Prediction of Heat Transfer During Condensation in Annuli

Abstract

1. Introduction

2. Previous Work

2.1. Experimental Studies

| Source | Dout/Din mm/mm (Flow Direction) | Dhyd (DHP) mm | Fluid | pr | G kg·m−2 s−1 | x | ReLT | WeGT | FrLT | Are Analyzable Data Provided? |

|---|---|---|---|---|---|---|---|---|---|---|

| Li et al. [8] | 17/12.7 (H) | 4.3 (10.5) | R-410A | 0.4347 0.5542 | 75 225 | 0.2 0.8 | 8830 26482 | 76 693 | 0.15 1.3 | Yes |

| Borchmann [9] | 38/ 31.2 (H) | 6.8 (15.0) | R-11 | 0.0373 | 29 286 | 0.55 1.0 | 1245 12278 | 39 3747 | 0.006 0.59 | Yes |

| He et al. [10] | 22.0/16.0 (H) | 6.0 (14.2) | R-410A | 0.5542 | 54 96 | 0.12 0.76 | 8628 15333 | 55 176 | 0.055 0.175 | Yes |

| Tang et al. [11] | 26.0/19.05 (H) | 6.95 (16.4) | R-134A | 0.2846 | 50 100 | 0.50 0.60 | 5436 10844 | 55 221 | 0.029 0.116 | Yes |

| 25.0/19.05 (H) | 5.9 (13.7) | R-134A | 0.2846 | 52 108 | 0.5 | 4746 9781 | 51 218 | 0.038 0.160 | Yes | |

| Wang et al. [12]) | 26.0/15.8 (H) | 10.2 (27.0) | R-11 | 0.059 | 13 103 | 0.5 | 1151 9198 | 8 538 | 0.00084 538 | Yes |

| Chen et al. [13] | 17.0/12.7 (H) | 4.3 (10.1) | R-410 | 0.5542 | 38 227 | 0.45 | 4255 25588 | 19 706 | 0.038 1.36 | Yes |

| R-22 | 0.3453 | 52 247 | 0.45 | 4004 18985 | 29 649 | 0.053 1.2 | Yes | |||

| 25.0/12.7 (H) | 12.3 (38.1) | R-410 | 0.5542 | 9 56 | 0.45 0.65 | 3692 24110 | 3 129 | 0.00067 0.029 | Yes | |

| R-22 | 0.3453 | 18 41 | 0.45 | 3896 11811 | 6 52 | 0.0012 0.011 | Yes | |||

| Miropoloskiy et al. [14] | 21.7/18.0 (VD) | 3.7 (8.16) | Water | 0.0361 0.4523 | 100 600 | 0.02 0.99 | 5115 42884 | 56 805 | 0.34 14.7 | Yes |

| Ruzaikin et al. [7] | 8.0/6.0 (H) | 2.0 (4.7) | NH3 | 0.1609 0.2593 | 80 200 | 0.13 0.78 | 1613 3707 | 52 359 | 1.1 6.3 | Yes |

| 11.0/6.0 (H) | 5.0 (14.2) | 0.1221 0.2032 | 41 122 | 0.09 0.80 | 1728 6151 | 44 300 | 0.100 0.987 | Yes | ||

| Cavallini et al. [2] | 38.5/24.0 (VD) | 14.5 (37.8) | R-11 | 0.0236 0.0329 | 58 187 | 0.47 1.0 | No | |||

