A Comparative Simulation Study of the Thermal Performances of the Building Envelope Wall Materials in the Tropics

Abstract

:1. Introduction

2. Previous Investigations

3. Building Envelope

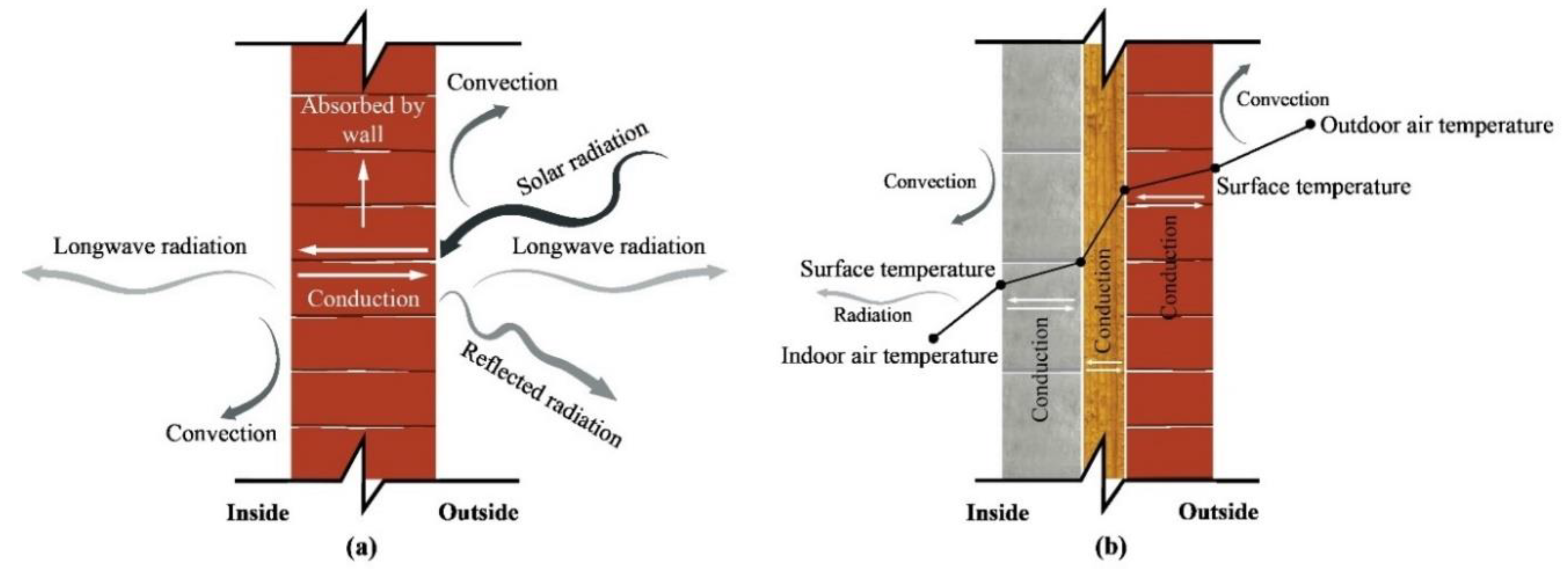

3.1. Heat Transfer Through the Envelope Walls

3.2. Thermophysical Properties of the Building Envelope Wall Materials

4. Thermal Performance Assessment of the Building

5. Tropical Climate Context

6. Simulation Methods

6.1. Governing Equations

6.2. Physical Model and Simulation Conditions

6.3. Simulation Phases

6.3.1. Phase 01: Different Wall Materials

6.3.2. Phase 02: Different Thicknesses of the Wall

6.3.3. Phase 03: Different Orientation of the Space

6.3.4. Phase 04: Different Wall Construction Types

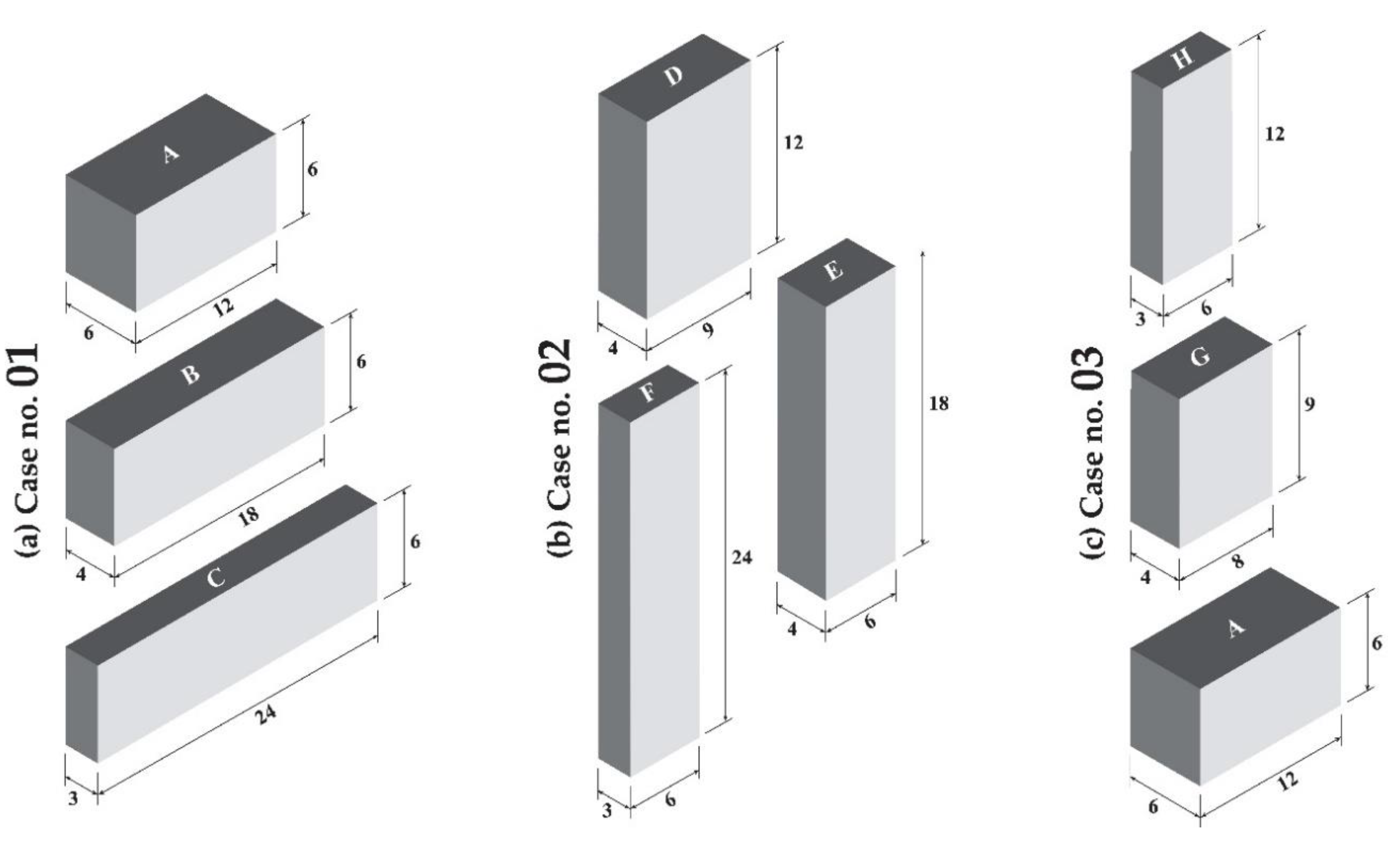

6.3.5. Phase 05: Different Shape Factors

- Case 1 (Group a): Buildings with similar volume, height, and floor area but different external surface areas.

