Abstract

Demand for a cleaner source of energy is increasing in India. In the search for alternate energy sources, coal bed methane gas receives considerable attention for its potential as a good energy source. During the coalification process, methane gas is captured in the coal seams and later released during coal mining operations. Coal bed methane separation is crucial for both economic benefit and methane emission reduction. The methane production from seams is an efficient way to reduce greenhouse emissions and provide a safe mining operation environment. In India, the production of coal bed methane on a commercial scale has been recently observed. In the present paper, an attempt is made to understand and establish a 3-D excavation of coal bed methane from reservoir simulation (COMET3) for Gondwana coal seams in the Sitarampur block of the Raniganj coalfield in India. The simulation study was carried out for a period of 25 years for the recovery of methane from the reservoir. It is observed from the simulation study that 372 million cubic meters CO2 equivalent greenhouse gas emissions can be prevented by the extraction of methane with space and time. The fracture gas concentration increases with time, and it is observed that fractures are fully saturated with gas in 3000 days.

1. Introduction:

While India is looking for a cleaner energy source, it is important to identify the potential of coal bed methane (CBM). CBM plays a vital role in the country’s economic development and makes the future mining environment safer without substantially adding to the atmospheric greenhouse gas emission levels. During the coalification process, methane is the pure form of methane trapped within coal seams and released during mining operations [1,2,3]. The depth of the coal seam significantly affects coal quality and gas content [4,5]. Most of the methane emission comes into the atmosphere from the underground coal mining activity [5,6,7]. Most coal mine accidents have resulted from methane gas emissions, which turns out to be an explosive gas; thus, it is necessary to degasify the coal seam for mine safety and the safety of mine workers [8,9,10,11]. The process of recovering methane gas directly from the surface, or by boreholes from the coal seam before mining activity, is commonly known as coal bed methane or virgin coal bed methane [12,13,14].

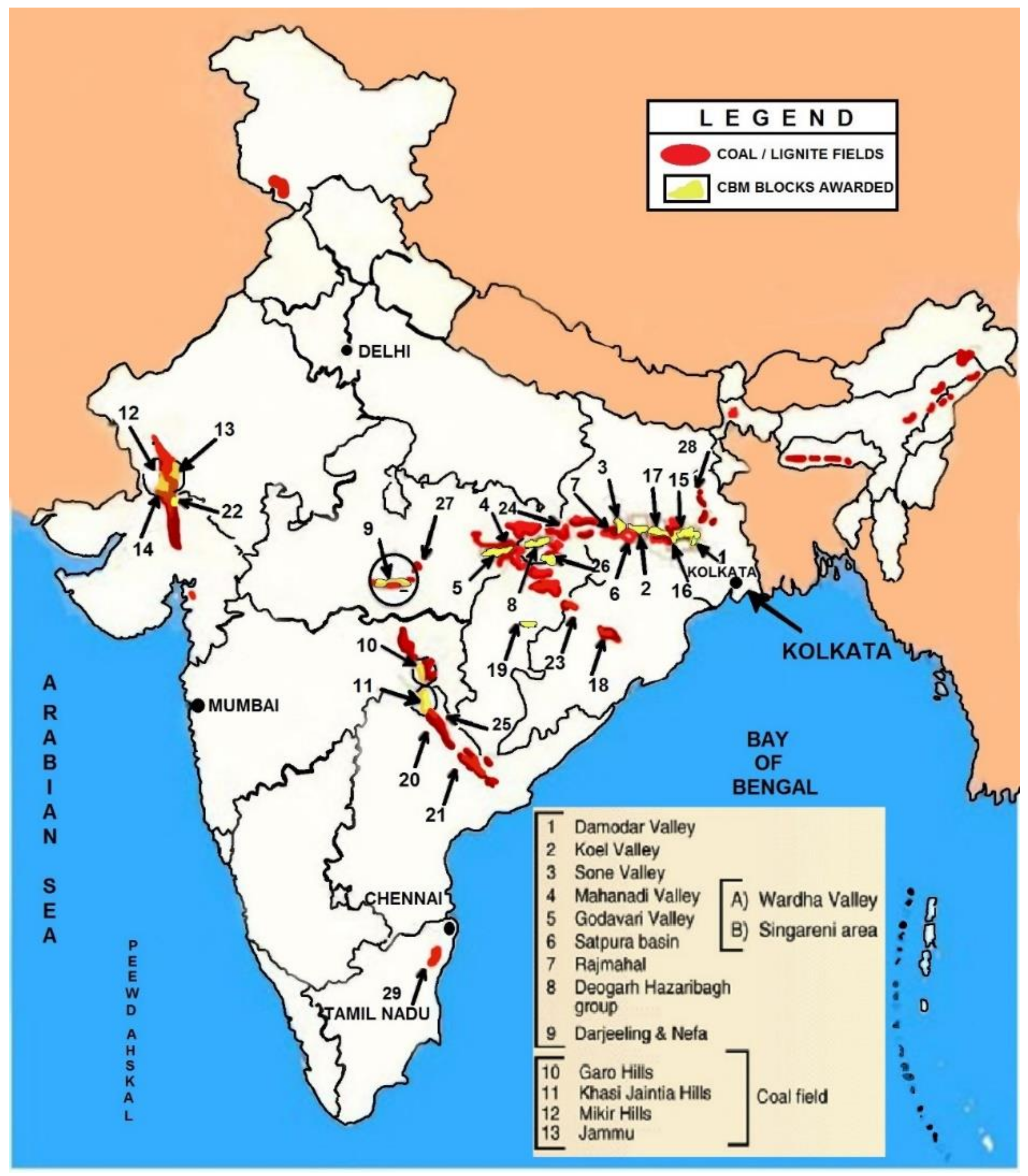

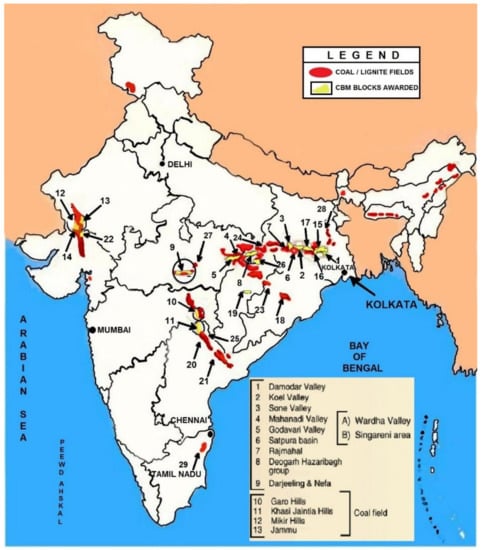

Methane concentration in virgin coal bed methane (VCBM) is generally very high (>90%), which makes it eventually an additional source for natural gas supplies [15,16,17,18,19,20,21,22,23]. Methane gas, released during the mining activity and therefore released into the atmosphere by the ventilation system, is known as ventilation air methane [24]. The methane concentration present in ventilation air methane (VAM) is significantly less, so it is not suitable for industrial utilization purposes [25]. However, currently developed oxidation technologies can generate electricity using thermal energy recovery by VAM as a fuel [26,27,28,29]. It contributes around 60–70% of total methane emissions into the atmosphere [30,31]. With coal mine methane (CMM) in underground mining of coal, methane is also recovered along with coal, so it is necessary to reduce methane concentration in the mine area for its proper workings, safety and efficient utilization [32,33]. Extraction of CMM is necessary for highly gassy seams and is essential before mining, and this captured gas from coal seams is a beneficial source of energy [34,35,36,37,38]. The world resource of CBM is assessed as around 1.4 × 1014 m3, which makes it a valuable conventional resource [39]. The coal basins present in India are divided into four categories according to their area, geological age, coal quality, gas resource and depth of coal occurrence, as shown in Figure 1 [40]. Raniganj coalfield is one of the largest coalfields, and the coal seams present in this area are thick and carry high-rank bituminous coal with the considerable resource of coal bed methane [15,16,17,18,19,20,21,22]. One virgin coal block from Sitarampur located in the Burdwan district of West Bengal was being explored by Mineral Development and Trading Corporation Limited, Kolkata. It may not be possible to mine out these coal seams without pre-mining degasification.

Figure 1.

Classification of coalfields based on CBM potential, India.

In this present investigation, one virgin highly gassy coal block from Sitarampur located in the Burdwan district of West Bengal was chosen for methane extraction. A simulation study was based on vertical wells degasification of the coal seams. Reservoir simulation was implemented to assess fracture gas saturation, matrix methane concentration and water production with time. The present numerical study’s finding is based on the fact that coal bed methane exploration and exploitation activity in India is still in the initial stages.

