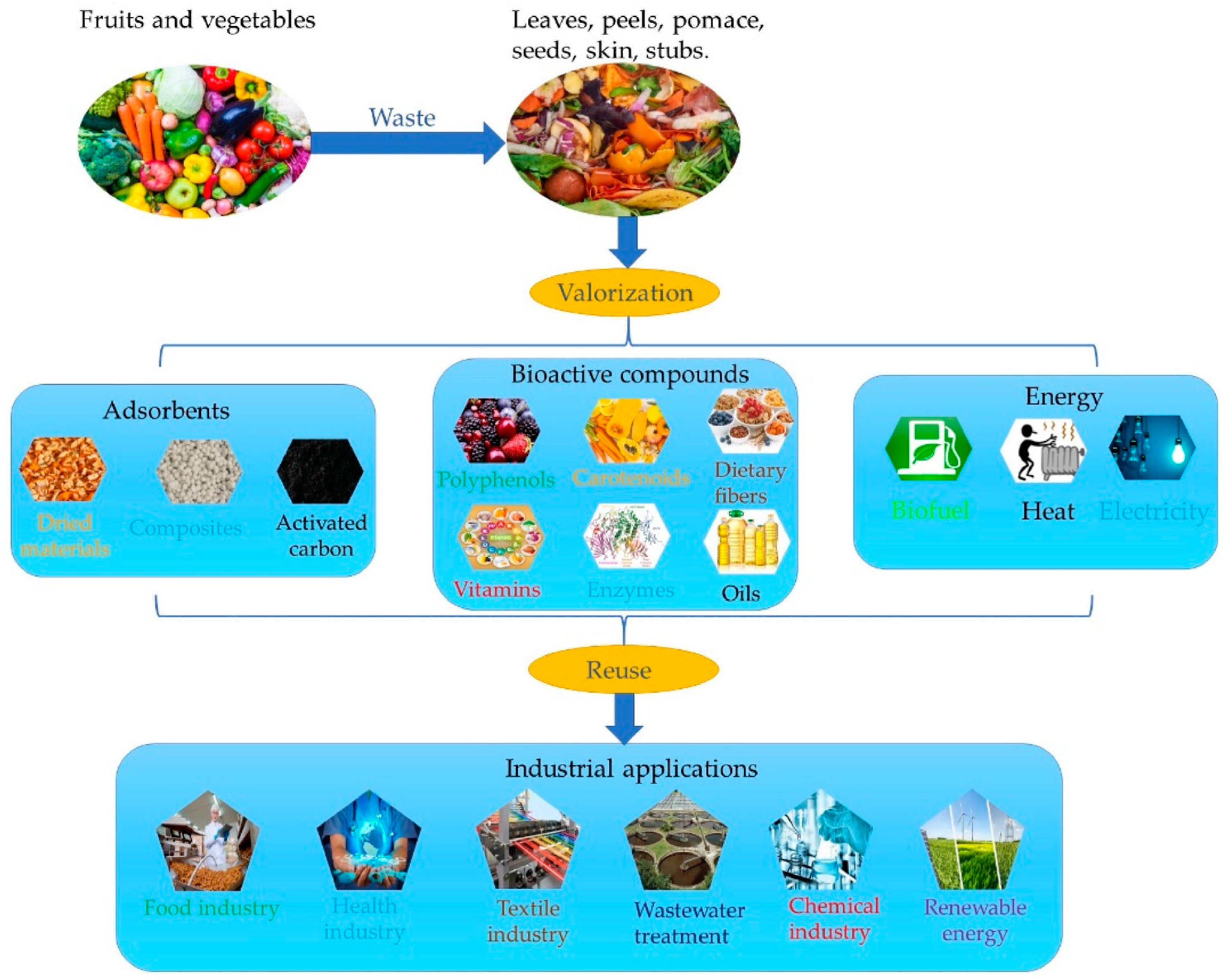

Valorization of Fruit and Vegetable Waste into Sustainable and Value-Added Materials

Abstract

1. Introduction

2. Sources of FVW

2.1. Industrial Processing Facilities

2.2. Retail Sectors

2.3. Consumers Households

3. Potential Uses of Some FVW as Sustainable and Value-Added Materials

3.1. Value-Added Products

3.1.1. Bioactive Compounds

3.1.2. Biopolymers

3.2. Food and Food Packaging

3.3. Agriculture

3.4. Energy

3.5. Water Purification

3.6. Other Applications

4. Extraction Methods

4.1. Ultrasound-Assisted Extraction (UAE) and Microwave-Assisted Extraction (MWAE)

4.2. Supercritical Fluid Extraction (SFE)

4.3. Pressurized Liquid Extraction (PLE) and Hot Water Extraction (PHWE)

4.4. Ohmic Heating-Assisted Extraction (OHAE)

4.5. Enzyme-Assisted Extraction (EAE)

5. Techno-Economic Assessment

6. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ganesh, K.S.; Sridhar, A.; Vishali, S. Utilization of fruit and vegetable waste to produce value-added products: Conventional utilization and emerging opportunities-A review. Chemosphere 2022, 287, 132221. [Google Scholar] [CrossRef]

- Mateus, A.R.S.; Pena, A.; Sanches-Silva, A. Unveiling the potential of bioactive compounds in vegetable and fruit by-products: Exploring phytochemical properties, health benefits, and industrial. Curr. Opin. Green Sustain. Chem. 2024, 48, 100938. [Google Scholar] [CrossRef]

- Zhu, Y.D.; Luan, Y.T.; Zhao, Y.N.; Liu, J.L.; Duan, Z.Q.; Ruan, R.G. Current Technologies and Uses for Fruit and Vegetable Wastes in a Sustainable System: A Review. Foods 2023, 12, 1949. [Google Scholar] [CrossRef]

- Tan, C.H.; Hii, C.L.; Borompichaichartkul, C.; Phumsombat, P.; Kong, I.; Pui, L.P. Valorization of fruits, vegetables, and their by-products: Drying and bio-drying. Dry. Technol. 2022, 40, 1514–1538. [Google Scholar] [CrossRef]

- Kultys, E.; Kurek, M.A. Green Extraction of Carotenoids from Fruit and Vegetable Byproducts: A Review. Molecules 2022, 27, 518. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.H.; Sun, Y.C.; Jin, M.Z.; Ripp, S.A.; Sayler, G.S.; Zhuang, J. Domestic plant food loss and waste in the United States: Environmental footprints and mitigation strategies. Waste Manag. 2022, 150, 202–207. [Google Scholar] [CrossRef] [PubMed]

- Lau, K.Q.; Sabran, M.R.; Shafie, S.R. Utilization of Vegetable and Fruit By-products as Functional Ingredient and Food. Front. Nutr. 2021, 8, 661693. [Google Scholar] [CrossRef] [PubMed]

