Adaptive Single Neuron Anti-Windup PID Controller Based on the Extended Kalman Filter Algorithm

Abstract

1. Introduction

- Single neuron PID controllersThese adaptive controllers are base on a single neuron whose inputs are the proportional error (P), integral of the error (I), and derivative of the error (D) (see Figure 1).

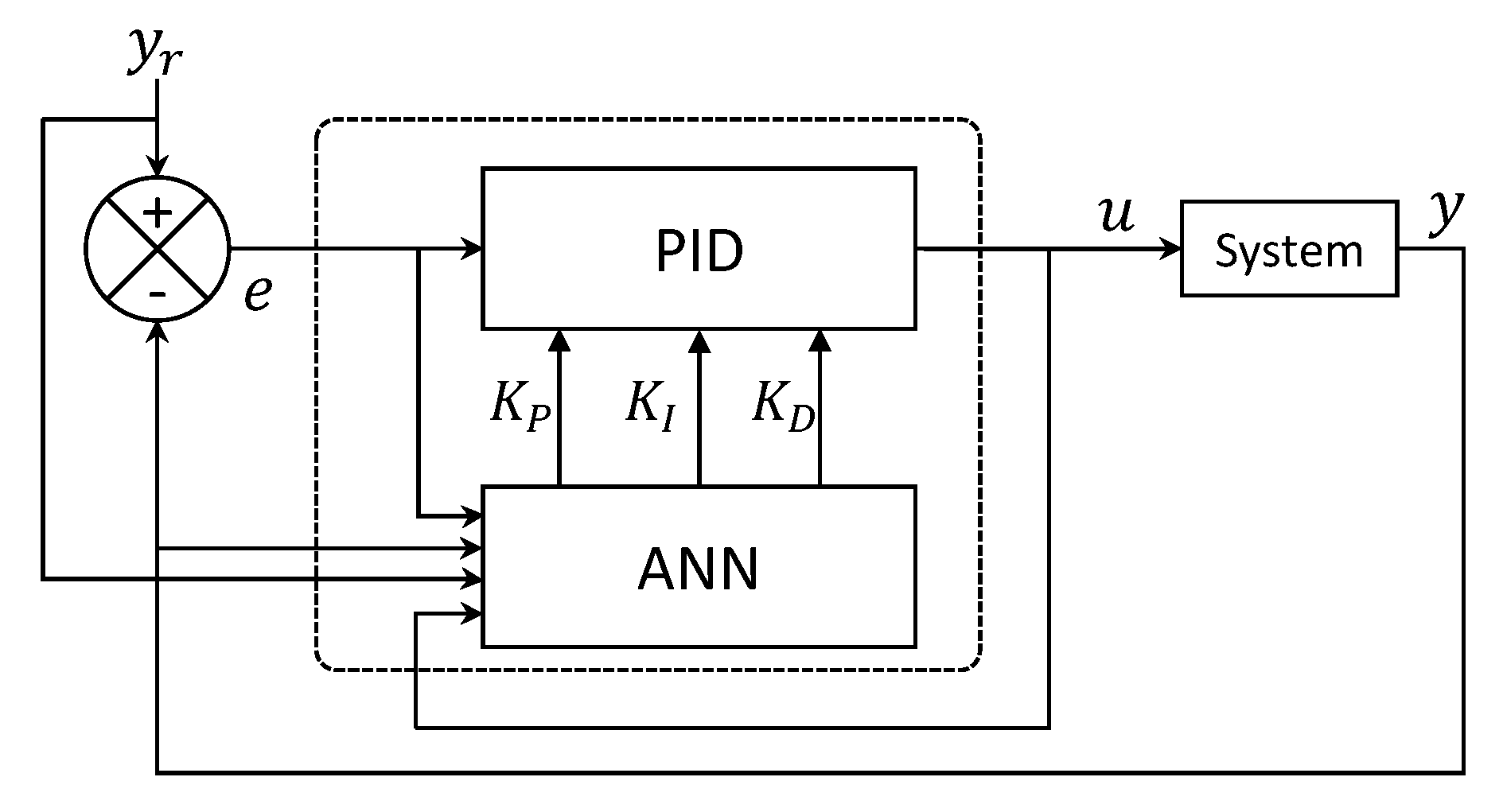

- Multi-layer neural PID controllersThese works are mainly based on an architecture as shown in Figure 2, where the output layer only has one neuron, and the immediately before layer to this output layer has three neurons, each one dedicated to the proportional gain (), the integral gain (), and the derivative gain (), respectively. The inputs are the proportional error (P), integral of the error (I), and derivative of the error (D). In some works, the inputs include the system output and its reference.