2. Methodology

COMET3 is one of the best, most stable, calibrated and known reservoir simulators; it is extensively used for three-dimensional (3D), two-phase, single or dual-porosity simulation for modeling gas and water production from coal seams and a single permeability model capable of modeling desorption controlled reservoirs. Therefore, it was used to simulate the production profile for two coal seams present in the block. COMET3 is well understood, based on the finite-difference method and specifically designed for modeling the flow of fluid in coal seams.

2.1. Numerical Modeling of CBM Process

In general, coal bed methane reservoir refers to a dual-porosity and naturally fractured reservoir. Dual-porosity is divided into two parts; the primary porosity is dominated by deposition condition and coalification, whereas the secondary porosity is dominated by water solution, natural fracturing and jointing. A large amount of gas formed during the maturation of coal is stored in a coal matrix (95–98%) by the adsorption process. Some gas is also present in the cleats system in free or dissolved form. The cleat system provides media for fluid flow in the coal seam formed during the regional burial and maturation [41,42,43,44,45]. The fracture zones affect the economic gas production of a reservoir [46,47,48]. When there is pressure reduction through dewatering, gas desorption starts from the matrix and diffuses to the cleat network system. This diffuse gas flows into the cleat system, produced by convective flow [49]. Many reservoir phenomena must be implicit before modeling coal beds for CBM recovery [50,51]. The change in permeability affects the gas flow rate, dual-porosity, heterogeneity and anisotropy in coals, and gas flow mechanism in the reservoir, including transport of gases by diffusion and flow in the cleats system [52,53,54,55,56,57]. The volume of gas involved or adsorbed on coal surface can be estimated by Langmuir’s isotherm.

2.2. Controlling Equations Used in Modeling

The basic mass conservation equations used for dual-porosity and the single permeability system are shown, respectively, in Equations (1) and (2).

For Conservation of Gas:

For Conservation of Water:

where ∇. is divergence operator, ∇ is gradient operator, Mg is gas phase mobility, Mw is water phase mobility, Rsw is gas solubility in water, bg is gas factor, bw is water shrinkage factor, pw is water pressure, γg is gas gradient, γw is water gradient, Z is elevation, qw is water flow rate, qg is gas flow rate, Ø is effective fracture porosity, Sg is gas saturation, Sw is water saturation, Pcgw is capillary pressure, Pg and Pw are related by capillary pressure, qm is described mathematically by Fick’s first law of diffusion, C is the average matrix gas concentration, τ is the sorption time defined by τ = 1//Dσ, where D is the diffusion coefficient and σ is the Warren and Root shape factor, and Vm is the bulk volume of a matrix element.

Pcgw = Pg − Pw

Sg + Sw = 1

2.3. The Assumptions Used for the Development of the Model

- (a)

- There is no thermal change occurring during the gas production from the reservoir.

- (b)

- The reservoir contains two phases: methane and water.

- (c)

- Methane is not soluble in water.

- (d)

- The flow of fluid inside the cleats or fracture system is assumed as laminar flow according to Darcy’s law [58] and flow measurement is done through relative permeability.

- (e)

- All matrix blocks are homogeneous; however, the matrix block is in equilibrium with the fracture system.

- (f)

- The thickness of the seam is alleged to be uniform.

- (g)

- Pseudo steady-state flow condition existed in between the matrix and fractures.

The above assumptions are the classic Warren and Root assumptions [59] and assume that the concentration throughout each matrix element is declining at the same rate.

2.4. Model Development

In numerical modeling and simulation practices, coal seams are represented as rectangular or cylindrical shape geometries. Cylindrical geometry was used to simulate the production profile of the present reservoir. In this model, a dual-porosity, single permeability, two phases (water and gas), single-component sorption model was selected to simulate both gas and water production from the reservoir and estimate gas recovery.

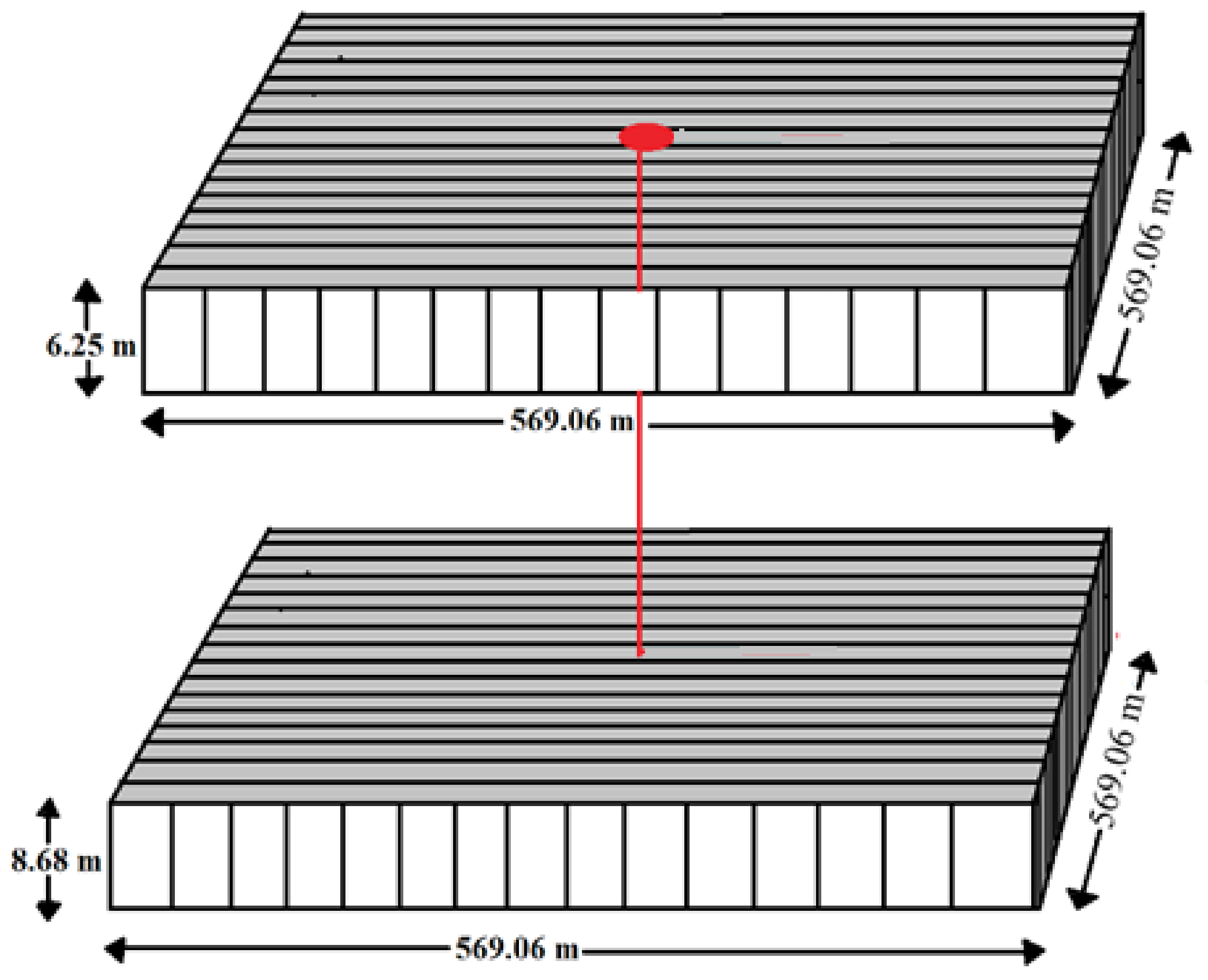

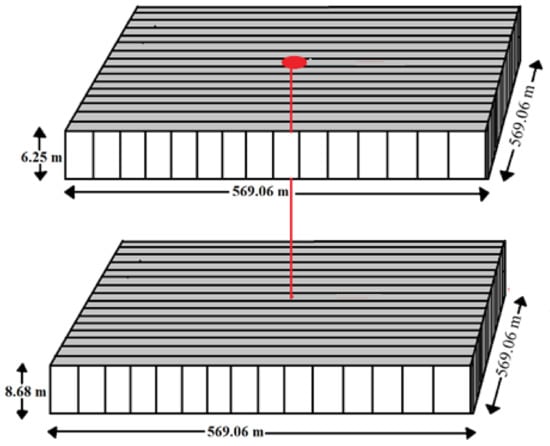

This model applied to a 569.06 × 569.06 × 14.93 m block of the coal seam. For the production of methane, the well diameter chosen was 0.1079 m. The simulation purpose model was distributed into 15 grid cells of 40.65 m in both the x and y direction and two grids of 14.93 m in z-direction in Figure 2. The various reservoir parameters which are inputs for the present study model are fracture properties, matrix properties, gas and water properties, basic reservoir properties such as reservoir temperature, reservoir pressure, coal seam thickness, sorption time of methane, and gas and water relative permeability curves. One vertical producer well is located in the centre of the coal matrix, and production results are used to simulate the gas production conditions in the field. The reservoir parameters in the present investigation are reported in Table 1.

