Concept and Development of Air Quality Sensor for Citizen Science †

Abstract

1. Introduction

- The device must be able to measure a universal set of indicators found in most AQI calculation methodologies;

- The device must be able to operate autonomously without a mains power supply;

- The device must have several possible ways to transfer and/or store data: online over Wi-Fi; online over another puncture if Wi-Fi is not available; offline to a memory card;

- The device components must be relatively cheap and available worldwide;

- The device must still be easy to assemble without requiring specialized technical skills.

2. Materials and Methods

2.1. Measured AQI Indicators

- Dust particles PM2.5 and PM10. Included in almost all existing AQI methodologies.

- Carbon monoxide (CO). Included in AQI methodologies used in Australia, China, and Mexico.

- Ozone (O3). Included in almost all existing AQI methodologies.

- Ammonia (NH3). Included in AQI methodologies used in India.

- Sulfur dioxide (SO2). Included in AQI methodologies used in Australia, China, Mexico, India, the UK, and the USA.

- Air temperature, relative humidity, and atmospheric pressure.

2.2. Sensor’s Components

- Sensing components of AQI indicators measurement;

- Main and additional electronic components;

- Enclosure and fastening components;

- Energy store components.

- Nova PM sensor SDS011 (Shandong Nova Technology Co.,Ltd., Shandong, China) is used to measure PM2.5 and PM10. This device is used by the monitoring station of the “Sensor.Community” project and considered as one of the most efficient optical PM sensors in the low-cost and DIY sector of the market [11,12,13,14];

- MQ7 sensor (Winsen, Zhengzhou, China) is used to measure the level of CO. The MQ is the widely spread series of compact electrochemical gas sensors which is used in many IoT citizen science projects [18,19,20]. It is well calibrated for different use cases [21,22,23,24] and can be replaced by “Prana Air” sensors in those countries where MQ sensors are not available.

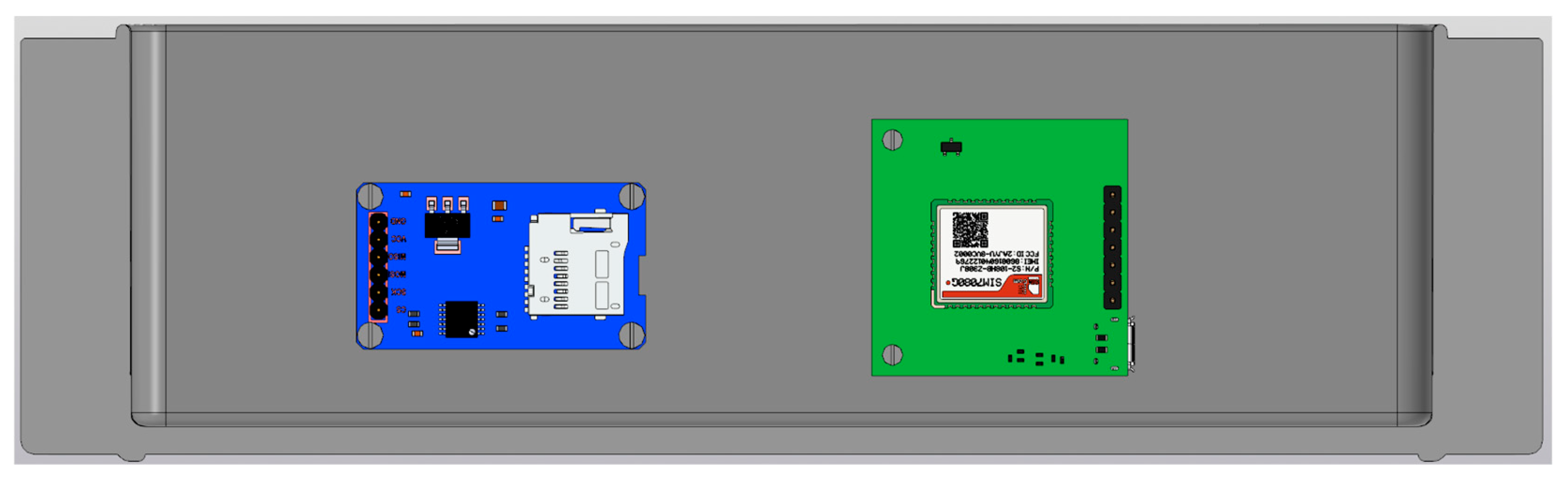

- ESP32 DevKit v1 (Espressif Systems, Shanghai, China) is used as the main board of the device. The controllers ESP by Espressif is widely used in IoT, citizen science, and DIY projects as an alternative to Arduino board. ESP series controllers possess more processor power and larger choice of board types and configurations [40,41]. The PM monitoring station of “Sensor.Community” project uses a NODE MCU v3 board with ESP8266 chip. This points out usage of the board from ESP series for the developed AQI device. Criteria for the chosen type of ESP board are chip power, built-in wi-fi, and number of microcontroller pins. To ensure the operations of all selected sensors ESP32 chip is used as the most progressive of ESP series [42,43]. Also to ensure operations of all sensors a large number of RX\TX pins (UART interface) is needed, thus ESP32 DevKit is selected as the board with maximum number of UART pins.

- ESP32 expansion board (Espressif Systems, Shanghai, China) is used to increase the number of UART pins. Despite selecting the ESP32 DevKit v1 as the board with the maximum number of RX\TX outputs, their number for all selected sensors is not sufficient and requires the usage of an expansion board for the device.

- MicroSD card module (Shenzhen Fetuoda Electronic Technology Co., Ltd., Shenzhen, China) is used to store and reserve the sensor data on an SD card.

- Spelsberg AL 2212-8 (Günther Spelsberg GmbH, Schalksmühle, Germany) is used as an enclosure for the device, it has 220*120*80 parameters. It provides IP66 protection, made from aluminum, thus more resistible for hits and falls and it is accessible for purchase in the large variety of countries. Of course, it could be replaced by some analog.

