Investigation of Impact Strength and Hardness of UHMW Polyethylene Composites Reinforced with Nano-Hydroxyapatite Particles Fabricated by Friction Stir Processing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Setup

2.3. Design of Experiments

2.4. Mechanical Testing

3. Results

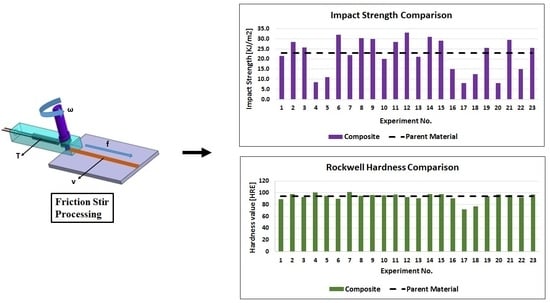

3.1. Mechanical Properties of the Composite

3.2. Analysis of Variance

3.3. Effects of FSP Parameters on Impact Strength of the Composite

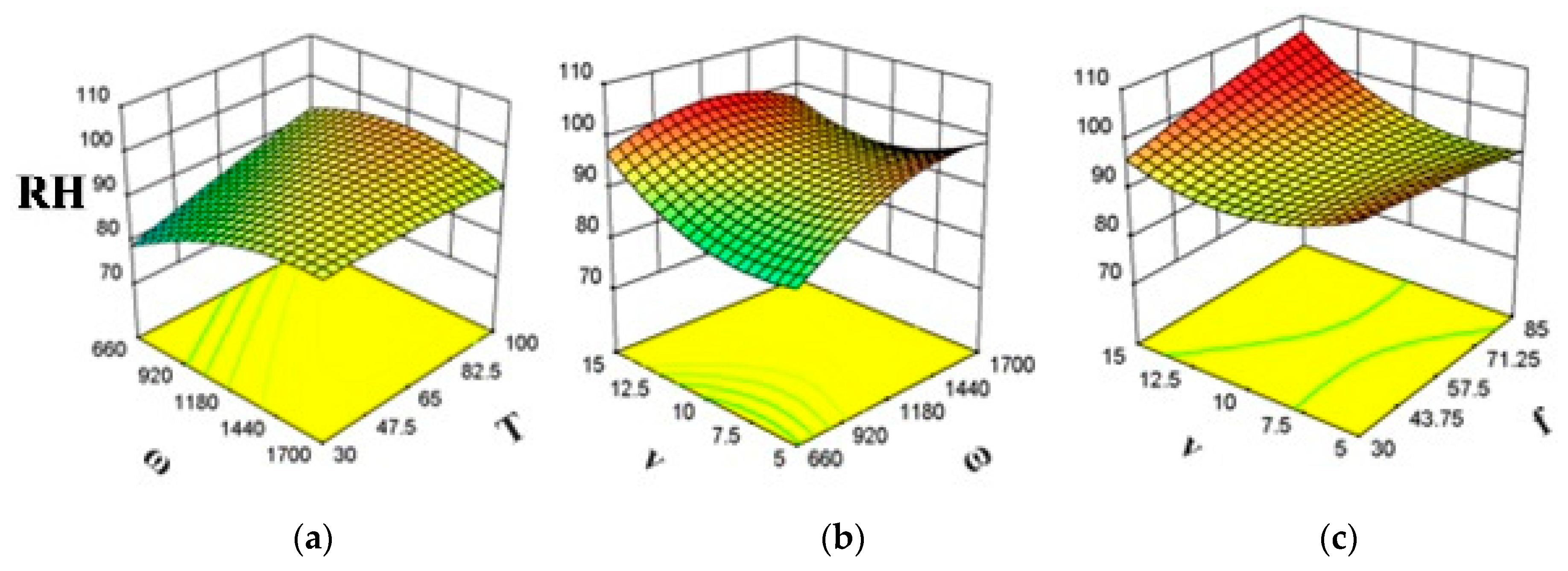

3.4. Effects of FSP Parameters on Hardness of the Composite

