Towards a Mechanistic Understanding of the Slagging Propensities of Petroleum Coke: Lessons Learned from Its Co-Combustion with Natural Gas in Oxygen-Enriched Atmospheres

Abstract

1. Introduction

- Given the well-resolved particle size distribution (PSD) of the parent PC fuel, can a constant density, shrinking sphere model (assuming no swelling) be employed to describe the evolution of the PSD of the fly ash particles? This may be justified given that PC generally lacks porosity and internal surface area [7]. Well-resolved fly ash PSD and velocity fields are critical to model particle impaction on a deposit surface [14].

- What is the appropriate criterion to use to model the capture of the impacting PC fly ash particles? While various capture criteria for the fly ash originating from both coal and biomass combustion have been reviewed extensively [15,16], their validity to model PC fly ash capture has not been ascertained. In fact, in a recent study by Fakourian et al. [17], two popular ash capture models (Kinetic energy stickiness model (KESM) based on critical velocity and a melt fraction stickiness model (MFSM)) both failed to predict the deposition rate of PC fly ash when employed in conjunction with a plug flow assumption for the flow field. In lieu of these shortcomings, we explore whether a well-resolved flow field near the deposit surface in conjunction with a particle kinetic energy (PKE)–particle viscosity (µP)-based capture criterion can be employed to accurately model the capture process.

- 3.

- Which are the appropriate models to use to estimate the density (ρ) and µP of PC fly ash when employing the PKE–µP-based capture criterion? How sensitive are the deposition rate predictions to the variations in these properties?