- Sagar, N.; Pareek, S.; Sharma, S.; Yahia, E.; Lobo, M. Fruit and Vegetable Waste: Bioactive Compounds, Their Extraction, and Possible Utilization. Compr. Rev. Food Sci. Food Saf. 2018, 17, 512–531. [Google Scholar] [CrossRef]

- Esparza, I.; Jiménez-Moreno, N.; Bimbela, F.; Ancín-Azpilicueta, C.; Gandía, L. [Fruit and vegetable waste management: Conventional and emerging approaches]. J. Environ. Manag. 2020, 265, 110510. [Google Scholar] [CrossRef]

- Cassani, L.; Gomez-Zavaglia, A. Sustainable Food Systems in Fruits and Vegetables Food Supply Chains. Front. Nutr. 2022, 9, 829061. [Google Scholar] [CrossRef]

- Ueda, J.M.; Pedrosa, M.C.; Heleno, S.A.; Carocho, M.; Ferreira, I.; Barros, L. Food Additives from Fruit and Vegetable By-Products and Bio-Residues: A Comprehensive Review Focused on Sustainability. Sustainability 2022, 14, 5212. [Google Scholar] [CrossRef]

- Matei, E.; Rapa, M.; Predescu, A.M.; Turcanu, A.A.; Vidu, R.; Predescu, C.; Bobirica, C.; Bobirica, L.; Orbeci, C. Valorization of Agri-Food Wastes as Sustainable Eco-Materials for Wastewater Treatment: Current State and New Perspectives. Materials 2021, 14, 4581. [Google Scholar] [CrossRef] [PubMed]

- Augustin, M.A.; Sanguansri, L.; Fox, E.M.; Cobiac, L.; Cole, M.B. Recovery of wasted fruit and vegetables for improving sustainable diets. Trends Food Sci. Technol. 2020, 95, 75–85. [Google Scholar] [CrossRef]

- Dilucia, F.; Lacivita, V.; Conte, A.; Del Nobile, M.A. Sustainable Use of Fruit and Vegetable By-Products to Enhance Food Packaging Performance. Foods 2020, 9, 857. [Google Scholar] [CrossRef] [PubMed]

- Tedesco, D.E.A.; Scarioni, S.; Tava, A.; Panseri, S.; Zuorro, A. Fruit and Vegetable Wholesale Market Waste: Safety and Nutritional Characterisation for Their Potential Re-Use in Livestock Nutrition. Sustainability 2021, 13, 9478. [Google Scholar] [CrossRef]

- Bas-Bellver, C.; Barrera, C.; Betoret, N.; Segui, L. Turning Agri-Food Cooperative Vegetable Residues into Functional Powdered Ingredients for the Food Industry. Sustainability 2020, 12, 1284. [Google Scholar] [CrossRef]

- Noor, A.; Moyle, P.M.; Malik, A.; Ziora, Z.M.; Pant, K.K. Transformative upcycling of fruit-vegetable waste for nutraceutical and pharmaceutical breakthroughs and circular economy evolution. Process Saf. Environ. Prot. 2024, 187, 1022–1036. [Google Scholar] [CrossRef]

- Nabi, B.G.; Mukhtar, K.; Ansar, S.; Hassan, S.A.; Hafeez, M.A.; Bhat, Z.F.; Khaneghah, A.M.; Ul Haq, A.; Aadil, R.M. Application of ultrasound technology for the effective management of waste from fruit and vegetable. Ultrason. Sonochem. 2024, 102, 106744. [Google Scholar] [CrossRef]

- Basri, M.S.M.; Shah, N.; Sulaiman, A.; Tawakkal, I.; Nor, M.Z.M.; Ariffin, S.H.; Ghani, N.H.A.; Salleh, F.S.M. Progress in the Valorization of Fruit and Vegetable Wastes: Active Packaging, Biocomposites, By-Products, and Innovative Technologies Used for Bioactive Compound Extraction. Polymers 2021, 13, 3503. [Google Scholar] [CrossRef]

- Rifna, E.J.; Misra, N.N.; Dwivedi, M. Recent advances in extraction technologies for recovery of bioactive compounds derived from fruit and vegetable waste peels: A review. Crit. Rev. Food Sci. Nutr. 2023, 63, 719–752. [Google Scholar] [CrossRef]

- Plaza, M.; Marina, M.L. Pressurized hot water extraction of bioactives. TRAC-Trends Anal. Chem. 2023, 166, 117201. [Google Scholar] [CrossRef]

- Plaza, M.; Turner, C. Pressurized hot water extraction of bioactives. TRAC-Trends Anal. Chem. 2015, 71, 39–54. [Google Scholar] [CrossRef]

- Tan, S.S.Y.; Shanmugham, M.; Chin, Y.L.; An, J.; Chua, C.K.; Ong, E.S.; Leo, C.H. Pressurized Hot Water Extraction of Mangosteen Pericarp and Its Associated Molecular Signatures in Endothelial Cells. Antioxidants 2023, 12, 1932. [Google Scholar] [CrossRef] [PubMed]

- Visnjevec, A.M.; Barp, L.; Lucci, P.; Moret, S. Pressurized liquid extraction for the determination of bioactive compounds in plants with emphasis on phenolics. TRAC-Trends Anal. Chem. 2024, 173, 117620. [Google Scholar] [CrossRef]

- Khalid, S.; Hassan, S.A.; Altemimi, A.B.; Chaudhary, K.; Raana, S.; Javaid, H.; Naeem, M.; Bhat, Z.F.; Aadil, R.M. Recovery of valuable substances from food waste by ohmic heating assisted extraction -A step towards sustainable production. Future Foods 2024, 9, 100365. [Google Scholar] [CrossRef]

- Ferreira-Santos, P.; Nobre, C.; Rodrigues, R.M.; Genisheva, Z.; Botelho, C.; Teixeira, J.A. Extraction of phenolic compounds from grape pomace using ohmic heating: Chemical composition, bioactivity and bioaccessibility. Food Chem. 2024, 436, 137780. [Google Scholar] [CrossRef] [PubMed]

- Gebre, G.D.; Gebremariam, S.N.; Keneni, Y.G.; Marchetti, J.M. Valorization of tropical fruit-processing wastes and byproducts for biofuel production. Biofuels Bioprod. Biorefining 2023, 17, 1807–1842. [Google Scholar] [CrossRef]

- Adamu, H.; Bello, U.; Yuguda, A.U.; Tafida, U.I.; Jalam, A.M.; Sabo, A.; Qamar, M. Production processes, techno-economic and policy challenges of bioenergy production from fruit and vegetable wastes. Renew. Sustain. Energy Rev. 2023, 186, 113686. [Google Scholar] [CrossRef]

- Hasan, M.M.; Islam, M.R.; Haque, A.R.; Kabir, M.R.; Khushe, K.J.; Hasan, S.M.K. Trends and challenges of fruit by-products utilization: Insights into safety, sensory, and benefits of the use for the development of innovative healthy food: A review. Bioresour. Bioprocess. 2024, 11, 10. [Google Scholar] [CrossRef]

