Removal of Endocrine Disrupting Chemicals from Water: Adsorption of Bisphenol-A by Biobased Hydrophobic Functionalized Cellulose

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Cellulose Fiber Hydrophobization

2.3. Cellulose Fiber Surface Characterization

2.4. BPA Analytical Determination

2.5. Adsorption Tests

3. Results and Discussion

3.1. Effect of pH

3.2. Regeneration and Reuse of Fiber

3.3. Effect of Water Matrix

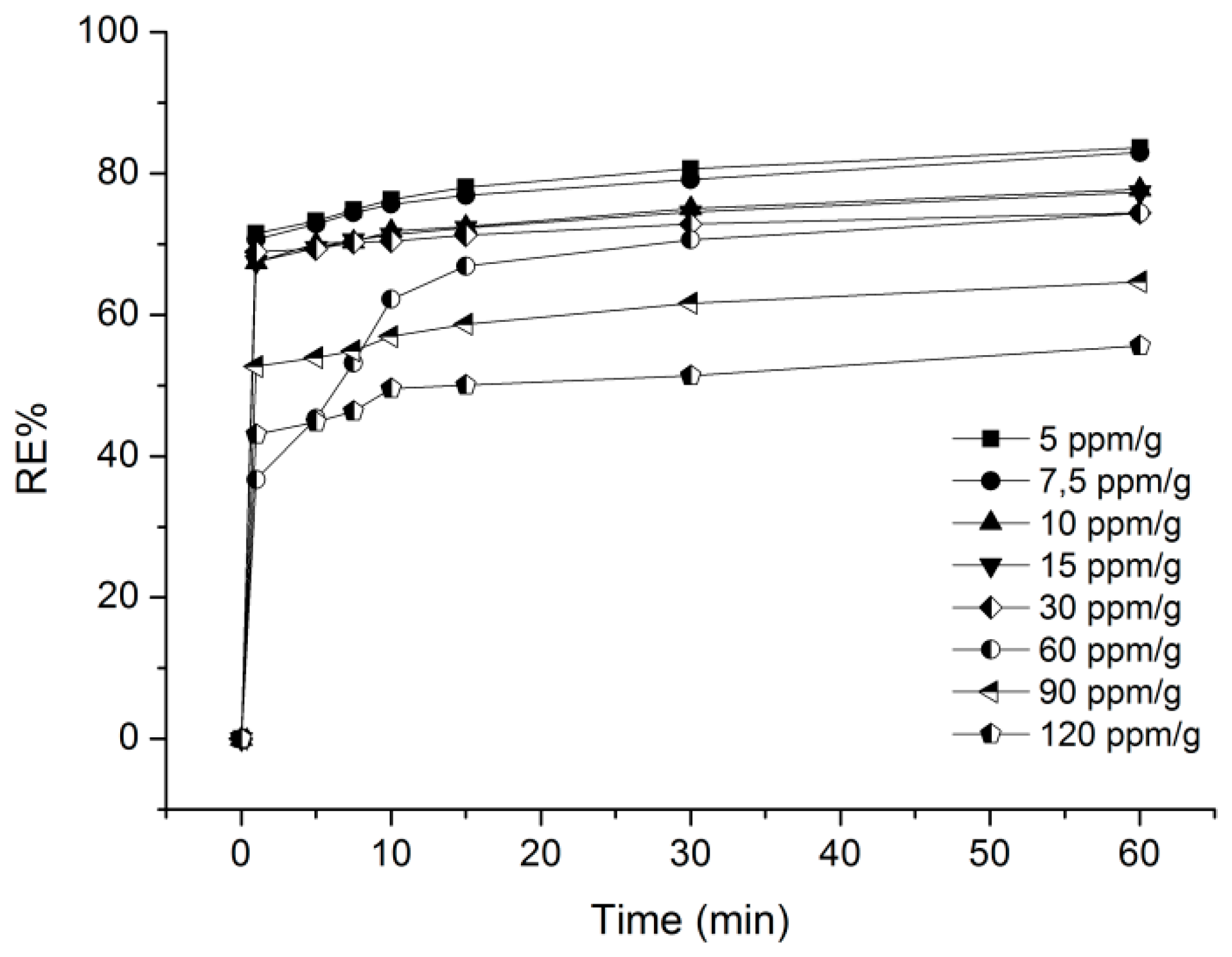

3.4. Adsorption Kinetics of BPA

3.5. Adsorption Isotherm

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- US Environmental Protection Agency (USEPA). Environmental protection agency—Endocrine disruptor screening program. In Report to Congress; USEPA: Washington, DC, USA, 2000. [Google Scholar]

- Zeng, G.M.; Zhang, C.; Huang, G.H.; Yu, J.; Wang, Q.; Li, J.; Xi, B.; Liu, H. Adsorption behavior of bisphenol A on sediments in Xiangjiang River, Central-south China. Chemosphere 2006, 65, 1490–1499. [Google Scholar] [CrossRef] [PubMed]

- Staples, C.A.; Dorn, P.B.; Klecka, G.M.; O’Block, S.T.; Harris, L.R. A review of the environmental fate, effects, and exposures of bisphenol A. Chemosphere 1998, 36, 2149–2173. [Google Scholar] [CrossRef]

- Kang, J.H.; Kondo, F.; Katayama, Y. Human exposure to bisphenol A. Toxicology 2006, 226, 79–89. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.Q.; Wong, C.K.C.; Zheng, J.S.; Bouwman, H.; Barra, R.; Wahlström, B.; Neretin, L.; Wong, M.H. Bisphenol A (BPA) in China: A review of sources, environmental levels, and potential human health impacts. Environ. Int. 2012, 42, 91–99. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, T.; Yasuhara, A.; Shiraishi, H.; Nakasugi, O. Bisphenol A in hazardous waste landfill leachates. Chemosphere 2001, 42, 415–418. [Google Scholar] [CrossRef]

