Abstract

Sustainable corn starch nanoparticles were prepared using media milling to stabilize omega-3-rich Pickering emulsions based on chia oil. The milling conditions were as follows: 24 h (milling time), 0.4–0.6 mm (bead diameter), 1600 rpm (impeller speed), 30% (volume occupied by the grinding media), 7% w/v (starch concentration), and 0, 0.07 and 1% w/v of sodium dodecyl sulfate (SDS). Nanosuspensions containing 7% w/v of starch and the three concentrations of SDS were filtered, centrifuged, homogenized, and spray-dried to obtain redispersible powders. The particle size ranges were 2288 ± 211, 385 ± 21, and 278 ± 11 nm with 0, 0.07 and 1% w/v of SDS, respectively. The most stable backscattering profiles obtained during a period of one week were observed with 0.07 and 1% w/v of SDS. Therefore, the surface dilatational rheology of these particles adsorbed at chia oil/water interfaces was studied. A rapid decrease in the interfacial tension within 1 h was obtained with 1% w/v of SDS (down to 3 mN/m). Moreover, the most stable particle size after redispersion was obtained with the highest concentration of SDS. Finally, Pickering emulsions were prepared, and significant coalescence was observed with 0 and 0.07% w/v of SDS (within a few minutes). Nonetheless, in the presence of 1% w/v of SDS, oil droplets showed mean diameters and polydispersity indexes of 280.13 ± 4.60 nm and 0.35 ± 0.02, respectively, with no significant variations during storage for around 1 month. The results show that wet-stirred media milling can be applied to produce sustainable, new food-grade starch nanoparticles able to deliver bioactive compounds from chia oil.

1. Introduction

The increased worldwide consumption of functional foods has boosted the design of new products through the incorporation of bioactive compounds. Chia oil (CO) is known for its rich content of α-linolenic acid (60–66%), with extensively reviewed health benefits [1]. However, the polyunsaturated fatty acids present make it prone to oxidation when exposed to environmental factors (air, light, and temperature). Hence, specific technological alternatives, such as Pickering emulsions, have been applied to stabilize omega-3-rich oils [2].

Pickering emulsions are those stabilized by micro and nanoparticles present at the interfacial area of two immiscible liquids. These dispersed systems possess several outstanding properties: greater physical stability, less toxicity, enhanced responses to external stimuli, and resistance to flocculation and coalescence [3]. Diverse biocompatible materials have been applied for the development of nanoparticles. Among them, starches of different botanical origins are recognized within the food industry as efficient stabilizers for Pickering emulsions [2,3].

The development of nanoparticles using physical top-down methodologies, such as wet-stirred media milling, offers several advantages: continuous operation, scalability, simple construction, enhanced size reduction velocity, and absence of organic solvents [4].

Based on the above context, the aim of this research was to obtain stable corn starch nanoparticles via wet-stirred media milling, in order to stabilize Pickering emulsions as delivery systems for chia oil. Compared with a previous work by our group [5], a higher oil load could be stabilized. Redispersible powders were prepared by spraying the nanosuspensions due to the enhanced conservation, storage, and transport of solid materials compared with the parent fluid suspensions.

2. Materials and Methods

2.1. Materials

Chia seed oil (CSO) (Nutracéutica Sturla SRL, Salta, Argentina) was obtained via cold pressing as described by Martínez et al. [6] with a pilot plant screw press (Komet Model CA 59 G, IBG Monforts, Mönchengladbach, Germany). On the other hand, corn starch was purchased from a local distributor (Distribuidora NICCO, Córdoba, Argentina); the stabilizer added during milling experiments was sodium dodecyl sulfate (SDS) (Sigma–Aldrich, San Luis, MO, USA). Other reagents were HPLC or analytical grade.

2.2. Milling Experimental Design

Corn starch nanoparticles were obtained via media milling using a NanoDisp® laboratory-scale mill (NanoDisp®, Córdoba, Argentina), which has been described in previous works [5,7].

Suspensions containing starch (7% w/v) and SDS in three different concentrations (0, 0.1, and 1% w/v) were milled according to Bordón et al. [5]. The milling conditions were the following: diameter of zirconia beads (0.4–0.6 mm); filling ratio with beads (30% v/v); impeller speed (1600 rpm); and milling time (24 h). The obtained nanosuspensions were subsequently filtered (200 ASTM screen, Zonytest, Buenos Aires, Argentina) (74 μm), centrifuged (13,000× g 40 min), and homogenized (18,000 rpm, 2 min, Ultraturrax homogenizer IKA T18, Janke & Kunkel GmbH, Staufen, Germany; subsequently, 1 cycle at 700 bar, in a high-pressure valve homogenizer, EmulsiFlex C5, Avestin, Ottawa, ON, Canada).

