An Experimental Study on the Shear Behaviors of Polymer-Sand Composite Materials after Immersion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sand and Polymer Stabilizer

, R2 = PEG and/or PPG.

, R2 = PEG and/or PPG.2.2. Polymer-Sand Composite Material Preparation

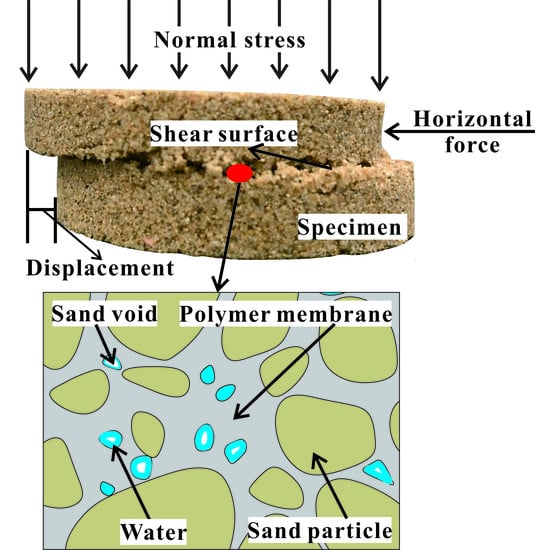

2.3. Direct Shear Test

3. Results

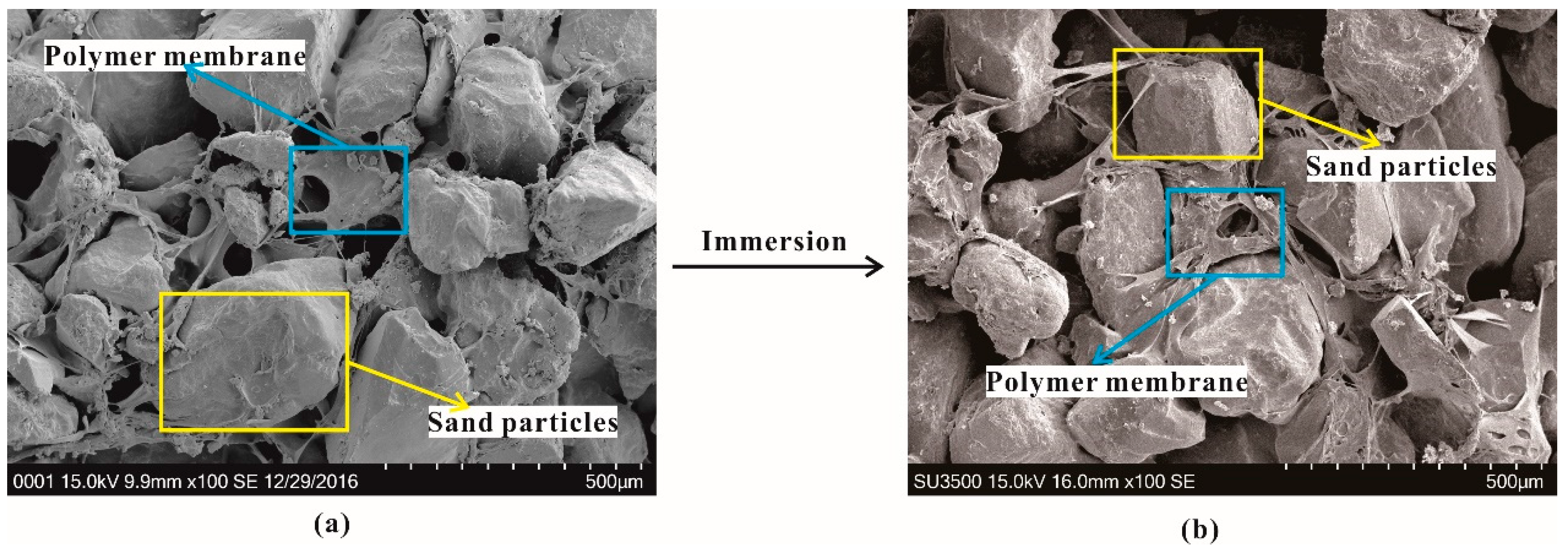

3.1. The SEM Studies and Analysis

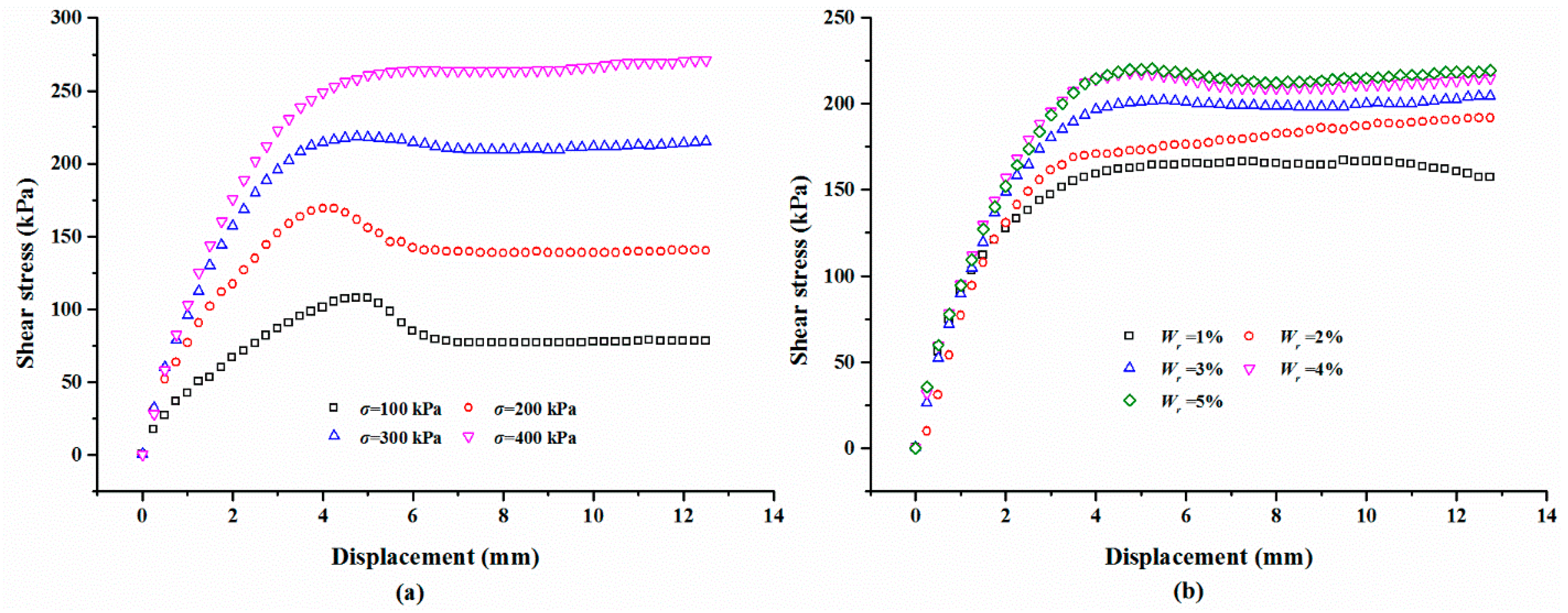

3.2. Direct Shear Test Results

3.2.1. The Effect of Curing Time on Shear Behaviors