| R-113 | 0.0295 0.0410 | 63 223 | 0.11 1.0 | No | ||||||

| Hashizume [6] | 25.0/15.88 (H) | 9.12. (23.4) | R-22 | 0.2710 0.3458 | No |

2.2. Correlations

3. Data Analysis

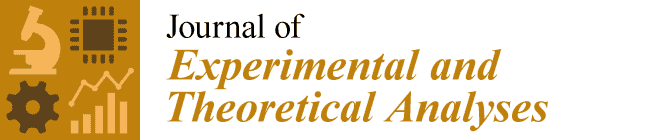

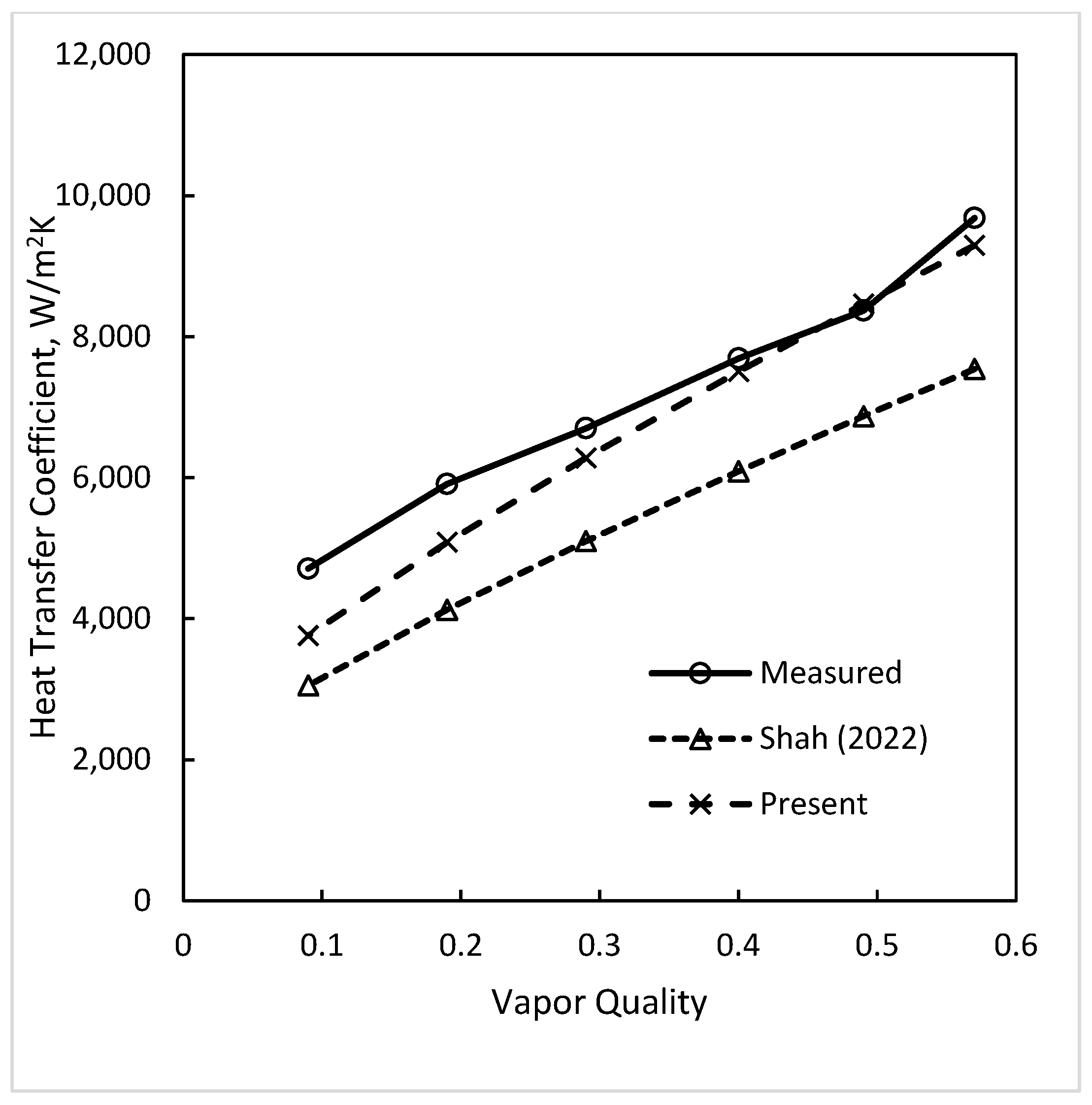

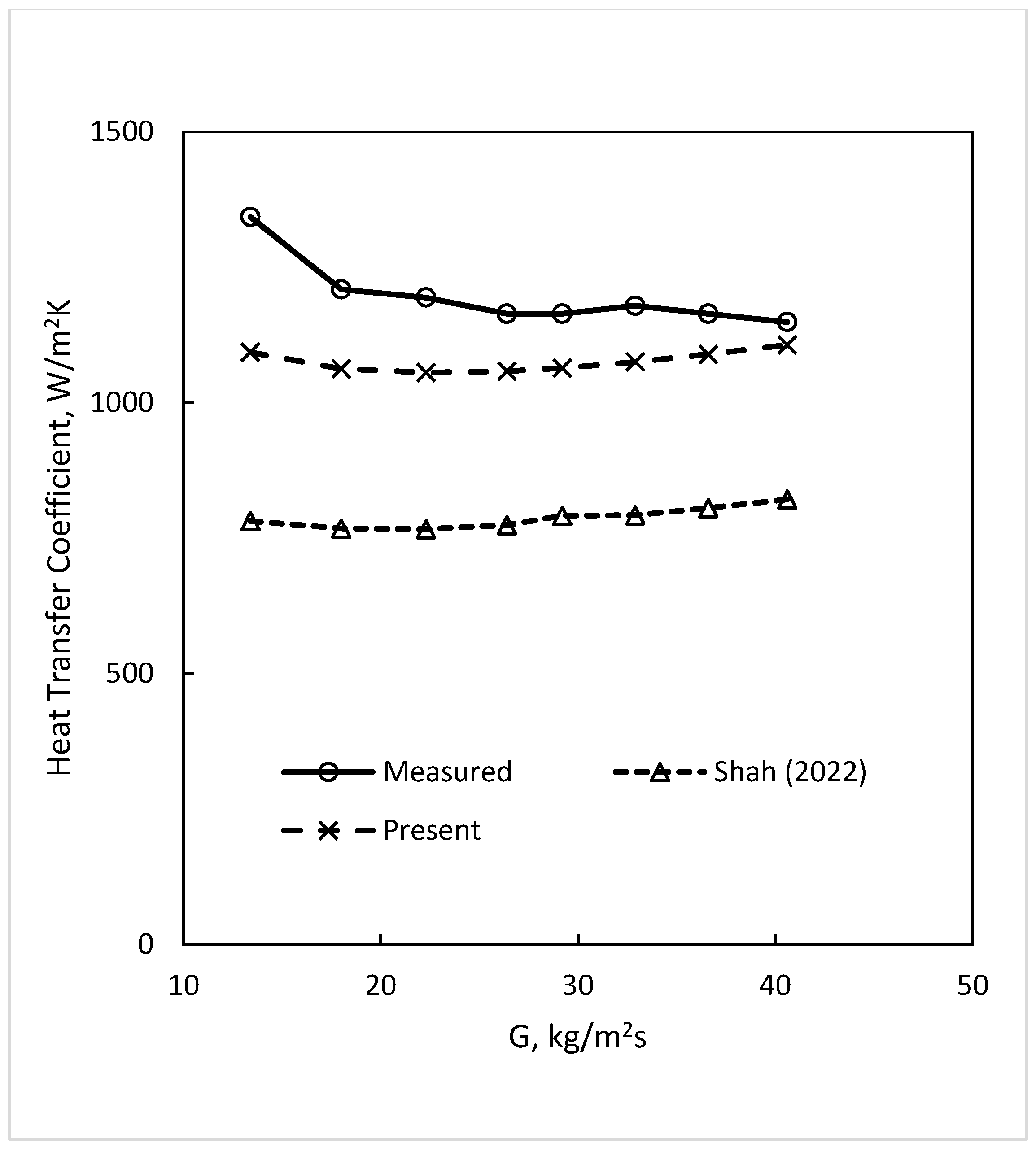

3.1. Comparison with Correlations for Tubes

3.1.1. Calculation Methodology

3.1.2. Results of Data Analysis

3.2. Development of Improved/New Correlation

3.2.1. First Approach

3.2.2. Second Approach

3.2.3. Third Approach

3.2.4. Selected New Correlation

4. Discussion

4.1. Accuracy of Test Data

4.2. Effect of Surface Tension, Mini/Macro Channel Boundary

4.3. Design Recommendation

5. Conclusions

- The literature on heat transfer during condensation in annuli was surveyed. It was found that there is no well-verified method for the prediction of heat transfer in annuli.

- Analyzable data were found from eight sources, all for condensation on the inner tube. Those were compared to general correlations which had been verified with a wide range of data for condensation in tubes, using the equivalent diameter recommended by them for partially cooled channels. Considering all data, none of them gave good agreement, the best being the Shah [3] correlation with MAD of 25.3%.

- A new correlation was developed by modifying the Shah (3) correlation. It gave a MAD of 19.2%. The MAD of other correlations were much higher. The data correlated included water, ammonia, and halocarbon refrigerants in vertical and horizontal annuli over a considerable range of flow rate and reduced pressure.

- There is need for more test data to cover a wider range of conditions, especially very small annular gaps, to further verify and improve the new correlation. Data are also needed for annuli in which condensation occurs on the outer tube or on both tubes, and on flow directions other than horizontal and vertically downwards.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AD | Average deviation, (-) |

| Bd | Bond number, (-) |

| Co | Confinement number, (-) |

| D | diameter of tube, m |

| DHP | equivalent diameter based on perimeter with heat transfer, m |

| DHYD | hydraulic equivalent diameter, m |

| DIN | outside diameter of the inner tube of annulus, m |

| DOUT | inside diameter of the outer tube of annulus, m |

| Eo | Eotvos number, (-) |

| FrLT | Froude number, (-) |

| G | total mass flux (liquid + vapor), kg m−2 s−1 |

| g | acceleration due to gravity, m s−2 |

| H | horizontal |

| h | heat transfer coefficient, W m−2 K−1 |

| hI | heat transfer coefficient given by Equation (6), W m−2 K−1 |