2.3. Characterization of Corn Starch Nanosuspensions

The obtained corn starch nanosuspensions were characterized according to average particle size (Zav), polydispersity index (PDI) (immediately after milling and after storage for one month), and ζ-potential via dynamic light scattering at 25 °C (Nano Zetasizer, Malvern Instruments, Worcestershire, UK) [5]. Moreover, the rheological behavior was assessed with a controlled-stress rheometer, Physica MCR 301 Anton Paar (Physica Messtechnik, Ostfildern, Germany) [7].

2.4. Preparation and Characterization of Pickering Emulsions Stabilized with Corn Starch Nanoparticles

The nanosuspensions obtained in Section 2.2 were filtered, centrifuged, and blended with CSO (solids/CO ratio: 1/1 w/w) via high-speed homogenization (14,000 rpm, 3 min). Afterward, these coarse emulsions were passed through a high-pressure valve homogenizer (2 cycles, 700 bar, EmulsiFlex C5, Avestin, Ottawa, ON, Canada) to produce fine emulsions. The oil droplet size distribution, polydispersity index, and ζ-potential were measured as described in Section 2.3.

2.5. Spray Drying and Characterization of Powders

The nanosuspensions obtained in Section 2.2 were spray-dried to obtain redispersible powders. The spray drying process was performed in laboratory scale equipment, Büchi B-290 (Büchi Labortechnik AG, Flawil, Switzerland), according to Fu et al. [8]. The obtained powders were redispersed in Milli-Q water to determine the Zav and the PDI as described in Section 2.3. The morphology of powders was assessed via scanning electron microscopy (SEM, LSM5 Pascal; Zeiss, Oberkochen, Germany). The transmittance profiles after redispersion were determined according to [9] (Vertical Scan Analyzer Quick Scan, Coulter Corp., Miami, FL, USA) and the interfacial tension at chia oil/water interfaces was measured with the pendant droplet method (TRACKER pendant droplet tensiometer IT Concept, Saint-Ouen-l’Aumône, France) as described in [10].

3. Results and Discussion

3.1. Characterization of Nanosuspensions and Pickering Emulsions

Nanomilling could modify the granular morphology and molecular structure in starch. Therefore, improved physicochemical properties are observed, such as low gelatinization temperature, enhanced paste viscosity and redispersion, and large specific surface area [2,3]. In order to obtain a stable nanosuspension, the selection of a stabilizer is of utmost importance, with potentially serious consequences for the system’s physical stability such as Ostwald ripening, aggregation, sedimentation, and cake formation during milling and storage [5]. In this work, different concentrations of SDS were explored to achieve electrostatic stabilization.