3.2.2. The Effect of Immersion Time on Shear Behaviors

3.2.3. The Effect of Polymer Content on Shear Behaviors

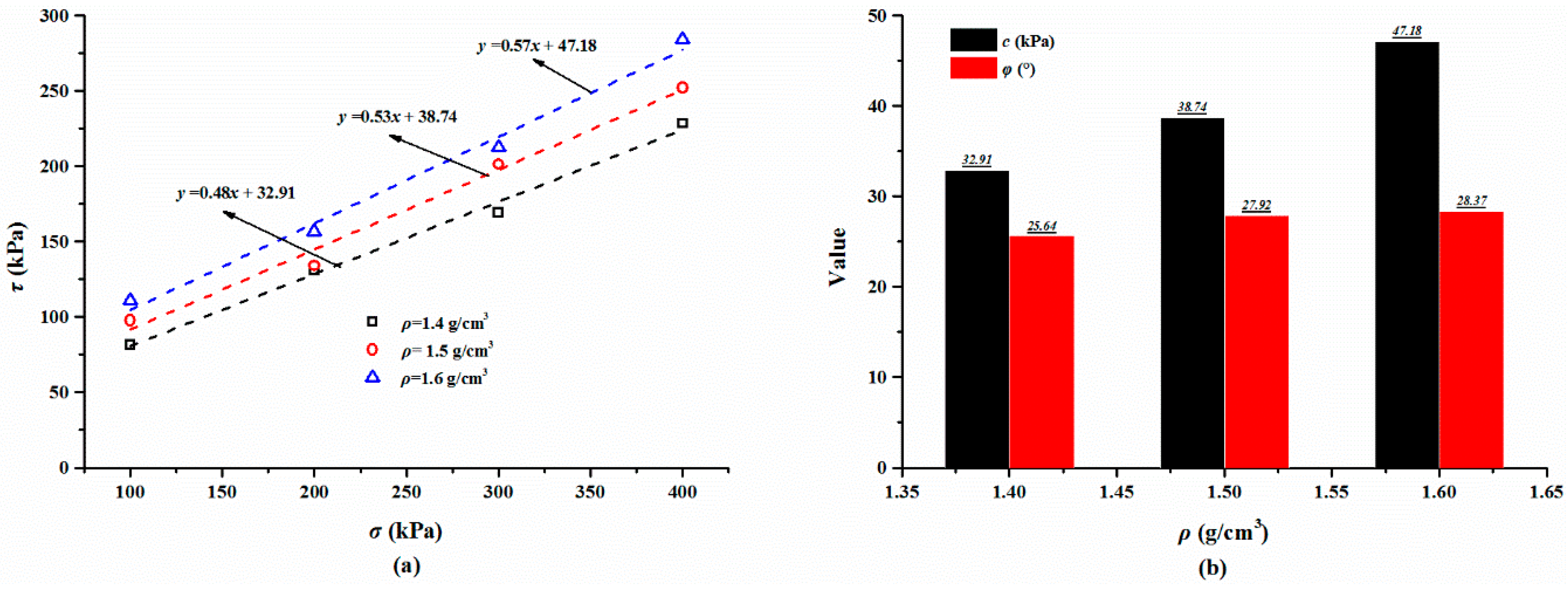

3.2.4. Effect of Sand Dry Density on Shear Behaviors

4. Discussion

5. Conclusions

- (1)

- The polymer-sand composite material still has good shear behaviors after immersion when compared to the only sand material. An increment in the curing time, polymer content, and dry density displays improvements in the shear properties, including the shear curves, shear strength, and shear strength parameters. The variation of the curing time and polymer content leads to a great change in the cohesion, while weakly affecting the friction angle, which fluctuating at around 25°. Both cohesion and the friction angle increase with an increment in the dry density, which varies from 32.91 to 47.18 kPa and 25.64° to 28.37° while the dry density increases from 1.4 to 1.6 g/cm3. However, the increase in the immersion time reduces the shear behaviors of this composite material after immersion. Similar to the curing time and polymer content, the immersion time significantly influences the cohesion and lightly affects the friction angle.

