Rolling Contact Performance of a Ti-Containing MoS2 Coating Operating Under Ambient, Vacuum, and Oil-Lubricated Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Deposition

2.2. Characterization

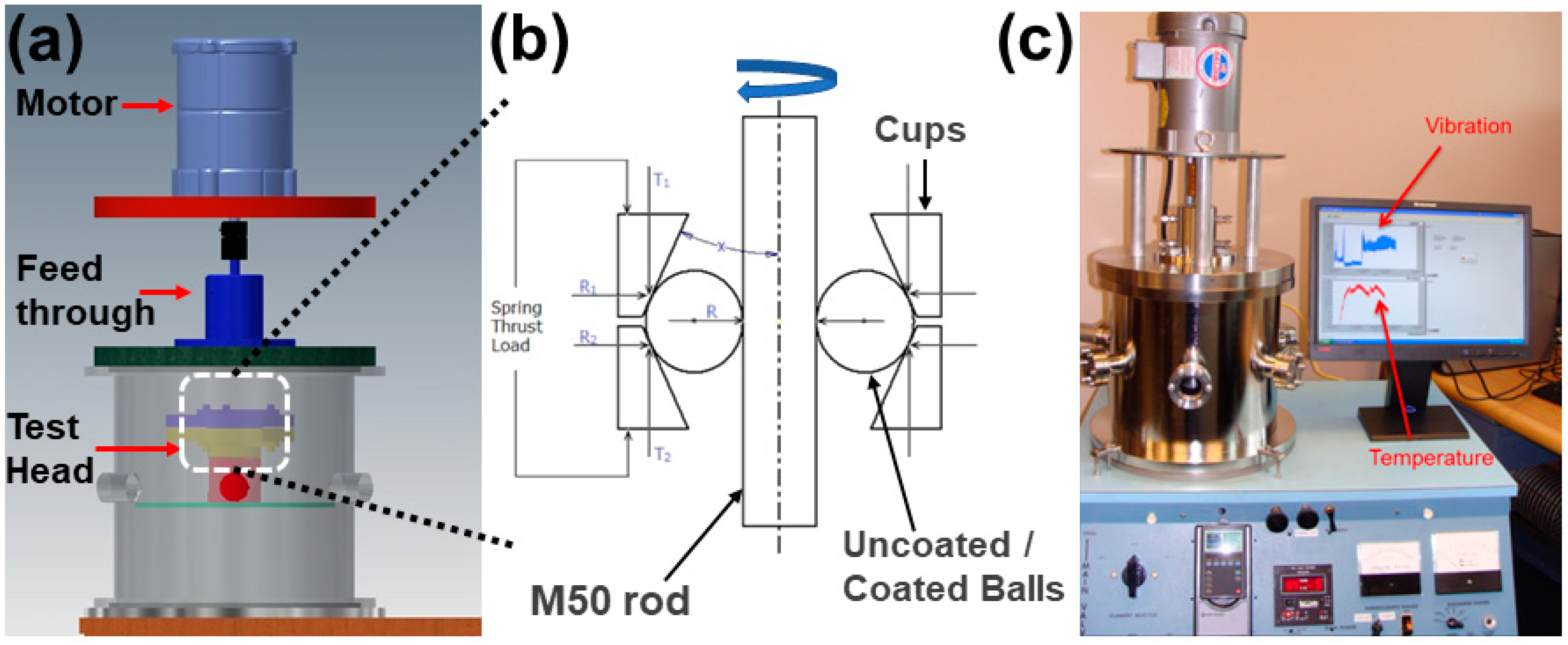

2.3. Tribological Test Apparatus and Procedure

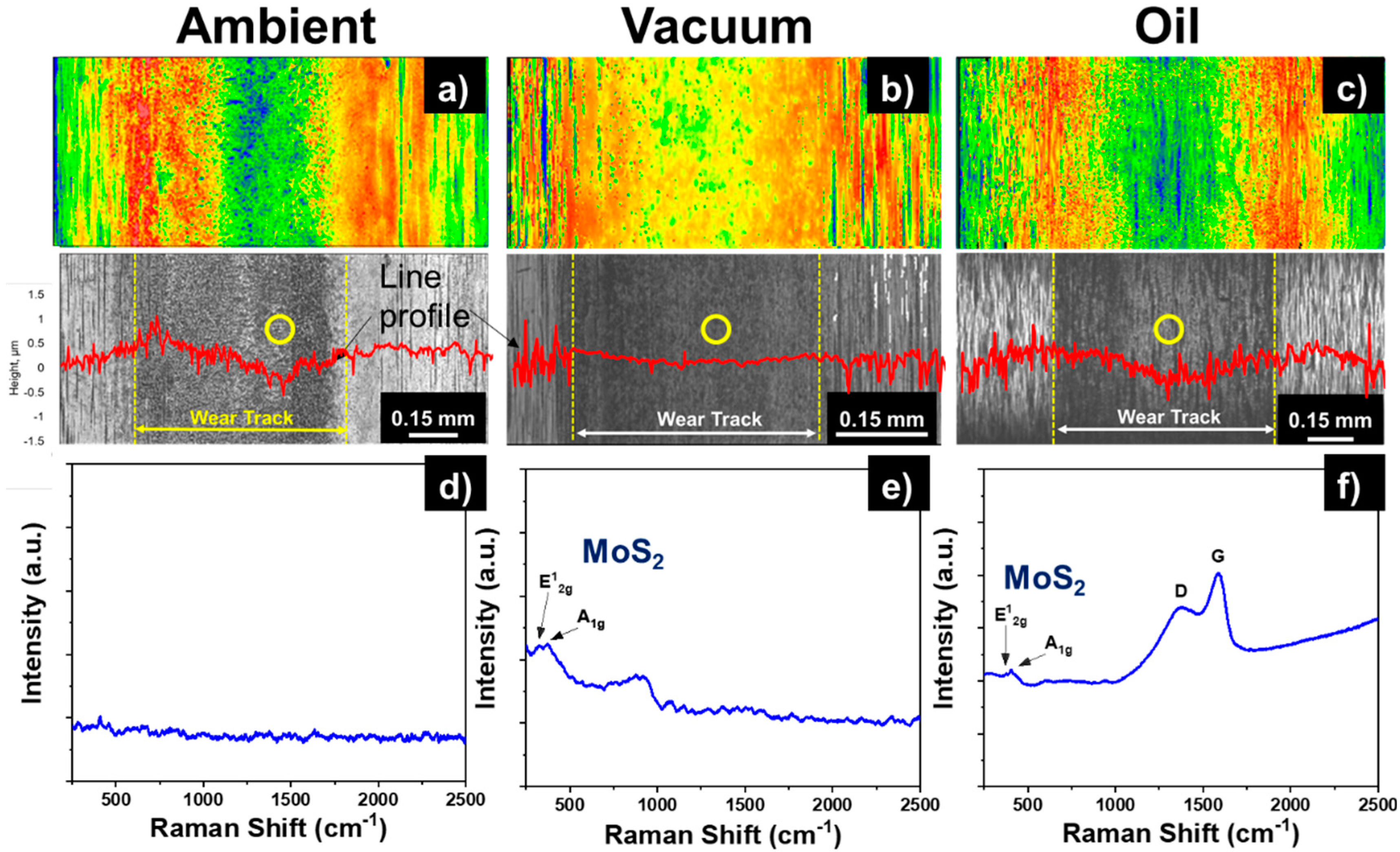

3. Results and Discussion

3.1. Characterization

3.2. Tribological (RCF) Performance

4. Conclusions

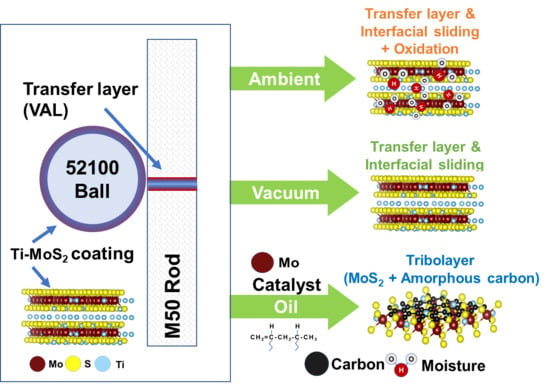

- In the ambient and vacuum tests, failures were determined to be associated with the onset of abrasive wear rather than fatigue or spalling. L50 lifetimes of tests performed in those environments were found to depend upon the amount of coating material available and its wear rate on the balls. That is, the Ti-MoS2 functioned as a barrier to the onset of abrasive wear between the steel alloys until the coating was sufficiently worn away.