- Tan, C.X.; Tan, S.T.; Tan, S.S. An overview of papaya seed oil extraction methods. Int. J. Food Sci. Technol. 2020, 55, 1506–1514. [Google Scholar] [CrossRef]

- Singh, B.; Singh, J.P.; Kaur, A.; Yadav, M.P. Insights into the chemical composition and bioactivities of citrus peel essential oils. Food Res. Int. 2021, 143, 110231. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, T.; Chowdhary, P.; Chaurasia, D.; Gnansounou, E.; Pandey, A.; Chaturvedi, P. Sustainable green processing of grape pomace for the production of value-added products: An overview. Environ. Technol. Innov. 2021, 23, 101592. [Google Scholar] [CrossRef]

- Pérez-Marroquín, X.A.; Estrada-Fernández, A.G.; García-Ceja, A.; Aguirre-Alvarez, G.; León-López, A. Agro-Food Waste as an Ingredient in Functional Beverage Processing: Sources, Functionality, Market and Regulation. Foods 2023, 12, 1583. [Google Scholar] [CrossRef] [PubMed]

- Gattuso, A.; Piscopo, A.; Romeo, R.; De Bruno, A.; Poiana, M. Recovery of Bioactive Compounds from Calabrian Bergamot Citrus Waste: Selection of Best Green Extraction. Agriculture 2023, 13, 1095. [Google Scholar] [CrossRef]

- Arias, A.; Feijoo, G.; Moreira, M.T. Exploring the potential of antioxidants from fruits and vegetables and strategies for their recovery. Innov. Food Sci. Emerg. Technol. 2022, 77, 102974. [Google Scholar] [CrossRef]

- Nirmal, N.P.; Khanashyam, A.C.; Mundanat, A.S.; Shah, K.; Babu, K.S.; Thorakkattu, P.; Al-Asmari, F.; Pandiselvam, R. Valorization of Fruit Waste for Bioactive Compounds and Their Applications in the Food Industry. Foods 2023, 12, 556. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Chen, G.; Diao, J.; Wang, C. Recent advances in exploring and exploiting soybean functional peptides-a review. Front. Nutr. 2023, 10, 1185047. [Google Scholar] [CrossRef] [PubMed]

- Stockli, S.; Dorn, M. Awareness, intention, and behavior: Three empirical perspectives on predicting the purchase of abnormally shaped fruits and vegetables. Resour. Conserv. Recycl. 2021, 168, 105431. [Google Scholar] [CrossRef]

- Tu, J.C.; Lee, Y.L.; Wei, M.Y. Analysis and Research on the Key Success Factors of Marketing Ugly Fruits and Vegetables. Sustainability 2018, 10, 2783. [Google Scholar] [CrossRef]

- Campos, A.C.; Santini, F.D.; Perin, M.G.; Ladeira, W. Effects of abnormally shaped fruits and vegetables on consumer’s willingness to buy: A meta-analytic study. J. Soc. Mark. 2022, 12, 556–586. [Google Scholar] [CrossRef]

- Yin, J.; Wang, Y.F.; Wang, Q.Y.; Zhang, S.; Wang, M.Z.; Feng, H.J.; Jiang, J.; Qiu, X.P.; Zhang, Y.F.; Chen, T. Generation of fruit and vegetable wastes in the farmers’ market and its influencing factors: A case study from Hangzhou, China. Waste Manag. 2022, 154, 331–339. [Google Scholar] [CrossRef]

- Yenerall, J.; Chen, R.T. Food Retailer, Restaurant, and Online Grocery Shopping Use and Household Food Waste: Evidence from US Households in 2022. J. Food Prod. Mark. 2023, 29, 232–254. [Google Scholar] [CrossRef]

- Mattsson, L.; Williams, H. Avoidance of Supermarket Food Waste-Employees’ Perspective on Causes and Measures to Reduce Fruit and Vegetables Waste. Sustainability 2022, 14, 10031. [Google Scholar] [CrossRef]

- Guarnieri, P.; de Aguiar, R.C.C.; Thome, K.M.; Watanabe, E.A.D. The Role of Logistics in Food Waste Reduction in Wholesalers and Small Retailers of Fruits and Vegetables: A Multiple Case Study. Logistics 2021, 5, 77. [Google Scholar] [CrossRef]

- Li, X.L.; Jiang, Y.; Qing, P. Estimates of Household Food Waste by Categories and Their Determinants: Evidence from China. Foods 2023, 12, 776. [Google Scholar] [CrossRef]

- Stancu, V.; Haugaard, P.; Lahteenmaki, L. Determinants of consumer food waste behaviour: Two routes to food waste. Appetite 2016, 96, 7–17. [Google Scholar] [CrossRef] [PubMed]

- Kavanaugh, M.; Quinlan, J.J. Consumer knowledge and behaviors regarding food date labels and food waste. Food Control 2020, 115, 107285. [Google Scholar] [CrossRef]

- Karanth, S.; Feng, S.; Patra, D.; Pradhan, A.K. Linking microbial contamination to food spoilage and food waste: The role of smart packaging, spoilage risk assessments, and date labeling. Front. Microbiol. 2023, 14, 1198124. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, M.; Zhu, Q.; Adhikari, B. Intelligent vegetable freshness monitoring system developed by integrating eco-friendly fluorescent sensor arrays with deep convolutional neural networks. Chem. Eng. J. 2024, 488, 150739. [Google Scholar] [CrossRef]

- Khalid, S.; Malik, A.U.; Ullah, M.I.; Khalid, M.S.; Javeed, H.M.R.; Naeem, M.A.; Naseer, A. Food waste: Causes and economic losses estimation at household level in Pakistan. Environ. Sci. Pollut. Res. 2023, 30, 99284–99297. [Google Scholar] [CrossRef]

- Liu, Z. A review on the emerging conversion technology of cellulose, starch, lignin, protein and other organics from vegetable-fruit-based waste. Int. J. Biol. Macromol. 2023, 242, 124804. [Google Scholar] [CrossRef] [PubMed]

- Pradhan, S.; Parthasarathy, P.; Mackey, H.R.; Al-Ansari, T.; McKay, G. Food waste biochar: A sustainable solution for agriculture application and soil–water remediation. Carbon Res. 2024, 3, 1–29. [Google Scholar] [CrossRef]

- Ahmad, I.K.; Mohamed, Z.S.; Amrul, N.F.; Quan, C.W.; Jalil, B.A.A.; Basri, N.E.A.; Azmi, M.R. Composting Fruit and Vegetable Waste Using Black Soldier Fly Larvae. J. Kejuruter. 2021, 33, 837–843. [Google Scholar] [CrossRef]

