The Effect of Carbon Black Content on Viscoelastic Properties of Vulcanized Natural Rubber †

Abstract

:1. Introduction

2. Materials and Method

2.1. Material Description

2.2. Experimental Procedure

3. Results and Discussion

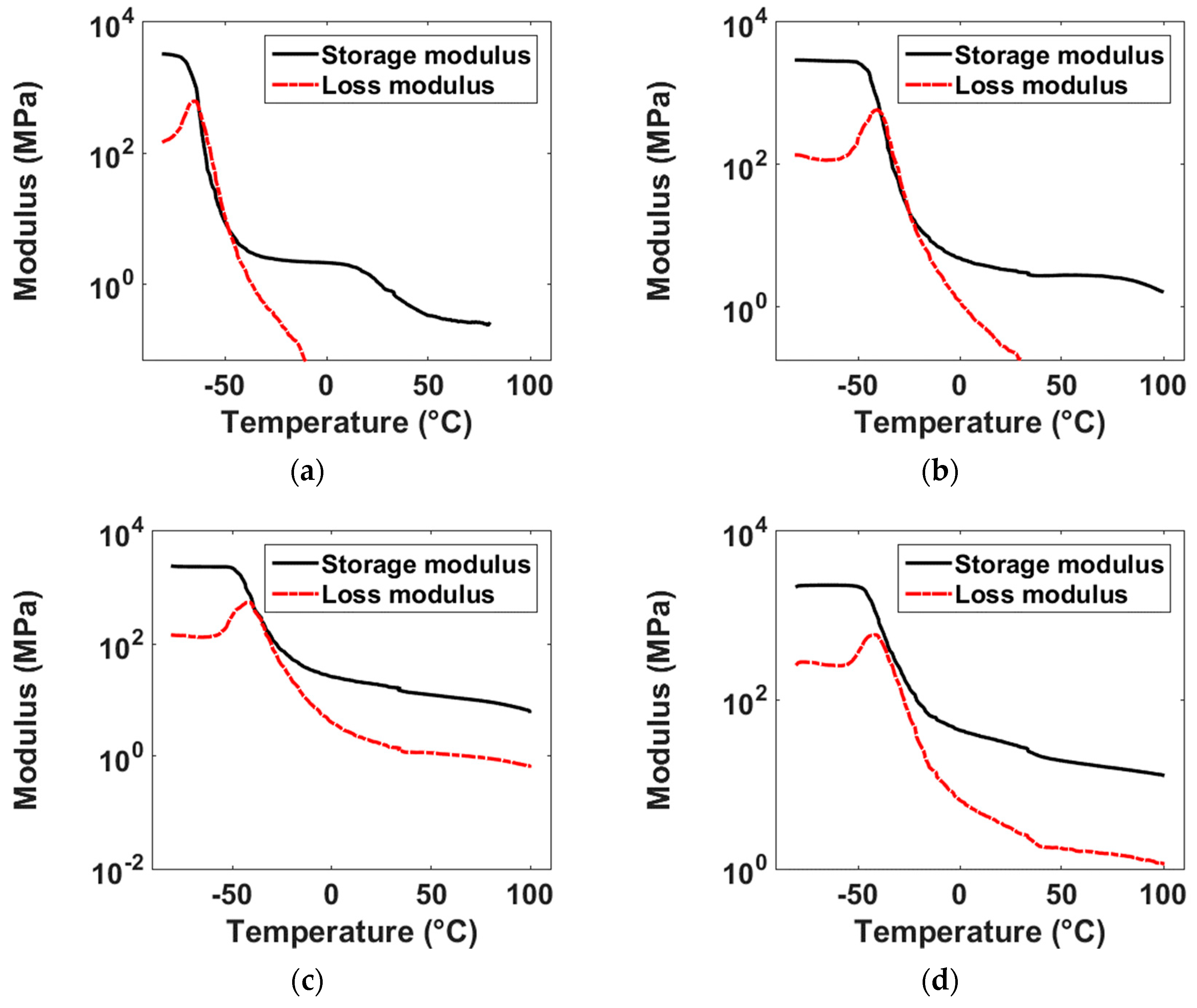

3.1. Effect of Fillers on Storage Modulus

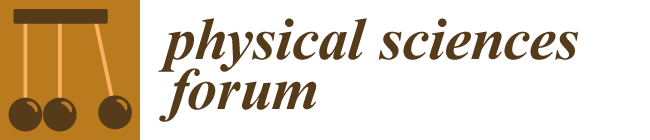

3.2. Effect of Fillers on Loss Modulus

3.3. Effect of Fillers on Loss Factor

4. Conclusions

- The E’ in glassy state is observed to increase with decreasing CB content. The decreasing E’ with increasing filler proportion is attributed to the dilution of polymers in the glassy state.

- The rubbery E’ increases with increasing CB content. This is due to the enhanced load transfer efficiency of material in the presence of rigid CB fillers.

- The coefficient of reinforcement exponentially decreases with increasing CB content. The low C-factor values of filled NRs indicate the effectiveness of reinforcement in enhancing the stiffness of filled rubber.

- The E” peaks at about 600 MPa for all filled rubber materials.

- The temperatures associated with E” peaks are referred as the glass transition temperature, which are noted to be about −65 °C and −45 °C for unfilled and filled NRs, respectively.

