Abstract

Spirulina (Spirulina platensis (Gomont) Geitler 1925) is a cyanobacteria used as an ecologically sound, nutrient-rich dietary supplement. These microalgae have the capability to produce the least-cost protein per unit area compared to livestock and are therefore being investigated to address malnutrition and food security. Apart from the variety of components, such as animal feed, fertilizer, and cosmetics, produced from Spirulina, phytoremediation of wastewater using Spirulina is an economically viable and environmentally sound tactic. A study was carried out with the objectives of the quick removal of waste from selected wastewaters produced by agro-based industries and the identification of suitable organic wastes as costless media for growing S. platensis for its powder production. Wastewater from fishponds and poultry units, grain-soaked water, and parboiled rice liquid waste were selected as treatments and inoculated with stock cultures of S. platensis. Treatments were replicated three times along with Zarrouk’s medium as standard control and arranged in a randomized complete block design. The chemical parameters of wastes, such as OD value, pH, and EC (mS/cm), and the growth of Spirulina were measured using a UH5300-Spectrophotometer with a wavelength of 560 nm at two-day intervals. The derived data were analyzed using SAS 9.4, and the significance of results among treatments was determined according to Duncan’s multiple range test, with p < 0.05. The results showed that poultry wastewater was a suitable medium for S. platensis growth, with a harvestable density of 0.8 at a very low concentration (25%) in 7 days compared to standard Zarrouk’s medium. The maximum and significant OD value of 1.313 was observed on day 15 in poultry wastewater and was non-significant among other treatments at p < 0.05. For fishpond wastewater, the maximum OD value of 0.567 was obtained on day 15. The pH value of poultry wastewater declined from 9.28 to 7.5 after 15 days. The EC values among the treatments were not significant. Among the selected liquid media, poultry wastewater promotes growth of S. platensis better than other locally available wastewaters tested. This experiment concludes that agro-based industries’ wastewater can be bio-remediated by Spirulina and that nutrient-enriched wastewater can be used for the mass culture of Spirulina without nutrient supplements.

1. Introduction

Spirulina (Spirulina platensis) is an important photo-autotrophic blue-green microalgae [1] which can be used for effective wastewater treatment [2]. The main sources of nutrients required for its growth are nitrate, urea, and ammonium salts. Treating wastewater will enable the effective recycling of waste produced from fish farming. Waste materials that are rich in a variety of concentrated nutrients, especially waste generated by “Pangasius” fish farming, produce more ammonia, which causes major water body pollution [3].

Spirulina can be grown well in swine wastewater, providing a possible solution for treating the waste produced in swine farming [4]. Growing microalgae in wastewater is a more economically feasible form of wastewater treatment [5]. Waste includes cheese whey, cow urine, and rainwater, which create suitable conditions for growing Spirulina [6]. Treating wastewater biologically will provide greater benefits by reducing environmental pollution due to wastewater discharge and providing low-cost media for the growth of microalgae.

Spirulina microalgae promote better recycling by the process of bioremediation, which involves the utilization of living organisms. Effluent collected from dairy discharge points on dairy farms provided a better yield of Spirulina than the control (NCIM growth medium) and COD/phosphate/EC was effectively removed from the effluent [7].

2. Experiments

2.1. Collection of Mother Culture

The Spirulina platensis mother culture was collected from OFFER Ceylon NGO, Jaffna, Sri Lanka.

2.2. Media Preparation and Inoculation

Zarrouk’s medium was prepared, and 250 mL of purified mother culture was added into the freshly prepared Zarrouk’s medium for growth [8]. The optical density (OD) value was measured at 560 nm wavelength using a UH-5300 spectrophotometer on alternative days for 15 days [6].

2.3. Sample Preparation

Various substrates of fishpond wastewater from inland freshwater ponds and poultry wastewater were prepared from the overnight soaking of 250 g of dried broiler droppings in one liter of water, grain-soaked water, and parboiled rice liquid waste, collected, and autoclaved at 121 °C for 15 min. The initial N, P, and K of all the wastes were measured using standard methods explained by Jackson (2005). Treatment ratios were arranged with various concentrations of water as T1–T4 to a total volume of 1000 mL (Table 1).

Table 1.

Different sets of treatments.

2.4. Culturing of Spirulina in Different Kinds of Wastewater

A pure Spirulina culture of 250 mL of was inoculated in twelve treatment flasks containing 1000 mL culture media. The temperature of the medium was maintained at 28–32 °C. All liquid wastes were aerated at the rate of 7 L/min using an Lp-60 (Resun) air pump for 24 h continuously. The setup was placed in indirect sunlight with the receiving point at 30 ± 2 °C. pH was adjusted daily in the range of 8.5–10. The culture was agitated by manual shaking [8].