- Hybrid neural PID controllersThese adaptive neural PID controllers are based on improving the performance of a conventional PID controller (Figure 3). Typically, the neural network chooses online the proportional gain (), the integral gain (), and the derivative gain () parameters of the controller. However, they tend to have slow learning rates, complex architectures, and high computational cost [4,23].

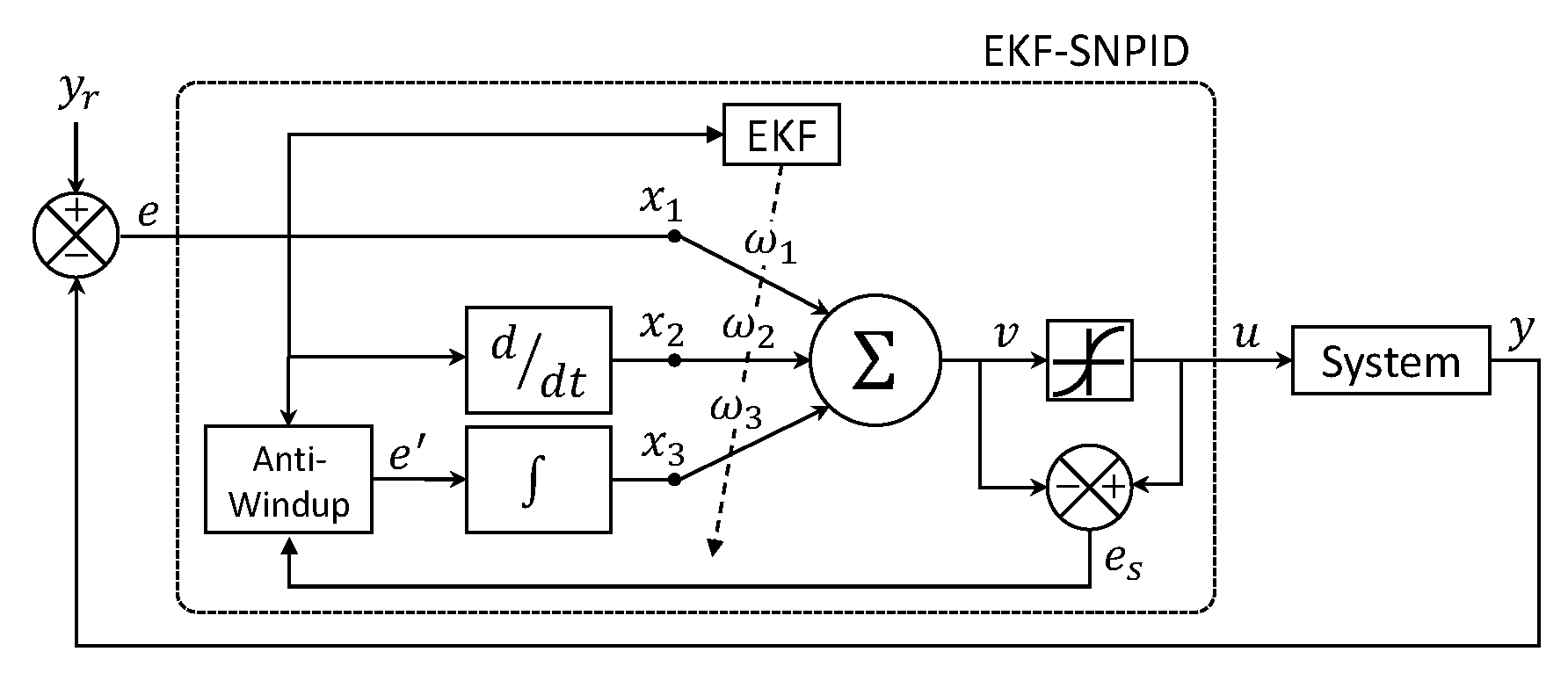

- in Section 2 the proposed adaptive neuron anti-windup PID controller is presented, where EKF neural PID controller is presented, where Section 2.1 explains the EKF training algorithm.