- The maximum tan δ value decreases with increasing CB content, which indicates a decrement in the damping characteristics of the vulcanizates upon addition of the rigid CB fillers.

- Similar to E” case, the tan δ peak shifts to higher temperature in the case of filled rubber. The maximum tan δ is observed at ~−55 °C for unfilled NR and ~−35 °C for the filled NRs. A temporal span of 10 °C is noted between the E” and tan δ peaks.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bhattacharya, M.; Bhowmick, A.K. Synergy in carbon black-filled natural rubber nanocomposites. Part I: Mechanical, dynamic mechanical properties, and morphology. J. Mater. Sci. 2010, 45, 6126–6138. [Google Scholar] [CrossRef]

- Mooney, M. A Theory of Large Elastic Deformation. J. Appl. Phys. 1940, 11, 582–592. [Google Scholar] [CrossRef]

- Lubliner, J. A model of rubber viscoelasticity. Mech. Res. Commun. 1985, 12, 93–99. [Google Scholar] [CrossRef]

- Gent, A.N. Relaxation processes in vulcanized rubber. I. Relation among stress relaxation, creep, recovery, and hysteresis. J. Appl. Polym. Sci. 1962, 6, 433–441. [Google Scholar] [CrossRef]

- Varughese, K.T.; Nando, G.B.; De, P.P.; De, S.K. Miscible blends from rigid poly(vinyl chloride) and epoxidized natural rubber. J. Mater. Sci. 1988, 23, 3894–3902. [Google Scholar] [CrossRef]

- Rahul, R.; Kitey, R. Effect of cross-linking on dynamic mechanical and fracture behaviour of epoxy variants. Compos. B 2016, 85, 336–342. [Google Scholar] [CrossRef]

- Grespacher, M.; O’Farrell, C.P.; Nikiel, L.; Yang, H.H. High frequency viscoelasticity of carbon black filled compounds. Rubber Chem. Tech. 1996, 69, 786–800. [Google Scholar] [CrossRef]

- Ikeda, Y.; Kohjiya, S. In situ formed silica particles in rubber vulcanizate by the sol-gel method. Polymer 1997, 38, 4417–4423. [Google Scholar] [CrossRef]

- Hu, X.-L.; Luo, W.-B.; Liu, X.; Li, M.; Huang, Y.-J.; Bu, J.-L. Temperature and frequency dependent rheological behaviour of carbon black filled natural rubber. Plast. Rubber Compos. 2013, 42, 416–420. [Google Scholar] [CrossRef]

- Warasitthinon, N.; Robertson, C.G. Interpretation of the tanδ peak height for particle-filled rubber and polymer nanocomposites with relevance to tire tread performance balance. Rubber Chem. Technol. 2018, 91, 577–594. [Google Scholar] [CrossRef]

- Pothan, L.A.; Oommen, Z.; Thomas, S. Dynamic mechanical analysis of banana fiber reinforced polyester composites. Compos. Sci. Technol. 2003, 63, 283–293. [Google Scholar] [CrossRef]

- Pothan, L.A.; George, C.N.; John, M.J.; Thomas, S. Dynamic Mechanical and Dielectric Behavior of Banana-Glass Hybrid Fiber Reinforced Polyester Composites. J. Reinf. Plast. Compos. 2009, 29, 1131–1145. [Google Scholar] [CrossRef] [Green Version]

- Karunakaran, K.; Singh, S.S.; Kitey, R. Investigating the role of filler shape on the dynamic mechanical properties of glass-filled epoxy composites. Polym. Compos. 2022. [Google Scholar] [CrossRef]

| Chemical/Ingredient | Proportion per Hundred Weights of Rubber (PHR) |

|---|---|

| Natural Rubber (smoked sheet, RMA) | 100 |

| Zinc Oxide | 5 |

| Stearic Acid | 1 |

| Accelerator CBS | 0.5 |

| Rubber Grade Sulphur | 2.5 |

| HAF N330 Carbon Black | 0, 20, 40, 60 |

| Aromatic Process Oil | 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bandyopadhyaya, S.; Kitey, R.; Upadhyay, C.S. The Effect of Carbon Black Content on Viscoelastic Properties of Vulcanized Natural Rubber. Phys. Sci. Forum 2022, 4, 9. https://doi.org/10.3390/psf2022004009

Bandyopadhyaya S, Kitey R, Upadhyay CS. The Effect of Carbon Black Content on Viscoelastic Properties of Vulcanized Natural Rubber. Physical Sciences Forum. 2022; 4(1):9. https://doi.org/10.3390/psf2022004009

Chicago/Turabian StyleBandyopadhyaya, Spandan, R. Kitey, and C. S. Upadhyay. 2022. "The Effect of Carbon Black Content on Viscoelastic Properties of Vulcanized Natural Rubber" Physical Sciences Forum 4, no. 1: 9. https://doi.org/10.3390/psf2022004009

APA StyleBandyopadhyaya, S., Kitey, R., & Upadhyay, C. S. (2022). The Effect of Carbon Black Content on Viscoelastic Properties of Vulcanized Natural Rubber. Physical Sciences Forum, 4(1), 9. https://doi.org/10.3390/psf2022004009