- Case 2 (Group b): Buildings with similar volume but different heights, floor areas, and external surface areas.

- Case 3 (Group c): Buildings with different heights, volumes, and floor areas but a similar surface area.

7. Results and Discussions

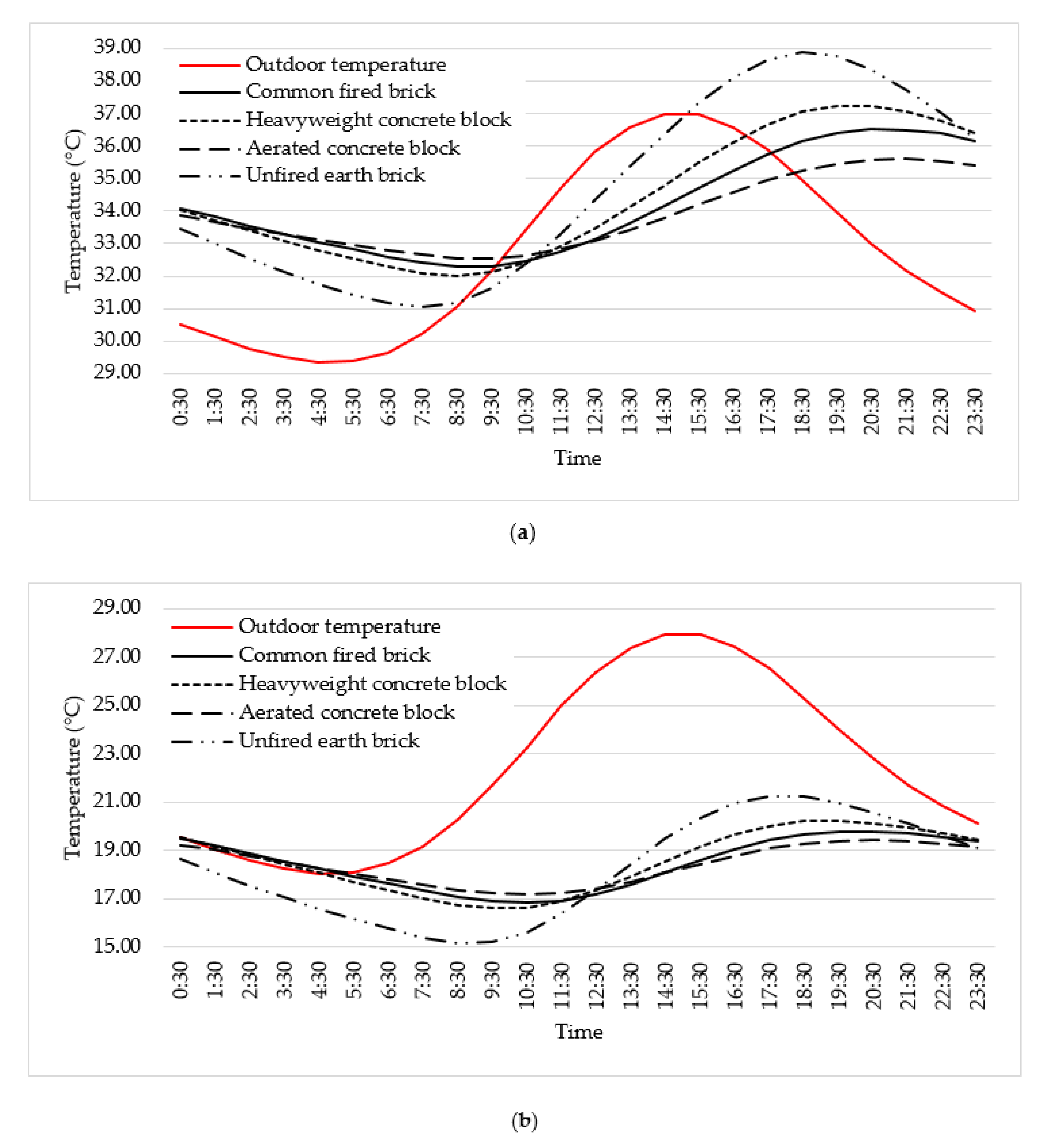

7.1. Effects of Materials’ Thermophysical Properties

7.2. Effects of Wall Thickness Variations

7.3. Effects of Different Orientations

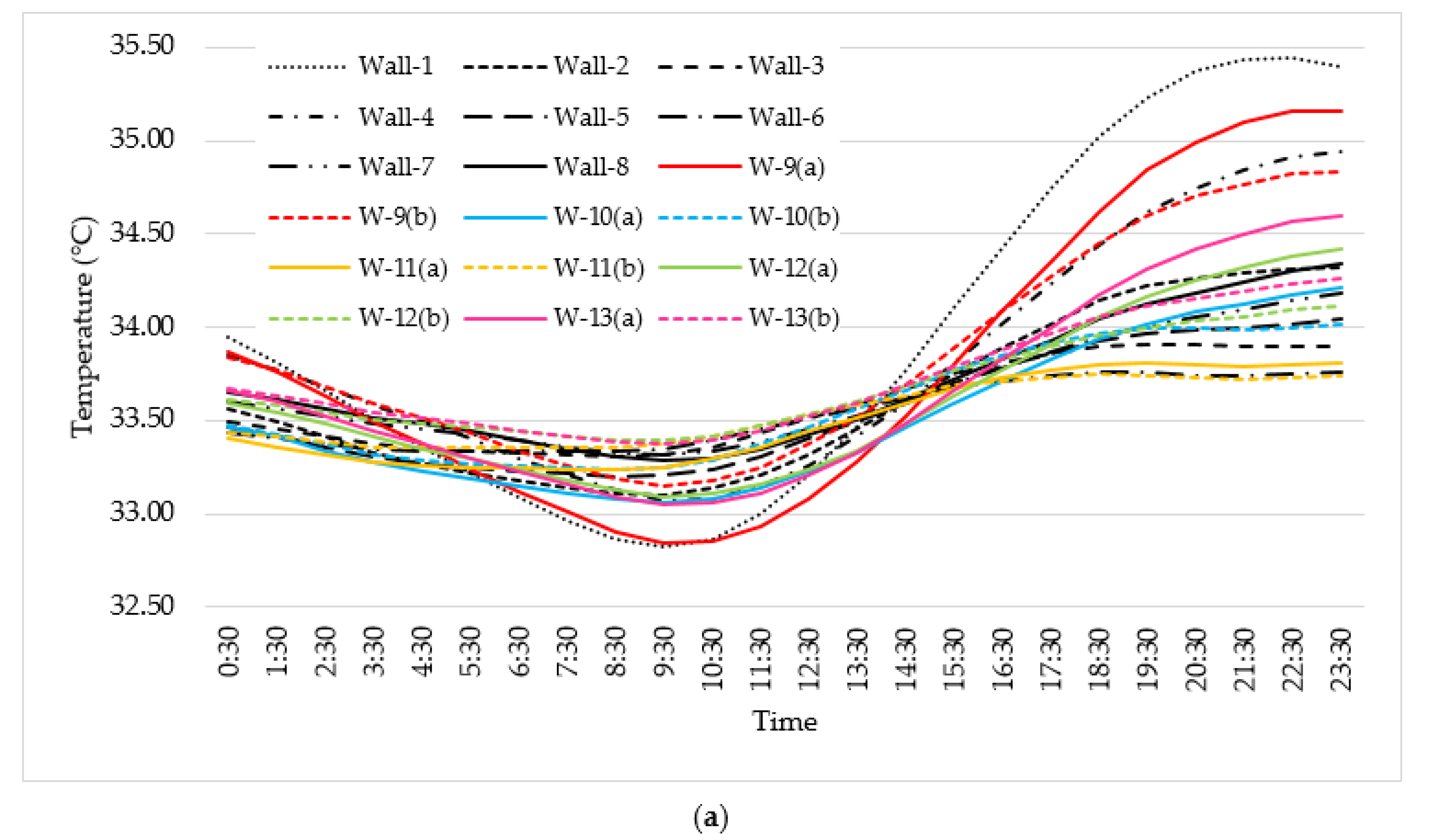

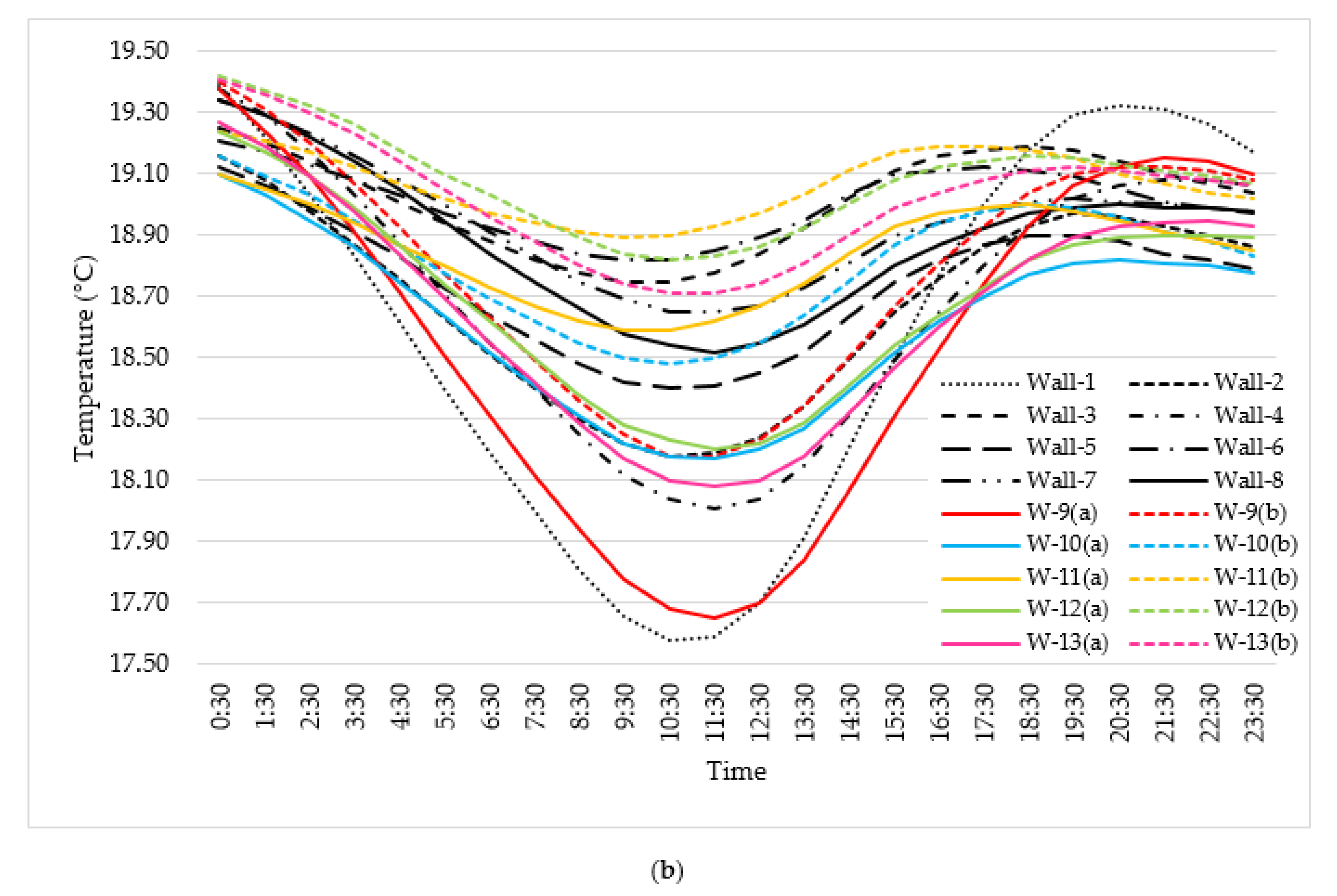

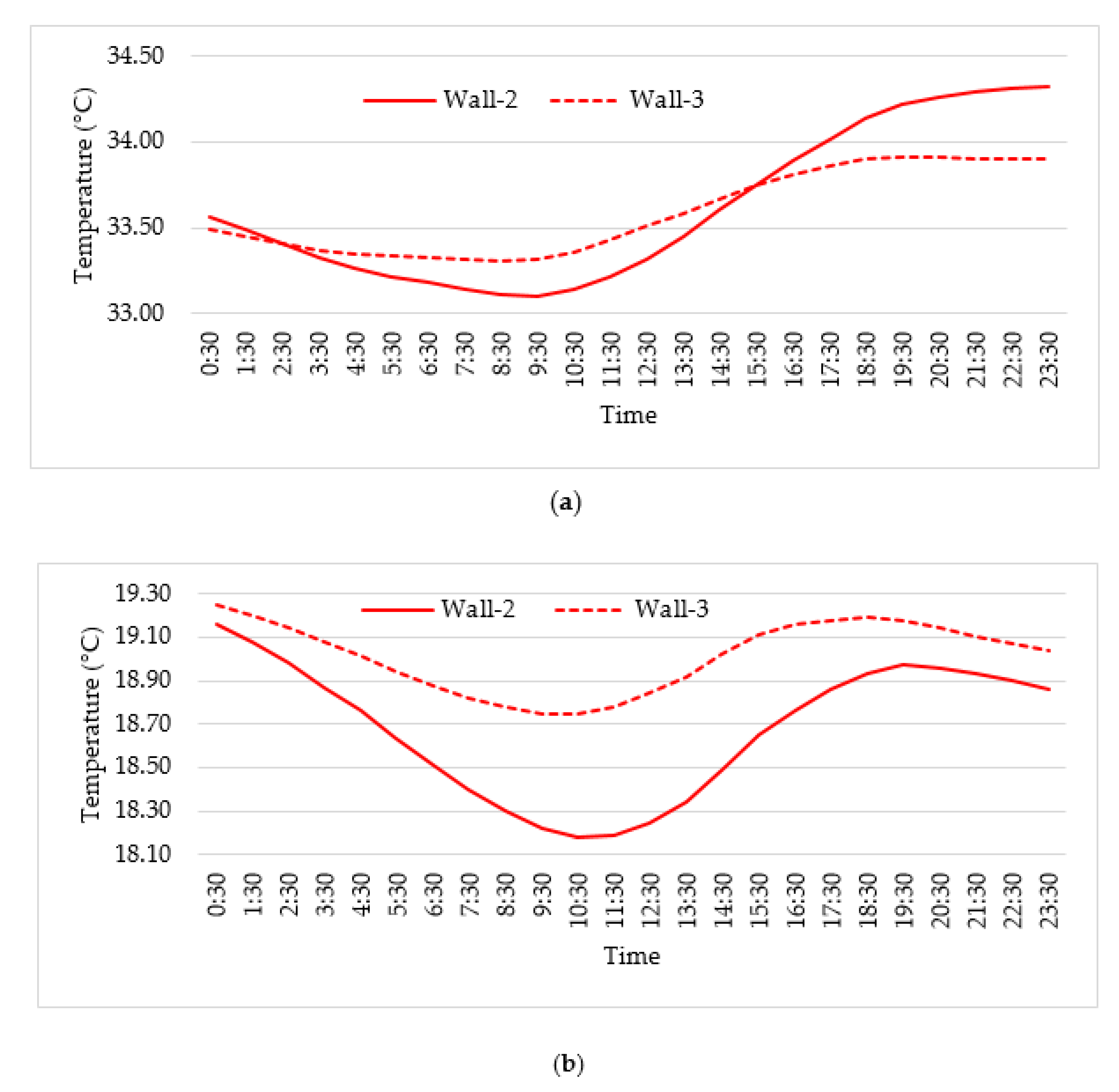

7.4. Effects of Different Wall Constructions

7.5. Effects of Different Shape Factors

- Case 1 (Group a): For the first case, buildings with an equal volume (432 m3), heated floor area (72 m2), and height (6 m) but different surface areas were simulated. The simulation results presented that with the increase of and ratio the energy demand increased. It is due to the increased exposed surface areas which caused additional heat gain and heat loss during the summer and winter respectively.

- Case 2 (Group b): In the second case, the volumes (432 m3) of the three modelled buildings were considered the same, however, heights, external surface areas, and net floor areas were different. It was found that, with the increase of height, the external surface area increased and the net floor area decreased. This indicates that and ratios are higher in the tall buildings. Besides, in the case of low height buildings, the ratios gradually reduced and lower ratios showed lesser energy consumption and heat gain [58].