- Zhang, S.K.; Fu, Q.B.; Li, H.S.; Wu, P.; Waterhouse, G.I.N.; Li, Y.J.; Ai, S.Y. A pectocellulosic bioplastic from fruit processing waste: Robust, biodegradable, and recyclable. Chem. Eng. J. 2023, 463, 142452. [Google Scholar] [CrossRef]

- Abdullah, A.H.; Awad-Allah, M.A.A.; Abd-Elkarim, N.A.A.; Ahmed, Z.F.R.; Taha, E.M.A. Carboxymethyl Cellulose from Banana Rachis: A Potential Edible Coating to Extend the Shelf Life of Strawberry Fruit. Agriculture 2023, 13, 1058. [Google Scholar] [CrossRef]

- Salimi, A.; Khodaiyan, F.; Askari, G.; Hosseini, S.S. A zero-waste approach towards a sustainable waste management of apple: Extraction of value-added products and their application as edible coating. Food Hydrocoll. 2024, 147, 109304. [Google Scholar] [CrossRef]

- Yu, J.; Fang, L.; Kim, S.; Kim, K.; Kim, M.; Lee, T. Valorization of fruit and vegetable byproducts for the beta-glucan production from Euglena gracilis. Bioresour. Technol. 2024, 394, 130213. [Google Scholar] [CrossRef]

- Merino, D.; Zych, A.; Athanassiou, A. Biodegradable and Biobased Mulch Films: Highly Stretchable PLA Composites with Different Industrial Vegetable Waste. ACS Appl. Mater. Interfaces 2022, 14, 46920–46931. [Google Scholar] [CrossRef]

- Ramamoorthy, K.; Dhanraj, R.; Vijayakumar, N.; Ma, Y.; Al Obaid, S.; Narayanan, M. Vegetable and fruit wastes: Valuable source for organic fertilizer for effective growth of short-term crops: Solanum lycopersicum and Capsicum annum. Environ. Res. 2024, 251, 118727. [Google Scholar] [CrossRef] [PubMed]

- Wu, R.; Chen, M.; Qin, Y.; Liu, S.; Li, X. Combined hydrothermal and biological treatments for valorization of fruit and vegetable waste into liquid organic fertilizer. Environ. Res. 2023, 221, 115262. [Google Scholar] [CrossRef]

- Pradhan, S.; Abdelaal, A.H.; Mroue, K.; Al-Ansari, T.; Mackey, H.R.; McKay, G. Biochar from vegetable wastes: Agro-environmental characterization. Biochar 2020, 2, 439–453. [Google Scholar] [CrossRef]

- Soltan, M.; Elsamadony, M.; Mostafa, A.; Awad, H.; Tawfik, A. Harvesting zero waste from co-digested fruit and vegetable peels via integrated fermentation and pyrolysis processes. Environ. Sci. Pollut. Res. 2019, 26, 10429–10438. [Google Scholar] [CrossRef] [PubMed]

- Chatterjee, B.; Mazumder, D. Valorization of fruit and vegetable waste in a novel three-stage hybrid anaerobic digester for enhanced biogas production: Performance study and microbial community analysis. Biochem. Eng. J. 2024, 209, 109403. [Google Scholar] [CrossRef]

- Martinez-Mendoza, L.J.; Lebrero, R.; Munoz, R.; Garcia-Depraect, O. Influence of key operational parameters on biohydrogen production from fruit and vegetable waste via lactate-driven dark fermentation. Bioresour. Technol. 2022, 364, 128070. [Google Scholar] [CrossRef] [PubMed]

- Korai, M.S.; Noonari, A.A.; Ali, M.; Rabab, N.; Rasheed, R.; Solangi, Z.A.; Bhatti, Z.A. Anaerobic Biodegradability and Biomethanation Potential of Fruit-Vegetable Wastes at Sindh, Pakistan. Pak. J. Anal. Environ. Chem. 2023, 24, 145–154. [Google Scholar] [CrossRef]

- Zaidi, Z.; Manchanda, A.; Sharma, A.; Shehnaz; Choudhry, A.; Sajid, M.; Khan, S.A.; Khan, A.; Chaudhry, S.A. Adsorptive removal of Methylene blue using fruit waste activated carbon and its binary metal oxide nanocomposite. Chem. Eng. J. Adv. 2023, 16, 100571. [Google Scholar] [CrossRef]

- Vaishna, V.R.; Sam, J.; Nair, R.R.; Akhina, M.K.; Haritha, K.; Prathish, K.P. Sustainable utilization of nutmeg fruit rind waste for Cr(VI) removal and resource recovery from industrial wastewater: An integrated approach. J. Environ. Chem. Eng. 2023, 11, 111495. [Google Scholar] [CrossRef]

- Negroiu, M.; Turcanu, A.A.; Matei, E.; Rapa, M.; Covaliu, C.I.; Predescu, A.M.; Pantilimon, C.M.; Coman, G.; Predescu, C. Novel Adsorbent Based on Banana Peel Waste for Removal of Heavy Metal Ions from Synthetic Solutions. Materials 2021, 14, 3946. [Google Scholar] [CrossRef]

- Țurcanu, A.A.; Matei, E.; Râpă, M.; Predescu, A.M.; Berbecaru, A.C.; Coman, G.; Predescu, C. Walnut Shell Biowaste Valorization via HTC Process for the Removal of Some Emerging Pharmaceutical Pollutants from Aqueous Solutions. Int. J. Mol. Sci. 2022, 23, 11095. [Google Scholar] [CrossRef]

- Zin, M.M.; Anucha, C.B.; Banvölgyi, S. Recovery of Phytochemicals via Electromagnetic Irradiation (Microwave-Assisted-Extraction): Betalain and Phenolic Compounds in Perspective. Foods 2020, 9, 918. [Google Scholar] [CrossRef]

- Nath, P.C.; Ojha, A.; Debnath, S.; Neetu, K.; Bardhan, S.; Mitra, P.; Sharma, M.; Sridhar, K.; Nayak, P.K. Recent advances in valorization of pineapple (Ananas comosus) processing waste and by-products: A step towards circular bioeconomy. Trends Food Sci. Technol. 2023, 136, 100–111. [Google Scholar] [CrossRef]

- Dhalaria, R.; Verma, R.; Kumar, D.; Puri, S.; Tapwal, A.; Kumar, V.; Nepovimova, E.; Kuca, K. Bioactive Compounds of Edible Fruits with Their Anti-Aging Properties: A Comprehensive Review to Prolong Human Life. Antioxidants 2020, 9, 1123. [Google Scholar] [CrossRef] [PubMed]

- Pistol, G.C.; Pertea, A.M.; Taranu, I. The Use of Fruit and Vegetable by-Products as Enhancers of Health Status of Piglets after Weaning: The Role of Bioactive Compounds from Apple and Carrot Industrial Wastes. Vet. Sci. 2024, 11, 15. [Google Scholar] [CrossRef] [PubMed]

