Processing, Microstructures and Mechanical Properties of a Ni-Based Single Crystal Superalloy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Preparation

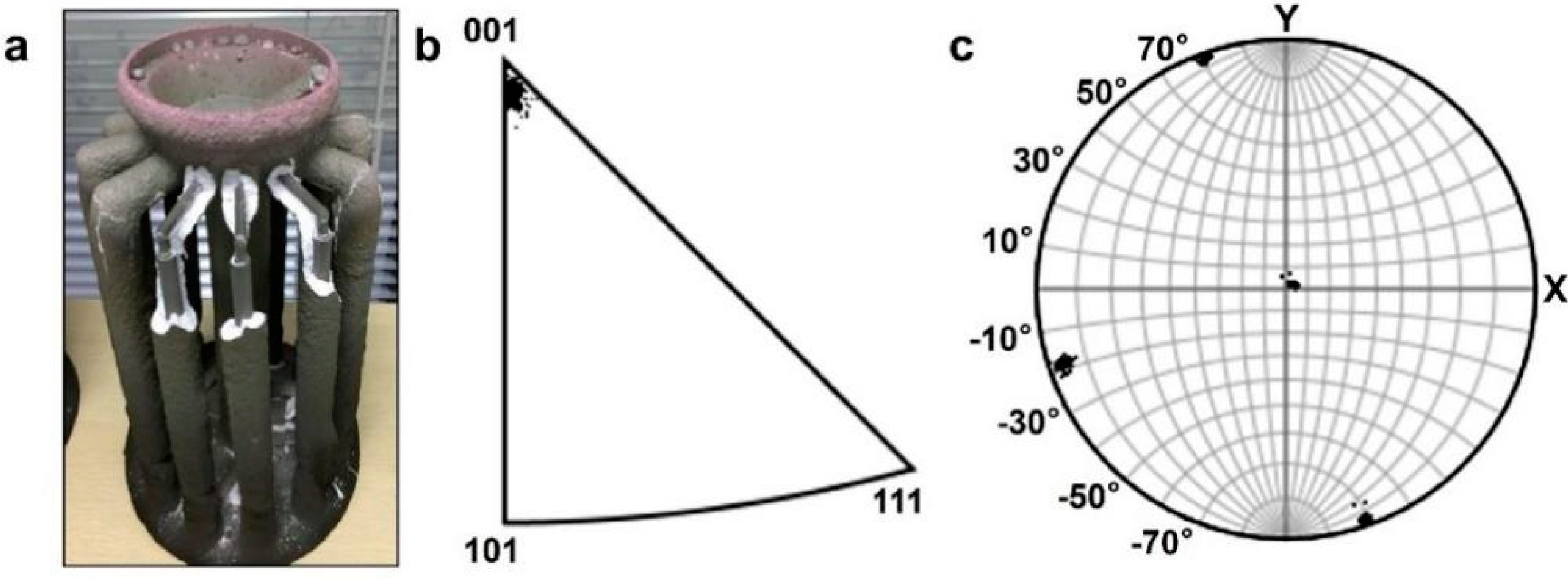

2.1.1. Single Crystal Growth

2.1.2. Heat Treatment

2.2. Microstructural Characterization

2.3. Mechanical Testing

3. Results and Discussion

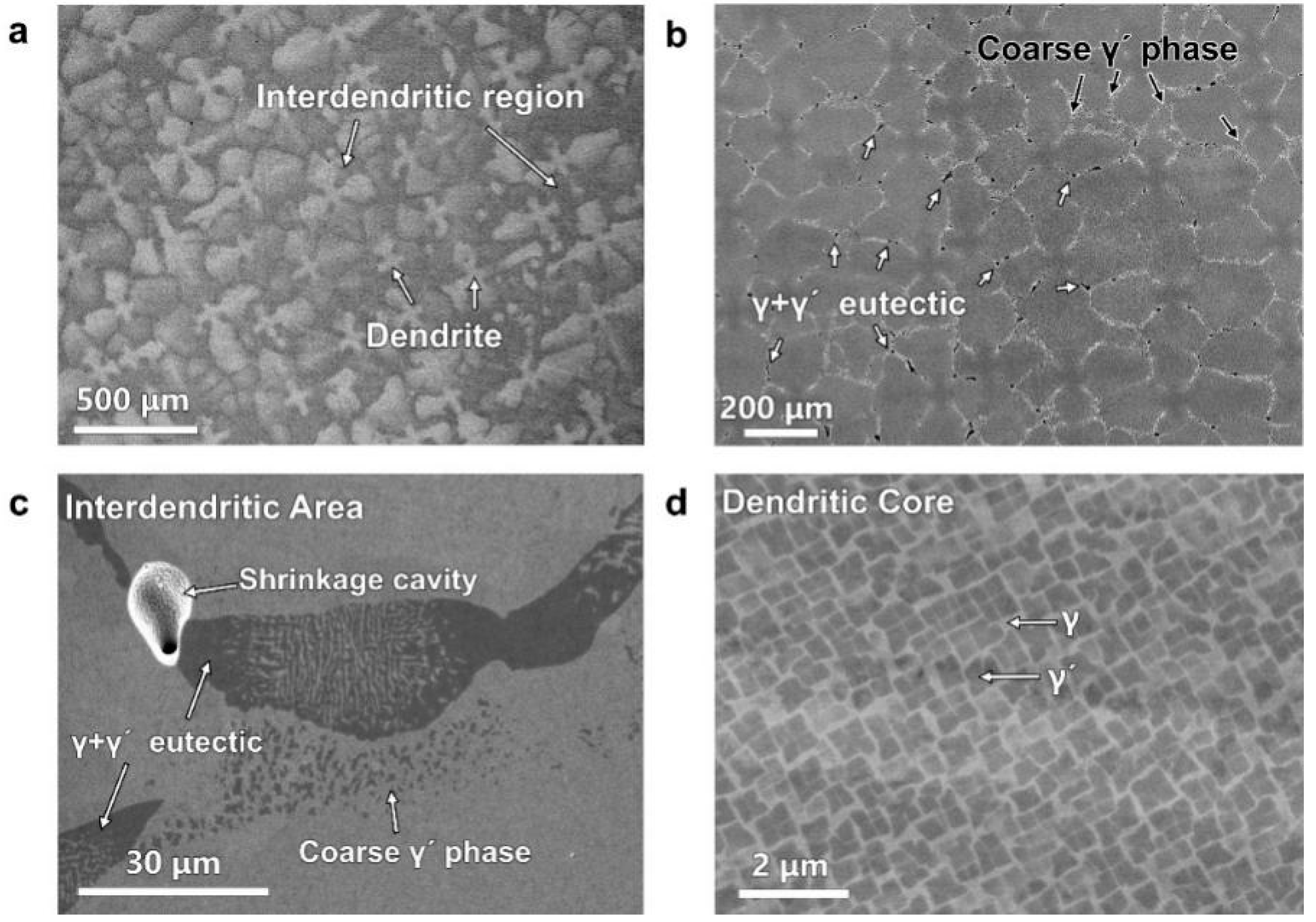

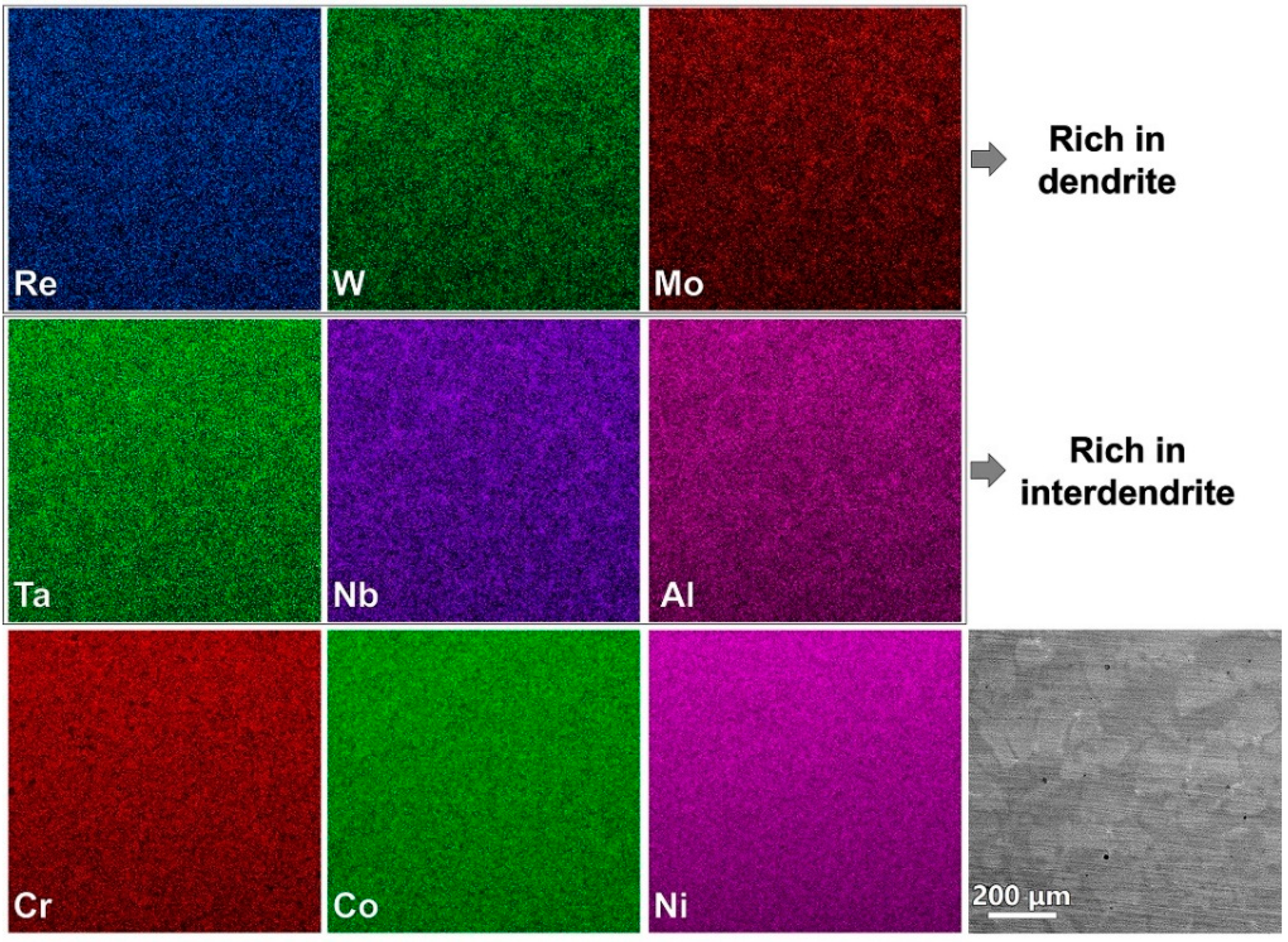

3.1. As-Grown Microstructure

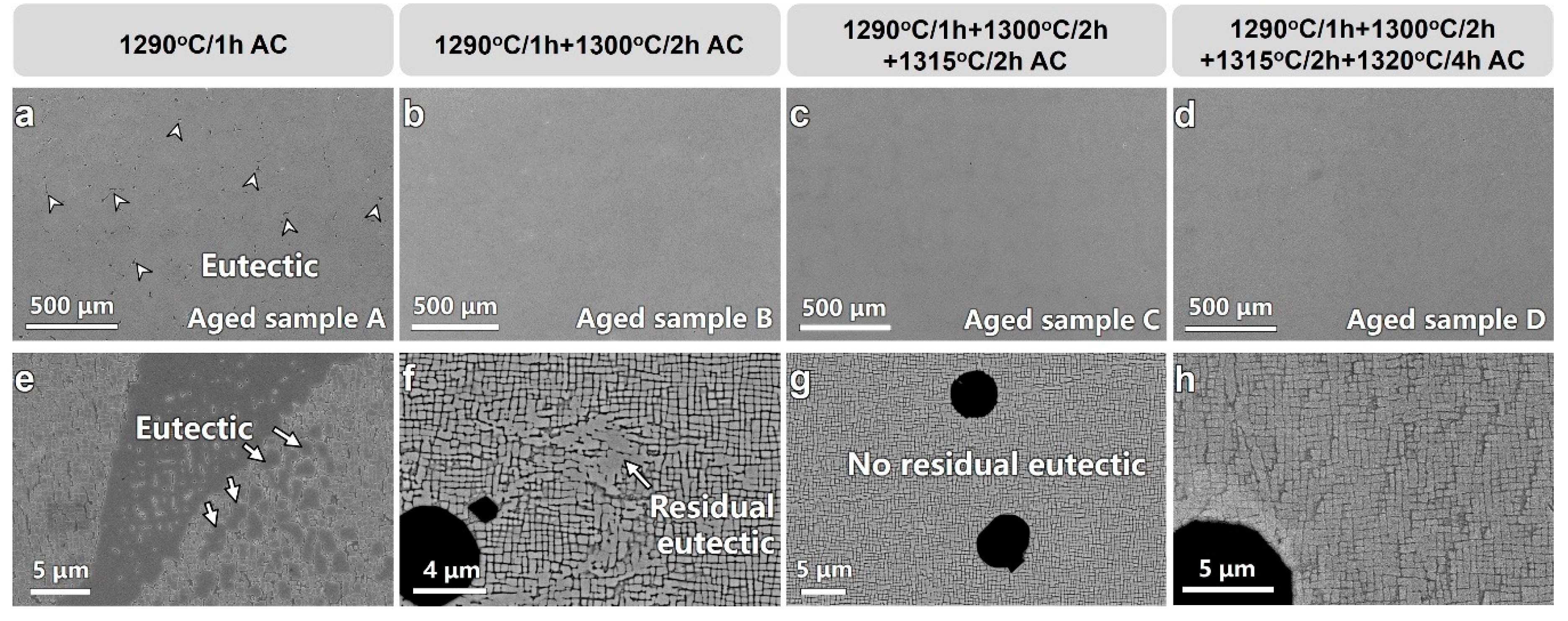

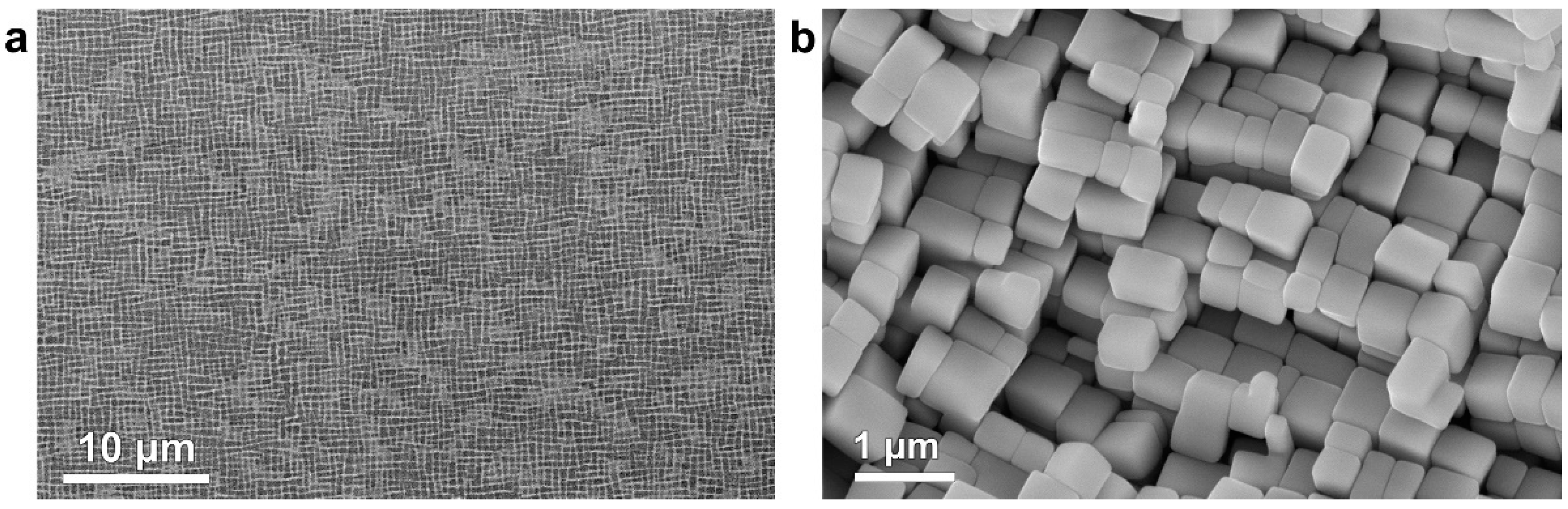