- (2)

- The shear behaviors of the polymer-sand composite material mainly depend on the integrity and stability of the elastic and viscous structure formed by the polymer membrane. When the specimen is immersed in water, the water content of the specimens increases. In the meantime, the membranes are softened, and therefore, the shear strength decreases with an increment in the immersion time. However, the curing time and polymer content both play positive effects on the integrity and stability of the three-dimensional bridge by increasing the membrane strength and adhesion contact of the sand particles. Unlike the curing time and polymer content, the sand dry density affects the membranes’ integrity through the tightness of the soil particle arrangement and determines the frictional action of soils. Thus, the shear strength of this material improves with an increase in the dry density.

Author Contributions

Funding

Conflicts of Interest

References

- Latifi, N.; Marto, A.; Eisazadeh, A. Structural characteristics of laterite soil treated by sh-85 and tx-85 (non-traditional) stabilizers. Electron. J. Geotech. Eng. 2013, 18, 1707–1718. [Google Scholar]

- Sand, F. Behavior of fabric- versus fiber-reinforced sand. Electron. J. Geotech. Eng. 1986, 112, 804–820. [Google Scholar]

- Cepuritis, R.; Mørtsell, E. Possibilities of improving crushed sand performance in fresh concrete by washing: A case study. Mater. Struct. 2016, 49, 5131–5146. [Google Scholar] [CrossRef]

- Hsieh, C.; Hsieh, M.W. Load plate rigidity and scale effects on the frictional behavior of sand/geomembrane interfaces. Geotext. Geomembr. 2003, 21, 25–47. [Google Scholar] [CrossRef]

- Izgin, M.; Wasti, Y. Geomembrane–sand interface frictional properties as determined by inclined board and shear box tests. Geotext. Geomembr. 1998, 16, 207–219. [Google Scholar] [CrossRef]

- Keramatikerman, M.; Chegenizadeh, A.; Nikraz, H. Experimental study on effect of fly ash on liquefaction resistance of sand. Soil Dyn. Earthq. Eng. 2017, 93, 1–6. [Google Scholar] [CrossRef]

- Wu, P.H.; Houben, L.J.M.; Scarpas, A.; Egyed, C.E.G.; De, L.R.R. Stiffness modulus and fatigue properties of cement stabilized sand with use of a synthetic modified-zeolite additive. In Proceedings of the Transportation Research Board Annual Meeting, Washington, DC, USA, 11–15 January 2015. [Google Scholar]

- Neeraja, V.S.; Manjari, K.G.; Babu, G.L.S. Numerical analysis of effect of orientation of fibers on stress-strain response of fiber reinforced soil. Int. J. Geotech. Eng. 2014, 8, 328–334. [Google Scholar] [CrossRef]

- Zhu, H.H.; Zhang, C.C.; Tang, C.S.; Shi, B.; Wang, B.J. Modeling the pullout behavior of short fiber in reinforced soil. Geotext. Geomembr. 2014, 42, 329–338. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, P.; Shan, S.; Yuan, H.; Yuan, B. Study on strength influence mechanism of fiber-reinforced expansive soil using jute. Geotech. Geol. Eng. 2016, 34, 1079–1088. [Google Scholar]

- Ye, B.; Cheng, Z.R.; Liu, C.; Zhang, Y.D.; Lu, P. Liquefaction resistance of sand reinforced with randomly distributed polypropylene fibres. Geosynth. Int. 2017, 24, 625–636. [Google Scholar] [CrossRef]

- Maity, J.; Chattopadhyay, B.C.; Mukherjee, S.P. Behaviour of different types of sand randomly mixing with various natural fibers. J. Inst. Eng. 2012, 93, 97–104. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A.; Papaliangas, T.T.; Konstantinidis, D.; Patronis, C. Shear strength of sands reinforced with polypropylene fibers. Geotech. Geol. Eng. 2013, 31, 401–423. [Google Scholar] [CrossRef]

- Tang, C.S.; Li, J.; Wang, D.Y.; Shi, B. Investigation on the interfacial mechanical behavior of wave-shaped fiber reinforced soil by pullout test. Geotext. Geomembr. 2016, 44, 872–883. [Google Scholar] [CrossRef]