2. Results and Discussion

2.1. Estimation of the Fly Ash PSD

2.2. Ash Deposition Rates (without Agglomeration)

2.3. Ash Deposition Rates (with Agglomeration in the OXY70 Scenario)

2.4. Sensitivity Analyses

3. Materials and Methods

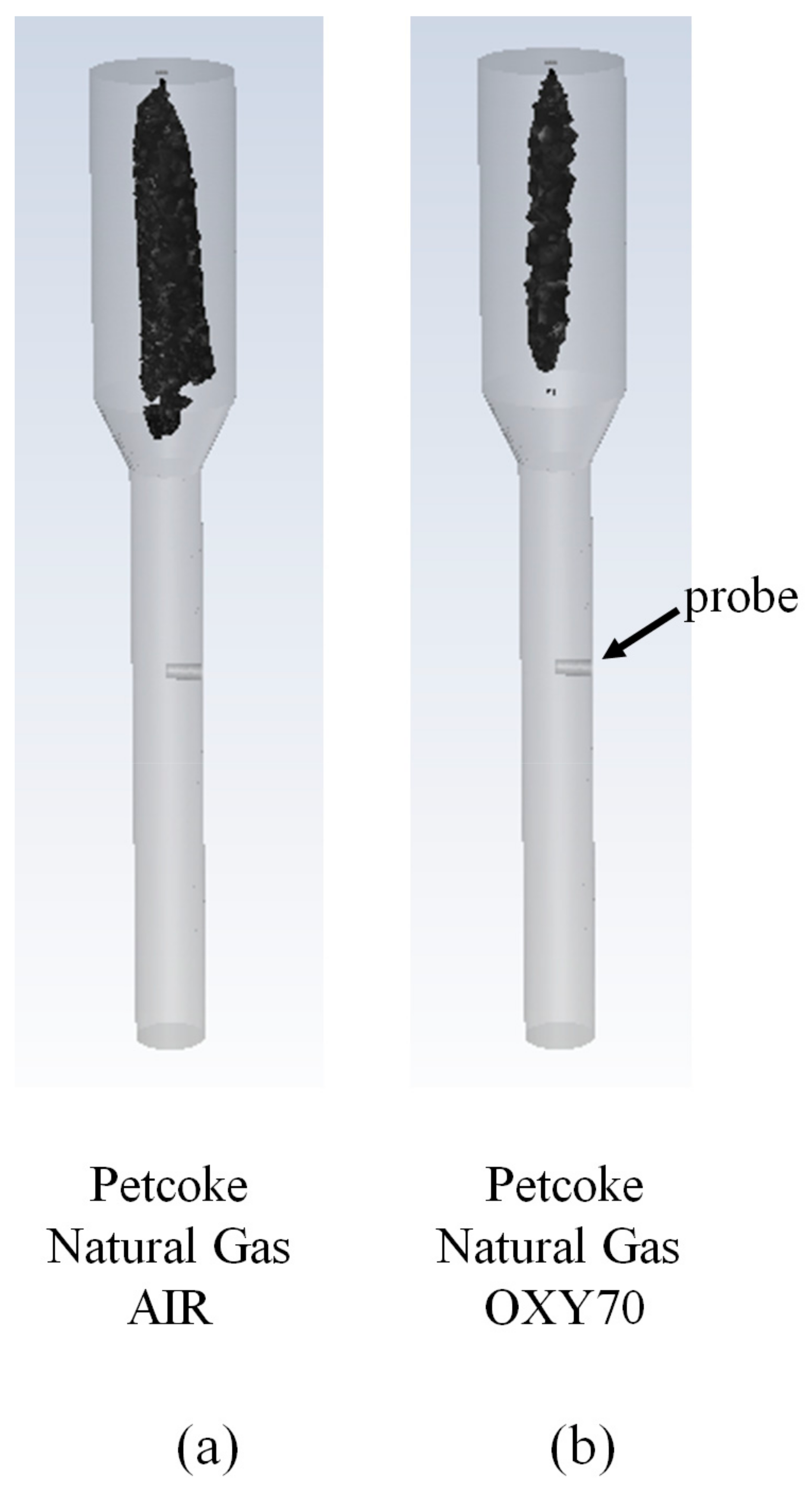

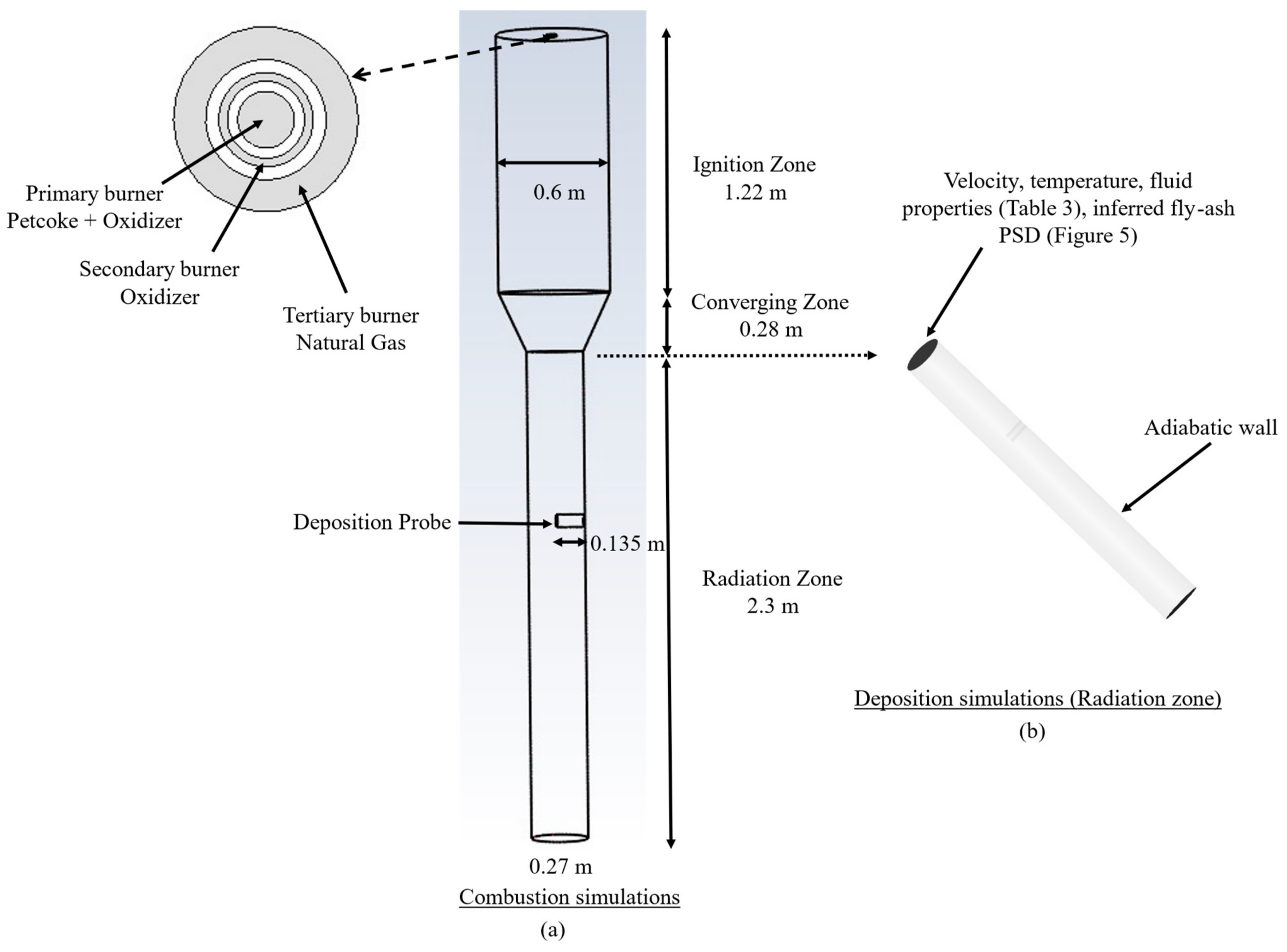

3.1. Simulation of PC Combustion

3.2. Particle Capture Criterion

3.2.1. PKE-Critical-Viscosity-Based Ash Capture Criterion

Senior and Srinivasachar Particle Viscosity Model [22]

