Volumetric Additive Manufacturing: Ushering in a New Era of Fabrication

Abstract

1. Introduction

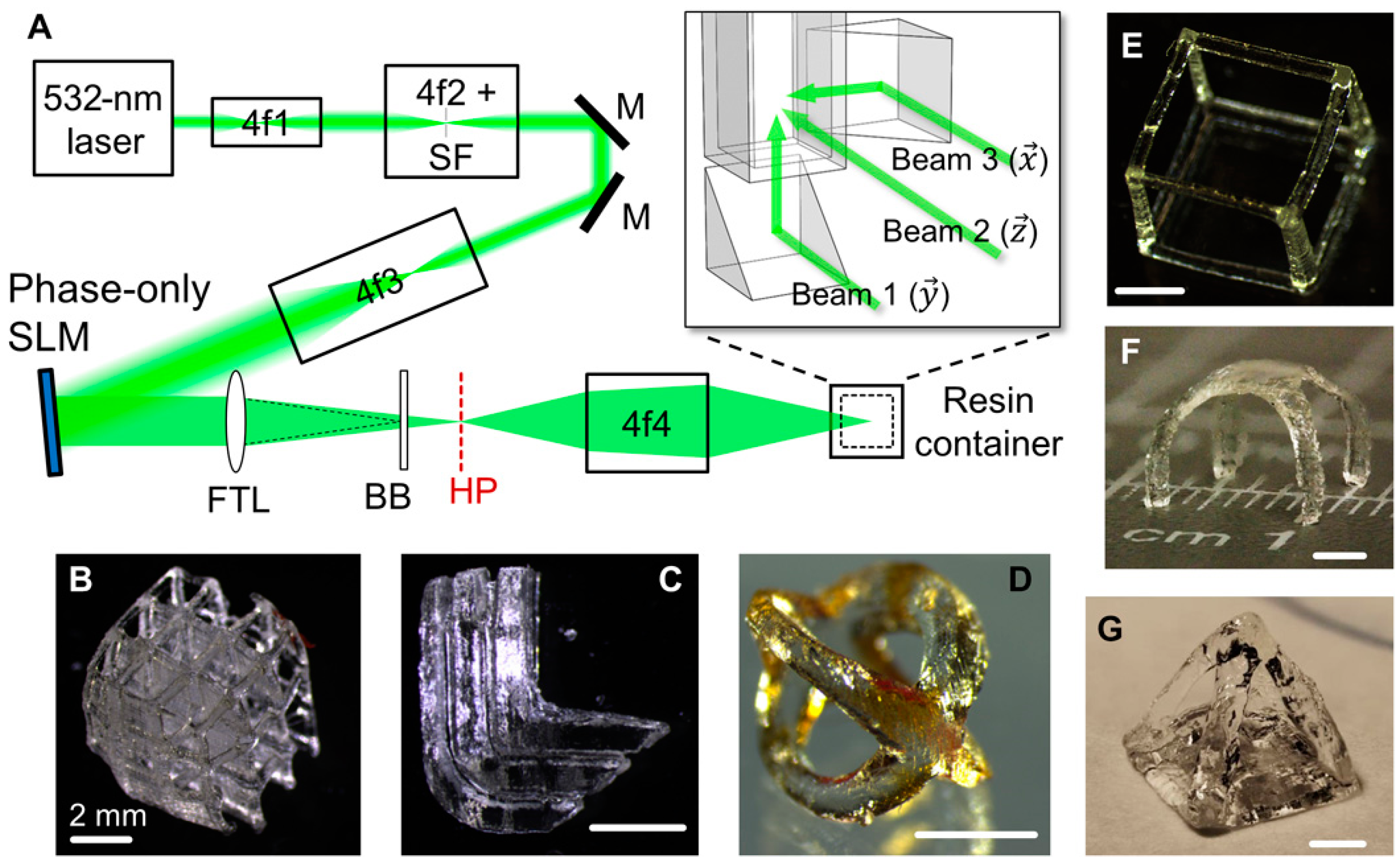

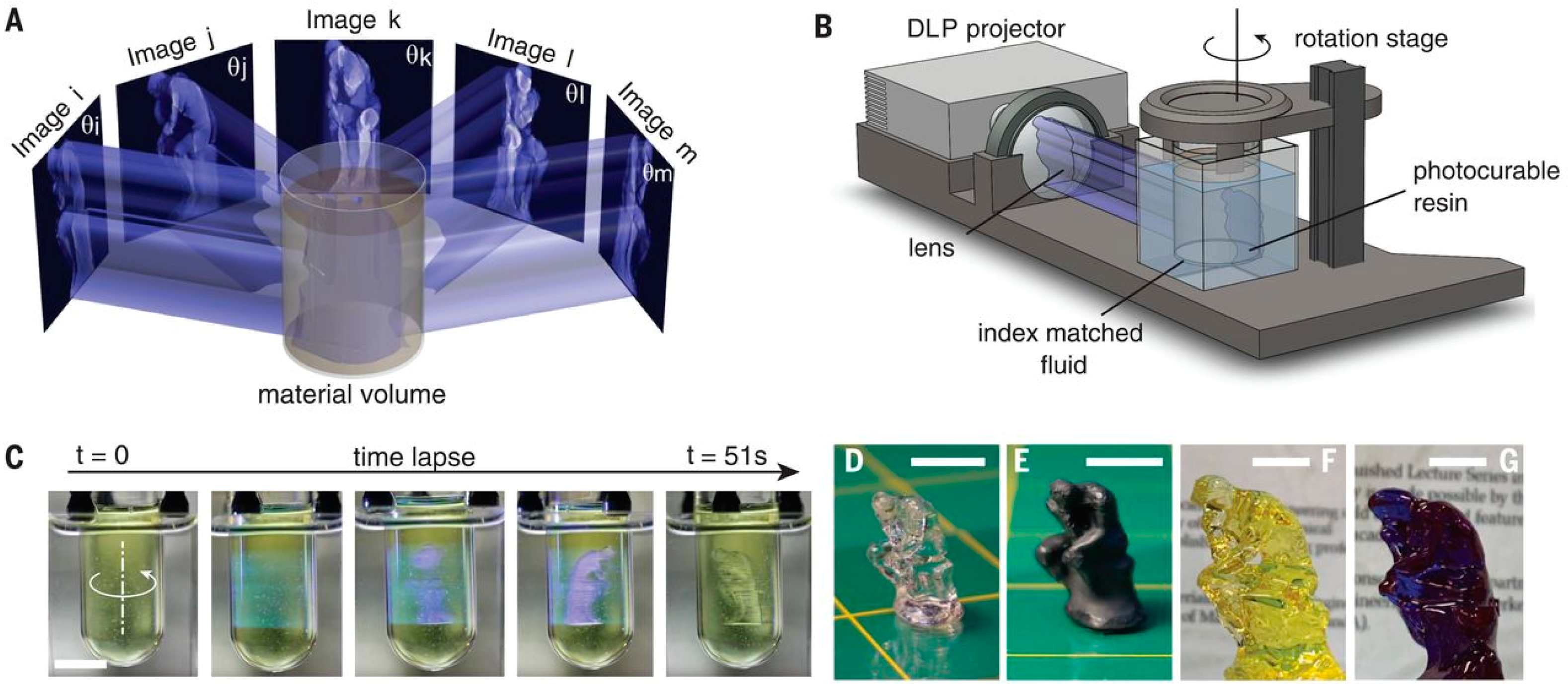

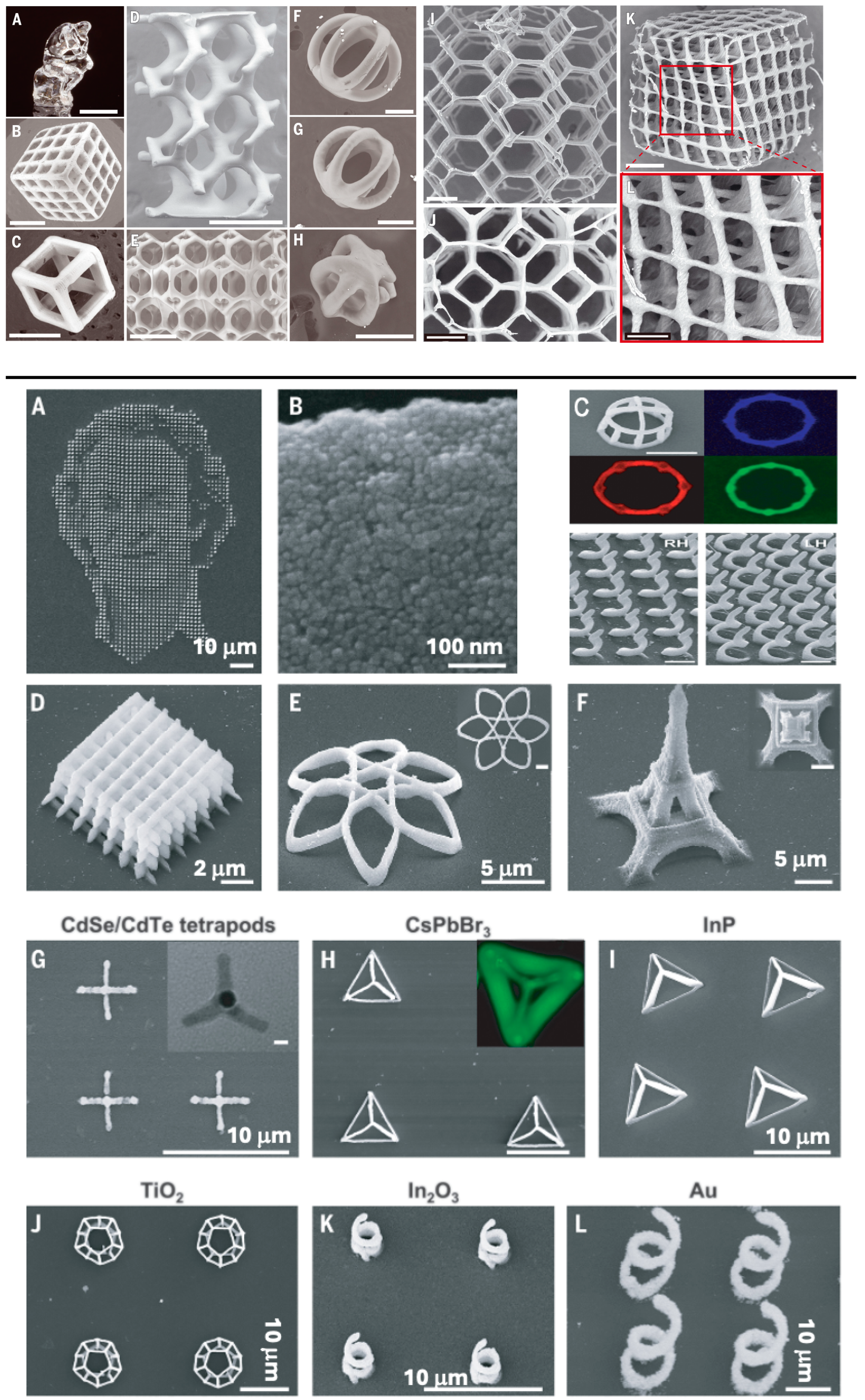

2. Volumetric Additive Manufacturing (VAM)

3. Print Materials

4. Future Directions and Research Needs

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| VAM | volumetric additive manufacturing |

| QD | quantum dot |

| SEM | scanning electron microscopy |

| DLP | digital light processing |

| 2D | two-dimensional |

| 3D | three-dimensional |

| PEGDA | poly(ethylene glycol)diacrylate |

| EDDF | energy deposition distribution field |

| PCPs | preceramic polymers |

| BDDA | 1,4-butanediol diacrylate |

| TPO | diphenyl(2,4,6-trimethylbenzoyl) phosphine oxide |

| TMPTA | trimethylolpropane triacrylate |

| HEMA | hydroxyethylmethacrylate |

| CQ | camphorquinone |

| EDAB | ethyl 4-(dimethylamino)benzoate |

References

- Barreto, J.E.F.; Kubrusly, B.S.; Lemos Filho, C.N.R.; Silva, R.S.; de Osterno Façanha, S.; dos Santos, J.C.C.; Cerqueira, G.S. 3D printing as a tool in anatomy teaching. Int. J. Innov. Educ. Res. 2022, 10, 58–71. [Google Scholar] [CrossRef]

