From Waste to Resource: Exploring the Current Challenges and Future Directions of Photovoltaic Solar Cell Recycling

Abstract

:1. Introduction

2. Problem Statement

- The necessity of innovative recycling technologies that balance cost-effectiveness with high recovery rates for valuable materials.

- The role of international collaboration and policy standardization in addressing regional disparities in recycling infrastructure and regulations.

- A forward-looking perspective on integrating circular economy principles to enhance the sustainability of the PV industry.

3. Overview of PV Solar Cells

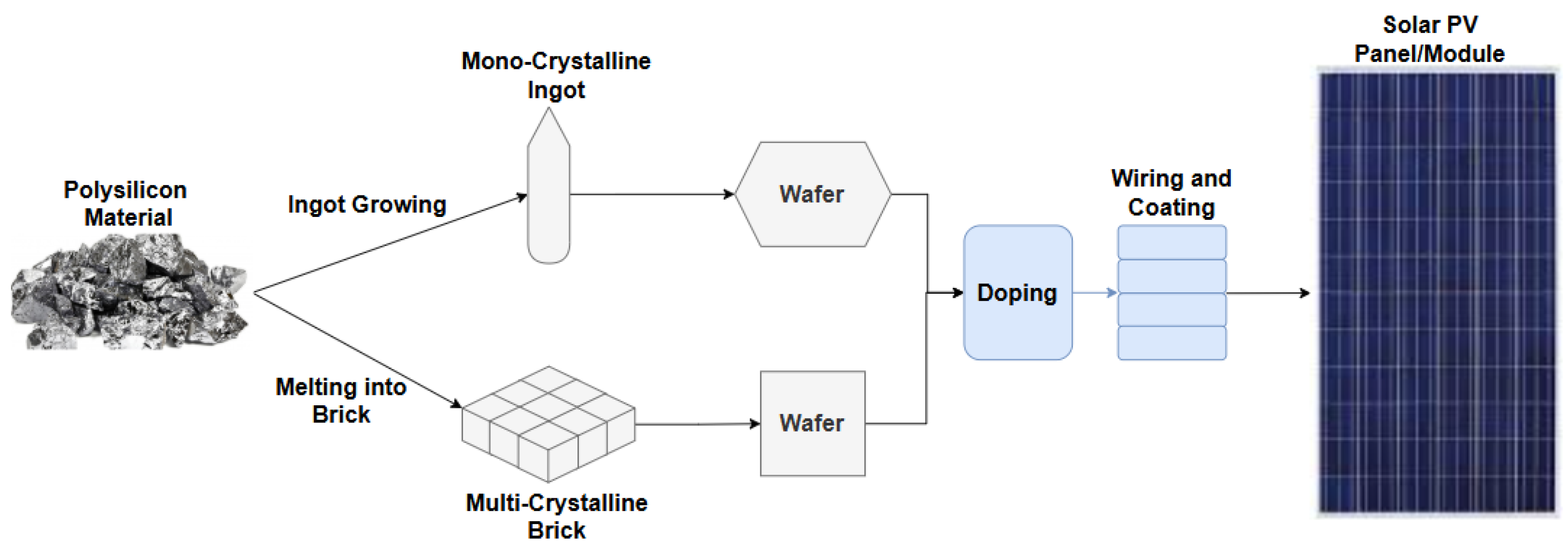

3.1. Crystalline Silicon Solar Cells

- Monocrystalline Silicon Solar Cells (Mono-Si): Monocrystalline silicon solar cells are made from a single continuous crystal structure. These cells are recognized for their high efficiency, typically ranging from 15% to 22%, due to the high purity of the silicon used [9,10]. The production process involves slicing thin wafers from a cylindrical silicon ingot, which is grown using the Czochralski method [11]. The uniformity of the crystal lattice in monocrystalline cells allows for efficient electron flow, resulting in better performance, especially in conditions of low sunlight. Monocrystalline cells are often characterized by their uniform black or dark blue color and their rounded edges [12], which result from the cylindrical shape of the silicon ingot. Due to their higher efficiency, monocrystalline solar panels are generally more expensive than other types [13]. They are widely used in residential and commercial applications where space is at a premium and high efficiency is desired.

- Polycrystalline Silicon Solar Cells (Poly-Si): Polycrystalline silicon solar cells, also known as multicrystalline silicon cells, are made from silicon crystals that are melted together and allowed to cool in a mould [14]. This process results in a cell composed of multiple small crystals, giving polycrystalline cells a distinctive bluish hue and a more fragmented appearance. Polycrystalline cells are generally less expensive to produce than monocrystalline cells because their manufacturing process is simpler and less energy-intensive [15]. The efficiency of polycrystalline cells typically ranges from 13% to 18% [16,17], slightly lower than that of monocrystalline cells. This lower efficiency is due to the presence of grain boundaries between the individual crystals, which can impede the flow of electrons and reduce the overall performance of the cell. Despite their lower efficiency, polycrystalline cells are popular in large-scale solar farms and residential installations.

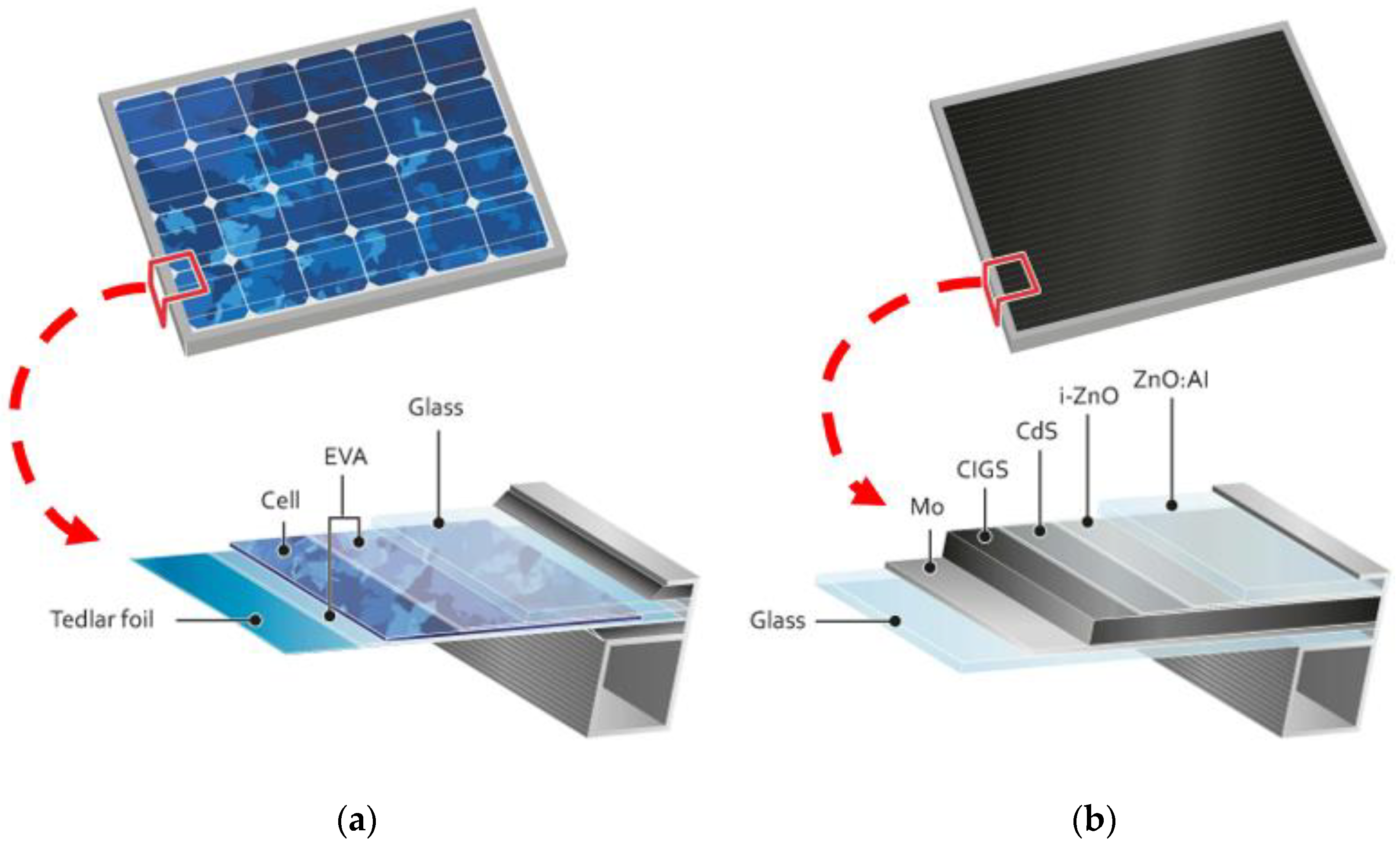

3.2. Thin-Film Solar Cells

- Cadmium Telluride (CdTe) Solar Cells: CdTe solar cells are the most commercially successful thin-film technology, accounting for the majority of the thin-film market share [18]. CdTe cells consist of a thin layer of cadmium telluride as the absorbing material, with cadmium sulfide (CdS) typically used as the window layer [19]. One of the key advantages of CdTe solar cells is their low production cost, which is achieved through a highly automated manufacturing process that involves the rapid deposition of materials onto a substrate. CdTe cells have an efficiency range of 10% to 16%, which is lower than crystalline silicon cells but comparable to other thin-film technologies [20]. However, they have the advantage of better performance in hot climates and under low-light conditions [21], making them suitable for large-scale solar farms in diverse environments. Despite their advantages, CdTe cells pose significant environmental concerns due to the toxicity of cadmium [22], a heavy metal that can be harmful to human health and the environment if not properly managed during disposal or recycling.

- Amorphous Silicon (a-Si) Solar Cells: a-Si solar cells are the earliest and most well-known thin-film technology. Unlike crystalline silicon cells, which have a well-ordered crystal lattice, amorphous silicon cells consist of a non-crystalline form of silicon [23]. This disordered structure allows for the production of very thin layers of silicon, reducing material costs and making the cells flexible and lightweight [24]. The efficiency of amorphous silicon cells is relatively low, typically ranging from 6% to 9% [25], due to the higher defect density in the amorphous structure, which impedes electron flow. However, a-Si cells have a unique advantage in that they can be deposited on a variety of substrates, including flexible materials, enabling their use in applications such as building-integrated photovoltaics (BIPVs) [26,27] and portable solar chargers [28]. The low cost and flexibility of a-Si cells make them attractive for specific niche markets, despite their lower efficiency.

- Copper Indium Gallium Selenide (CIGS) Solar Cells: CIGS solar cells are another promising thin-film technology, known for their high efficiency and versatility. CIGS cells consist of a compound of copper, indium, gallium, and selenium, which serves as the absorbing layer [29]. The composition of CIGS cells can be fine-tuned to optimize performance, making them one of the most efficient thin-film technologies, with efficiencies ranging from 12% to >24% [30]. CIGS cells are typically more efficient than other thin-film technologies like CdTe and a-Si, and they offer greater flexibility in terms of substrate options, including glass, metal, and plastic [31]. This flexibility, combined with their relatively high efficiency, makes CIGS cells suitable for a wide range of applications, from rooftop installations to portable devices. However, the manufacturing process for CIGS cells is more complex and costly than those for other thin-film technologies [32], which has limited their market penetration.

