Microstructure and Mechanical Properties of the Ni/Ti/Nb Multilayer Composite Manufactured by Accumulative Pack-Roll Bonding

Abstract

:1. Introduction

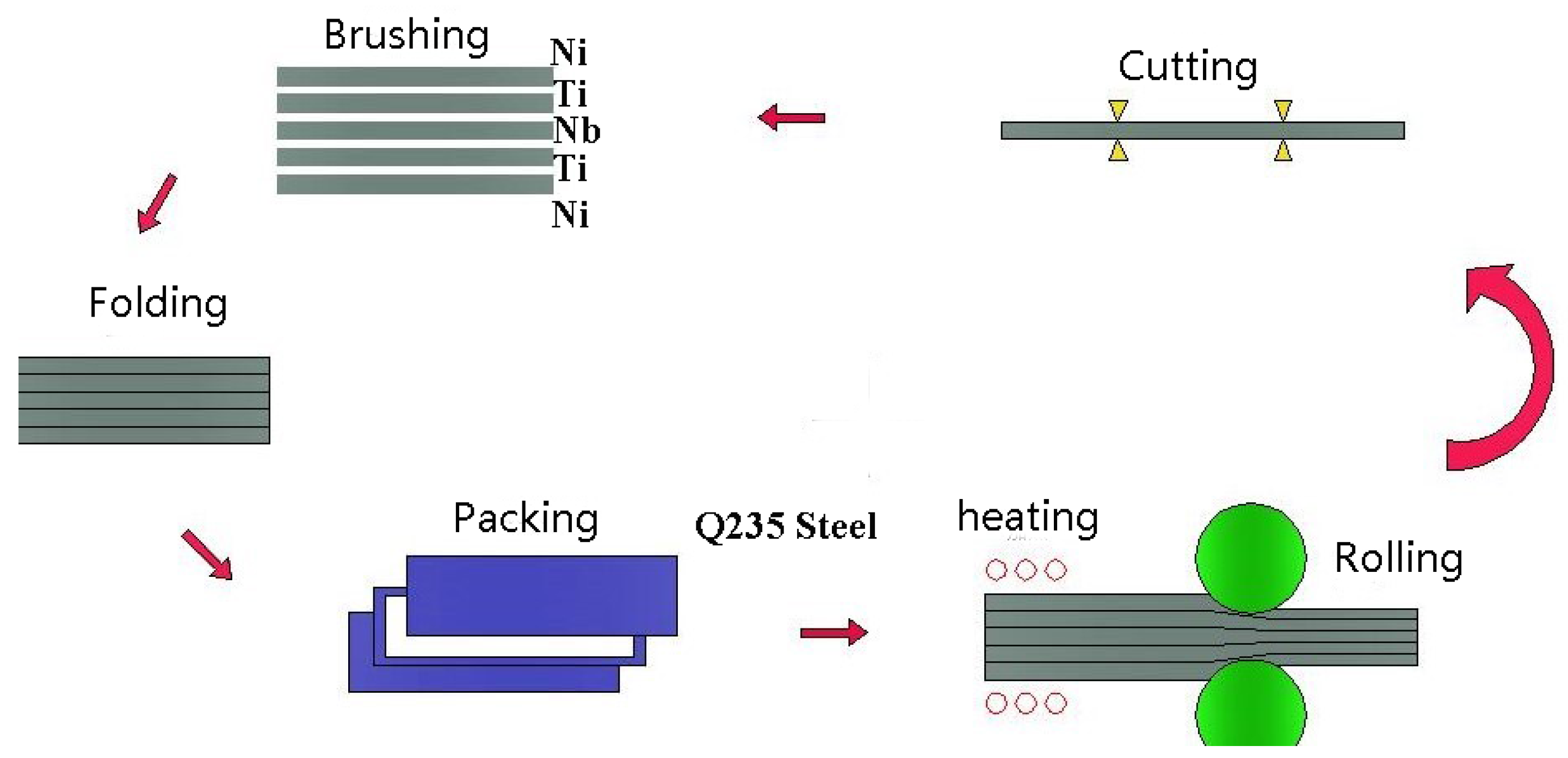

2. Experimental Procedures

3. Results and Discussion

3.1. Microstructure Evolution

3.2. Interface Investigation

3.3. Mechanical Properties

3.3.1. Tensile Test

3.3.2. Micro-Hardness

3.3.3. Fractography

4. Conclusions

- (1)

