O&M Models for Ocean Energy Converters: Calibrating through Real Sea Data

Abstract

:1. Introduction

2. Methodology

2.1. Global Economic Model

2.1.1. Economic Modelling

2.1.2. Environmental Impacts

2.2. Model Integration

2.3. Development of the OPERA O&M Model

3. Case Studies

3.1. OPERA O&M Model

- Scenario (Inputs)

3.2. OPERA Simplified Approach

3.3. DTOcean O&M Module

4. Results and Discussion

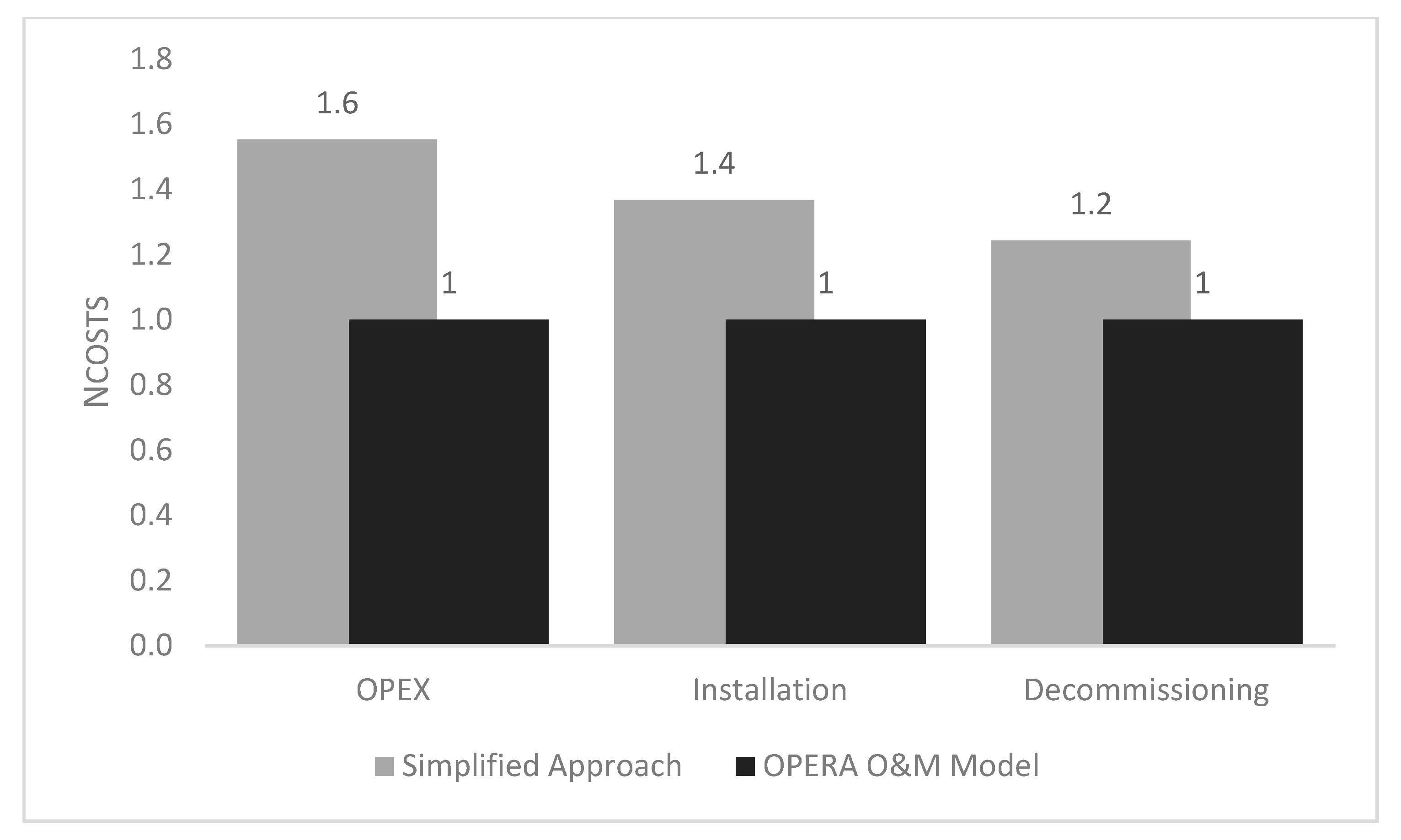

4.1. OPERA O&M Model vs Simplified Approach

4.2. OPERA O&M Model vs DTOcean O&M Module

5. Conclusions and Recommendations

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ADCP | Acoustic Doppler Current Profiler |

