Evaluation of the Effects of Cultivar and Location on the Interaction of Lentil Seed Characteristics with Optimal Cooking Time

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Materials

2.2. Determination of Raw Seed Characteristics

2.3. Assessment of Cooking Quality

2.3.1. Characteristics of Cooked Seeds

2.3.2. Determination of Optimum Cooking Time

2.3.3. Organoleptic Broth and Seed Aroma Evaluation

2.3.4. Seed Hardness Testing

2.4. Statistical Analyses

3. Results and Discussion

3.1. Raw Seed Characteristics

3.2. Analysis of Cooked Seed Characteristics

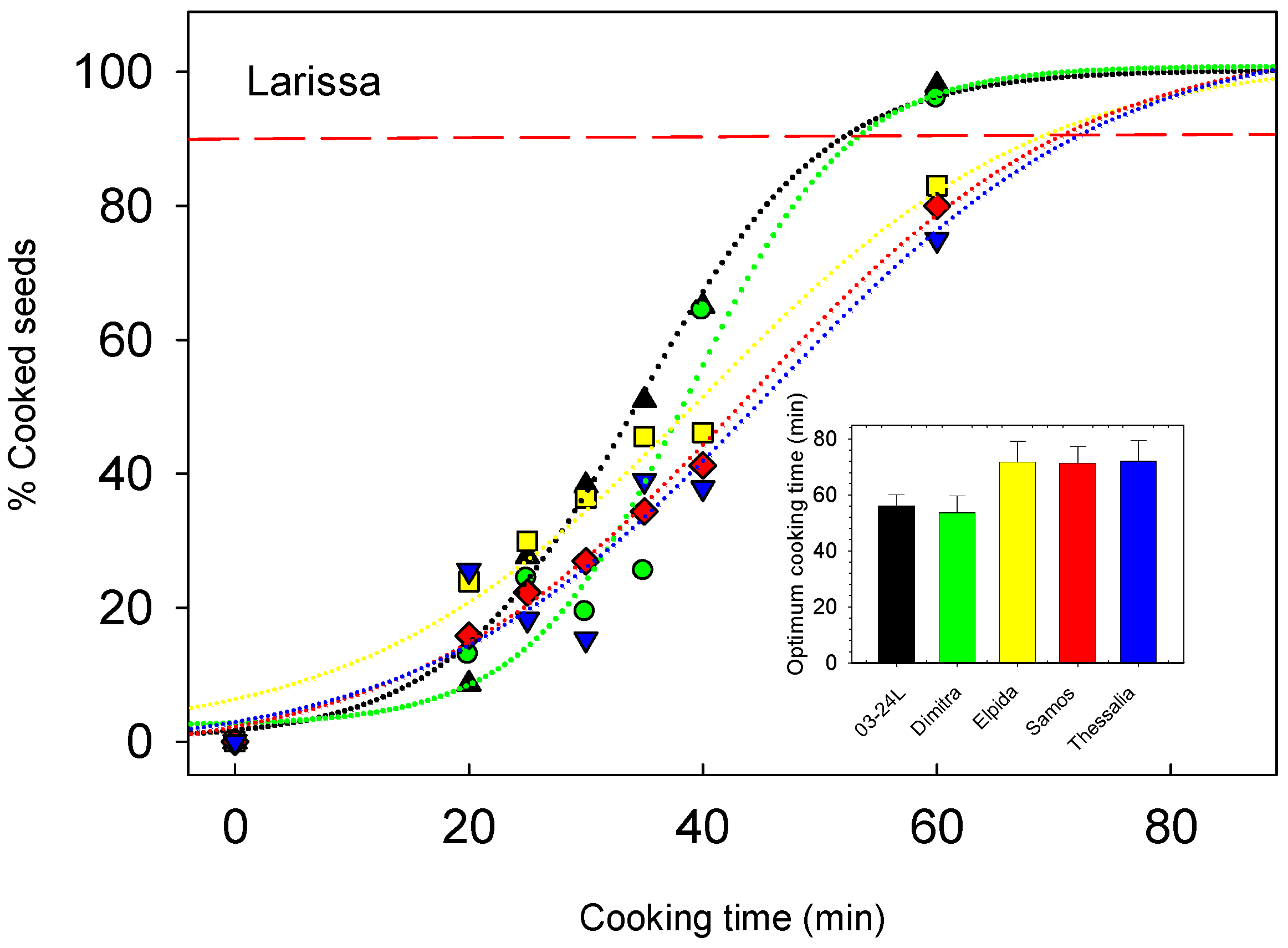

3.3. Determination of Optimum Cooking Time