3.5. Empirical Models and Validation

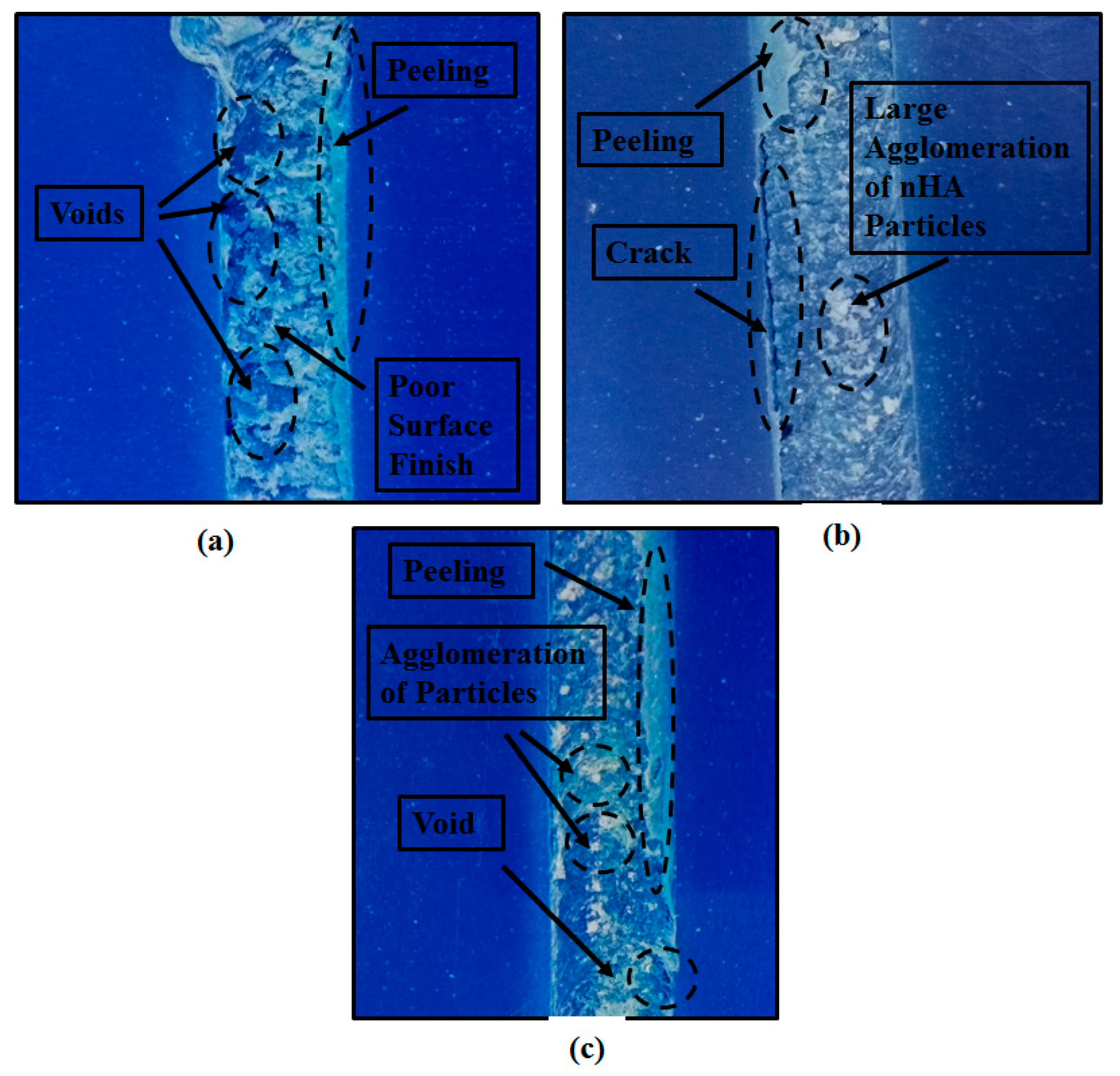

3.6. Microscopic and Macroscopic Analysis

3.7. Optimum Conditions

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Stein, H.L. Ultra-High Molecular Weight Polyethylene (UHMWPE). In Guide to Engineering Plastics Families: Thermoplastic Resins, Engineering Materials Handbook; ASM international: Novelty, OH, USA, 1992; Volume 2. [Google Scholar]

- Vallet-Regi, M. Bio-Ceramics with Clinical Applications; John Wiley & Sons: Chichester, UK, 2014. [Google Scholar]