| AEP | Annual Energy Production |

| BiMEP | Biscay Marine energy Platform |

| CAPEX | Capital Expenditure |

| COE | Cost of Energy |

| CWR | Capture Width Ratio |

| DTOcean | Design Tool for Ocean Energy Arrays |

| EIA | Environmental Impact Assessment |

| EMEC | European Marine Energy Centre |

| EnFAIT | Enabling Future Arrays in Tidal |

| EPBT | Energy Pay Back in Time |

| ERA | Environmental Risk Assessment |

| EROI | Energy Return of Investment |

| GWP | Global Warming Potential |

| IC | Initial Costs |

| IRR | Internal Rate of Return |

| JEDI | Jobs and Economic Development Impacts |

| LCA | Life-Cycle Assessment |

| LCOE | Levelised Cost of Energy |

| Me | Maintenance Effort |

| MTTF | Mean Time To Failure |

| NPV | Net Present Value |

| OPERA | Open Sea Operating Experience to Reduce Wave Energy Cost |

| OPEX | Operational Expenditure |

| O&M | Operational and Maintenance |

| PTO | Power Take-Off |

| RAM | Reliability Assessment Module |

| R&D | Research and Development |

| SCOE | Social Cost of Energy |

| SEA | Strategic Impact Assessment |

| STDV | Standard Deviation |

| TIC | Total Initial Costs |

| TRL | Technology Readiness Level |

References

- Huckerby, J.; Jeffrey, H.; Sedgwick, J.; Jay, B.; Finlay, L. An International Vision for Ocean Energy, Version II; Ocean Energy Systems Implementing Agreement: France, Paris, 2012. [Google Scholar]

- Crooks, D.; de Andres, A.; Medina-Lopez, E.; Jeffrey, H. Demonstration of a Socio-economic Cost of Energy Analysis of a Wave Energy Converter Array; EWTEC: Cork, Ireland, 2017. [Google Scholar]

- Ocean Energy Forum. Ocean Energy Strategic Roadmap 2016, Building Ocean Energy for Europe. Available online: https://webgate.ec.europa.eu/maritimeforum/sites/maritimeforum/files/OceanEnergyForum_Roadmap_Online_Version_08Nov2016.pdf (accessed on 1 November 2016).

- Policy and Innovation Group. UK Ocean Energy Review; ETIPOCEAN: Edinburgh, UK, 2017. [Google Scholar]

- OPERA. Open Sea Operating Experience to Reduce Wave Energy Costs, European Commission Funded Project, Grant Agreement No 654444. 2016. Available online: www.opera-h2020.eu/ (accessed on 22 January 2019).

- European Commission. Available online: https://ec.europa.eu/programmes/horizon2020/en (accessed on 8 February 2019).

- de Andres, A.; Medina-Lopez, E.; Crooks, D.; Roberts, O.; Jeffrey, H. On the reversed LCOE calculation: Design constraints for wave energy commercialization. Int. J. Mar. Energy 2017, 18, 88–108. [Google Scholar] [CrossRef]

- Wave Energy Scotland. Structural Materials and Manufacturing Processes; Scotland government: Edinburgh, UK, 2016.