- Case 3 (Group c): For this group of buildings, the surface areas of the buildings were equal (216 m2) but building heights were increased gradually. The results showed that with the increase of height, the volume and net floor area decreased. Also, both the and ratios increased and it caused the energy demand to decrease. In this case, another factor which is can be considered. It can be seen that for the equal surface area of the spaces with the decrease of heated floor area the ratio also decreased which caused a reduction in the energy demand. But the result was converse for group b, however, in that group increased surface area explains the heat gain and loss.

8. Conclusions

- The heat transfer rate into the building highly depends on the thermophysical properties of the wall materials. It can be seen that the material’s capability to dampen the indoor temperature fluctuation is inversely proportional to the U-value and thermal diffusivity. Besides, materials having high heat storage capacity decreased the DF, while high thermal diffusivity contributed to the reverse effects. The ACB performed the best of the four types of materials analysed because of its lowest U-value and thermal diffusivity while UFB with the highest U-value and thermal diffusivity performed the worst.

- The analysis was extended by altering the thickness of the material and the results showed that the thermal mass improved with an increased thickness which also resulted in better thermal efficiency as it induced a decrease in DF.

- The exterior walls of a building can be built as a single layer or multilayers to provide sufficient thermal storage capacity to achieve proper DF and TL. The simulation results revealed that the inclusion of layers and insulation to the wall contributed to decreasing the DF. Besides, the location of the insulation layers had no impact on the overall U-value of the walls but significantly affected the DF. When different walls were constructed only with common fired brick, the best performance was achieved by the cavity wall W-6. However, among all other configurations examined with the combination of fired brick and concrete blocks, the cavity wall W-11(a) performed the best. In both cases, insulation was located outside the wall (near the heat entrance point).

- Moreover, the energy consumption of the spaces significantly varied depending on the shape factor of the spaces. The results indicated that the energy consumption increased with the increase of surface area and volume of the building. However, it decreased as the heated floor area decreased.

- Also, the spatial orientations influenced the thermal performances of the external walls as the maximum surface area exposed to the solar radiation caused high heat gain. The best performance for the tropical climate conditions was obtained for the building having the elongated surfaces oriented to the north-south.