3.2. Heat Treatment

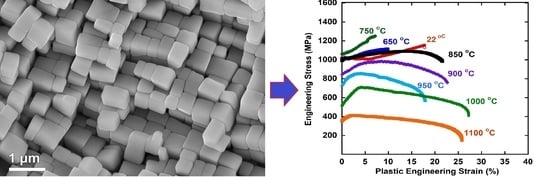

3.3. Tensile Properties

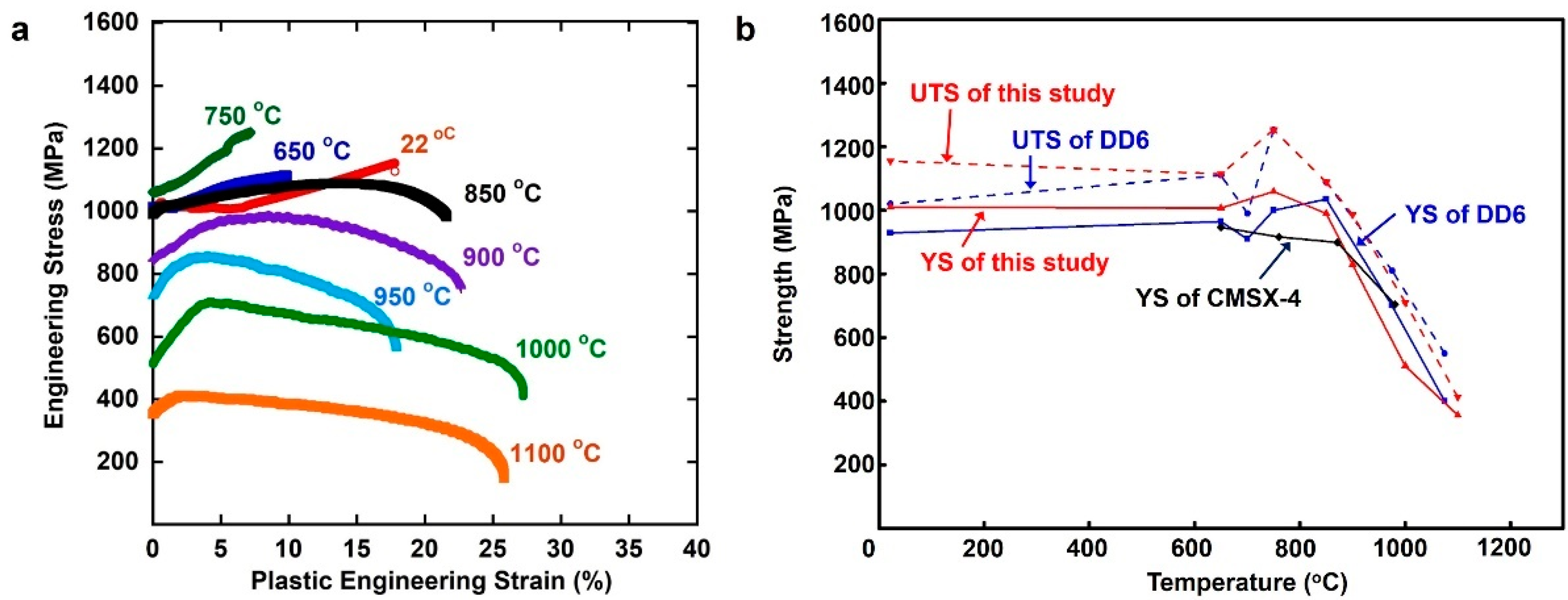

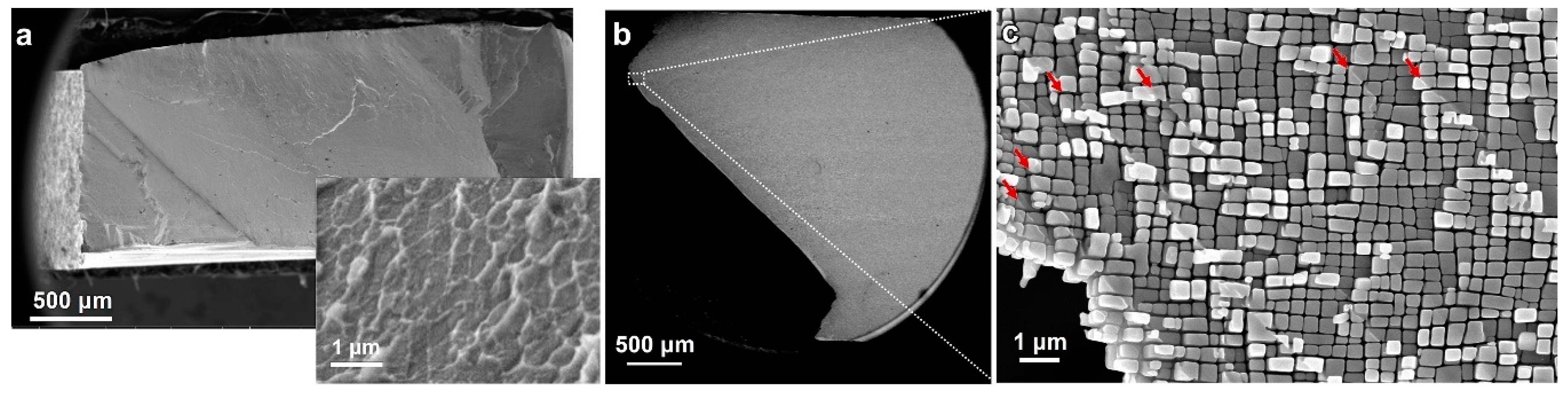

3.4. Fracture Analysis

4. Summary and Conclusions

- (1)

- The as-grown microstructure is of a typical dendrite and there are significant compositional and microstructural differences between the dendritic arms and interdendritic regions. Refractory elements Re, W, and Mo segregate at the dendritic arms. Meanwhile, γ′-forming elements, as well as eutectic-forming elements (Al, Ta, Nb), segregate at the interdendritic region, resulting in coarse γ′ precipitates and eutectic microstructures.

- (2)

- The solid solution treatment window has been determined to be 1280–1350 °C based on DSC results. A solution heat treatment procedure (1290 °C/1 h + 1300 °C/2 h + 1315 °C/2 h + 1325 °C/4 h + 1330 °C/4 h AC) has been identified to effectively eliminate eutectics at interdendritic regions and achieve compositional homogeneity without incipient melting. Combined with the subsequent aging heat treatment (1120 °C/4 h AC + 870 °C/24 h AC), homogeneous γ/γ′ two-phase structures (size of γ′ precipitate around 400 nm) have been obtained.

- (3)

- The tensile strength of our alloy is comparable to typical commercial CMSX-4 and DD6 alloys. The strength of the alloy increases with an increase in temperature from RT to 750 °C, 1059 MPa YS, and 1253 MPa UTS at 750 °C vs. 1010 MPa YS and 1155 MPa UTS at RT. Above this temperature, both YS and UTS decrease with the increase in temperature.

- (4)

- Subsequent fracture analysis demonstrates that the γ phase is ductile at all test temperatures but the γ′ phase appears to dominate the tensile properties. At RT, the γ′ phase exhibits a small degree of ductility, and the alloy fractures in a ductile manner. At intermediate temperatures, due to limited ductility of the γ′ phase, a rapid propagation of cracks by the shearing of the γ′ phase occurs, which is consistence with the “intermediate temperature brittleness” in Ni-based SX superalloys. At higher temperatures, necking occurs. Both the γ and γ′ phases become ductile, resulting in enhanced plastic deformation before fracture.