- Cable channels ID 3.49*6.09 OD Square Silicon Shielded Wire (Guangzhou Nafini Technology Co., Ltd., Guangzhou, China) is used to protect wires from the board to external components of the device. They provide IP68 protection.

- Rubber protective covers ZF-65-U (Optima Premium, Moscow, Russia) are used to house the external sensors of the device.

- Gland fasteners PG-9 4-8 DKC 52600 (Dielectric cable systems, Tver, Russia) are used to fasten the cable channels to the enclosure on the one side and to the rubber protective covers on the other side. Glands provide IP68 protection.

- Silicone Tube ID 6*8 OD (Shenzhen Tiasen Technology Co., Ltd., Shenzhen, China) is used to provide air intake of the SDS011 sensor.

- Screws of different diameters (M1.6, M2, M2.5, M3, M6) are used to fasten the components inside of enclosure.

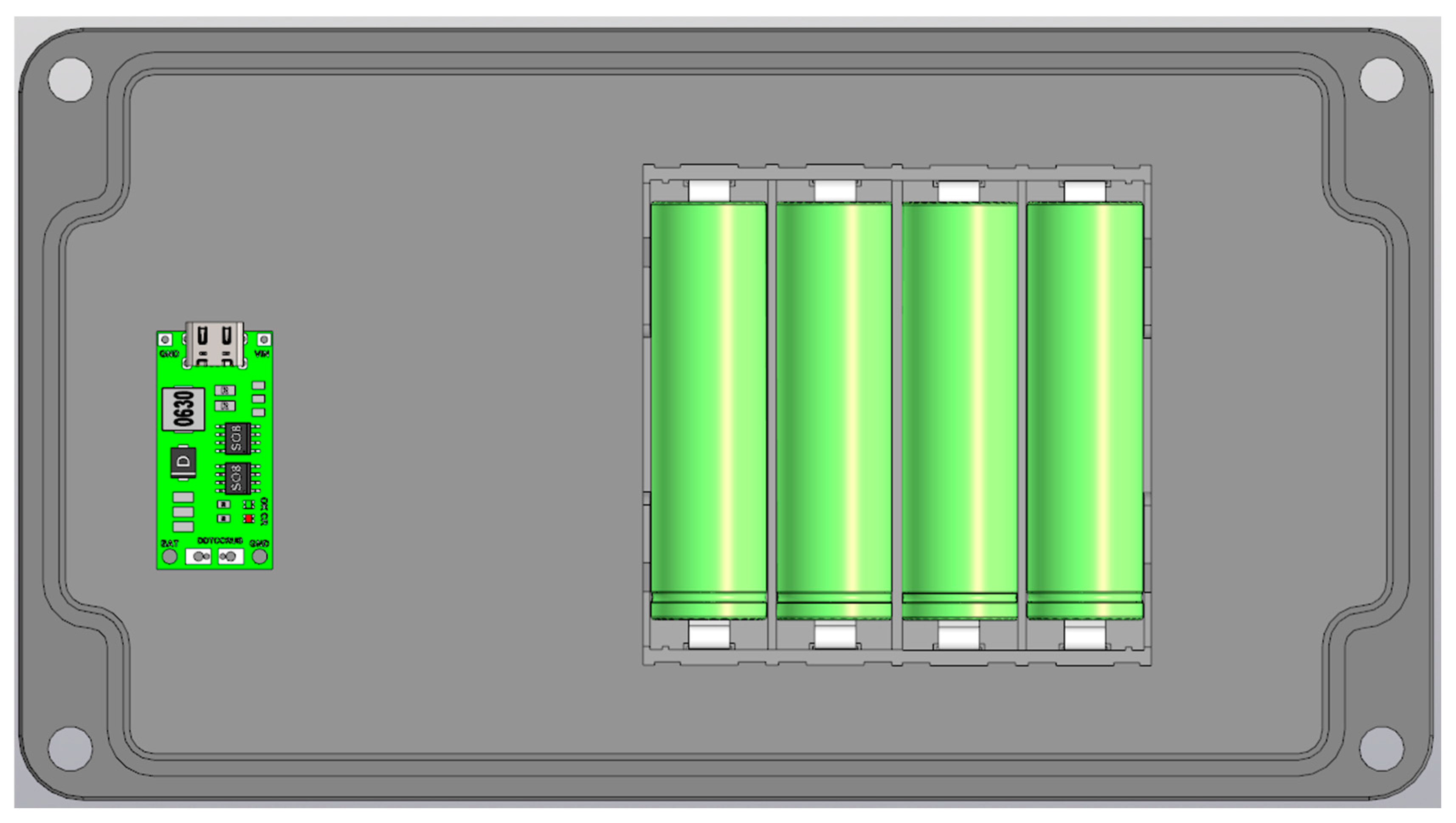

- Four Li-ion Panasonic NCR18650B 3400 mA*h Li-ion rechargeable batteries;

- 4X 18650 battery holder to connect the batteries;

- TZT DDTCCRUB (Shenzhen TZT Technology co., Ltd., Shenzhen, China) device is used to balance the charge level between batteries.