- Fukazawa, H.; Watanabe, M.; Shiraishi, F.; Shiraishi, H.; Shiozawa, T.; Matsushita, H.; Yoshiyasu, T. Formation of chlorinated derivatives of Bisphenol A in waste paper recycling plants and their estrogenic activities. J. Health Sci. 2002, 48, 242–249. [Google Scholar] [CrossRef]

- Heemken, O.P.; Reincke, H.; Stachel, B.; Theobald, N. The occurrence of xenoestrogens in the Elbe river and the North Sea. Chemosphere 2001, 45, 245–259. [Google Scholar] [CrossRef]

- Lee, H.B.; Peart, T.E.; Gris, G.; Chan, J. Endocrine-disrupting chemicals in industrial wastewater samples in Toronto, Ontario. Water Qual. Res. J. Can. 2002, 37, 459–472. [Google Scholar] [CrossRef]

- Colin, A.; Bach, C.; Rosin, C.; Munoz, J.F.; Dauchy, X. Is drinking water a major route of human exposure to alkylphenol and bisphenol contaminants in France? Arch. Environ. Contam. Toxicol. 2014, 66, 86–99. [Google Scholar] [CrossRef] [PubMed]

- Kleywegt, S.; Pileggi, V.; Yang, P.; Hao, C.; Zhao, X.; Rocks, C.; Thach, S.; Cheung, P.; Whitehead, B. Pharmaceuticals, hormones and bisphenol A in untreated source and finished drinking water in Ontario, Canada, occurrence and treatment efficiency. Sci. Total Environ. 2011, 409, 1481–1488. [Google Scholar] [CrossRef] [PubMed]

- Rochester, J.R. Bisphenol A and human health: A review of the literature. Reprod. Toxicol. 2013, 42, 132–155. [Google Scholar] [CrossRef] [PubMed]