Author Contributions

Funding

Conflicts of Interest

References

- Šujanová, P.; Rychtáriková, M.; Mayor, T.S.; Hyder, A. A Healthy, Energy-Efficient and Comfortable Indoor Environment, a Review. Energies 2019, 12, 1414. [Google Scholar] [CrossRef] [Green Version]

- Gou, S.; Nik, V.M.; Scartezzini, J.L.; Zhao, Q.; Li, Z. Passive design optimization of newly-built residential buildings in Shanghai for improving indoor thermal comfort while reducing building energy demand. Energy Build. 2018, 169, 484–506. [Google Scholar] [CrossRef]

- Radivojević, A.; Đukanović, L. Energy Resources and Building Performance; Konstantinou, T., Ignjatović, N.C., Zbašnik-Senegačnik, M., Eds.; TU Delft Open: Rotterdam, The Netherlands, 2018; pp. 61–86. ISBN 978-94-6366-034-1. [Google Scholar]

- Zhang, Y.; Li, N.; Dong, L.; Lang, M. Study on modern application of traditional building materials based on geographical background. In Proceedings of the UIA 2017 Seoul World Architects Congress, Seoul, Korea, 3−10 September 2017. [Google Scholar]

- Nguyen, A.T.; Truong, N.S.H.; Rockwood, D.; Le, A.D.T. Studies on sustainable features of vernacular architecture in different regions across the world: A comprehensive synthesis and evaluation. Front. Arch. Res. 2019, 8, 535–548. [Google Scholar] [CrossRef]

- Rodriguez, C.M.; D’Alessandro, M. Indoor thermal comfort review: The tropics as the next frontier. Urban Clim. 2019, 29, 100488. [Google Scholar] [CrossRef]

- Kuik, O.J.; Lima, M.B.; Gupta, J. Energy security in a developing world. Wiley Interdiscip. Rev. Clim. Chang. 2011, 2, 627–634. [Google Scholar] [CrossRef] [Green Version]

- Njiru, C.W.; Letema, S.C. Energy Poverty and Its Implication on Standard of Living in Kirinyaga, Kenya. J. Energy 2018. [Google Scholar] [CrossRef] [Green Version]

- Pathirana, S.; Rodrigo, A.; Halwatura, R. Effect of building shape, orientation, window to wall ratios and zones on energy efficiency and thermal comfort of naturally ventilated houses in tropical climate. Int. J. Energy Environ. Eng. 2019, 10, 107–120. [Google Scholar] [CrossRef]

- Makaka, G.; Meyer, E. Temperature stability of traditional and low-cost modern housing in the Eastern Cape, South Africa. J. Build. Phys. 2006, 30, 71–86. [Google Scholar] [CrossRef]

- Mohammad, S.; Shea, A. Performance evaluation of modern building thermal envelope designs in the semi-arid continental climate of Tehran. Buildings 2013, 3, 674–688. [Google Scholar] [CrossRef] [Green Version]

- Besagni, G.; Borgarello, M. The determinants of residential energy expenditure in Italy. Energy 2018, 165, 369–386. [Google Scholar] [CrossRef]

- Jazaeri, J.; Gordon, R.L.; Alpcan, T. Influence of building envelopes, climates, and occupancy patterns on residential HVAC demand. J. Build. Eng. 2019, 22, 33–47. [Google Scholar] [CrossRef]

- Schlueter, A.; Thesseling, F. Building information model-based energy/exergy performance assessment in early design stages. Autom. Constr. 2009, 18, 153–163. [Google Scholar] [CrossRef]

- Karlsson, F.; Rohdin, P.; Persson, M.L. Measured and predicted energy demand of a low energy building: Important aspects when using building energy simulation. Build. Serv. Eng. Res. Technol. 2007, 28, 223–235. [Google Scholar] [CrossRef]

- Lotfabadi, P.; Hançer, P. A comparative study of traditional and contemporary building envelope construction techniques in terms of thermal comfort and energy efficiency in hot and humid climates. Sustainability 2019, 11, 3582. [Google Scholar] [CrossRef] [Green Version]

- Zune, M.; Rodrigues, L.; Gillott, M. Vernacular passive design in Myanmar housing for thermal comfort. Sustain. Cities Soc. 2020, 54, 101992. [Google Scholar] [CrossRef]

- Chowdhury, S.; Ahmed, K.S.; Hamada, Y. Thermal performance of building envelope of ready-made garments (RMG) factories in Dhaka, Bangladesh. Energy Build. 2015, 107, 144–154. [Google Scholar] [CrossRef]

- Udawattha, C.; Halwatura, R. Thermal performance and structural cooling analysis of brick, cement block, and mud concrete block. Adv. Build. Energy Res. 2018, 12, 150–163. [Google Scholar] [CrossRef]

- Kalua, A. Envelope thermal design optimization for urban residential buildings in Malawi. Buildings 2016, 6, 13. [Google Scholar] [CrossRef] [Green Version]

- Ascione, F.; Bianco, N.; De Masi, R.F.; Mauro, G.M.; Vanoli, G.P. Design of the building envelope: A novel multi-objective approach for the optimization of energy performance and thermal comfort. Sustainability 2015, 7, 10809–10836. [Google Scholar] [CrossRef] [Green Version]

- Zhu, L.; Hurt, R.; Correia, D.; Boehm, R. Detailed energy saving performance analyses on thermal mass walls demonstrated in a zero energy house. Energy Build. 2009, 41, 303–310. [Google Scholar] [CrossRef]

- Rattanongphisat, W.; Rordprapat, W. Strategy for energy efficient buildings in tropical climate. In Energy Procedia, Proceedings of the 2013 International Conference on Alternative Energy in Developing Countries and Emerging Economies Strategy, Bangkok, Thailand, 30–31 May 2013; Elsevier Procedia: Amsterdam, The Netherlands, 2014; Volume 52, pp. 10–17. [Google Scholar]

- Sadeghifam, A.N.; Marsono, A.K.; Kiani, I.; Isikdag, U.; Bavafa, A.A.; Tabatabaee, S. Energy analysis of wall materials using building information modeling (BIM) of public buildings in the tropical climate countries. J. Teknol. 2016, 78, 35–41. [Google Scholar] [CrossRef] [Green Version]

- Kisilewicz, T. On the role of external walls in the reduction of energy demand and the mitigation of human thermal discomfort. Sustainability 2019, 11. [Google Scholar] [CrossRef] [Green Version]

- Strzałkowski, J.; Garbalińska, H. Thermal simulation of building performance with different loadbearing materials. Iop Conf. Ser. Mater. Sci. Eng. 2018, 415, 012014. [Google Scholar]

- Sadineni, S.B.; Madala, S.; Boehm, R.F. Passive building energy savings: A review of building envelope components. Renew. Sustain. Energy Rev. 2011, 15, 3617–3631. [Google Scholar] [CrossRef]

- Gorantla, K.K.; Shaik, S.; Settee, A.B.T.P. Simulation of various wall and window glass material for energy efficient building design. Key Eng. Mater. 2016, 692, 9–16. [Google Scholar] [CrossRef]

- Watson, D. Climatic Design: Energy-Efficient Building Principles and Practices; McGraw Hill Higher Education: New York, NY, USA, 1983; ISBN 978-0070684782. [Google Scholar]

- Givoni, B. Man, Climate and Architecture, 2nd ed.; Applied Science Publishers: London, UK, 1976; pp. 1–144. ISBN 978-0853346784. [Google Scholar]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Asan, H. Numerical computation of time lags and decrement factors for different building materials. Build. Environ. 2006, 41, 615–620. [Google Scholar] [CrossRef]

- Toure, P.M.; Dieye, Y.; Gueye, P.M.; Faye, M.; Sambou, V. Influence of envelope thickness and solar absorptivity of a test cell on time lag and decrement factor. J. Build. Phys. 2020, 43, 338–350. [Google Scholar] [CrossRef]