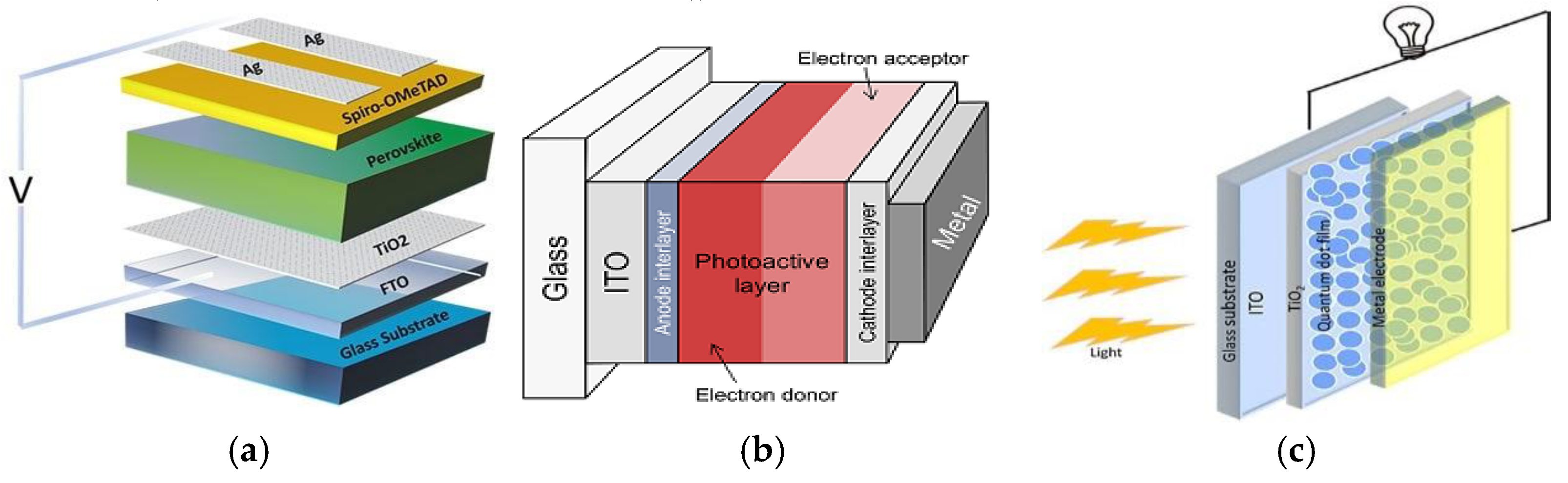

3.3. Emerging PV Technologies

- Perovskite Solar Cells: These solar cells have garnered significant attention in recent years due to their remarkable efficiency improvements and the potential for low-cost production. The term “perovskite” refers to the crystal structure of the materials used in these cells [33], typically a compound of lead or tin halide with an organic component. Perovskite cells have achieved efficiencies exceeding 25% in laboratory settings [34], rivalling those of crystalline silicon cells, and they are continuing to improve rapidly. One of the key advantages of perovskite cells is the ability to manufacture them using solution-based processes, such as printing or coating, which could significantly reduce production costs. Moreover, perovskite materials can be tuned to absorb different wavelengths of light [35], enabling their use in tandem with other PV technologies to create highly efficient multi-junction cells. However, challenges remain, particularly in terms of the long-term stability of perovskite cells and the toxicity of lead-based materials, which must be addressed before commercialization on a large scale.

- Organic Photovoltaic (OPV) Cells: OPV cells represent a class of PV technology that uses organic molecules or polymers to absorb light and generate electricity. OPV cells are flexible, lightweight, and can be produced using low-cost, roll-to-roll manufacturing techniques [36]. While the efficiency of OPV cells is currently lower than that of other PV technologies, typically ranging from 5% to 20% [37], their unique properties make them attractive for applications where flexibility and a low weight are critical, such as in wearable electronics or portable solar chargers. The main challenges facing OPV technology are the relatively low efficiency and limited stability of organic materials [38], which degrade more quickly than inorganic materials when exposed to sunlight and environmental conditions. Nevertheless, ongoing research is focused on improving the efficiency and durability of OPV cells, with the goal of making them competitive with other PV technologies in specific markets.

- Quantum Dot Solar Cells: Quantum dot solar cells are an emerging technology that uses nanoscale semiconductor particles—known as quantum dots—to absorb sunlight and generate electricity [39]. Quantum dots have unique optical and electronic properties that can be tuned by changing their size, enabling the development of solar cells with tailored absorption spectra. This tunability offers the potential for highly efficient multi-junction cells [40], where different layers of quantum dots are optimized to absorb different parts of the solar spectrum [41]. While still in the experimental stage, quantum dot solar cells have shown promise in achieving high efficiencies, particularly when used in tandem with other PV technologies. The main challenges facing quantum dot cells include the scalability of production [42], stability of the materials, and potential environmental and health risks associated with the use of heavy metals in quantum dots.