| hLS | heat transfer coefficient assuming liquid phase flowing alone in the tube, Wm−2 K−1 |

| hLT | heat transfer coefficient with total mass flowing as liquid, W m−2 K−1 |

| hNu | heat transfer coefficient given by Equation(7), the Nusselt equation, W m−2 K−1 |

| hTP | two-phase heat transfer coefficient, W m−2 K−1 |

| Jg | dimensionless vapor velocity defined by Equation (11) |

| k | thermal conductivity, W m−1 K−1 |

| MAD | mean absolute deviation, (-) |

| N | number of data points, (-) |

| p | pressure, Pa |

| pc | critical pressure, Pa |

| pr | reduced pressure = p/pc, (-) |

| Pr | Prandtl number, (-) |

| ReLS | Reynolds number assuming liquid phase flowing alone, = G (1 − x)DμL−1, (-) |

| ReLT | Reynolds number for all mass flowing as liquid = GDμL−1, (-) |

| T | Temperature, K |

| TSAT | saturation temperature, oC |

| Tw | wall temperature, oC |

| ΔT | = (TSAT−Tw), K |

| WeGT | Weber number for all mass flowing as vapor, defined by Equation (12), (-) |

| VD | vertically downward |

| x | vapor quality, (-) |

| Z | Shah’s correlating parameter defined by Equation (3), (-) |

| Greek | |

| μ | dynamic viscosity, Pa·s |

| ρ | density, kg m−3 |

| ∑ | Mathematical symbol for summation |

| σ | Surface tension, Nm−1 |

| Subscripts | |

| G | vapor |

| L | liquid |

References

- Shah, M.M. CHART correlation for saturated boiling heat transfer; equations and further study. ASHRAE Trans. 1982, 88, 165–196. [Google Scholar]

- Cavallini, A.; Frizzeri, S.; Rossetto, L. Condensation of refrigerants inside annuli. In Proceedings of the International Heat Transfer Conference, Munich, Germany, 6–10 September 1982; pp. 45–51. [Google Scholar] [CrossRef]

- Shah, M.M. Improved correlation for heat transfer during condensation in mini and macrochannels. Int. J. Heat Mass Transf. 2022, 194, 123069. [Google Scholar] [CrossRef]

- Shah, M.M. Comprehensive correlations for heat transfer during condensation in conventional and mini/micro channels in all orientations. Int. J. Refrig. 2016, 67, 22–41. [Google Scholar] [CrossRef]

- Shah, M.M. Two-Phase Heat Transfer; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Hashizume, K. Local two-phase heat transfer in double-tube heat exchanger. In Heat Exchangers Theory and Practice; Taborek, J., Hewitt, G.F., Afgan, N., Eds.; Hemisphere Publishing Corporation: New York, NY, USA, 1981. [Google Scholar]

- Ruzaikin, V.; Lukashov, I.; Breus, A.; Tsegelnyk, Y.; Plankovskyy, S. Ammonia condensation in the horizontal and vertical straight inner-grooved tubes and annuli. Int. J. Heat Mass Transf. 2024, 233, 126031. [Google Scholar] [CrossRef]

