Abstract

The objective of this study was to evaluate the changes in the textures of slice images of radish subjected to lacto-fermentation. The models developed for individual color channels of images and color spaces RGB, Lab, YUV, and XYZ were used to distinguish between fresh and lacto-fermented radishes. The discrimination accuracy reached 100% in the case of models built for each color space and color channels B, b, Z, and U. In these cases, the values of TP Rate, Precision, F-Measure, ROC Area, and PRC Area were equal to 1.000. The usefulness of image analysis for the evaluation of the postharvest processing of radish was proven.

1. Introduction

Radish (Raphanus sativus L.) is a vegetable with fleshy roots belonging to the Brassicaceae family. Radish is widely cultivated around the world as its roots are rich in carbohydrates, vitamin C, minerals, protein, crude fiber, polyphenols, folic acid, and glucosinolate [1,2]. The edible parts of radishes are the roots as well as the leaves and sprouts. The color of the radish root surface is mostly red, white, purple, green, or black and the flesh is white. The red color of the root depends on the content of anthocyanin pigments. The root can be consumed raw, e.g., in salads, or processed and preserved. It can also be cooked, salted, dried [3], and pickled or fermented [3,4,5,6]. Fermentation is very beneficial for preserving and prolonging the shelf life of fresh vegetables and allows obtaining products with unique flavors, aromas, textures, and chemical compositions [4].

There are many methods of identifying and classifying agricultural and horticultural products. Image-based methods, especially those that rely on image features, have been noted as effective methods [7,8,9]. In addition, the results of previous studies performed by the author of this paper indicated that the textures extracted from the images allow for an accurate, objective, fast, and inexpensive quality evaluation of food products [10,11,12]. Machine learning (ML) can be useful for food quality evaluation based on empirical data. The information provided by intelligent systems can be also used to extend the shelf life of food products [13]. Nowadays, machine learning is often combined with image processing [14]. Such procedures are useful in practice for the postharvest classification of horticultural products and can be more effective than a manual approach [15].

The objective of this study was to evaluate the changes in the textures of slice images of radish subjected to lacto-fermentation after harvesting. The models for distinguishing between the lacto-fermented and fresh radishes were developed based on the texture features of slice images.

2. Materials and Methods

2.1. Materials

The radishes were harvested from a garden located in northeastern Poland. One hundred and twenty radishes were collected. After harvesting, radish roots were washed using potable water and air-dried under room conditions. Sixty radish roots were subjected to spontaneous lacto-fermentation and the other sixty were intended for immediate imaging after harvesting in fresh form. The lacto-fermentation was carried out in glass jars using the whole radish roots and potable water including sodium chloride (table salt), at a final concentration of 3%, in a brine of horseradish, garlic, and dill. The samples were stored at room temperature of about 20 °C (3 days). Then, a lower temperature of 11 ± 1 °C was applied. These samples were stored for two months before imaging.