3. Results and Discussion

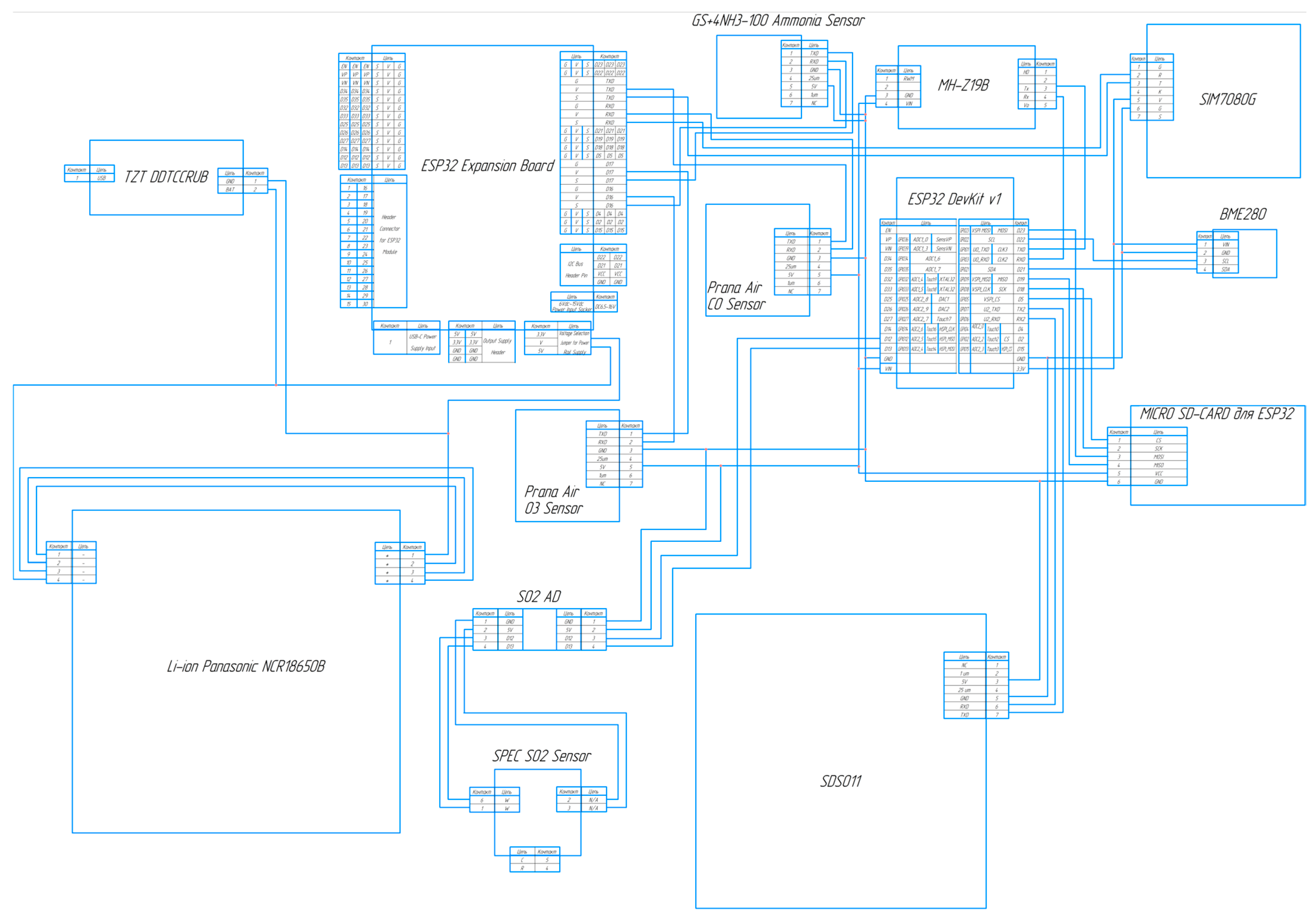

3.1. Electrical Circuit Desing

3.2. Sensor Design

3.2.1. General View of Device

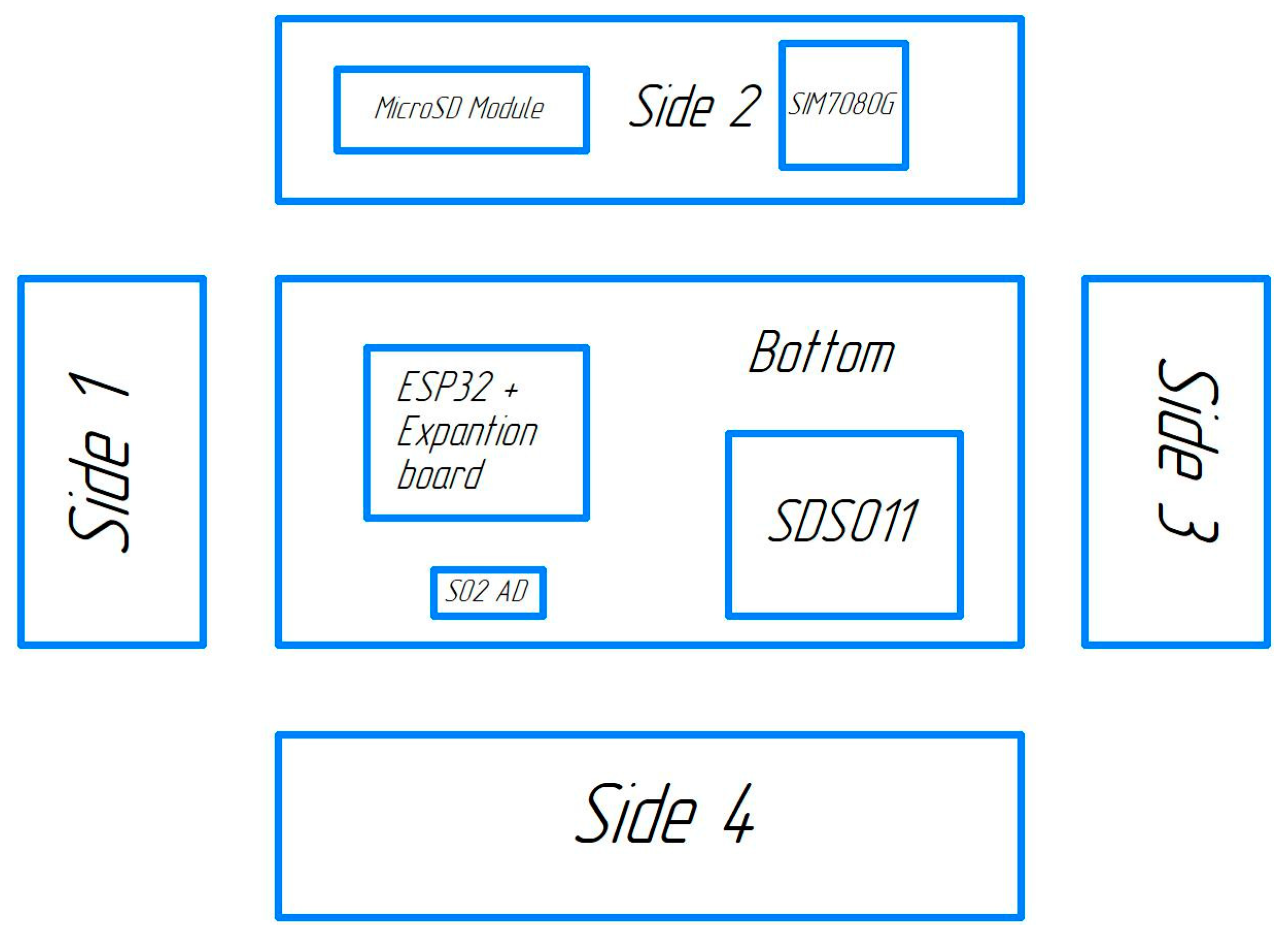