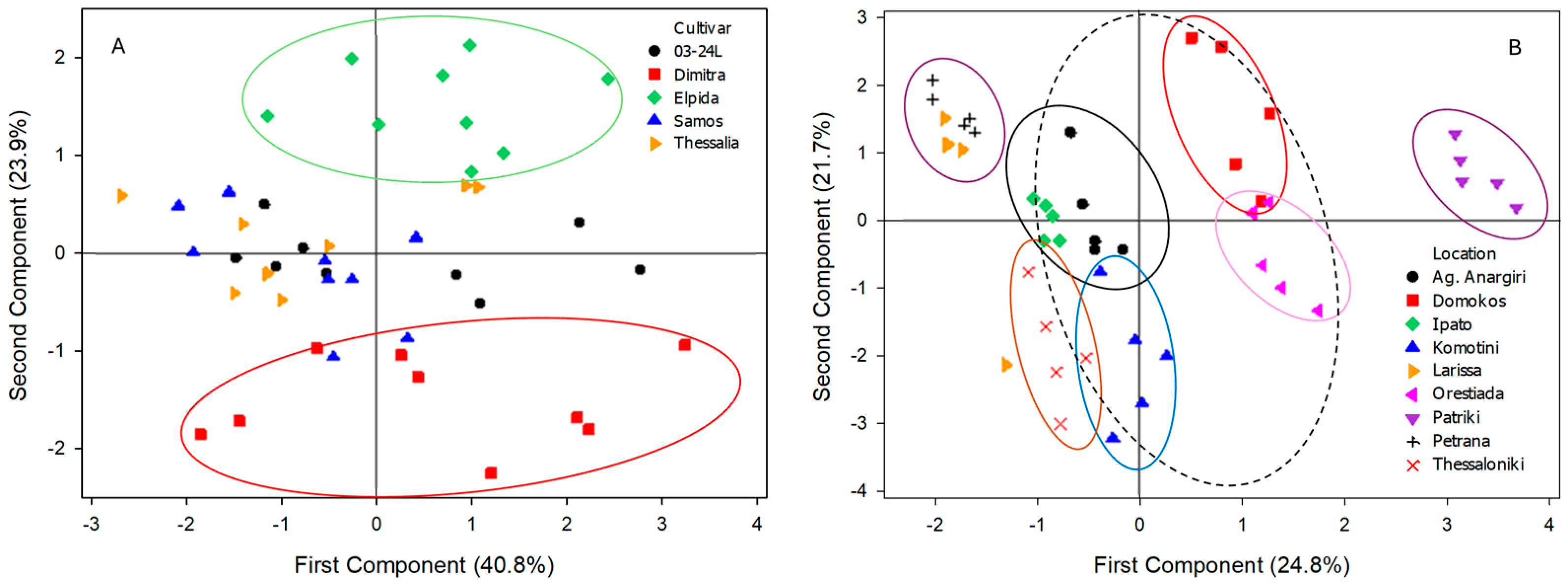

3.4. Pearson Correlation and PCA Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Addise, N.; Asfaw, T. Evaluation of chickpea and lentil grain for protein content. In Nile Valley Regional Program on Cool Season Food Legumes; Annual Report 1992/93, Ethiopia ICARDA/NVRP Doc-029; ICARDA: Aleppo, Syria, 1993. [Google Scholar]

- Nanos, G.D.; Gerasopoulos, D. Fruits, vegetables, legumes, and grains. In The Mediterranean Diet: Constituents and Health Promotion; Matalas, A.-L., Zampelas, A., Stavrinos, V., Eds.; CRC Press: Boca Raton, FL, USA, 2001; Volume 97, pp. 125–155. [Google Scholar] [CrossRef]