- The Ni/Ti/Nb multilayer composite was manufactured by ARB technology up to five passes. The deformation of each layer was relatively uniform in the initial stage of the ARB process. After the fourth pass, the Ni/Ti interface was still relatively straight, while the Ti/Nb interface was unevenly deformed.

- (2)

- As the number of ARB process increased, the grain size of the composite decreased. After five passes, the microstructure of Ni was equiaxed grains with a decreased grain size of 200 nm, and finer equiaxed grains were visible near the interface of the Ni layer. No dynamic recrystallization occurred in the Ti and Nb layers. The laminar structure of the Nb layer was observed and the grains were oriented parallel to the rolling direction.

- (3)

- As the number of ARB process increased, the tensile strength of the composite increased significantly and the elongation decreased. After five passes, the tensile strength of the composite reached 792.3 MPa.

- (4)

- The micro-hardness of the three metals gradually increased during the ARB process, especially a rapid increase appeared after the first pass. After five passes, the micro-hardness of the Ni, Ti, and Nb were increased to 270.2, 307.4, and 243.4 HV.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wadsworth, J.; Lesuer, D.R. Ancient and modern laminated composites—From the Great Pyramid of Gizeh to Y2K. Mater. Charct. 2000, 45, 289–313. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.P.; Zhang, G.P.; Wang, W.; Tan, J.; Zhu, S.J. On interface strengthening ability in metallic multilayers. Scr. Mater. 2007, 57, 117–120. [Google Scholar] [CrossRef]

- Cao, J.; Song, X.G.; Wu, L.Z.; Qi, J.L.; Feng, J.C. Characterization of Al/Ni multilayers and their application in diffusion bonding of TiAl to TiC cermet. Thin Solid Film. 2012, 520, 3528–3531. [Google Scholar] [CrossRef]

- Cao, J.; Feng, J.C.; Li, Z.R. Microstructure and fracture properties of reaction-assisted diffusion bonding of TiAl intermetallic with Al/Ni multilayer foils. J. Alloy. Compd. 2008, 466, 363–367. [Google Scholar] [CrossRef]

- Fan, M.; Yu, W.; Wang, W.; Guo, X.; Jin, K.; Miao, R.; Hou, W.; Kim, N.; Tao, J. Microstructure and mechanical properties of thin-multilayer Ti/Al laminates prepared by one-step explosive bonding. J. Mater. Eng. Perform. 2017, 26, 277–285. [Google Scholar] [CrossRef]

- Saito, Y.; Tsuji, N.; Utsunomiya, H.; Sakai, T.; Hong, R.G. Ultra-fine grained bulk aluminum produced by accumulative roll-bonding (ARB) process. Scr. Mater. 1998, 39, 1221–1227. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–107. [Google Scholar] [CrossRef]

- Segal, V.M. Equal channel angular extrusion: From macromechanics to structure formation. Mater. Sci. Eng. A 1999, 271, 322–333. [Google Scholar] [CrossRef]

- Sakai, G.; Horita, Z.; Langdon, T.G. Grain refinement and superplasticity in an aluminum alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2005, 393, 344–351. [Google Scholar] [CrossRef]

- Tsuji, N.; Ito, Y.; Saito, Y.; Minamino, Y. Strength and ductility of ultrafine grained aluminum and iron produced by ARB and annealing. Scr. Mater. 2002, 47, 893–899. [Google Scholar] [CrossRef]