2.2. Image Processing

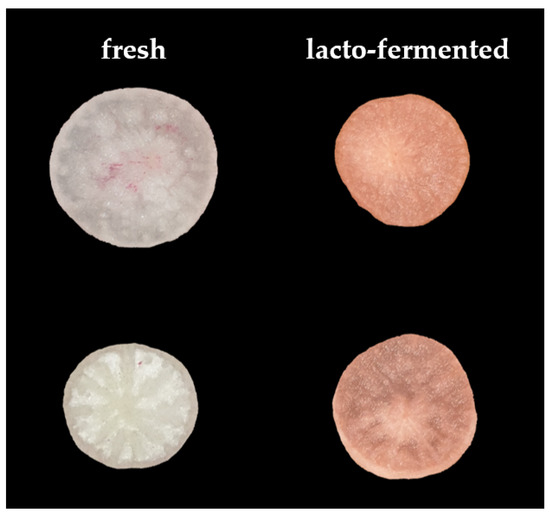

For both fresh and fermented samples, 50 representative undamaged radishes were selected. Each radish root was cut in half using a sharp knife and one slice for each half was obtained. For each root, two images of cross-sections were acquired with the use of a digital camera. Thus, 100 slice images of fresh radishes and 100 slice images of lacto-fermented radishes were obtained. The examples are shown in Figure 1. The images were converted to color channels R, G, B, L, a, b, U, V, X, Y, and Z using the MaZda software (Łódź University of Technology, Institute of Electronics, Łódź, Poland) [16]. Color channels R (red), G (green), and B (blue) create the RGB color space; color channels L (lightness component from black to white), a (green for negative values and red for positive values), and b (blue for negative values and yellow for positive values)—Lab color space; color channels X (represents the color information), Y (lightness), and Z (represents the color information)—XYZ color space; and color channels Y (luminance of the color), U (determines the color itself—chromaticity), and V (determines the color itself—chromaticity)—YUV color space [17].

Figure 1.

The slice images of lacto-fermented and fresh radish.

2.3. Discrimination of Lacto-Fermented and Fresh Radish Samples

The effect of lacto-fermentation on the radish quality was evaluated using the innovative discriminative models built based on sets of selected textures of images. The texture selection and discrimination analysis were performed using the WEKA application (Machine Learning Group, University of Waikato) [18,19,20]. The models were developed for individual color channels R, G, B, L, a, b, U, V, X, Y, and Z and color spaces RGB, Lab, YUV, and XYZ using different machine learning algorithms from the groups of Trees, Bayes, Functions, Rules, and Lazy. The classification was performed using the 10-fold cross-validation mode. The data set was randomly divided into 10 parts. Each part was considered as the test set and the remaining—as the training sets in turn. The results were presented as the averages of 10 estimates for learning carried out 10 times using different training sets [20]. The accuracies of discrimination for fresh and lacto-fermented radishes, average accuracies for both samples as well as True Positive Rate (TP Rate), Precision, F-Measure, Receiver Operating Characteristic Area (ROC Area), and Precision-Recall Area (PRC Area) were determined. The formulas for the computation of the above metrics are presented in Equations (1)–(8) [15,21]:

where TP—True Positive; TN—True Negative; FP—False Positive; and FN—False Negative.

Accuracy = (TP + TN)/(TP + FP + TN + FN) × 100

TP Rate (Recall) = TP/(TP + FN)

FP Rate = FP/(FP + TN)

Precision = TP/(TP + FP)

F1-Measure = 2TP/(2TP + FP + FN)

ROC Area = Area Under TP Rate vs. FP Rate Curve

Recall = TP/(TP + FN)

PRC Area = Area Under Precision vs. Recall Curve

The evaluation of the effectiveness of discrimination models and the selection of algorithms were performed based on the most satisfactory values of the above performance metrics. Therefore, the results obtained using the Logistic and Multi Class Classifier were chosen to be presented in this paper. The parameters applied in the WEKA for the Logistic algorithm were: batchSize: 100; debug: False; doNotCheckCapabilities: False; useConjugateGradientDescent: False ridge: 1 × 10−8, and for the Multi Class Classifier: batchSize: 100; debug: False; doNotCheckCapabilities: False; randomWidthFactor: 2.0; seed: 1; classifier: Logistic −R 1 × 10−8 −M −1; logLossDecoging: False; usePairwiseCoupling: False; method: 1-against-all.