- Ninou, E.; Papathanasiou, F.; Vlachostergios, D.N.; Mylonas, I.; Kargiotidou, A.; Pankou, C.; Papadopoulos, I.; Sinapidou, E.; Tokatlidis, I. Intense Breeding within Lentil Landraces for High-Yielding Pure Lines Sustained the Seed Quality Character-istics. Agriculture 2019, 9, 175. [Google Scholar] [CrossRef]

- Dhull, S.B.; Kinabo, J.; Uebersax, M.A. Nutrient profile and effect of processing methods on the composition and functional properties of lentils (Lens culinaris Medik): A review. Legume Sci. 2022, 5, e156. [Google Scholar] [CrossRef]

- Bhatty, R.S. Comparisons of good- and poor-cooking lentils. J. Sci. Food Agric. 1995, 68, 489–496. [Google Scholar] [CrossRef]

- Kumar, S.; Bamboriya, S.D.; Rani, K.; Meena, R.S.; Sheoran, S.; Loyal, A.; Kumawat, A.; Jhariya, M.K. Grain legumes: A diversified diet for sustainable livelihood, food, and nutritional security. In Elsevier eBooks; Elsevier: Amsterdam, The Netherlands, 2022; pp. 157–178. [Google Scholar] [CrossRef]

- Nosworthy, M.G.; Neufeld, J.; Frohlich, P.; Young, G.; Malcolmson, L.; House, J.D. Determination of the protein quality of cooked Canadian pulses. Food Sci. Nutr. 2017, 5, 896–903. [Google Scholar] [CrossRef]

- Siva, N.; Thavarajah, D.; Johnson, C.R.; Duckett, S.; Jesch, E.D.; Thavarajah, P. Can lentil (Lens culinaris Medikus) reduce the risk of obesity? J. Funct. Foods 2017, 38, 706–715. [Google Scholar] [CrossRef]

- Motte, J.; Tyler, R.; Milani, A.; Courcelles, J.; Der, T. Pea and lentil flour quality as affected by roller milling configuration. Legume Sci. 2021, 3, e97. [Google Scholar] [CrossRef]

- Singh, K.M.; Singh, A. Lentil in India: An Overview Munich Personal REPEC Archive. (N.D.). Available online: https://mpra.ub.uni-muenchen.de/59319/ (accessed on 28 July 2024).

- Portman, D.; Blanchard, C.; Maharjan, P.; McDonald, L.S.; Mawson, J.; Naiker, M.; Panozzo, J.F. Blending studies using wheat and lentil cotyledon flour—Effects on rheology and bread quality. Cereal Chem. 2018, 95, 849–860. [Google Scholar] [CrossRef]

- Turfani, V.; Narducci, V.; Durazzo, A.; Galli, V.; Carcea, M. Technological, nutritional and functional properties of wheat bread enriched with lentil or carob flours. Food Sci. Technol. 2017, 78, 361–366. [Google Scholar] [CrossRef]

- Taheri, S.; Brodie, G.; Gupta, D. Fluidisation of lentil seeds during microwave drying and disinfection could prevent detrimental impacts on their chemical and biochemical characteristics. Food Sci. Technol. 2020, 129, 109534. [Google Scholar] [CrossRef]

- Joshi, M.; Timilsena, Y.; Adhikari, B. Global production, processing and utilization of lentil: A review. J. Integr. Agric. 2017, 16, 2898–2913. [Google Scholar] [CrossRef]

- Ruiz, J.M.; Buatois, Q.; Chambaron, S.; Monnery-Patris, S.; Arvisenet, G. French consumers know the benefits of pulses, but do not choose them: An exploratory study combining indirect and direct approaches. Appetite 2019, 141, 104311. [Google Scholar] [CrossRef] [PubMed]

- Bhatty, R.S.; Nielsen, M.A.; Slinkard, A.E. Comparison of the Cooking Quality of Laird and Commercial Chilean Lentils Grown in the Canadian Prairies. Can. Inst. Food Sci. Technol. J. 1983, 16, 104–110. [Google Scholar] [CrossRef]

- Theologidou, G.S.; Lazaridou, A.; Zorić, L.; Tsialtas, I.T. Cooking Quality of Lentils Produced under Mediterranean Conditions. Crop. Sci. 2018, 58, 2121–2130. [Google Scholar] [CrossRef]