- Section 3 presents the implementation of the propose adaptive controller for position tracking of an omnidirectional mobile robot. In Section 3.1 the robot kinematics are presented for illustrative purposes, Section 3.2 presents the conventional PID controller implementation scheme, and Section 3.3 presents the adaptive control scheme.

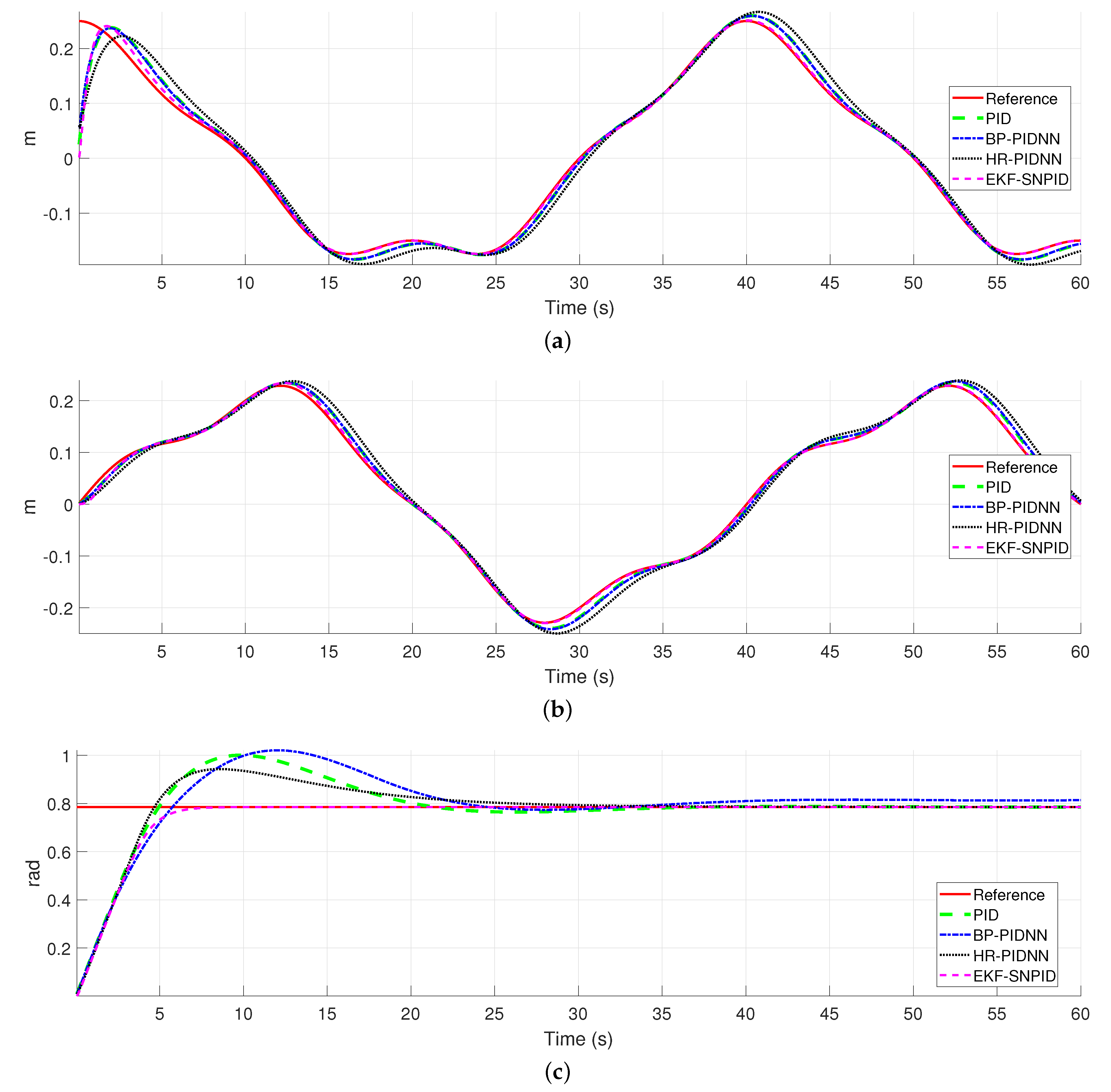

- in Section 4, both simulation (Section 4.1) and experimental results (Section 4.3) are presented, showing the performance of the proposed single neuron PID controller against the conventional PID and others neural PID controllers.