Urbain et al. [23] Particle Viscosity Model

3.2.2. Weber-Number-Based Ash Capture Criterion

4. Conclusions

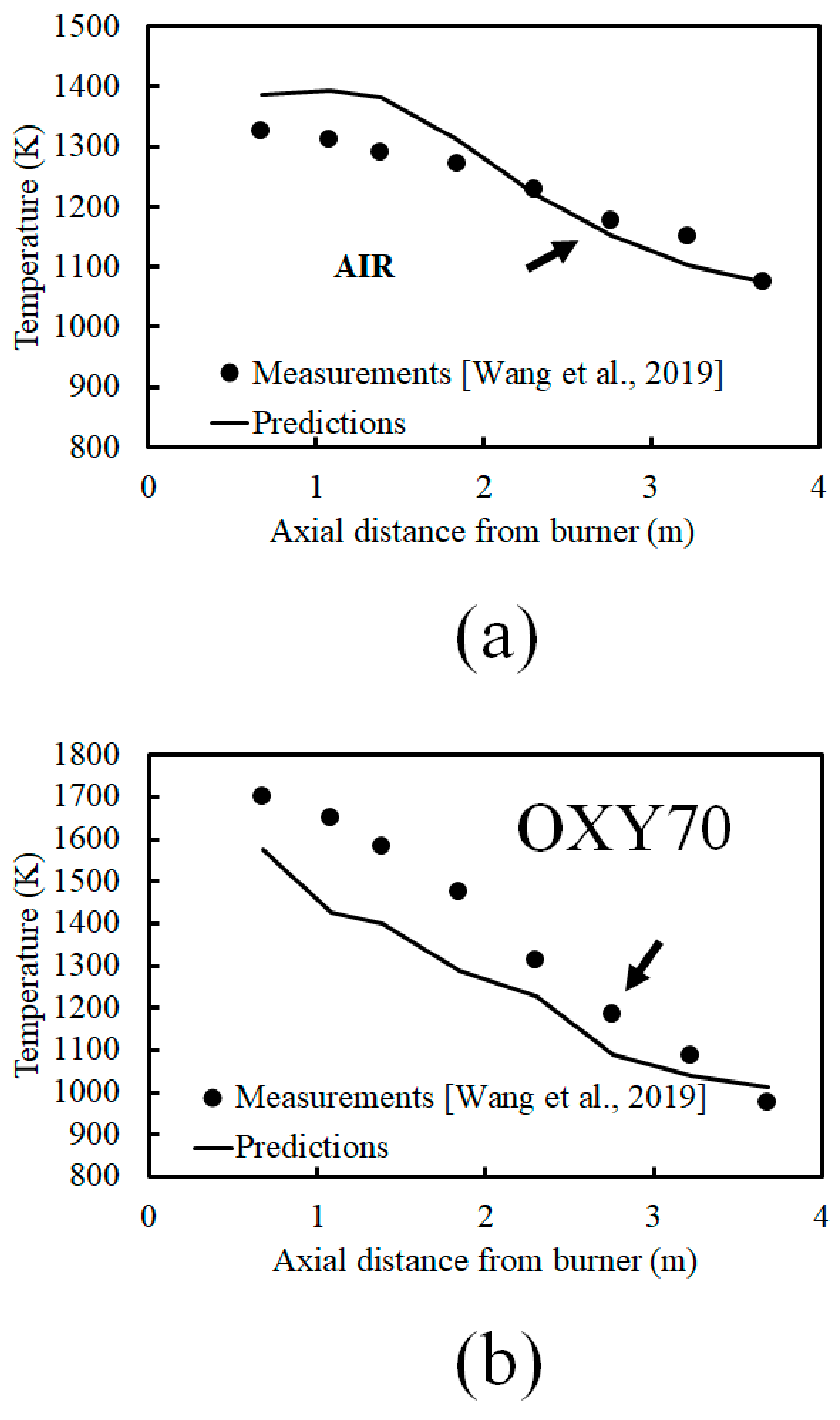

- The predicted gas temperatures near the deposit probe were in reasonable agreement with the measurements for both combustion conditions. In addition, the velocity field surrounding the probe was adequately resolved using a fine boundary layer mesh as per the criterion recommended for predicting particle impaction accurately [14]. Simulations showed complete carbon burnout before reaching the probe, concurring with carbon-free deposits obtained from the experiments. Therefore, the adequacy of the combustion models employed in the simulations was established.

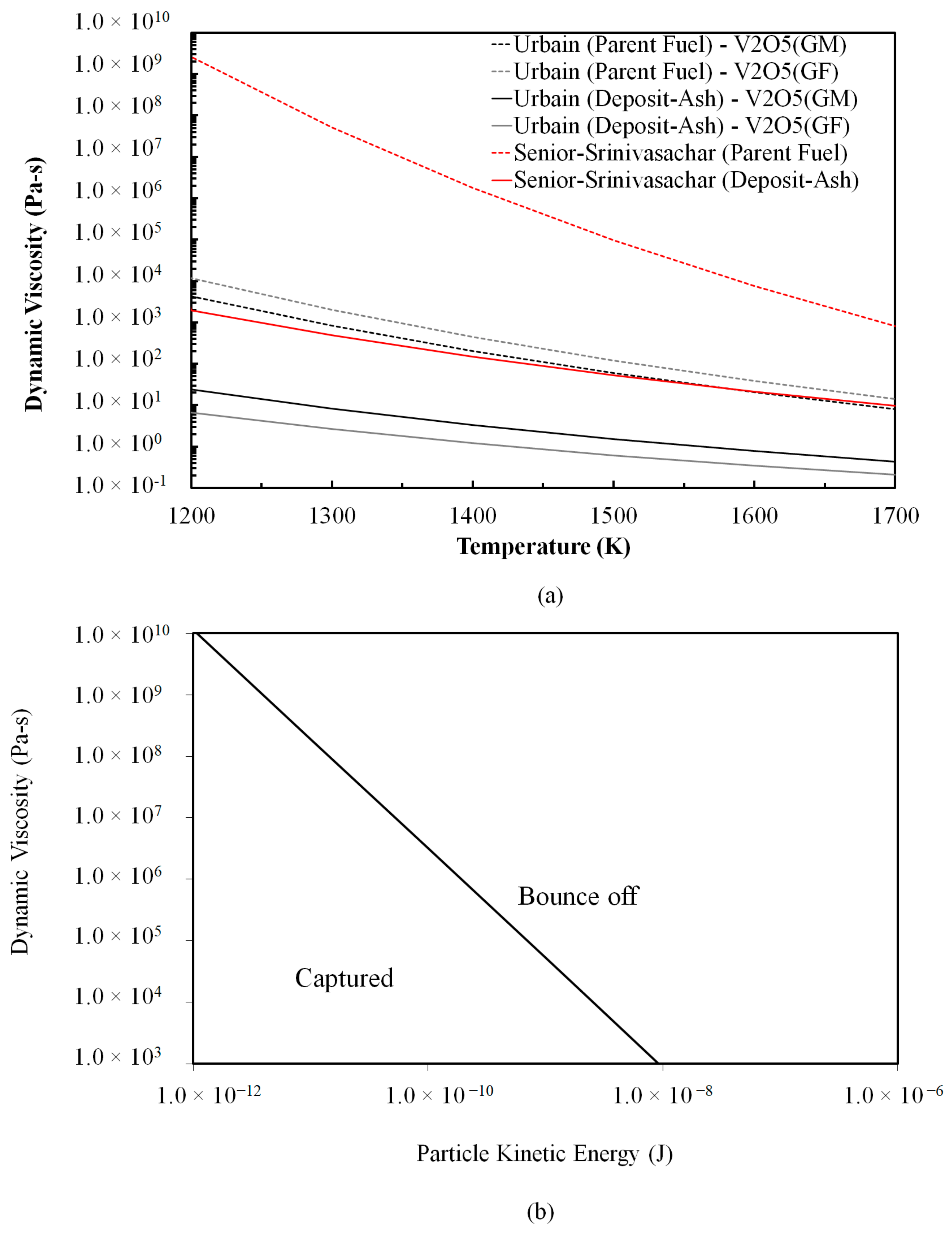

- In order to assess the robustness of our predictions and conclusions regarding the use of the PKE– capture criterion, deposition rate prediction sensitivities to the particle viscosity () model were assessed using two commonly used model formulations: the Senior and Srinivasachar [22] and the Urbain et al. [23] models. In addition, both parent fuel ash composition and the deposit ash compositions were employed to estimate in view of the fact that the ash deposits in the experiments were found to be significantly enriched in Fe (which may promote stickiness). The deposition rate predictions were close to the measurements and were insensitive to the model formulation employed as long as the deposit ash composition was employed in the µP calculations (to account for the Fe enrichment). based on the Senior and Srinivasachar [22] model which has previously been found to be accurate in modeling the deposition rates from coal and biomass fly ash in this temperature range (1200 K–1400 K) [19,20,24] underestimated the deposition rates. This likely points to the fact that the fly ash composition for determining is a more important factor for deposition rate prediction than the exact model formulation for .