- Tayengwa, T.; Mapiye, C. Citrus and Winery Wastes: Promising Dietary Supplements for Sustainable Ruminant Animal Nutrition, Health, Production, and Meat Quality. Sustainability 2018, 10, 3718. [Google Scholar] [CrossRef]

- Martí-Quijal, F.J.; Khubber, S.; Remize, F.; Tomasevic, I.; Roselló-Soto, E.; Barba, F.J. Obtaining Antioxidants and Natural Preservatives from Food By-Products through Fermentation: A Review. Fermentation 2021, 7, 106. [Google Scholar] [CrossRef]

- Santamarina, A.B.; Mesquita, L.M.; Casagrande, B.P.; Sertorio, M.N.; de Souza, D.V.; Mennitti, L.V.; Ribeiro, D.A.; Estadella, D.; Ventura, S.P.M.; de Rosso, V.V.; et al. Supplementation of carotenoids from peach palm waste (Bactris gasipaes) obtained with an ionic liquid mediated process displays kidney anti-inflammatory and antioxidant outcomes. Food Chem. -X 2022, 13, 100245. [Google Scholar] [CrossRef] [PubMed]

- Sharma, M.; Usmani, Z.; Gupta, V.K.; Bhat, R. Valorization of fruits and vegetable wastes and by-products to produce natural pigments. Crit. Rev. Biotechnol. 2021, 41, 535–563. [Google Scholar] [CrossRef] [PubMed]

- Carrillo, C.; Nieto, G.; Martínez-Zamora, L.; Ros, G.; Kamiloglu, S.; Munekata, P.E.S.; Pateiro, M.; Lorenzo, J.M.; Fernández-López, J.; Viuda-Martos, M.; et al. Novel Approaches for the Recovery of Natural Pigments with Potential Health Effects. J. Agric. Food Chem. 2022, 70, 6864–6883. [Google Scholar] [CrossRef]

- Lombardelli, C.; Benucci, I.; Mazzocchi, C.; Esti, M. Green Enzymatic Recovery of Functional Bioactive Compounds from Unsold Vegetables: Storability and Potential Health Benefits. Appl. Sci. 2022, 12, 12249. [Google Scholar] [CrossRef]

- Lombardelli, C.; Benucci, I.; Mazzocchi, C.; Esti, M. A Novel Process for the Recovery of Betalains from Unsold Red Beets by Low-Temperature Enzyme-Assisted Extraction. Foods 2021, 10, 236. [Google Scholar] [CrossRef]

- Rosa, M.E.; Ferreira, A.M.; Neves, C.; Almeida, M.R.; Barros, R.; Cristovao, A.C.; Sousa, A.C.A.; Reis, P.M.; Rebelo, L.P.N.; Esperança, J.; et al. Valorisation of red beet waste: One-step extraction and separation of betalains and chlorophylls using thermoreversible aqueous biphasic systems. Green Chem. 2023, 25, 1852–1864. [Google Scholar] [CrossRef]

- Phan, K.; Raes, K.; Van Speybroeck, V.; Roosen, M.; De Clerck, K.; De Meester, S. Non-food applications of natural dyes extracted from agro-food residues: A critical review. J. Clean. Prod. 2021, 301, 126920. [Google Scholar] [CrossRef]

- Tiwari, S.; Yawale, P.; Upadhyay, N. Carotenoids: Extraction strategies and potential applications for valorization of under-utilized waste biomass. Food Biosci. 2022, 48, 101812. [Google Scholar] [CrossRef]

- Kainat, S.; Arshad, M.S.; Khalid, W.; Zubair Khalid, M.; Koraqi, H.; Afzal, M.F.; Noreen, S.; Aziz, Z.; Al-Farga, A. Sustainable novel extraction of bioactive compounds from fruits and vegetables waste for functional foods: A review. Int. J. Food Prop. 2022, 25, 2457–2476. [Google Scholar] [CrossRef]

- Ben-Othman, S.; Joudu, I.; Bhat, R. Bioactives from Agri-Food Wastes: Present Insights and Future Challenges. Molecules 2020, 25, 510. [Google Scholar] [CrossRef] [PubMed]

- Spiridon, I.; Darie-Nita, R.N.; Hitruc, G.E.; Ludwiczak, J.; Spiridon, I.A.C.; Niculaua, M. New opportunities to valorize biomass wastes into green materials. J. Clean. Prod. 2016, 133, 235–242. [Google Scholar] [CrossRef]

- Spiridon, I.; Anghel, N.C.; Darie-Nita, R.N.; Iwanczuk, A.; Ursu, R.G.; Spiridon, I.A. New composites based on starch/Ecoflex®/biomass wastes: Mechanical thermal, morphological and antimicrobial properties. Int. J. Biol. Macromol. 2020, 156, 1435–1444. [Google Scholar] [CrossRef] [PubMed]

- Syed, R.; Ding, H.H.; Hui, D.F.; Wu, Y. Physicochemical and functional properties of pigeon pea (Cajanus cajan) protein and non-starch polysaccharides. Bioact. Carbohydr. Diet. Fibre 2022, 28, 100317. [Google Scholar] [CrossRef]

- Kaur, N.; Chavan, A. Production of Single-Cell Protein from Fruit and Vegetable Waste Using an Isolated Strain of Lactobacillus sp. Ind. Biotechnol. 2022, 18, 304–313. [Google Scholar] [CrossRef]

- Hoorfar, J. Global Safety of Fresh Produce: A Handbook of Best Practice, Innovative Commercial Solutions and Case Studies; Woodhead Publishing: Sawston, UK, 2014; Volume 260, pp. 1–436. [Google Scholar]

- Kumar, S.; Reddy, A.R.L.; Basumatary, I.B.; Nayak, A.; Dutta, D.; Konwar, J.; Das Purkayastha, M.; Mukherjee, A. Recent progress in pectin extraction and their applications in developing films and coatings for sustainable food packaging: A review. Int. J. Biol. Macromol. 2023, 239, 124281. [Google Scholar] [CrossRef]

- Alexander Mendez, D.; Jose Fabra, M.; Gomez-Mascaraque, L.; Lopez-Rubio, A.; Martinez-Abad, A. Modelling the Extraction of Pectin towards the Valorisation of Watermelon Rind Waste. Foods 2021, 10, 738. [Google Scholar] [CrossRef]

- Mada, T.; Duraisamy, R.; Guesh, F. Optimization and characterization of pectin extracted from banana and papaya mixed peels using response surface methodology. Food Sci. Nutr. 2022, 10, 1222–1238. [Google Scholar] [CrossRef] [PubMed]

- Otalora Gonzalez, C.M.; De’Nobili, M.D.; Rojas, A.M.; Basanta, M.F.; Gerschenson, L.N. Development of functional pectin edible films with fillers obtained from red cabbage and beetroot. Int. J. Food Sci. Technol. 2021, 56, 3662–3669. [Google Scholar] [CrossRef]