- Li, W.; Wang, J.; Guo, Y.; Gu, Z.; Wang, X.; Sun, Z.; Tang, W.; Kukulka, D.J. Two-phase heat transfer of R410A in annuli outside enhanced tubes with micro-fin and dimple. Int. J. Heat Mass Transf. 2021, 175, 121370. [Google Scholar] [CrossRef]

- Borchman, J. Heat transfer of high velocity vapors condensing in annuli. ASHRAE Trans. 1967, 73, VI. 2.1–VI. 2.13. [Google Scholar]

- He, Y.; Wu, J.; Li, W.; Dou, B.; Zheng, B.; Zhang, J.; Tang, W. Condensation heat transfer on the outer surface of a horizontal annulus having surface enhancement. Int. J. Heat Mass Transf. 2023, 201, 123588. [Google Scholar] [CrossRef]

- Tang, W.; Kulkuka, D.J.; Li, W.; Smith, R. Comparison of the evaporation and condensation heat transfer coefficients on the external surface of tubes in the annulus of a tube-in-tube heat exchanger. Energies 2020, 13, 952. [Google Scholar] [CrossRef]

- Wang, S.; Zhou, X.; Lin, P.; Deng, S.; Yang, X. Forced convective condensation of nonazeotropic refrigerant mixtures in horizontal annulus with petal shaped fin tubes. J. Therm. Sci. 1995, 4, 169–173. [Google Scholar] [CrossRef]

- Chen, J.X.; Chen, X.; He, Y.; Kukulka, D.; Li, W.; Liu, L.; Ma, L.; Smith, R.; Zhang, B. Investigation on flow condensation of refrigerant in annulus of smooth and enhanced tube-in-tube heat exchanger. Heat Mass Transf. 2019, 55, 223–234. [Google Scholar] [CrossRef]

- Miropoloskiy, Z.L.; Shneerova, R.I.; Teputnev, V.V. The influence of steam flowing and condensing in a duct on heat transfer to liquid film. In Proceedings of the International Heat Transfer Conference Digital Library, Toronto, ON, Canada, 7–11 August 1978; Volume 2, pp. 431–436. [Google Scholar]

- Shah, M.M. A general correlation for heat transfer during film condensation inside pipes. Int. J. Heat Mass Transf. 1979, 22, 547–556. [Google Scholar] [CrossRef]

- Ananiev, E.P.; Boyko, I.D.; Kruzhilin, G.N. Heat transfer in the presence of steam condensation in horizontal tubes. Int. Dev. Heat Transf. 1961, 2, 290–295. [Google Scholar]

- McAdams, W. Heat Transmission, 3rd ed.; McGraw-Hill: New York, NY, USA, 1954. [Google Scholar]

- Kim, S.; Mudawar, I. Universal approach to predicting heat transfer coefficient for condensing mini/micro-channel flow. Int. J. Heat Mass Transf. 2013, 56, 238–250. [Google Scholar] [CrossRef]

- Dorao, C.A.; Fernandino, M. Simple and general correlation for heat transfer during flow condensation inside plain pipes. Int. J. Heat Mass Transf. 2018, 122, 290–305. [Google Scholar] [CrossRef]

- Hosseini, S.H.; Moradkhani, M.A.; Valizadeh, M.; Zendehboudi, A.; Olazar, M. A general heat transfer correlation for flow condensation in single port mini and macro channels using genetic programming. Int. J. Refrig. 2020, 119, 376–389. [Google Scholar] [CrossRef]

- Moradkhani, M.A.; Hosseini, S.H.; Song, M. Robust and general predictive models for condensation heat transfer inside conventional and mini/micro channel heat exchangers. Appl. Therm. Eng. 2022, 201, 117737. [Google Scholar] [CrossRef]

- Nie, F.; Wang, H.; Zhao, Y.; Song, Q.; Yan, S.; Gong, M. A universal correlation for flow condensation heat transfer in horizontal tubes based on machine learning. Int. J. Therm. Sci. 2023, 184, 107994. [Google Scholar] [CrossRef]

- Marinheiro, M.M.; Marchetto, D.B.; Furlan, G.; de Souza Netto, A.T.; Tibiriçá, C.B. A robust and simple correlation for internal flow condensation. Appl. Therm. Eng. 2024, 236, 121811. [Google Scholar] [CrossRef]

- Moser, K.W.; Webb, R.L.; Na, B. A new equivalent Reynolds number model for condensation in smooth tubes. J. Heat Transf. 1998, 120, 410–416. [Google Scholar] [CrossRef]

- Traviss, D.; Rohsenow, W.; Baron, A. Forced-convection condensation inside tubes: A heat transfer equation for condenser design. ASHRAE Trans. 1973, 79, 157–165. [Google Scholar]

- Lemmon, E.W.; Huber, L.; McLinden, M.O. NIST Reference Fluid Thermodynamic and Transport Properties; REFPROP Version 9.1; NIST: Gaithersburg, MD, USA, 2013. [Google Scholar]

- Alferov, N.S.; Rybin, R.A. Heat transfer in annular channel. In Convective Heat Transfer in Two-Phase and One Phase Flows; Borishanskii, V.M., Paleev, I.I., Eds.; Israel Program for Scientific Translations: Jerusalem, Israel, 1969; pp. 115–134. [Google Scholar]

- Shah, M.M. Further study and development of correlations for heat transfer during subcooled boiling in plain channels. Fluids 2023, 8, 245. [Google Scholar] [CrossRef]