- Since PC ash is also characterized by high concentrations of , which may either play the role of a glass former (GF) or a glass modifier (GM), particle viscosities () were also individually estimated using as a GF or GM when employed to estimate the parameters in the Urbain et al. [23] model. In regard to the temperature range of interest in this study, the predictions differed by less than an order of magnitude depending on whether was employed as a GF or GM and did not impact the deposition rate predictions.

- Employing a critical Weber number () of unity as a capture criterion also resulted in deposition rate predictions close to the measurements for the PC–AIR combustion scenario. However, a critical Weber number () of 10.0 with a modified fly ash PSD was necessary to match the measurements for the PC–OXY70 scenario. Therefore, we caution against using such a simplistic ad hoc criterion to match deposition rates in one scenario and extend it to other scenarios since they cannot be universally and generally applied in this manner. For instance, ~80% of the impacting fly ash particles in the PC AIR scenario had a particle Weber number in the range of 0.1 < We < 1.0 which meant that a five-fold variation in deposition rate prediction is associated with the narrow range of 0.1 < < 1.0.

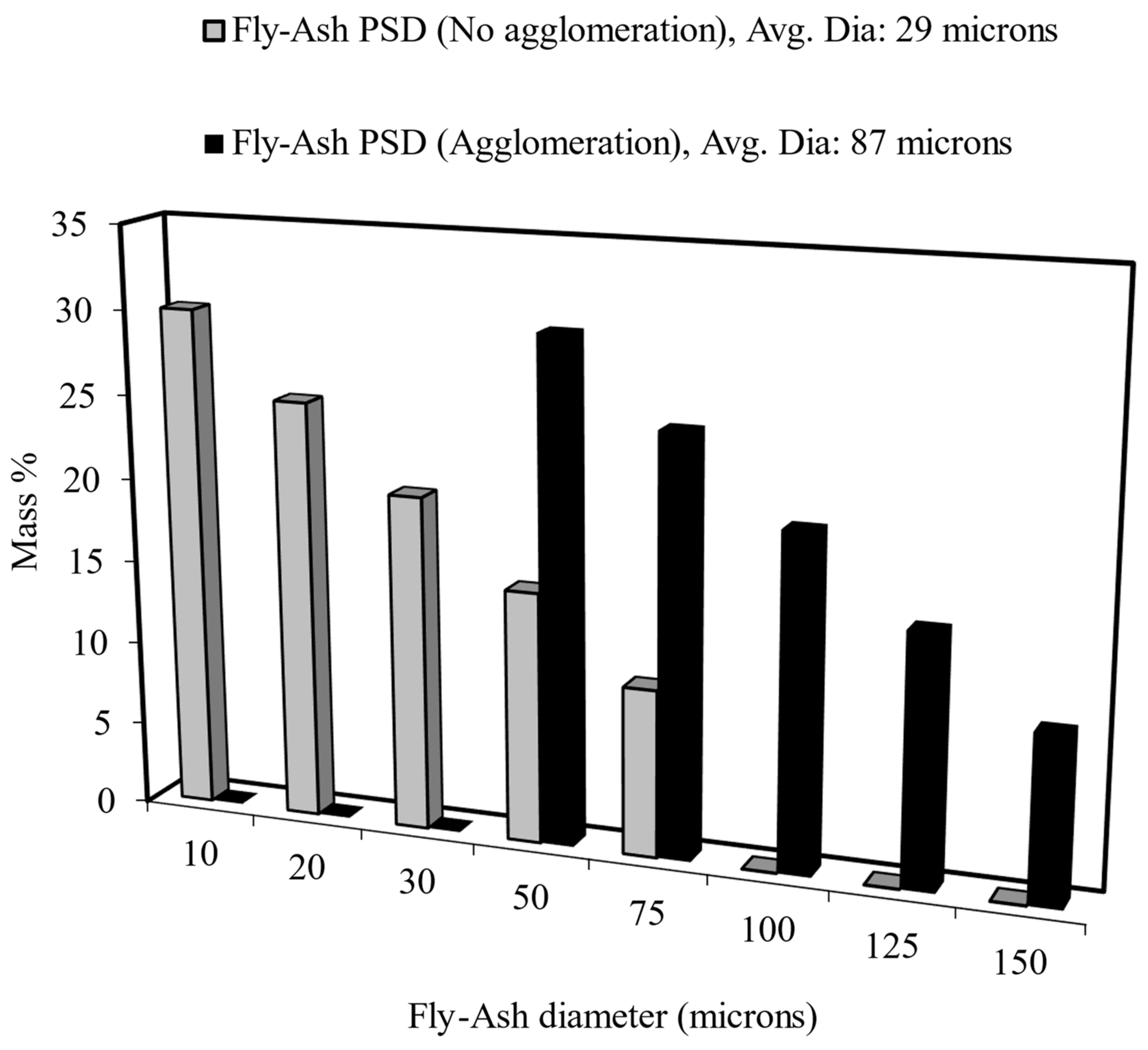

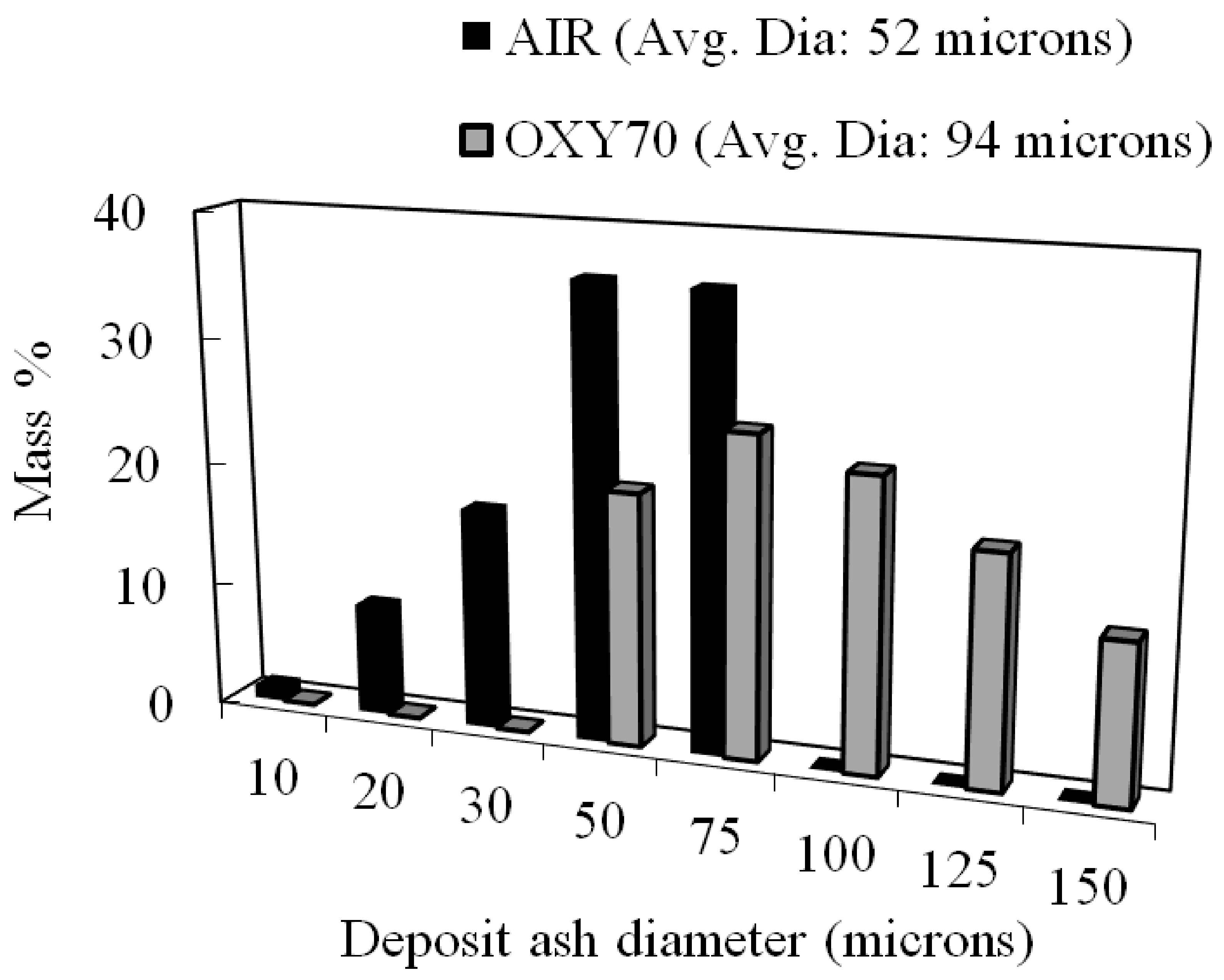

- The impaction rates in the PC-OXY70 scenario were significantly lower than the measured deposition rates. This necessitated an ad hoc modification of the fly ash PSD to a coarser range that may be attributed to agglomeration resulting from a longer residence time and higher temperatures. The mass-weighted diameter increase in the fly ash PSD in the OXY70 scenario (which was deemed necessary to match the measured deposit rates) was found to be in line with the measured PSD shifts between AIR and OXY70 fly ash observed in previous studies within this combustor [21].

- Our deposition rate predictions were relatively insensitive to and temperature variations in the PC-AIR and PC-OXY70 scenarios, respectively, thereby establishing the robustness of our inferred PSD as well as the PKE– capture criterion.