- Erskine, W.; Williams, P.C.; Nakkoul, H. Genetic and environmental variation in the seed size, protein, yield, and cooking quality of lentils. Field Crop. Res. 1985, 12, 153–161. [Google Scholar] [CrossRef]

- Ross, K.A.; Alejo-Lucas, D.; Malcolmson, L.; Arntfield, S.D.; Cenkowski, S. Interpretation of the force–deformation curves of cooked red lentils (Lens culinaris). J. Texture Stud. 2009, 40, 109–126. [Google Scholar] [CrossRef]

- Bressani, R.; Elías, L.G. Seed quality and nutritional goals in pea, lentil, faba bean and chickpea breeding. In World Crops: Cool Season Food Legumes; Current Plant Science and Biotechnology in Agriculture; Summerfield, R.J., Ed.; Springer: Dordrecht, The Netherland, 1988; pp. 381–404. [Google Scholar] [CrossRef]

- Svarna, M.; Mavromatis, A.; Vlachostergios, D.N.; Gerasopoulos, D. Modeling the effects of seed maturity on cooking time of ‘Dimitra’ lentils. Foods 2022, 12, 42. [Google Scholar] [CrossRef]

- Iliadis, C. Effects of harvesting procedure, storage time and climatic conditions on cooking time of lentils (Lens culinaris Medikus). J. Sci. Food Agric. 2001, 81, 590–593. [Google Scholar] [CrossRef]

- Bhatty, R.S. Composition and Quality of Lentil (Lens culinaris Medik): A Review. Can. Inst. Food Sci. Technol. J. 1988, 21, 144–160. [Google Scholar] [CrossRef]

- Vlachostergios, D.N.; Noulas, C.; Kargiotidou, A.; Baxevanos, D.; Tigka, E.; Pankou, C.; Kostoula, S.; Beslemes, D.; Irakli, M.; Tziouvalekas, M.; et al. Identification of the optimum environments for the high yield and quality traits of lentil genotypes evaluated in Multi-Location trials. Sustainability 2021, 13, 8247. [Google Scholar] [CrossRef]

- Iliadis, C. Influence of genotype and soil type on cooking time in lentil (Lens culinaris Medikus). Int. J. Food Sci. Technol. 2003, 38, 89–93. [Google Scholar] [CrossRef]

- Özer, M.S.; Kaya, F. Physical, chemical and physicochemical properties of some lentil varieties grown in Turkey. J. Food Agric. Environ. 2010, 8, 610–613. [Google Scholar]

- Jood, S.; Bishnoi, S.; Sharma, A. Chemical analysis and physico-chemical properties of chickpea and lentil cultivars. Nahrung 1998, 42, 71–74. [Google Scholar] [CrossRef]

- Wood, J.A. Evaluation of Cooking Time in Pulses: A Review. Cereal Chem. 2017, 94, 32–48. [Google Scholar] [CrossRef]

- Shrestha, R.; Rizvi, A.H.; Sarker, A.; Darai, R.; Paneru, R.B.; Vandenberg, A.; Singh, M. Genotypic Variability and Genotype × Environment Interaction for Iron and Zinc Content in Lentil under Nepalese Environments. Crop Sci. 2018, 58, 2503–2510. [Google Scholar] [CrossRef]

- Irakli, M.; Kargiotidou, A.; Tigka, E.; Beslemes, D.; Fournomiti, M.; Pankou, C.; Stavroula, K.; Tsivelika, N.; Vlachostergios, D.N. Genotypic and Environmental Effect on the Concentration of Phytochemical Contents of Lentil (Lens culinaris L.). Agronomy 2021, 11, 1154. [Google Scholar] [CrossRef]

- Myrtsi, E.D.; Vlachostergios, D.N.; Petsoulas, C.; Koulocheri, S.D.; Evergetis, E.; Haroutounian, S.A. Eleven Greek legume beans: Assessment of genotypic effect on their phytochemical content and antioxidant properties. Antioxidants 2024, 13, 459. [Google Scholar] [CrossRef] [PubMed]