- Cavallini, A.; Del Col, D.; Doretti, L.; Matkovic, M.; Rossetto, L.; Zilio, C. Condensation in horizontal smooth tubes: A new heat transfer model for heat exchanger design. Heat Transf. Eng. 2006, 27, 31–38. [Google Scholar] [CrossRef]

- Kandlikar, S.G. Fundamental issues related to flow boiling in mini channels and micro channels. Exp. Therm. Fluid Sci. 2002, 26, 389–407. [Google Scholar] [CrossRef]

- Brauner, N.; Ullmann, A. The prediction of flow boiling maps in minichannels. In Proceedings of the 4th Japanese-European Two-Phase Flow Group Meeting, Kyoto, Japan, 24–28 September 2006. [Google Scholar]

- Kew, P.; Cornwell, K. Correlations for prediction of flow boiling heat transfer in small-diameter channels. Appl. Therm. Eng. 1997, 17, 705–715. [Google Scholar] [CrossRef]

- Ong, C.L.; Thome, J.R. Macro-to-microchannel transition in two-phase flow: Part 1—Two-phase flow patterns and film thickness measurements. Exp. Therm. Fluid Sci. 2011, 35, 37–47. [Google Scholar] [CrossRef]

- Shah, M.M. Applicability of correlations for boiling/condensing in macrochannels to minichannels. Heat Mass Transf. Res. J. 2018; 2, 20–32. [Google Scholar]

| Source | Dout/Din mm/mm (Orient.) | Dhyd (DHP) mm | Fluid | N | Deviation, % Mean Absolute Average | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Kim & Mudawar [18] | Ananiev et al. [16] | Dorao & Fernandino [19] | Hosseini et al. [20] | Moradkhani et al. [21] | Moser et al. [24] | Marinheiro et al. [23] | Shah [3] | New Correlation | |||||