- Tang, C.S.; Wang, D.Y.; Cui, Y.J.; Shi, B.; Li, J. Tensile strength of fiber reinforced soil. J. Mater. Civ. Eng. 2016, 28, 04016031-1–04016031-13. [Google Scholar] [CrossRef]

- Little, D.N. Comparison of in-situ resilient moduli of aggregate base courses with and without low percentages of lime stabilization. ASTM Spec. Tech. Publ. 1992, 15. [Google Scholar] [CrossRef]

- Sebesta, S. Use of microcracking to reduce shrinkage cracking in cement-treated bases. Trans. Res. Rec. J. Trans. Res. Board 2005, 1936, 3–11. [Google Scholar] [CrossRef]

- Li, X. Shrinkage Cracking of Soils and Cementitiously-Stabilized Soils: Mechanisms and Modeling. Ph.D. Thesis, Washington State University, Pillman, DC, USA, 2014. [Google Scholar]

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.C. Effects of xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 2015, 74, 65–72. [Google Scholar] [CrossRef]

- Latifi, N.; Horpibulsuk, S.; Meehan, C.L.; Majid, M.Z.A.; Tahir, M.M.; Mohamad, E.T. Improvement of problematic soils with biopolymer—An environmentally friendly soil stabilizer. J. Mater. Civ. Eng. 2016, 29, 04016204. [Google Scholar] [CrossRef]

- Tingle, J.S.; Newman, J.K.; Larson, S.L.; Weiss, C.A.; Rushing, J.F. Stabilization mechanisms of nontraditional additives. Trans. Res. Rec. J. Trans. Res. Board 2007, 1989, 59–67. [Google Scholar] [CrossRef]

- Sukmak, P.; Horpibulsuk, S.; Shen, S.L. Strength development in clay–fly ash geopolymer. Constr. Build. Mater. 2013, 40, 566–574. [Google Scholar] [CrossRef]

- Suksiripattanapong, C.; Horpibulsuk, S.; Chanprasert, P.; Sukmak, P.; Arulrajah, A. Compressive strength development in fly ash geopolymer masonry units manufactured from water treatment sludge. Constr. Build. Mater. 2015, 82, 20–30. [Google Scholar] [CrossRef]

- Latifi, N.; Meehan, C.L.; Majid, M.Z.A.; Horpibulsuk, S. Strengthening montmorillonitic and kaolinitic clays using a calcium-based non-traditional additive: A micro-level study. Appl. Clay Sci. 2016, 132–133, 182–193. [Google Scholar] [CrossRef]

- Liu, J.; Bai, Y.; Song, Z.; Lu, Y.; Qian, W.; Kanungo, D.P. Evaluation of strength properties of sand modified with organic polymers. Polymers 2018, 10, 287. [Google Scholar] [CrossRef]

- Rezaeimalek, S.; Huang, J.; Bin-Shafique, S. Evaluation of curing method and mix design of a moisture activated polymer for sand stabilization. Constr. Build. Mater. 2017, 146, 210–220. [Google Scholar] [CrossRef]

- Ajalloeian, R.; Matinmanesh, H.; Abtahi, S.M.; Rowshanzamir, M. Effect of polyvinyl acetate grout injection on geotechnical properties of fine sand. Geomech. Geoeng. 2013, 8, 86–96. [Google Scholar] [CrossRef]

- Tzounis, L.; Debnath, S.; Rooj, S.; Fischer, D.; Mäder, E.; Das, A.; Stamm, M.; Heinrich, G. High performance natural rubber composites with a hierarchical reinforcement structure of carbon nanotube modified natural fibers. Mater. Des. 2014, 58, 1–11. [Google Scholar] [CrossRef]