- Arslan, A.; Erdogan, I. Use of 3D Printers for Teacher Training and Sample Activities. Int. J. Progress. Educ. 2021, 17, 343–360. [Google Scholar] [CrossRef]

- Thyssen, C.; Meier, M. 3D Printing as an Element of Teaching—Perceptions and Perspectives of Teachers at German Schools. Front. Educ. 2023, 8, 1233337. [Google Scholar] [CrossRef]

- Ford, S.; Minshall, T. Invited Review Article: Where and How 3D Printing Is Used in Teaching and Education. Addit. Manuf. 2019, 25, 131–150. [Google Scholar] [CrossRef]

- Prashar, G.; Vasudev, H.; Bhuddhi, D. Additive Manufacturing: Expanding 3D Printing Horizon in Industry 4.0. Int. J. Interact. Des. Manuf. 2023, 17, 2221–2235. [Google Scholar] [CrossRef]

- Zhou, L.; Miller, J.; Vezza, J.; Mayster, M.; Raffay, M.; Justice, Q.; Al Tamimi, Z.; Hansotte, G.; Sunkara, L.D.; Bernat, J. Additive Manufacturing: A Comprehensive Review. Sensors 2024, 24, 2668. [Google Scholar] [CrossRef]

- Cao, T.; Zhang, Q.; Thompson, J.E. Designing, Constructing, and Using an Inexpensive Electronic Buret. J. Chem. Educ. 2014, 92, 106–109. [Google Scholar] [CrossRef]

- Scalise, G. Milestones in Microelectronics. Jpn. Spotlight 2008, 25–27. Available online: https://www.jef.or.jp/journal/pdf/161th_cover07.pdf (accessed on 9 February 2025).

- ISO/TC 261-Additive Manufacturing. Available online: https://www.iso.org/committee/629086/x/catalogue/p/1/u/0/w/0/d/0 (accessed on 9 February 2025).

- Shine, K.M.; Schlegel, L.; Ho, M.; Boyd, K.; Pugliese, R. From the Ground up: Understanding the Developing Infrastructure and Resources of 3D Printing Facilities in Hospital-Based Settings. 3D Print. Med. 2022, 8, 21. [Google Scholar] [CrossRef]

- Diment, L.E.; Thompson, M.S.; Bergmann, J.H.M. Clinical Efficacy and Effectiveness of 3D Printing: A Systematic Review. BMJ Open 2017, 7, e016891. [Google Scholar] [CrossRef]

- Hellman, S.; Frisch, P.; Platzman, A.; Booth, P. 3D Printing in a Hospital: Centralized Clinical Implementation and Applications for Comprehensive Care. Digit. Health 2023, 9, 20552076231221900. [Google Scholar] [CrossRef]

- Tack, P.; Victor, J.; Gemmel, P.; Annemans, L. 3D-Printing Techniques in a Medical Setting: A Systematic Literature Review. Biomed. Eng. Online 2016, 15, 115. [Google Scholar] [CrossRef]

- Whyte, D.J.; Doeven, E.H.; Sutti, A.; Kouzani, A.Z.; Adams, S.D. Volumetric Additive Manufacturing: A New Frontier in Layer-Less 3D Printing. Addit. Manuf. 2024, 84, 104094. [Google Scholar] [CrossRef]

- Shusteff, M.; Browar, A.E.M.; Kelly, B.E.; Henriksson, J.; Weisgraber, T.H.; Panas, R.M.; Fang, N.X.; Spadaccini, C.M. One-Step Volumetric Additive Manufacturing of Complex Polymer Structures. Sci. Adv. 2017, 3, eaao5496. [Google Scholar] [CrossRef]