3. Results and Discussion

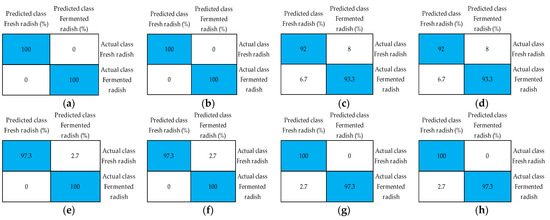

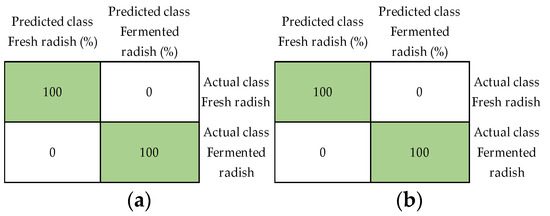

Among the tested machine learning algorithms, the Logistic and Multi Class Classifier turned out to be the most effective and produced high discrimination accuracies reaching 100% and values of TP Rate, Precision, F-Measure, ROC Area, and PRC Area equal to 1.000. The high values of these metrics indicated large changes in selected textures of lacto-fermented radishes compared to the non-processed ones, allowing for the complete distinction between these samples. In the case of models built for sets of textures selected for individual color channels of images, the best results were obtained for channels B, b, Z, and U. The confusion matrices are presented in Figure 2 and the values of average accuracy and other metrics are shown in Table 1. Fresh and lacto-fermented radish slices were correctly discriminated in 100% and the other performance metrics were equal to 1.000 for both Logistic and Multi Class Classifier. In the case of color channel R, both Logistic and Multi Class Classifier algorithms provided 92.7% of the discrimination of fresh and lacto-fermented samples. The fresh radishes were correctly discriminated in 92% and the lacto-fermented samples in 93.3%. The models developed based on sets of textures selected from color channel L and color channel Y provided average accuracies of 98.7% for the Logistic and Multi Class Classifier algorithms. The models built for the textures selected from individual color spaces RGB, Lab, XYZ, and YUV, using the Logistic and Multi Class Classifier, produced accuracies of 100% for both fresh and lacto-fermented radish samples (Figure 3) with the values of other metrics equal to 1.000 (Table 2).

Figure 2.

Confusion matrices for the discrimination of fresh and lacto-fermented radish roots using models built based on the textures of slice images from each of the color channels: B, b, Z, and U using the Logistic algorithm (a), each of the color channels: B, b, Z, and U using the Multi Class Classifier algorithm (b), color channel R and Logistic (c), color channel R and Multi Class Classifier (d), color channel L and Logistic (e), color channel L and Multi Class Classifier (f), color channel Y and Logistic (g), and color channel Y and Multi Class Classifier (h).

Table 1.

The discrimination of fresh and lacto-fermented radish roots using models developed for selected individual color channels B, b, Z, U, R, L, and Y of slice images.

Figure 3.

Confusion matrices for the discrimination of fresh and lacto-fermented radish roots using models built based on textures from color spaces RGB, Lab, XYZ, and YUV of slice images using different algorithms: Logistic for each of the color spaces: RGB, Lab, XYZ, and YUV (a), Multi-Class Classifier for each of the color spaces: RGB, Lab, XYZ, and YUV (b).

Table 2.

The discrimination of fresh and lacto-fermented radish roots using models developed for color spaces RGB, Lab, XYZ, and YUV of slice images.

The models built based on the textures of slice images were useful for distinguishing fresh and lacto-fermented radishes. Future work can focus on the use of deep learning to distinguish between fresh and lacto-fermented radishes. Traditional machine learning requires human-driven steps of the extraction and selection of features from the acquired images [22,23]. There are reports on the use of traditional machine learning for the quality evaluation of lacto-fermented beetroot [24,25] and pickles [26]. The application of deep learning enables performing feature extraction and classification based on raw images. Therefore, it is beneficial for discrimination purposes [27].

4. Conclusions

The results demonstrated the effect of lacto-fermentation on the radish root quality expressed in the changes in textures of cross-section images. The developed models allowed for distinguishing between fresh and lacto-fermented radish slices with an accuracy of up to 100%. The most successful results were provided by the Logistic and Multi Class Classifier machine learning algorithms for the sets of image textures selected for individual color channels B, b, Z, and U and individual color spaces RGB, Lab, XYZ, and YUV. By demonstrating the usefulness of the combination of image processing and machine learning to evaluate the effect of lacto-fermentation on the changes in radish flesh, this approach can also be recommended for application in the quality evaluation of other fermented products as well as for other preservation techniques.