- The capture rates were close to 100% across the investigated scenarios resulting from the sticky Fe-rich fly ash. Such high capture rates (>50%) are in line with previous studies [19,20,32,33,39]. The study therefore highlights the importance of resolving the impaction rates accurately through well-resolved fly ash PSD and velocity fields. For the range of velocities encountered in this study (0.4 m/s–1.0 m/s), the fly ash PSD in the size range of 10 µm to 150 µm needs to be resolved accurately. Naturally, the fly ash PSD size range of importance may shift to finer size fractions at higher gas velocities [24,39].

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| d | Diameter, m |

| PKE | Particle kinetic energy, J |

| Re | Reynolds number |

| Stk | Stokes Number |

| T | Temperature, K |

| u | Velocity, m/s |

| We | Weber number |

| x | Molar fraction |

| Greek Symbols | |

| Δ | Boundary layer cell height, m |

| γ | Surface tension, N/m |

| η | Efficiency |

| ρ | Density, kg/m3 |

| µ | Viscosity, kg/m-s |

| Subscripts | |

| cr | Denotes critical |

| g | Denotes gas |

| P | Denotes particle |

References

- Bryers, R.W. Utilization of petroleum coke and petroleum coke/coal blends as a means of steam raising. Fuel Process. Technol. 1995, 44, 121–141. [Google Scholar] [CrossRef]

- Pisa, G.D.; Bondi, G. SNOX™ Flue Gas Treatment Technology for Boilers Burning Petcoke, Giandomenico Bondi-Raffineria di Gela, Rio De Janeiro, 28–30 May 2008.

- Pak, D.F.; Kucherov, V.V.; Shabanov, I.I.; Epikhin, A.N.; Treskov, I.V.; Kudryavtsev, S.A. Innovative Technologies in the Repowering of the Nizhnekamsk CHPP by Upgrading the TGME-464 Boiler to Combust Pulverized Petroleum Coke. Power Technol. Eng. 2019, 52, 714–719. [Google Scholar] [CrossRef]

- Hirayama, Y.A.; Hishida, M.A.; Yamamoto, Y.O.; Makiura, S.; Arakawa, Y.; Okamoto, A. Operation results of power station with petroleum coke firing boiler. Mitsubishi Heavy Ind. Tech. Rev. 2007, 44, 1–7. [Google Scholar]

- Wang, J.; Anthony, E.J.; Abanades, J.C. Clean and efficient use of petroleum coke for combustion and power generation. Fuel 2004, 83, 1341–1348. [Google Scholar] [CrossRef]

- Pearce, R.; Grusha, J. Reliant Energy Tangential Low NOx System at Limestone Unit 2 Cuts Texas Lignite, PRB, and Pet Coke NOx. 2001. Available online: https://www.lexissecuritiesmosaic.com/gateway/FedReg/files_tp_firsys_01_02.pdf (accessed on 12 January 2024).