- Castoria, G.; Giovannelli, P.; Lombardi, M.; De Rosa, C.; Giraldi, T.; de Falco, A.; Barone, M.V.; Abbondanza, C.; Migliaccio, A.; Auricchio, F. Tyrosine phosphorylation of estradiol receptor by Src regulates its hormone-dependent nuclear export and cell cycle progression in breast cancer cells. Oncogene 2012, 31, 4868–4877. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Di Donato, M.; Cernera, G.; Giovannelli, P.; Galasso, G.; Bilancio, A.; Migliaccio, A.; Castoria, G. Recent advances on bisphenol-A and endocrine disruptor effects on human prostate cancer. Mol. Cell. Endocrinol. 2017, 457, 35–42. [Google Scholar] [CrossRef] [PubMed]

- Braun, J.M.; Kalkbrenner, A.E.; Calafat, A.M.; Yolton, K.; Ye, X.; Dietrich, K.N.; Lanphear, B.P. Impact of early-life bisphenol A exposure on behavior and executive function in children. Pediatrics 2011, 128, 873–882. [Google Scholar] [CrossRef] [PubMed]

- Rees-Clayton, E.M.; Todd, M.; Dowd, J.B.; Aiello, A.E. The impact of bisphenol A and triclosan on immune parameters in the U.S. population, NHANES 2003–2006. Environ. Health Persp. 2011, 119, 390–396. [Google Scholar] [CrossRef] [PubMed]

- Joseph, L.; Flora, J.R.V.; Park, Y.-G.; Badawy, M.; Saleh, H.; Yoon, Y. Removal of natural organic matter from potential drinking water sources by combined coagulation and adsorption using carbon nanomaterials. Sep. Purif. Technol. 2012, 95, 64–72. [Google Scholar] [CrossRef]

- Westerhoff, P.; Yoon, Y.; Snyder, S.; Wert, E. Fate of endocrine-disruptor, pharmaceutical, and personal care product chemicals during simulated drinking water treatment processes. Environ. Sci. Technol. 2005, 39, 6649–6663. [Google Scholar] [CrossRef] [PubMed]

- Joseph, L.; Zaib, Q.; Khan, I.A.; Berge, N.D.; Park, Y.-G.; Saleh, N.B.; Yoon, Y. Removal of bisphenol A and 17α-ethinyl estradiol from landfill leachate using single-walled carbon nanotubes. Water Res. 2011, 45, 4056–4068. [Google Scholar] [CrossRef] [PubMed]

- Nam, S.W.; Jung, C.; Li, H.; Yu, M.; Flora, J.R.V.; Boateng, L.K.; Her, N.; Zoh, K.D.; Yoon, Y. Adsorption characteristics of diclofenac and sulfamethoxazole to graphene oxide in aqueous solution. Chemosphere 2015, 136, 20–26. [Google Scholar] [CrossRef] [PubMed]

- Muhamad, M.S.; Salim, M.R.; Lau, W.J.; Yusop, Z. A review on bisphenol A occurrences, health effects and treatment process via membrane technology for drinking water. Environ. Sci. Pollut. Res. 2016, 23, 11549–11567. [Google Scholar] [CrossRef] [PubMed]

- de Oliveira, L.K.; Moura, A.L.A.; Barbosa, V.; Parreira, R.L.T.; Banegas, R.S.; Caramori, G.F.; Ciuffi, K.J.; Molina, E.F. Removal of the emerging contaminant bisphenol A by an ureasil-PEO hybrid membrane: Experimental study and molecular dynamic simulation. Environ. Sci. Pollut. Res. 2017, 24, 18421–18433. [Google Scholar] [CrossRef] [PubMed]