- Kelly, B.E.; Bhattacharya, I.; Heidari, H.; Shusteff, M.; Spadaccini, C.M.; Taylor, H.K. Volumetric Additive Manufacturing via Tomographic Reconstruction. Science 2019, 363, 1075–1079. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharya, I.; Toombs, J.; Taylor, H. High Fidelity Volumetric Additive Manufacturing. Addit. Manuf. 2021, 47, 102299. [Google Scholar] [CrossRef]

- Loterie, D.; Delrot, P.; Moser, C. High-Resolution Tomographic Volumetric Additive Manufacturing. Nat. Commun. 2020, 11, 852. [Google Scholar] [CrossRef] [PubMed]

- Madrid-Wolff, J.; Toombs, J.; Rizzo, R.; Bernal, P.N.; Porcincula, D.; Walton, R.; Wang, B.; Kotz-Helmer, F.; Yang, Y.; Kaplan, D.; et al. A Review of Materials Used in Tomographic Volumetric Additive Manufacturing. MRS Commun. 2023, 13, 764–785. [Google Scholar] [CrossRef] [PubMed]

- Kollep, M.; Konstantinou, G.; Madrid-Wolff, J.; Boniface, A.; Hagelüken, L.; Sasikumar, P.V.W.; Blugan, G.; Delrot, P.; Loterie, D.; Brugger, J.; et al. Tomographic Volumetric Additive Manufacturing of Silicon Oxycarbide Ceramics. Adv. Eng. Mater. 2022, 24, 2101345. [Google Scholar] [CrossRef]

- Toombs, J.T.; Luitz, M.; Cook, C.C.; Jenne, S.; Li, C.C.; Rapp, B.E.; Kotz-Helmer, F.; Taylor, H.K. Volumetric Additive Manufacturing of Silica Glass with Microscale Computed Axial Lithography. Science 2022, 376, 308–312. [Google Scholar] [CrossRef]

- Li, F.; Liu, S.F.; Liu, W.; Hou, Z.W.; Jiang, J.; Fu, Z.; Wang, S.; Si, Y.; Lu, S.; Zhou, H.; et al. 3D Printing of Inorganic Nanomaterials by Photochemically Bonding Colloidal Nanocrystals. Science 2023, 381, 1468–1474. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.F.; Hou, Z.W.; Lin, L.; Li, F.; Zhao, Y.; Li, X.Z.; Zhang, H.; Fang, H.H.; Li, Z.; Sun, H.B. 3D Nanoprinting of Semiconductor Quantum Dots by Photoexcitation-Induced Chemical Bonding. Science 2022, 377, 1112–1116. [Google Scholar] [CrossRef] [PubMed]

- Kermavnar, T.; Shannon, A.; O’Sullivan, K.J.; McCarthy, C.; Dunne, C.P.; O’Sullivan, L.W. Three-Dimensional Printing of Medical Devices Used Directly to Treat Patients: A Systematic Review. 3D Print Addit. Manuf. 2021, 8, 366–408. [Google Scholar] [CrossRef] [PubMed]

- Guttridge, C.; Shannon, A.; O’Sullivan, A.; O’Sullivan, K.J.; O’Sullivan, L.W. Biocompatible 3D Printing Resins for Medical Applications: A Review of Marketed Intended Use, Biocompatibility Certification, and Post-Processing Guidance. Ann. 3D Print. Med. 2022, 5, 100044. [Google Scholar] [CrossRef]

- Liu, F.; Chen, Q.; Liu, C.; Ao, Q.; Tian, X.; Fan, J.; Tong, H.; Wang, X. Natural Polymers for Organ 3D Bioprinting. Polymers 2018, 10, 1278. [Google Scholar] [CrossRef]