- Under oil-lubricated (boundary lubrication) conditions, L50 was found to depend on the durability and composition of tribofilms formed on the surfaces of the uncoated M50 rods. The tribofilms were found to be comprised of mixtures of MoS2 crystallites and an amorphous hydrocarbon (a-C:H). The crystalline MoS2 in the tribofilm obviously originated from the amorphous Ti-MoS2 coating and likely underwent a thermodynamic phase transition as a result of the applied Hertz stress and frictional heating in the contact. The a-C:H in the tribofilm probably originated from a catalytic scission of the polyalphaolefin molecules caused by the d-band character of the Mo and/or Ti in the coating, similar to the results reported by Erdemir et al. [43].

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Vazirisereshk, M.R.; Martini, A.; Strubbe, D.A.; Baykara, M.Z. Solid lubrication with MoS2: A review. Lubricants 2019, 7, 57. [Google Scholar] [CrossRef]

- Scharf, T.W.; Prasad, S.V. Solid lubricants: A review. J. Mater. Sci. 2013, 48, 511–531. [Google Scholar] [CrossRef]

- Sliney, H. Solid lubricant materials for high temperatures—A review. Tribol. Int. 1982, 15, 303–315. [Google Scholar] [CrossRef]

- Hilton, M.R.; Bauer, R.; Fleischauer, P.D. Tribological performance and deformation of sputter-deposited MoS2 solid lubricant films during sliding wear and indentation contact. Thin Solid Films 1990, 188, 219–236. [Google Scholar] [CrossRef]

- Renevier, N.M.; Lobiondo, N.; Fox, V.C.; Teer, D.G.; Hampshire, J. Performance of MoS2/metal composite coatings used for dry machining and other industrial applications. Surf. Coat. Technol. 2000, 123, 84–91. [Google Scholar] [CrossRef]

- Sliney, H. Solid Lubricants. Available online: https://catalogue.nla.gov.au/Record/4036403 (accessed on 22 October 2019).

- Zhao, X.; Perry, S.S. The Role of water in modifying friction within MoS2 sliding interfaces. ACS Appl. Mater. Interfaces 2010, 2, 1444–1448. [Google Scholar] [CrossRef]

- Curry, J.F.; Wilson, M.A.; Luftman, H.S.; Strandwitz, N.C.; Argibay, N.; Chandross, M.; Sidebottom, M.A.; Krick, B.A. Impact of microstructure on MoS2 oxidation and friction. ACS Appl. Mater. Interfaces 2017, 9, 28019–28026. [Google Scholar] [CrossRef]

- Stupp, B.C. Synergistic effects of metals co-sputtered with MoS2. Thin Solid Films 1981, 84, 257–266. [Google Scholar] [CrossRef]

- Scharf, T.W.; Goeke, R.S.; Kotula, P.G.; Prasad, S.V. Synthesis of Au-MoS(2) nanocomposites: Thermal and friction-induced changes to the structure. ACS Appl. Mater. Interfaces 2013, 5, 11762–11767. [Google Scholar] [CrossRef]

- Scharf, T.W.; Kotula, P.G.; Prasad, S.V. Friction and wear mechanisms in MoS2/Sb2O3/Au nanocomposite coatings. Acta Mater. 2010, 58, 4100–4109. [Google Scholar] [CrossRef]

- Furlan, K.P.; de Mello, J.D.B.; Klein, A.N. Self-lubricating composites containing MoS2: A review. Tribol. Int. 2018, 120, 280–298. [Google Scholar] [CrossRef]

- Zhang, X.; Luster, B.; Church, A.; Muratore, C.; Voevodin, A.A.; Kohli, P.; Aouadi, S.; Talapatra, S. Carbon nanotube-MoS2 composites as solid lubricants. ACS Appl. Mater. Interfaces 2009, 1, 735–739. [Google Scholar] [CrossRef] [PubMed]

- Mutyala, K.C.; Wu, Y.A.; Erdemir, A.; Sumant, A.V. Graphene–MoS2 ensembles to reduce friction and wear in DLC-steel contacts. Carbon 2019, 146, 524–527. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, B.; Yang, J.; Zhang, H.; Zhang, Q.; Tang, H.; Li, C. MoS2/reduced graphene oxide hybrid structure and its tribological properties. RSC Adv. 2015, 5, 89682–89688. [Google Scholar] [CrossRef]