- in Section 5, important conclusions are presented and discussed.

2. Adaptive Single Neuron PID Controller Based on the Extended Kalman Filter Algorithm

2.1. Adaptive Neuron Training Based on the EKF Algorithm

3. Implementation of the Adaptive Neuron PID Controller for an Omnidirectional Mobile Robot

3.1. Omnidirectional Mobile Robot Kinematics

3.2. Conventional Velocity Control Design

3.3. Control Scheme Using the Adaptive Single Neuron PID Controller

4. Results

4.1. Simulation Results

- a sinusoidal trajectory is computed as

- a rose curve trajectory generated as

4.1.1. Simulation Test: Sinusoidal Reference

4.1.2. Simulation Test: Rose Curve Reference

4.2. Anti-Windup Tests

- An approximated trapezoidal trajectory which is calculated as

Simulation Test: Trapezoidal Reference

4.3. Experimental Results

- a sinusoidal trajectory is computed as

- a rose curve trajectory with offsets is generated as

4.3.1. Experimental test: sinusoidal reference

4.3.2. Experimental Test: Rose Curved Reference

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ANN | Artificial Neural Networks |

| PID | Proporional Integrative Derivative |

| P | Proportional error |

| I | Integral of the error |

| D | Derivative of the error |

| DOF | Degrees of freedom |

| BP-PIDNN | Neuron PID controller trained with Back Propagation algorithm |

| HR-PIDNN | Neuron PID controller trained with Hebbian learning rule |

| EKF-SNPID | Single neuron PID controller trained with Extended Kalman filter |

| m | meters |

| m/s | meters per second |

| s | seconds |

| rad | radian |

| rad/s | radian per second |

| RMS | Root Mean Square |

| MAD | Mean Absolute Deviation |

References

- Åström, K.; Hägglund, T. Pid Controllers; Setting the standard for automation; International Society for Measurement and Control: Research Triangle Park, NC, USA, 1995. [Google Scholar]

- Tian, Y.C.; Tadé, M.O.; Tang, J. A nonlinear PID controller with applications. In Proceedings of the 14th IFAC World Congress 1999, Beijing, Chia, 5–9 July 1999; Volume 32, pp. 2657–2661. [Google Scholar] [CrossRef]

- Ogata, K. Modern Control Engineering; Instrumentation and controls series; Prentice Hall: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Chen, Y.m.; He, Y.l.; Zhou, M.f. Decentralized PID neural network control for a quadrotor helicopter subjected to wind disturbance. J. Cent. South Univ. 2015, 22, 168–179. [Google Scholar] [CrossRef]

- Hernández-Alvarado, R.; García-Valdovinos, L.; Salgado-Jiménez, T.; Gómez-Espinosa, A.; Fonseca-Navarro, F. Neural network-based self-tuning PID control for underwater vehicles. Sensors 2016, 16, 1429. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Li, W. Single Neuron PID Model Reference Adaptive Control Based on RBF Neural Network. In Proceedings of the International Conference on Machine Learning and Cybernetics, Dalian, China, 18–21 August 20006; pp. 3021–3025. [Google Scholar] [CrossRef]

- Haykin, S. Neural Networks and Learning Machines; Pearson Education: London, UK, 2011. [Google Scholar]

- Baek, J.; Jin, M.; Han, S. A New Adaptive Sliding-Mode Control Scheme for Application to Robot Manipulators. IEEE Trans. Ind. Electron. 2016, 63, 3628–3637. [Google Scholar] [CrossRef]

- Rahmani, M.; Ghanbari, A.; Ettefagh, M.M. Robust adaptive control of a bio-inspired robot manipulator using bat algorithm. Expert Syst. Appl. 2016, 56, 164–176. [Google Scholar] [CrossRef]

- Chen, Y.; Kong, H.; Li, Z.; Ke, F. Trajectory-Tracking for a Mobile Robot Using Robust Predictive Control and Adaptive Control. In Proceedings of the 3rd International Conference on Advanced Robotics and Mechatronics (ICARM), Singapore, 18–20 July 2018; pp. 30–35. [Google Scholar]