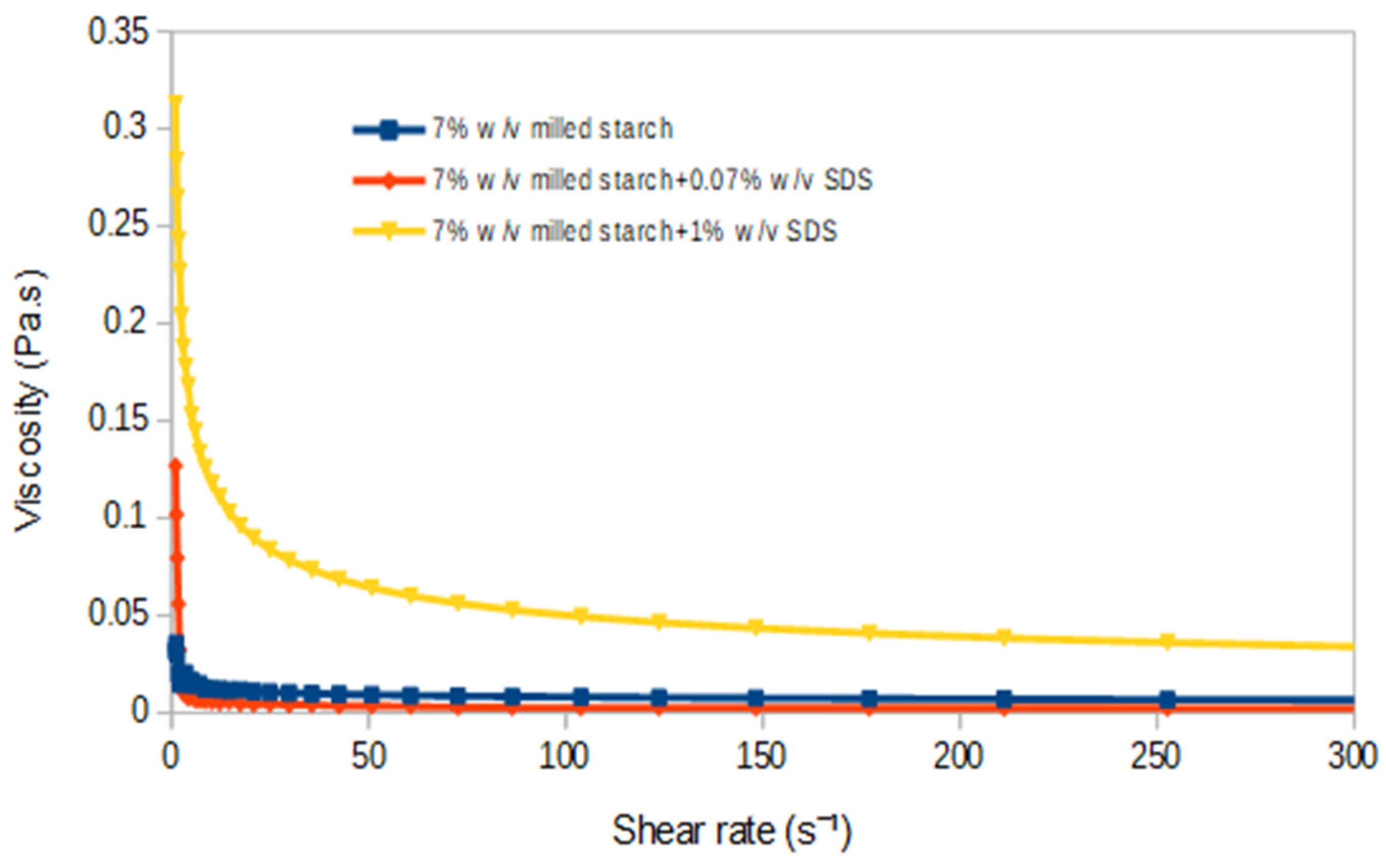

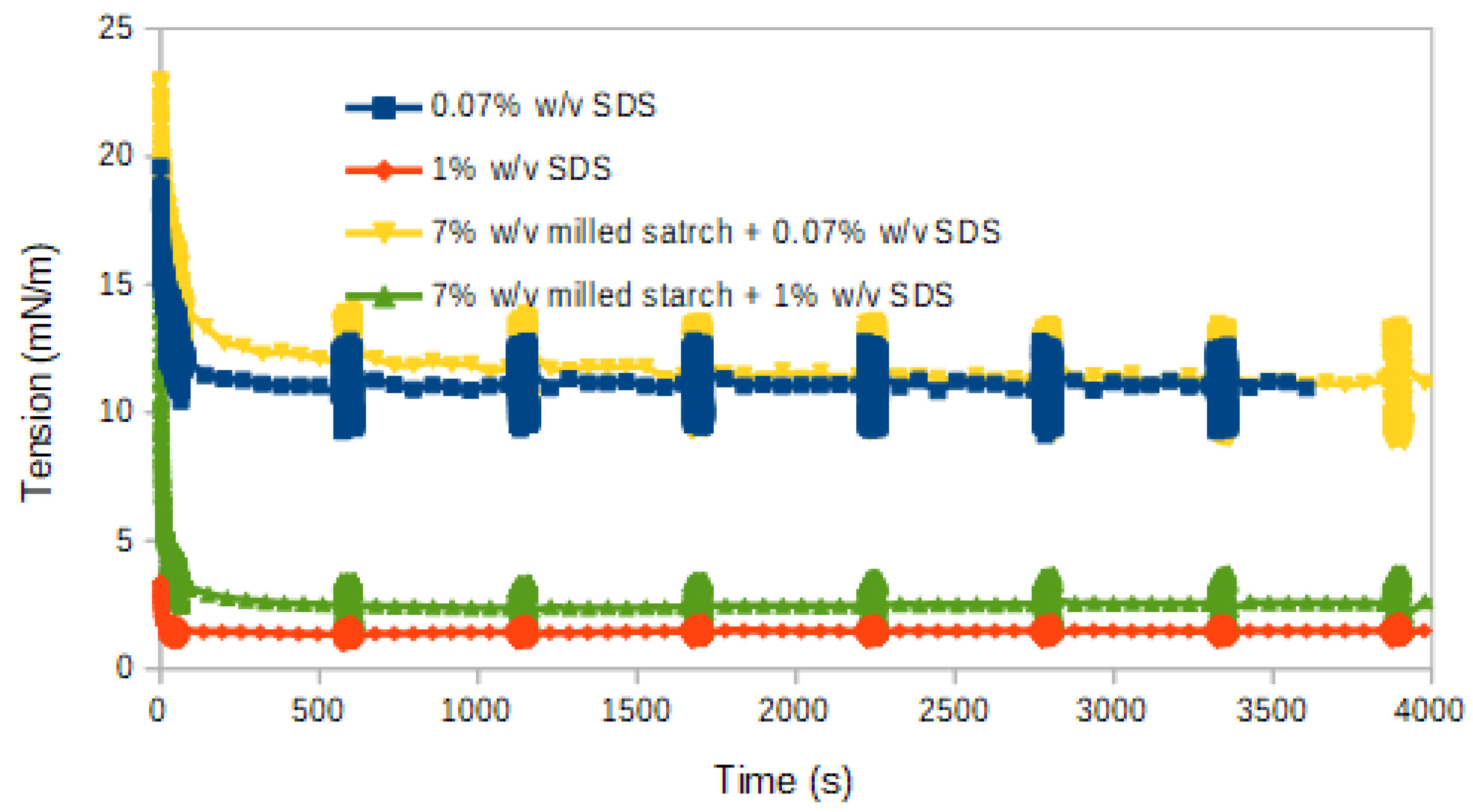

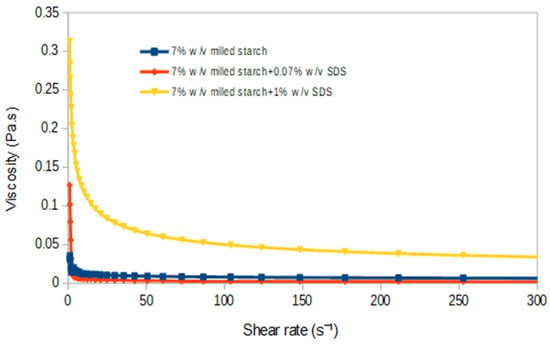

The average particle size and polydispersity index of fresh corn starch nanosuspensions after storage for one month are given in Table 1. Moreover, the rheological properties are shown. The initial particle size of starch suspensions before milling operations was 15 µm. As the surfactant concentration increases, the stability of the particle size is significantly enhanced (p < 0.05), as suggested by the lower values of Zav in fresh nanosuspensions and after storage. The PDI values are also significantly improved with the highest addition of surfactant. The increased electrical charge of nanoparticles, given by the ζ-potential values, might account in part for the enhanced stability [5]. As also shown in Table 1 and Figure 1, the increased concentration of SDS also enhanced the viscosity (p < 0.05) of nanosuspensions, providing an additional stabilization mechanism [7].

Table 1.

Main properties of corn starch nanosuspensions.

Figure 1.

The viscosity of the corn starch nanosuspensions used to develop Pickering emulsions.