- Chi, F.; Wang, Y.; Wang, R.; Li, G.; Peng, C. An investigation of optimal window-to-wall ratio based on changes in building orientations for traditional dwellings. Sol. Energy 2020, 195, 64–81. [Google Scholar] [CrossRef]

- Yarramsetty, S.; Rohullah, M.S.; Sivakumar, M.V.N.; Raj, P.A. An investigation on energy consumption in residential building with different orientation: A BIM approach. Asian J. Civ. Eng. 2020, 21, 253–266. [Google Scholar] [CrossRef]

- Nayak, J.K.; Prajapati, J.A. Handbook on Energy Conscious. Buildings; Indian institute of technology, Bombay and Solar energy Center and Ministry of Non-Conventional Energy Sources: Bombay, India, 2006. [Google Scholar]

- Vincelas, F.F.C.; Ghislain, T.; Robert, T. Effects of the type of building materials on the thermal behavior of building in the hot dry climates: A case study of Maroua city, Cameroon. Int. J. Innov. Sci. Eng. Technol. 2017, 4, 1–13. [Google Scholar]

- Wonorahardjo, S.; Sutjahja, I.M.; Mardiyati, Y.; Andoni, H.; Thomas, D.; Achsani, R.A.; Steven, S. Characterising thermal behaviour of buildings and its effect on urban heat island in tropical areas. Int. J. Energy Env. Eng. 2020, 11, 129–142. [Google Scholar] [CrossRef] [Green Version]

- Evangelisti, L.; Guattari, C.; Gori, P.; Vollaro, R.D.L. In situ thermal transmittance measurements for investigating differences between wall models and actual building performance. Sustainability 2015, 7, 10388–10398. [Google Scholar] [CrossRef] [Green Version]

- Zheng, K.; Cho, Y.K.; Wang, C.; Li, H. Noninvasive Residential Building Envelope R -Value Measurement Method Based on Interfacial Thermal Resistance. J. Archi.T. Eng. 2016, 22, A4015002. [Google Scholar] [CrossRef]

- Corasaniti, S.; Potenza, M.; Coppa, P.; Bovesecchi, G. Comparison of different approaches to evaluate the equivalent thermal diffusivity of building walls under dynamic conditions. Int. J. Therm. Sci. 2020, 150, 106232. [Google Scholar] [CrossRef]

- Demezhko, D.Y. Measurements of the thermal effusivity of solid materials by the contact method. Instruments Exp. Technol. 2011, 54, 867–871. [Google Scholar] [CrossRef]

- Verbeke, S.; Audenaert, A. Thermal inertia in buildings: A review of impacts across climate and building use. Renew. Sustain. Energy Rev. 2018, 82, 2300–2318. [Google Scholar] [CrossRef]

- Reilly, A.; Kinnane, O. The impact of thermal mass on building energy consumption. Appl. Energy 2017, 198, 108–121. [Google Scholar] [CrossRef] [Green Version]

- Kuczyński, T.; Staszczuk, A. Experimental study of the influence of thermal mass on thermal comfort and cooling energy demand in residential buildings. Energy 2020, 195, 116984. [Google Scholar]

- Gregory, K.; Moghtaderi, B.; Sugo, H.; Page, A. Effect of thermal mass on the thermal performance of various Australian residential constructions systems. Energy Build. 2008, 40, 459–465. [Google Scholar] [CrossRef]

- Badea, N. Design for Micro-Combined Cooling, Heating and Power Systems: Stirling Engines and Renewable Power Systems; Springer: Berlin/Heidelberg, Germany, 2014; ISBN 978-1-4471-6254-4. [Google Scholar]

- Hsieh, C.; Wu, I. Applying building information modelling in evaluating building energy performance. Gerontechnology 2012, 11, 170. [Google Scholar] [CrossRef]

- Kontoleon, K.J.; Bikas, D.K. The effect of south wall’s outdoor absorption coefficient on time lag, decrement factor and temperature variations. Energy Build. 2007, 39, 1011–1018. [Google Scholar] [CrossRef]

- El Fgaier, F.; Lafhaj, Z.; Antczak, E.; Chapiseau, C. Dynamic thermal performance of three types of unfired earth bricks. Appl. Therm. Eng. 2016, 93, 377–383. [Google Scholar] [CrossRef]

- Sun, C.; Shu, S.; Ding, G.; Zhang, X.; Hu, X. Investigation of time lags and decrement factors for different building outside temperatures. Energy Build. 2013, 61, 1–7. [Google Scholar] [CrossRef]

- Soudani, L.; Woloszyn, M.; Fabbri, A.; Morel, J.C.; Grillet, A.C. Energy evaluation of rammed earth walls using long term in-situ measurements. Sol. Energy 2017, 141, 70–80. [Google Scholar] [CrossRef]

- Feng, G.; Sha, S.; Xu, X. Analysis of the Building Envelope Influence to Building Energy Consumption in the Cold Regions. In Procedia Engineering, Proceeding of the 8th International Cold Climate HVAC 2015 Conference, Dalian, China, 20–23 October 2015; Elsevier Procedia: Amsterdam, The Netherlands, 2016; Volume 146, pp. 244–250. [Google Scholar]

- Peng, H.; Li, M.; Lou, S.; He, M.; Huang, Y.; Wen, L. Investigation on spatial distribution and thermal properties of typical residential buildings in South China’s Pearl River Delta. Energy Build. 2020, 206, 109555. [Google Scholar] [CrossRef]

- Depecker, P.; Menezo, C.; Virgone, J.; Lepers, S. Design of buildings shape and energetic consumption. Build. Environ. 2001, 36, 627–635. [Google Scholar] [CrossRef]

- Ratti, C.; Raydan, D.; Steemers, K. Building form and environmental performance: Archetypes, analysis and an arid climate. Energy Build. 2003, 35, 49–59. [Google Scholar] [CrossRef]

- Lylykangas, K. Shape Factor as an Indicator of Heating Energy Demand. In Proceedings of the 15 Internationales Holzbau-Forum 09, Garmisch, Germany, 2 December 2009. [Google Scholar]

- Lim, H.S.; Kim, G. Analysis of Energy Performance on Envelope Ratio Exposed to the Outdoor. Adv. Civ. Eng. 2018. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; Wu, D.; Li, X.; Hou, S.; Liu, C.; Jones, P. Effect of geometric factors on the energy performance of high-rise office towers in Tianjin, China. Build. Simul. 2017, 10, 625–641. [Google Scholar] [CrossRef] [Green Version]

- Premrov, M.; Leskovar, V.Ž.; Mihalič, K. Influence of the building shape on the energy performance of timber-glass buildings in different climatic conditions. Energy 2016, 108, 201–211. [Google Scholar] [CrossRef]

- Dutta, A.; Samanta, A.; Neogi, S. Influence of orientation and the impact of external window shading on building thermal performance in tropical climate. Energy Build. 2017, 139, 680–689. [Google Scholar] [CrossRef]

- Raji, B.; Tenpierik, M.J.; Van den Dobbelsteen, A. Early-stage design considerations for the energy-efficiency of high-rise office buildings. Sustainability 2017, 9, 623. [Google Scholar] [CrossRef] [Green Version]

- Valladares-Rendón, L.G.; Schmid, G.; Lo, S.L. Review on energy savings by solar control techniques and optimal building orientation for the strategic placement of façade shading systems. Energy Build. 2017, 140, 458–479. [Google Scholar] [CrossRef]

- Wang, W.; Rivard, H.; Zmeureanu, R. Floor shape optimization for green building design. Adv. Eng. Informatics. 2006, 20, 363–378. [Google Scholar] [CrossRef]

- Kiprop, J. WorldAtlas. Available online: https://www.worldatlas.com/articles/what-is-a-tropical-climate.html (accessed on 15 April 2020).