- Pirník, R.; Hruboš, M.; Nemec, D.; Mravec, T.; Božek, P. Integration of Inertial Sensor Data into Control of the Mobile Platform. In Proceedings of the 2015 Federated Conference on Software Development and Object Technologies, Zilina, Slovakia, 19 November 2015; Janech, J., Kostolny, J., Gratkowski, T., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 271–282. [Google Scholar]

- Wang, H.; Guo, D.; Liang, X.; Chen, W.; Hu, G.; Leang, K.K. Adaptive Vision-Based Leader–Follower Formation Control of Mobile Robots. IEEE Trans. Ind. Electron. 2017, 64, 2893–2902. [Google Scholar] [CrossRef]

- Carlucho, I.; Paula, M.D.; Wang, S.; Petillot, Y.; Acosta, G.G. Adaptive low-level control of autonomous underwater vehicles using deep reinforcement learning. Robot. Auton. Syst. 2018, 107, 71–86. [Google Scholar] [CrossRef]

- Makavita, C.D.; Jayasinghe, S.G.; Nguyen, H.D.; Ranmuthugala, D. Experimental Study of Command Governor Adaptive Control for Unmanned Underwater Vehicles. IEEE Trans. Control. Syst. Technol. 2019, 27, 332–345. [Google Scholar] [CrossRef]

- Kebria, P.M.; Khosravi, A.; Nahavandi, S.; Shi, P.; Alizadehsani, R. Robust Adaptive Control Scheme for Teleoperation Systems With Delay and Uncertainties. IEEE Trans. Cybern. 2019, 1–11. [Google Scholar] [CrossRef]

- Bozek, P.; Ivandic, Z.; Lozhkin, A.; Lyalin, V.; Tarasov, V. Solutions to the characteristic equation for industrial robot’s elliptic trajectories. Tehnicki vjesnik Technical Gazette 2016, 23, 1017–1023. [Google Scholar]

- Bako, B.; Božek, P. Trends in Simulation and Planning of Manufacturing Companies. In Proceedings of the International Conference on Manufacturing Engineering and Materials, ICMEM, Nový Smokovec, Slovakia, 6–10 June 2016; Volume 149, pp. 571–575. [Google Scholar]

- Liu, T.; Juang, J. A single neuron PID control for twin rotor MIMO system. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Singapore, 14–17 July 2009; pp. 186–191. [Google Scholar] [CrossRef]

- Rivera-Mejía, J.; Léon-Rubio, A.; Arzabala-Contreras, E. PID based on a single artificial neural network algorithm for intelligent sensors. J. Appl. Res. Technol. 2012, 10, 262–282. [Google Scholar] [CrossRef]

- Lopez-Franco, C.; Gomez-Avila, J.; Alanis, A.; Arana-Daniel, N.; Villaseñor, C. Visual servoing for an autonomous hexarotor using a neural network based PID controller. Sensors 2017, 17, 1865. [Google Scholar] [CrossRef] [PubMed]

- Jiao, J.; Chen, J.; Qiao, Y.; Wang, W.; Wang, C.; Gu, L. Single Neuron PID Control of Agricultural Robot Steering System Based on Online Identification. In Proceedings of the IEEE Fourth International Conference on Big Data Computing Service and Applications (BigDataService), Bamberg, Germany, 26–29 March 2018; pp. 193–199. [Google Scholar] [CrossRef]

- Shu, H.; Pi, Y. PID neural networks for time-delay systems. Comput. Chem. Eng. 2000, 24, 859–862. [Google Scholar] [CrossRef]

- Shu, H.; Guo, X.; Shu, H. PID neural networks in multivariable systems. In Proceedings of the IEEE Internatinal Symposium on Intelligent Control, Vancouver, BC, Canada, 30 October 2002; pp. 440–444. [Google Scholar] [CrossRef]

- Sento, A.; Kitjaidure, Y. Neural network controller based on PID using an extended Kalman filter algorithm for multi-variable non-linear control system. In Proceedings of the Eighth International Conference on Advanced Computational Intelligence (ICACI), Chiang Mai, Thailand, 14–16 February 2016; pp. 302–309. [Google Scholar] [CrossRef]

- Zeng, G.Q.; Xie, X.Q.; Chen, M.R.; Weng, J. Adaptive population extremal optimization-based PID neural network for multivariable nonlinear control systems. Swarm Evol. Comput. 2019, 44, 320–334. [Google Scholar] [CrossRef]