- Azushima, A.; Kopp, R.; Korhonen, A.; Yang, D.Y.; Micari, F.; Lahoti, G.D.; Groche, P.; Yanagimoto, J.; Tsuji, N.; Rosochowski, A.; et al. Severe plastic deformation (SPD) processes for metals. CIRP Ann. Manuf. Technol. 2008, 57, 716–735. [Google Scholar] [CrossRef]

- Chang, H.; Zheng, M.Y.; Gan, W.M.; Wu, K.; Maawad, E.; Brokmeier, H.G. Texture evolution of the Mg/Al laminated composite fabricated by the accumulative roll bonding. Scr. Mater. 2009, 61, 717–720. [Google Scholar] [CrossRef]

- Wu, K.; Chang, H.; Maawad, E.; Gan, W.M.; Brokmeier, H.G.; Zheng, M.Y. Microstructure and mechanical properties of the Mg/Al laminated composite fabricated by accumulative roll bonding (ARB). Mater. Sci. Eng. A 2010, 527, 3073–3078. [Google Scholar] [CrossRef]

- Chang, H.; Zheng, M.Y.; Xu, C.; Fan, G.D.; Brokmeier, H.G.; Wu, K. Microstructure and mechanical properties of the Mg/Al multilayer fabricated by accumulative roll bonding (ARB) at ambient temperature. Mater. Sci. Eng. A 2013, 543, 249–256. [Google Scholar] [CrossRef]

- Yang, D.K.; Cizek, P.; Hodgson, P.D.; Wen, C.E. Microstructure evolution and nanograin formation during shear localization in cold-rolled titanium. Acta Mater. 2010, 58, 4536–4548. [Google Scholar] [CrossRef]

- Yang, D.K.; Cizek, P.; Hodgson, P.D.; Wen, C.E. Ultrafine equiaxed-grain Ti/Al composite produced by accumulative roll bonding. Scr. Mater. 2010, 62, 321–324. [Google Scholar] [CrossRef]

- Eizadjou, M.; Talachi, A.K.; Manesh, H.D.; Shahabi, H.S.; Janghorban, K. Investigation of structure and mechanical properties of multi-layered Al/Cu composite produced by accumulative roll bonding (ARB) process. Compos. Sci. Technol. 2008, 68, 2003–2009. [Google Scholar] [CrossRef]

- Mozaffari, A.; Hosseini, M.; Manesh, H.D. Al/Ni metal intermetallic composite produced by accumulative roll bonding and reaction annealing. J. Alloy. Compd. 2011, 509, 9938–9945. [Google Scholar] [CrossRef]

- Mozaffari, A.; Manesh, H.D.; Janghorban, K. Evaluation of mechanical properties and structure of multilayered Al/Ni composites produced by accumulative roll bonding (ARB) process. J. Alloy. Compd. 2010, 489, 103–109. [Google Scholar] [CrossRef]

- Mahdavian, M.M.; Khatami-Hamedani, H.; Abedi, H.R. Macrostructure evolution and mechanical properties of accumulative roll bonded Al/Cu/Sn multilayer composite. J. Alloy. Compd. 2017, 703, 605–613. [Google Scholar] [CrossRef]

- Alizadeh, M.; Samiei, M. Fabrication of nanostructured Al/Cu/Mn metallic multilayer composites by accumulative roll bonding process and investigation of their mechanical properties. Mater. Des. 2014, 56, 680–684. [Google Scholar] [CrossRef]

- Shabani, A.; Toroghinejad, M.R.; Shafyei, A. Fabrication of Al/Ni/Cu composite by accumulative roll bonding and electroplating processes and investigation of its microstructure and mechanical properties. Mater. Sci. Eng. A 2012, 558, 386–393. [Google Scholar] [CrossRef]