Author Contributions

Funding

Conflicts of Interest

References

- Reed, R.C. Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006; pp. 1–28. [Google Scholar]

- Ru, Y.; Zhang, H.; Pei, Y.; Li, S.; Gong, S. Substitutng Mo for Re in equal weight for Ni based single crystal superalloy. Materialia 2019, 6, 100278. [Google Scholar] [CrossRef]

- Long, H.; Mao, S.; Liu, Y.; Zhang, Z.; Han, X. Microstructural and compositional design of Ni-based single crystalline superalloys—A review. J. Alloy. Compd. 2018, 743, 203–220. [Google Scholar] [CrossRef]

- Pollock, T.M. Alloy design for aircraft engines. Nat. Mater. 2016, 15, 809–815. [Google Scholar] [CrossRef]

- Erickson, G.L. The development and application of CMSX-10. In Superalloys 1996, Proceedings of the Eighth International Symposium on Superalloys, Seven Springs, PA, USA, 22–26 September 1996; Kissinger, R., Ed.; The Minerals, Metals & Materials Society: Warrendale, PA, USA, 1996; pp. 35–44. [Google Scholar]

- Petrushin, N.B.; Elyutin, E.S.; Visik, E.M.; Golynets, S.A. Development of a single-crystal fifth-generation nickel superalloy. Russ. Metall. 2017, 6, 38–51. [Google Scholar] [CrossRef]

- Kawagishi, K.; Yeh, A.C.; Yokokawa, T.; Kobayashi, T.; Koizumi, Y.; Harada, H. Development of an oxidation-resistant high-strength sith-generation single-crytal superalloy TMS-238. In Superalloys 2012, Proceedings of the Eighth International Symposium on Superalloys, Seven Springs, PA, USA, 9–13 September 2012; Huron, E.C., Reed, R.C., Eds.; Wiley: Hoboken, NJ, USA, 2012; pp. 189–195. [Google Scholar]

- Sato, A.; Harada, H.; Yeh, A.C.; Kawagishi, K.; Kobayashi, T.; Koizumi, Y.; Yokokawa, T.; Zhang, J.X. A 5th generation SC superalloy with balanced high temperature properties and processability. In Superalloys 2008, Proceedings of the Eleventh International Symposium on Superalloys, Champion, PA, USA, 14–18 September 2008; Reed, R.C., Green, K.A., Eds.; The Minerals, Metals & Materials Society: Warrendale, PA, USA, 2008; pp. 131–138. [Google Scholar]

- Ding, Q.; Lao, Z.; Wei, H.; Li, J.; Bei, H.; Zhang, Z. Site occupancy of alloying elements in γ′ phase of nickel-base single crystal superalloys. Intermetallics 2020, 161, 106772. [Google Scholar] [CrossRef]

- Liu, L.; Huang, T.W.; Zhang, J.; Fu, H.Z. Microstructure and stress rupture properties of single crystal superalloy CMSX-2 under high thermal gradient directional solidification. Mater. Lett. 2007, 61, 227–230. [Google Scholar] [CrossRef]

- Tian, S.G.; Xue, Y.C.; Zeng, Z. Influence of solution temperature on compositions segregation and creep behavior of a single crystal nickel-based superalloy. Mater. Sci. Forum 2013, 747, 690–696. [Google Scholar] [CrossRef]

- Kearsey, R.M.; Beddoes, J.C.; Jaansalu, K.M.; Thompson, W.T.; Au, P. The effects of Re, W and Ru on microsegregation behaviour in single crystal superalloy system. In Superalloys 2004, Proceedings of the Tenth International Symposium on Superalloys, Seven Springs, PA, USA, 19–23 September 2004; Green, K.A., Ed.; The Minerals, Metals & Materials Society: Warrendale, PA, USA, 2004; pp. 801–810. [Google Scholar]

- Seo, S.M.; Lee, J.H.; Yoo, Y.S.; Jo, C.Y.; Miyahara, H.; Ogi, K. Solute redistribution during planar and dendritic growth of directionally solidified Ni-based superalloy CMSX-10. In Superalloys 2008, Proceedings of the Eleventh International Symposium on Superalloys, Champion, PA, USA, 14–18 September 2008; Reed, R.C., Green, K.A., Eds.; The Minerals, Metals & Materials Society: Warrendale, PA, USA, 2008; pp. 277–286. [Google Scholar]

- Yu, Z.; Qiang, J.; Zhang, J.; Lin, L. Microstructure evolution during heat treatment of superalloys loaded with different amounts of carbon. J. Mater. Res. 2015, 30, 2064–2072. [Google Scholar] [CrossRef]