- Baxevanos, D.; Kargiotidou, A.; Noulas, C.; Kouderi, A.-M.; Aggelakoudi, M.; Petsoulas, C.; Tigka, E.; Mavromatis, A.; Tokatlidis, I.; Beslemes, D.; et al. Lentil cultivar evaluation in diverse organic Mediterranean environments. Agronomy 2024, 14, 790. [Google Scholar] [CrossRef]

- IIFC: Hellenic Agricultural Organization Demeter, Institute of Industrial and Forage Crops. 2016. Available online: https://ipsw.gr/en/services/legumes-varieties/itemlist/category/162-lentil-lens-culinaris-medik (accessed on 2 September 2024).

- Beck, H.E.; Zimmermann, N.E.; McVicar, T.R.; Vergopolan, N.; Berg, A.; Wood, E.F. Present and future Köppen-Geiger climate classification maps at 1-km resolution. Sci. Data 2018, 5, 180214. [Google Scholar] [CrossRef]

- Joshi, M.; Adhikari, B.; Panozzo, J.; Aldred, P. Water uptake and its impact on the texture of lentils (Lens culinaris). J. Food Eng. 2010, 100, 61–69. [Google Scholar] [CrossRef]

- Scanlon, M.G.; Malcolmson, L.J.; Arntfield, S.D.; Watts, B.; Ryland, D.; Prokopowich, D.J. Micronization Pretreatments for Reducing the Cooking Time of Lentils. J. Sci. Food Agric. 1998, 76, 23–30. [Google Scholar] [CrossRef]

- Abdel-Aal, E.-S.M.; Ragaee, S.; Rabalski, I.; Warkentin, T.; Vandenberg, A. Nutrient content and viscosity of Saskatchewan-grown pulses in relation to their cooking quality. Can. J. Plant Sci./Can. J. Plant Sci. 2019, 99, 67–77. [Google Scholar] [CrossRef]

- Palacios, L.T.; Guindón, F.; Maglia, F.; Bermejo, C. Identification of Macrosperma and Microsperma Lentil (Lens culinaris Medik) Genotypes with Superior Nutritional, Industrial, and Productive Traits to Get Transgressive Segregants. ACS Agric. Sci. Technol. 2023, 3, 683–693. [Google Scholar] [CrossRef]

- Akdeniz, H.; Koc, A.; Hosafliglu, I.; Hossain, A.; Islam, M.S.; Hafez, E.; El Sabagh, A. Evaluation of phenology, growth, yield and technological characteristics of some winter green lentil (Lens culinaris medik.) Genotypes grown under Mediterranean environment. Fresenius Environ. Bull. 2019, 28, 5430–5434. [Google Scholar]

- Bhatty, R.S. Relationship between physical and chemical characters and cooking quality in lentil. J. Agric. Food Chem. 1984, 32, 1161–1164. [Google Scholar] [CrossRef]

| Cultivation Locations | Climate Type * | Altitude | Soil pH | Soil Organic Matter (%) | Average Temp.** (°C) | Precipitation *** (mm) |

|---|---|---|---|---|---|---|

| Ag. Anargiri | BSk/Csa | 121 | 7.4 | 1.4 | 13.7 | 85.8 |

| Domokos | BSk | 500 | 7.1 | 1.7 | 11.3 | 81.8 |

| Ipato | Csa | 118 | 7.9 | 1.4 | 14.1 | 78.8 |

| Komotini | BSk | 32 | 8.1 | 1.2 | 13.5 | 105 |

| Larissa | BSk/Csa | 77 | 7.7 | 1.1 | 13.9 | 72.0 |

| Orestiada | Csa | 26 | 7.8 | 1.7 | 12.6 | 118.3 |

| Petrana | Cfa | 476 | 7.9 | 2.1 | 10.1 | 133.6 |

| Patriki | Cfa | 50 | 7.9 | 1.2 | 13.4 | 68.6 |

| Thessaloniki | BSk | 5 | 8.1 | 1.0 | 14.0 | 107.8 |

| DF | MTS (g) | PGS (%) | Seed L* | Seed a* | Seed b* | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| PARTIAL ETA SQR (η2) | |||||||||||