- Conn, R.E.; Shan, J.; Vatsky, J. Low NOx Combustion Systems for Minimizing NOx and Fly Ash LOI: Wall-Firing Petcoke and T-Firing Severe Slagging Coal; Advanced Burner Technologies Corporation: Kennesaw, GA, USA, 2003. [Google Scholar]

- Hower, J.C.; Thomas, G.A.; Mardon, S.M.; Trimble, A.S. Impact of co-combustion of petroleum coke and coal on fly ash quality: Case study of a western Kentucky power plant. Appl. Geochem. 2005, 20, 1309–1319. [Google Scholar] [CrossRef]

- Cain-Borgman, C. Petroleum coke refueling of underutilized oil-fired assets produces low cost power. In Proceedings of the Power-Gen Conference, Las Vegas, NV, USA, 6 December 2005. [Google Scholar]

- Fan, Y.; Si, P. The Study of Numerical Simulation of Oxygen enriched Burner System. CFD Lett. 2010, 2, 197–207. [Google Scholar]

- Yuzbasi, N.S.; Selcuk, N. Pyrolysis and combustion behavior of ternary fuel blends in air and oxy-fuel conditions by using TGA-FTIR. Combust. Sci. Technol. 2012, 184, 1152–1163. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, J.; Li, X.; Yu, D.; Xu, M.; Wendt, J.O.L. Ash aerosol partitioning and ash deposition during the combustion of petroleum coke/natural gas mixtures. Fuel 2019, 256, 115982. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Wendt, J.O.L. On ash deposition rates from air and oxy-combustion of pulverized coal, petroleum coke, and biomass. Energy Fuels 2019, 33, 5849–5858. [Google Scholar] [CrossRef]

- Weber, R.; Schaffel-Mancini, N.; Mancini, M.; Kupka, T. Fly ash deposition modelling: Requirements for accurate predictions of particle impaction on tubes using RANS-based computational fluid dynamics. Fuel 2013, 108, 586–596. [Google Scholar] [CrossRef]

- Kleinhans, U.; Wieland, C.; Frandsen, F.J.; Spliethoff, H. Ash formation and deposition in coal and biomass fired combustion systems: Progress and challenges in the field of ash particle sticking and rebound behavior. Prog. Energy Combust. Sci. 2018, 68, 65–168. [Google Scholar] [CrossRef]

- Cai, Y.; Tay, K.; Zheng, Z.; Yang, W.; Wang, H.; Zeng, G.; Li, Z.; Boon, S.K.; Subbaiah, P. Modeling of ash formation and deposition processes in coal and biomass fired boilers: A comprehensive review. Appl. Energy 2018, 230, 1447–1544. [Google Scholar] [CrossRef]

- Fakourian, S.; McAllister, Z.; Fry, A.; Wang, Y.; Li, X.; Wendt, J.O.; Dai, J. Modeling ash deposit growth rates for a wide range of solid fuels in a 100 kW combustor. Fuel Process. Technol. 2021, 217, 106777. [Google Scholar] [CrossRef]

- Bool, L.E., III; Peterson, T.W.; Wendt, J.O. The partitioning of iron during the combustion of pulverized coal. Combust. Flame. 1995, 100, 262–270. [Google Scholar] [CrossRef][Green Version]

- Krishnamoorthy, G. Aerodynamic influences on the outer ash deposition rates during oxy-coal combustion. Clean. Chem. Eng. 2022, 3, 100057. [Google Scholar] [CrossRef]

- Krishnamoorthy, G. Modeling Ash Deposition and Shedding during Oxy-Combustion of Coal/Rice Husk Blends at 70% Inlet O2. Int. J. Coal Sci. Technol. 2023, 10, 27. [Google Scholar] [CrossRef]

- Wu, J.; Wang, Y.; Han, J.; Li, X.; Yu, D.; Xu, M.; Wendt, J.O. Ash Formation and Deposition in Oxy-fuel Combustion of Rice Husk, Coal, and Their Blend with 70% Inlet O2. Energy Fuels 2019, 34, 890–899. [Google Scholar] [CrossRef]

- Senior, C.L.; Srinivasachar, S. Viscosity of ash particles in combustion systems for prediction of particle sticking. Energy Fuels 1995, 9, 277–283. [Google Scholar] [CrossRef]

- Urbain, G.; Bottinga, Y.; Richet, P. Viscosity of liquid silica, silicates and alumino-silicates. Geochim. Cosmochim. Acta 1982, 46, 1061–1072. [Google Scholar] [CrossRef]

- Krishnamoorthy, G.; Bloom, E.; Viswanathan, K.; Patwardhan, S.S.; Stadem, D.J.; Benson, S. Measurements and Prediction of Ash Deposition in a Cyclone-Fired Boiler Operating under Variable Load Conditions. Fluids 2023, 8, 305. [Google Scholar] [CrossRef]

- Vargas, S.; Frandsen, F.J.; Dam-Johansen, K. Rheological properties of high-temperature melts of coal ashes and other silicates. Prog. Energy Combust. Sci. 2001, 27, 237–429. [Google Scholar] [CrossRef]

- Doweidar, H.; Megahed, A.; Gohar, I.A. Mixed ionic-electronic conduction in sodium borate glasses with low V2O5 content. J. Phys. D Appl. Phys. 1986, 19, 1939. [Google Scholar] [CrossRef]

- D’Souza, S.A.; Banik, S.; Vuthaluru, H.B.; Pisupati, S.V. Comparison of Natural and Synthetic Petroleum Coke Slag Viscosities under Reducing Conditions: Applicability of Predictive Models Using Factsage and Modified Urbain Model. Fuels 2021, 2, 37–47. [Google Scholar] [CrossRef]

- Alekhnovich, A.N.; Bogomolov, V.V.; Artem’eva, N.V. Petroleum coke characteristics and use in power industry. Power Technol. Eng. 2019, 53, 339–343. [Google Scholar] [CrossRef]

- Chen, J.; Lu, X. Progress of petroleum coke combusting in circulating fluidized bed boilers—A review and future perspectives. Resour. Conserv. Recycl. 2007, 49, 203–216. [Google Scholar] [CrossRef]

- Góral, D.; Wylenżek, A. The efficient coal alternative. Petroleum coke-fired CFB boilers in Europe. In Proceedings of the Coal Gen Europe, Warsaw, Poland, 14–16 February 2012. [Google Scholar]

- Yong, S.Z. Multiphase Models of Slag Layer Built-Up in Solid Fuel Gasification and Combustion. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2010. [Google Scholar]

- Krishnamoorthy, G.; Nguyen, N.D.T. Modeling outer ash deposition rates in second generation atmospheric pressure oxy-fuel combustion systems. Combust. Sci. Technol. 2023, 195, 3440–3455. [Google Scholar] [CrossRef]

- Beckmann, A.M.; Mancini, M.; Weber, R.; Seebold, S.; Müller, M. Measurements and CFD modeling of a pulverized coal flame with emphasis on ash deposition. Fuel 2016, 167, 168–179. [Google Scholar] [CrossRef]