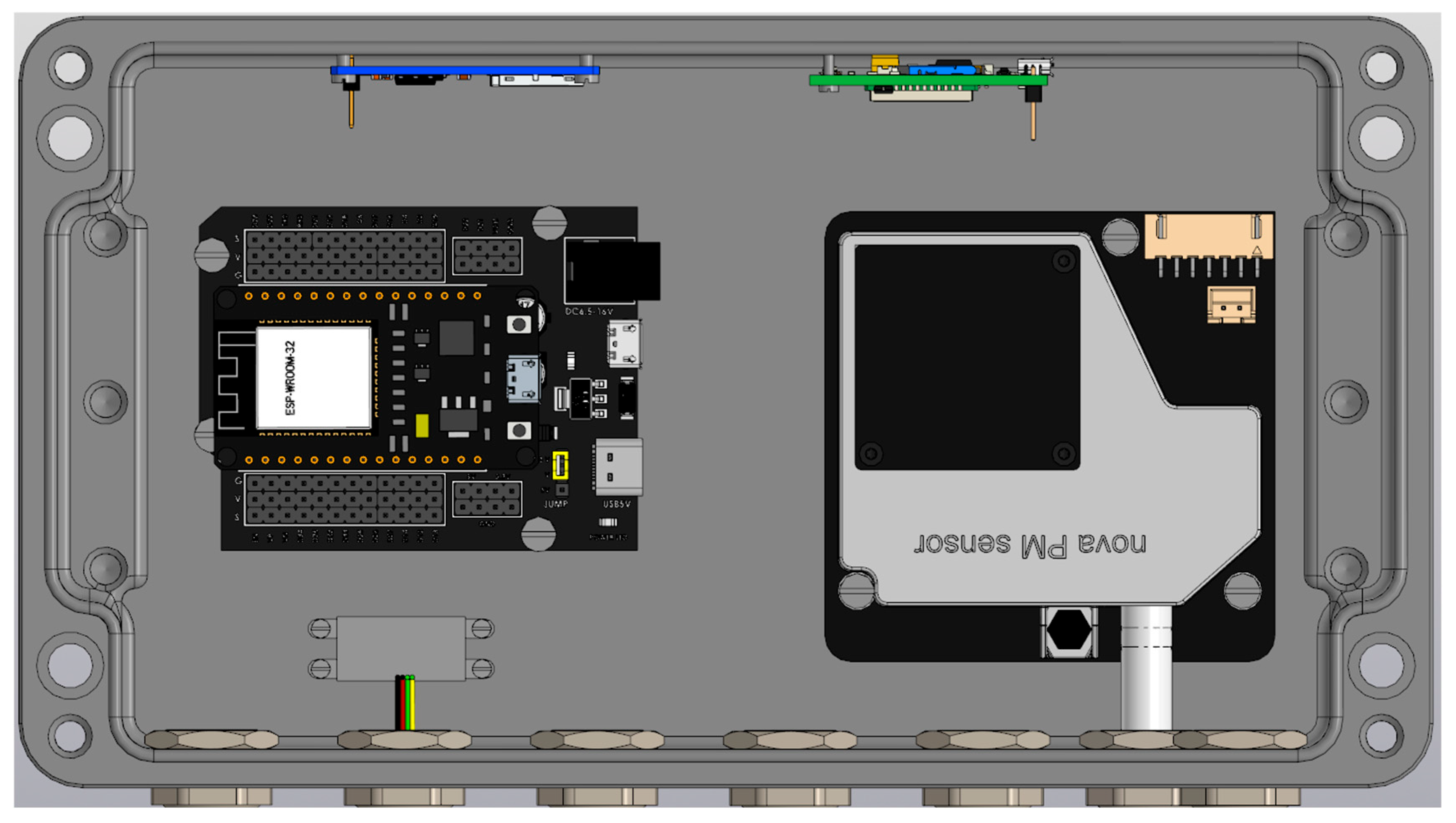

3.2.2. Components’ Placement in the Enclosure

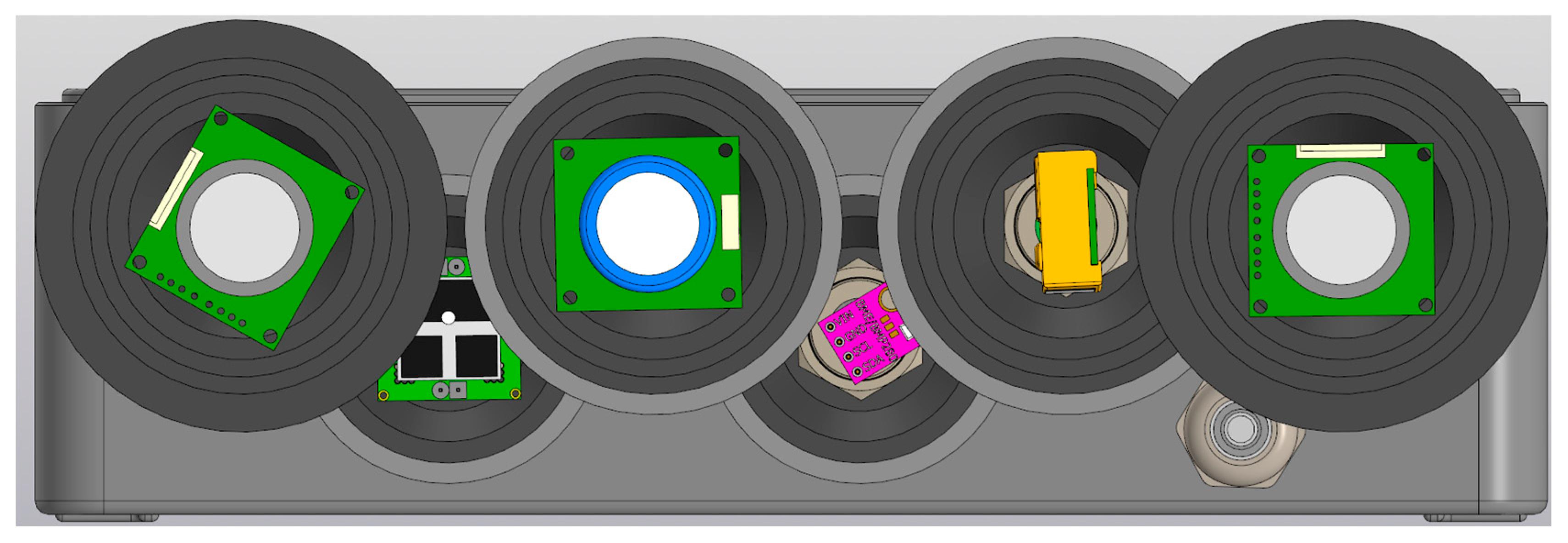

3.2.3. Components’ Placement on the Cover

3.2.4. Dust Sensor Tube Fastening

3.2.5. External Components Fastening

3.3. Sensor Operation Modes and Lifetime

3.4. Economic Assessement

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Pin Number | BME280 | ESP32 Expansion Board |