| Cultivar | 7 | 0.98 | *** | 0.69 | *** | 0.10 | *** | 0.69 | *** | 0.35 | *** |

| Location | 1 | 0.84 | *** | 0.49 | *** | 0.03 | *** | 0.37 | *** | 0.28 | *** |

| Cultivar × Location | 28 | 0.79 | *** | 0.61 | *** | 0.29 | *** | 0.34 | *** | 0.31 | *** |

| MAIN EFFECTS | MEANS | ||||||||||

| Cultivar | 03-24L | 44.78 | c | 44.77 | c | 54.98 | c | 6.85 | a | 24.10 | c |

| Dimitra | 33.13 | e | 60.12 | a | 57.34 | a | 2.73 | bc | 25.83 | a | |

| Elpida | 62.89 | a | 58.48 | a | 55.56 | bc | 2.40 | c | 25.09 | b | |

| Samos | 41.30 | d | 41.77 | d | 55.39 | bc | 2.88 | b | 25.51 | a | |

| Thessalia | 48.80 | b | 53.71 | b | 56.36 | b | 2.92 | b | 25.76 | a | |

| Location | Ag. Anargyroi | 39.11 | g | 53.57 | c | 56.60 | b | 3.75 | bc | 24.91 | de |

| Domokos | 45.43 | d | 54.43 | bc | 56.91 | b | 3.34 | c | 24.89 | de | |

| Ipato | 47.99 | c | 53.02 | c | 54.90 | d | 3.99 | b | 25.27 | cd | |

| Komotini | 49.40 | b | 59.96 | a | 56.76 | b | 3.92 | bc | 24.43 | e | |

| Larissa | 42.14 | e | 43.49 | d | 54.95 | cd | 3.80 | bc | 25.81 | b | |

| Orestiada | 46.09 | d | 46.48 | d | 53.43 | e | 5.01 | a | 25.59 | bc | |

| Patriki | 50.47 | a | 51.16 | c | 58.61 | a | 3.73 | bc | 24.52 | e | |

| Petrana | 41.34 | f | 45.95 | d | 57.59 | ab | 2.13 | d | 26.48 | a | |

| Thessaloniki | 42.25 | e | 57.28 | ab | 56.32 | bc | 2.50 | d | 25.10 | cd | |

| DF | PMI (%) | POS (%) | PFT (g) | OCH | OTT | OSA | OBA | Broth L* | Broth a* | Broth b* | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PARTIAL ETA SQR (η2) | |||||||||||

| Cultivar | 4 | 0.10 * | 0.20 *** | 0.02 *** | 0.02 ns | 0.04 ns | 0.04 ns | 0.22 *** | 0.12 * | 0.25 *** | 0.04 ns |

| Location | 8 | 0.21 ** | 0.45 *** | 0.03 *** | 0.06 ns | 0.20 * | 0.12 * | 0.36 *** | 0.36 *** | 0.33 *** | 0.14 * |

| Cult. × Loc. | 30 | 0.09 ns | 0.15 ns | 0.04 *** | 0.05 ns | 0.37 * | 0.15 * | 0.22 ns | 0.24 ns | 0.60 ns | 0.16 ns |

| MAIN EFFECTS | MEANS | ||||||||||

| Cultivar | 03-24L | 109.88 ab | 19.84 a | 119.8 ab | 2.81 a | 2.96 a | 3.08 a | 2.78 b | 51.02 b | 1.69 a | 14.35 a |

| Dimitra | 114.18 a | 14.92 b | 102.4 c | 2.94 a | 2.61 a | 3.14 a | 3.14 a | 53.64 a | 1.07 c | 12.97 a | |

| Elpida | 113.55 a | 21.37 a | 114.3 b | 2.63 a | 2.79 a | 2.88 a | 2.46 c | 51.21 b | 1.87 a | 14.12 a | |

| Samos | 105.69 b | 12.04 b | 126.7 a | 2.78 a | 2.85 a | 3.13 a | 2.59 bc | 53.66 a | 1.29 b | 13.14 a | |

| Thessalia | 105.84 b | 11.45 b | 121.9 ab | 2.68 a | 2.70 a | 2.94 a | 2.57 bc | 52.62 ab | 1.46 b | 13.04 a | |