- Sarangi, P.K.; Mishra, S.; Mohanty, P.; Singh, P.K.; Srivastava, R.K.; Pattnaik, R.; Adhya, T.K.; Das, T.; Lenka, B.; Gupta, V.K.; et al. Food and fruit waste valorisation for pectin recovery: Recent process technologies and future prospects. Int. J. Biol. Macromol. 2023, 235, 123929. [Google Scholar] [CrossRef] [PubMed]

- Bhatia, L.; Sarangi, P.K.; Singh, A.K.; Srivastava, R.K.; Chandel, A.K. Pre-, Pro-, and Postbiotics Development from Vegetable, Fruit, and Lignocellulosic Biomass: A Perspective. Food Biosci. 2024, 61, 104589. [Google Scholar] [CrossRef]

- Freire, M.O.D.; Neto, J.; Lemos, D.E.D.; de Albuquerque, T.M.R.; Garcia, E.F.; de Souza, E.L.; Alves, J.L.D. Limosilactobacillus fermentum Strains as Novel Probiotic Candidates to Promote Host Health Benefits and Development of Biotherapeutics: A Comprehensive Review. Probiotics Antimicrob. Proteins 2024. [Google Scholar] [CrossRef]

- Das, S.; Kalyani, M.I. From trash to treasure: Review on upcycling of fruit and vegetable wastes into starch based bioplastics. Prep. Biochem. Biotechnol. 2023, 53, 713–727. [Google Scholar] [CrossRef] [PubMed]

- Kringel, D.H.; Dias, A.R.G.; Zavareze, E.d.R.; Gandra, E.A. Fruit Wastes as Promising Sources of Starch: Extraction, Properties, and Applications. Starch-Starke 2020, 72. [Google Scholar] [CrossRef]

- Jayanthi, B.; Vinoth, S.; Hariharan, M.; Raja, R.K.; Kamaraj, C.; Narayanan, M. Valorization of agro-industry wastes for nanocellulose fabrication and its multifunctional applications. Biocatal. Agric. Biotechnol. 2024, 57, 103124. [Google Scholar] [CrossRef]

- Langyan, S.; Yadava, P.; Khan, F.N.; Dar, Z.A.; Singh, R.; Kumar, A. Sustaining Protein Nutrition Through Plant-Based Foods. Front. Nutr. 2022, 8, 772573. [Google Scholar] [CrossRef]

- Fang, B.C.; Peng, Z.C.; Chen, B.C.; Rao, J.J. Unconventional sources of vegetable proteins: Technological properties. Curr. Opin. Food Sci. 2024, 57, 101150. [Google Scholar] [CrossRef]

- Luthria, D.L.; Lu, Y.J.; John, K.M.M. Bioactive phytochemicals in wheat: Extraction, analysis, processing, and functional properties. J. Funct. Foods 2015, 18, 910–925. [Google Scholar] [CrossRef]

- Pereira, J.A.M.; Berenguer, C.V.; Andrade, C.F.P.; Camara, J.S. Unveiling the Bioactive Potential of Fresh Fruit and Vegetable Waste in Human Health from a Consumer Perspective. Appl. Sci. 2022, 12, 2747. [Google Scholar] [CrossRef]

- Tedesco, D.E.A.; Conti, C.; Lovarelli, D.; Biazzi, E.; Bacenetti, J. Bioconversion of fruit and vegetable waste into earthworms as a new protein source: The environmental impact of earthworm meal production. Sci. Total Environ. 2019, 683, 690–698. [Google Scholar] [CrossRef] [PubMed]

- Cappellozza, S.; Leonardi, M.G.; Savoldelli, S.; Carminati, D.; Rizzolo, A.; Cortellino, G.; Terova, G.; Moretto, E.; Badaile, A.; Concheri, G.; et al. A First Attempt to Produce Proteins from Insects by Means of a Circular Economy. Animals 2019, 9, 278. [Google Scholar] [CrossRef] [PubMed]

- Zahid, M.; Khalid, S.; Raana, S.; Amin, S.; Javaid, H.; Arshad, R.; Jahangeer, A.; Ahmad, S.; Hassan, S.A. Unveiling the anti-oxidative potential of fruits and vegetables waste in prolonging the shelf stability of vegetable oils. Future Foods 2024, 10, 100328. [Google Scholar] [CrossRef]

- Li, Y.S.; Yang, J.X.; Sun, L.P.; Liu, B.Z.; Li, H.; Peng, L.C. Crosslinked fish scale gelatin/alginate dialdehyde functional films incorporated with carbon dots derived from pomelo peel waste for active food packaging. Int. J. Biol. Macromol. 2023, 253, 127290. [Google Scholar] [CrossRef]

- Duque-Acevedo, M.; Belmonte-Urena, L.J.; Batlles-delaFuente, A.; Camacho-Ferre, F. Management of Agricultural Waste Biomass: A case study of Fruit and Vegetable Producer Organizations in southeast Spain. J. Clean. Prod. 2022, 359, 131972. [Google Scholar] [CrossRef]

- Latif, M.B.; Islam, M.A.; Hossain, M.S.; Aurpa, S.S. Effect of Sludge Content on the Decomposition of Different Types of Food Waste. Sustainability 2023, 15, 2782. [Google Scholar] [CrossRef]

- Azevedo, A.; Lapa, N.; Moldao, M.; Duarte, E. Opportunities and challenges in the anaerobic co-digestion of municipal sewage sludge and fruit and vegetable wastes: A review. Energy Nexus 2023, 10, 100202. [Google Scholar] [CrossRef]

- Younas, F.; Younas, S.; Bibi, I.; Farooqi, Z.U.R.; Hameed, M.A.; Mohy-Ud-Din, W.; Shehzad, M.T.; Hussain, M.M.; Shakil, Q.; Shahid, M.; et al. A critical review on the separation of heavy metal(loid)s from the contaminated water using various agricultural wastes. Int. J. Phytoremediation 2024, 26, 349–368. [Google Scholar] [CrossRef] [PubMed]

- Aguilar-Rosero, J.; Urbina-López, M.E.; Rodríguez-González, B.E.; León-Villegas, S.X.; Luna-Cruz, I.E.; Cárdenas-Chávez, D.L. Development and Characterization of Bioadsorbents Derived from Different Agricultural Wastes for Water Reclamation: A Review. Appl. Sci. 2022, 12, 2740. [Google Scholar] [CrossRef]

- Karim, A.; Raji, Z.; Karam, A.; Khalloufi, S. Valorization of Fibrous Plant-Based Food Waste as Biosorbents for Remediation of Heavy Metals from Wastewater-A Review. Molecules 2023, 28, 4205. [Google Scholar] [CrossRef] [PubMed]

- Patil, H.; Patil, Y.; Maiti, S.; Athalye, A.; Adivarekar, R.V. Valorization of fruit vegetable waste for semi-synthetic leather. Iran. Polym. J. 2024, 33, 597–605. [Google Scholar] [CrossRef]