3.4. Summary

4. Materials Used in the Production of PV Solar Cells

4.1. Materials in Crystalline Silicon Solar Cells

4.2. Materials in Thin-Film Solar Cells

4.3. Materials in Emerging PV Technologies

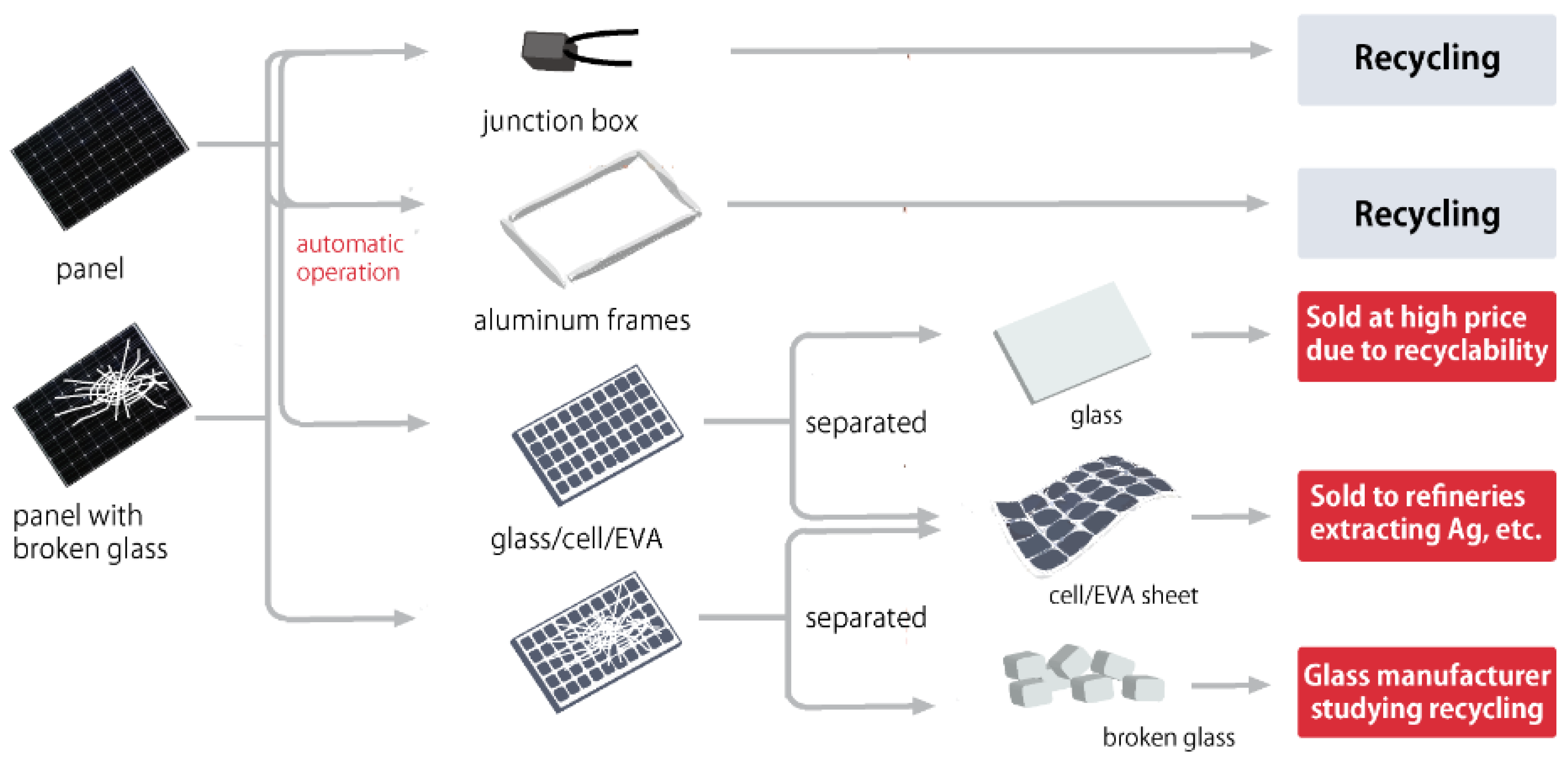

5. Recycling Techniques

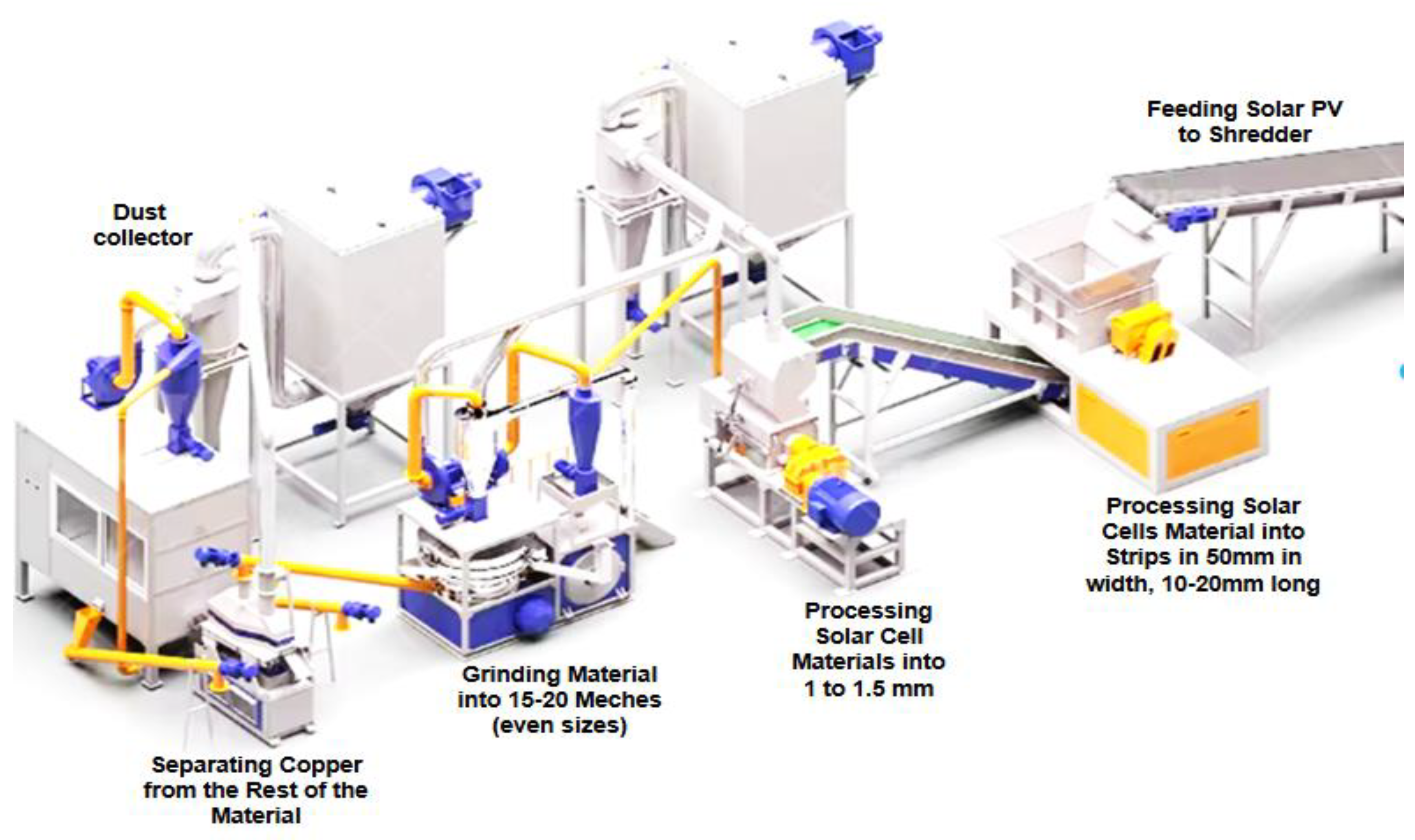

5.1. Mechanical Recycling

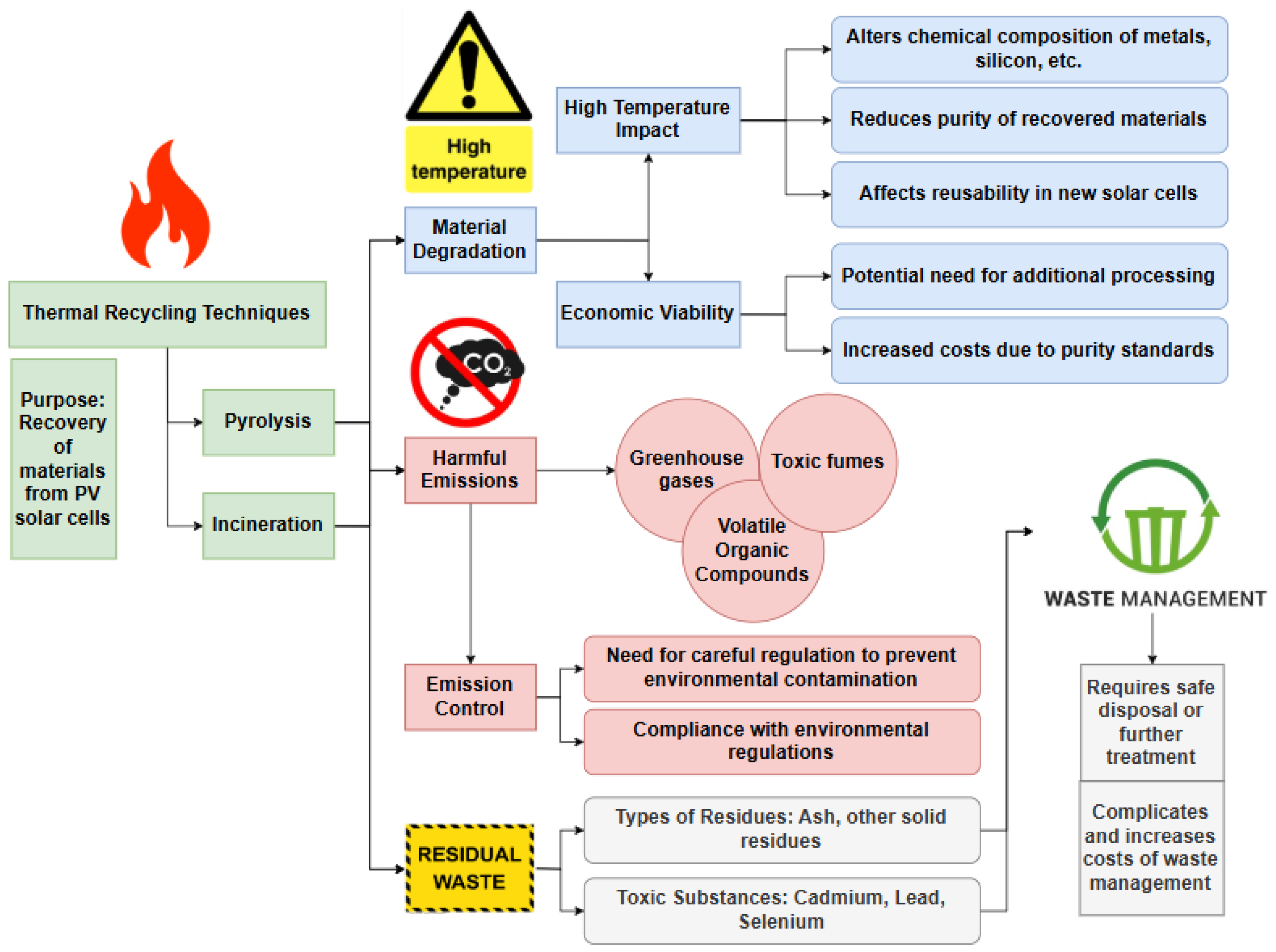

5.2. Thermal Recycling

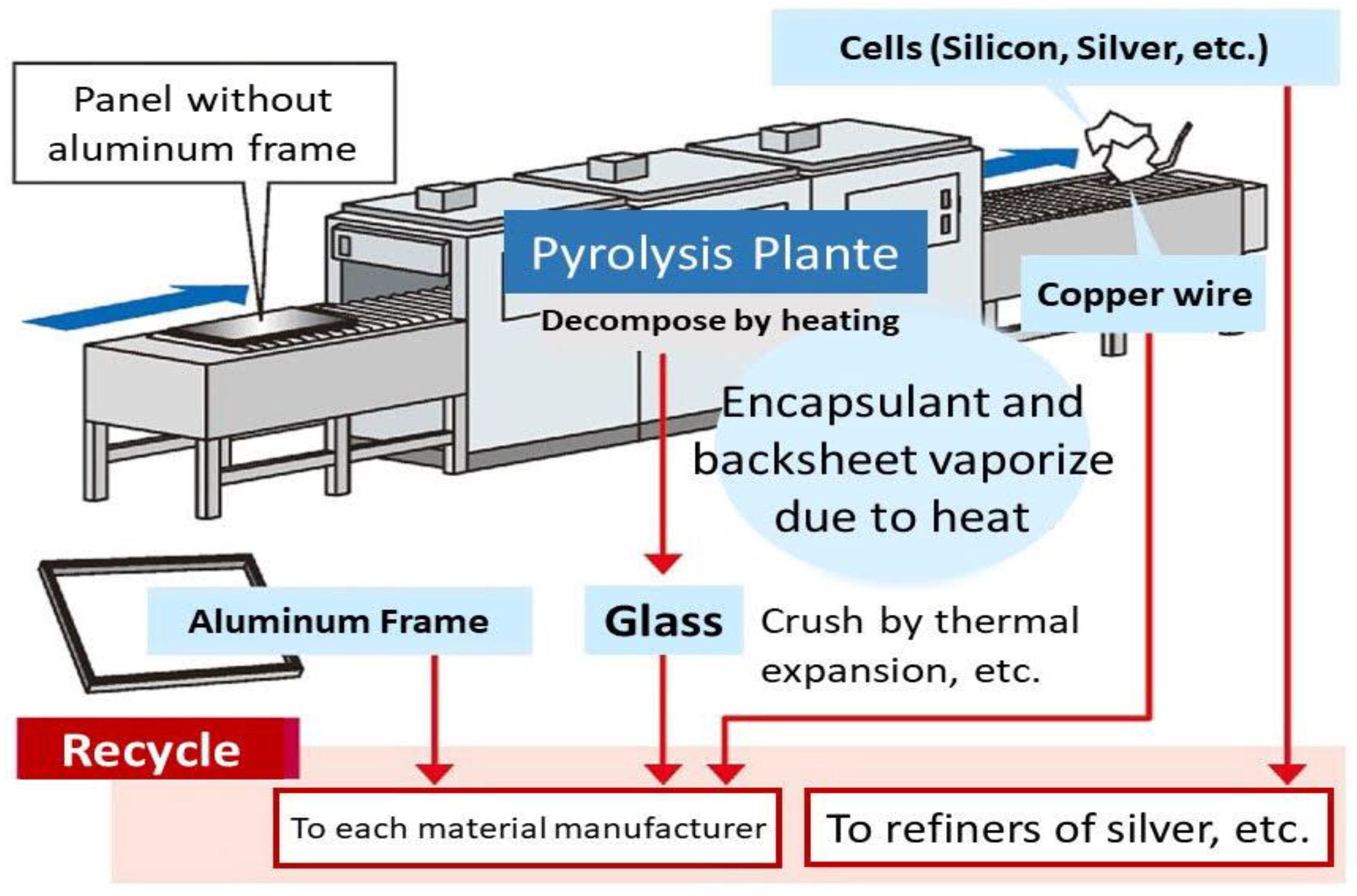

5.2.1. Pyrolysis

5.2.2. Incineration

5.3. Environmental Considerations and Challenges

5.4. Chemical Recycling

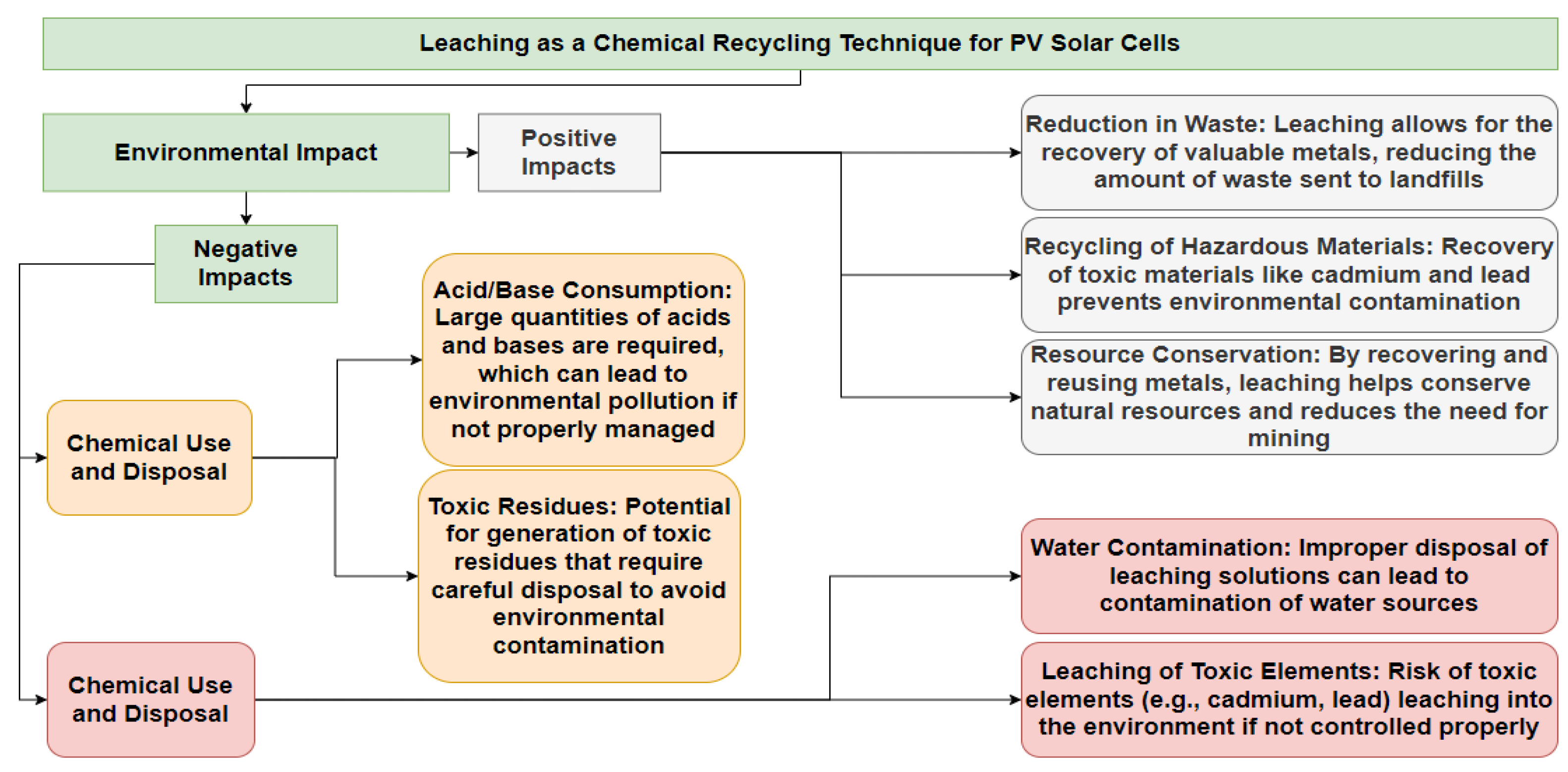

5.4.1. Leaching

- In crystalline silicon solar cells, leaching is primarily used to recover metals like silver and aluminium. The process typically involves crushing the solar cells into small pieces, followed by immersion in a leaching solution, such as nitric acid (HNO3) [104] or hydrochloric acid (HCl) [105]. The acid dissolves the silver contacts, separating them from the silicon and glass. The dissolved silver can then be precipitated out of the solution, purified, and reused in the production of new solar cells or other electronic applications. Additionally, leaching can be used to recover aluminium from the back-side metallization of the cells. The aluminium is dissolved in a basic solution, such as sodium hydroxide (NaOH) [106], and then precipitated and purified. The remaining silicon and glass are usually left intact, allowing for potential recovery and reuse.

