Optimal System Configuration and Operation Strategies of Flexible Hybrid Nuclear-Solar Power Plants. In Proceedings of the 33rd International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Osaka, Japan, 29 June–3 July 2020. [Google Scholar]

- Al Kindi, A.; Christos, N. Markides Hybrid Nuclear-Solar Power. Ph.D. Thesis, Imperial College London Department of Chemical Engineering, London, UK, 2023. [Google Scholar]

- Popov, P.; Borissova, A. Innovative Configuration of a Hybrid Nuclear-Parabolic Through Solar Power Plant. Int. J. Sustain. Energy 2018, 37, 616–639. [Google Scholar] [CrossRef]

- Tauveron, N.; Pham, Q.T.; Alpy, N. Hybridization of a small modular reactor with a solar power plant using a supercritical carbon dioxide brayton cycle. In Proceedings of the 3rd European Supercritical CO2 Conference, Paris, France, 19–20 September 2019. [Google Scholar]

- White, B.T.; Lindley, B.; Raza, T.; Wagner, M. Thermodynamic Modeling of a Supercritical Steam Rankine Cycle for an Integrated CSP-Nuclear System. In Proceedings of the SolarPACES 2022 28th International Conference Solar Power Chemical Energy Systems, Albuquerque, NM, USA, 27–30 September 2022. [Google Scholar]

- Naserbegi, A.; Aghaie, M. Exergy Optimization of Nuclear-Solar Dual Proposed Power Plant Based on GWO Algorithm. Prog. Nucl. Energy 2021, 140, 103925. [Google Scholar] [CrossRef]

| Range of Temp. | Collector | Tracking | Concentration | Temperature | HTF | Application | Performance Analysis | Reference |

|---|---|---|---|---|---|---|---|---|

| LOW TEMPERATURE 50–150 °C | FPC | No | No | 50–80 °C | Air or Water 50–100 | Domestic water heating District heating Cleaning process Food agriculture drying Hydrogen AEM/PEM Heating of water and chemical for (50–80 °C) Air heating Domestic water heating District heating Galvanic bath | High efficiency at low temperatures; limited scalability for high-temperature applications. Efficiency range: 30–70% | [24,25,26,27,28,29,30,31] |

| ETC | No | No | 50–120 °C | Water 50–120 | ETC insulation is better than FPC, enabling higher efficiency in lower environmental temperatures. Efficiency range: 20–50% | [32,33,34] | ||

| CPC | No | Yes (3–10) | 50–180 °C | Water 50–150 | Moderate efficiency with improved acceptance of DNI, allowing for higher heat collection and operating temperature. Efficiency range: 25–55% | [35,36,37] | ||

| MEDIUM TEMPERATURE 150–400 °C | FVC | No | No | 100–200 °C | Water 50–150 | Solar cooling Steam production for steam Solar dry Water disinfection Desalination Heating liquid sulfur in the nickel industry Power plant Agrifood processes | Simplicity in design but no tracking leads to lower efficiency. Efficiency range: 60–80% | [38] |

| PTC | Yes (1 axis) | Yes (10–100) | 100–400 °C | Water, oil, or direct steam Molten salt sCO2 | PTCs are effective for large-scale plants, with high-temperature operation that requires more complex heat transfer systems. Land use 45% Efficiency range: 60–80% | [39,40,41,42,43,44,45,46] | ||

| LFR | Yes (1-axis) | Yes (10–100) | 100–400 °C | Water, oil, or direct steam Molten salt | Lower efficiency than PTC but cheaper and easier to install. Higher land use with respect to other technologies in order to avoid self-shading phenomena. Land use 66% Efficiency range: 40–65% | [47,48,49,50] | ||

| HIGH TEMPERATURE: 400–1200 °C | PTC | YES (1 axis) | Yes (>100) | 595 °C | Molten salt | Electricity | Specialized HTFs for high-temperature operation are required. Efficiency range: 60–80% | [51,52] |

| Solar Dish | Yes (2 axes) | Yes (100–1000) | 400–1200 °C | Oil, helium, or steam Molten salt | Electricity Power plant SMR steam methane reforming and (850 °C) SG steam gasification for SOEC cell Steam methane reforming Iron-oxide-based redox pair cycle (1200 °C) Sulfur iodine cycle (850 °C) Sulfur hybrid 1200 °C Water splitting Biomass Gasification Thermochemical water splitting Two-step thermochemical process based on MgO/Mg redox reaction Methane cracking (1800 °C) High-temperature electrolysis (650 °C) | High efficiency due to point-focus design, but challenging to scale up. Complexity in heat volumetric receiver Efficiency range: 45–72 % | [53,54,55,56] | |

| Solar Tower | Yes (2 axes) | Yes (100–1000) | 400–1200 °C | Oil, helium, steam, or molten salt sCO2 | Best efficiency among CSP technologies; highly scalable but complex thermal management Complexity in heat volumetric receiver Efficiency range: 70–90% | [56,57,58,59] |

| Coolant | Base | Reactor Types | Developing Countries (Operational/Licensing Phase) | Max Output [MWe] | Output T [°C] | Fuel Type |

|---|---|---|---|---|---|---|

| Water | Land | PWR/PHWR/BWR | ARG, CAN, CHN, CZE, FRA, JPN, KOR, RUS, CHE, GBR, and USA | 450/300/250 | 280–330 | UO2 pellets |

| Water | PWR | CHN, KOR, and RUS | 325 | |||

| Gas | Land | HTGR/GFR | CAN, CHN, JPN, RUS, ZAF, and USA | 300/265 | 600–950 | TRISO (U/Th) and UC pellets |