- Benny, N.; Shams, R.; Dash, K.K.; Pandey, V.K.; Bashir, O. Recent trends in utilization of citrus fruits in production of eco-enzyme. J. Agric. Food Res. 2023, 13, 100657. [Google Scholar] [CrossRef]

- Martins, R.; Barbosa, A.; Advinha, B.; Sales, H.; Pontes, R.; Nunes, J. Green Extraction Techniques of Bioactive Compounds: A State-of-the-Art Review. Processes 2023, 11, 2255. [Google Scholar] [CrossRef]

- Kumar, K.; Srivastav, S.; Sharanagat, V.S. Ultrasound assisted extraction (UAE) of bioactive compounds from fruit and vegetable processing by-products: A review. Ultrason. Sonochem. 2021, 70, 105325. [Google Scholar] [CrossRef] [PubMed]

- Dash, D.R.; Pathak, S.S.; Pradhan, R.C. Improvement in novel ultrasound-assisted extraction technology of high value-added components from fruit and vegetable peels. J. Food Process Eng. 2021, 44, 13658. [Google Scholar] [CrossRef]

- Kaur, B.; Panesar, P.S.; Anal, A.K. Standardization of ultrasound assisted extraction for the recovery of phenolic compounds from mango peels. J. Food Sci. Technol. -Mysore 2022, 59, 2813–2820. [Google Scholar] [CrossRef]

- Biswas, R.; Sarkar, A.; Alam, M.; Roy, M.; Hasan, M.M.M. Microwave and ultrasound-assisted extraction of bioactive compounds from Papaya: A sustainable green process. Ultrason. Sonochem. 2023, 101, 106677. [Google Scholar] [CrossRef]

- Ray, A.; Dubey, K.K.; Marathe, S.J.; Singhal, R. Supercritical fluid extraction of bioactives from fruit waste and its therapeutic potential. Food Biosci. 2023, 52, 102418. [Google Scholar] [CrossRef]

- Ubeyitogullari, A.; Ciftci, O.N. Enhancing the bioaccessibility of lycopene from tomato processing byproducts via supercritical carbon dioxide extraction. Curr. Res. Food Sci. 2022, 5, 553–563. [Google Scholar] [CrossRef]

- Vigano, J.; Brumer, I.Z.; de Campos Braga, P.A.; da Silva, J.K.; Marostica Junior, M.R.; Reyes Reyes, F.G.; Martinez, J. Pressurized liquids extraction as an alternative process to readily obtain bioactive compounds from passion fruit rinds. Food Bioprod. Process. 2016, 100, 382–390. [Google Scholar] [CrossRef]

- Pagano, I.; Piccinelli, A.L.; Celano, R.; Campone, L.; Gazzerro, P.; Russo, M.; Rastrelli, L. Pressurized hot water extraction of bioactive compounds from artichoke by-products. Electrophoresis 2018, 39, 1899–1907. [Google Scholar] [CrossRef]

- Gumustepe, L.; Kurt, N.; Aydin, E.; Ozkan, G. Comparison of ohmic heating- and microwave-assisted extraction techniques for avocado leaves valorization: Optimization and impact on the phenolic compounds and bioactivities. Food Sci. Nutr. 2023, 11, 5609–5620. [Google Scholar] [CrossRef]

- Saad, N.; Louvet, F.; Tarrade, S.; Meudec, E.; Grenier, K.; Landolt, C.; Ouk, T.S.; Bressollier, P. Enzyme-Assisted Extraction of Bioactive Compounds from Raspberry (Rubus idaeus L.) Pomace. J. Food Sci. 2019, 84, 1371–1381. [Google Scholar] [CrossRef] [PubMed]

- Pires, J.A.; Gomes, W.P.C.; Teixeira, N.N.; Melchert, W.R. Effect of drying methods on nutritional constitutes of fermented grape residue. J. Food Sci. Technol. -Mysore 2022, 59, 3458–3463. [Google Scholar] [CrossRef] [PubMed]

- Janiszewska-Turak, E.; Kolakowska, W.; Pobiega, K.; Gramza-Michalowska, A. Influence of Drying Type of Selected Fermented Vegetables Pomace on the Natural Colorants and Concentration of Lactic Acid Bacteria. Appl. Sci. 2021, 11, 7864. [Google Scholar] [CrossRef]

- Janiszewska-Turak, E.; Rybak, K.; Pobiega, K.; Nikodem, A.; Gramza-Michalowska, A. Sustainable Production and Characteristics of Dried Fermented Vegetables. Fermentation 2022, 8, 659. [Google Scholar] [CrossRef]

- Plazzotta, S.; Cottes, M.; Simeoni, P.; Manzocco, L. Evaluating the environmental and economic impact of fruit and vegetable waste valorisation: The lettuce waste study-case. J. Clean. Prod. 2020, 262, 121435. [Google Scholar] [CrossRef]

- Joensuu, K.; Harrison, E.; Hartikainen, H. What to Do with Food Waste? A Holistic Feasibility Framework to Evaluate Different Solutions. Sustainability 2022, 14, 3004. [Google Scholar] [CrossRef]

- More, P.R.; Jambrak, A.R.; Arya, S.S. Green, environment-friendly and sustainable techniques for extraction of food bioactive compounds and waste valorization. Trends Food Sci. Technol. 2022, 128, 296–315. [Google Scholar] [CrossRef]

| Designation Purpose | Process | Features | Ref. | |

|---|---|---|---|---|

| Food and Food Packaging | ||||

| Citrus peels | Pectocellulosic active food packaging films | Casting | Improved mechanical properties, easy recycling, rapid biodegradation, water stability, water vapor barrier properties, and antioxidant activity | [54] |

| Stem, peel, and rachis parts of the banana plant | Edible coatings of strawberry fruits | Dip-coating | Extension of the shelf-life by 6 days at 22 °C and 16 days at 4 °C | [55] |

| Carrot, leek, celery, and cabbage waste | Coloring flavoring agents, natural preservatives for reformulated processed foods | Hot air drying or freeze-drying | Stable powders with highly reduced water activity levels | [16] |

| Apple pomace | Pectin and phenolic compounds, pullulan, and single-cell protein | Extraction yields of pectin and phenolic were 28.37% and 3.42%, respectively; high antioxidant capacity demonstrated by DPPH, 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid (ABTS) and ferric ion reducing antioxidant potential (FRAP) tests | [56] | |

| Orange peel, apple pomace, beet pomace, ginseng residue, and corn steep liquor | Carbon sources for Euglena gracilis cultivation for beta-glucan production | Extraction for 40 min at a temperature of 121 °C and a pressure of 1.3 atm | 15 ± 1.1 g/L of glucose, sucrose, and fructose | [57] |