- Gomez-Avila, J. Chapter 5—Adaptive PID Controller Using a Multilayer Perceptron Trained With the Extended Kalman Filter for an Unmanned Aerial Vehicle. In Artificial Neural Networks for Engineering Applications; Alanis, A.Y., Arana-Daniel, N., López-Franco, C., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 55–63. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, X.; Bi, M.; Xu, S. An adaptive neural PID controller for torque control of hybrid electric vehicle. In Proceedings of the 6th International Conference on Computer Science Education (ICCSE), Singapore, 3–5 August 2011; pp. 901–903. [Google Scholar] [CrossRef]

- Bobtsov, A.; Guirik, A.; Budko, M.; Budko, M. Hybrid parallel neuro-controller for multirotor unmanned aerial vehicle. In Proceedings of the 8th International Congress on Ultra Modern Telecommunications and Control Systems and Workshops (ICUMT), Lisbon, Portugal, 18–20 October 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Åström, K.; Murray, R. Feedback Systems: An Introduction for Scientists and Engineers. In Feedback Systems: An Introduction for Scientists and Engineers; Princeton University Press: Princeton, NJ, USA, 2008. [Google Scholar]

- Kumar, S.; Negi, R. A comparative study of PID tuning methods using anti-windup controller. In Proceedings of the 2nd International Conference on Power, Control and Embedded Systems, Allahabad, India, 17–19 December 2012; pp. 1–4. [Google Scholar] [CrossRef]

- Angel, L.; Viola, J.; Paez, M. Evaluation of the windup effect in a practical PID controller for the speed control of a DC-motor system. In Proceedings of the IEEE 4th Colombian Conference on Automatic Control (CCAC), Medellín, Colombia, 15–18 October 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Bohn, C.; Atherton, D.P. An analysis package comparing PID anti-windup strategies. IEEE Control. Syst. Mag. 1995, 15, 34–40. [Google Scholar]

- Kheirkhahan, P. Robust anti-windup control design for PID controllers. In Proceedings of the 17th International Conference on Control, Automation and Systems (ICCAS), Jeju, South Korea, 18–21 October 2017; pp. 1622–1627. [Google Scholar] [CrossRef]

- Haykin, S. Kalman Filtering and Neural Networks. In Adaptive and Cognitive Dynamic Systems: Signal Processing, Learning, Communications and Control; Wiley: Hoboken, NJ, USA, 2004. [Google Scholar]

- Alanis, A.; Sanchez, E. Discrete-Time Neural Observers: Analysis and Applications; Elsevier Science: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Moradi, M.H.; Katebi, M.R.; Johnson, M.A. Predictive PID control: A new algorithm. In Proceedings of the IECON’01, 27th Annual Conference of the IEEE Industrial Electronics Society (Cat. No.37243), Denver, CO, USA, 29 November–2 December 2001; Volume 1, pp. 764–769. [Google Scholar] [CrossRef]

- Sanchez, E.; Alanis, A.; Loukianov, A. Discrete-Time High Order Neural Control: Trained with Kalman Filtering; Studies in Computational Intelligence; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Feldkamp, L.A.; Prokhorov, D.V.; Feldkamp, T.M. Conditioned adaptive behavior from Kalman filter trained recurrent networks. In Proceedings of the International Joint Conference on Neural Networks, Portland, OR, USA, 20–24 July 2003; Volume 4, pp. 3017–3021. [Google Scholar]

- Camacho, J.D.; Villaseñor, C.; Alanis, A.Y.; Lopez-Franco, C.; Arana-Daniel, N. KAdam: Using the Kalman Filter to Improve Adam algorithm. In Progress in Pattern Recognition, Image Analysis, Computer Vision, and Applications; Nyström, I., Hernández Heredia, Y., Milián Núñez, V., Eds.; Springer International Publishing: Cham, Swityerland, 2019; pp. 429–438. [Google Scholar]

- Alanis, A.; Arana-Daniel, N.; Lopez-Franco, C. Artificial Neural Networks for Engineering Applications; Elsevier Science: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Rios, J.; Alanis, A.; Lopez-Franco, C.; Arana-Daniel, N.; Sanchez, E. Neural Networks Modelling and Control: Applications for Unknown Nonlinear Delayed Systems in Discrete-Time; Elsevier Science & Technology: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Sanchez, E.; Alanis, A. Redes Neuronales: Conceptos Fundamentales y Aplicaciones a Control Automático; Automática Robótica, Pearson Educación: Madrid, Spain, 2006. [Google Scholar]