- Song, D.; Xu, Y.; Liu, S.; Wen, L.; Wang, X. Progress of 3D Bioprinting in Organ Manufacturing. Polymers 2021, 13, 3178. [Google Scholar] [CrossRef]

| Standard | Organization/Standard |

|---|---|

| “Practice for Reporting Data for Test Specimens Prepared by Additive Manufacturing” | ASTM/F2971 |

| “Guide for Evaluating Mechanical Properties of Metal Materials Made via Additive Manufacturing Processes” | ASTM/F3122 |

| “Specification for AM File Format (AMF) Version 1.2” | EN ISO/ASTM/52915 |

| “Guidelines for Design for Additive Manufacturing” | EN ISO/ASTM/52910 |

| “Guide for Additive Manufacturing—General Principles” | ISO/ASTM 52901 |

| “Terminology for Additive Manufacturing—General Principles” | EN ISO/ASTM/52900 |

| “Terminology for Additive Manufacturing Coordinate Systems and Test Methodologies” | EN ISO/ASTM/52921 |

| “Guide for Characterizing Properties of Metal Powders Used for AM Processes” | ASTM/F3049 |

| “Specification for Powder Bed Fusion of Plastic Materials” | ASTM/F3091/3091M |

| “Guide for Directed Energy Deposition of Metals” | ASTM/F3187 |

| “Additive manufacturing—General principles—Part positioning, coordinates and orientation” | ISO 17295:2023 |

| “Additive manufacturing—General principles—Part 2: Overview of process categories and feedstock” | ISO 17296-2:2015 |

| “Additive manufacturing of plastics—Environment, health, and safety—Test method for determination of particle and chemical emission rates from desktop material extrusion 3D printer” | ISO 27548:2024 |

| “Additive manufacturing—General principles—Fundamentals and vocabulary” | ISO/ASTM 52900:2021 |

| “Additive manufacturing—General principles—Requirements for purchased AM parts” | ISO/ASTM 52901:2017 |

| “Additive manufacturing—Test artefacts—Geometric capability assessment of additive manufacturing systems” | ISO/ASTM 52902:2023 |

| “Additive manufacturing—Material extrusion-based additive manufacturing of plastic materials—Part 1: Feedstock materials” | ISO/ASTM 52903-1:2020 |

| “Additive manufacturing—Material extrusion-based additive manufacturing of plastic materials—Part 2: Process equipment” | ISO/ASTM 52903-2:2020 |

| “Additive manufacturing of metals—Process characteristics and performance—Metal powder bed fusion process to meet critical applications” | ISO/ASTM 52904:2024 |

| “Additive manufacturing of metals—Non-destructive testing and evaluation—Defect detection in parts” | ISO/ASTM TR 52905:2023 |

| “Additive manufacturing—Non-destructive testing—Intentionally seeding flaws in metallic parts” | ISO/ASTM TR 52906:2022 |

| “Additive manufacturing—Feedstock materials—Methods to characterize metal powders” | ISO/ASTM 52907:2019 |

| “Additive manufacturing of metals—Finished part properties—Post-processing, inspection and testing of parts produced by powder bed fusion” | ISO/ASTM 52908:2023 |

| “Additive manufacturing of metals—Finished part properties—Orientation and location dependence of mechanical properties for metal parts” | ISO/ASTM 52909:2024 |

| “Additive manufacturing—Design—Requirements, guidelines and recommendations” | ISO/ASTM 52910:2018 |

| “Additive manufacturing—Design—Part 1: Laser-based powder bed fusion of metals” | ISO/ASTM 52911-1:2019 |

| “Additive manufacturing—Design—Part 2: Laser-based powder bed fusion of polymers” | ISO/ASTM 52911-2:2019 |

| “Additive manufacturing—Design—Part 3: PBF-EB of metallic materials” | ISO/ASTM 52911-3:2023 |

| “Additive manufacturing—Design—Functionally graded additive manufacturing” | ISO/ASTM TR 52912:2020 |

| “Specification for additive manufacturing file format (AMF) Version 1.2” | ISO/ASTM 52915:2020 |

| “Additive manufacturing for medical—Data—Optimized medical image data” | ISO/ASTM TR 52916:2022 |

| “Additive manufacturing—Round robin testing—General guidelines” | ISO/ASTM TR 52917:2022 |

| “Additive manufacturing—Qualification principles—Requirements for industrial additive manufacturing processes and production sites” | ISO/ASTM 52920:2023 |

| “Additive manufacturing of polymers—Qualification principles—Classification of part properties” | ISO/ASTM 52924:2023 |