- Gupta, S.; Riyad, M.F. Synthesis and tribological behavior of novel UHMWPE-Ti3SiC2 composites. Polym. Compos. 2016, 39, 254–262. [Google Scholar] [CrossRef]

- Kurtz, S.M. Ultra high molecular weight polyethylene in total joint replacement and medical devices. In UHMWPE Biomaterials Handbook; Academic Press: NY, USA, 2009. [Google Scholar]

- Huang, H.Y.; Liu, Z.H.; Feng, T. O-6-85-In vivo evaluation of porous Hydroxylapatite ceramic as cervical vertebra substitute. Clin. Neurol. Neurosurg. 1997, 99, S20–S21. [Google Scholar] [CrossRef]

- Mishra, R.S.; Mahoney, M.W.; McFadden, S.X.; Mara, N.A.; Mukherjee, A.K. High strain rate superplasticity in a friction stir processed 7075 Al alloy. Scr. Mater. 1999, 42, 163–168. [Google Scholar] [CrossRef]

- Wei, H.; Tariq, M.; Hussain, G.; Khan, I.; Imran Khan, M.; Khan, W.A. Butt Joining of Bi-Layered Aluminum Sheets through Friction Stir Welding: Tensile Stresses, Bending Stresses, Residual Stresses, and Fractrography. Metals 2019, 9, 384. [Google Scholar] [CrossRef]

- Tariq, M.; Khan., I.; Hussain, G.; Farooq, U. Microstructure and micro-hardness analysis of friction stir welded bi-layered laminated aluminum sheets. Int. J. Lightweight Mater. Manuf. 2019. [Google Scholar] [CrossRef]

- Panneerselvam, K.; Lenin, K. Investigation on effect of tool forces and joint defects during FSW of polypropylene plate. Procedia Eng. 2012, 38, 3927–3940. [Google Scholar] [CrossRef]

- Strand, S. Joining plastics—can friction stir welding compete? In Proceedings of the Electrical Insulation Conference and Electrical Manufacturing and Coil Winding Technology Conference, Indianapolis, IN, USA, 25–25 September 2003; pp. 321–326. [Google Scholar]

- Kumar, R.; Singh, R.; Ahuja, I.P.S. Friction stir welding of ABS-15Al sheets by introducing compatible semi-consumable shoulder-less pin of PA6-50Al. Measurement 2019, 131, 461–472. [Google Scholar] [CrossRef]

- Azarsa, E.; Mostafapour, A. On the feasibility of producing polymer–metal composites via novel variant of friction stir processing. J. Manuf. Process. 2013, 15, 682–688. [Google Scholar] [CrossRef]

- Khan, I.; Hussain, G.; Tariq, M.; Ilyas, M. Fabrication of UHMW polyethylene/nano-hydroxyapatite biocomposite via heat-assisted friction stir processing. Int. J. Adv. Manuf. Tech. 2018, 96, 3651–3663. [Google Scholar] [CrossRef]

- Sheikh-Ahmad, J.Y.; Ali, D.S.; Deveci, S.; Almaskari, F.; Jarrar, F. Friction stir welding of high density polyethylene—Carbon black composite. J. Mater. Process. Technol. 2019, 264, 402–413. [Google Scholar] [CrossRef]

- Abdel-Gwad, E.F.; Omar, A.B.; Radwan, A.H. Load ability of Friction Stir Welded Joints of High Density Polyethylene. Int. J. Tech. Res. Appl. 2015, 32, 25–32. [Google Scholar]

- Azarsa, E.; Mostafapour, A. Experimental investigation on flexural behavior of friction stir welded high density polyethylene sheets. J. Manuf. Process. 2014, 16, 149–155. [Google Scholar] [CrossRef]

- Scialpi, A.; Troughton, M.; Andrews De Filippis, L.A.C. Viblade™: Friction stir welding for plastics. Weld. Int. 2009, 23, 846–855. [Google Scholar] [CrossRef]

- Hussain, G.; Khan, I. Characteristics of Friction Stir Processed UHMW Polyethylene Based Composite. In IOP Conference Series: Materials Science and Engineering, Wuhan, China, 10–12 November 2017; IOP Publishing: Bristol, UK, 2018. [Google Scholar] [CrossRef]