- Leung, H.; Haykin, S. The complex backpropagation algorithm. IEEE Trans. Signal Process. 1991, 39, 2101–2104. [Google Scholar] [CrossRef]

- Ruck, D.W.; Rogers, S.K.; Kabrisky, M.; Maybeck, P.S.; Oxley, M.E. Comparative analysis of backpropagation and the extended Kalman filter for training multilayer perceptrons. IEEE Trans. Pattern Anal. Mach. Intell. 1992, 686–691. [Google Scholar] [CrossRef]

- Kundu, A.S.; Mazumder, O.; Dhar, A.; Lenka, P.K.; Bhaumik, S. Scanning Camera and Augmented Reality Based Localization of Omnidirectional Robot for Indoor Application. Procedia Comput. Sci. 2017, 105, 27–33. [Google Scholar] [CrossRef]

- Wu, J.; Lv, C.; Zhao, L.; Li, R.; Wang, G. Design and implementation of an omnidirectional mobile robot platform with unified I/O interfaces. In Proceedings of the IEEE International Conference on Mechatronics and Automation (ICMA), Changchun, China, 5–8 August 2017; pp. 410–415. [Google Scholar] [CrossRef]

- Zhang, G.; Qin, W.; Qin, Q.; He, B.; Liu, G. Varying gain MPC for consensus tracking with application to formation control of omnidirectional mobile robots. In Proceedings of the 12th World Congress on Intelligent Control and Automation (WCICA), Guilin, China, 12–15 June 2016; pp. 2957–2962. [Google Scholar] [CrossRef]

- Sharifi, M.; Young, M.; Chen, X.; Clucas, D.; Pretty, C. Mechatronic design and development of a non-holonomic omnidirectional mobile robot for automation of primary production. Cogent Eng. 2016, 3. [Google Scholar] [CrossRef]

- Li, Z.; Yang, C.; Su, C.; Deng, J.; Zhang, W. Vision-Based Model Predictive Control for Steering of a Nonholonomic Mobile Robot. IEEE Trans. Control. Syst. Technol. 2016, 24, 553–564. [Google Scholar] [CrossRef]

- Tsai, C.; Tai, F.; Lee, Y. Motion controller design and embedded realization for Mecanum wheeled omnidirectional robots. In Proceedings of the 9th World Congress on Intelligent Control and Automation, Taipei, Taiwan, 21–25 June 2011; pp. 546–551. [Google Scholar] [CrossRef]

- Viboonchaicheep, P.; Shimada, A.; Kosaka, Y. Position rectification control for Mecanum wheeled omni-directional vehicles. In Proceedings of the IECON’03, 29th Annual Conference of the IEEE Industrial Electronics Society (IEEE Cat. No.03CH37468), Roanoke, VA, USA, 2–6 November 2003; Volume 1, pp. 854–859. [Google Scholar] [CrossRef]

- Taheri, H.; Qiao, B.; Ghaeminezhad, N. Kinematic Model of a Four Mecanum Wheeled Mobile Robot. Int. J. Comput. Appl. 2015, 113, 6–9. [Google Scholar] [CrossRef]

- Ardiyanto, I. Task Oriented Behavior-Based State-Adaptive PID (Proportional Integral Derivative) Control for Low-Cost Mobile Robot. In Proceedings of the Second International Conference on Computer Engineering and Applications, Bali Island, Indonesia, 26–29 March 2010; Volume 1, pp. 103–107. [Google Scholar] [CrossRef]

- Normey-Rico, J.E.; Alcalá, I.; Gómez-Ortega, J.; Camacho, E.F. Mobile robot path tracking using a robust PID controller. Control. Eng. Pract. 2001, 9, 1209–1214. [Google Scholar] [CrossRef]

- Carlucho, I.; Paula, M.D.; Villar, S.A.; Acosta, G.G. Incremental Q-learning strategy for adaptive PID control of mobile robots. Expert Syst. Appl. 2017, 80, 183–199. [Google Scholar] [CrossRef]

- Khalil, H.K. Nonlinear Systems, 3rd ed.; Prentice-Hall: Upper Saddle River, NJ, USA, 2002; The book can be consulted by contacting: PH-AID: Wallet, Lionel. [Google Scholar]