- Duan, X.D.; He, X.X.; Wang, D.; Mezyk, S.P.; Otto, S.C.; Marfil Vega, R.; Mills, M.A.; Dionysiou, D.D. Decomposition of iodinated pharmaceuticals by UV254 nm-assisted advanced oxidation processes. J. Hazard. Mater. 2017, 323, 489–499. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Zhao, J.; Li, Y. Removal of bisphenol A and 4-n-nonylphenol coupled to nitrate reduction using acclimated activated sludge under anaerobic conditions. J. Chem. Technol. Biotechnol. 2013, 89, 391–400. [Google Scholar] [CrossRef]

- Wang, G.; Wu, F.; Zhang, X.; Luo, M.; Deng, N. Enhanced photodegradation of bisphenol A in the presence of β-cyclodextrin under UV light. J. Chem. Technol. Biotechnol. 2006, 81, 805–811. [Google Scholar] [CrossRef]

- Eio, E.J.; Kawai, M.; Niwa, C.; Ito, M.; Yamamoto, S.; Toda, T. Biodegradation of bisphenol A by an algal-bacterial system. Environ. Sci. Pollut. Res. 2015, 22, 15145–15153. [Google Scholar] [CrossRef] [PubMed]

- Davididou, K.; Hale, E.; Lane, N.; Chatzisymeon, E.; Pichavant, A.; Hochepied, J.F. Photocatalytic treatment of saccharin and bisphenol-A in the presence of TiO2 nanocomposites tuned by Sn (IV). Catal. Today 2017, 287, 3–9. [Google Scholar] [CrossRef]

- Outsiou, A.; Frontistis, Z.; Ribeiro, R.S.; Antonopoulou, M.; Konstantinou, I.K.; Silva, A.M.T.; Faria, J.L.; Gomes, H.T.; Mantzavinos, D. Activation of sodium persulfate by magnetic carbon xerogels (CX/CoFe) for the oxidation of bisphenol A: Process variables effects, matrix effects and reaction pathways. Water Res. 2017, 124, 97–107. [Google Scholar] [CrossRef] [PubMed]

- Rivas, F.J.; Encinas, A.; Acedo, B.; Beltran, F.J. Mineralization of bisphenol A by advanced oxidation processes. J. Chem. Technol. Biotechnol. 2008, 84, 589–594. [Google Scholar] [CrossRef]

- Rivero, M.J.; Alonso, E.; Dominguez, S.; Ribao, P.; Ibañez, R.; Ortiz, I.; Irabien, A. Kinetic analysis and biodegradability of the Fenton mineralization of bisphenol A. J. Chem. Technol. Biotechnol. 2014, 89, 1228–1234. [Google Scholar] [CrossRef]

- Zacharakis, A.; Chatzisymeon, E.; Binas, V.; Frontistis, Z.; Venieri, D.; Mantzavinos, D. Solar photocatalytic degradation of bisphenol A on immobilized ZnO or TiO2. Int. J. Photoenergy 2013, 1–9, 570–587. [Google Scholar] [CrossRef]

- Snyder, S.A.; Adham, S.; Redding, A.M.; Cannon, F.S.; DeCarolis, J.; Oppenheimer, J.; Wert, E.C.; Yoon, Y. Role of membranes and activated carbon in the removal of endocrine disruptors and pharmaceuticals. Desalination 2007, 202, 156–181. [Google Scholar] [CrossRef]

- Ioannou-Ttofa, L.; Foteinis, S.; Chatzisymeon, E.; Fatta-Kassinos, D. The environmental footprint of a membrane bioreactor treatment process through Life Cycle Analysis. Sci. Total Environ. 2016, 568, 306–318. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nakanishi, A.; Tamai, M.; Kawasaki, N.; Nakamura, T.; Tanada, S. Adsorption characteristics of bisphenol A onto carbonaceous materials produced from wood chips as organic waste. J. Colloid Interface Sci. 2002, 252, 393–396. [Google Scholar] [CrossRef] [PubMed]

- Asada, T.; Oikawa, K.; Kawata, K.; Ishihara, S.; Iyobe, T. Study of removal effect of bisphenol-A and B-estradiol by porous carbon. J. Health Sci. 2004, 50, 588–593. [Google Scholar] [CrossRef]