- In thin-film solar cells, leaching plays a crucial role in recovering the semiconductor materials that are embedded in the glass or other substrates. For example, in CdTe solar cells, leaching can be used to extract cadmium and tellurium. The process typically involves using acids, such as sulfuric acid (H2SO4) [107], to dissolve the CdTe layer from the glass substrate. The cadmium and tellurium can then be separated, purified, and reused. Given the toxicity of cadmium, careful control of the leaching process is essential to prevent environmental contamination. For CIGS solar cells, leaching is used to recover copper, indium, gallium, and selenium. A combination of acids, such as hydrochloric acid and nitric acid [108], may be used to selectively dissolve these metals. The resulting solutions are then treated to precipitate the individual metals, which can be purified and reused. The remaining glass substrate can often be recycled separately.

- In emerging technologies like perovskite solar cells, leaching is used to recover lead and other materials from the cells. Given the potential environmental and health risks associated with lead, the leaching process must be carefully managed. Acidic solutions, such as acetic acid [109] or nitric acid [92,110], can dissolve the lead compounds in perovskite cells, allowing for their recovery and safe disposal or reuse. Researchers are also exploring less toxic alternatives to lead in perovskites, which would simplify the recycling process and reduce the need for stringent environmental controls.

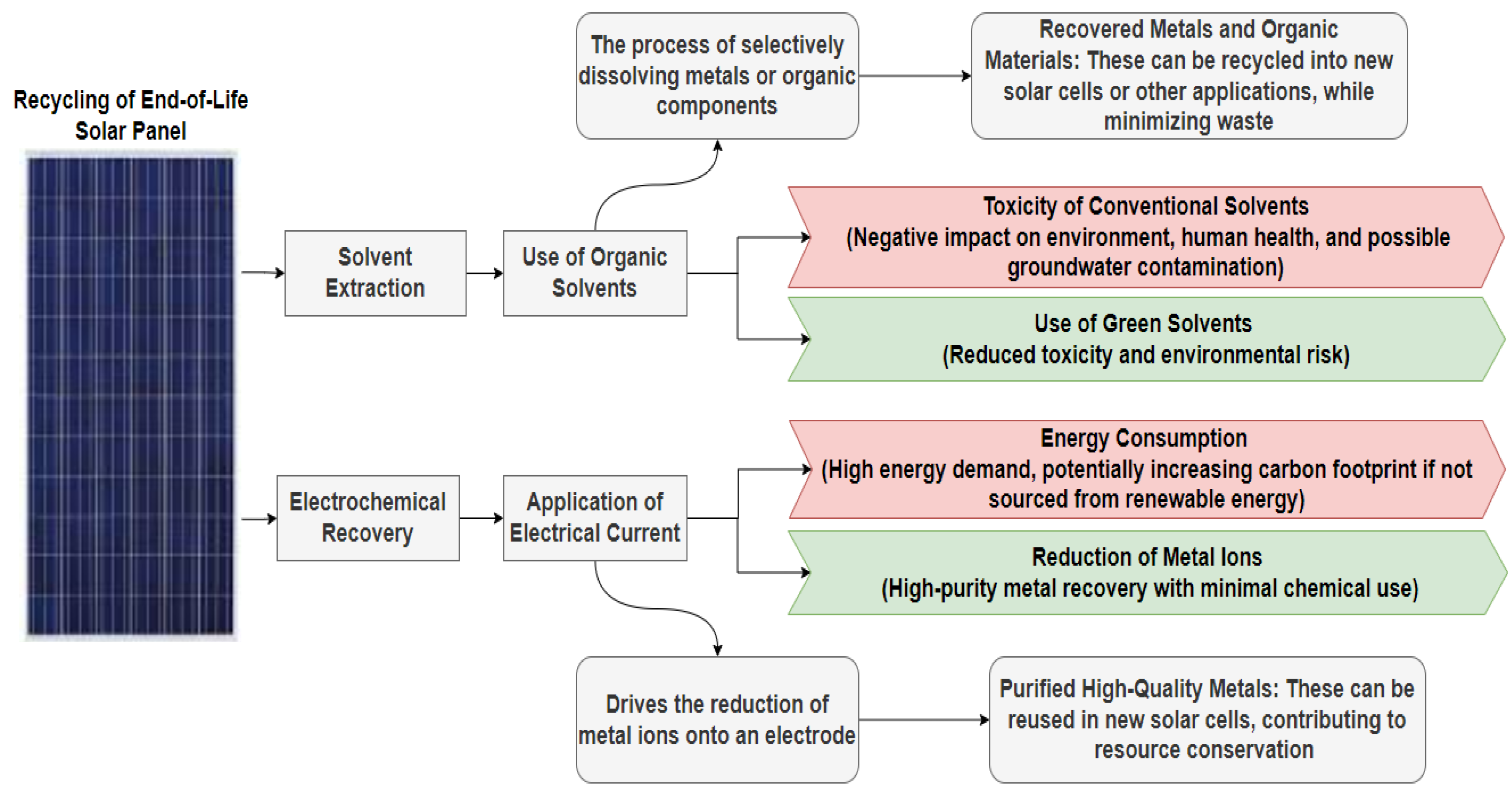

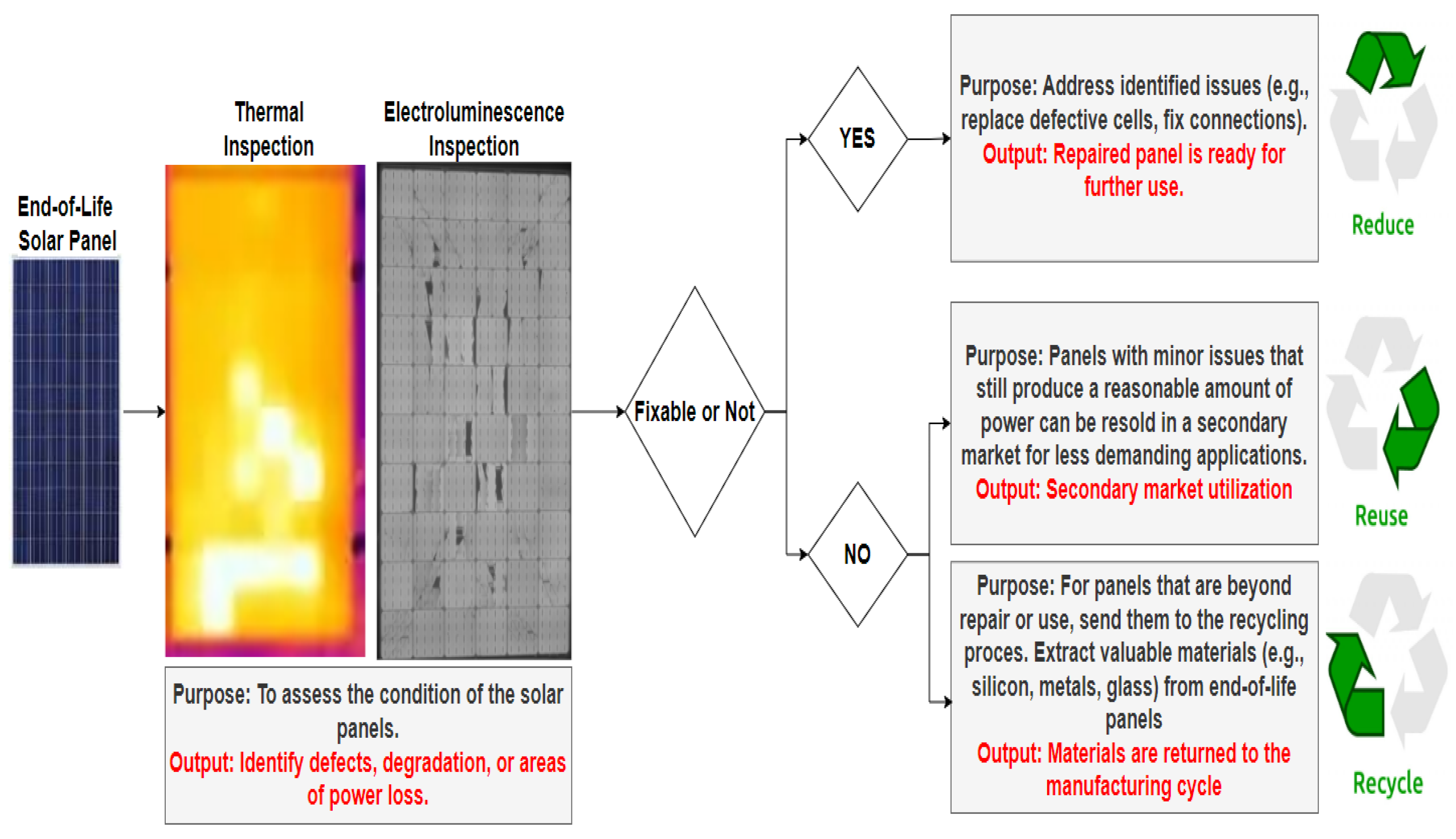

5.4.2. Solvent Extraction and Electrochemical Recovery

- In crystalline silicon solar cells, solvent extraction is less commonly used, but it can play a role in purifying the metals recovered during the leaching process. For example, solvent extraction may be employed to separate silver from other metals dissolved in the acid leachate [111,112]. By carefully choosing the solvent and adjusting the pH of the solution, the silver can be selectively extracted, leaving other metals behind.

- In thin-film technologies, solvent extraction is more commonly applied, particularly for complex mixtures of metals. For instance, in the recycling of CIGS cells, solvent extraction can be used to separate copper, indium, gallium, and selenium from each other after they have been dissolved by leaching. Different solvents, such as kerosene [113] or aliphatic hydrocarbons [114], can be used to selectively extract each metal, which can then be recovered by further chemical processing.

- For emerging technologies like perovskite solar cells, solvent extraction may be used to recover organic components or to purify the metals extracted during leaching [115]. Given the organic nature of many perovskite materials, solvent extraction offers a way to separate these components from the inorganic materials in the cells. Researchers are also investigating the use of green solvents—solvents that are environmentally friendly and less toxic—to improve the sustainability of the recycling process [116,117].

- In crystalline silicon solar cells, electrochemical recovery is often used to purify the silver recovered from the leaching process. The silver ions in the leachate are reduced and deposited onto a cathode, forming high-purity silver that can be reused in new solar cells or other electronic applications [121]. This method is highly efficient and allows for the recovery of silver with minimal impurities.

- Electrochemical recovery is also applicable to thin-film technologies, particularly for the recovery of metals like copper and indium from CIGS cells. After leaching and solvent extraction, the metal ions in the solution can be electrochemically reduced and deposited onto electrodes. This process can produce high-purity metals that are suitable for reuse in new solar cells or other industries [119]. In the case of CdTe cells, electrochemical recovery can be used to recover tellurium from the leachate [122]. The tellurium ions are reduced and deposited onto an electrode, where they can be collected, purified, and reused. The electrochemical process is carefully controlled to ensure that the recovered tellurium is of high purity, which is critical in its reuse in new solar cells.