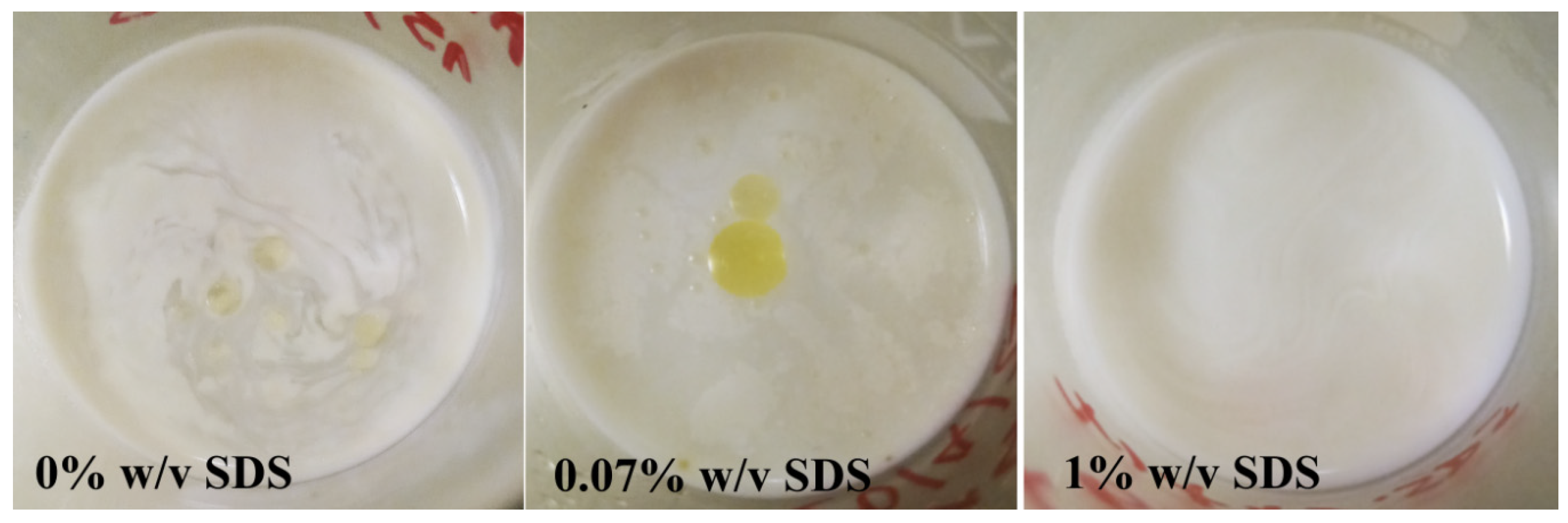

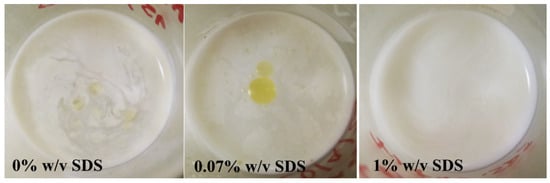

Regarding the interaction between starch and SDS, it is presumed that amylose forms left-handed helices with an internal hydrophobic cavity where ligands can reside. Although amylose has the ability to form complexes with diverse compounds, this process seems to be more favorable for charged salts of different fatty acids. These ligands produce an amylose non-retrogradable complex that remains soluble in water due to ionic group repulsion [11]. The SDS molecule exhibits a steric and functional similarity to these salts of fatty acids; therefore, this mechanism could be involved in the stabilization of nanosuspensions and emulsions. Indeed, the most stable oil droplet size in fresh emulsions was detected for the highest concentration of SDS, as can be seen in Figure 2. Immediately after their preparation, significant coalescence was observed with 0 and 0.07% w/v SDS. Those emulsions with the highest stability exhibited mean oil droplet sizes of 280 ± 4 and 292 ± 5 nm after their preparation and storage (one month), respectively. The electrical charge value was −25.40 ± 0.40 mV.

Figure 2.

Photographs of Pickering emulsions containing chia oil and stabilized using corn starch nanoparticles obtained via media milling (7% w/v starch). From left to right: increasing concentration of SDS.

The formation of amylose complexes drastically modifies the properties of starch, improving its use in many relevant industrial applications. Amylose complexes have amphiphilic characteristics that reduce the interfacial tension at water/oil interfaces. These complexes also alter both the solubility and the emulsifying capacity with respect to amylose and the ligand. Moreover, when particles are adsorbed, they form a steric thick barrier on the droplet surface, which makes them resistant to destabilization phenomena such as coalescence and flocculation [11].