| Agriculture | ||||

| Plasticized PLA loaded with spinach stems (SS), tomato pomace (TP), and cocoa shells (CS) up to 30 wt% of each vegetable residue | Biodegradable agricultural mulch films | Twin-screws extruder; compression molding | The material has low water solubility (1–15 wt%) and moisture content (1–3 wt%), with a water vapor permeability up to 3 × 10−10 g s−1 m−1 Pa−1, comparable to that of Mater-Bi | [58] |

| Vegetable wastes include rotten peels, stems of spinach, and scrapped portions of FVW | Organic fertilizer | Aerobic solid-state fermentation | Solid organic fertilizer leads to effective growth of Solanum lycopersicum and Capsicum annum crops | [59] |

| Tomato, Chinese cabbage (Brassica rapa L. ssp. pekinensis), kale (Brassica oleracea L. var. acephala DC.), apple (Malus pumila Mill.), banana (Musa nana Lour.), and lettuce (Lactuca sativa Linn.) waste | Liquid organic fertilizer | Hydrothermal treatment (temperature of 165 °C and retention time of 45 min) and biological treatments | Hydrolyzed liquid met the requirements of regulating fertilizing products | [60] |

| Cauliflower and cabbage wastes; banana peels | Biochar for soil amendment | Fifty grams of each feedstock are pyrolyzed at different temperatures (300, 400, 500 and 600 °C) | The biochar yield decreased as the pyrolysis temperature increased; pH of 7.62 ± 0.03; cation exchange capacity (CEC) in the range of 37 to 60 cmolc kg−1 | [61] |

| Energy | ||||

| Fruit and vegetable peels | Hydrogen and biochar | Fermentation/pyrolysis | H2 production for vegetable waste such as spinach, pea, and tomato of 1.61 ± 0.36, 6.93 ± 0.78, 5.34 ± 0.30 mmol, respectively, and fruit peels like banana and orange of 7.48 ± 0.53 and 1.03 ± 0.16 mmol, respectively; maximal chemical oxygen demand (COD) removal efficiency of 56.2 ± 4.6% for a mixture of pea, banana, tomato, and orange peels | [62] |

| Mixture of shredded FVW | Biogas | Three-stage hybrid AD system comprises a first-stage semi-anaerobic suspended-growth hydrolytic reactor, a second-stage strictly anaerobic down-flow hybrid acidogenic reactor, and a third-stage up-flow hybrid methanogenic reactor | A maximum CH4 yield of 484 mL/g CODremoved and a bio-H2 yield of 54.5 mL/g chemical oxygen demand (CODremoved) from the methanogenic stage; a maximum biogas yield of 781.8 mL/g CODremoved | [63] |

| FVW | Biohydrogen | Lactate-driven dark fermentation | H2 yield of 49.5 NmL/g volatile solids (VSfed) at a remarkable rate of 976.4 NmL H2/L-h was achieved at pH 7; 5% total solids (TS) and 1800 mg initial cell biomass concentrations (VSS)/L | [64] |

| Methane | Anaerobic digestion process | 258–367 NmL/gm volatile solids (VS) for fruit waste; 274–407 NmL/gm VS for vegetable waste | [65] | |

| Water Purification | ||||

| Fruit waste-derived activated carbon, (FWAC) and its binary metal oxide hybrid nanocomposite (Fe-Ni/FWAC) | Methylene blue removal | Carbonization in a muffle furnace at 400 °C for 2 h; precipitation and calcination | The adsorption capacities of the FWAC were 204.082, 217.391, and 312.5 mg/g, while those of the Fe-Ni/FWAC were found to be 256.41, 303.03, and 370.37 mg/g at 303, 313, and 323 K, respectively | [66] |

| Nutmeg fruit rind waste | Removal of hexavalent chromium (Cr(VI)) from real textile wastewater | Drying at 70 °C for 24 h; baking at 103 °C; powdering and sieving as the particle size was less than 250 µm | The adsorption capacity 9.35 mg/g at 0.1 g L−1 dosage sorbent and 10 mg L−1 concentration of sorbate | [67] |

| Banana peel waste incorporated into sodium alginate | Heavy metal removal from synthetic solutions | Drying in an oven at 140 °C for 4 h and two-stage pyrolysis in a calcination furnace; microbead formation in 1% sodium alginate | 100% removal of Cr, Cu, Pb, and Zn | [68] |

| Walnut shell biowaste | Removal of paracetamol and methylene blue | Hydrothermal carbonization | Removal efficiencies of 99.3% for methylene blue and 60% for paracetamol | [69] |

| Extraction Method | Advantages | Barriers | Ref. |

|---|---|---|---|

| Ultrasound-assisted extraction (UAE) |

|

| [5,18,19] |

| A pretreatment step including blanching, drying, and milling is necessary | [118] | ||

| A defatting step before drying and milling is necessary Direct contact of ultrasonic horns with the fruit and vegetables waste should be avoided during extraction | |||

| Prevents the thermal degradation of heat-sensible bioactive components due to low-temperature extraction | Industrial application needs to be scaled up | [119] | |

| Microwave-assisted extraction (MWAE) |

|

| [20] |

| Pressurized hot water extraction (PHWE) |

|

| [20,21,22,23] |

| Pressurized liquid extraction (PLE) |

|

| [5,20,24] |

| Supercritical fluid extraction (SFE) |

| The presence of humidity, coupled with contaminants, in laboratory-grade CO2 could impede the extraction process | [5,20] |

| Pulsed electric field-assisted extraction (PEFAE) |

| There is a need to adapt to each type of sample, as the process parameters are dependent on the electrical conductivity and texture of the raw material | [5] |

| Ohmic heating-assisted extraction (OHAE) |

| The selection of the most appropriate food waste streams is an essential step | [25,26] |

| Enzyme-assisted extraction (EAE) |

| A high cost of enzymes relative to volume and a high dependence of enzymes on pH and temperature | [5,79] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Râpă, M.; Darie-Niță, R.N.; Coman, G. Valorization of Fruit and Vegetable Waste into Sustainable and Value-Added Materials. Waste 2024, 2, 258-278. https://doi.org/10.3390/waste2030015

Râpă M, Darie-Niță RN, Coman G. Valorization of Fruit and Vegetable Waste into Sustainable and Value-Added Materials. Waste. 2024; 2(3):258-278. https://doi.org/10.3390/waste2030015

Chicago/Turabian StyleRâpă, Maria, Raluca Nicoleta Darie-Niță, and George Coman. 2024. "Valorization of Fruit and Vegetable Waste into Sustainable and Value-Added Materials" Waste 2, no. 3: 258-278. https://doi.org/10.3390/waste2030015

APA StyleRâpă, M., Darie-Niță, R. N., & Coman, G. (2024). Valorization of Fruit and Vegetable Waste into Sustainable and Value-Added Materials. Waste, 2(3), 258-278. https://doi.org/10.3390/waste2030015