- Electrochemical recovery is also being explored for use in emerging technologies like perovskite solar cells. Given the presence of lead in many perovskite cells, electrochemical methods can be used to recover and purify lead from the leachate [92,123], minimizing environmental risks and allowing for safe disposal or reuse. Researchers are also investigating the use of electrochemical techniques to recover other materials from perovskite cells, including organic components [124] and alternative metals.

6. Economic Impact of Recycling Solar PV Panels

6.1. Economic Considerations: Cost-Effectiveness of Recycling Processes

6.2. Challenges and Barriers: Addressing the Cost of Recycling, Lack of Infrastructure, and Technical Limitations

7. Conclusions

- Recycling Techniques: The study identified mechanical, thermal, and chemical recycling as the primary methods employed in PV solar cell recycling. Each technique presents unique advantages and challenges, with mechanical processes being more straightforward but less efficient in material recovery, while chemical methods offer higher purity but are costlier and more complex. Emerging hybrid approaches, combining mechanical and chemical processes, have shown the potential to enhance efficiency and scalability, providing a promising direction for future developments.

- Economic and Environmental Impacts: The economic feasibility of recycling remains a significant barrier. The high costs associated with the recovery of valuable materials, such as silver and silicon, and the complexity of the processes involved often outweigh the financial returns. However, the environmental benefits, including significant reductions in waste and resource conservation, underscore the importance of advancing these technologies. Developing cost-effective recycling methods and integrating renewable energy into recycling operations are highlighted as crucial steps to enhance both economic and environmental outcomes. The paper underscores that investment in recycling infrastructure and innovation is crucial in achieving these benefits on a larger scale.

- Policy and Regulations: The paper emphasizes the critical role of government policies and regulatory frameworks in facilitating the development of a sustainable PV recycling industry. EPR schemes, incentives for recycling, and international collaboration are highlighted as key mechanisms to drive industry engagement and ensure compliance with environmental standards. Furthermore, harmonized international regulations could standardize recycling practices, promoting a global approach to PV waste management.

- Future Directions: A significant takeaway from the review is the need for continued research and development in this field. Innovations in material science, such as the development of more easily recyclable PV materials, and advancements in recycling technology, particularly in reducing process costs and increasing efficiency, are vital. The integration of these advancements into existing solar energy infrastructure will be essential in achieving a circular economy in the solar industry. The paper also highlights the potential of “design-for-recyclability” principles, which could streamline material recovery and reduce waste, making future PV systems inherently more sustainable.

- Industry Collaboration: The paper stresses the importance of collaboration across the solar industry, from manufacturers to recyclers, to create a cohesive and efficient recycling ecosystem. The standardization of processes and materials, coupled with a shared commitment to sustainability, will be critical in overcoming the current challenges.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Demir, A.; Dinçer, A.E.; Yılmaz, K. A novel method for the site selection of large-scale PV farms by using AHP and GIS: A case study in İzmir, Türkiye. Sol. Energy 2023, 259, 235–245. [Google Scholar] [CrossRef]

- Badran, G.; Dhimish, M. Comprehensive study on the efficiency of vertical bifacial photovoltaic systems: A UK case study. Sci. Rep. 2024, 14, 18380. [Google Scholar] [CrossRef] [PubMed]

- Hassan, S.; Dhimish, M. Broad-scale Electroluminescence analysis of 5 million+ photovoltaic cells for defect detection and degradation assessment. Renew. Energy 2024, 237, 121868. [Google Scholar] [CrossRef]

- Evro, S.; Wade, C.; Tomomewo, O. Solar PV technology cost dynamics and challenges for US new entrants. Am. J. Energy Res. 2023, 11, 11. [Google Scholar] [CrossRef]

- Downie, C. Strategies for Survival: The International Energy Agency’s response to a new world. Energy Policy 2020, 141, 111452. [Google Scholar] [CrossRef]

- Kim, J.; Rabelo, M.; Padi, S.P.; Yousuf, H.; Cho, E.C.; Yi, J. A review of the degradation of photovoltaic modules for life expectancy. Energies 2021, 14, 4278. [Google Scholar] [CrossRef]

- Chowdhury, M.S.; Rahman, K.S.; Chowdhury, T.; Nuthammachot, N.; Techato, K.; Akhtaruzzaman, M.; Amin, N. An overview of solar photovoltaic panels’ end-of-life material recycling. Energy Strategy Rev. 2020, 27, 100431. [Google Scholar] [CrossRef]

- Ballif, C.; Haug, F.J.; Boccard, M.; Verlinden, P.J.; Hahn, G. Status and perspectives of crystalline silicon photovoltaics in research and industry. Nat. Rev. Mater. 2022, 7, 597–616. [Google Scholar] [CrossRef]

- Lv, Y.; Zhuang, Y.F.; Wang, W.J.; Wei, W.W.; Sheng, J.; Zhang, S.; Shen, W.Z. Towards high-efficiency industrial p-type mono-like Si PERC solar cells. Sol. Energy Mater. Sol. Cells 2020, 204, 110202. [Google Scholar] [CrossRef]

- Dhimish, M.; Hu, Y. Rapid Testing on the Effect of Cracks on Solar Cells Output Power Performance and Thermal Operation. Sci. Rep. 2022, 12, 12168. [Google Scholar] [CrossRef] [PubMed]

- Chatelain, M.; Albaric, M.; Pelletier, D.; Veirman, J.; Letty, E. Numerical method for thermal donors formation simulation during silicon Czochralski growth. Sol. Energy Mater. Sol. Cells 2021, 219, 110785. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, B.; Li, X.; Gao, Z.; Zhou, Y.; Li, M.; Jia, R. A novel additive for rapid and uniform texturing on high-efficiency monocrystalline silicon solar cells. Sol. Energy Mater. Sol. Cells 2021, 222, 110947. [Google Scholar] [CrossRef]

- Rathore, N.; Panwar, N.L.; Yettou, F.; Gama, A. A comprehensive review of different types of solar photovoltaic cells and their applications. Int. J. Ambient. Energy 2021, 42, 1200–1217. [Google Scholar] [CrossRef]

- Prishya, A.A.; Chopra, L. Comprehensive review on uses of silicon dioxide in solar cell. Mater. Today Proc. 2023, 72, 1471–1478. [Google Scholar] [CrossRef]

- Ayadi, O.; Shadid, R.; Bani-Abdullah, A.; Alrbai, M.; Abu-Mualla, M.; Balah, N. Experimental comparison between Monocrystalline, Polycrystalline, and Thin-film solar systems under sunny climatic conditions. Energy Rep. 2022, 8, 218–230. [Google Scholar] [CrossRef]

- Onno, A.; Reich, C.; Li, S.; Danielson, A.; Weigand, W.; Bothwell, A.; Holman, Z.C. Understanding what limits the voltage of polycrystalline CdSeTe solar cells. Nat. Energy 2022, 7, 400–408. [Google Scholar] [CrossRef]

- Sun, Z.; Chen, X.; He, Y.; Li, J.; Wang, J.; Yan, H.; Zhang, Y. Toward efficiency limits of crystalline silicon solar cells: Recent progress in high-efficiency silicon heterojunction solar cells. Adv. Energy Mater. 2022, 12, 2200015. [Google Scholar] [CrossRef]

- Bosio, A. CdTe-based photodetectors and solar cells. In Handbook of II-VI Semiconductor-Based Sensors and Radiation Detectors: Volume 2, Photodetectors; Springer International Publishing: Cham, Switzerland, 2023; pp. 205–230. [Google Scholar]

- Faremi, A.A.; Akindadelo, A.T.; Adekoya, M.A.; Adebayo, A.J.; Salau, A.O.; Oluyamo, S.S.; Olubambi, P.A. Engineering of window layer cadmium sulphide and zinc sulphide thin films for solar cell applications. Results Eng. 2022, 16, 100622. [Google Scholar] [CrossRef]

- Barbato, M.; Artegiani, E.; Bertoncello, M.; Meneghini, M.; Trivellin, N.; Mantoan, E.; Meneghesso, G. CdTe solar cells: Technology, operation and reliability. J. Phys. D Appl. Phys. 2021, 54, 333002. [Google Scholar] [CrossRef]

- Pires, A.M.; Braga, M.; Rüther, R. Performance assessment of bare and anti-reflective coated CdTe photovoltaic systems in comparison to multicrystalline Si in Brazil. Prog. Photovolt. Res. Appl. 2021, 29, 1105–1124. [Google Scholar] [CrossRef]

- Genchi, G.; Sinicropi, M.S.; Lauria, G.; Carocci, A.; Catalano, A. The effects of cadmium toxicity. Int. J. Environ. Res. Public Health 2020, 17, 3782. [Google Scholar] [CrossRef]

- Panigrahi, J.; Komarala, V.K. Progress on the intrinsic a-Si: H films for interface passivation of silicon heterojunction solar cells: A review. J. Non-Cryst. Solids 2021, 574, 121166. [Google Scholar] [CrossRef]

- Wijewardane, S.; Kazmerski, L.L. Inventions, innovations, and new technologies: Flexible and lightweight thin-film solar PV based on CIGS, CdTe, and a-Si: H. Sol. Compass 2023, 7, 100053. [Google Scholar] [CrossRef]

- Shah, A. Amorphous silicon solar cells. In Solar Cells and Modules; Springer: Cham, Switzerland, 2020; pp. 139–161. [Google Scholar]

- Chung, M.H. Comparison assessment of semi-transparent solar cell for BIPV windows. LHI J. Land Hous. Urban Aff. 2020, 11, 87–94. [Google Scholar]

- Kar, S.; Banerjee, S.; Chanda, C.K. Performance study of Amorphous-Si thin-film solar cell for the recent application in photovoltaics. Mater. Today Proc. 2023, 80, 1286–1290. [Google Scholar] [CrossRef]

- Lim, H.; Na, D.; Lee, C.R.; Seo, H.K.; Kwon, O.H.; Kim, J.K.; Seo, I. An integrated device of a lithium-ion battery combined with silicon solar cells. Energies 2021, 14, 6010. [Google Scholar] [CrossRef]

- Salhi, B. The photovoltaic cell based on CIGS: Principles and technologies. Materials 2022, 15, 1908. [Google Scholar] [CrossRef] [PubMed]

- Boukortt, N.E.I.; Patanè, S. Single junction-based thin-film CIGS solar cells optimization with efficiencies approaching 24.5%. Optik 2020, 218, 165240. [Google Scholar] [CrossRef]

- Ramanujam, J.; Bishop, D.M.; Todorov, T.K.; Gunawan, O.; Rath, J.; Nekovei, R.; Romeo, A. Flexible CIGS, CdTe and a-Si: H based thin film solar cells: A review. Prog. Mater. Sci. 2020, 110, 100619. [Google Scholar] [CrossRef]

- Powalla, M.; Paetel, S.; Ahlswede, E.; Wuerz, R.; Wessendorf, C.D.; Magorian Friedlmeier, T. Thin-Film Solar Cells Exceeding 22% Solar Cell Efficiency: An Overview on CdTe-, Cu(In, Ga)Se₂-, and Perovskite-Based Materials. Appl. Phys. Rev. 2018, 5, 041602. [Google Scholar] [CrossRef]

- Liu, S.P.; Qiu, X.C.; Guo, J.; Chen, P.A.; Liu, Y.; Wei, H.; Xia, J.N.; Xie, H.H.; Hu, Y.Y. Efficient p-doping of P3HT for hole transporting materials in perovskite solar cells. Rare Met. 2022, 41, 2575–2581. [Google Scholar] [CrossRef]