- Michael-Welte, T.; Bakken-Sperstad, I.; Høegh-Sørum, E.; Lorentzen-Kolstad, M. Integration of Degradation Processes in a Strategic Offshore Wind Farm O&M Simulation Model. Energies 2017, 10, 925. [Google Scholar] [Green Version]

- Merizalde, Y.; Hernández-Callejo, L.; Duque-Perez, O.; Alonso-Gómez, V. Maintenance Models Applied to Wind Turbines. Energies 2019, 12, 225. [Google Scholar] [CrossRef]

- Sønderkær-Nielsen, J.; Dalsgaard-Sør, J. Methods for Risk-Based Planning of O&M of Wind Turbines. Energies 2014, 7, 6645–6664. [Google Scholar] [Green Version]

- Gray, A. O&M Simulation Tool—USER Guide; Wave Energy Scotland: Scotland, UK, 2017.

- Oceantec. 2017. Available online: http://www.oceantecenergy.com/ (accessed on 7 November 2018).

- Idom. 2019. Available online: https://www.idom.com/ (accessed on 8 February 2019).

- OPERA. Deliverable D7.2, Operating Data Input for Models of Levelised And Society Cost and Life Cycle Assessment for Wave Energy; University of Edinburgh: Edinburgh, UK, 2017. [Google Scholar]

- Natural Resources Canada. RETScreen 4.0. 2019. Available online: http://retscreen.software.informer.com/4.0/ (accessed on 7 July 2017).

- Dalton, G. Navitas Techno-economic software for ocean renewable energy. Available online: https://slideplayer.com/slide/6632399/ (accessed on 8 July 2017).

- Wave Venture TE. Available online: http://www.wave-venture.com/software/ (accessed on 7 July 2017).

- Chozas, J.F.; Kofoed, J.P.; Jensen, N.E.H. User Guide—COE Calculation Tool for Wave Energy Converters; Ver. 1.6.; Aalborg University: Aalborg, Denmark, 2014. [Google Scholar]

- Iberdrola Engineering & Construction. Iberdrola Engineering Heads Up The Uhindar Project, Which Aims to Develop a New System for the Generation of Wave Energy. 2012. Available online: http://www.iberdrolaingenieria.com/ibding/noticias.do?op=det&id=147 (accessed on 8 July 2017).

- Greendelta. OpenLCA. 2018. Available online: http://www.openlca.org/ (accessed on 8 July 2017).

- Siemens. Scoe—Society’s Costs Of Electricity: How Society Should Find Its Optimal Energy Mix; Siemens: Munich, Germany, 2014. [Google Scholar]

- NREL. JEDI Marine and Hydrokinetic Model: User Reference Guide; National Renewable Energy Laboratory: Gordon, CO, USA, 2011.

- Department of Energy and Climate Change (DECC). Future Leasing for Offshore Wind Farms and Licensing for Offshore Oil & Gas and Gas Storage; UK Offshore Energy Strategic Environmental Assessment. DECC: London, UK, 2009.

- New Brunswick Department of Energy. Bay of Fundy Ecosystem Partnership’s Strategic Environmental Assessment; New Brunswick Joint Response: Fredericton, NB, Canada, 2009.

- U. S. Department of Energy (DOE). Report to Congress on the Potential Environmental Effects of Marine and Hydrokinetic Energy Technologies; Wind and Hydropower Technologies Program; Energy Efficiency and Renewable Work; U.S. Department of Energy: Washington, DC, USA, 2009.

- EquiMar. Equitable Testing and Evaluation of Marine Energy Extraction Devices in Terms of Performance, Cost and Environmental Impacts; D6.2.2—Scientific Guidelines on Environmental Assessment; European Union’s FP7/2007–2013 under Grant Agreement No. FP721338. Available online: https://tethys.pnnl.gov/sites/default/files/publications/EquiMar_D6.2.2.pdf (accessed on 1 December 2010).

- The Life Cycle Inventory Data Version V2.1; Ecoinvent: Zurich, Switzerland, 2009.

- James Fisher Marine Services. Mojo Mermaid. 2015. Available online: http://mojomermaid.com/ (accessed on 7 July 2017).