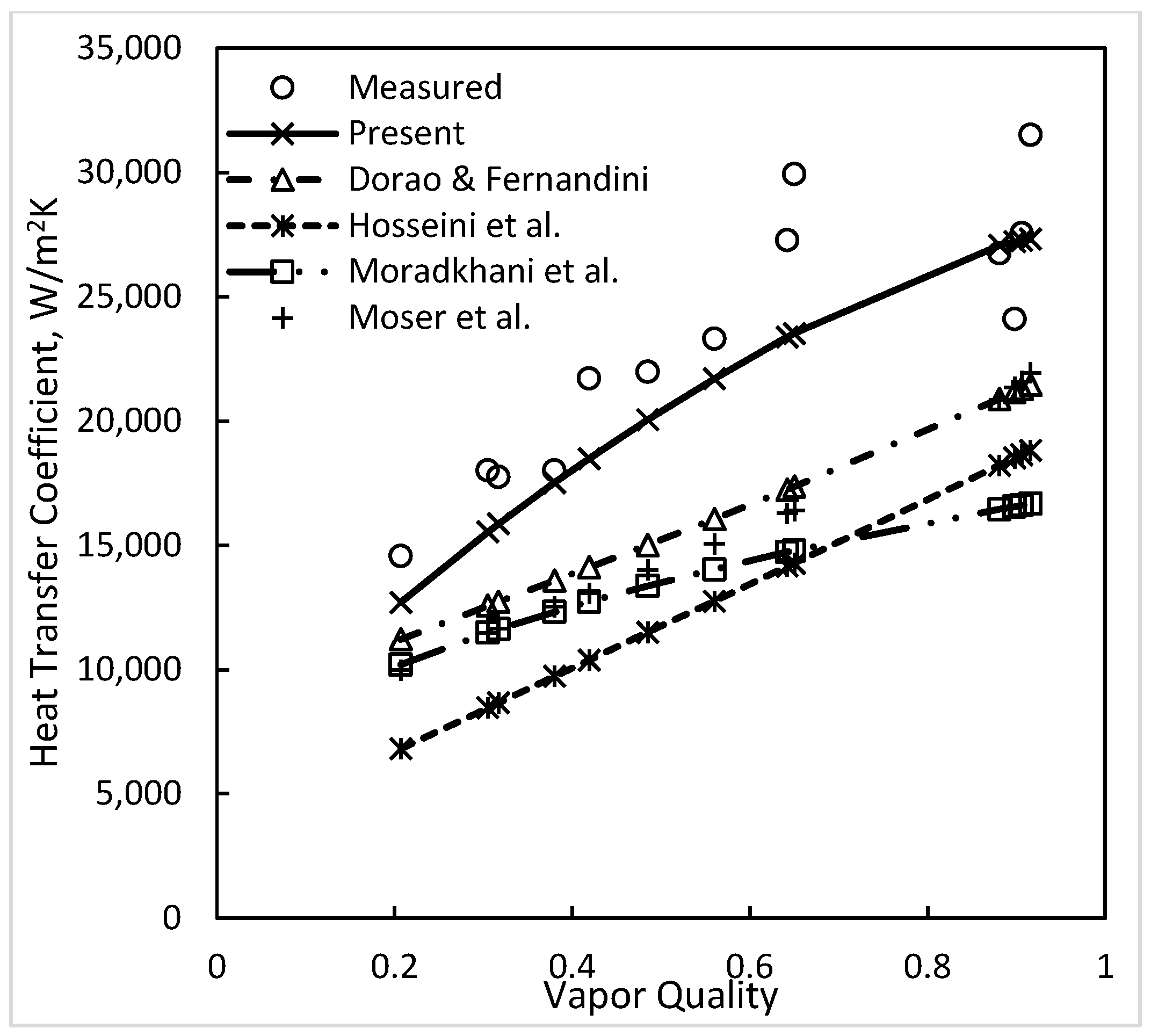

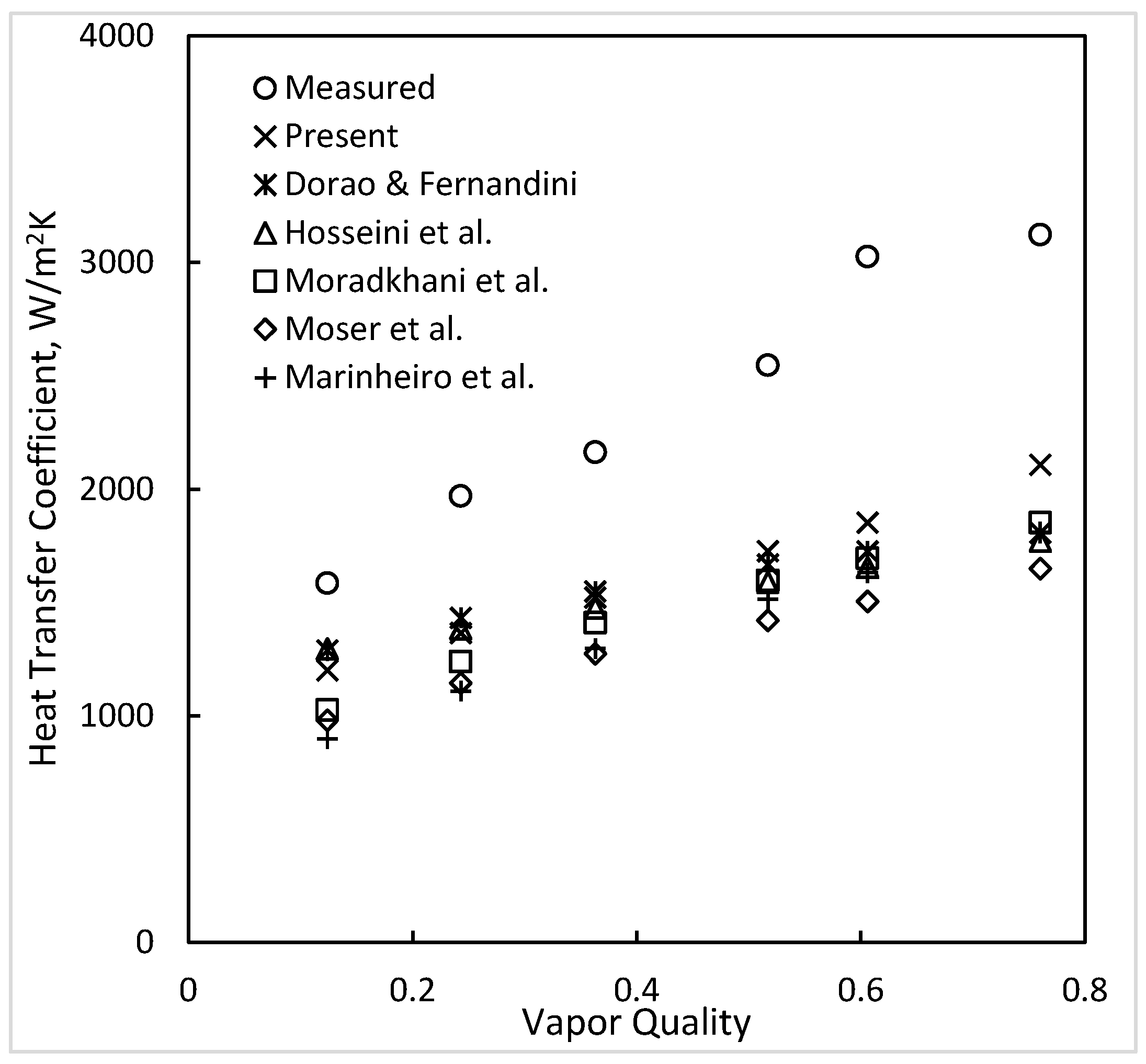

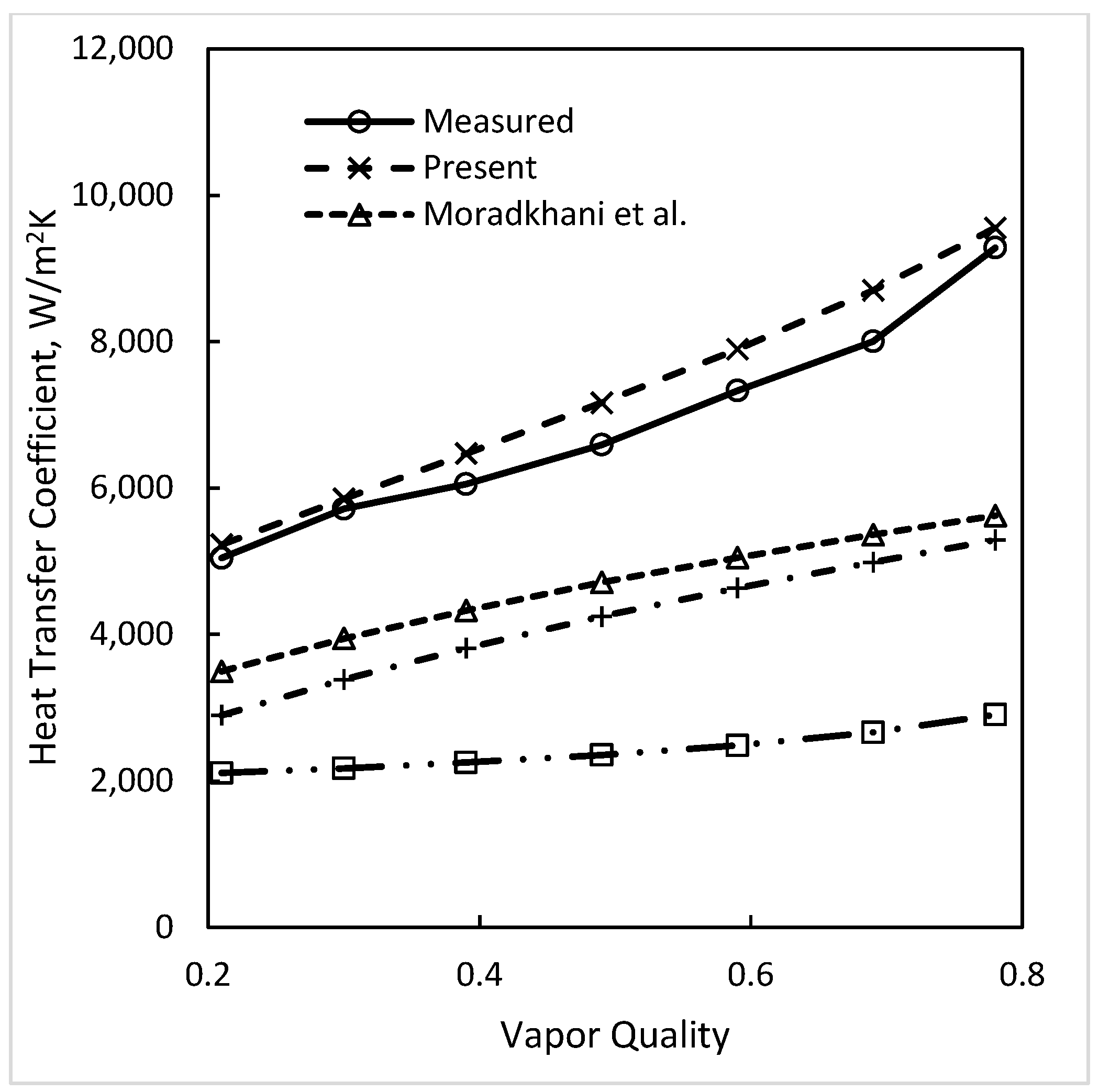

| Li et al. [8] * | 17/12.7 (H) | 4.3 (10.5) | R-410A | 13 | 10.1 −6.2 | 12.5 −9.0 | 24.9 24.9 | 17.7 17.7 | 29.3 29.3 | 22.9 22.1 | 21.3 21.3 | 10.5 5.2 | 17.8 15.6 |

| Borchmann [9] | 38/ 31.2 (H) | 6.8 (15.0) | R-11 | 5 | 13.1 −6.5 | 28.1 −28.1 | 33.5 −33.5 | 16.6 −16.3 | 5.6 −2.0 | 20.9 −20.9 | 24.3 −24.3 | 30.3 −30.3 | 24.1 −17.1 |

| He et al. [10] | 22.0/16.0 (H) | 6.0 (14.2) | R-410A | 18 | 53.2 −53.3 | 66.8 −66.1 | 36.4 −36.4 | 30.1 −30.1 | 44.6 −44.6 | 50.9 −50.9 | 47.6 −47.6 | 46.5 −46.5 | 33.0 −33.0 |

| Tang et al. [11] | 26.0/19.05 (H) | 6.95 (16.4) | R-134a | 6 | 18.1 −18.1 | 29.3 −29.3 | 29.4 29.4 | 61.1 61.1 | 16.3 16.3 | 7.6 5.3 | 16.5 16.5 | 14.5 14.5 | 41.7 41.7 |

| 25.0/19.05 (H) | 5.9 (13.7) | R-134a | 7 | 20.7 20.7 | 10.4 10.1 | 77.2 77.2 | 129.2 129.2 | 62.2 62.2 | 52.1 52.1 | 65.4 65.4 | 52.0 52.0 | 87.7 87.7 | |