| 1 | VIN | 3.3 V |

| 2 | GND | GND_R |

| 3 | SCL | D22 |

| 4 | SDA | D21 |

| Pin Number | SIM7080G | ESP32 Expansion Board |

| 1 | G | |

| 2 | R | RX0 |

| 3 | T | TX0 |

| 4 | K | |

| 5 | V | 3.3 V |

| 6 | G | GND_R |

| 7 | S | |

| Pin Number | MicroSD Card Module | ESP32 Expansion Board |

| 1 | CS | D5 |

| 2 | SCK | D18 |

| 3 | MOSI | D23 |

| 4 | MISO | D19 |

| 5 | VCC | VIN |

| 6 | GND | GND_L |

| Pin Number | MH-Z19B Sensor | ESP32 Expansion Board |

| 1 | PWM | |

| 2 | ||

| 3 | GND | GND_L |

| 4 | VIN | VIN |

| 1.1 | HD | |

| 2.1 | ||

| 3.1 | TX | TX0 |

| 4.1 | RX | RX0 |

| 5 | V0 | |

| Pin Number | Nova SDS011 Sensor | ESP32 Expansion Board |

| 1 | NC | |

| 2 | 1 um | |

| 3 | 5 V | VIN |

| 4 | 25 um | |

| 5 | GND | GND_R |

| 6 | RXD | RX2 |

| 7 | TXD | TX2 |

| Pin Number | MQ137 (or GS+4NH3-100) | ESP32 Expansion Board |

| 1 | TXD | TX2 |

| 2 | RXD | RX2 |

| 3 | GND | GND_L |

| 4 | 25 um | |

| 5 | 5 V | VIN |

| 6 | 1 um | |

| 7 | NC | |

| Pin Number | MQ7 (or Prana Air CO) | ESP32 Expansion Board |

| 1 | TXD | TX0 |

| 2 | RXD | RX0 |

| 3 | GND | GND_L |

| 4 | 25 um | |

| 5 | 5 V | VIN |

| 6 | 1 um | |

| 7 | NC | |

| Pin Number | MQ131 (or Prana Air O3) | ESP32 Expansion Board |

| 1 | TXD | TX2 |

| 2 | RXD | RX2 |

| 3 | GND | GND_L |

| 4 | 25 um | |

| 5 | 5 V | VIN |

| 6 | 1 um | |

| 7 | NC | |

| Pin Number | SPEC SO2 Sensor | SO2 AD |

| 1 | W | D32 |

| 2 | N/A | |

| 3 | N/A | |

| 4 | R | 5 V |

| 5 | C | GND |

| 6 | W | D33 |

| Pin Number | SO2 AD | ESP32 Expansion Board |

| 1 | GND | GND_L |

| 2 | 5 V | VIN |

| 3 | D32 | D32 |

| 4 | D33 | D33 |

| Pin Number | Li-ion Panasonic NCR18650B | TZT DDTCCRUB |

| 1 | K − 1 | BAT |

| 2 | Ot + 1 k − 2 | |

| 3 | Ot + 2 k − 3 | |

| 4 | Ot + 3 k − 4 | Ot − 4 k GND |

| Pin Number | TZT DDTCCRUB | ESP32 Expansion Board |

| 1 | BAT | 5 V |

| 2 | GND | GND |

Appendix B

| № | Component Name | Amount | Price, $. | Total, $. |

|---|---|---|---|---|

| 1 | ESP32 DevKit v1 | 1 | 7.19 | 7.19 |

| 2 | Nova PM SDS011 | 1 | 24.39 | 24.39 |

| 3 | MQ7 (or Prana Air CO) | 1 | 7.83 | 7.83 |

| 4 | MQ131 (or Prana Air O3) | 1 | 11.36 | 11.36 |

| 5 | SPEC SO2 with AD module | 1 | 4.34 | 4.34 |

| 6 | MH-Z19B | 1 | 19.26 | 19.26 |

| 7 | ESP32 Expansion Board | 1 | 1.96 | 1.96 |

| 8 | SIM7080G | 1 | 18.71 | 18.71 |

| 9 | MicroSD card module | 1 | 2.25 | 2.25 |

| 10 | MQ137 (or GS+4NH3-100) | 1 | 15.41 | 15.41 |

| 11 | BME280 | 1 | 2.25 | 2.25 |

| 12 | TZT DDTCCRUB board | 1 | 0.65 | 0.65 |

| 13 | Spelsberg AL 2212-8 220*120*60 | 1 | 38.66 | 38.66 |

| 14 | Li-ion Panasonic NCR18650B | 4 | 6.29 | 25.16 |

| 15 | Battery holder 4X 18650 | 1 | 0.54 | 0.54 |

| 16 | Cable USB type-C Hoco, 1 m | 1 | 2.67 | 2.67 |

| 17 | Gland PG-9 4-8 DKC 52600 | 13 | 0.62 | 8.06 |

| 18 | Rubber protective covers ZF-65-U | 6 | 3.89 | 23.34 |

| 19 | SMARTBUY MICROSDHC 16G | 1 | 3.85 | 3.85 |

| 20 | Cable Channel ID 3.49*6.09 OD, 1 m | 1 | 3.62 | 3.62 |

| 21 | Screw A.M3-6g*7 | 7 | 0.39 | 2.73 |

| 22 | Screw A.M2-6g*6 | 4 | 0.22 | 0.88 |

| 23 | Screw A.M1.6-6g*8 | 2 | 0.28 | 0.56 |

| 24 | Screw A.M1.6-6g*6 | 4 | 0.27 | 1.08 |

| 25 | Screw A.M2.5-6g*5 | 8 | 0.27 | 2.16 |

| 26 | Screw A.M6-6g*30 | 4 | 0.44 | 1.76 |

| 27 | Silicone Tube ID 6*8 OD | 1 | 5.93 | 5.93 |

| 28 | Wires 319030000 (set of 60 pieces, 20 cm) | 1 | 4.88 | 4.88 |

| In total | 241.74 | |||

References

- Sensor.Community. Available online: https://sensor.community/ (accessed on 11 July 2025).

- World’s Air Pollution: Real-Time Air Quality Index. Available online: https://waqi.info/ (accessed on 11 July 2025).

- Air-Matters. Available online: https://air-matters.com (accessed on 11 July 2025).

- Breathe.Moscow. Available online: https://breathe.moscow (accessed on 11 July 2025).

- Nebo. Available online: https://nebo.live/ (accessed on 11 July 2025).

- Ren, F.R.; Tian, Z.; Shen, Y.T.; Chiu, Y.H.; Lin, T.Y. Energy, CO2, and AQI efficiency and improvement of the Yangtze River Economic Belt. Energies 2019, 12, 647. [Google Scholar] [CrossRef]

- Li, Y.; Chiu, Y.H.; Lu, L.C. Energy, CO2, AQI and economic performance in 31 cities in China: A slacks-based dynamic data envelopment analysis. Carbon Manag. 2019, 10, 269–286. [Google Scholar] [CrossRef]

- Tsai, W.T.; Lin, Y.Q. Trend analysis of air quality index (AQI) and greenhouse gas (GHG) emissions in Taiwan and their regulatory countermeasures. Environments 2021, 8, 29. [Google Scholar] [CrossRef]

- Nicholas, E.S.; Ukoha, P.O. An Assessment of Atmospheric Pollutants (PM2.5, PM10, CO2, SO2, NO2 and CO) Concentrations on Air Quality Using Air Quality Index in Eastern Nigeria. J. Chem. Soc. Niger. 2023, 48, 704–714. [Google Scholar] [CrossRef]

- Li, Y.; Chiu, Y.H.; Lu, L.C. Regional energy, CO2, and economic and air quality index performances in China: A meta-frontier approach. Energies 2018, 11, 2119. [Google Scholar] [CrossRef]

- Budde, M.; Schwarz, A.D.; Müller, T.; Laquai, B.; Streibl, N.; Schindler, G.; Köpke, M.; Riedel, T.; Dittler, A.; Beigl, M. Potential and limitations of the low-cost SDS011 particle sensor for monitoring urban air quality. ProScience 2018, 5, 12. [Google Scholar]

- Božilov, A.; Tasić, V.; Živković, N.; Lazović, I.; Blagojević, M.; Mišić, N.; Topalović, D. Performance assessment of NOVA SDS011 low-cost PM sensor in various microenvironments. Environ. Monit. Assess. 2022, 194, 595. [Google Scholar] [CrossRef]

- Wardoyo, A.Y.P.; Dharmawan, H.A.; Nurhuda, M.; Adi, E.T.P. Optimization of PM2.5 Measurement System Using NOVA SDS011 Sensor. J. Phys. Conf. Ser. 2020, 1428, 012053. [Google Scholar] [CrossRef]