Figure 2.

Grid view of block used for reservoir simulation.

Table 1.

Input parameters used for simulation study.

In this present study, a mathematical model was used to estimate the deviations in fracture gas saturation, water production and matrix methane concentration. In the end, the numerical values were noted for the highest saturation point at different time intervals. Methane and water production rates have been systematized for a specific time spell.

3. Results and Discussions

Pressure and concentration gradient plays an imperative role in gas production from the reservoir. Since lower coal seams are the primary target for CBM production, most of the coal bed methane reservoirs are considered water-saturated. It is necessary to depressurize the reservoir by a dewatering process for improving gas production. Dewatering augments the gas flow through the cleats system towards the production well, and thus, the productivity of the well gets advances.

3.1. Matrix Methane Concentration

Methane is found in a coal bed as adsorbed and this adsorbed form constitutes 90% of the total amount of gas. It is the gas generated during the formation process and stored in the pores within coal seams. The transport of gas in coal seams is believed to occur in three distinct stages. The first step involves desorption of gas from the micro-pores’ walls due to continuous pressure decline. The gas diffuses through the interconnected micro-pores from the region of higher concentration in the cleat system towards lower concentration. The gas is then transported through the coal seam cleat network under Darcy flow conditions.

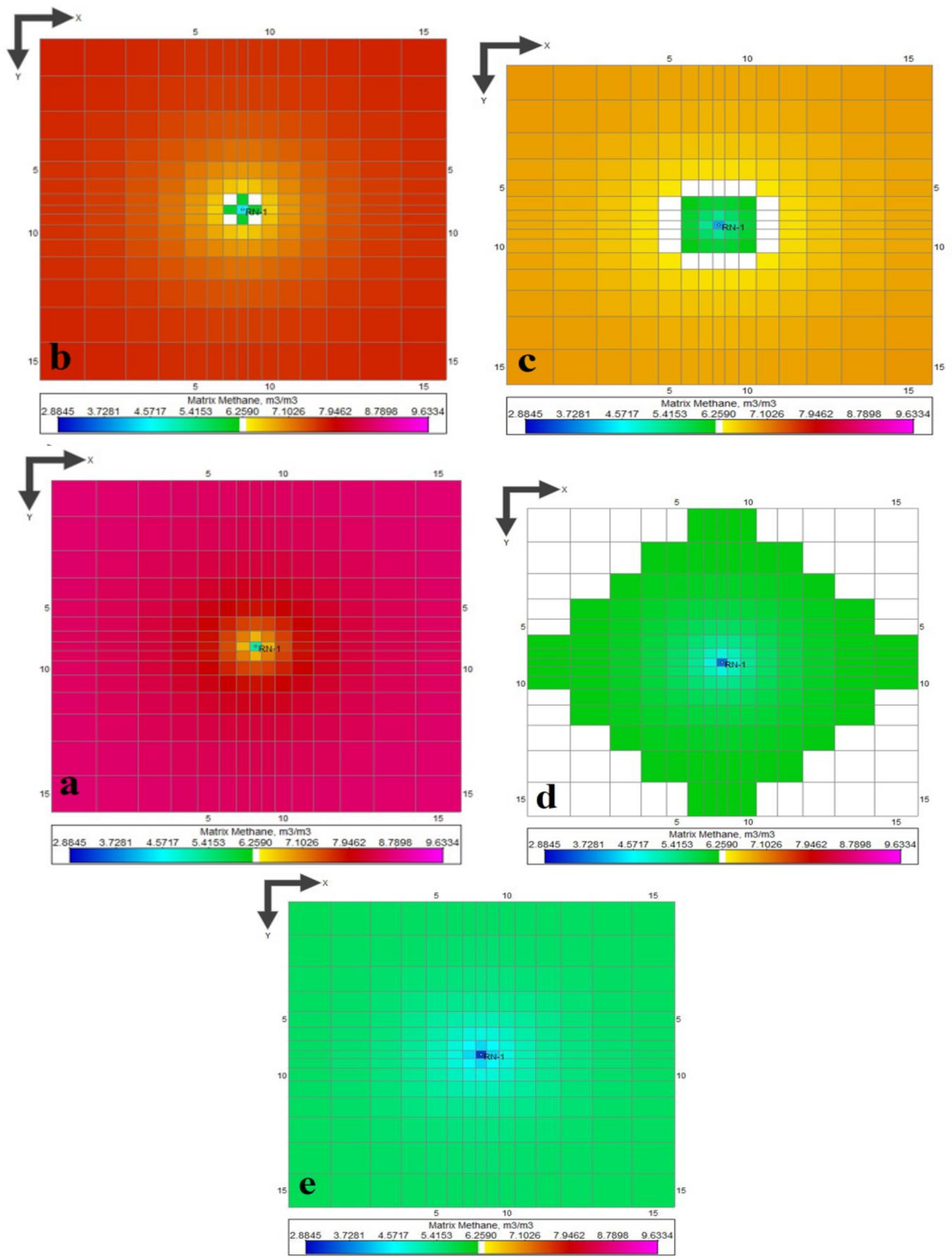

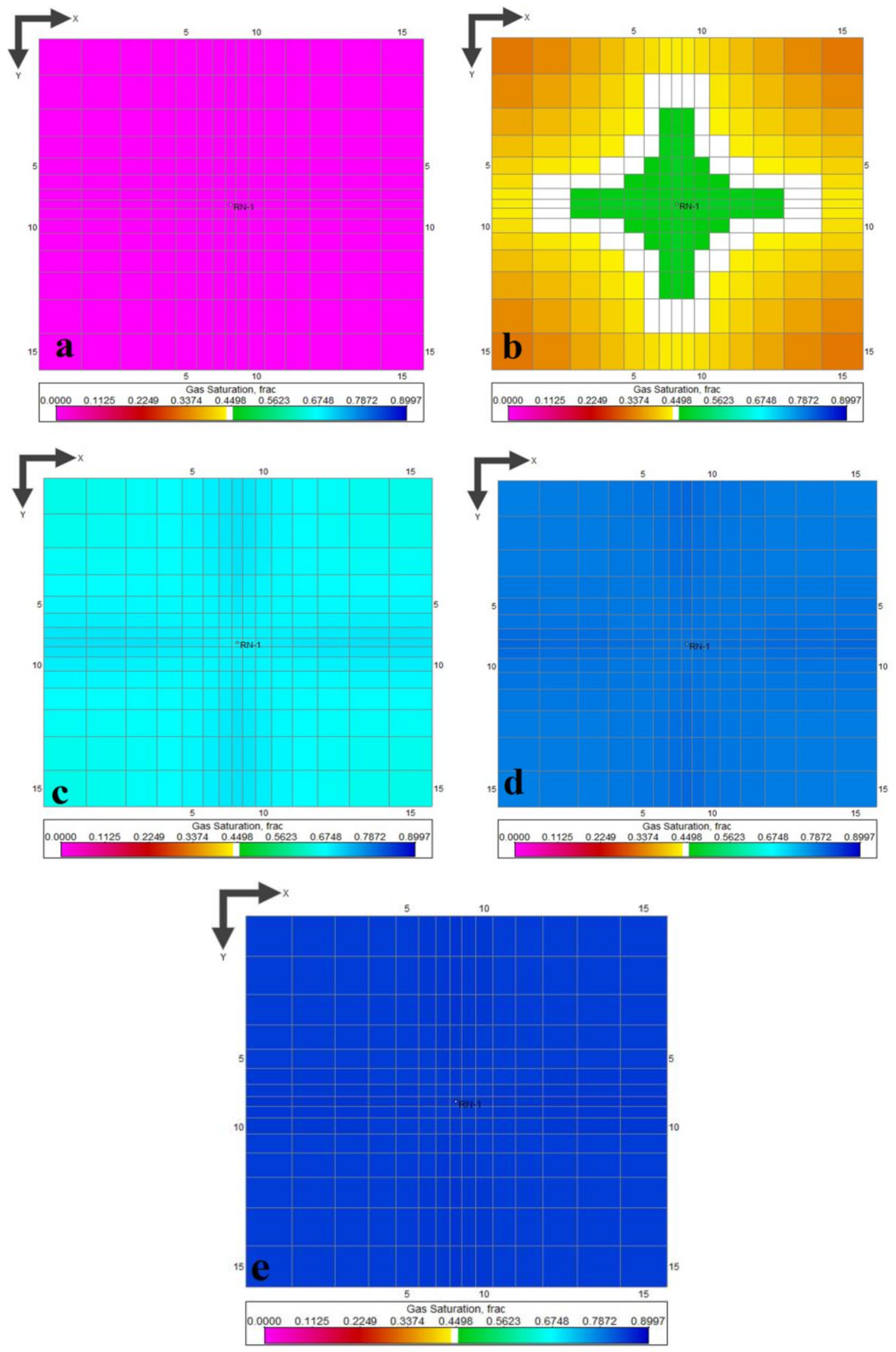

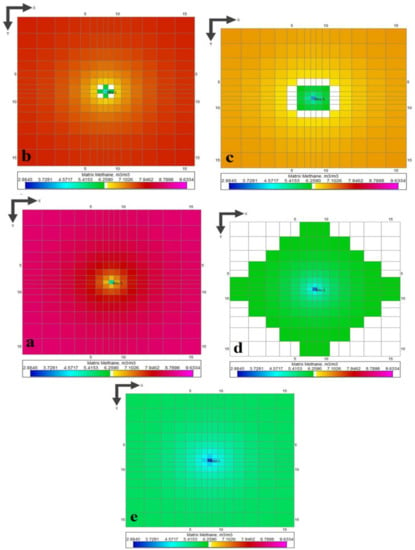

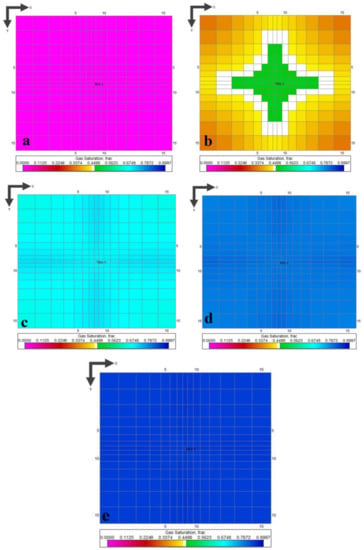