- Yoon, Y.; Westerhoff, P.; Snyder, S.A.; Esparza, M. HPLC fluorescence detection and adsorption of bisphenol A, 17β-estradiol, and 17α-ethynyl estradiol on powdered activated carbon. Water Res. 2003, 37, 3530–3537. [Google Scholar] [CrossRef]

- Lazim, Z.M.; Hadibarata, T.; Puteh, M.H.; Yusop, Z. Adsorption characteristics of bisphenol A onto low-cost modified phyto-waste material in aqueous solution. Water Air Soil Pollut. 2015, 226, 34–45. [Google Scholar] [CrossRef]

- Tursi, A.; Beneduci, A.; Chidichimo, F.; De Vietro, N.; Chidichimo, G. Remediation of hydrocarbons polluted water by hydrophobic functionalized cellulose. Chemosphere 2018, 201, 530–539. [Google Scholar] [CrossRef] [PubMed]

- Arias, F.; Beneduci, A.; Chidichimo, F.; Furia, E.; Straface, S. Study of the adsorption of mercury (II) on lignocellulosic materials under static and dynamic conditions. Chemosphere 2017, 180, 11–23. [Google Scholar] [CrossRef] [PubMed]

- Gabriele, B.; Cerchiara, T.; Salerno, G.; Chidichimo, G.; Vetere, M.V.; Alampi, C.; Gallucci, M.C.; Conidi, C.; Cassano, A. A new physical-chemical process for the efficient production of cellulose fibers from Spanish broom (Spartium junceum L.). Bioresour. Technol. 2009, 101, 724–729. [Google Scholar] [CrossRef] [PubMed]

- Agenzia Nazionale per la protezione dell’Ambiente (APAT). Metodi analitici per le acque/APAT; IRSA-CNR. In Manuali e Linee Guida 29/2003; APAT: Roma, Italy, 2003; ISBN 8844800837. [Google Scholar]

- Henze, M.; Comeau, Y. Wastewater characterization. In Biological Wastewater Treatment: Principles, Modelling and Design; Henze, M., van Loosdrecht, M.C.M., Ekama, G.A., Brdjanovic, D., Eds.; IWA Publishing: London, UK, 2008; pp. 33–52. ISBN 1843391880. [Google Scholar]

- Boehm, H.P. Chapter thirteen—Surface chemical characterization of carbons from adsorption studies. In Adsorption by Carbons; Bottani, E.J., Tascón, J.M.D., Eds.; Elsevier: Amsterdam, NL, USA, 2008; pp. 301–327. ISBN 9780080444642. [Google Scholar]

- Bismarck, A.; Aranberri-Askargorta, I.; Springer, J.; Lampke, T.; Wielage, B.; Stamboulis, A.; Limbach, H.H. Surface characterization of flax, hemp and cellulose fibers; surface properties and the water uptake behavior. Polym. Compos. 2002, 23, 872–894. [Google Scholar] [CrossRef]

- Limousin, G.; Gaudet, J.P.; Charlet, L.; Szenknect, S.; Barthes, V.; Krimissa, M. Sorption isotherms: A review on physical bases, modeling and measurement. Appl. Geochem. 2007, 22, 249–275. [Google Scholar] [CrossRef]

- Atkins, P.; De Paula, J. Physical Chemistry, 8th ed.; W. H. Freeman and Company: New York, NY, USA, 2006. [Google Scholar]

- Chang, K.L.; Hsieh, J.F.; Ou, B.M.; Chang, M.H.; Hseih, W.Y.; Lin, J.H.; Huang, P.J.; Wong, K.F.; Chen, S.T. Adsorption studies on the removal of an endocrine-disrupting compound (bisphenol A) using activated carbon from rice straw agricultural waste. Sep. Sci. Technol. 2012, 47, 1514–1521. [Google Scholar] [CrossRef]