- Weber, K.; Kramer, T.; Fischer, C.; Pohl, T. Testing and Inter-comparison of Low-Cost Sensors (SDS 011) and Mid-Cost Sensors (AN2 and AN3) for Particulate Matter. In Mid-Term and 1st International Networking Workshop of the SmartAQnet Project; Karlsruhe Institute of Technology: Munich, Germany, 2018; p. 17. [Google Scholar]

- Snyder, M. Closed System Evaluation of VerdeTerra’s Indoor Air Purification System in Relation to CO2 Scrubbing; VerdeTerra: Atlanta, GA, USA, 2024. [Google Scholar]

- Roshan, S.A.; Jayachandran, S.K.; Kandasamy, M.; Anusuyadevi, M. Design and Evaluation of an Affordable Hypoxic Chamber with Comprehensive Environmental Control for Research Applications. bioRxiv 2023. [Google Scholar] [CrossRef]

- Rodríguez-Huerta, R.; Martínez-Castillo, J.; Morales-González, E.; Herrera-May, A.L. Development of a Monitoring System for CO/CO2 with Android. In Proceedings of the 2019 IEEE International Conference on Engineering Veracruz (ICEV), Veracruz, Mexico, 14–17 October 2019; IEEE: Piscataway, NJ, USA, 2019; Volume 1, pp. 1–6. [Google Scholar]

- Easterline, L.M.; Putri, A.A.Z.R.; Atmaja, P.S.; Dewi, A.L.; Prasetyo, A. Smart Air Monitoring with IoT-based MQ-2, MQ-7, MQ-8, and MQ-135 Sensors using NodeMCU ESP32. Procedia Comput. Sci. 2024, 245, 815–824. [Google Scholar] [CrossRef]

- Sai, K.B.K.; Subbareddy, S.R.; Luhach, A.K. IOT based air quality monitoring system using MQ135 and MQ7 with machine learning analysis. Scalable Comput. Pract. Exp. 2019, 20, 599–606. [Google Scholar] [CrossRef]

- Jadhav, R.J.; Radhakrishnan, P.; Jadhav, D.A.; Ashreetha, B.; Divya, J.; Mukherjee, S. Internet of Things Enabled Gas Leakage Detection Over Industrial Areas using Powerful MQ Series Sensor and Controller. In Proceedings of the 2024 International Conference on Inventive Computation Technologies (ICICT), Kathmandu, Nepal, 24–26 April 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1679–1686. [Google Scholar]

- Sugianto, M.A.; Zulfikar, Z. Design of a Carbon Monoxide Gas Measurement Tool Using Microcontroller-Based MQ-7 Gas Sensor in Households. NEWTON Netw. Inf. Technol. 2024, 3, 36–47. [Google Scholar] [CrossRef]

- Kobbekaduwa, N.; Oruthota, P.; De Mel, W.R. Calibration and implementation of heat cycle requirement of MQ-7 semiconductor sensor for detection of carbon monoxide concentrations. Adv. Technol. 2021, 1, 377–392. [Google Scholar] [CrossRef]

- Babu, K.S.; Nagaraja, C. Calibration of MQ-7 and Detection of Hazardous Carbon Mono-oxide Concentration in Test Canister. Int. J. Adv. Res. Ideas Innov. Technol. 2018, 4, 18–24. [Google Scholar]

- Carrillo-Amado, Y.R.; Califa-Urquiza, M.A.; Ramón-Valencia, J.A. Calibration and standardization of air quality measurements using MQ sensors. Respuestas 2020, 25, 70–77. [Google Scholar] [CrossRef]

- Rathnayake, L.R.S.D.; Sakura, G.B.; Weerasekara, N.A.; Sandaruwan, P.D. Machine Learning-based Calibration Approach for Low-cost Air Pollution Sensors MQ-7 and MQ-131. Nat. Environ. Pollut. Technol. 2024, 23, 70–77. [Google Scholar] [CrossRef]

- Sinambela, M.; Nugraha, M.R.; Widodo, A.; Kadir, J.S.P.; Yasir, A.M.; Aji, T.W. IoT-Based Air Quality Monitoring System Design and Development Using ESP32. In Proceedings of the 2024 Ninth International Conference on Informatics and Computing (ICIC), Medan, Indonesia, 24–25 October 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–6. [Google Scholar]

- Listyarini, S.; Warlina, L.; Sambas, A. The Air Quality Monitoring Tool Based on Internet of Things to Monitor Pollution Emissions Continuously. Environ. Ecol. Res. 2022, 10, 824–829. [Google Scholar] [CrossRef]

- Wijaya, G.T.; Nugraha, I.G.D. Prediction system of chicken meat expiration time based on polynomial regression using NodeMCU ESP8266 and MQ137 sensor. In Proceedings of the AIP Conference Proceedings, Bali, Indonesia, 22–23 September 2021; AIP Publishing LLC: Melville, NY, USA, 2021; Volume 2376, p. 040015. [Google Scholar]

- Mulyono, T.; Rofi’i, I.; Nurhayati, A.Y.; Hariadi, Y.C.; Octaviani, L.A. Measuring the Amount of Ammonia Gas in Cattle Using The MQ137 Sensor in Rawan Village, Mayang District, and Member District with The Goal Of Raising Public Health Standards. J. Inov. Sains Dan Teknol. Untuk Masy. 2024, 2, 22–30. [Google Scholar] [CrossRef]

- Lambey, V.; Prasad, A.D. Measurement of PM10, PM2. 5, NO2, and SO2 Using Sensors. In Applied Geography and Geoinformatics for Sustainable Development: Proceedings of ICGGS 2022; Springer International Publishing: Cham, Switzerland, 2022; pp. 89–99. [Google Scholar]

- Longo, D.; Giudice, G.; D’Arrigo, G.; Sciuto, A. Portable Spectroscopy System for Environmental Monitoring: An SO2 Case Study. IEEE Sens. J. 2022, 22, 11135–11143. [Google Scholar] [CrossRef]