Methane is produced through a vertical well situated close to the centre of the field. Figure 3a–e show the variations of methane concentration along the coal seams with time, ranging from 1000 days to 9000 days. It is apparent that the concentration of methane is high in the coal seams before production and reduced continuously after the production started. The gas production rate incessantly increased with time and obtained its peak value of 2713.2 m3/d in 1948 days and subsequently started to decrease. The coal quickly desorbed approximately 1.2 Mm3 of methane in 730 days while it desorbed methane at a rate of 2308 m3/d in 4000 days and with the rate of approx. 1504 m3/d in 8000 days. With the continuous gas production process, the rate of desorption declines, and it was found to be at the rate of 1345.2 m3/d in 9125 days from the beginning of the process.

Figure 3.

(a–e). Matrix methane concentration in the area over a period of 1000 days, 3000 days, 5000 days, 7000 days and 9000 days, respectively.

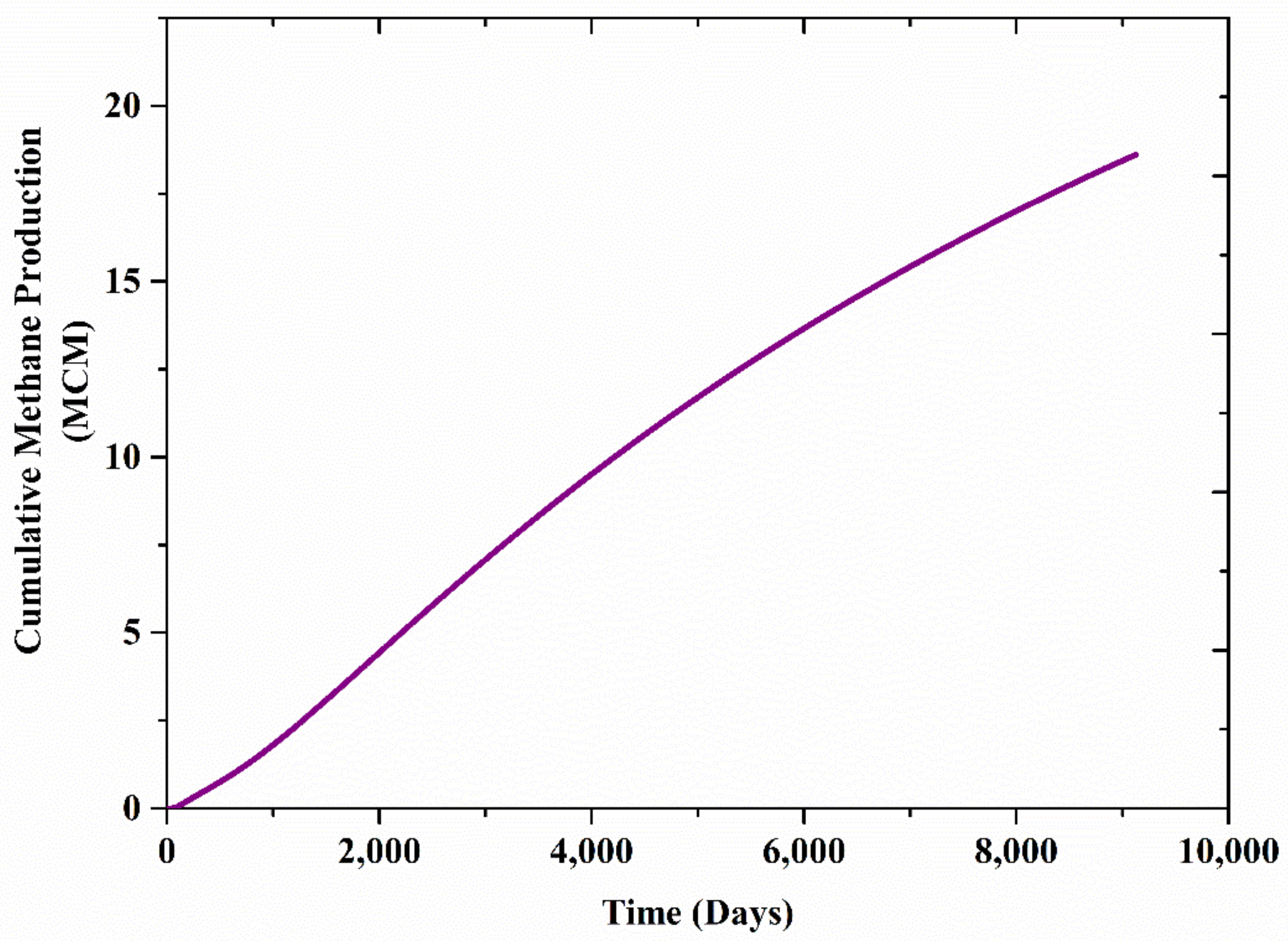

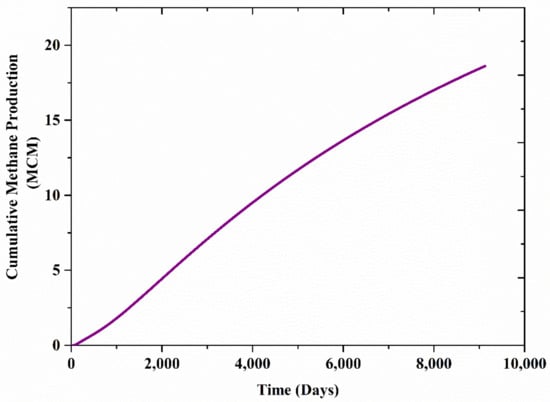

The information came from cumulative methane production; it has been observed that during the initial stage, the methane production rate is low for specific periods of time and achieves a constant rate until 70 days (Figure 4). The wells produce 9.51 Mm3 in 4000 days and 17.01 Mm3 in 8000 days. The well produces 13,783.70 m3 in 70 days, and after that, as the production goes on, the cumulative methane produced is up to 2.95 Mm3 and 6.56 Mm3 in 1450 days and 2800 days, respectively. The well will produce around 18.6 Mm3 in a time duration of 9125 days.

Figure 4.

Cumulative methane production vs. time.

3.2. Fracture Gas Saturation

Permeability is known to be the primary factor affecting methane and water recovery rates from coal wells. Because the permeability of coals is controlled by fractures in the coal, it can vary significantly as a function of pressure and gas concentration and can be highly variable on a well to well basis. The permeability of coal can vary by several orders of magnitude with a pressure change of 3500 kPa. Also, coal permeability is believed to increase as the gas is desorbed from matrix structure associated with desorption of gas.