- Ren, C.; Sun, Y.; Ma, S. Passivity-based control of an omnidirectional mobile robot. Robot. Biomim. 2016, 3, 10. [Google Scholar] [CrossRef] [PubMed]

- Shukla, S.; Singh, P.; Behera, L. A passivity based system design for non-holonomic mobile robot in presence of delay and traffic disturbances. In Proceedings of the 12th IEEE Conference on Industrial Electronics and Applications (ICIEA), Siem Reap, Cambodia, 18–20 June 2017; pp. 733–738. [Google Scholar] [CrossRef]

| Measure | Method | |||

|---|---|---|---|---|

| RMS | PID | 4.6702 | 1.8181 | 6.6922 |

| BP-PIDNN | 5.0489 | 1.7526 | 6.7741 | |

| HR-PIDNN | 9.4373 | 3.9668 | 8.5651 | |

| EKF-SNPID | 4.1447 | 5.0465 | 5.0092 | |

| MAD | PID | 3.0401 | 1.6364 | 3.0477 |

| BP-PIDNN | 3.1118 | 1.5772 | 3.1253 | |

| HR-PIDNN | 6.2210 | 3.5599 | 4.7817 | |

| EKF-SNPID | 1.2864 | 2.6786 | 1.9203 |

| Measure | Method | |||

|---|---|---|---|---|

| RMS | PID | 2.0057 | 8.5850 | 1.4285 |

| BP-PIDNN | 1.8210 | 9.6169 | 1.5274 | |

| HR-PIDNN | 2.7587 | 1.8114 | 1.3674 | |

| EKF-SNPID | 1.8662 | 3.7495 | 1.2650 | |

| MAD | PID | 1.0300 | 6.6289 | 6.6001 |

| BP-PIDNN | 9.6779 | 7.4597 | 7.7155 | |

| HR-PIDNN | 1.8695 | 1.4109 | 5.9445 | |

| EKF-SNPID | 4.9995 | 5.7139 | 3.4104 |

| Measure | Method | |||

|---|---|---|---|---|

| RMS | PID | 1.0232 | 2.4106 | 1.3638 |

| EKF-SNPID | 8.6468 | 7.8939 | 1.1402 | |

| MAD | PID | 4.8462 | 2.1612 | 5.3743 |

| EKF-SNPID | 2.9027 | 5.6546 | 3.7291 |

| Measure | Method | |||

|---|---|---|---|---|

| RMS | PID | 3.8207 | 3.4422 | 1.3833 |

| EKF-SNPID | 2.6344 | 2.0574 | 1.1510 | |

| MAD | PID | 2.9415 | 2.7517 | 5.4825 |

| EKF-SNPID | 1.2798 | 1.3251 | 3.8303 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernandez-Barragan, J.; Rios, J.D.; Alanis, A.Y.; Lopez-Franco, C.; Gomez-Avila, J.; Arana-Daniel, N. Adaptive Single Neuron Anti-Windup PID Controller Based on the Extended Kalman Filter Algorithm. Electronics 2020, 9, 636. https://doi.org/10.3390/electronics9040636

Hernandez-Barragan J, Rios JD, Alanis AY, Lopez-Franco C, Gomez-Avila J, Arana-Daniel N. Adaptive Single Neuron Anti-Windup PID Controller Based on the Extended Kalman Filter Algorithm. Electronics. 2020; 9(4):636. https://doi.org/10.3390/electronics9040636

Chicago/Turabian StyleHernandez-Barragan, Jesus, Jorge D. Rios, Alma Y. Alanis, Carlos Lopez-Franco, Javier Gomez-Avila, and Nancy Arana-Daniel. 2020. "Adaptive Single Neuron Anti-Windup PID Controller Based on the Extended Kalman Filter Algorithm" Electronics 9, no. 4: 636. https://doi.org/10.3390/electronics9040636

APA StyleHernandez-Barragan, J., Rios, J. D., Alanis, A. Y., Lopez-Franco, C., Gomez-Avila, J., & Arana-Daniel, N. (2020). Adaptive Single Neuron Anti-Windup PID Controller Based on the Extended Kalman Filter Algorithm. Electronics, 9(4), 636. https://doi.org/10.3390/electronics9040636