3.2. Characterization of Powders

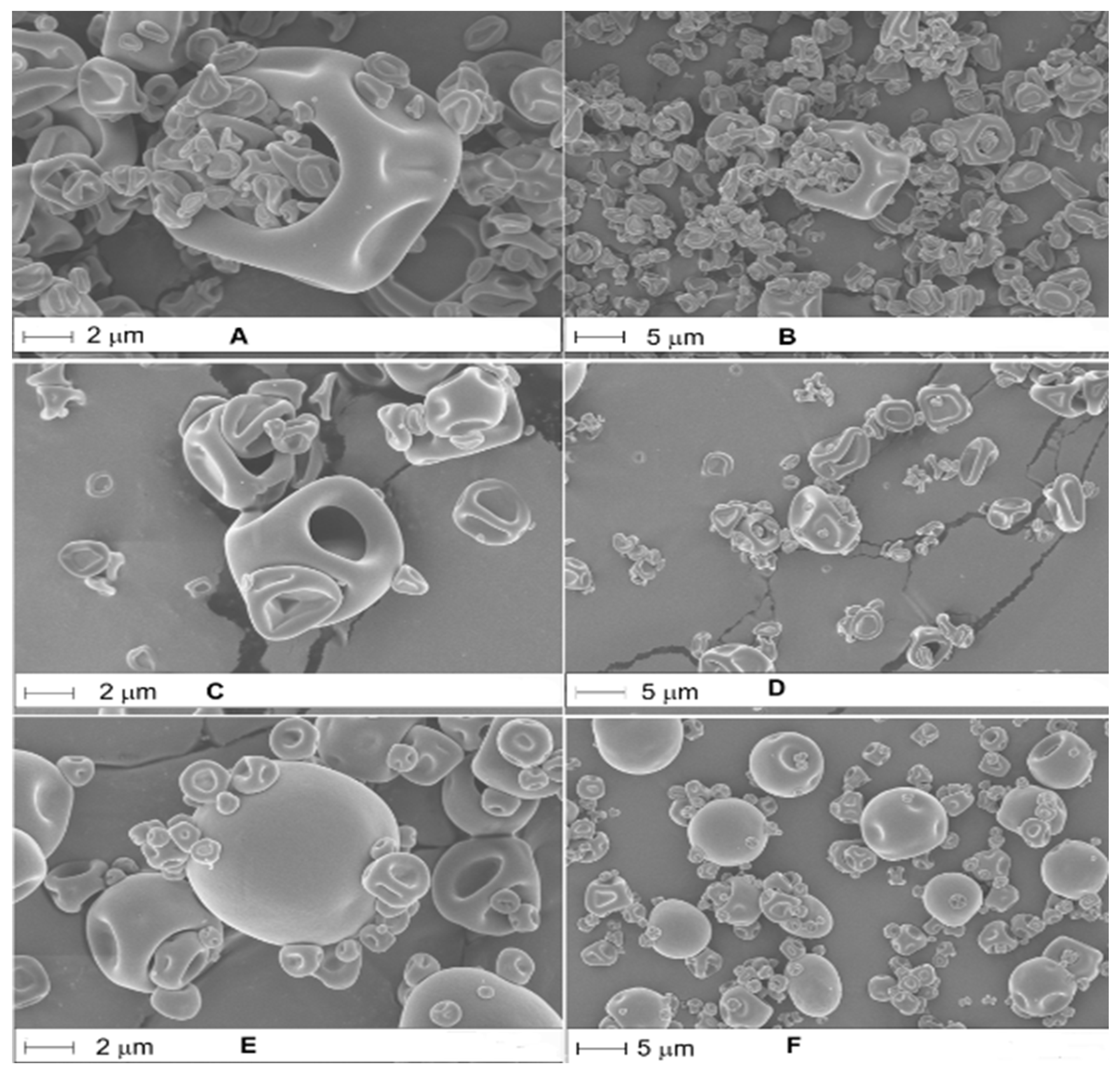

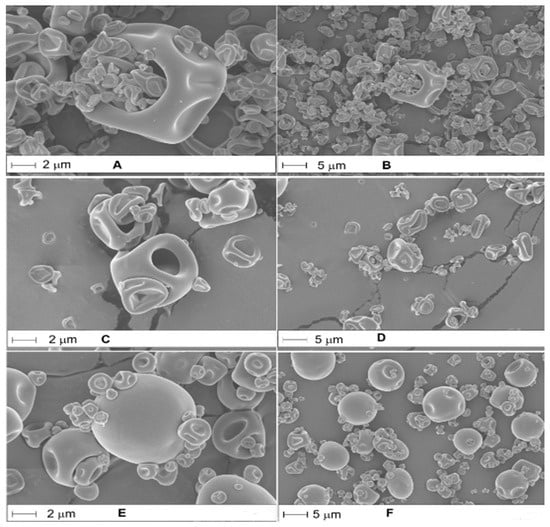

Redispersible powders were prepared by spray drying nanosuspensions. The particle size and polydispersity index of powders immediately after spray drying and storage for one month are shown in Table 2. SEM micrographs of powders and the transmittance profiles after redispersion are given in Figure 3 and Figure 4, respectively. Regarding the particle morphology, the structure of granules was significantly modified and the particles were swollen considerably as a result of milling. After spray drying, volumetric shrinkage was remarkably observed. In this context, the development of wrinkled morphologies in gelatinized starch particles after milling might obey the same mechanisms found for maltodextrins and whey proteins [5,8].

Table 2.

Particle size of spray-dried powders.

Figure 3.

SEM micrographs of powders obtained from the spray drying of corn starch nanosuspensions; 7% w/v milled starch: (A) (5000×), (B) (2000×); 7% w/v milled starch + 0.07% w/v SDS: (C) (5000×), (D) (2000×); and 7% w/v milled starch + 1% w/v SDS: (E) (5000×), (F) (2000×).