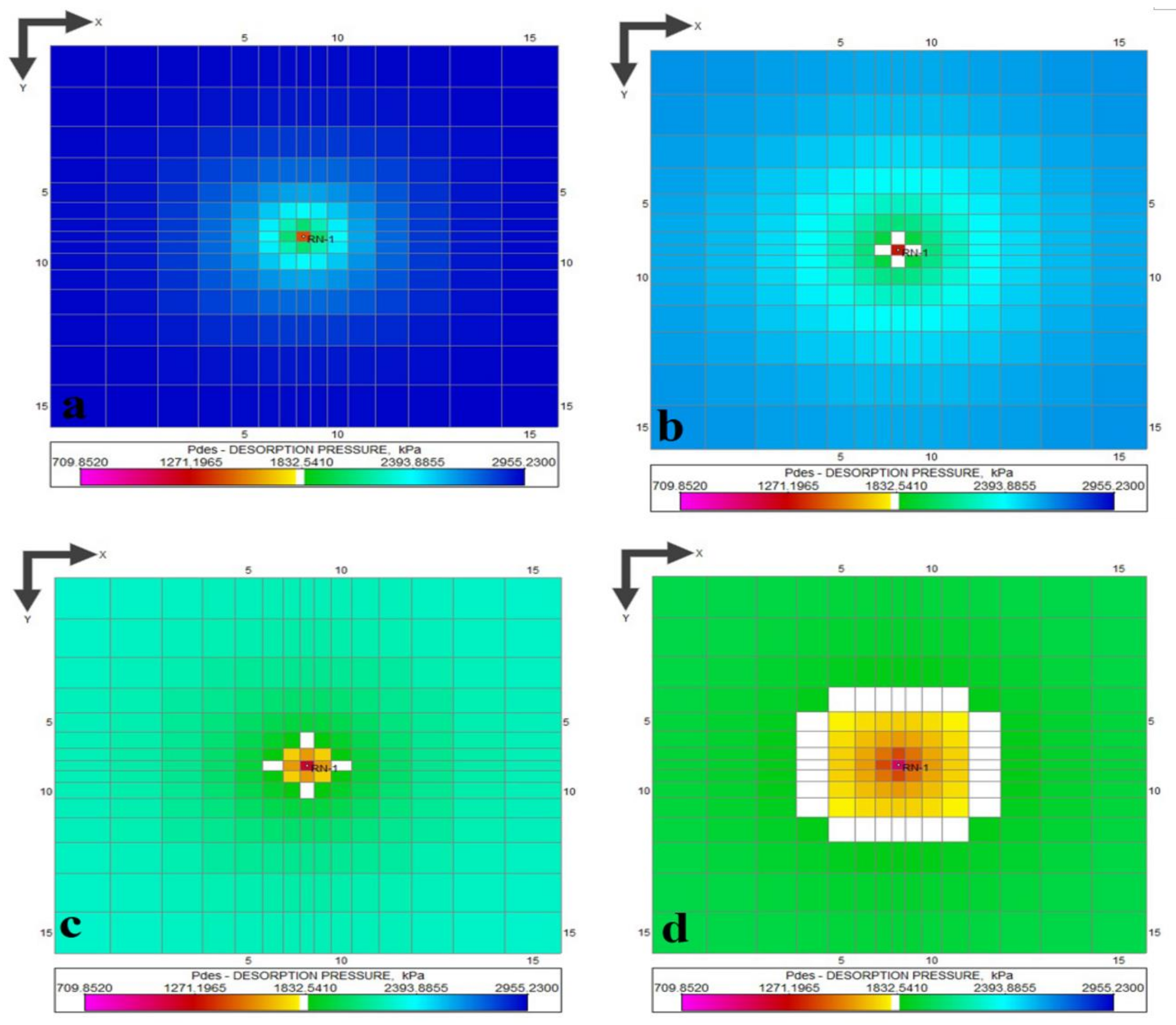

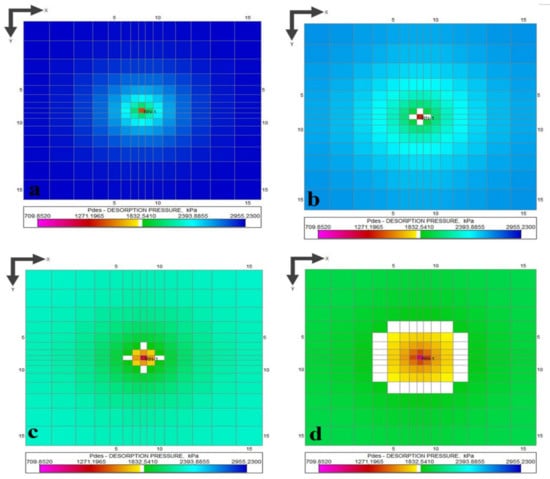

The change in fracture gas saturation with time and space for the field is clearly seen in Figure 5a–e. At the beginning of production, dewatering reduces the reservoir pressure so that the gas can be easily diffused from micro-pores to the fracture system. Dewatering improves the saturation level of fracture gas, which enhances gas production. The water production helps to raise the % saturation of coal with time (as shown in Figure 5b). At the beginning of production, higher fracture saturation is experienced around the production well. An attempt has been made by taking advantage of grid graphs to approximate the volume of methane produced with space and time. The grid plots noticeably depict the distribution of gas. It helps to visualize the gas concentration changes during the gas recovery process from the coal matrix for a period of 9125 days.

Figure 5.

(a–e). Fracture gas saturation in the area over a period of 0 days, 1000 days, 2000 days, 3000 days and 4000 days, respectively.