- Asgarpour, M.; van de Pieterman, R. O&M Cost Reduction of Offshore Wind Farms—A Novel Case Study; ECN: The Hague, The Netherlands, 2014. [Google Scholar]

- Maples, B.; Saur, G.; Hand, M.; van de Pietermen, R. Installation, Operation, and Maintenance Strategies to Reduce the Cost of Offshore Wind Energy; National Renewable Energy Laboratory 2 Energy Research Centre of the Netherlands: Petten, The Netherlands, 2013. [Google Scholar]

- Douard, F. A probabilistic approach to introduce risk measurement indicators to an offshore wind project evaluation—Improvement to an existing tool ecume. Energy Procedia 2012, 24, 255–262. [Google Scholar] [CrossRef]

- OutSmart. 2019. Available online: http://out-smart.eu/ (accessed on 26 April 2017).

- DTOcean Project, Optimal Design Tools for Ocean Energy Arrays, European Commission Funded Project, Grant Agreement No 60859. 2015. Available online: http://www.dtocean.eu/ (accessed on 11 February 2019).

- Endrerud, E.O.; Liyanage, J.P.; Keseric, N. Marine Logstics Decision Support for Operation and Maintenance of Offshore Wind Parks with A Multi Method Simulation Model; IEEE: Georgia, GA, USA, 2014. [Google Scholar]

- Drori, G. Underlying Causes of Mooring Lines Failures Across the Industry; BP: London, UK, 2015. [Google Scholar]

- ISO. ISO 14224: Petroleum, Petrochemical and Natural Gas Industries—Collection and Exchange of Reliability and Maintenance Data for Equipment; BSI Standards Limited: London, UK, 2006. [Google Scholar]

- BiMEP. Available online: https://bimep.com/pages/bimep (accessed on 1 November 2018).

- EMEC. Available online: https://emec.org.uk/ (accessed on 1 November 2018).

- O’Connor, M.; Lewis, T.; Dalton, G. Techno-Economic performance of the Pelamis P1 and Wavestar at different ratings and various locations in Europe. Renew. Energy 2012, 50, 889–900. [Google Scholar] [CrossRef]

- Guanche, R.; de Andrés, A.D.; Simal, P.D.; Vidal, C. Uncertainty analysis of wave energy farms financial indicators. Renew. Energy 2014, 68, 570–580. [Google Scholar] [CrossRef]

- O’Connor, M.; Lewis, T.; Dalton, G. Operational expenditure costs for wave energy projects and impacts on financial returns. Renew. Energy 2013, 50, 1119–1131. [Google Scholar] [CrossRef] [Green Version]

- Myhr, A.; Bjerkseter, C.; Ågotnes, A. Levelised cost of energy for offshore floating wind turbines in a life cycle perspective. Renew. Energy 2013, 66, 714–728. [Google Scholar] [CrossRef]

- DTOcean. DTOcean User Manual. 2016. Available online: https://setis.ec.europa.eu/dt-ocean/ (accessed on 12 March 2019).

- DTOcean. DTOcean Technical Manual. 2016. Available online: https://setis.ec.europa.eu/dt-ocean/ (accessed on 12 March 2019).

- DTOceanPlus Project, DTOcean+, European Union’s Horizon 2020 Research and Innovation Programme under Grant Agreement n° 785921. 2018. Available online: https://www.dtoceanplus.eu (accessed on 8 February 2019).

- Nova Innovation. 2018. Available online: https://www.novainnovation.com/ (accessed on 13 February 2018).

- EnFAIT. Enabling Future Arrays in Tidal, European Commission Funded Project, Grant Agreement No 745862. 2017. Available online: www.enfait.eu/ (accessed on 6 February 2019).