2.5. Statistical Analysis

All the data collected in the study were analyzed by Microsoft Excel 2013 and SAS software (9.4 version). Duncan’s multiple range test (DMRT) was used to determine the least significant differences among the treatments at p < 0.05.

3. Results and Discussion

3.1. Chemical Parameters of Various Selected Liquid Wastes

The parameters of pH and EC were measured at the beginning and the end of the culturing period (Table 2). The pH of the parboiled rice wastewater reduced from day one to the final day from the value of 5.21 to 6.01, and a pH increase was non-significant at p < 0.05. However, the pH value of fishpond grain-soaked wastewater was lowered significantly, and poultry wastewater highly significant. Similarly, the EC value was not significantly lower in parboiled rice wastewater, whereas in all other wastes EC values were increased significantly at p < 0.05. The N% of the poultry wastewater reduced significantly from 3.2% to 2.4%, whereas in other wastes tested N, P, and K levels were reduced but not significantly.

Table 2.

Chemical parameters of various selected liquid wastes.

3.2. Determination of Spirulina platensis Growth in Different Wastewaters

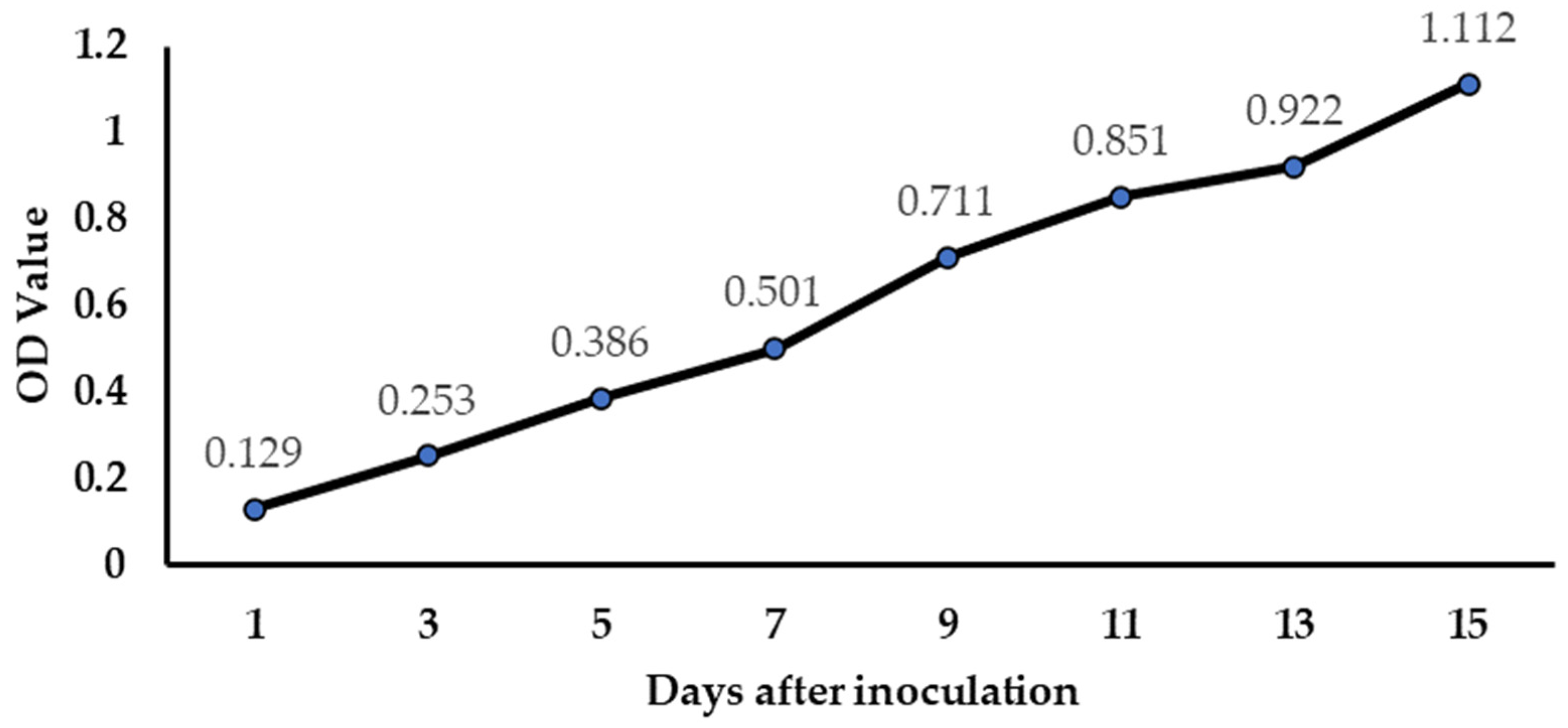

Growth of Spirulina in Zarrouk’s medium was steady and the OD value growth indicator was increased from 0.129 at the day of inoculation to 1.112 after day 15 of inoculation (Figure 1).