- Tzounis, L.; Pegel, S.; Zafeiropoulos, N.E.; Avgeropoulos, A.; Paipetis, A.S.; Stamm, M. Shear alignment of a poly(styrene-butadiene-styrene) triblock copolymer/mwcnt nanocomposite. Polymer 2017, 131, 1–9. [Google Scholar] [CrossRef]

- Zandieh, A.R.; Yasrobi, S.S. Retracted article: Study of factors affecting the compressive strength of sandy soil stabilized with polymer. Geotech. Geol. Eng. 2010, 28, 139–145. [Google Scholar] [CrossRef]

- Liu, J.; Feng, Q.; Wang, Y.; Zhang, D.; Wei, J.; Kanungo, D.P. Experimental study on unconfined compressive strength of organic polymer reinforced sand. Int. J. Polym. Sci. 2018, 2018, 3503415. [Google Scholar] [CrossRef]

- Ueng, T.S.; Wang, Z.F.; Chu, M.C.; Ge, L. Laboratory tests for permeability of sand during liquefaction. Soil Dyn. Earthq. Eng. 2017, 100, 249–256. [Google Scholar] [CrossRef]

- Liu, J.; Qi, X.; Zhang, D.; Feng, Q.; Wang, Y.; Kanungo, D.P. Study on the permeability characteristics of polyurethane soil stabilizer reinforced sand. Adv. Mater. Sci. Eng. 2017, 2017, 5240186. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Z.; Song, Z.; Bai, Y.; Qian, W.; Wei, J.; Kanungo, D.P. Tensile behavior of polyurethane organic polymer and polypropylene fiber-reinforced sand. Polymers 2018, 10, 499. [Google Scholar] [CrossRef]

- Hataf, N.; Ghadir, P.; Ranjbar, N. Investigation of soil stabilization using chitosan biopolymer. J. Clean. Prod. 2018, 170, 1493–1500. [Google Scholar] [CrossRef]

- Chang, I.; Im, M.J.; Cho, G.C. Geotechnical engineering behaviors of gellan gum biopolymer treated sa. Can. Geotech. J. 2016, 53, 1658–1670. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Cho, G.C. Soil strengthening using thermo-gelation biopolymers. Constr. Build. Mater. 2015, 77, 430–438. [Google Scholar] [CrossRef]

| Weight Percentage Content (%) | Size Distribution Range of Sand Particle (mm) | ||||||

| 2–1 | 1–0.5 | 0.5–0.25 | 0.25–0.1 | 0.1–0.075 | |||

| 0.2 1 | 17.1 | 48.9 | 31.7 | 2.1 | |||

| Physical Parameters | Dry Density ρ (g/cm3) | Void Ratio e | Specific Gravity Gs | Uniformity Coefficient Cu | Gradation Coefficient Cc | ||

| ρmax = 1.69 | ρmin = 1.36 | emax = 0.97 | emin = 0.59 | 2.65 | 2.27 | 1.13 | |

| PH | Specific Gravity Gs | Viscosity (mPa·s) | Solid Content (%) | Coagulation Time (s) |

|---|---|---|---|---|

| 7 | 1.15 | 650–800 | 88 | 60–1600 |

| Test Number | Polymer Content (%) | Dry Density (g/cm3) | Curing Time (hour) | Immersion Time (hour) | Shear Strength (kPa) | Shear Strength Parameters | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| σ = 100 kPa | σ = 200 kPa | σ = 300 kPa | σ = 400 kPa | c (kPa) | φ (°) | |||||