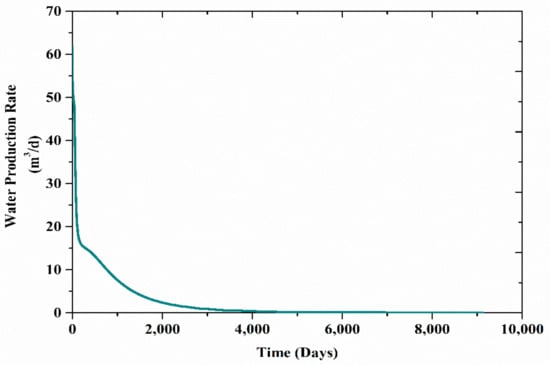

3.3. Water Production

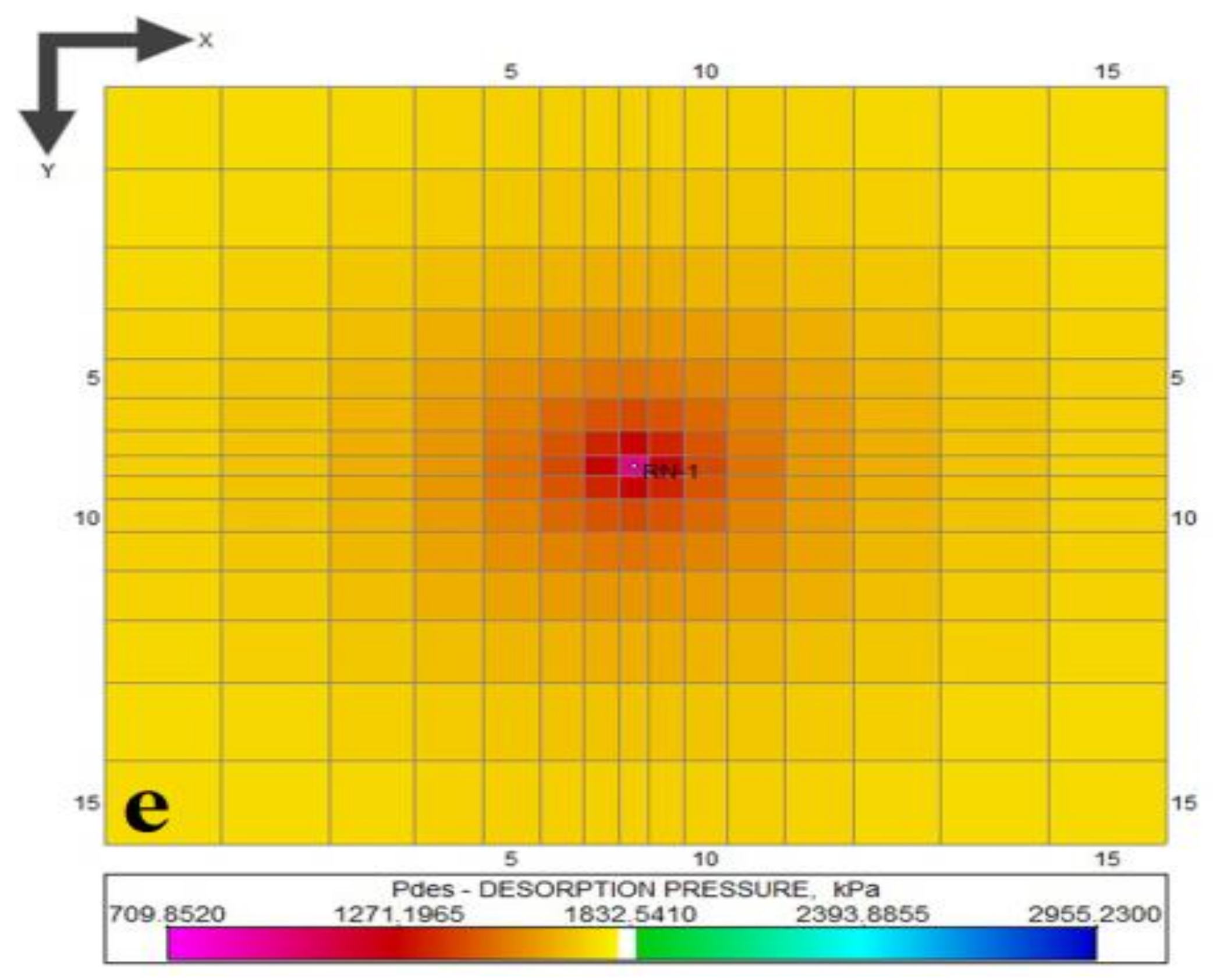

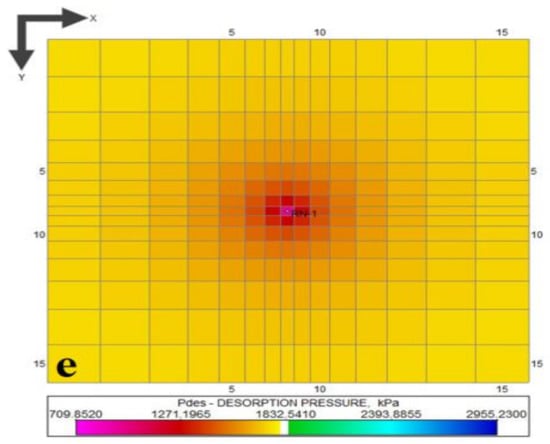

Water production is one of the initial steps for CBM extraction from a reservoir. In general, CBM reservoirs are considered as water-saturated, and water develops the hydrostatic pressure to hold gas in coal seams. The depressurizing is done by dewatering so that the reservoir pressure comes below the saturation pressure of methane, and gas production starts from the CBM well. So, the water production rate becomes a significant factor that affects the recovery of methane from CBM reservoirs. Figure 6a–e show variations of desorption pressure with water production and time, ranging from 1 day to 6939 days. It is evident that the water production rate is initially high, and slowly it is reduced. The water production rate incessantly declined with time and attained its peak value of 50.7 m3/d at the beginning of the first month. The reservoir quickly dewatered approximately 3729.5 m3 of water in 90 days while it released a total of 22,117.3 m3 in 6939 days.

Figure 6.

(a–e). Effect of water production on desorption pressure the area over a period of 1000 days, 3000 days, 5000 days, 7000 days and 9000 days, respectively.

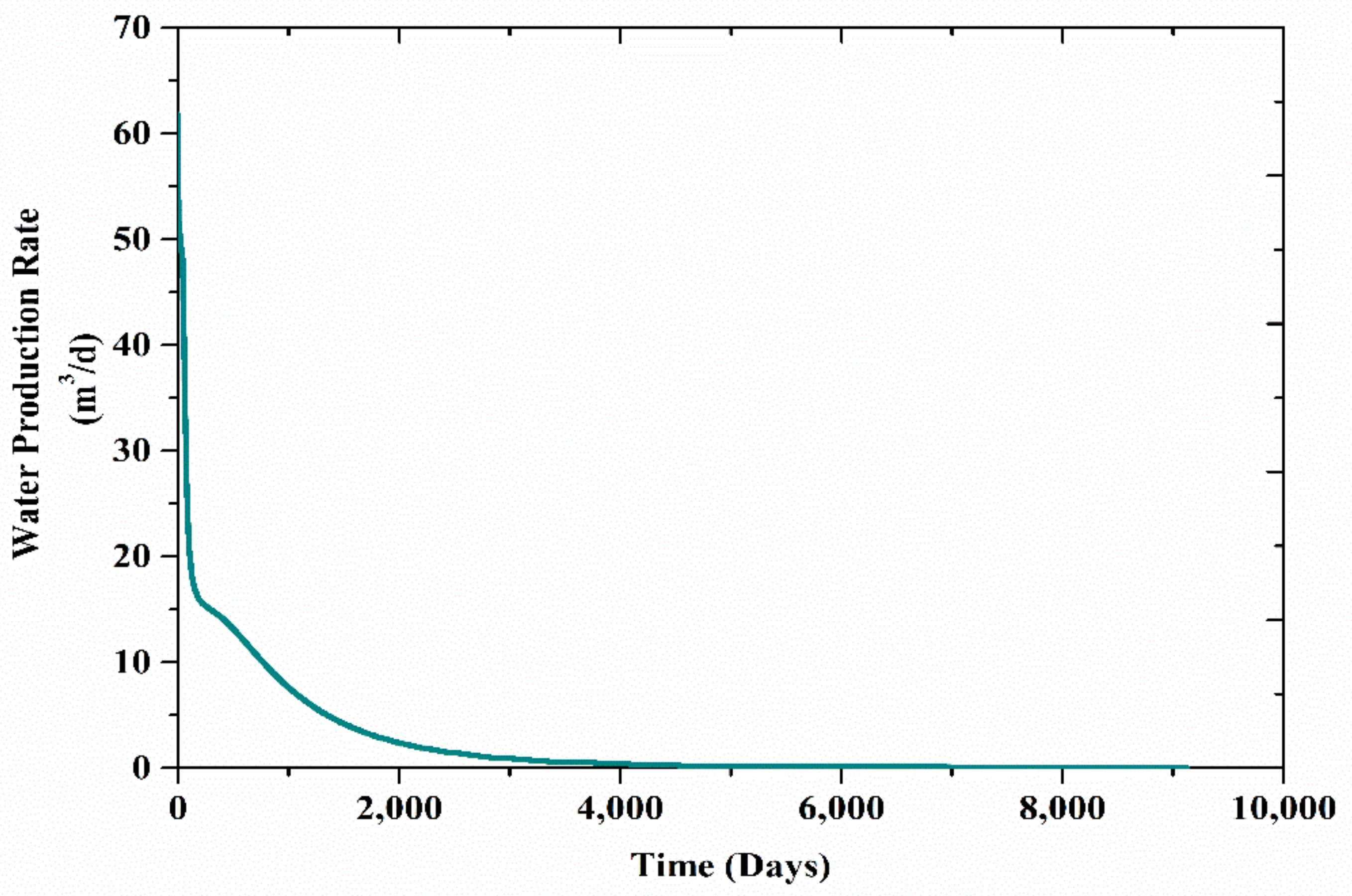

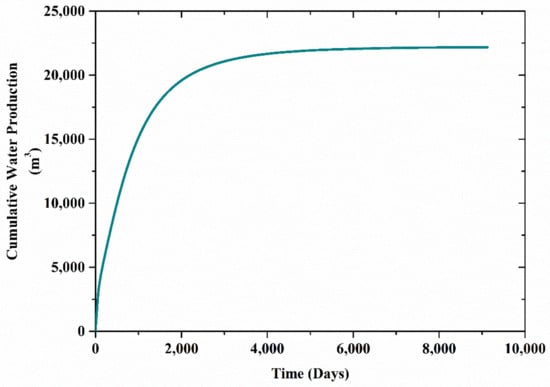

The plots of cumulative water and water production rate from the vertical well designated show that the rate of water production is slightly high for starting days. It is observed in the field that water production increases at an incline speed constantly monitored up to 60 days, and after that, it started declining for the remaining duration from 9125 days (Figure 7 and Figure 8).

Figure 7.

Cumulative water production vs. time.

Figure 8.

Water production rate vs. time.

3.4. Scope for Future

Currently, there are many comprehensive policies available which support the resource estimation and analysis at various active sites in India. The salient features of new CBM policy are as follows: (i) coordination between multiple agencies, (ii) simultaneous mining of coal and CBM, (iii) use of CBM from existing coal mines, and (iv) pricing of CBM. The above policy might be helpful to attract new companies for extraction of valuables from potential sites.

The present study illustrates that simulation study on an area provides precise information which could be used as foundations for actual resource estimation and analysis. Reservoir production data will be very helpful to provide detailed information about various source rock properties (coal), methane production capacity, methane production rate and the feasibility of production followed by economic data. Modifying models based on production data from coal bed methane reservoirs helps to estimate carbon storage sites. Economic analysis with details can be involved in judging the commercial value of ECBM wells.

4. Conclusions

The Sitarampur block of the Raniganj coalfield is bountiful in gas content with good permeability. The present study illustrates that a tremendous amount of gas recovery can be possible from these coal seams with less water production. The extraction of methane also improves the safety of coal mines. The recovery of methane from such a highly gassy seam helps protect our atmosphere from global warming and provides an alternative energy source. This study also approximates the technical feasibility of vertical wells for degasification of coal seams present in the block.