Figure 1.

Growth of Spirulina platensis in ideal Zarrouk’s medium.

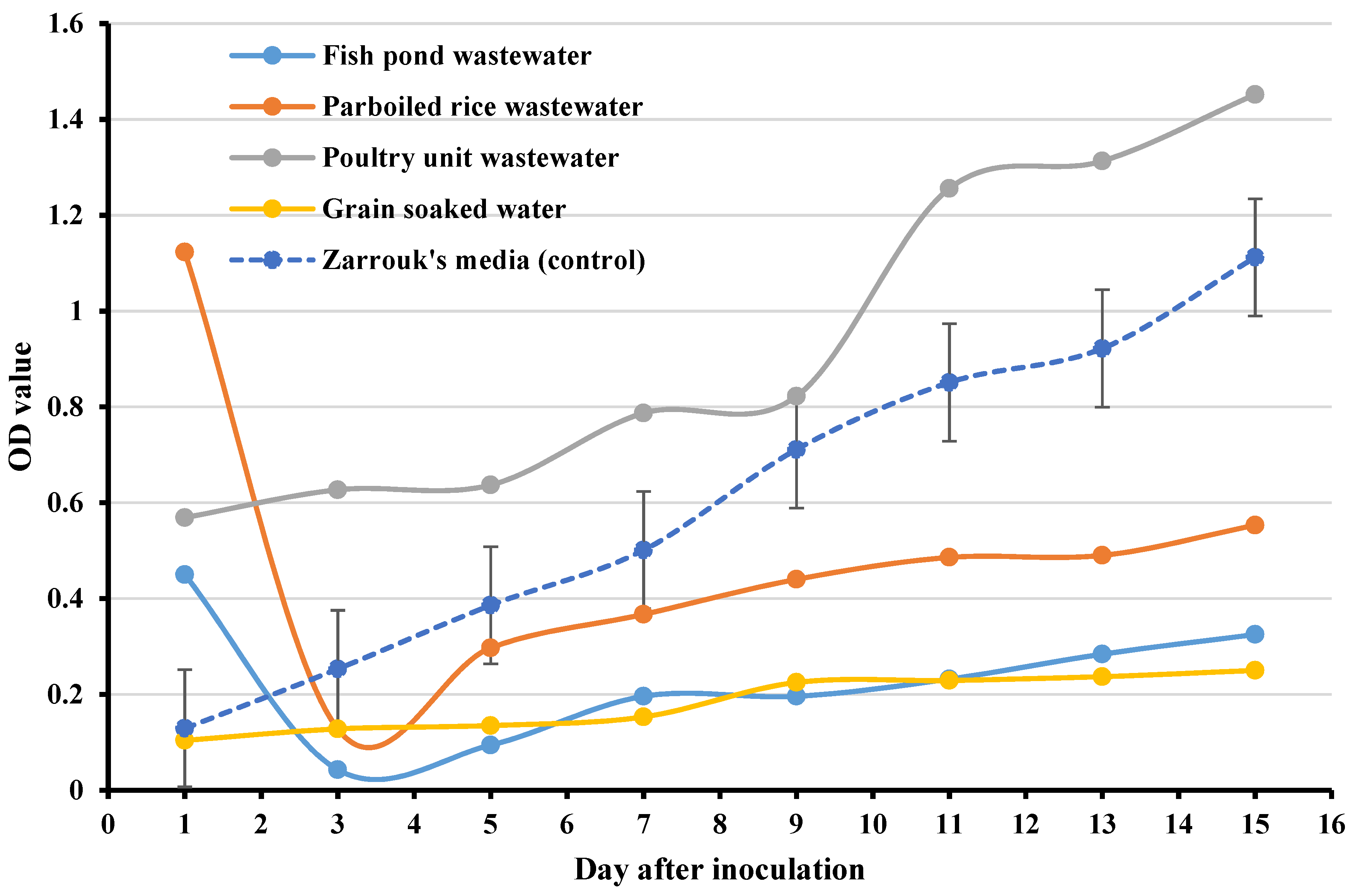

Growth of Spirulina in terms of OD in the fishpond wastewater is shown in Figure 2. In all concentrations, the growth of Spirulina was observed, but the growth in fishpond wastewater increased with the ratio of 750 mL of wastewater to 250 mL of fish tank wastewater (T3), which had a higher potential for Spirulina growth than other treatment concentrations. This shows increasing OD values from 0.047 to 0.567 in fifteen days of growth. From day 7 to day 9, the OD values decreased in all concentrations, and a exponential increase was observed from day 9.