- Mahdavian, M.M.; Ghalandari, L.; Reihanian, M. Accumulative roll bonding of multilayered Cu/Zn/Al: An evaluation of microstructure and mechanical properties. Mater. Sci. Eng. A 2013, 579, 99–107. [Google Scholar] [CrossRef]

- Motevalli, P.D.; Eghbali, B. Microstructure and mechanical properties of Tri-metal Al/Ti/Mg laminated composite processed by accumulative roll bonding. Mater. Sci. Eng. A 2015, 628, 135–142. [Google Scholar] [CrossRef]

- Qu, P.; Zhou, L.; Acoff, V.L. Deformation Textures of Aluminum in a Multilayered Ti/Al/Nb Composite Severely Deformed by Accumulative Roll Bonding. Mater. Charct. 2015, 107, 367–375. [Google Scholar] [CrossRef]

- Ghalandari, L.; Moshksar, M.M. High-strength and high-conductive Cu/Ag multilayer produced by ARB. J. Alloy. Compd. 2010, 506, 172–178. [Google Scholar] [CrossRef]

- Dehsorkhi, R.N.; Qods, F.; Tajally, M. Investigation on microstructure and mechanical properties of Al–Zn composite during accumulative roll bonding (ARB) process. Mater. Sci. Eng. A 2011, 530, 63–72. [Google Scholar] [CrossRef]

- Ghalandari, L.; Mahdavian, M.M.; Reihanian, M. Microstructure evolution and mechanical properties of Cu/Zn multilayer processed by accumulative roll bonding (ARB). Mater. Sci. Eng. A 2014, 593, 145–153. [Google Scholar] [CrossRef]

- Hood, G.M.; Schultz, R.J. Ultra-fast solute diffusion in α-Ti and α-Zr. Philos. Mag. 1972, 26, 329–336. [Google Scholar] [CrossRef]

- Gibbs, G.B.; Graham, D.; Tomlin, D.H. Diffusion in titanium and titanium-niobium alloys. Philos. Mag. 1963, 8, 1269–1282. [Google Scholar] [CrossRef]

- Mashhadi, A.; Atrian, A.; Ghalandari, L. Mechanical and microstructural investigation of Zn/Sn multilayered composites fabricated by accumulative roll bonding (ARB) process. J. Alloy. Compd. 2017, 727, 1314–1323. [Google Scholar] [CrossRef]

| Materials | Element (wt. %) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nb | Ni | Ti | Cu | Si | Fe | Mn | Zn | C | |

| Ni | - | Bal | - | 0.002 | 0.01 | 0.01 | 0.03 | - | 0.011 |

| Ti | - | - | Bal | 0.01 | 0.4 | 0.3 | - | 0.04 | 0.01 |

| Nb | Bal | - | - | - | 0.001 | 0.001 | 0.03 | - | 0.003 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, N.; Ren, X.; Liang, J. Microstructure and Mechanical Properties of the Ni/Ti/Nb Multilayer Composite Manufactured by Accumulative Pack-Roll Bonding. Metals 2020, 10, 354. https://doi.org/10.3390/met10030354

Ye N, Ren X, Liang J. Microstructure and Mechanical Properties of the Ni/Ti/Nb Multilayer Composite Manufactured by Accumulative Pack-Roll Bonding. Metals. 2020; 10(3):354. https://doi.org/10.3390/met10030354

Chicago/Turabian StyleYe, Nan, Xueping Ren, and Juhua Liang. 2020. "Microstructure and Mechanical Properties of the Ni/Ti/Nb Multilayer Composite Manufactured by Accumulative Pack-Roll Bonding" Metals 10, no. 3: 354. https://doi.org/10.3390/met10030354

APA StyleYe, N., Ren, X., & Liang, J. (2020). Microstructure and Mechanical Properties of the Ni/Ti/Nb Multilayer Composite Manufactured by Accumulative Pack-Roll Bonding. Metals, 10(3), 354. https://doi.org/10.3390/met10030354