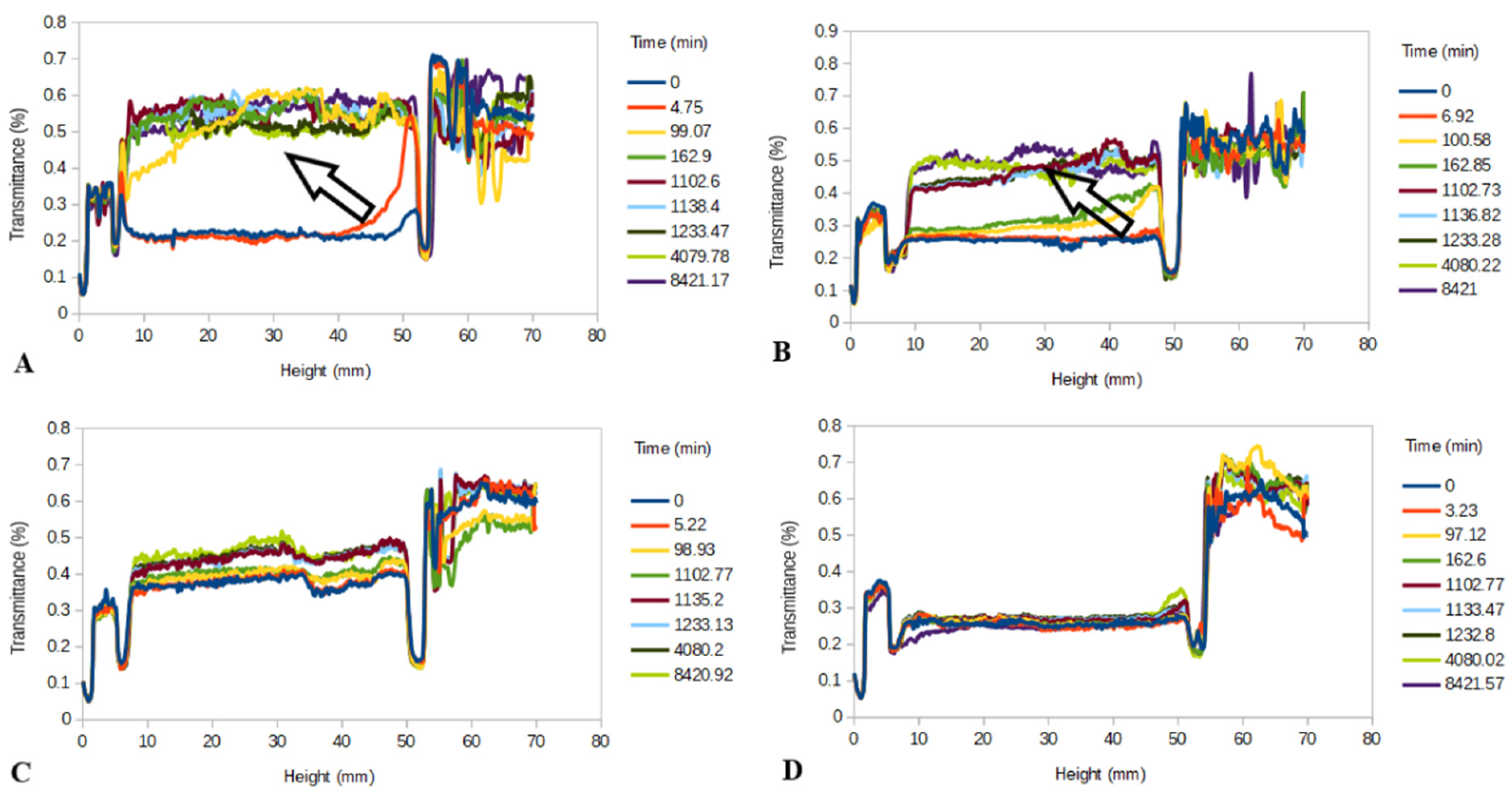

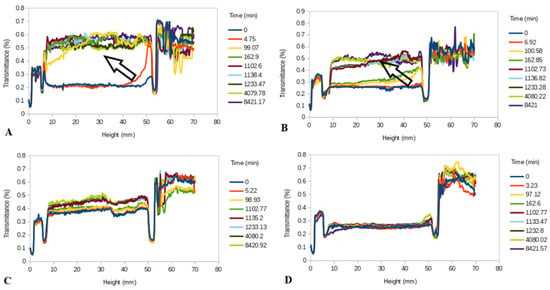

Figure 4.

Transmittance (%) profiles of redispersed powders; (A) (native starch); (B) (7% w/v milled starch); (C) (7% w/v milled starch + 0.07% w/v SDS); and (D) (7% w/v milled starch + 1% w/v SDS).

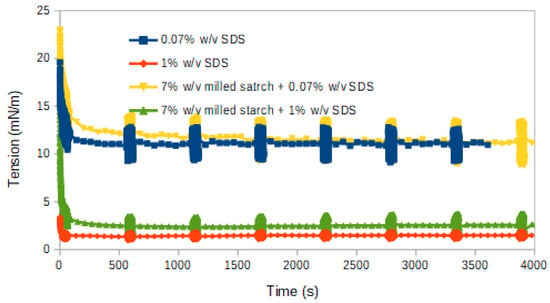

According to Table 2, and with a similar tendency observed in nanosuspensions (Section 3.1), the highest concentration of SDS significantly enhances (p < 0.05) the dispersion of powders. In addition, the uniformity of the transmittance profile along the tubes during the measurement period is enhanced as the concentration of SDS increases. These profiles evidence a rapid sedimentation of particles for native starch and for milled starch without added surfactant, as indicated by the arrows in the figure (Figure 4A,B). Given the enhanced transmittance profiles of powders containing SDS, these were studied for their interfacial properties. Finally, as can be seen in Figure 5, a rapid decrease in the interfacial tension (down to 3 mN/m) was observed in those nanoparticles formulated with the highest concentration of SDS. The mechanisms explained in the previous section might account for these latter observations.

Figure 5.

Interfacial tension determined at the chia oil/water interface using pendant droplet measurements.

4. Conclusions

The physical stability of corn starch nanosuspensions was significantly influenced by the concentration of surfactant (SDS). Moreover, the stability of oil droplet size during storage for one month in those Pickering emulsions containing chia oil in high loads might be explained by the adsorption and arrangement of starch nanoparticles at oil/water interfaces.

The results also demonstrated a promising stabilization of spray-dried Pickering emulsions for extending the shelf-life of chia oil within these delivery systems. Finally, this work shows that media milling can be utilized as a green methodology to develop sustainable nanoparticles able to deliver diverse bioactive compounds from different sources.