- Fuchs, G.E. Solution heat treatment response of a third generation single crystal Ni-based superalloy. Mater. Sci. Eng. A 2001, 300, 52–60. [Google Scholar] [CrossRef]

- Hegde, S.R.; Kearsey, R.M.; Beddoes, J. Design of solutionizing heat treatments for an experimental single crystal superalloy. In Superalloys 2008, Proceedings of the Eleventh International Symposium on Superalloys, Champion, PA, USA, 14–18 September 2008; Reed, R.C., Green, K.A., Eds.; The Minerals, Metals & Materials Society: Warrendale, PA, USA, 2008; pp. 301–310. [Google Scholar]

- Grosdidier, T.; Hazotte, A.; Simon, A. Precipition and dissolution processes in γ/γ′ single crystal nickel-based superalloys. Mater. Sci. Eng. A 1998, 256, 183–196. [Google Scholar] [CrossRef]

- Ren, W.; Niu, C.; Ding, B.; Zhong, Y.; Yu, J.; Ren, Z.; Liu, W.; Ren, L.; Liaw, P.K. Improvement in creep life of a nickel-based single-crystal superalloy via composition homogeneity on the multiscales by magnetic-field-assisted directional solidification. Sci. Rep. 2018, 8, 1452. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hillier, G.S.; Bhadeshia, H.K.D.H. Homogenizaion of single crystal superalloys. In Perspectives in Metallurgical Development, Proceedings of the Centenary Conference, Sheffield, UK, 16–18 July 1984; Beech, J., Ed.; Metals Society: London, UK, 1984; pp. 183–187. [Google Scholar]

- Sluytman, J.S.V.; Pollock, T.M. Optimal precipitate shapes in nickel-base γ-γ′ alloys. Acta Mater. 2012, 60, 1771–1783. [Google Scholar] [CrossRef]

- Liu, J.; Yu, J.; Jin, T.; Sun, X.; Guan, H.; Hu, Z. Influence of temperature on tensile behavior and deformation mechanism of Re-containing single crystal superalloy. Trans. Nonferrous Met. Soc. China 2011, 21, 1518–1523. [Google Scholar] [CrossRef]

- Matuszewski, K.; Rettig, R.; Matysiak, H.; Peng, Z.; Povstugar, I.; Choi, P.; Müller, J.; Raabe, D.; Singer, R.F. Effect of ruthenium on the precipitation of topologically close packed phases in Ni-based superalloys of 3rd and 4th generation. Acta Mater. 2015, 95, 274–283. [Google Scholar] [CrossRef]

- Yang, J.X.; Zheng, Q.; Sun, X.F.; Guan, H.R.; Hu, Z.Q. Morphological evolution of γ′ phase in K465 superalloy during prolonged aging. Mater. Sci. Eng. A 2007, 457, 148–155. [Google Scholar] [CrossRef]

- Rae, C.M.F.; Reed, R.C. The precipitation of topologically close-packed phases in rhenium-containing superalloys. Acta Mater. 2001, 49, 4113–4125. [Google Scholar] [CrossRef]

- Huang, M.; Cheng, Z.; Xiong, J.; Li, J.; Hu, J.; Liu, Z.; Zhu, J. Coupling between Re segregation and γ/γ′ interfacial dislocation during high-temperature, low-stress creep of a nickel-based single-crystal superalloy. Acta Mater. 2014, 76, 294–305. [Google Scholar] [CrossRef]

- Garimell, L.; Liaw, P.K.; Klarstrom, D.L. Fatigue behavior in nickel-based superalloys: A literature review. J. Miner. Met. Mater. Soc. 1997, 49, 67. [Google Scholar] [CrossRef]

- Smith, T.M.; Unocic, R.R.; Deutchman, H.; Mills, M.J. Creep deformation mechanism mapping in nickel base disk superalloys. Mater. High. Temp. 2016, 33, 372–383. [Google Scholar] [CrossRef]

- Sulzer, S.; Reed, R. Critical assessment 31: On the modelling of tertiary creep in single-crystal superalloys. Mater. Sci. Technol. 2018, 34, 2174–2201. [Google Scholar] [CrossRef]

- Nabarro, F.R.N. Rafting in superalloys. Metall. Mater. Trans. A 1995, 27, 513–530. [Google Scholar] [CrossRef]

- Pollock, T.M.; Argon, A.S. Directional coarsening in nickel-base single crystals with high volume fractions of coherent precepitates. Acta Metall. et Mater. 1994, 42, 1859–1874. [Google Scholar] [CrossRef]

- Li, J.R.; Zhao, J.Q.; Liu, S.Z.; Han, M. Effects of low angle boundaries on the mechanical properties of single crystal superalloy DD6. In Superalloys 2008, Proceedings of the Eleventh International Symposium on Superalloys, Champion, PA, USA, 14–18 September 2008; Reed, R.C., Green, K.A., Eds.; The Minerals, Metals & Materials Society: Warrendale, PA, USA, 2008; pp. 443–450. [Google Scholar]