| Liquid metal | Land | LMFR | CAN, ITA, JAP, KOR, RUS, SWE, and USA | 450 | 500–650 | MOX, U-Zr, and (U, Pu)2N3 |

| Molten salt | Land | MSR/FHR | CAN, CHN, DNK, JPN, NLD, GBR, and USA | 300/140 | 600–800 | TRISO and (U, Th)F4 + salts |

| Type of Nuclear Reactor | Nuclear Power | Solar Collector | Solar Power | Point Integration | Solar Field | TES | Main Results | REF |

|---|---|---|---|---|---|---|---|---|

| Lead Cooled Reactor (LFR) | 950 MWth varying PWR 20–1900 MWth | Solar tower | 670 MWth TES | CSP parallel with NP Charging Molten Salt | 1.27 × 106 m2 (127 ha) | YES | -Hybrid has better ability to dispatch electricity at times when electricity prices are high. -Improves the capability to work neatly with the design point. -Cost saving from turbine economy of scale. −10% benefit on electricity price -Best impact when solar and nuclear are in the same order (250 MW nuclear and 160 MW solar). | [108] |

| Nuscale | 160 MWth | Solar tower | 0–71 MWth | NP series with CSP Steam generation | 0.36 km2 (Reflective area) | YES | -Solar heat to electrical efficiency 56%. -System can deliver flexible power ranging from 55 to 100% -The LCOE is 78 USD/MWh less than CSP and comparable with the LCOE of nuclear energy. | [110,111]. |

| KAIST MMR Supercritical CO2 | 36.2 MWth (basic unit) Nuclear to solar ratio 1.3 ÷ 5.7 | Solar tower and PTC | 63.35 MWth + Reheat 27.15 MWth (CSP + TES) | CSP in parallel to MMR integration in recompression reheating Solar salt –570 °C | 0.52 km2 | YES | -Reduced solar field area by 2.35 times. -High-capacity factor of MMR than MMR alone; of 2.35 of the solar field. -For remote applications- reduction in transportation and installation. -Does not always satisfy 100% of the energy demand but it is possible to overcome this problem by increasing the ratio of MMR power. | [109] |

| NuScale SMR | 160 MWth | Solar tower Tonopah Solar energy | 213.168 MWth Salt at 565 °C | CSP in series with Nuclear CSP integration after the reactor Exchanger Superheater and Reheater Of steam gas turbine | 0.41 km2 (9247 heliostats) | YES | -The superheating of steam after the reactor allows an increase in electrical efficiency by 37.5.%. - CSP reaches 56.2% efficiency in the gas turbine. -Reduction in cost and land occupation. | [106] |

| NuScale SMR | 160 MWth | PTC | 86 MWth | CSP in series with Nuclear CSP integration after the reactor Exchanger Superheater and Reheater Of steam gas turbine | 62.26 ha collector field area (23.36 ha reflective area) | YES | −13.56 cent/kWh. -The superheating of live steam by PTC increases the nuclear efficiency by 33%. -CSP is more efficient for cycle reduction in land occupation and cost reduction. | [112] |

| Nucsale SMR | 160 MWth | Solar tower | 86 MWth | Solar tower CSP in parallel | YES | -Brayton cycles instead of Rankine cycles. -Increased efficiency by 11%. | [113] | |

| SmAHTR Fluorinated salt cooled small modular advanced temperature reactor | 125 MWth 50 MWel Parametric analysis for 0,50,100 MWe SMR | Solar tower | Parametric analysis for 200, 150, 100 MWe CSP | Parallel SMR and CSP with PCM thermal storage | YES Storage with PCM | -Fluctuation of heat generation, reduced start/stop of generation. -Large TES smaller CSP field. -Higher efficiency. -Optimal conf 200 Mwe 50% nuclear and 50%CSP and 14.8 thermal storage. | [107] | |

| Lead Fast reactor | 950 MWth | CSP | 750 MWth | -CSP + LFR increases dispatchability. | [114] | |||

| NuScale | 157 MWth 70.2 MWel - | Solar tower | 62.574 MWth | Parallel SMR | 93.32 ha helostat field 0.1913 ha reflective area Storage 948 MWhr (15 hr) (nitrate salt) Desalination system MWth 28.47 | YES 948 MWhr | -Plant efficiency from 27.03% to 30.18%. -The heat at a lower temperature allows the desalination of water (82.11 kg/s). | [115] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bartali, R.; De Bona, E.; Bolognese, M.; Vaccari, A.; Testi, M.; Crema, L. Hybrid Small Modular Nuclear Reactor with Concentrated Solar Power: Towards 4+ Reactors? Solar 2025, 5, 12. https://doi.org/10.3390/solar5010012

Bartali R, De Bona E, Bolognese M, Vaccari A, Testi M, Crema L. Hybrid Small Modular Nuclear Reactor with Concentrated Solar Power: Towards 4+ Reactors? Solar. 2025; 5(1):12. https://doi.org/10.3390/solar5010012

Chicago/Turabian StyleBartali, Ruben, Emanuele De Bona, Michele Bolognese, Alessandro Vaccari, Matteo Testi, and Luigi Crema. 2025. "Hybrid Small Modular Nuclear Reactor with Concentrated Solar Power: Towards 4+ Reactors?" Solar 5, no. 1: 12. https://doi.org/10.3390/solar5010012

APA StyleBartali, R., De Bona, E., Bolognese, M., Vaccari, A., Testi, M., & Crema, L. (2025). Hybrid Small Modular Nuclear Reactor with Concentrated Solar Power: Towards 4+ Reactors? Solar, 5(1), 12. https://doi.org/10.3390/solar5010012