- Yang, T.; Gao, L.; Lu, J.; Ma, C.; Du, Y.; Wang, P.; Zhao, K. One-stone-for-two-birds strategy to attain beyond 25% perovskite solar cells. Nat. Commun. 2023, 14, 839. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Dong, Q.; Yan, Y.; Fang, Z.; Mi, G.; Pei, M.; Wang, S.; Zhang, L.; Liu, J.; Chen, M.; et al. Al2O3 nanoparticles as surface modifier enables deposition of high-quality perovskite films for ultra-flexible photovoltaics. Adv. Powder Mater. 2024, 3, 100142. [Google Scholar] [CrossRef]

- Cui, Y.; Yao, H.; Hong, L.; Zhang, T.; Tang, Y.; Lin, B.; Hou, J. Organic photovoltaic cell with 17% efficiency and superior processability. Natl. Sci. Rev. 2020, 7, 1239–1246. [Google Scholar] [CrossRef]

- Upama, M.B.; Mahmud, M.A.; Conibeer, G.; Uddin, A. Trendsetters in High-Efficiency Organic Solar Cells: Toward 20% Power Conversion Efficiency. Solar RRL 2020, 4, 1900342. [Google Scholar] [CrossRef]

- Dolara, A.; di Fazio, G.; Leva, S.; Manzolini, G.; Simonetti, R.; Terenzi, A. Outdoor assessment and performance evaluation of OPV modules. IEEE J. Photovolt. 2021, 11, 391–399. [Google Scholar] [CrossRef]

- Albaladejo-Siguan, M.; Baird, E.C.; Becker-Koch, D.; Li, Y.; Rogach, A.L.; Vaynzof, Y. Stability of quantum dot solar cells: A matter of (life) time. Adv. Energy Mater. 2021, 11, 2003457. [Google Scholar] [CrossRef]

- Chen, J.; Jia, D.; Johansson, E.M.; Hagfeldt, A.; Zhang, X. Emerging perovskite quantum dot solar cells: Feasible approaches to boost performance. Energy Environ. Sci. 2021, 14, 224–261. [Google Scholar] [CrossRef]

- Yuan, J.; Hazarika, A.; Zhao, Q.; Ling, X.; Moot, T.; Ma, W.; Luther, J.M. Metal halide perovskites in quantum dot solar cells: Progress and prospects. Joule 2020, 4, 1160–1185. [Google Scholar] [CrossRef]

- Selopal, G.S.; Zhao, H.; Wang, Z.M.; Rosei, F. Core/shell quantum dots solar cells. Adv. Funct. Mater. 2020, 30, 1908762. [Google Scholar] [CrossRef]

- Badran, G.; Dhimish, M. Short-term performance and degradation trends in bifacial versus monofacial PV systems: A U.K. case study. IEEE J. Photovolt. 2024, 14, 861–864. [Google Scholar] [CrossRef]

- Tian, J.; Wei, K.; Deng, X.; Ma, W. A Study of the Effect of Quartz-to-Cristobalite Transformation on SiC Generation in Metallurgical-Grade Silicon Production. Silicon 2024, 16, 3155–3164. [Google Scholar] [CrossRef]

- He, Y.; Ma, W.; Xing, A.; Hu, M.; Liu, S.; Yang, X.; Zhou, W. A review of the process on the purification of metallurgical grade silicon by solvent refining. Mater. Sci. Semicond. Process. 2022, 141, 106438. [Google Scholar] [CrossRef]

- Lahti, A.; Santonen, M.; Rad, Z.J.; Miettinen, M.; Ebrahimzadeh, M.; Lehtiö, J.P.; Eklund, M. Polycrystalline silicon, a molecular dynamics study: II. Grains, grain boundaries and their structure. Model. Simul. Mater. Sci. Eng. 2024, 32, 065026. [Google Scholar] [CrossRef]

- Petkowski, J.J.; Bains, W.; Seager, S. On the potential of silicon as a building block for life. Life 2020, 10, 84. [Google Scholar] [CrossRef]

- Chang, N.L.; Wright, M.; Egan, R.; Hallam, B. The technical and economic viability of replacing n-type with p-type wafers for silicon heterojunction solar cells. Cell Rep. Phys. Sci. 2020, 1, 100069. [Google Scholar] [CrossRef]

- Arora, I.; Chawla, H.; Chandra, A.; Sagadevan, S.; Garg, S. Advances in the strategies for enhancing the photocatalytic activity of TiO2: Conversion from UV-light active to visible-light active photocatalyst. Inorg. Chem. Commun. 2022, 143, 109700. [Google Scholar] [CrossRef]

- Kho, T.C.; Fong, K.C.; Stocks, M.; McIntosh, K.; Franklin, E.; Phang, S.P.; Blakers, A. Excellent ONO passivation on phosphorus and boron diffusion demonstrating a 25% efficient IBC solar cell. Prog. Photovolt. Res. Appl. 2020, 28, 1034–1044. [Google Scholar] [CrossRef]

- Isikgor, F.H.; Zhumagali, S.; Merino, L.V.T.; De Bastiani, M.; McCulloch, I.; De Wolf, S. Molecular engineering of contact interfaces for high-performance perovskite solar cells. Nat. Rev. Mater. 2023, 8, 89–108. [Google Scholar] [CrossRef]

- Balaji, N.; Raval, M.C.; Saravanan, S. Review on metallization in crystalline silicon solar cells. Sol. Cells 2020, 25. [Google Scholar] [CrossRef]

- Libraro, S.; Lehmann, M.; Leon, J.D.; Allebé, C.; Descoeudres, A.; Ingenito, A.; Haug, F.J. Interactions between aluminium and fired passivating contacts during fire-through metallization. Sol. Energy Mater. Sol. Cells 2023, 249, 112051. [Google Scholar] [CrossRef]

- Oh, W.; Park, J.; Dimitrijev, S.; Kim, E.K.; Park, Y.S.; Lee, J. Metallization of crystalline silicon solar cells for shingled photovoltaic module application. Sol. Energy 2020, 195, 527–535. [Google Scholar] [CrossRef]

- Sharma, B.K.; Desai, U.; Singh, A.; Singh, A. Effect of vinyl acetate content on the photovoltaic-encapsulation performance of ethylene vinyl acetate under accelerated ultra-violet aging. J. Appl. Polym. Sci. 2020, 137, 48268. [Google Scholar] [CrossRef]

- Marshall, J.E.; Zhenova, A.; Roberts, S.; Petchey, T.; Zhu, P.; Dancer, C.E.; Goodship, V. On the solubility and stability of polyvinylidene fluoride. Polymers 2021, 13, 1354. [Google Scholar] [CrossRef]

- Hu, X.; An, A.K.; Chopra, S.S. Life cycle assessment of the polyvinylidene fluoride polymer with applications in various emerging technologies. ACS Sustain. Chem. Eng. 2022, 10, 5708–5718. [Google Scholar] [CrossRef]

- Artegiani, E.; Gasparotto, A.; Meneghini, M.; Meneghesso, G.; Romeo, A. How the selenium distribution in CdTe affects the carrier properties of CdSeTe/CdTe solar cells. Sol. Energy 2023, 260, 11–16. [Google Scholar] [CrossRef]

- Paithankar, J.G.; Kushalan, S.; Nijil, S.; Hegde, S.; Kini, S.; Sharma, A. Systematic toxicity assessment of CdTe quantum dots in Drosophila melanogaster. Chemosphere 2022, 295, 133836. [Google Scholar] [CrossRef]

- Chen, G.; Li, X.; Abbas, M.; Fu, C.; Su, Z.; Tang, R.; Liang, G. Tellurium doping inducing defect passivation for highly effective antimony selenide thin film solar cell. Nanomaterials 2023, 13, 1240. [Google Scholar] [CrossRef]

- Boubakeur, M.; Aissat, A.; Arbia, M.B.; Maaref, H.; Vilcot, J.P. Enhancement of the efficiency of ultra-thin CIGS/Si structure for solar cell applications. Superlattices Microstruct. 2020, 138, 106377. [Google Scholar] [CrossRef]

- Alarifi, I.M. Advanced selection materials in solar cell efficiency and their properties—A comprehensive review. Mater. Today Proc. 2023, 81, 403–414. [Google Scholar] [CrossRef]

- Isabela, C.B.; Lameirinhas, R.A.M.; Torres, J.P.N.; Fernandes, C.A. Comparative study of the copper indium gallium selenide (CIGS) solar cell with other solar technologies. Sustain. Energy Fuels 2021, 5, 2273–2283. [Google Scholar]

- Wang, B.; Biesold, G.M.; Zhang, M.; Lin, Z. Amorphous inorganic semiconductors for the development of solar cell, photoelectrocatalytic and photocatalytic applications. Chem. Soc. Rev. 2021, 50, 6914–6949. [Google Scholar] [CrossRef] [PubMed]

- Ji, X.; Fritz, N.J.; Jeong, H.; Lu, P.; Lin, J.W.; Braun, P.V.; Cahill, D.G. Lithium trapping, hydrogen content, and solid electrolyte interphase growth in electrodeposited silicon anodes by ion beam analysis. J. Power Sources 2024, 614, 235039. [Google Scholar] [CrossRef]

- Chen, P.; Hou, J.; Wang, L. Metal-organic framework-tailored perovskite solar cells. Microstructures 2022, 2, 2022014. [Google Scholar] [CrossRef]

- Lodders, K.; Fegley, B., Jr. Solar system abundances and condensation temperatures of the halogens fluorine, chlorine, bromine, and iodine. Geochemistry 2023, 83, 125957. [Google Scholar] [CrossRef]

- Imam, A.; Gondal, M.A.; Wudil, Y.S. Systematic investigation of LiI incorporation effects into MAPbI3-precursors for enhanced photodetection applications. Appl. Mater. Today 2024, 37, 102152. [Google Scholar] [CrossRef]

- Ye, L.; Ke, H.; Liu, Y. The renaissance of polythiophene organic solar cells. Trends Chem. 2021, 3, 1074–1087. [Google Scholar] [CrossRef]

- Lee, S.H.; Ko, S.J.; Eom, S.H.; Kim, H.; Kim, D.W.; Lee, C.; Yoon, S.C. Composite interlayer consisting of alcohol-soluble polyfluorene and carbon nanotubes for efficient polymer solar cells. ACS Appl. Mater. Interfaces 2020, 12, 14244–14253. [Google Scholar] [CrossRef]

- Klipfel, N.; Xia, J.; Čulík, P.; Orlandi, S.; Cavazzini, M.; Shibayama, N.; Nazeeruddin, M.K. Zn (II) and Cu (II) tetrakis (diarylamine) phthalocyanines as hole-transporting materials for perovskite solar cells. Mater. Today Energy 2022, 29, 101110. [Google Scholar] [CrossRef]

- Shaban, M.; Benghanem, M.; Almohammedi, A.; Rabia, M. Optimization of the active layer P3HT: PCBM for organic solar cell. Coatings 2021, 11, 863. [Google Scholar] [CrossRef]

- Usmani, B.; Ranjan, R.; Gupta, S.K.; Gupta, R.K.; Nalwa, K.S.; Garg, A. Inverted PTB7-Th: PC71BM organic solar cells with 11.8% PCE via incorporation of gold nanoparticles in ZnO electron transport layer. Sol. Energy 2021, 214, 220–230. [Google Scholar] [CrossRef]

- Duan, L.; Zhang, Y.; He, M.; Deng, R.; Yi, H.; Wei, Q.; Uddin, A. Burn-in degradation mechanism identified for small molecular acceptor-based high-efficiency nonfullerene organic solar cells. ACS Appl. Mater. Interfaces 2020, 12, 27433–27442. [Google Scholar] [CrossRef]

- Li, K.; Yang, X.; Lu, Y.; Xue, J.; Lu, S.; Zheng, J.; Tang, J. Fabrication and optimization of CdSe solar cells for possible top cell of silicon-based tandem devices. Adv. Energy Mater. 2022, 12, 2200725. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, H.; Shi, G.; Li, Y.; Gao, Y.; Fang, S.; Ma, W. Merging Passivation in Synthesis Enabling the Lowest Open-Circuit Voltage Loss for PbS Quantum Dot Solar Cells. Adv. Mater. 2023, 35, 2207293. [Google Scholar] [CrossRef]