- Thomson, R.; Harrison, G.; Chick, J. Full Life Cycle Assessment of a Wave Energy Converter. In Proceedings of the Renewable Power Generation 2011, Edinburgh, UK, 6–8 September 2011. [Google Scholar]

- Douglas, A.C.; Harrison, G.P.; Chick, J.P. Life cycle assessment of the Seagen marine current turbine. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2008, 222, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Dalton, G.; Madden, D.; Daly, M.C. Life Cycle Assessment of the Wavestar. In Proceedings of the 9th International Conference on Ecological Vehicles and Renewable Energies, EVER, Monte-Carlo, Monaco, 25–27 March 2014. [Google Scholar]

| Case Study | Scenario | O&M Values | Array Size | Technology |

|---|---|---|---|---|

| OPERA Simplified Approach | OPERA | Simplified representation | Single Device | Wave |

| OPERA O&M Model | OPERA | Real sea data | Single Device | Wave |

| DTOcean O&M Module | EnFAIT | Real sea data | Array of three devices | Tidal |

| Name of Variable | Description |

|---|---|

| Item ref no. | Item name |

| Item details | Detail of the element, e.g., component or overall element (device; moorings and anchors; electrical equipment) |

| Planned operation (1/years) | Value between 0–1. Periodicity of interventions in a year (1/year). There is no standardized way for defining a failure in the wind/wave energy industry. This analysis defines a failure as a visit to a turbine. |

| Uncertainty level | Probability of deviating from the average failure rate (1–4) |

| Mean time between failures (1/ years) | Average time between failures (1/year) |

| Category | Three categories are typical for failure rates definition: Incipient, Critical, Degradation. |

| Failure mode | The manner in which an equipment or machine failure can occur. An example of a failure mode is corrosion, which might cause metal degradation and failure |

| Failure effect on the power production (0%–100%) | Impact of failure on energy production (0–1) |

| Action needed | Description of the intervention |

| Est. duration (hours) | Required duration time for action, excluding travel time |

| Location | Onsite or port maintenance |

| Vessels | Name of Vessel 1 required |

| Vessel aux 1 | Name of Vessel 2 required |

| Vessel aux 2 | Name of Vessel 3 required |

| Equipment | Necessary additional equipment for the repair |

| Equipment cost (€/h) | Equipment cost |

| Personnel | Additional personnel description |

| Personnel cost (€/h) | Hourly personnel cost |

| Parts/consumables | Description of materials needed |

| Parts/consumables cost (€) | Material cost |

| Hs(m) | Maximum operational wave height |

| Towing required | Yes vs NO |

| Mounting time (h) | If one operation needs to be completed at port. Mounting and dis-mounting time of the element is considered |

| N operations | Number of operations of this type in a farm |

| Preparation Time (h) | Previous working time at port |

| Case | Site | Rated Power (MW) | Installation Costs as % of TIC | EX as % of CAPEX | Decommissioning Costs as % of Installation Costs |

|---|---|---|---|---|---|

| OPERA O&M Model | EMEC | 0.25 | 30% | 3.7% | 89% |

| 10 | 27% | 3.3% | 89% | ||

| 18 | 26% | 3.1% | 89% | ||

| BiMEP | 0.25 | 22% | 3.7% | 88% | |

| 10 | 21% | 3.3% | 88% | ||

| 18 | 21% | 3.1% | 88% | ||

| Simplified Approach | - | - | 33% | 5% | 80% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bloise Thomaz, T.; Crooks, D.; Medina-Lopez, E.; van Velzen, L.; Jeffrey, H.; Lopez Mendia, J.; Rodriguez Arias, R.; Ruiz Minguela, P. O&M Models for Ocean Energy Converters: Calibrating through Real Sea Data. Energies 2019, 12, 2475. https://doi.org/10.3390/en12132475

Bloise Thomaz T, Crooks D, Medina-Lopez E, van Velzen L, Jeffrey H, Lopez Mendia J, Rodriguez Arias R, Ruiz Minguela P. O&M Models for Ocean Energy Converters: Calibrating through Real Sea Data. Energies. 2019; 12(13):2475. https://doi.org/10.3390/en12132475

Chicago/Turabian StyleBloise Thomaz, Tianna, David Crooks, Encarni Medina-Lopez, Leonore van Velzen, Henry Jeffrey, Joseba Lopez Mendia, Raul Rodriguez Arias, and Pablo Ruiz Minguela. 2019. "O&M Models for Ocean Energy Converters: Calibrating through Real Sea Data" Energies 12, no. 13: 2475. https://doi.org/10.3390/en12132475