The underground coal mines are the main source of methane emissions in India due to their mining activity. The extraction of methane before mining operations ameliorates coal mine workers’ safety along with coal’s economic production. The coal seams present in the Sitarampur block are highly gassy in nature. The recovery of methane from such highly gassy seams helps protect our atmosphere from global warming. Methane is a valuable fuel with good calorific value which is easily recovered from underground coal mines. The simulation study shows that lower coal seams are more suitable for coal bed methane recovery. The present study illustrates that a tremendous amount of gas recovery can be possible from these coal seams with less water production. This study also estimates the technical feasibility of a vertical well for the degasification of the coal seam.

- (a)

- This study illustrates that the chosen coal seams of the Sitarampur block can produce an expected 18.60 MCM of methane and 22,117.30 m3 of water over a period of 9125 days.

- (b)

- These coals desorbed methane slowly and attain a peak value of the gas production rate of 2713.2 m3/d in 1948 days, which shows that the gas desorption rate is low in both coal seams.

- (c)

- The fracture gas concentration increases with time, and it is observed that fractures are fully saturated with gas in 3000 days. The gas concentration is high near the production well due to a quick diffusion rate of gas and water production.

- (d)

- This study concludes that approximately 70% of gas recovery can be achieved by this method over a period of 9125 days.

- (e)

- A simulation study demonstrates that the extraction of methane can prevent 372 MCM equivalent CO2 emissions.

- (f)

- The desorption study of coal samples shows that the gas content of coal samples increases with depth.

List of Abbreviation

| CBM | Coal Bed Methane |

| VCBM | Virgin Coal Bed Methane |

| VAM | Ventilation Air Methane |

| CMM | Coal Mine Methane |

| ECBM | Enhanced Coal Bed Methane |

Author Contributions

Conceptualization, D.S.P., V.K.S. and A.K.S.; Data curation, V.K.S.; Formal analysis, D.S.P., R.C.C., V.K.S. and A.K.S.; Investigation, R.C.C., V.K.S. and A.K.S.; Methodology, V.K.S. and A.K.S.; Project administration, V.K.S. and A.K.S.; Resources, D.S.P., V.K.S. and A.K.S.; Software, A.K.S.; Supervision, V.K.S. and A.K.S.; Validation, V.K.S.; Visualization, V.K.S. and A.K.S.; Writing – original draft, D.S.P. and R.C.C.; Writing – review & editing, R.C.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not Applicable.

Informed Consent Statement

Not Applicable.

Data Availability Statement

Not Applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Park, S.Y.; Liang, Y. Biogenic methane production from coal: A review on recent research and development on microbially enhanced coalbed methane (MECBM). Fuel 2016, 166, 258–267. [Google Scholar] [CrossRef]

- Robbins, S.J.; Evans, P.N.; Esterle, J.S.; Golding, S.D.; Tyson, G.W. The effect of coal rank on biogenic methane potential and microbial composition. Int. J. Coal Geol. 2016, 154, 205–212. [Google Scholar] [CrossRef]

- Guo, H.; Cheng, Y.; Huang, Z.; Urynowicz, M.A.; Liang, W.; Han, Z.; Liu, J. Factors affecting co-degradation of coal and straw to enhance biogenic coalbed methane. Fuel 2019, 244, 240–246. [Google Scholar] [CrossRef]

- Ritter, D.; Vinson, D.; Barnhart, E.; Akob, D.M.; Fields, M.W.; Cunningham, A.B.; Orem, W.; McIntosh, J.C. Enhanced microbial coalbed methane generation: A review of research, commercial activity, and remaining challenges. Int. J. Coal Geol. 2015, 146, 28–41. [Google Scholar] [CrossRef]

- Karacan, C.Ö.; Ruiz, F.A.; Cotè, M.; Phipps, S. Coal mine methane: A review of capture and utilization practices with benefits to mining safety and to greenhouse gas reduction. Int. J. Coal Geol. 2011, 86, 121–156. [Google Scholar] [CrossRef]

- Zhou, F.; Xia, T.; Wang, X.; Zhang, Y.; Sun, Y.; Liu, J. Recent developments in coal mine methane extraction and utilization in China: A review. J. Nat. Gas Sci. Eng. 2016, 31, 437–458. [Google Scholar] [CrossRef]

- Limbri, H.; Gunawan, C.; Rosche, B.; Scott, J. Challenges to developing methane biofiltration for coal mine ventilation air: A review. Water Air Soil Pollut. 2013, 224, 1566. [Google Scholar] [CrossRef]

- Ali, M.; Paul, S.; Chatterjee, R. Cleat orientation from ground mapping and image log studies for in situ stress analysis: Coal bed methane exploration in South Karanpura Coalfield, India. Energy Fuels 2017, 31, 6812–6824. [Google Scholar] [CrossRef]

- Chatterjee, R.; Paul, S. Classification of coal seams for coal bed methane exploitation in central part of Jharia coalfield, India–A statistical approach. Fuel 2013, 111, 20–29. [Google Scholar] [CrossRef]

- Garg, A.; Kankal, B.; Shukla, P. Methane emissions in India: Sub-regional and sectoral trends. Atmos. Environ. 2011, 45, 4922–4929. [Google Scholar] [CrossRef]

- Paul, S.; Chatterjee, R. Determination of in-situ stress direction from cleat orientation mapping for coal bed methane exploration in south-eastern part of Jharia coalfield, India. Int. J. Coal Geol. 2011, 87, 87–96. [Google Scholar] [CrossRef]

- Gao, L.; Mastalerz, M.; Schimmelmann, A. The origin of coalbed methane. In Coal Bed Methane; Elsevier: Amsterdam, The Netherlands, 2020; pp. 3–34. [Google Scholar]

- Mastalerz, M.; Drobniak, A. Coalbed Methane: Reserves, Production, and Future Outlook. In Future Energy; Elsevier: Amsterdam, The Netherlands, 2020; pp. 97–109. [Google Scholar]

- Moore, T.A. Coalbed methane: A review. Int. J. Coal Geol. 2012, 101, 36–81. [Google Scholar] [CrossRef]

- Akanksha Singh, A.; Mohanty, D.; Jena, H.; Panwar, D.S. Prospective evaluation of hydrocarbon generation potential of Umarsar lignite, India. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 664–675. [Google Scholar] [CrossRef]

- Panwar, D.; Saxena, V.; Rani, A.; Singh, A.; Kumar, V. Source rock evaluation of the Gondwana coals in Raniganj coalfield, India. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 1395–1402. [Google Scholar] [CrossRef]

- Panwar, D.; Saxena, V.; Singh, A.; Prashant, Y.; Yadav, A. Seam quality and gas resource estimation in kulti block of Raniganj coal field West Bengal India. Int. J. Eng. Res. Sci. Technol. 2016, 5, 1–9. [Google Scholar]

- Panwar, D.; Saxena, V.; Suman, S.; Kumar, V.; Singh, A. Physicochemical study of coal for CBM extraction in Raniganj coal field, India. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 1182–1189. [Google Scholar] [CrossRef]

- Panwar, D.S.; Saxena, V.K.; Chaurasia, R.C.; Singh, A.K. Prospective evaluation of coal bed methane in Raniganj coal field, India. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 946–954. [Google Scholar] [CrossRef]

- Panwar, D.S.; Saxena, V.K.; Yadav, A.M.; Singh, A.K. Natural Gas Recovery: A Case Study of Field Scale Development in Raniganj Coal Field West Bengal, India. Int. J. Eng. Res. Sci. Technol. 2016, 5, 51–57. [Google Scholar]

- Panwar, D.S.; Suman, S.; Singh, A.; Saxena, V.; Chaurasia, R.C. Assessment of hydrocarbon generation potential of bituminous coal from Raniganj Basin, India. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 824–834. [Google Scholar] [CrossRef]

- Panwar, D.; Chaurasia, R.C.; Saxena, V.; Singh, A.K. Geochemical investigation of hydrocarbon generation potential of coal from Raniganj Basin, India. J. Pet. Explor. Prod. Technol. 2021, 11, 3627–3636. [Google Scholar] [CrossRef]

- Panwar, D.S.; Chaurasia, R.C.; Akansha Jena, S.S. Hydrocarbon generation and gasification study of Valia lignite, Gujrat, India. Energy Sources Part A Recovery Util. Environ. Eff. 2021. [Google Scholar] [CrossRef]

- Aydın, G.; Karakurt, I.; Aydıner, K. Investigating the effects of methane drainage on the operating performances of mines. In Proceedings of the 3rd Balkan Mining Congress, Izmir, Turkey, 1–3 October 2009; pp. 575–583. [Google Scholar]

- Mallett, C.; Su, S. Progress in developing ventilation air methane mitigation and utilisation technologies. In Proceedings of the 3rd International Methane & Nitrous Oxide Mitigation Conference, Beijing, China, 17–21 November 2003. [Google Scholar]

- Lei, J.; Niu, R.; Wang, S.; Li, J. The Pd/Na-ZSM-5 catalysts with different Si/Al ratios on low concentration methane oxidation. Solid State Sci. 2020, 101, 106097. [Google Scholar] [CrossRef]