- Grossiord, C.; Varlot, K.; Martin, J.; Le Mogne, T.; Esnouf, C.; Inoue, K. MoS2 single sheet lubrication by molybdenum dithiocarbamate. Tribol. Int. 1998, 31, 737–743. [Google Scholar] [CrossRef]

- Chhowalla, M.; Amaratunga, G.G.A.J. Thin films of fullerene-like MoS2 nanoparticles with ultra-low friction and wear. Nature 2000, 407, 164–167. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, W. MoS2 hollow microspheres used as a green lubricating additive for liquid paraffin. Tribol. Int. 2017, 114, 315–321. [Google Scholar] [CrossRef]

- Rabaso, P.; Dassenoy, F.; Ville, F.; Diaby, M.; Vacher, B.; Le Mogne, T.; Belin, M.; Cavoret, J. An Investigation on the Reduced Ability of IF-MoS2 nanoparticles to reduce friction and wear in the presence of dispersants. Tribol. Lett. 2014, 55, 503–516. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, K.; Hu, E.; Guo, J.; Han, C.; Hu, X. Double hollow MoS2 nano-spheres: Synthesis, tribological properties, and functional conversion from lubrication to photocatalysis. Appl. Surf. Sci. 2017, 392, 1144–1152. [Google Scholar] [CrossRef]

- Singh, H.; Mutyala, K.C.; Mohseni, H.; Scharf, T.W.; Evans, R.D.; Doll, G.L. Tribological performance and coating characteristics of sputter deposited Ti doped MoS2 in rolling and sliding contact. Tribol. Trans. 2015, 58, 767–777. [Google Scholar] [CrossRef]

- Zabinski, J.S.; Donley, M.S.; Walck, S.D.; Schneider, T.R.; Mcdevitt, N.T. The effects of dopants on the chemistry and tribology of sputter-deposited MoS2 films. Tribol. Trans. 1995, 38, 894–904. [Google Scholar] [CrossRef]

- Singh, H.; Mutyala, K.C.; Evans, R.D.; Doll, G.L. An investigation of material and tribological properties of Sb2O3/Au-doped MoS2 solid lubricant films under sliding and rolling contact in different environments. Surf. Coat. Technol. 2015, 284, 281–289. [Google Scholar] [CrossRef]

- Singh, H.; Mutyala, K.C.; Evans, R.D.; Doll, G.L. An atom probe tomography investigation of Ti–MoS2 and MoS2–Sb2O3–Au films. J. Mater. Res. 2017, 32, 1710–1717. [Google Scholar] [CrossRef]

- Vidakis, N.; Antoniadis, A.; Bilalis, N. The VDI 3198 indentation test evaluation of a reliable qualitative control for layered compounds. J. Mater. Process. Technol. 2003, 143–144, 481–485. [Google Scholar] [CrossRef]

- Salloom, R.; Ayyagari, A.V.; Mukherjee, S. Nanoengineered hypereutectoid steel with superior hardness and wear resistance. J. Mater. Eng. Perform. 2019, 28, 2202–2211. [Google Scholar] [CrossRef]

- Glover, D. A ball-rod rolling contact fatigue tester. In Rolling Contact Fatigue Testing of Bearing Steels; Hoo, J., Ed.; ASTM International: West Conshohocken, PA, USA, 1982; pp. 107–124. [Google Scholar]

- Eichler, J.W.; Matthews, A.; Leyland, A.; Doll, G.L. The Influence of coatings on the oil-out performance of rolling bearings. Surf. Coat. Technol. 2007, 202, 1073–1077. [Google Scholar] [CrossRef]

- Mutyala, K.C.; Singh, H.; Evans, R.D.; Doll, G.L. Effect of diamond-like carbon coatings on ball bearing performance in normal, oil-starved, and debris-damaged conditions. Tribol. Trans. 2016, 59, 1039–1047. [Google Scholar] [CrossRef]

- Lubrecht, A.A.; Venner, C.H.; Colin, F. Film thickness calculation in elasto-hydrodynamic lubricated line and elliptical contacts: The Dowson, Higginson, Hamrock contribution. Proc. Inst. Mech. Eng. Part. J. J. Eng. Tribol. 2009, 223, 511–515. [Google Scholar] [CrossRef]

- Kelly, P.J.; Arnell, R.D. Magnetron sputtering: A review of recent developments and applications. Vacuum 2000, 56, 159–172. [Google Scholar] [CrossRef]