| Wang et al. [12] | 26.0/15.8 (H) | 10.2 (27.0) | R-11 | 10 | 62.2 −25.4 | 64.0 −64.0 | 34.6 −34.6 | 40.0 −40.0 | 38.9 −38.9 | 55.9 −55.9 | 44.6 −44.6 | 46.8 −46.8 | 31.5 −31.5 |

| Chen et al. [13] | 17.0/12.7 (H) | 4.3 (10.1) | R-410A | 9 | 12.3 0.9 | 23.6 −15.6 | 23.2 22.6 | 22.2 22.2 | 28.1 20.9 | 29.7 18.4 | 22.6 16.3 | 11.7 −6.6 | 19.9 13.7 |

| R-22 | 8 | 25.9 17.4 | 21.6 −16.7 | 18.0 17.8 | 9.0 8.7 | 24.7 19.1 | 23.7 10.2 | 21/8 18.0 | 7.8 −6.8 | 16.3 12.6 | |||

| 25.0/12.7 (H) | 12.3 (38.1) | R-410 | 22 | 49.8 −32.9 | 76.5 −76.5 | 33.3 −31.2 | 42.9 −42.9 | 49.1 −49.1 | 4.3 −64.3 | 53.1 −53.1 | 45.7 −45.7 | 27.6 −25.7 | |

| R-22 | 8 | 130.1 122.5 | 76.3 −76.3 | 22.5 −22.5 | 53.7 −53.7 | 45.7 −45.7 | 64.9 −64.9 | 48.2 −48.2 | 34.1 −34.1 | 9.9 −9.9 | |||

| Miropoloskiy et al. [14] | 21.7/18.0 (VD) | 3.7 (8.16) | Water | 96 | 20.7 18.9 | 12.2 0.3 | 27.9 −17.4 | 29.0 −23.0 | 28,1 −19.7 | 26.8 −26.8 | 27.6 −21.7 | 23.7 −23.7 | 12.7 −10.6 |