| Location | Ag. Anargyroi | 108.27 bc | 12.12 d | 111.6 cd | 3.00 a | 2.87 a | 3.29 a | 2.50 cd | 53.27 cd | 1.18 ef | 13.21 bc |

| Domokos | 115.14 ab | 21.44 b | 115.8 bc | 2.97 a | 2.67 a | 3.08 abc | 2.80 bc | 53.96 b | 1.24 ed | 14.35 abc | |

| Ipato | 106.42 c | 10.89 d | 125.5 ab | 2.85 ab | 2.13 b | 3.33 a | 3.27 a | 55.22 ab | 1.50 bcd | 12.28 bc | |

| Komotini | 120.38 a | 30.23 a | 101.7 d | 2.81 ab | 2.80 a | 3.00 abc | 2.50 cd | 50.62 d | 1.39 bcde | 12.50 bc | |

| Larissa | 102.86 c | 3.21 e | 135.0 a | 2.70 ab | 3.00 a | 2.77 c | 3.23 a | 51.38 cd | 1.63 b | 13.85 abc | |

| Orestiada | 109.23 bc | 18.80 bc | 112.2 cd | 2.75 ab | 3.08 a | 2.88 bc | 2.28 d | 50.84 dc | 2.13 a | 15.83 a | |

| Patriki | 102.19 c | 13.97 cd | 125.8 ab | 2.33 b | 2.80 a | 3.20 abc | 2.93 ab | 56.74 a | 0.95 f | 11.90 c | |

| Petrana | 104.60 c | 9.46 de | 136.7 a | 2.56 ab | 3.07 a | 3.13 abc | 2.47 cd | 51.51 cd | 1.46 bcd | 13.46 abc | |

| Thessaloniki | 116.46 ab | 21.55 b | 106.8 cd | 2.91 ab | 2.83 a | 2.95 abc | 2.59 bcd | 50.01 d | 1.30 ecd | 12.30 bc | |

| Cultivar: | 03-24L | Dimitra | Elpida | Samos | Thessalia | MEANS (Location) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Location: | ||||||||||||

| Ag. Anargyroi | 54.3 ± 5.1 | 38.9 ± 3.2 | 52.1 ± 6.8 | 49.6 ± 7 | 57.4 ± 4 | 50.5 C | ||||||

| Domokos | 47.4 ± 5.1 | 44.7 ± 3.2 | 53.7 ± 6.8 | 57.4 ± 11 | 56.1 ± 9 | 51.9 C | ||||||

| Ipato | 50.2 ± 3.4 | 45.3 ± 4.6 | 57.2 ± 6.1 | 49.9 ± 9.9 | 54.7 ± 4.5 | 51.5 C | ||||||

| Komotini | 51.6 ± 4.8 | 48.5 ± 1.9 | 42.6 ± 3.6 | 48.4 ± 8.2 | 50.9 ± 3.5 | 48.4 C | ||||||

| Larisa | 56.0 ± 4 | 53.6 ± 6 | 71.7 ± 7.4 | 71.3 ± 5.9 | 72.0 ± 7.4 | 64.9 A | ||||||

| Orestiada | 47.0 ± 3.4 | 50.1 ± 3.7 | 54.3 ± 1.3 | 54.2 ± 4 | 54.1 ± 3.2 | 51.9 C | ||||||

| Patriki | 52.4 ± 6.9 | 54.5 ± 2.4 | 56.6 ± 2.4 | 63.6 ± 9.6 | 66.5 ± 11 | 58.7 B | ||||||

| Petrana | 62.9 ± 11 | 59.8 ± 13 | 71.7 ± 10 | 71.9 ± 11 | 58.7 ± 16 | 65.0 A | ||||||

| Thessaloniki | 69.6 ± 5.7 | 45.7 ± 5.6 | 58.4 ± 9.2 | 56.5 ± 6.6 | 61.7 ± 8.4 | 58.4 B | ||||||