- ANSYS, Inc. ANSYS Fluent Theory Guide; Release 21.1, Online Manual Resource; ANSYS, Inc.: Canonsburg, PA, USA, 2021. [Google Scholar]

- Krishnamoorthy, G.; Wolf, C. Assessing the Role of Particles in Radiative Heat Transfer during Oxy-Combustion of Coal and Biomass Blends. J. Combust. 2015, 2015, 793683. [Google Scholar] [CrossRef]

- Krishnamoorthy, G. A new weighted-sum-of-gray-gases model for oxy-combustion scenarios. Int. J. Energy Res. 2013, 14, 1752–1763. [Google Scholar] [CrossRef]

- Krishnamoorthy, G.; Kuznia, M.E.; Smith, K.M.; Seames, W.S.; Wang, Y.; Wendt, J.O. Aerodynamic effects on outer ash deposition rates in second generation atmospheric pressure oxy-coal combustion systems. Fuel 2021, 303, 121217. [Google Scholar] [CrossRef]

- Mills Kenneth, K.; Rhine, J.M. The measurement and estimation of the physical properties of slags formed during coal gasification: 1. Properties relevant to fluid flow. Fuel 1989, 68, 193–200. [Google Scholar] [CrossRef]

- Yang, X.; Szuhánszki, J.; Tian, Y.; Ingham, D.; Ma, L.; Pourkashanian, M. Understanding the effects of oxyfuel combustion and furnace scale on biomass ash deposition. Fuel 2019, 247, 36–46. [Google Scholar] [CrossRef]

| References | Summary |

|---|---|

| R. Pearce and J. Grusha [6] | PC co-firing with lignite and Powder River Basin coal (PRB) were evaluated in an 820 MW lignite-fired unit. Effective mixing/blending of PC with other fuels in pulverizers can be challenging. NOx emissions increased with PC in fuel, but the emission might be reduced through selective staging of the combustion air. Lower ash content in PC improved furnace surface cleanliness but resulted in lower firing zone temperatures and steam temperatures. |

| R.E. Conn et al. [7] | Fly ash loss of ignition (LOI) and NOx emissions were assessed in two 660 MW opposed-fired units that fired PC, Colombian coal, and their blends. Fly ash LOI ranged from 18 to 25% when the fuels were co-fired in the same burner/mills. However, LOI reduced to 12 to 15% when PC and coal were fired in separate burners. PC was identified as a difficult fuel to ignite but not so hard to burnout when finely ground. |

| J.C. Hower et al. [8] | The fly ash resulting from the co-combustion of a high Sulfur Illinois Basin coal and PC in a 444-MW power station were collected from an electrostatic precipitator array. Unburned PC accounted for a large fraction of coarse particles (>25 µm). In contrast, V and Ni in the fly ash were mostly found in the finer fly ash size fractions (<25 µm) suggesting their mobility during the combustion process. |

| References | Summary |

|---|---|

| C. Cain-Borgman [9] | A proprietary oxygen-based combustion technology that enabled the retrofit and conversion of existing oil-fired utility boilers to allow the use of 100% petroleum coke as fuel was explored. This involved the selective use of oxygen to stably and efficiently burn PC with a reduced combustion residence time. The enabling technology also allowed the retention of most, if not all, of the original furnace steaming capacity. Additionally, the amount of produced in the furnace was reduced. |

| Fan and Si [10] | The ignition point, burnout temperature and burnout time significantly reduced in oxygen-enriched oxidizer atmospheres (33%) across PC particles of difference sizes. |

| N. Yuzbasi and N. Selcuk [11] | Co-firing of PC with medium volatile bituminous coal and indigenous lignite was carried out in fluidized bed combustion (FBC) in and mixtures with oxygen concentrations ranging from 21% to 30%. Higher oxygen concentrations resulted in higher weight loss rates, lower ignition temperature, lower burnout temperature, and lower peak temperature. |

| Y. Wang et al. [12,13] | A total of 11 different fuels including PC were combusted in AIR and OXY70 (70 vol % O2 in the oxidizer stream) in a 100 kW entrained combustor to measure their ash deposition rates using a wall-temperature-controlled probe. While the outer deposition rates of PC were in general lower than that of coal due to the lower ash content, the OXY70 conditions resulted in significantly enhanced deposition rates (~4.7 times) in contrast to combustion in AIR. |

| Units | AIR | OXY70 | |

|---|---|---|---|

| Solid fuel rate | kg/s | 3.778 × 10−4 | |

| Ash % | % | 2.99 | |

| Ash flow rate | kg/s | 1.13 × 10−5 | |

| Ash particle density | kg/m3 | 2500 | 2500 |

| Flue gas density | kg/m3 | 0.3 | 0.3 |

| Flue gas viscosity | Pa-s | 1.6 × 10−5 | 1.4 × 10−5 |

| Flue gas velocity | m/s | 1.0 | 0.4 |

| Flue gas temperature | K | 1250 | 1400 |

| Units: g/m2-h | Measured Deposition Rates [12] | Predicted Impaction Rates (Fly Ash PSD–No Agglomeration) |

|---|---|---|

| Petcoke AIR | 33 | 43 |

| Petcoke OXY70 | 156 | 48 |

| Units: g/m2-h | Measured Deposition Rates [12] | Predicted Deposition Rates [Fly Ash PSD–No Agglomeration] (Percentage Capture) | |||||

|---|---|---|---|---|---|---|---|

| Viscosity Model [Composition] | Urbain (V2O5–Glass Former) [Parent Fuel] | Urbain (V2O5–Glass Former) [Fly Ash] | Urbain (V2O5–Glass Modifier) [Parent Fuel] | Urbain (V2O5–Glass Modifier) [Fly Ash] | Senior and Srinivasachar [Parent Fuel] | Senior and Srinivasachar [Fly Ash] | |

| Petcoke AIR | 33 | 43 (100) | 43 (100) | 43 (100) | 43 (100) | 4 (9) | 43 (100) |

| Petcoke OXY70 | 156 | 48 (100) | 48 (100) | 48 (100) | 48 (100) | 9 (19) | 48 (100) |

| Units: g/m2-h | Measured Deposition Rates [12] | Predicted Deposition Rates [Fly Ash PSD–No Agglomeration] (Percentage Capture) | |