| Ruzaikin et al. [7] | 8.0/6.0 | 2.0 (4.7). | NH3 | 60 | 62.0 62.0 | 32.4 32.3 | 29.2 29.2 | 13.4 −2.7 | 55.3 55.3 | 18.3 17.3 | 31.1 31.1 | 34.9 34.7 | 15.0 13.1 |

| 11.0/6.0 | 5.0 (14.2) | 50 | 32.3 20.5 | 24.8 −24.4 | 11.9 4.0 | 22.8 −1.7 | 20.6 −20.5 | 31.4 −31.4 | 15.5 −12.8 | 15.0 −3.6 | 15.0 −3.6 | ||

| All sources | 312 | 38.1 18.2 | 30.2 −13.1 | 27.2 −1.2 | 28.5 −9.9 | 35.5 −3.2 | 31.8 −18.2 | 30.4 −8.7 | 25.3 −26.5 | 19.2 −2.4 | |||

| Source | Dout/Din Mm/mm (Orient.) | Dhyd (DHP) mm | Fluid (Glide, K) ** | N | Deviation, % Mean Absolute (Upper Line) Average (Lower Line) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Shah [3] Published | Shah [3] DHYD Used Throughout | Shah [3] with Alferov-Rybin Cor. | New Correlation | ||||||

| Li et al. [8] | 17.0/12.7 (H) | 4.3 (10.5) | R-410A (0.1) | 13 | 10.5 5.2 | 17.8 15.6 | 12.6 6.1 | 17.8 15.6 | |

| Borchmann [9] | 38/ 31.2 (H) | 6.8 (15.0) | R-11 | 5 | 30.3 −30.3 | 24.1 −17.1 | 31.4 −31.1 | 24.1 −17.1 | |

| He et al. [10] | 22.0/16.0 (H) | 6.0 (14.2) | R-410A (0.1) | 18 | 46.5 −46.5 | 33.0 −33.0 | 40.2 −40.2 | 33.0 −33.0 | |

| Tang et al. [11] | 26.0/19.05 (H) | 6.95 (16.4) | R-134a | 6 | 14.5 14.5 | 41.7 41.7 | 25.3 25.3 | 41.7 41.7 | |

| 25.0/19.05 (H) | 5.9 (13.7) | R-134a | 7 | 52.0 52.0 | 87.7 87.7 | 63.8 63.8 | 87.7 87.7 | ||

| Wang et al. [12] | 26.0/15.8 (H) | 10.2 (27.0) | R-11 | 10 | 46.8 −46.8 | 31.5 −31.5 | 35.0 −35.0 | 31.5 −31.5 | |

| Chen et al. [13] | 17.0/12.7 (H) | 4.3 (10.1) | R-410 | 9 | 11.7 −6.6 | 19.9 13.7 | 13.7 0.3 | 19.9 13.7 | |

| R-22 | 8 | 7.8 −6.8 | 16.3 12.6 | 7.7 −1.1 | 16.3 12.6 | ||||

| 25.0/12.7 (H) | 12.3 (38.1) | R-410 | 22 | 45.7 −45.7 | 27.6 −25.7 | 27.1 −24.8 | 27.6 −25.7 | ||

| R-22 | 8 | 34.1 −34.1 | 9.9 −9.9 | 9.9 −9.9 | 9.9 −9.9 | ||||

| Miropoloskiy et al. [14] | 21.7/18.0 (VD) | 3.7 (8.16) | Water | 96 | 23.7 −23.7 | 12.7 −12.6 | 26.0 −26.0 | 12.7 −12.6 | |

| Ruzaikin et al. [7] | 8.0/6.0 (H) | 2.0 (4.7) | Ammonia | 60 | 15.0 13.1 | 34.9 34.7 | 14.8 −5.7 | 15.0 13.1 | |

| 11.0/6.0 (H) | 5.0 (14.2) | 50 | 24.7 −24.3 | 15.0 −3.6 | 19.1 18.0 | 15.0 −3.6 | |||

| All sources | MAD %, giving equal weight to each data point | 312 | 25.3 −26.5 | 23.0 1.7 | 23.2 −9.2 | 19.2 −2.4 | |||

| Parameter | Range |

|---|---|

| DHYD, mm | 2.0–12.3 |

| DHP, mm | 8.2–27.0 |

| Annular gap, mm | 1.0–6.15 |

| DOUT/DIN | 1.2–1.97 |

| Fluids | Water, ammonia, R-11, R-22, R-113, R-134a, R-410A |

| Flow direction | Horizontal, vertical downwards |

| pr | 0.0236–0.5542 |

| G, kg/m2 s | 9–600 |

| x | 0.02–1.0 |

| ReLT | 1245–42,884 |

| WeGT | 8–805 |

| FrLT | 0.00084–338 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shah, M.M. Prediction of Heat Transfer During Condensation in Annuli. J. Exp. Theor. Anal. 2024, 2, 134-151. https://doi.org/10.3390/jeta2040011

Shah MM. Prediction of Heat Transfer During Condensation in Annuli. Journal of Experimental and Theoretical Analyses. 2024; 2(4):134-151. https://doi.org/10.3390/jeta2040011

Chicago/Turabian StyleShah, Mirza M. 2024. "Prediction of Heat Transfer During Condensation in Annuli" Journal of Experimental and Theoretical Analyses 2, no. 4: 134-151. https://doi.org/10.3390/jeta2040011

APA StyleShah, M. M. (2024). Prediction of Heat Transfer During Condensation in Annuli. Journal of Experimental and Theoretical Analyses, 2(4), 134-151. https://doi.org/10.3390/jeta2040011