- Nadaraju, F.; Maddocks, A.; Zanganeh, J.; Moghtaderi, B. Ventilation air methane: A simulation of an optimised process of abatement with power and cooling. Min. Technol. 2020, 129, 9–21. [Google Scholar] [CrossRef]

- Su, S.; Agnew, J.J.F. Catalytic combustion of coal mine ventilation air methane. Fuel 2006, 85, 1201–1210. [Google Scholar] [CrossRef]

- Yang, X.; Li, Z.; Zhang, C.; Wang, H.; Zhang, E.; Xing, Y.; Xiao, P.; Yang, R.T.; Liu, Y.; Webley, P.A. Practical separation performance evaluation of coal mine methane upgrading with carbon molecular sieves. Chem. Eng. J. 2019, 367, 295–303. [Google Scholar] [CrossRef]

- Carothers, P.; Deo, M. Technical and Economic Assessment: Mitigation of Methane Emissions from Coal Mine Ventilation Air; Environmental Protection Agency, Climate Protection Division: Washington, DC, USA, 2000. [Google Scholar]

- Karakurt, I.; Aydin, G.; Aydiner, K. The effect of geologic features on methane emissions at underground coal mines. In Proceedings of the 2nd National Workers Health Occupational Safety in Mining, Adana, Turkey, 1–3 October 2009; pp. 151–158. [Google Scholar]

- Bibler, C.J.; Marshall, J.S.; Pilcher, R.C. Status of worldwide coal mine methane emissions and use. Int. J. Coal Geol. 1998, 35, 283–310. [Google Scholar] [CrossRef]

- Cheng, Y.-P.; Wang, L.; Zhang, X.-L. Environmental impact of coal mine methane emissions and responding strategies in China. Int. J. Greenh. Gas Control. 2011, 5, 157–166. [Google Scholar] [CrossRef]

- Gao, J.; Guan, C.; Zhang, B. China’s CH4 emissions from coal mining: A review of current bottom-up inventories. Sci. Total Environ. 2020, 725, 138295. [Google Scholar] [CrossRef]

- Karacan, C.Ö.; Warwick, P.D. Assessment of coal mine methane (CMM) and abandoned mine methane (AMM) resource potential of longwall mine panels: Example from Northern Appalachian Basin, USA. Int. J. Coal Geol. 2019, 208, 37–53. [Google Scholar] [CrossRef]

- Kholod, N.; Evans, M.; Pilcher, R.C.; Roshchanka, V.; Ruiz, F.; Coté, M.; Collings, R. Global methane emissions from coal mining to continue growing even with declining coal production. J. Clean. Prod. 2020, 256, 120489. [Google Scholar] [CrossRef]

- Sinha, S.K.; Panigrahi, D. Leveraging Coal Mine Methane/Ventilation Air Methane for Improving Ventilation Standards in Indian Underground Coal Mines and to Reduce Its Carbon Footprints. In Proceedings of the 11th International Mine Ventilation Congress; Springer: Berlin/Heidelberg, Germany, 2019; pp. 355–363. [Google Scholar]

- Su, S.; Beath, A.; Guo, H.; Mallett, C. An assessment of mine methane mitigation and utilisation technologies. Prog. Energy Combust. Sci. 2005, 31, 123–170. [Google Scholar] [CrossRef]

- Su, S.; Chen, H.; Teakle, P.; Xue, S. Characteristics of coal mine ventilation air flows. J. Environ. Manag. 2008, 86, 44–62. [Google Scholar] [CrossRef]

- Hamawand, I.; Yusaf, T.; Hamawand, S.G. Coal seam gas and associated water: A review paper. Renew. Sustain. Energy Rev. 2013, 22, 550–560. [Google Scholar] [CrossRef]

- Feng, R.; Chen, S.; Bryant, S. Investigation of Anisotropic Deformation and Stress-Dependent Directional Permeability of Coalbed Methane Reservoirs. Rock Mech. Rock Eng. 2020, 53, 625–639. [Google Scholar] [CrossRef]

- Jing, Z.; Balucan, R.D.; Underschultz, J.R.; Pan, S.; Steel, K.M. Chemical stimulation for enhancing coal seam permeability: Laboratory study into permeability variation and coal structure examination. Int. J. Coal Geol. 2020, 219, 103375. [Google Scholar] [CrossRef]

- Laubach, S.E.; Marrett, R.A.; Olson, J.E.; Scott, A.R. Characteristics and origins of coal cleat: A review. Int. J. Coal Geol. 1998, 35, 175–207. [Google Scholar] [CrossRef]

- Tian, L.; Cao, Y.; Liu, S.; Shi, B.; Liu, J.; Elsworth, D. Coalbed methane reservoir fracture evaluation through the novel passive microseismic survey and its implications on permeable and gas production. J. Nat. Gas Sci. Eng. 2020, 76, 103181. [Google Scholar] [CrossRef]

- Laubach, S.E.; Olson, J.E.; Gross, M.R. Mechanical and fracture stratigraphy. AAPG Bull. 2009, 93, 1413–1426. [Google Scholar] [CrossRef]

- Laxminarayana, C.; Crosdale, P.J. Role of coal type and rank on methane sorption characteristics of Bowen Basin, Australia coals. Int. J. Coal Geol. 1999, 40, 309–325. [Google Scholar] [CrossRef]

- Levine, J.R. Coalification: The Evolution of Coal as Source Rock and Reservoir Rock for Oil and Gas: Chapter 3; AAPG: Tulsa, OK, USA, 1993. [Google Scholar]

- Rani, S.; Padmanabhan, E.; Prusty, B.K. Review of gas adsorption in shales for enhanced methane recovery and CO2 storage. J. Pet. Sci. Eng. 2019, 175, 634–643. [Google Scholar] [CrossRef]

- Chattaraj, S.; Mohanty, D.; Kumar, T.; Halder, G.; Mishra, K. Comparative study on sorption characteristics of coal seams from Barakar and Raniganj formations of Damodar Valley Basin, India. Int. J. Coal Geol. 2019, 212, 103202. [Google Scholar] [CrossRef]

- Fang, H.; Sang, S.; Liu, S. A Methodology for Characterizing the Multiscale Pores and Fractures in Anthracite and Semi-Anthracite Coals and Its Application in Analysis of the Storage and Permeable Capacity of Coalbed Methane. SPE Reserv. Eval. Eng. 2020, 23, 177–186. [Google Scholar] [CrossRef]

- Scott, A.R. Hydrogeologic factors affecting gas content distribution in coal beds. Int. J. Coal Geol. 2002, 50, 363–387. [Google Scholar] [CrossRef]

- Feng, Q.; Tian, M.; Huang, Z.; Zeng, M.; Wang, T.; Zhang, W.; Wang, X.; Wang, J. Study on Reservoir Properties’ Varying Laws and Production Features of CBM Wells. In Proceedings of the International Field Exploration and Development Conference 2018; Je, L., Ed.; Springer: Singapore, 2020; pp. 304–315. [Google Scholar]

- Liu, T.; Liu, S.; Lin, B.; Fu, X.; Zhu, C.; Yang, W.; Zhao, Y. Stress response during in-situ gas depletion and its impact on permeability and stability of CBM reservoir. Fuel 2020, 266, 117083. [Google Scholar] [CrossRef]

- Peng, Z.; Li, X.; Sun, Z. A relative permeability model for CBM reservoir. Oil Gas Sci. Technol.—Rev. D’ifp Energ. Nouv. 2020, 75, 2. [Google Scholar] [CrossRef]

- Talapatra, A.; Karim, M. The influence of moisture content on coal deformation and coal permeability during coalbed methane (CBM) production in wet reservoirs. J. Pet. Explor. Prod. Technol. 2020, 10, 1907–1920. [Google Scholar] [CrossRef]

- Zhang, F.; Liu, X.; Ma, G.; Feng, D. Experimental and theoretical study on influencing factor of fracture width in coalbed methane reservoir. Arab. J. Geosci. 2019, 12, 558. [Google Scholar] [CrossRef]

- Zhang, K.; Du, F.; Nojabaei, B. Effect of Pore Size Heterogeneity on Hydrocarbon Fluid Distribution and Transport in Nanometer-Sized Porous Media. In Proceedings of the SPE Eastern Regional Meeting, Charleston, WV, USA, 21–23 October 2019. [Google Scholar]

- Darcy, H.P.G. Les Fontaines Publiques de la Ville de Dijon. Exposition et Application des Principes à Suivre et des Formules à Employer dans les Questions de Distribution D’eau, etc; Dalamont: Dijon, France, 1856. [Google Scholar]

- Warren, J.E.; Root, P.J. The Behavior of Naturally Fractured Reservoirs. SPE J. 1963, 3, 245–255. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).