Author Contributions

Conceptualization, M.G.B., M.L.M., P.D.R., S.D.P., M.C.P., C.C.-S. and V.P.R.H.; methodology, M.G.B., L.L.-V., N.C., M.L.M., P.D.R., C.C.-S. and V.P.R.H.; software, M.G.B. and M.L.M.; validation, M.G.B., L.L.-V., N.C., M.L.M., M.C.P., C.C.-S. and V.P.R.H.; formal analysis, M.G.B., M.L.M., P.D.R., C.C.-S. and V.P.R.H.; investigation, M.G.B., L.L.-V., N.C., M.L.M., P.D.R., C.C.-S. and V.P.R.H.; resources, M.L.M., P.D.R., S.D.P., M.C.P., C.C.-S. and V.P.R.H.; data curation, M.G.B., M.L.M., P.D.R., S.D.P., M.C.P., C.C.-S. and V.P.R.H.; writing—original draft preparation, M.G.B., M.L.M. and P.D.R.; writing—review and editing, M.G.B. and M.L.M.; visualization, M.G.B. and M.L.M.; project administration, P.D.R. and S.D.P.; Funding acquisition, M.L.M., P.D.R., S.D.P., M.C.P., C.C.-S. and V.P.R.H. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the grant Ia ValSe-Food-CYTED (119RT0567), MinCyT-PIOBio (Decreto Nº 349/2022-Res. Mi. Nº 00000043/2022), CONICET (PIP 2021–2023 11220200102830CO), ANPCyT (PICT 2019-01122), and SeCyT-UNC, Cordoba, Argentina.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Acknowledgments

The authors would like to acknowledge the support of Ia ValSe-Food-CYTED, MinCyT, CONICET, ANPCyT, and SeCyT-UNC, Cordoba, Argentina.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Marcillo-Parra, V.; Tupuna-Yerovi, D.S.; González, S.; Ruales, J. Encapsulation of bioactive compounds from fruit and vegetable by-products for food application—A review. Trends Food Sci. Technol. 2021, 116, 11–23. [Google Scholar] [CrossRef]

- Zhu, F. Starch based Pickering emulsions: Fabrication, properties, and applications. Trends Food Sci. Technol. 2019, 85, 129–137. [Google Scholar] [CrossRef]

- Gonzalez-Ortiz, D.; Pochat-Bohatier, C.; Cambedouzou, J.; Bechelany, M.; Miele, P. Current trends in Pickering emulsions: Particle morphology and applications. Engineering 2020, 6, 468–482. [Google Scholar] [CrossRef]

- Breitung-Faes, S.; Kwade, A. Mill, material, and process parameters-A mechanistic model for the set-up of wet-stirred media milling processes. Adv. Powder Technol. 2019, 30, 1425–1433. [Google Scholar] [CrossRef]

- Bordón, M.G.; Martínez, M.L.; Chiarini, F.; Bruschini, R.; Camacho, N.; Severini, H.; Palma, S.D.; Ribotta, P.D. Preparation of corn starch nanoparticles by wet-stirred media milling for chia oil vehiculization. Biol. Life Sci. Forum. 2022, 17, 1. [Google Scholar] [CrossRef]

- Martínez, M.L.; Marín, M.A.; Faller, C.M.S.; Revol, J.; Penci, M.C.; Ribotta, P.D. Chia (Salvia hispanica L.) oil extraction: Study of processing parameters. LWT Food Sci. Technol. 2012, 47, 78–82. [Google Scholar] [CrossRef]

- Bordón, M.G.; Paredes, A.J.; Camacho, N.M.; Penci, M.C.; González, A.; Palma, S.D.; Ribotta, P.D.; Martínez, M.L. Formulation, spray-drying and physicochemical characterization of functional powders loaded with chia seed oil and prepared by complex coacervation. Powder Technol. 2021, 391, 479–493. [Google Scholar] [CrossRef]

- Fu, Z.-Q.; Wang, L.-J.; Li, D.; Adhikari, B. Effects of partial gelatinization on structure and thermal properties of corn starch after spray drying. Carbohydr. Polym. 2012, 88, 1319–1325. [Google Scholar] [CrossRef]

- Bordón, M.G.; Alasino, N.P.X.; Vilanueva-Lazo, A.; Carrera-Sánchez, C.; Pedroche-Jiménez, J.; Millán-Linares, M.C.; Ribotta, P.D.; Martínez, M.L. Scale-up and optimization of the spray drying conditions for the development of functional microparticles based on chia oil. Food Bioprod. Process. 2021, 130, 48–67. [Google Scholar] [CrossRef]

- Felix, M.; Romero, A.; Carrera-Sánchez, C.; Guerrero, A. Assessment of interfacial viscoelastic properties of Faba bean (Vicia faba) protein-adsorbed O/W layers as a function of pH. Food Hydrocoll. 2019, 90, 353–359. [Google Scholar] [CrossRef]

- Hay, W.; Fanta, G.; Felker, F.; Peterson, S.; Skory, C.; Hojilla-Evangelista, M.; Biresaw, G.; Selling, G. Emulsification properties of amylose-fatty sodium salt inclusion complexes. Food Hydrocoll. 2019, 90, 490–499. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).