| MEANS (Cultivar) | ||||||||||||

| 54.6 | B | 49.0 | C | 57.6 | AB | 58.1 | AB | 59.1 | A | |||

| PARTIAL ETA SQR (η2) | ||||||||||||

| Cultivar | 0.31 *** | |||||||||||

| Location | 0.91 *** | |||||||||||

| Cultivar × Location | 0.37 *** | |||||||||||

| MTS | PGS | Seed L* | Seed a* | Seed b* | PMI | POS | PFT | OTT | OCH | OBA | OSA | Broth L* | Broth a* | Broth b* | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PGS | 0.039 | ||||||||||||||

| Seed L* | −0.071 | 0.129 | |||||||||||||

| Seed a* | 0.065 | −0.351 * | −0.505 *** | ||||||||||||

| Seed b* | −0.244 | 0.063 | 0.042 | −0.416 ** | |||||||||||

| PMI | −0.083 | 0.487 *** | 0.018 | −0.099 | −0.086 | ||||||||||

| POS | 0.19 | 0.324 * | −0.121 | 0.221 | −0.316 | 0.797 | |||||||||

| PFT | 0.22 | −0.52 *** | 0.01 | 0.519 *** | −0.505 *** | −0.453 ** | −0.133 | ||||||||

| OTT | −0.299 | 0.168 | −0.274 | 0.186 | 0.065 | 0.414 ** | 0.277 | −0.302 | |||||||

| OCH | −0.341 * | 0.16 | −0.387 * | 0.209 | 0.071 | 0.382 * | 0.218 | −0.327 * | 0.95 | ||||||

| OBA | −0.246 | 0.143 | −0.138 | 0.105 | −0.087 | 0.073 | −0.153 | 0.094 | 0.023 | 0.129 | |||||

| OSA | −0.155 | 0.09 | 0.143 | −0.157 | 0.143 | 0.225 | −0.045 | −0.198 | 0.077 | 0.057 | 0.33 * | ||||

| Broth L* | 0.004 | −0.093 | 0.21 | −0.209 | 0.021 | −0.281 | −0.382 * | 0.148 | −0.266 | −0.248 | 0.148 | 0.131 | |||

| Broth a* | 0.421 ** | −0.113 | −0.162 | 0.295 | 0.045 | −0.057 | 0.037 | 0.059 | −0.007 | 0.01 | −0.186 | −0.06 | −0.403 ** | ||

| Broth b* | 0.035 | −0.201 | 0.05 | 0.262 | −0.203 | 0.279 | 0.251 | 0.192 | 0.158 | 0.163 | −0.016 | 0.24 | 0.082 | 0.136 | |

| OCT | 0.403 ** | −0.351 * | 0.025 | 0.02 | 0.036 | −0.391 * | −0.199 | 0.224 | −0.167 | −0.192 | −0.304 | −0.401 ** | 0.076 | 0.094 | −0.155 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarakatsianos, D.; Polyzou, D.; Mavromatis, A.; Vlachostergios, D.N.; Gerasopoulos, D. Evaluation of the Effects of Cultivar and Location on the Interaction of Lentil Seed Characteristics with Optimal Cooking Time. Seeds 2024, 3, 575-588. https://doi.org/10.3390/seeds3040039

Sarakatsianos D, Polyzou D, Mavromatis A, Vlachostergios DN, Gerasopoulos D. Evaluation of the Effects of Cultivar and Location on the Interaction of Lentil Seed Characteristics with Optimal Cooking Time. Seeds. 2024; 3(4):575-588. https://doi.org/10.3390/seeds3040039

Chicago/Turabian StyleSarakatsianos, Dimitrios, Dimitra Polyzou, Athanasios Mavromatis, Dimitrios N. Vlachostergios, and Dimitrios Gerasopoulos. 2024. "Evaluation of the Effects of Cultivar and Location on the Interaction of Lentil Seed Characteristics with Optimal Cooking Time" Seeds 3, no. 4: 575-588. https://doi.org/10.3390/seeds3040039

APA StyleSarakatsianos, D., Polyzou, D., Mavromatis, A., Vlachostergios, D. N., & Gerasopoulos, D. (2024). Evaluation of the Effects of Cultivar and Location on the Interaction of Lentil Seed Characteristics with Optimal Cooking Time. Seeds, 3(4), 575-588. https://doi.org/10.3390/seeds3040039