Figure 2.

Growth of Spirulina platensis in different wastewaters.

In parboiled rice wastewater, the growth of Spirulina in terms of optical density (OD) was associated with a decreasing trend of OD values (Figure 2). When considering the treatment T1 (wastewater-to-distilled water volume, 250 mL:750 mL), a steady and slow increasing trend of OD values of 0.091 to 0.470 was observed. The best performance was observed at a lower concentration of parboiled rice effluent. Overall, the growth of Spirulina in parboiled rice water was much lower than in fishpond wastewater.

In poultry wastewater, all treatments had an effect on the growth of Spirulina over the period. Among the four concentrations, the ratio of waste-to-water was 250 mL:750 mL (T1) showed a better environment for the growth of Spirulina, and in T1 growth increased with the OD range of 0.269 to 1.452—more than it did for all the other treatments.

The overall growth performance of Spirulina in grain-soaked water was not satisfactory in terms of OD values. The maximum OD value obtained was 0.298 with a minimum of 0.25 across all concentrations. In comparison to standard Zarrouk’s medium, growth of Spirulina was better in poultry wastewater at a low concentration of 1:3. Fishpond and poultry wastewater are rich in nitrogen, carbonate, and bicarbonate, which are essential nutrients for Spirulina growth [9]. Grain-soaked water and parboiled rice wastewater do not contain sources of nitrogen and bicarbonate [10,11].

Initially, after the inoculation, OD values increased due to cultural adaptation to the new environment, in which period the growth is referred to as being in the lag phase. At day 7–9, the culture begins to show exponential growth due to adaptation to the environment [12,13]. Soni et al. (2019) reported that the maximum OD value at 560 nm was 0.5 in an open pond system. However, in the current experiment, the maximum value of 1.112 was obtained for poultry wastewater in laboratory conditions, and the growth observed in this concentration shows a tremendous response over time. These variations were mainly due to the continuous agitation and O2 supply to the cells in the laboratory conditions and the proper care of cultures [14,15,16,17]. The ability of S. platensis to absorb ammonia present in fishpond and poultry wastewater is a favorable factor for microalgae growth [3]. Madkour et al. (2012) reported that S. platensis could utilize ammonium nitrate most efficiently and that growth was enhanced by increasing concentrations of ammonium nitrate, resulting in a maximum biomass of 0.353 g/L. Further increasing the concentration limited growth. The growth parameters in urea showed a significant decrease associated with increasing urea concentrations [12,18]. These findings tally with the current investigation.

4. Conclusions

Among the selected liquid media, poultry wastewater promotes better growth of S. platensis than the other locally available wastewaters tested. This experiment concludes that agro-based industries’ wastewater can be bio-remediated by growing Spirulina, and nutrient-enriched poultry unit wastewater can be used for the cheap mass culture of Spirulina without nutrient supplements and without the high costs of commercially available growing media.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/IECAG2021-09716/s1.

Author Contributions

All authors contributed equally. G.M., N.T., and K.P. conceived the research idea; J.V. conducted experiments; J.V. and K.P. wrote the manuscript; G.M. and N.T. edited the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

This research was carried out in a JICA granted laboratory at the Department of Agricultural Biology, Faculty of Agriculture, University of Jaffna. The authors thank the Japanese government for supporting the research and providing the laboratory complex through the JICA grant. The authors wish to thank K. Uthayakumar and S. Arunsan in the Department of Agricultural Biology, Faculty of Agriculture, University of Jaffna for their technical assistance throughout this research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ariede, M.B.; Candido, T.M.; Jacome, A.L.M.; Velasco, M.V.R.; de Carvalho, J.C.M.; Baby, A.R. Cosmetic attributes of algae—A review. Algal Res. 2017, 25, 483–487. [Google Scholar] [CrossRef]

- Dolatabadi, S.; Hosseini, S.A. Wastewater treatment using Spirulina Platensis. J. Chem. Biol. Phys. Sci. 2016, 6, 1239–1246. [Google Scholar]

- Delrue, F.; Alaux, E.; Moudjaoui, L.; Gaignard, C.; Fleury, G.; Perilhou, A.; Richaud, P.; Petitjean, M.; Sassi, J.F. Optimization of Arthrospira platensis (Spirulina) growth: From laboratory scale to pilot scale. Fermentation 2017, 3, 59. [Google Scholar] [CrossRef] [Green Version]

- Cheunbarn, S.; Peerapornpisal, Y. Cultivation of Spirulina platensis using anaerobically swine wastewater treatment effluent. Int. J. Agric. Biol. 2010, 12, 586–590. Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.1037.4007&rep=rep1&type=pdf (accessed on 3 January 2022).