- Balasubramanian, A. World Climate Zones; Centre for Advanced Studies in Earth Science, University of Mysore: Mysore, India, 2013. [Google Scholar]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World map of the Köppen-Geiger climate classification updated. Meteorol Zeitschrift. 2006, 15, 259–263. [Google Scholar] [CrossRef]

- Integrated Environmental Solutions Virtual Environment (IES-VE). Available online: https://iesve.com/ (accessed on 24 April 2020).

- Ji, Y.; Fitton, R.; Swan, W.; Webster, P. Assessing overheating of the UK existing dwellings—A case study of replica Victorian end terrace house. Build. Environ. 2014, 77, 1–11. [Google Scholar] [CrossRef]

- Ji, Y.; Lee, A.; Swan, W. Building dynamic thermal model calibration using the Energy House facility at Salford. Energy Build. 2019, 191, 224–234. [Google Scholar] [CrossRef] [Green Version]

- Ben, H.; Steemers, K. Energy retrofit and occupant behaviour in protected housing: A case study of the Brunswick Centre in London. Energy Build. 2014, 80, 120–130. [Google Scholar] [CrossRef]

- Tong, J.C.K.; Tse, J.M.Y.; Jones, P.J. Development of thermal evaluation tool for detached houses in Mongolia. Energy Build. 2018, 173, 81–90. [Google Scholar] [CrossRef]

- Moran, F.; Blight, T.; Natarajan, S.; Shea, A. The use of Passive House Planning Package to reduce energy use and CO2 emissions in historic dwellings. Energy Build. 2014, 75, 216–227. [Google Scholar] [CrossRef]

- IES-VE. IES-VE User Guide, ApacheSim Calculation Methods. 2011. Available online: http://www.iesve.com/downloads/help/Thermal/Reference/ApacheSimCalculationMethods.pdf (accessed on 24 April 2020).

- A Technical Manual for SBEM, UK Volume. 2018. Available online: https://www.uk-ncm.org.uk/filelibrary/SBEM-Technical-Manual_v5.2.g_20Nov15.pdf (accessed on 8 April 2020).

- Khatun, M.A.; Rashid, M.B.; Hygen, H.O. Climate of Bangladesh, MET Report; Bangladesh Meteorological Department and Norwegian Meteorological Institute: Decca, Bangladesh, 2016; ISSN 2387-4201. [Google Scholar]

- Bangladesh Meteorological Department. Available online: www.bmd.gov.bd (accessed on 4 March 2020).

- Zhu, Z.; Jin, X.; Li, Q.; Meng, Q. Experimental Study on the Thermal Performance of Ventilation Wall with Cladding Panels in Hot and Humid Area. Procedia Eng. 2015, 121, 410–414. [Google Scholar] [CrossRef] [Green Version]

- Braham, D.; Barnard, N.; Jaunzens, D. BRE Digest 454 Part. 1: Thermal Mass in Office Buildings: An Introduction; Building Research Establishment: Watford, UK, 2001; ISBN 1-86081-466-472. [Google Scholar]

- Fernandez, N.P. Thermal Performance of Buildings with Post-Tensioned Timber Structure Compared with Concrete and Steel Alternatives; University of Canterbury, 2012; Available online: https://core.ac.uk/download/pdf/35467597.pdf (accessed on 6 May 2020).

- Andelkovic, B.V.; Stojanvic, B.V.; Stojiljkovic, M.M.; Janevski, J.N.; Stojanovic, M.B. Thermal mass impact on energy performance of a low, medium and heavy mass building in Belgrade. Therm. Sci. 2012, 16, S507–S520. [Google Scholar]

- Aste, N.; Torre, S.D.; Talamo, C.; Adhikari, R.S.; Rossi, C. Innovative Models for Sustainable Development in Emerging African Countries; Springer Nature: Basel, Switzerland, 2015; ISBN 978-3-030-33322-5. [Google Scholar]

- Vijayalakshmi, M.M.; Natarajan, E.; Shanmugasundaram, V. Thermal behaviour of building wall elements. J. Appl Sci. 2006, 6, 3128–3133. [Google Scholar]

- Ozel, M. Thermal performance and optimum insulation thickness of building walls with different structure materials. Appl. Eng. 2011, 31, 3854–3863. [Google Scholar] [CrossRef]

- De Saulles, T. Thermal Mass Explained; CentER (The Concrete Centre): Camberley, UK, 2011; ISBN 978-1-904818-71. [Google Scholar]

| Materials | CFB | ACB | HCB | UFB | Cavity Insulation | Insulation Board | |||

|---|---|---|---|---|---|---|---|---|---|

| Thickness (mm) | 222 | 222 | 222 | 125 | 222 | 300 | 400 | 50 | 40 |

| Density (kg/m3) | 1922 | 750 | 2300 | 1788 | 1788 | 1788 | 1788 | 32 | 32 |

| Thermal conductivity (W/mK) | 0.73 | 0.24 | 1.63 | 0.90 | 0.90 | 0.90 | 0.90 | 0.08 | 0.04 |

| Specific heat capacity (J/kgK) | 837 | 1000 | 1000 | 545 | 545 | 545 | 545 | 837 | 837 |

| Thermal diffusivity (10−7 m2/s) | 4.52 | 3.20 | 7.09 | 9.23 | 9.23 | 9.23 | 9.23 | ||

| Thermal effusivity (Ws1/2/m2K) | 1081.45 | 424.26 | 1936.23 | 936.49 | 936.49 | 936.49 | 936.49 | ||

| U-value (W/m2K) | 2.10 | 0.91 | 3.09 | 3.24 | 2.40 | 1.99 | 1.63 | ||

| R-value (m2K/W) | 0.30 | 0.93 | 0.15 | 0.14 | 0.25 | 0.33 | 0.44 | ||

| DF (Summer day) | 0.55 | 0.40 | 0.68 | 1.78 | 1.02 | 0.63 | 0.35 | ||

| Thermal mass (kJ/m2K) | 160.87 | 75 | 230 | 60.90 | 97.45 | 97.45 | 97.45 | ||

| Yearly energy consumption (MWh) | 17.60 | 11.70 | 22.60 | 24.80 | 19.40 | 17.10 | 15.30 | ||