- Battisti, M.G.; Friesenbichler, W. Injection-moulding compounding of PP polymer nanocomposites. Strojniški vestnik J. Mech. Eng. 2013, 59, 662–668. [Google Scholar] [CrossRef]

- Mostafapour, A.; Taghizad Asad, F. Investigations on joining of Nylon 6 plates via novel method of heat assisted friction stir welding to find the optimum process parameters. Sci. Technol. Weld. Joining 2016, 21, 660–669. [Google Scholar] [CrossRef]

- Jones, B.; Goos, P. I-optimal versus D-optimal split-plot response surface designs. J. Qual. Technol. 2012, 44, 85–101. [Google Scholar] [CrossRef]

| Property | Value and Units | Symbol |

|---|---|---|

| Ultimate tensile strength | 18.6 MPa | UTS |

| Tensile modulus | 160 MPa | E |

| Strain at failure | 8.3 mm/mm | e failure |

| Impact strength (u-notched) | 23 KJ/m2 | I-S |

| Rockwell hardness | 94 HRE | RH |

| Melting temperature range | 130–138 °C | MP |

| Nature | semi crystalline | - |

| Density | 0.958 Kg/m3 | - |

| Size | 500 mm × 500 mm × 5 mm | - |

| Parameters | Symbols | Units | Levels | ||

|---|---|---|---|---|---|

| −1 | 0 | +1 | |||

| Spindle Speed | ω | rpm | 660 | 1200 | 1700 |

| Traverse Speed | f | mm/min | 30 | 48 | 85 |

| Volume Fraction | v | % | 5 | 10 | 15 |

| Shoulder Temperature | T | °C | 30 | 65 | 100 |

| Exp. No. | ω | f | v | T |

|---|---|---|---|---|

| 1 | 660 | 30 | 15 | 65 |

| 2 | 1700 | 30 | 5 | 30 |

| 3 | 660 | 48 | 5 | 65 |

| 4 | 1700 | 85 | 15 | 100 |

| 5 | 660 | 85 | 15 | 30 |

| 6 | 1700 | 30 | 10 | 100 |

| 7 | 660 | 48 | 15 | 100 |

| 8 | 1700 | 85 | 10 | 30 |

| 9 | 660 | 30 | 10 | 100 |

| 10 | 1700 | 48 | 15 | 30 |

| 11 | 1200 | 48 | 5 | 65 |

| 12 | 660 | 30 | 5 | 100 |

| 13 | 660 | 85 | 10 | 100 |

| 14 | 1700 | 85 | 5 | 100 |

| 15 | 1200 | 48 | 5 | 65 |

| 16 | 1700 | 48 | 10 | 65 |

| 17 | 660 | 85 | 5 | 30 |

| 18 | 660 | 48 | 10 | 30 |

| 19 | 1200 | 48 | 10 | 100 |

| 20 | 1700 | 85 | 15 | 100 |

| 21 | 1200 | 30 | 15 | 30 |

| 22 | 1700 | 48 | 10 | 65 |

| 23 | 1200 | 48 | 10 | 100 |

| Exp. No. | I-S | Relative I-S | RH | Relative RH |

|---|---|---|---|---|

| KJ/m2 | % | HRE | % | |

| 1 | 21.50 | 93.48 | 89.10 | 94.79 |

| 2 | 28.46 | 123.75 | 97.60 | 103.83 |

| 3 | 25.61 | 111.34 | 92.30 | 98.19 |

| 4 | 8.50 | 36.96 | 100.40 | 106.81 |

| 5 | 11.00 | 47.83 | 95.00 | 101.06 |

| 6 | 32.00 | 139.13 | 90.00 | 95.74 |

| 7 | 22.00 | 95.65 | 101.00 | 107.45 |

| 8 | 30.32 | 131.85 | 94.80 | 100.85 |

| 9 | 29.84 | 129.75 | 96.00 | 102.13 |

| 10 | 20.00 | 86.96 | 95.80 | 101.91 |

| 11 | 29.10 | 126.52 | 96.80 | 102.98 |

| 12 | 33.12 | 144.00 | 93.00 | 98.94 |

| 13 | 21.06 | 91.55 | 90.33 | 96.10 |

| 14 | 31.00 | 134.78 | 97.60 | 103.83 |

| 15 | 29.10 | 126.52 | 97.50 | 103.72 |

| 16 | 14.93 | 64.92 | 90.60 | 96.38 |