| T1 | 2 | 1.4 | 1 | 48 | 63.69 | 115.38 | 142.30 | 204.80 | 18.98 | 24.23 |

| T2 | 2 | 1.4 | 6 | 48 | 69.23 | 119.23 | 158.30 | 219.48 | 19.10 | 26.10 |

| T3 | 2 | 1.4 | 24 | 48 | 79.24 | 128.84 | 166.34 | 225.95 | 30.67 | 25.64 |

| T4 | 2 | 1.4 | 48 | 48 | 81.73 | 130.76 | 169.22 | 228.39 | 32.91 | 25.64 |

| T5 | 2 | 1.4 | 72 | 48 | 99.53 | 146.15 | 177.56 | 249.70 | 47.76 | 25.64 |

| T6 | 2 | 1.4 | 48 | 1 | 99.03 | 155.38 | 211.53 | 246.14 | 53.65 | 26.10 |

| T7 | 2 | 1.4 | 48 | 6 | 92.73 | 138.46 | 206.72 | 242.04 | 40.93 | 27.02 |

| T8 | 2 | 1.4 | 48 | 24 | 85.57 | 135.30 | 173.07 | 229.62 | 38.42 | 25.17 |

| T9 | 2 | 1.4 | 48 | 48 | 81.73 | 130.76 | 169.22 | 228.39 | 32.91 | 25.64 |

| T10 | 2 | 1.4 | 48 | 72 | 84.23 | 121.15 | 162.54 | 227.52 | 31.04 | 25.17 |

| T11 | 2 | 1.4 | 48 | 168 | 78.46 | 119.23 | 167.83 | 219.61 | 28.27 | 25.27 |

| T12 | 2 | 1.4 | 48 | 216 | 76.61 | 112.69 | 162.51 | 212.94 | 26.48 | 24.70 |

| T13 | 1 | 1.4 | 48 | 48 | 73.07 | 104.23 | 159.06 | 214.37 | 18.00 | 25.64 |

| T14 | 2 | 1.4 | 48 | 48 | 81.73 | 130.76 | 169.22 | 228.39 | 32.91 | 25.64 |

| T15 | 3 | 1.4 | 48 | 48 | 99.99 | 151.02 | 196.62 | 241.20 | 54.91 | 25.17 |

| T16 | 4 | 1.4 | 48 | 48 | 107.69 | 169.22 | 218.11 | 248.95 | 67.83 | 25.17 |

| T17 | 5 | 1.4 | 48 | 48 | 122.69 | 183.65 | 220.54 | 269.14 | 79.94 | 24.70 |

| T18 | 2 | 1.4 | 48 | 48 | 81.73 | 130.76 | 169.22 | 228.39 | 32.91 | 25.64 |

| T19 | 2 | 1.5 | 48 | 48 | 97.61 | 134.22 | 201.17 | 251.99 | 38.74 | 27.92 |

| T20 | 2 | 1.6 | 48 | 48 | 110.76 | 156.72 | 212.35 | 283.88 | 47.18 | 28.37 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Bai, Y.; Li, D.; Wang, Q.; Qian, W.; Wang, Y.; Kanungo, D.P.; Wei, J. An Experimental Study on the Shear Behaviors of Polymer-Sand Composite Materials after Immersion. Polymers 2018, 10, 924. https://doi.org/10.3390/polym10080924

Liu J, Bai Y, Li D, Wang Q, Qian W, Wang Y, Kanungo DP, Wei J. An Experimental Study on the Shear Behaviors of Polymer-Sand Composite Materials after Immersion. Polymers. 2018; 10(8):924. https://doi.org/10.3390/polym10080924

Chicago/Turabian StyleLiu, Jin, Yuxia Bai, Ding Li, Qiongya Wang, Wei Qian, Ying Wang, Debi Prasanna Kanungo, and Jihong Wei. 2018. "An Experimental Study on the Shear Behaviors of Polymer-Sand Composite Materials after Immersion" Polymers 10, no. 8: 924. https://doi.org/10.3390/polym10080924

APA StyleLiu, J., Bai, Y., Li, D., Wang, Q., Qian, W., Wang, Y., Kanungo, D. P., & Wei, J. (2018). An Experimental Study on the Shear Behaviors of Polymer-Sand Composite Materials after Immersion. Polymers, 10(8), 924. https://doi.org/10.3390/polym10080924