- Bautista-Toledo, I.; Ferro-Garcia, M.A.; Rivera-Utrilla, J.; Moreno-Castilla, C.; Vegas Fernandez, F.J. Bisphenol A removal from water by activated carbon. Effect of carbon characteristics and solution chemistry. Environ. Sci. Technol. 2005, 39, 6246–6250. [Google Scholar] [CrossRef] [PubMed]

- Cerchiara, T.; Chidichimo, G.; Rondi, G.; Gallucci, M.C.; Gattuso, C.; Luppi, B.; Bigucci, F. Chemical Composition, morphology and tensile properties of Spanish broom (Spartium junceum L.) fibres in comparison with flax (Linum usitatissimum L.). Fibres Text. East. Eur. 2014, 22, 25–28. [Google Scholar]

| C0/W (ppm/g) | k21 (g mg−1 min−1) | qe1 (mg g−1) | R2 |

|---|---|---|---|

| 5 | 7.175 (1.140) | 0.21 (0.04) | 0.99935 |

| 7.5 | 4.629 (0.885) | 0.31 (0.03) | 0.99913 |

| 10 | 4.311 (0.590) | 0.39 (0.02) | 0.99940 |

| 15 | 2.937 (0.393) | 0.58 (0.02) | 0.99940 |

| 30 | 0.757 (0.155) | 1.73 (0.04) | 0.99917 |

| 60 | 0.219 (0.123) | 2.29 (0.05) | 0.99637 |

| 90 | 0.353 (0.115) | 2.95 (0.07) | 0.99869 |

| 120 | 0.273 (0.101) | 3.37 (0.04) | 0.99775 |

| Adsorbent | qmax (mg g−1) | Contact Time | pH | Isotherm Model | Reference |

|---|---|---|---|---|---|

| Coir pitch | 4.31 | 24 h | 3 | Langmuir | [37] |

| Coconut shell | 4.16 | 24 h | 3 | Langmuir | [37] |

| Durian peel | 4.18 | 24 h | 3 | Langmuir | [37] |

| SB Functionalized fiber (FF) | 4.86 | 1 h | 5 | Langmuir | This study |

| ACs from Rice Straw | 181.19 | 1.5 h | 2.35 | Langmuir | [47] |

| ACs from Almond shell | 188.90 | — | 2–8 | Langmuir | [48] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tursi, A.; Chatzisymeon, E.; Chidichimo, F.; Beneduci, A.; Chidichimo, G. Removal of Endocrine Disrupting Chemicals from Water: Adsorption of Bisphenol-A by Biobased Hydrophobic Functionalized Cellulose. Int. J. Environ. Res. Public Health 2018, 15, 2419. https://doi.org/10.3390/ijerph15112419

Tursi A, Chatzisymeon E, Chidichimo F, Beneduci A, Chidichimo G. Removal of Endocrine Disrupting Chemicals from Water: Adsorption of Bisphenol-A by Biobased Hydrophobic Functionalized Cellulose. International Journal of Environmental Research and Public Health. 2018; 15(11):2419. https://doi.org/10.3390/ijerph15112419

Chicago/Turabian StyleTursi, Antonio, Efthalia Chatzisymeon, Francesco Chidichimo, Amerigo Beneduci, and Giuseppe Chidichimo. 2018. "Removal of Endocrine Disrupting Chemicals from Water: Adsorption of Bisphenol-A by Biobased Hydrophobic Functionalized Cellulose" International Journal of Environmental Research and Public Health 15, no. 11: 2419. https://doi.org/10.3390/ijerph15112419

APA StyleTursi, A., Chatzisymeon, E., Chidichimo, F., Beneduci, A., & Chidichimo, G. (2018). Removal of Endocrine Disrupting Chemicals from Water: Adsorption of Bisphenol-A by Biobased Hydrophobic Functionalized Cellulose. International Journal of Environmental Research and Public Health, 15(11), 2419. https://doi.org/10.3390/ijerph15112419