| “Additive manufacturing of polymers—Feedstock materials—Qualification of materials for laser-based powder bed fusion of parts” | ISO/ASTM 52925:2022 |

| “Additive manufacturing of metals—Qualification principles—Part 1: General qualification of operators” | ISO/ASTM 52926-1:2023 |

| “Additive manufacturing of metals—Qualification principles—Part 2: Qualification of operators for PBF-LB” | ISO/ASTM 52926-2:2023 |

| “Additive manufacturing of metals—Qualification principles—Part 3: Qualification of operators for PBF-EB” | ISO/ASTM 52926-3:2023 |

| “Additive manufacturing of metals—Qualification principles—Part 4: Qualification of operators for DED-LB” | ISO/ASTM 52926-4:2023 |

| “Additive manufacturing of metals—Qualification principles—Part 5: Qualification of operators for DED-Arc” | ISO/ASTM 52926-5:2023 |

| “Additive manufacturing—General principles—Main characteristics and corresponding test methods” | ISO/ASTM 52927:2024 |

| “Additive manufacturing of metals— Feedstock materials—Powder life cycle management” | ISO/ASTM 52928:2024 |

| “Additive manufacturing—Qualification principles—Installation, operation and performance (IQ/OQ/PQ) of PBF-LB equipment” | ISO/ASTM TS 52930:2021 |

| “Additive manufacturing of metals—Environment, health and safety—General principles for use of metallic materials” | ISO/ASTM 52931:2023 |

| “Additive manufacturing—Environment, health and safety—Test method for the hazardous substances emitted from material extrusion type 3D printers in the non-industrial places” | ISO/ASTM 52933:2024 |

| “Additive manufacturing of metals—Qualification principles—Qualification of coordination personnel” | ISO/ASTM 52935:2023 |

| “Additive manufacturing of polymers—Qualification principles—Part 1: General principles and preparation of test specimens for PBF-LB” | ISO/ASTM 52936-1:2023 |

| “Additive manufacturing for construction—Qualification principles—Structural and infrastructure elements” | ISO/ASTM 52939:2023 |

| “Additive manufacturing—System performance and reliability—Acceptance tests for laser metal powder-bed fusion machines for metallic materials for aerospace application” | ISO/ASTM 52941:2020 |

| “Additive manufacturing—Qualification principles—Qualifying machine operators of laser metal powder bed fusion machines and equipment used in aerospace applications” | ISO/ASTM 52942:2020 |

| “Additive manufacturing for aerospace—Process characteristics and performance—Part 2: Directed energy deposition using wire and arc” | ISO/ASTM 52943-2:2024 |

| “Additive manufacturing for automotive—Qualification principles—Generic machine evaluation and specification of key performance indicators for PBF-LB/M processes” | ISO/ASTM 52945:2023 |

| “Additive manufacturing of metals—Qualification principles—Installation, operation and performance (IQ/OQ/PQ) of PBF-EB equipment” | ISO/ASTM TS 52949:2025 |

| “Additive manufacturing—General principles—Overview of data processing” | ISO/ASTM 52950:2021 |

| “Additive manufacturing of metals—Feedstock materials—Correlating of rotating drum measurement with powder spreadability in PBF-LB machines” | ISO/ASTM TR52952:2023 |

| “Additive manufacturing for aerospace—General principles—Part classifications for additive manufactured parts used in aviation” | ISO/ASTM 52967:2024 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thompson, J.E. Volumetric Additive Manufacturing: Ushering in a New Era of Fabrication. Hardware 2025, 3, 2. https://doi.org/10.3390/hardware3010002

Thompson JE. Volumetric Additive Manufacturing: Ushering in a New Era of Fabrication. Hardware. 2025; 3(1):2. https://doi.org/10.3390/hardware3010002

Chicago/Turabian StyleThompson, Jonathan E. 2025. "Volumetric Additive Manufacturing: Ushering in a New Era of Fabrication" Hardware 3, no. 1: 2. https://doi.org/10.3390/hardware3010002

APA StyleThompson, J. E. (2025). Volumetric Additive Manufacturing: Ushering in a New Era of Fabrication. Hardware, 3(1), 2. https://doi.org/10.3390/hardware3010002