Author Contributions

Conceptualization, E.R.; methodology, E.R.; software, E.R.; validation, E.R.; formal analysis, E.R.; investigation, E.R.; resources, E.R.; data curation, E.R.; writing—original draft preparation, E.R. and A.A.; writing—review and editing, E.R.; visualization, E.R.; supervision, E.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, Y.; Zhao, X.; Ma, Y.; Zhang, L.; Jiang, Y.; Liang, H.; Wang, D. Transcriptome and metabolome profiling to elucidate mechanisms underlying the blue discoloration of radish roots during storage. Food Chem. 2021, 362, 130076. [Google Scholar] [CrossRef]

- Yousaf, M.; Bashir, S.; Raza, H.; Shah, A.N.; Iqbal, J.; Arif, M.; Bukhari, M.A.; Muhammad, S.; Hashim, S.; Alkahtani, J.; et al. Role of nitrogen and magnesium for growth, yield and nutritional quality of radish. Saudi J. Biol. Sci. 2021, 28, 3021–3030. [Google Scholar] [CrossRef]

- Gamba, M.; Asllanaj, E.; Raguindin, P.F.; Glisic, M.; Franco, O.H.; Minder, B.; Bussler, W.; Metzger, B.; Kern, H.; Muka, T. Nutritional and phytochemical characterization of radish (Raphanus sativus): A systematic review. Trends Food Sci. Technol. 2021, 113, 205–218. [Google Scholar] [CrossRef]

- Rao, Y.; Tao, Y.; Chen, X.; She, X.; Qian, Y.; Li, Y.; Du, Y.; Xiang, W.; Li, H.; Liu, L. The characteristics and correlation of the microbial communities and flavors in traditionally pickled radishes. LWT 2020, 118, 108804. [Google Scholar] [CrossRef]

- Malisorn, C.; Suntornsuk, W. Optimization of β-carotene production by Rhodotorula glutinis DM28 in fermented radish brine. Bioresour. Technol. 2008, 99, 2281–2287. [Google Scholar] [CrossRef]

- Jiang, J.; Shi, B.; Zhu, D.; Cai, Q.; Chen, Y.; Li, J.; Qi, K.; Zhang, M. Characterization of a novel bacteriocin produced by Lactobacillus sakei LSJ618 isolated from traditional Chinese fermented radish. Food Control 2012, 23, 338–344. [Google Scholar] [CrossRef]

- Andersen, J.O.; Henriksen, C.B.; Laursen, J.; Nielsen, A.A. Computerised image analysis of biocrystallograms originating from agricultural products. Comput. Electron. Agric. 1999, 22, 51–69. [Google Scholar] [CrossRef]

- Mollazade, K.; Omid, M.; Tab, F.A.; Kalaj, Y.R.; Mohtasebi, S.S.; Zude, M. Analysis of texture-based features for predicting mechanical properties of horticultural products by laser light backscattering imaging. Comput. Electron. Agric. 2013, 98, 34–45. [Google Scholar] [CrossRef]

- Hossain, E.; Hossain, M.F.; Rahaman, M.A. A color and texture based approach for the detection and classification of plant leaf disease using KNN classifier. In Proceedings of the 2019 International Conference on Electrical, Computer and Communication Engineering (ECCE), Cox’s Bazar, Bangladesh, 7–9 February 2019; pp. 1–6. [Google Scholar]

- Ropelewska, E. The Application of Machine Learning for Cultivar Discrimination of Sweet Cherry Endocarp. Agriculture 2021, 11, 6. [Google Scholar] [CrossRef]

- Ropelewska, E. The use of seed texture features for discriminating different cultivars of stored apples. J. Stored Prod. Res. 2020, 88, 101668. [Google Scholar] [CrossRef]

- Ropelewska, E.; Szwejda-Grzybowska, J. A comparative analysis of the discrimination of pepper (Capsicum annuum L.) based on the cross-section and seed textures determined using image processing. J. Food Process Eng. 2021, 44, e13694. [Google Scholar] [CrossRef]