| Wall ID | Description of Walls (From Outer to Inner Side) | U-Value (W/m2K) | R-Value (m2K/W) | DF (Summer Day) | Thermal Mass (kJ/m2k) | Yearly Energy Consumption (MWh) |

|---|---|---|---|---|---|---|

| W-1 | 13 mm plaster, 222 mm common fired brick, 13 mm plaster | 1.57 | 0.47 | 0.34 | 147.76 | 15 |

| W-2 | 13 mm plaster, 222 mm common fired brick, 40 mm insulation board, 13 mm plaster | 0.64 | 1.40 | 0.16 | 7.80 | 10.20 |

| W-3 | 13 mm plaster, 40 mm insulation board, 222 mm common fired brick, 13 mm plaster | 0.64 | 1.40 | 0.08 | 147.76 | 10.20 |

| W-4 | 13 mm plaster, 105 mm common fired brick, 50 mm clear cavity, 105 mm common fired brick, 13 mm plaster | 1.25 | 0.63 | 0.24 | 147.76 | 13.40 |

| W-5 | 13 mm plaster, 105 mm common fired brick, 50 mm clear cavity, 105 mm common fired brick, 40 mm insulation board, 13 mm plaster | 0.58 | 1.56 | 0.11 | 7.80 | 9.90 |

| W-6 | 13 mm plaster, 40 mm insulation board, 105 mm common fired brick, 50 mm clear cavity, 105 mm common fired brick, 13 mm plaster | 0.58 | 1.56 | 0.05 | 147.76 | 9.80 |

| W-7 | 13 mm plaster, 105 mm common fired brick, 50 mm cavity insulation, 105 mm common fired brick, 13 mm plaster | 0.78 | 1.11 | 0.11 | 147.76 | 11 |

| W-8 | 13 mm plaster, 105 mm common fired brick, 25 mm clear cavity, 25 mm cavity insulation, 105 mm common fired brick, 13 mm plaster | 0.88 | 0.96 | 0.14 | 147.76 | 11.50 |

| W-9 (a) | 13 mm plaster, 105 mm common fired brick, 50 mm clear cavity, 100 mm aerated concrete block, 13 mm plaster | 0.93 | 0.90 | 0.30 | 73.05 | 11.80 |

| W-9 (b) | 13 mm plaster, 105 mm common fired brick, 50 mm clear cavity, 100 mm heavyweight concrete block, 13 mm plaster | 1.39 | 0.55 | 0.22 | 207.90 | 14.10 |

| W-10 (a) | 13 mm plaster, 105 mm common fired brick, 50 mm clear cavity, 100 mm aerated concrete block, 40 mm insulation board, 13 mm plaster | 0.50 | 1.83 | 0.15 | 7.80 | 9.50 |

| W-10 (b) | 13 mm plaster, 105 mm common fired brick, 50 mm clear cavity, 100 mm heavyweight concrete block, 40 mm insulation board, 13 mm plaster | 0.61 | 1.48 | 0.10 | 7.80 | 10 |

| W-11 (a) | 13 mm plaster, 40 mm insulation board, 105 mm common fired brick, 50 mm clear cavity, 100 mm aerated concrete block, 13 mm plaster | 0.50 | 1.83 | 0.07 | 73.05 | 9.40 |

| W-11 (b) | 13 mm plaster, 40 mm insulation board, 105 mm common fired brick, 50 mm clear cavity, 100 mm heavyweight concrete block, 13 mm plaster | 0.61 | 1.48 | 0.05 | 207.90 | 10 |

| W-12 (a) | 13 mm plaster, 105 mm common fired brick, 50 mm cavity insulation, 100 mm aerated concrete block, 13 mm plaster | 0.64 | 1.38 | 0.17 | 73.05 | 10.30 |

| W-12 (b) | 13 mm plaster, 105 mm common fired brick, 50 mm cavity insulation, 100 mm heavyweight concrete block, 13 mm plaster | 0.84 | 1.03 | 0.09 | 207.90 | 11.30 |

| W-13 (a) | 13 mm plaster, 105 mm common fired brick, 25 mm clear cavity, 25 mm cavity insulation, 100 mm aerated concrete block, 13 mm plaster | 0.71 | 1.23 | 0.20 | 73.05 | 10.60 |

| W-13(b) | 13 mm plaster, 105 mm common fired brick, 25 mm clear cavity, 25 mm cavity insulation, 100 mm heavyweight concrete block, 13 mm plaster | 0.95 | 0.88 | 0.12 | 207.90 | 11.90 |

| Building Form. | Height (m) | Yearly Energy Consumption (MWh) | ||||||

|---|---|---|---|---|---|---|---|---|

| Case no. 01 | ||||||||

| A | 6 | 432 | 216 | 72 | 0.50 | 3.00 | 0.17 | 17.60 |

| B | 6 | 432 | 264 | 72 | 0.61 | 3.70 | 0.17 | 19.80 |

| C | 6 | 432 | 324 | 72 | 0.75 | 4.50 | 0.17 | 22.50 |

| Case no. 02 | ||||||||

| D | 12 | 432 | 312 | 36 | 0.72 | 9.00 | 0.08 | 19.00 |

| E | 18 | 432 | 360 | 24 | 0.83 | 15.00 | 0.06 | 20.20 |

| F | 24 | 432 | 432 | 18 | 1.00 | 24.00 | 0.04 | 22.90 |

| Case no. 03 | ||||||||

| A | 6 | 432 | 216 | 72 | 0.50 | 3.00 | 0.17 | 17.60 |

| G | 9 | 288 | 216 | 32 | 0.75 | 6.80 | 0.11 | 13.70 |

| H | 12 | 216 | 216 | 18 | 1.00 | 12.00 | 0.08 | 12.30 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jannat, N.; Hussien, A.; Abdullah, B.; Cotgrave, A. A Comparative Simulation Study of the Thermal Performances of the Building Envelope Wall Materials in the Tropics. Sustainability 2020, 12, 4892. https://doi.org/10.3390/su12124892

Jannat N, Hussien A, Abdullah B, Cotgrave A. A Comparative Simulation Study of the Thermal Performances of the Building Envelope Wall Materials in the Tropics. Sustainability. 2020; 12(12):4892. https://doi.org/10.3390/su12124892

Chicago/Turabian StyleJannat, Nusrat, Aseel Hussien, Badr Abdullah, and Alison Cotgrave. 2020. "A Comparative Simulation Study of the Thermal Performances of the Building Envelope Wall Materials in the Tropics" Sustainability 12, no. 12: 4892. https://doi.org/10.3390/su12124892