- Panjan, P.; Čekada, M.; Panjan, M.; Kek-Merl, D. Growth defects in PVD hard coatings. Vacuum 2009, 84, 209–214. [Google Scholar] [CrossRef]

- Anders, A. A structure zone diagram including plasma-based deposition and ion etching. China Surf. Eng. 2016, 29, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Spalvins, T. Lubrication with sputtered MoS2 films. A S L E Trans. 1971, 14, 267–274. [Google Scholar] [CrossRef] [Green Version]

- Sadeghi, F.; Jalalahmadi, B.; Slack, T.S.; Raje, N.; Arakere, N.K. A review of rolling contact fatigue. J. Tribol. 2009, 131, 041403. [Google Scholar] [CrossRef]

- Weibull, W. A statistical distribution function of wide applicability. J. Appl. Mech. 1951, 18, 293–297. [Google Scholar]

- Danyluk, M.; Dhingra, A. Rolling contact fatigue using solid thin film lubrication. Wear 2012, 274–275, 368–376. [Google Scholar] [CrossRef]

- Stoyanov, P.; Chromik, R.R.; Goldbaum, D.; Lince, J.R.; Zhang, X. Microtribological performance of Au–MoS2 and Ti–MoS2 coatings with varying contact pressure. Tribol. Lett. 2010, 40, 199–211. [Google Scholar] [CrossRef]

- Ferrari, A.; Robertson, J. Resonant Raman spectroscopy of disordered, amorphous, and diamondlike carbon. Phys. Rev. B 2001, 64, 075414. [Google Scholar] [CrossRef] [Green Version]

- Mutyala, K.C.; Singh, H.; Fouts, J.A.; Evans, R.D.; Doll, G.L. Influence of MoS2 on the rolling contact performance of bearing steels in boundary lubrication: A different approach. Tribol. Lett. 2016, 61, 20. [Google Scholar] [CrossRef]

- Paul, A.; Singh, H.; Mutyala, K.C.; Doll, G.L. An improved solid lubricant for bearings operating in space and terrestrial environments. In Proceedings of the 44th Aerospace Mechanisms Symposium, Cleveland, OH, USA, 16–18 May 2018; pp. 141–149. [Google Scholar]

- Erdemir, A.; Ramirez, G.; Eryilmaz, O.L.; Narayanan, B.; Liao, Y.; Kamath, G.; Sankaranarayanan, S.K.R.S. Carbon-based tribofilms from lubricating oils. Nature 2016, 536, 67–71. [Google Scholar] [CrossRef]

| Operating Environment | Test Pair (M50 rod vs …) | Slope (β) | L10 | L50 | L50/L50(uncoated) |

|---|---|---|---|---|---|

| Ambient | Uncoated Balls | 2.27 | 0.05 | 0.11 | 1.00 |

| Coated Balls | 11.68 | 3.15 | 3.70 | 34.91 | |

| Vacuum | Uncoated Balls | 1.04 | 0.14 | 0.88 | 1.00 |

| Coated Balls | 1.98 | 5.61 | 14.54 | 16.52 | |

| Oil | Uncoated Balls | 2.91 | 38.51 | 73.57 | 1.00 |

| Coated Balls | 1.71 | 52.69 | 158.62 | 2.16 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, H.; Mutyala, K.C.; Doll, G.L. Rolling Contact Performance of a Ti-Containing MoS2 Coating Operating Under Ambient, Vacuum, and Oil-Lubricated Conditions. Coatings 2019, 9, 752. https://doi.org/10.3390/coatings9110752

Singh H, Mutyala KC, Doll GL. Rolling Contact Performance of a Ti-Containing MoS2 Coating Operating Under Ambient, Vacuum, and Oil-Lubricated Conditions. Coatings. 2019; 9(11):752. https://doi.org/10.3390/coatings9110752

Chicago/Turabian StyleSingh, Harpal, Kalyan C. Mutyala, and Gary L. Doll. 2019. "Rolling Contact Performance of a Ti-Containing MoS2 Coating Operating Under Ambient, Vacuum, and Oil-Lubricated Conditions" Coatings 9, no. 11: 752. https://doi.org/10.3390/coatings9110752

APA StyleSingh, H., Mutyala, K. C., & Doll, G. L. (2019). Rolling Contact Performance of a Ti-Containing MoS2 Coating Operating Under Ambient, Vacuum, and Oil-Lubricated Conditions. Coatings, 9(11), 752. https://doi.org/10.3390/coatings9110752