- Nturambirwe, J.F.I.; Opara, U.L. Machine learning applications to non-destructive defect detection in horticultural products. Biosyst. Eng. 2020, 189, 60–83. [Google Scholar] [CrossRef]

- Yamamoto, K.; Guo, W.; Yoshioka, Y.; Ninomiya, S. On Plant Detection of Intact Tomato Fruits Using Image Analysis and Machine Learning Methods. Sensors 2014, 14, 12191–12206. [Google Scholar] [CrossRef]

- Piedad, E., Jr.; Larada, J.I.; Pojas, G.J.; Ferrer, L.V.V. Postharvest classification of banana (Musa acuminata) using tier-based machine learning. Postharvest Biol. Technol. 2018, 145, 93–100. [Google Scholar] [CrossRef]

- Szczypinski, P.M.; Strzelecki, M.; Materka, A.; Klepaczko, A. MaZda—A software package for image texture analysis. Comput. Meth. Prog. Biomed. 2009, 94, 66–76. [Google Scholar] [CrossRef]

- Ibraheem, N.A.; Hasan, M.M.; Khan, R.Z.; Mishra, P.K. Understanding Color Models: A Review. ARPN J. Sci. Technol. 2012, 2, 265–275. [Google Scholar]

- Bouckaert, R.R.; Frank, E.; Hall, M.; Kirkby, R.; Reutemann, P.; Seewald, A.; Scuse, D. WEKA Manual for Version 3-9-1; The University of Waikato: Hamilton, New Zealand, 2016. [Google Scholar]

- Frank, E.; Hall, M.A.; Witten, I.H. The WEKA Workbench. In Online Appendix for Data Mining: Practical Machine Learning Tools and Techniques, Morgan Kaufmann, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Witten, I.H.; Frank, E. Data mining. In Practical Machine Learning Tools and Techniques, 2nd ed.; Elsevier: San Francisco, CA, USA, 2005. [Google Scholar]

- Ropelewska, E.; Cai, X.; Zhang, Z.; Sabanci, K.; Aslan, M.F. Benchmarking Machine Learning Approaches to Evaluate the Cultivar Differentiation of Plum (Prunus domestica L.) Kernels. Agriculture 2022, 12, 285. [Google Scholar] [CrossRef]

- Ropelewska, E.; Sabanci, K.; Aslan, M.F. Discriminative Power of Geometric Parameters of Different Cultivars of Sour Cherry Pits Determined Using Machine Learning. Agriculture 2021, 11, 1212. [Google Scholar] [CrossRef]

- Ropelewska, E. Diversity of plum stones based on image texture parameters and machine learning algorithms. Agronomy 2022, 12, 762. [Google Scholar] [CrossRef]

- Ropelewska, E.; Wrzodak, A. The Use of Image Analysis and Sensory Analysis for the Evaluation of Cultivar Differentiation of Freeze-Dried and Lacto-Fermented Beetroot (Beta vulgaris L.). Food Anal. Methods 2021, 15, 1026–1041. [Google Scholar] [CrossRef]

- Ropelewska, E.; Wrzodak, A.; Sabanci, K.; Aslan, M.F. Effect of lacto-fermentation and freeze-drying on the quality of beetroot evaluated using machine vision and sensory analysis. Eur. Food Res. Technol. 2022, 248, 153–161. [Google Scholar] [CrossRef]

- Ariana, D.P.; Lu, R. Hyperspectral waveband selection for internal defect detection of pickling cucumbers and whole pickles. Comput. Electron. Agric. 2010, 74, 137–144. [Google Scholar] [CrossRef]

- Sabanci, K.; Aslan, M.F.; Ropelewska, E.; Unlersen, M.F.; Durdu, A. A Novel Convolutional-Recurrent Hybrid Network for Sunn Pest–Damaged Wheat Grain Detection. Food Anal. Methods 2022, 15, 1748–1760. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).