- Riech, I.; Castro-Montalvo, C.; Wittersheim, L.; Giácoman-Vallejos, G.; González-Sánchez, A.; Gamboa-Loira, C.; Méndez-Gamboa, J. Experimental methodology for the separation materials in the recycling process of silicon photovoltaic panels. Materials 2021, 14, 581. [Google Scholar] [CrossRef]

- Wang, J.; Feng, Y.; Shi, M.; He, Y. A comparative study of mechanical crushing and pyrolysis techniques for separation and recovery of discarded polycrystalline silicon photovoltaic modules. Sol. Energy Mater. Sol. Cells 2024, 275, 113020. [Google Scholar] [CrossRef]

- Li, J.; Yan, S.; Li, Y.; Wang, Z.; Tan, Y.; Li, J.; Li, P. Recycling Si in waste crystalline silicon photovoltaic panels after mechanical crushing by electrostatic separation. J. Clean. Prod. 2023, 415, 137908. [Google Scholar] [CrossRef]

- Curtin, A.M.; Vail, C.A.; Buckley, H.L. CdTe in thin film photovoltaic cells: Interventions to protect drinking water in production and end-of-life. Water-Energy Nexus 2020, 3, 15–28. [Google Scholar] [CrossRef]

- Dobra, T.; Thajer, F.; Wiesinger, G.; Vollprecht, D.; Pomberger, R. Selective delamination by milling as a first step in the recycling of photovoltaic modules. Environ. Technol. 2023, 44, 3437–3445. [Google Scholar] [CrossRef] [PubMed]

- Salazar, R.B.J.; Tenório, J.A.S.; Espinosa, D.C.R.; Baltazar, M.D.P.G. Streamlined process with a sustainable approach for photovoltaic module recycling. Sustain. Mater. Technol. 2024, 41, e01047. [Google Scholar] [CrossRef]

- Máčalová, K.; Václavík, V.; Dvorský, T.; Figmig, R.; Charvát, J.; Lupták, M. The use of glass from photovoltaic panels at the end of their life cycle in cement composites. Materials 2021, 14, 6655. [Google Scholar] [CrossRef] [PubMed]

- Maani, T.; Celik, I.; Heben, M.J.; Ellingson, R.J.; Apul, D. Environmental impacts of recycling crystalline silicon (c-SI) and cadmium telluride (CDTE) solar panels. Sci. Total Environ. 2020, 735, 138827. [Google Scholar] [CrossRef]

- Akhter, M.; Al Mansur, A.; Islam, M.I.; Lipu, M.H.; Karim, T.F.; Abdolrasol, M.G.; Alghamdi, T.A. Sustainable strategies for crystalline solar cell recycling: A review on recycling techniques, companies, and environmental impact analysis. Sustainability 2024, 16, 5785. [Google Scholar] [CrossRef]

- Chen, W.S.; Chen, Y.J.; Lee, C.H.; Cheng, Y.J.; Chen, Y.A.; Liu, F.W.; Chueh, Y.L. Recovery of valuable materials from the waste crystalline-silicon photovoltaic cell and ribbon. Processes 2021, 9, 712. [Google Scholar] [CrossRef]

- Rizos, V.; Righetti, E.; Kassab, A. Understanding the barriers to recycling critical raw materials for the energy transition: The case of rare earth permanent magnets. Energy Rep. 2024, 12, 1673–1682. [Google Scholar] [CrossRef]

- Park, S.Y.; Park, J.S.; Kim, B.J.; Lee, H.; Walsh, A.; Zhu, K.; Jung, H.S. Sustainable lead management in halide perovskite solar cells. Nat. Sustain. 2020, 3, 1044–1051. [Google Scholar] [CrossRef]

- Liu, F.W.; Cheng, T.M.; Chen, Y.J.; Yueh, K.C.; Tang, S.Y.; Wang, K.; Chueh, Y.L. High-yield recycling and recovery of copper, indium, and gallium from waste copper indium gallium selenide thin-film solar panels. Sol. Energy Mater. Sol. Cells 2022, 241, 111691. [Google Scholar] [CrossRef]

- de Souza, R.A.; Veit, H.M. Study of electrostatic separation to concentrate silver, aluminum, and silicon from solar panel scraps. Circ. Econ. 2023, 2, 100027. [Google Scholar] [CrossRef]

- Liu, F.W.; Biesold, G.; Zhang, M.; Lawless, R.; Correa-Baena, J.P.; Chueh, Y.L.; Lin, Z. Recycling and recovery of perovskite solar cells. Mater. Today 2021, 43, 185–197. [Google Scholar] [CrossRef]

- Chen, B.; Fei, C.; Chen, S.; Gu, H.; Xiao, X.; Huang, J. Recycling lead and transparent conductors from perovskite solar modules. Nat. Commun. 2021, 12, 5859. [Google Scholar] [CrossRef] [PubMed]

- Dogu, O.; Pelucchi, M.; Van de Vijver, R.; Van Steenberge, P.H.; D’hooge, D.R.; Cuoci, A.; Van Geem, K.M. The chemistry of chemical recycling of solid plastic waste via pyrolysis and gasification: State-of-the-art, challenges, and future directions. Prog. Energy Combust. Sci. 2021, 84, 100901. [Google Scholar] [CrossRef]

- Mao, D.; Yang, S.; Ma, L.; Ma, W.; Yu, Z.; Xi, F.; Yu, J. Overview of life cycle assessment of recycling end-of-life photovoltaic panels: A case study of crystalline silicon photovoltaic panels. J. Clean. Prod. 2023, 434, 140320. [Google Scholar] [CrossRef]

- Deng, R.; Zhuo, Y.; Shen, Y. Recent progress in silicon photovoltaic module recycling processes. Resour. Conserv. Recycl. 2022, 187, 106612. [Google Scholar] [CrossRef]

- Kuczyńska-Łażewska, A.; Klugmann-Radziemska, E.; Witkowska, A. Recovery of valuable materials and methods for their management when recycling thin-film CdTe photovoltaic modules. Materials 2021, 14, 7836. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Ma, B.; Wang, C.; Hu, D.; Lü, Y.; Chen, Y. Recycling and recovery of spent copper—Indium—Gallium—Diselenide (CIGS) solar cells: A review. Int. J. Miner. Metall. Mater. 2023, 30, 989–1002. [Google Scholar] [CrossRef]

- Tian, X.; Stranks, S.D.; You, F. Life cycle assessment of recycling strategies for perovskite photovoltaic modules. Nat. Sustain. 2021, 4, 821–829. [Google Scholar] [CrossRef]

- Majewski, P.; Al-shammari, W.; Dudley, M.; Jit, J.; Lee, S.H.; Myoung-Kug, K.; Sung-Jim, K. Recycling of solar PV panels-product stewardship and regulatory approaches. Energy Policy 2021, 149, 112062. [Google Scholar] [CrossRef]

- Markert, E.; Celik, I.; Apul, D. Private and externality costs and benefits of recycling crystalline silicon (c-Si) photovoltaic panels. Energies 2020, 13, 3650. [Google Scholar] [CrossRef]

- Almaie, S.; Vatanpour, V.; Rasoulifard, M.H.; Koyuncu, I. Volatile organic compounds (VOCs) removal by photocatalysts: A review. Chemosphere 2022, 306, 135655. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Zhao, F.; Shi, W.; Lu, H.; Zhou, X.; Guo, Y.; Yu, G. Super water-extracting gels for solar-powered volatile organic compounds management in the hydrological cycle. Adv. Mater. 2022, 34, 2110548. [Google Scholar] [CrossRef]

- Chakankar, M.; Su, C.H.; Hocheng, H. Leaching of metals from end-of-life solar cells. Environ. Sci. Pollut. Res. 2019, 26, 29524–29531. [Google Scholar] [CrossRef] [PubMed]

- Šleiniūtė, A.; Urbelytė, L.; Denafas, J.; Kosheleva, A.; Denafas, G. Feasibilities for silicon recovery from solar cells waste by treatment with nitric acid. Chemija 2020, 31. [Google Scholar] [CrossRef]

- Luo, M.; Liu, F.; Zhou, Z.; Jiang, L.; Jia, M.; Lai, Y.; Zhang, Z. A comprehensive hydrometallurgical recycling approach for the environmental impact mitigation of EoL solar cells. J. Environ. Chem. Eng. 2021, 9, 106830. [Google Scholar] [CrossRef]

- Chen, W.S.; Chen, Y.J.; Yueh, K.C.; Cheng, C.P.; Chang, T.C. Recovery of valuable metal from Photovoltaic solar cells through extraction. IOP Conf. Ser. Mater. Sci. Eng. 2020, 720, 012007. [Google Scholar] [CrossRef]

- Malinowska, B.; Rakib, M.; Durand, G. Cadmium recovery and recycling from chemical bath deposition of CdS thin layers. Prog. Photovolt. Res. Appl. 2002, 10, 215–228. [Google Scholar] [CrossRef]

- Teknetzi, I.; Holgersson, S.; Ebin, B. Valuable metal recycling from thin film CIGS solar cells by leaching under mild conditions. Sol. Energy Mater. Sol. Cells 2023, 252, 112178. [Google Scholar] [CrossRef]

- Kim, B.J.; Kim, D.H.; Kwon, S.L.; Park, S.Y.; Li, Z.; Zhu, K.; Jung, H.S. Selective dissolution of halide perovskites as a step towards recycling solar cells. Nat. Commun. 2016, 7, 11735. [Google Scholar] [CrossRef]

- Le Khac, D.; Chowdhury, S.; Najm, A.S.; Luengchavanon, M.; mebdir Holi, A.; Jamal, M.S.; Selvanathan, V. Efficient laboratory perovskite solar cell recycling with a one-step chemical treatment and recovery of ITO-coated glass substrates. Sol. Energy 2024, 267, 112214. [Google Scholar] [CrossRef]

- Cho, S.Y.; Kim, T.Y.; Sun, P.P. Recovery of silver from leachate of silicon solar cells by solvent extraction with TOPO. Sep. Purif. Technol. 2019, 215, 516–520. [Google Scholar] [CrossRef]

- Click, N.; Teknetzi, I.; Tam, E.P.L.; Tao, M.; Ebin, B. Innovative recycling of high purity silver from silicon solar cells by acid leaching and ultrasonication. Sol. Energy Mater. Sol. Cells 2024, 270, 112834. [Google Scholar] [CrossRef]

- Chen, W.S.; Lee, C.H. Recycling Solar Cell. In Circular Economy and Sustainable Energy Materials: A Net-Zero Emissions Approach; Springer: Berlin/Heidelberg, Germany, 2024; p. 172. [Google Scholar]

- Cyrs, W.D.; Avens, H.J.; Capshaw, Z.A.; Kingsbury, R.A.; Sahmel, J.; Tvermoes, B.E. Landfill waste and recycling: Use of a screening-level risk assessment tool for end-of-life cadmium telluride (CdTe) thin-film photovoltaic (PV) panels. Energy Policy 2014, 68, 524–533. [Google Scholar] [CrossRef]

- Lin, D.; Liu, Z.; Li, X.; Cao, Z.; Xiong, R. Development of metal-recycling technology in waste crystalline-silicon solar cells. Clean Energy 2023, 7, 532–546. [Google Scholar] [CrossRef]

- Kim, H.S.; An, Y.J.; Kwak, J.I.; Kim, H.J.; Jung, H.S.; Park, N.G. Sustainable green process for environmentally viable perovskite solar cells. ACS Energy Lett. 2022, 7, 1154–1177. [Google Scholar] [CrossRef]