|---|---|---|---|

| Deposition Criterion | 0.1 | 1.0 | |

| Petcoke AIR | 33 | 9 (21) | 43 (100) |

| Petcoke OXY70 | 156 | 10 (20) | 48 (100) |

| Units: g/m2-h | Measured Deposition Rates [12] | Predicted Impaction Rates (Fly Ash PSD–Agglomeration) |

|---|---|---|

| Petcoke OXY70 | 156 | 158 |

| Units: g/m2-h | Measured Deposition Rates [12] | Predicted Deposition Rates [Fly Ash PSD–Agglomeration] (Percentage Capture) | |||||

|---|---|---|---|---|---|---|---|

| Viscosity Model [Composition] | Urbain (V2O5–Glass Former) [Parent Fuel] | Urbain (V2O5–Glass Former) [Fly Ash] | Urbain (V2O5–Glass Modifier) [Parent Fuel] | Urbain (V2O5–Glass Modifier) [Fly Ash] | Senior and Srinivasachar [Parent Fuel] | Senior and Srinivasachar [Fly Ash] | |

| Petcoke OXY70 | 156 | 158 (100) | 158 (100) | 158 (100) | 158 (100) | 0 (0) | 158 (100) |

| Units: g/m2-h | Measured Deposition Rates [12] | Predicted Deposition Rates (Fly Ash PSD–Agglomeration) (Percentage Capture) | ||

|---|---|---|---|---|

| Deposition Criterion | Wecr = 0.1 | Wecr = 1.0 | Wecr = 10.0 | |

| Petcoke OXY70 | 156 | 6 (4) | 82 (52) | 158 (100) |

| Petcoke–AIR (Fly Ash PSD–No Agglomeration) Measured Deposition Rate: 33 g/m2-h | ||||||

|---|---|---|---|---|---|---|

| Deposition Criterion | Wecr = 1.0 | Urbain (V2O5–Glass Modifier) [Fly Ash] | ||||

| Gas temperature (K) | 1200 | 1250 | 1300 | 1200 | 1250 | 1300 |

| Predicted deposition rate (g/m2-h) | 43 | 43 | 43 | 43 | 43 | 43 |

| Petcoke–OXY70 (Fly Ash PSD–Agglomeration) Measured Deposition Rate: 156 g/m2-h | ||||||

|---|---|---|---|---|---|---|

| Deposition Criterion | Wecr = 10.0 | Urbain (V2O5–Glass Modifier) [Fly Ash] | ||||

| Gas temperature (K) | 1300 | 1350 | 1400 | 1300 | 1400 | 1500 |

| Predicted deposition rate (g/m2-h) | 158 | 158 | 159 | 158 | 158 | 159 |

| Proximate Analysis (wt. %) | Ultimate Analysis (wt. %, Dry Ash Free) | |||

|---|---|---|---|---|

| Petroleum coke | Fixed Carbon | 86.26 | C | 82.51 |

| Volatiles | 10.18 | H | 6.02 | |

| Ash | 2.99 | N | 1.71 | |

| Moisture | 0.57 | S | 5.65 | |

| HHV (kJ/kg) | 34.4 | O | 0.49 | |

| Petcoke AIR | Petcoke OXY70 | |

|---|---|---|

| Petcoke mass flow rate (kg/h) | 1.36 | 1.36 |

| Natural gas mass flow rate (kg/h) (Tertiary burner) | 1.36 | 1.36 |

| Primary burner oxidizer mass flow rate (kg/h) | 10.8 | 10.8 |

| Primary burner species concentrations (mol %) | ||

| O2 | 21 | 21 |

| N2 | 79 | 0 |

| CO2 | 0 | 79 |

| Secondary burner oxidizer mass flow rate (kg/h) | 30.6 | 7.2 |

| Secondary burner species concentrations (mol %) | ||

| O2 | 21 | 100 |

| N2 | 79 | 0 |

| CO2 | 0 | 0 |

| Physics Being Modeled | Modeling Option |

|---|---|

| Particle devolatilization (heterogeneous) | Constant rate (50, 1/s) |

| Char oxidation (heterogeneous) | Shrinking sphere * (density fixed at 2500 kg/m3 and PSD varies depending on mass consumption) |

| Volatile combustion (homogeneous) (2-step reaction) Step 1: C0.35H18.7O0.09N0.3824 + 4.80 O2 → 0.35 CO + 9.35 H2O + 0.1912 N2 Step 2: CO + 0.5 O2 → CO2 | Finite rate/Eddy dissipation |

| Turbulence | Realizable k-epsilon |

| Particle Drag law | Morsi-Alexander |

| Model describing radiative transport | Discrete Ordinates |

| Particle radiative property | Particle-burnout-dependent absorption (Qabs) and scattering efficiencies (Qscat) [35] * |

| Particle scattering phase function | Anisotropic (forward scattering) |

| Gas-phase radiative property | non-gray weighted sum of gray gases [36] * |

| Ash capture/Deposition | Particle Kinetic Energy-critical-viscosity-based criterion [19] *, Weber-number-based capture criterion [37] * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, N.D.T.; Krishnamoorthy, G. Towards a Mechanistic Understanding of the Slagging Propensities of Petroleum Coke: Lessons Learned from Its Co-Combustion with Natural Gas in Oxygen-Enriched Atmospheres. Methane 2024, 3, 65-85. https://doi.org/10.3390/methane3010005

Nguyen NDT, Krishnamoorthy G. Towards a Mechanistic Understanding of the Slagging Propensities of Petroleum Coke: Lessons Learned from Its Co-Combustion with Natural Gas in Oxygen-Enriched Atmospheres. Methane. 2024; 3(1):65-85. https://doi.org/10.3390/methane3010005

Chicago/Turabian StyleNguyen, Nghia Duc Tin, and Gautham Krishnamoorthy. 2024. "Towards a Mechanistic Understanding of the Slagging Propensities of Petroleum Coke: Lessons Learned from Its Co-Combustion with Natural Gas in Oxygen-Enriched Atmospheres" Methane 3, no. 1: 65-85. https://doi.org/10.3390/methane3010005

APA StyleNguyen, N. D. T., & Krishnamoorthy, G. (2024). Towards a Mechanistic Understanding of the Slagging Propensities of Petroleum Coke: Lessons Learned from Its Co-Combustion with Natural Gas in Oxygen-Enriched Atmospheres. Methane, 3(1), 65-85. https://doi.org/10.3390/methane3010005