- Markou, G.; Chatzipavlidis, I.; Georgakakis, D. Cultivation of Arthrospira (Spirulina) platensis in olive-oil mill wastewater treated with sodium hypochlorite. Bioresour. Technol. 2012, 112, 234–241. [Google Scholar] [CrossRef] [PubMed]

- Joshi, M.; Kaur, K.; Mishra, T.; Singh, S. To evaluate lab scale cultivation of Spirulina by using different substrates and to evaluate its chlorophyll and protein content. Int. Res. J. Biol. Sci. 2014, 3, 22–30. [Google Scholar]

- Kulkarni, S.D.; Auti, T.; Saraf, S. Bioremediation study of dairy effluent by using Spirulina platensis. Res. J. Life Sci. Bioinform. Pharm. Chem. Sci 2016, 1, 317. [Google Scholar] [CrossRef]

- Dineshkumar, R.; Narendran, R.; Sampathkumar, P. Cultivation of Spirulina platensis in different selective media. Indian J. Geo Mar. Sci. 2016, 45, 1749–1754. Available online: https://nopr.niscair.res.in/handle/123456789/40537 (accessed on 3 January 2022).

- Rajasekaran, C.; Ajeesh, C.M.; Balaji, S.; Shalini, M.; Ramamoorthy, S.I.V.A.; Ranjan, D.A.S.; Fulzele, D.P.; Kalaivani, T. Effect of modified Zarrouk’s medium on growth of different Spirulina strains. Walailak J. Sci. Technol. (WJST) 2016, 13, 67–75. Available online: https://103.58.148.28/index.php/wjst/article/view/1416 (accessed on 3 January 2022).

- Gil de los Santos, D.; Gil Turnes, C.; Rochedo Conceição, F. Bioremediation of parboiled rice effluent supplemented with biodiesel-derived glycerol using Pichia pastoris X-33. Sci. World J. 2012, 2012, 492925. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mukherjee, C.; Chowdhury, R.; Sutradhar, T.; Begam, M.; Ghosh, S.M.; Basak, S.K.; Ray, K. Parboiled rice effluent: A wastewater niche for microalgae and cyanobacteria with growth coupled to comprehensive remediation and phosphorus biofertilization. Algal Res. 2016, 19, 225–236. [Google Scholar] [CrossRef]

- MadkoGhofar, H.S.A.; Jahromi, M.J.; Ikhsan, F.N.M.; Samsudin, A.A. The effects of varying dilution levels of wastewater on the cultivation of Spirulina sp. Malays. J. Anim. Sci. 2019, 22, 25–33. [Google Scholar]

- ur, F.F.; Kamil, A.E.W.; Nasr, H.S. Production and nutritive value of Spirulina platensis in reduced cost media. Egypt. J. Aquat. Res. 2012, 38, 51–57. [Google Scholar] [CrossRef] [Green Version]

- Ranjith, L.; Shukla, S.P.; Vennila, A.; Purushothaman, C.S. Growth performance of Spirulina (Arthrospira) platensis in a low cost medium: An assessment. Acta Biol. Indica 2013, 2, 335–342. Available online: https://bioscipub.com/journals/abi/pdf/335-342.pdf (accessed on 3 January 2022).

- Habib, M.A.B. A review on culture, production and use of spirulina as food for humans and feeds for domestic animals and fish. In FAO Fisheries and Aquaculture Circular; No. 1034; FAO: Rome, Italy, 2008; Volume 33, p. 14. [Google Scholar]

- Kim, Y.S.; Lee, S.H. Quantitative analysis of Spirulina platensis growth with CO2 mixed aeration. Environ. Eng. Res. 2018, 23, 216–222. [Google Scholar] [CrossRef] [Green Version]

- Soni, R.A.; Sudhakar, K.; Rana, R.S. Comparative study on the growth performance of Spirulina platensis on modifying culture media. Energy Rep. 2019, 5, 327–336. [Google Scholar] [CrossRef]

- Shen, Y.; Yuan, W.; Pei, Z.J.; Wu, Q.; Mao, E. Microalgae mass production methods. Trans. ASABE 2009, 52, 1275–1287. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).