- Kusuma, H.A.; Suhendra, T.; Devendra, D.; Setyono, D.E.D. Evaluating the Accuracy of BMP280 and BME280 Sensors for Sea Level in a Coastal Environment: A Field Study at Tanjung Siambang Pier. ILMU Kelaut. Indones. J. Mar. Sci. 2023, 28, 189. [Google Scholar]

- Ryu, C.J.; Kim, J.A.; Kim, J.S.; Yun, G.Y.; Heo, S.H.; Hong, S.J. Evaluation of Temperature and Humidity of a Thermo-Hygrostat of PET/CT Equipment using a Temperature and Humidity Sensor (BME 280). J. Korean Soc. Radiol. 2020, 14, 15–22. [Google Scholar]

- Vovna, O.V.; Laktionov, I.S.; Koyfman, O.O.; Stashkevych, I.I.; Lebediev, V.A. Study of metrological characteristics of low-cost digital temperature sensors for greenhouse conditions. Serbian J. Electr. Eng. 2020, 17, 1–20. [Google Scholar] [CrossRef]

- Jain, G.H. MOS gas sensors: What determines our choice? In Proceedings of the 2011 Fifth International Conference on Sensing Technology, Palmerston North, New Zealand, 28 November–1 December 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 66–72. [Google Scholar]

- Nadargi, D.Y.; Umar, A.; Nadargi, J.D.; Lokare, S.A.; Akbar, S.; Mulla, I.S.; Suryavanshi, S.S.; Bhandari, N.L.; Chaskar, M.G. Gas sensors and factors influencing sensing mechanism with a special focus on MOS sensors. J. Mater. Sci. 2023, 58, 559–582. [Google Scholar] [CrossRef]

- Gutmacher, D.; Foelmli, C.; Vollenweider, W.; Hoefer, U.; Wöllenstein, J. Comparison of gas sensor technologies for fire gas detection. Procedia Eng. 2011, 25, 1121–1124. [Google Scholar] [CrossRef]

- Awang, Z. Gas sensors: A review. Sens. Transducers 2014, 168, 61–75. [Google Scholar]

- Dhall, S.; Mehta, B.R.; Tyagi, A.K.; Sood, K. A review on environmental gas sensors: Materials and technologies. Sens. Int. 2021, 2, 100116. [Google Scholar] [CrossRef]

- Kareem, H.; Dunaev, D. The working principles of esp32 and analytical comparison of using low-cost microcontroller modules in embedded systems design. In Proceedings of the 2021 4th International Conference on Circuits, Systems and Simulation (ICCSS), Kuala Lumpur, Malaysia, 26–28 May 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 130–135. [Google Scholar]

- Didi, Z.; El Azami, I. IoT, Comparative Study Between the Use of Arduino Uno, Esp32, and Raspberry pi in Greenhouses. In Proceedings of the International Conference on Digital Technologies and Applications, Fez, Morocco, 28–30 January 2022; Springer International Publishing: Cham, Switzerland, 2022; pp. 718–726. [Google Scholar]

- Maier, A.; Sharp, A.; Vagapov, Y. Comparative analysis and practical implementation of the ESP32 microcontroller module for the internet of things. In Proceedings of the 2017 Internet Technologies and Applications (ITA), Wrexham, UK, 12–15 September 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 143–148. [Google Scholar]

- Rak, F.; Wiora, J. Comparison of ESP programming platforms. Comput. Sci. Inf. Technol. 2021, 2, 77–86. [Google Scholar] [CrossRef]

- Herrero, R. Working with NB-IoT and LTE-M. In Practical Internet of Things Networking: Understanding IoT Layered Architecture; Springer International Publishing: Cham, Switzerland, 2023; pp. 403–426. [Google Scholar]

- Blom, A. NB-IoT Coverage: Development of a Measuring Instrument for NB-IoT. Bachelor’s Thesis, Karlstad University, Karlstad, Sweden, 2021. [Google Scholar]

- Fort, E.H.; Blanco-Carmona, P.; Garcia-Oya, J.R.; Muñoz-Chavero, F.; Gonzalez-Carvajal, R.; Serrano-Chacon, A.R.; Mascort-Albea, E.J. Wireless and low-power system for synchronous and real-time structural-damage assessment. IEEE Sens. J. 2023, 23, 13648–13658. [Google Scholar] [CrossRef]

- Hill, A.P.; Prince, P.; Snaddon, J.L.; Doncaster, C.P.; Rogers, A. AudioMoth: A low-cost acoustic device for monitoring biodiversity and the environment. HardwareX 2019, 6, e00073. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gordienko, D.; Polkhanova, V.; Sochilov, S.; Varlamova, A.; Vikulov, A. Concept and Development of Air Quality Sensor for Citizen Science. Environ. Earth Sci. Proc. 2025, 34, 13. https://doi.org/10.3390/eesp2025034013

Gordienko D, Polkhanova V, Sochilov S, Varlamova A, Vikulov A. Concept and Development of Air Quality Sensor for Citizen Science. Environmental and Earth Sciences Proceedings. 2025; 34(1):13. https://doi.org/10.3390/eesp2025034013

Chicago/Turabian StyleGordienko, Dmitriy, Valeriia Polkhanova, Semen Sochilov, Anastasia Varlamova, and Alexander Vikulov. 2025. "Concept and Development of Air Quality Sensor for Citizen Science" Environmental and Earth Sciences Proceedings 34, no. 1: 13. https://doi.org/10.3390/eesp2025034013

APA StyleGordienko, D., Polkhanova, V., Sochilov, S., Varlamova, A., & Vikulov, A. (2025). Concept and Development of Air Quality Sensor for Citizen Science. Environmental and Earth Sciences Proceedings, 34(1), 13. https://doi.org/10.3390/eesp2025034013