| 17 | 8.00 | 34.78 | 72.00 | 76.60 |

| 18 | 12.50 | 54.35 | 77.00 | 81.91 |

| 19 | 25.54 | 111.03 | 94.10 | 100.11 |

| 20 | 8.00 | 34.78 | 97.20 | 103.40 |

| 21 | 29.50 | 128.26 | 96.00 | 102.13 |

| 22 | 14.93 | 64.92 | 92.00 | 97.87 |

| 23 | 25.54 | 111.03 | 97.10 | 103.30 |

| Base Material | 23.00 | 100.00 | 94.00 | 100.00 |

| Source | RH | I-S | ||

|---|---|---|---|---|

| p-Value | Significance (Yes/No) | p-Value | Significance (Yes/No) | |

| Model | Quadr. * (0.01) | Y | 2FI (0.01) | Y |

| ω | 0.01 | Y | 0.19 | N |

| f | 0.43 | N | 0.05 | Y |

| v | 0.05 | Y | 0.01 | Y |

| T | 0.01 | Y | 0.13 | N |

| ωf | 0.38 | N | 0.52 | N |

| ωv | 0.02 | Y | 0.07 | N |

| ωT | 0.01 | Y | 0.01 | Y |

| fv | 0.02 | Y | 0.39 | N |

| fT | 0.84 | N | 0.70 | N |

| vT | 0.15 | N | 0.02 | Y |

| ω2 | 0.06 | N | - | - |

| f2 | 0.78 | N | - | - |

| v2 | 0.02 | Y | - | - |

| T2 | 0.72 | N | - | - |

| S. No. | Process Parameters | I-S (KJ/m2) | HR (HRE) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ω | f | v | T | Pred 1 | Exp 2 | % Error | Pred | Exp | % Error | |

| 1 | 1200 | 48 | 5 | 45 | 21.53 | 21.8 | −1.25 | 94.39 | 94.2 | 0.02 |

| 2 | 660 | 85 | 7.5 | 30 | 10.14 | 10.05 | 0.8 | 74.6 | 78.2 | −4.82 |

| 3 | 660 | 85 | 13 | 45 | 12.26 | 12.51 | −2.03 | 89.02 | 92 | −3.3 |

| Scenario | Processing Parameters | Mechanical Properties | Desirability | ||||

|---|---|---|---|---|---|---|---|

| ω | f | v | T | I-S (KJ/m2) | RH (HRE) | ||

| 1 (generic) | 1200 | 48 | 5 | 75 | 29.2 | 99.35 | 0.89 |

| 2 (from test plan) | 1200 | 48 | 5 | 65 | 26.5 | 97.80 | 0.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, I.; Hussain, G.; A Al-Ghamdi, K.; Umer, R. Investigation of Impact Strength and Hardness of UHMW Polyethylene Composites Reinforced with Nano-Hydroxyapatite Particles Fabricated by Friction Stir Processing. Polymers 2019, 11, 1041. https://doi.org/10.3390/polym11061041

Khan I, Hussain G, A Al-Ghamdi K, Umer R. Investigation of Impact Strength and Hardness of UHMW Polyethylene Composites Reinforced with Nano-Hydroxyapatite Particles Fabricated by Friction Stir Processing. Polymers. 2019; 11(6):1041. https://doi.org/10.3390/polym11061041

Chicago/Turabian StyleKhan, Imran, Ghulam Hussain, Khalid A Al-Ghamdi, and Rehan Umer. 2019. "Investigation of Impact Strength and Hardness of UHMW Polyethylene Composites Reinforced with Nano-Hydroxyapatite Particles Fabricated by Friction Stir Processing" Polymers 11, no. 6: 1041. https://doi.org/10.3390/polym11061041

APA StyleKhan, I., Hussain, G., A Al-Ghamdi, K., & Umer, R. (2019). Investigation of Impact Strength and Hardness of UHMW Polyethylene Composites Reinforced with Nano-Hydroxyapatite Particles Fabricated by Friction Stir Processing. Polymers, 11(6), 1041. https://doi.org/10.3390/polym11061041