- Kim, H.J.; Gong, O.Y.; Kim, Y.J.; Yoon, G.W.; Han, G.S.; Shin, H.; Jung, H.S. Environmentally Viable Solvent Management in Perovskite Solar Cell Recycling Process. ACS Energy Lett. 2023, 8, 4330–4337. [Google Scholar] [CrossRef]

- Modrzynski, C.; Blaesing, L.; Hippmann, S.; Bertau, M.; Bloh, J.Z.; Weidlich, C. Electrochemical recycling of photovoltaic modules to recover metals and silicon wafers. Chem. Ing. Tech. 2021, 93, 1851–1858. [Google Scholar] [CrossRef]

- Petersen, H.A.; Myren, T.H.; O’Sullivan, S.J.; Luca, O.R. Electrochemical methods for materials recycling. Mater. Adv. 2021, 2, 1113–1138. [Google Scholar] [CrossRef]

- Yang, E.H.; Lee, J.K.; Lee, J.S.; Ahn, Y.S.; Kang, G.H.; Cho, C.H. Environmentally friendly recovery of Ag from end-of-life c-Si solar cell using organic acid and its electrochemical purification. Hydrometallurgy 2017, 167, 129–133. [Google Scholar] [CrossRef]

- Isherwood, P.J. Reshaping the module: The path to comprehensive photovoltaic panel recycling. Sustainability 2022, 14, 1676. [Google Scholar] [CrossRef]

- Vinayagamoorthi, R.; Bhargav, P.B.; Ahmed, N.; Balaji, C.; Aravinth, K.; Krishnan, A.; Ramasamy, P. Recycling of end of life photovoltaic solar panels and recovery of valuable components: A comprehensive review and experimental validation. J. Environ. Chem. Eng. 2024, 12, 111715. [Google Scholar] [CrossRef]

- Joshi, S.; Chaudhary, K.; Lodhi, K.; Goyat, M.S.; Gupta, T.K. Techniques for Recycling and Recovery of Perovskites Solar Cells. Perovskite Based Mater. Energy Storage Devices 2023, 151, 89–110. [Google Scholar]

- Schmidt, F.; Amrein, M.; Hedwig, S.; Kober-Czerny, M.; Paracchino, A.; Holappa, V.; Lenz, M. Organic solvent free PbI2 recycling from perovskite solar cells using hot water. J. Hazard. Mater. 2023, 447, 130829. [Google Scholar] [CrossRef] [PubMed]

- Granata, G.; Altimari, P.; Pagnanelli, F.; De Greef, J. Recycling of solar photovoltaic panels: Techno-economic assessment in waste management perspective. J. Clean. Prod. 2022, 363, 132384. [Google Scholar] [CrossRef]

- Deng, R.; Chang, N.L.; Ouyang, Z.; Chong, C.M. A techno-economic review of silicon photovoltaic module recycling. Renew. Sustain. Energy Rev. 2019, 109, 532–550. [Google Scholar] [CrossRef]

- Dhimish, M.; Tyrrell, A.M. Photovoltaic bypass diode fault detection using artificial neural networks. IEEE Trans. Instrum. Meas. 2023, 72, 1–10. [Google Scholar] [CrossRef]

- Hanisch, C. Is extended producer responsibility effective? Environ. Sci. Technol. 2000, 34, 170A–175A. [Google Scholar] [CrossRef]

- Li, K.; Qin, Y.; Zhu, D.; Zhang, S. Upgrading waste electrical and electronic equipment recycling through extended producer responsibility: A case study. Circ. Econ. 2023, 2, 100025. [Google Scholar] [CrossRef]

- Dhimish, M.; Theristis, M.; d’Alessandro, V. Photovoltaic hotspots: A mitigation technique and its thermal cycle. Optik 2024, 300, 171627. [Google Scholar] [CrossRef]

- Pruthviraj, U.; Kashyap, Y.; Baxevanaki, E.; Kosmopoulos, P. Solar photovoltaic hotspot inspection using unmanned aerial vehicle thermal images at a solar field in south India. Remote Sens. 2023, 15, 1914. [Google Scholar] [CrossRef]

- Dhimish, M. Defining the best-fit machine learning classifier to early diagnose photovoltaic solar cells hot-spots. Case Stud. Therm. Eng. 2021, 25, 100980. [Google Scholar] [CrossRef]

- Dhimish, M.; Badran, G. Investigating defects and annual degradation in UK solar PV installations through thermographic and electroluminescent surveys. Npj Mater. Degrad. 2023, 7, 14. [Google Scholar] [CrossRef]

- Dhimish, M.; Tyrrell, A.M. Optical Filter Design for Daylight Outdoor Electroluminescence Imaging of PV Modules. Photonics 2024, 11, 63. [Google Scholar] [CrossRef]

- dos Reis Benatto, G.A.; Mantel, C.; Spataru, S.; Lancia, A.A.S.; Riedel, N.; Thorsteinsson, S.; Sera, D. Drone-based daylight electroluminescence imaging of PV modules. IEEE J. Photovolt. 2020, 10, 872–877. [Google Scholar] [CrossRef]

- Hassan, S.; Dhimish, M. Enhancing solar photovoltaic modules quality assurance through convolutional neural network-aided automated defect detection. Renew. Energy 2023, 219, 119389. [Google Scholar] [CrossRef]

- Sharma, A.; Pandey, S.; Kolhe, M. Global review of policies & guidelines for recycling of solar PV modules. Int. J. Smart Grid Clean Energy 2019, 8, 597–610. [Google Scholar]

- Aşkın, A.; Kılkış, Ş.; Akınoğlu, B.G. Recycling photovoltaic modules within a circular economy approach and a snapshot for Türkiye. Renew. Energy 2023, 208, 583–596. [Google Scholar] [CrossRef]

- Shrestha, N.; Zaman, A. Decommissioning and Recycling of End-of-Life Photovoltaic Solar Panels in Western Australia. Sustainability 2024, 16, 526. [Google Scholar] [CrossRef]

- Farrell, C.C.; Osman, A.I.; Doherty, R.; Saad, M.; Zhang, X.; Murphy, A.; Rooney, D.W. Technical Challenges and Opportunities in Realising a Circular Economy for Waste Photovoltaic Modules. Renew. Sustain. Energy Rev. 2020, 128, 109911. [Google Scholar] [CrossRef]

- Yu, H.F.; Hasanuzzaman, M.; Rahim, N.A.; Amin, N.; Nor Adzman, N. Global Challenges and Prospects of Photovoltaic Materials Disposal and Recycling: A Comprehensive Review. Sustainability 2022, 14, 8567. [Google Scholar] [CrossRef]

- Wang, X.; Tian, X.; Chen, X.; Ren, L.; Geng, C. A Review of End-of-Life Crystalline Silicon Solar Photovoltaic Panel Recycling Technology. Sol. Energy Mater. Sol. Cells 2022, 248, 111976. [Google Scholar] [CrossRef]

- First Solar. Sustainability Overview: Recycling and End-of-Life Management. Available online: https://www.firstsolar.com/en/Sustainability/Recycling (accessed on 3 December 2024).

- Veolia. Solar Panel Recycling: Europe’s First Solar Panel Recycling Facility. Available online: https://www.veolia.com/en/what-we-do/our-services/solar-panel-recycling (accessed on 3 December 2024).

- Reclaim PV Recycling. Recycling Solar Panels to Recover Valuable Materials. Available online: https://sinovoltaics.com/learning-center/recycling/reclaim-solar-pv-recycling (accessed on 3 December 2024).

- PV Cycle. Recycling Solar Modules in Europe. Available online: https://www.pvcycle.org/ (accessed on 3 December 2024).

- Rystad Energy. Renewable Energy Insights: Solar Module Recycling Technologies. Available online: https://www.rystadenergy.com/ (accessed on 3 December 2024).

- RESOLAR. RESOLAR Signed an Investment Contract for a 140,000-ton Photovoltaic Module Recycling Factory with Luoshan County, Xinyang City, Henan Province. Available online: https://www.resolartech.com/en/news/gongsixinwen_442039/resolar_luoshan_sign_contract.html (accessed on 3 December 2024).

- Trinasolar. Trinasolar Produces World’s First Fully Recycled c-Si Module, a Milestone in Sustainability. Available online: https://static.trinasolar.com/eu-en/resources/newsroom/eu-trinasolar-produces-world%E2%80%99s-first-fully-recycled-c-si-module-milestone (accessed on 3 December 2024).

- PVTIME. China’s First Module Recycling Line Kicks off by Yellow River Company in Qinghai Province. Available online: https://www.pvtime.org/chinas-first-module-recycling-line-kicks-off-by-yellow-river-company-in-qinghai-province/ (accessed on 3 December 2024).

| Technology | Efficiency Range (%) | Materials Used | Recyclability Challenges | Applications |

|---|---|---|---|---|

| Crystalline Silicon | 15–22 | Silicon, silver, aluminium | Difficulty in separating encapsulants | Residential, commercial |

| Thin-Film (CdTe, CIGS) | 10–16 | Cadmium, tellurium, indium, selenium | Toxic materials requiring careful handling | Large-scale solar farms |

| Perovskite | 20–25 | Lead halides, organic components | Stability and toxicity of lead compounds | Experimental, niche |

| Organic PV (OPV) | 5–20 | Conjugated polymers, fullerenes | Limited lifespan and recyclability | Wearable electronics, BIPV |

| Quantum Dot | 6–16 | CdSe, PbS, other nanoparticles | Scalability and toxicity of materials | Research, specialized uses |

| Company/ Organization | Recycling Approach | Progress/Outcome |

|---|---|---|

| First Solar (USA) | Closed-loop recycling | Recycling up to 90% of materials from thin-film panels; has established recycling facilities globally [143]. |

| Veolia (France) | Mechanical recycling for crystalline panels | Europe’s first dedicated plant for solar panel recycling, processing 1300 tons annually [144]. |

| Reclaim PV (Australia) | End-of-life recycling services | Specialized in recovering high-value materials like silicon and aluminium [145]. |

| PV Cycle (Europe) | Voluntary take-back programmes | Offers collection and recycling across EU; has recovered 95% of materials from PV modules in recent years [146]. |

| Rystad Energy (Norway) | Advanced mechanical separation | Conducting research and pilot projects to improve recycling efficiency for solar modules [147]. |

| RESOLAR Energy Technology (China) | Utilizes the “GST Green Separation Method” to recycle PV modules into glass, metals, and high-grade silicon | Operates China’s first 10,000-ton recycling line, processing 900 tons/month; collaborated on a fully recycled PV module [148]. |

| Trina Solar (China) | Developed chemical and wet silver extraction technologies for recycling high-value materials | Produced the world’s first fully recycled crystalline silicon PV module with over 20% efficiency [149]. |

| Yellow River Upstream Hydropower Development (China) | Integrates a closed-loop system for PV module recycling | Established the first module recycling line in Qinghai Province, reducing resource waste [150]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Badran, G.; Lazarov, V.K. From Waste to Resource: Exploring the Current Challenges and Future Directions of Photovoltaic Solar Cell Recycling. Solar 2025, 5, 4. https://doi.org/10.3390/solar5010004

Badran G, Lazarov VK. From Waste to Resource: Exploring the Current Challenges and Future Directions of Photovoltaic Solar Cell Recycling. Solar. 2025; 5(1):4. https://doi.org/10.3390/solar5010004

Chicago/Turabian StyleBadran, Ghadeer, and Vlado K. Lazarov. 2025. "From Waste to Resource: Exploring the Current Challenges and Future Directions of Photovoltaic Solar Cell Recycling" Solar 5, no. 1: 4. https://doi.org/10.3390/solar5010004

APA StyleBadran, G., & Lazarov, V. K. (2025). From Waste to Resource: Exploring the Current Challenges and Future Directions of Photovoltaic Solar Cell Recycling. Solar, 5(1), 4. https://doi.org/10.3390/solar5010004