- Sengupta, A.; Putatunda, S.K.; Bartosiewicz, L.; Hangas, J.; Nailos, P.J.; Peputapeck, M.; Alberts, F.E. Tensile behavior of a new single-crystal nickel-based superalloy (CMSX-4) at room and elevated temperatures. J. Mater. Eng. Perform. 1994, 3, 73–81. [Google Scholar] [CrossRef]

- Wahl, J.; Harris, K. New single crystal suprealloys, CMSX-7 and CMSX-8. In Superalloys 2012, Proceedings of the Eighth International Symposium on Superalloys, Seven Springs, PA, USA, 9–13 September 2012; Huron, E.C., Reed, R.C., Eds.; Wiley: Hoboken, NJ, USA, 2012; pp. 177–188. [Google Scholar]

- Elliott, A.J.; Pollock, T.M. Thermal analysis of the Bridgman and liquid-metal-cooled directional solidification investment casting processes. Metall. Mater. Trans. A 2007, 38, 871–882. [Google Scholar] [CrossRef]

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: New York, NY, USA, 2006; pp. 81–90. [Google Scholar]

- Dieter, G.E. Mechanical Metallurgy; McGraw-Hill Book Company: New York, NY, USA, 1961; pp. 110–117. [Google Scholar]

- Li, J.R.; Zhong, Z.G.; Tang, D.Z.; Liu, S.Z.; Wei, P.; Wei, P.Y.; Wu, Z.T.; Huang, D.; Han, M. A low-cost second generation single crystal superalloy DD6. In Superalloys 2000, Proceedings of the Ninth International Symposium on Superalloys, Champion, PA, USA, 17–21 September 2000; Green, K.A., Pollock, T.M., Kissinger, R., Eds.; The Minerals, Metals & Materials Society: Warrendale, PA, USA, 2000; pp. 777–783. [Google Scholar]

- Veyssière, P.; Saada, G. Chapter 53 Microscopy and plasticity of the L12 γ′ phase. Dislocations Solids 1995, 10, 253–441. [Google Scholar]

- Rentenberger, C.; Karnthaler, H.P. The stability of screw dipoles in Ni3Al studied by TEM. Intermetallics 2008, 16, 571–579. [Google Scholar] [CrossRef]

- Rentenberger, C.; Karnthale, H.P. TEM study of the friction stress acting on edge dislocations in Ni3Al. Intermetallics 2003, 11, 601–609. [Google Scholar] [CrossRef]

| Alloys | Cr | Co | Mo | W | Ta | Re | Nb | Al | Ti | Hf | Ni | Reference |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Our alloy | 4.2 | 8.8 | 2.2 | 9.0 | 8.0 | 2.3 | 0.5 | 5.1 | 0.1 | Bal. | ||

| DD6 | 4.3 | 9.0 | 2.0 | 8.0 | 7.5 | 2.0 | 0.5 | 5.6 | 0.1 | Bal. | [31] | |

| CMSX-4 | 6.5 | 9 | 0.6 | 6 | 6.5 | 3 | - | 5.6 | 1 | 0.1 | Bal. | [32] |

| CMSX-7 | 6 | 10 | 0.6 | 9.0 | 9.0 | - | - | 5.7 | 0.8 | 0.2 | Bal. | [33] |

| CMSX-8 | 5.4 | 10 | 0.6 | 8.0 | 8 | 1.5 | - | 5.7 | 0.7 | 0.1 | Bal. | [34] |

| Sample | Heat Treatment |

|---|---|

| A | 1290 °C/1 h air cooling (AC) |

| B | 1290 °C/1 h + 1300 °C/2 h AC |

| C | 1290 °C/1 h + 1300 °C/2 h + 1315 °C/2 h AC |

| D | 1290 °C/1 h + 1300 °C/2 h + 1315 °C/2 h + 1320 °C/4 h AC |

| E | 1290 °C/1 h + 1300 °C/2 h + 1315 °C/2 h + 1330 °C/4 h AC |

| F | 1290 °C/1 h + 1300 °C/2 h + 1315 °C/2 h + 1340 °C/4 h AC |

| G | 1290 °C/1 h + 1300 °C/2 h + 1315 °C/2 h + 1350 °C/4 h AC |

| H | 1290 °C/1 h + 1300 °C/2 h + 1315 °C/2 h + 1360 °C/4 h AC |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, Q.; Bei, H.; Zhao, X.; Gao, Y.; Zhang, Z. Processing, Microstructures and Mechanical Properties of a Ni-Based Single Crystal Superalloy. Crystals 2020, 10, 572. https://doi.org/10.3390/cryst10070572

Ding Q, Bei H, Zhao X, Gao Y, Zhang Z. Processing, Microstructures and Mechanical Properties of a Ni-Based Single Crystal Superalloy. Crystals. 2020; 10(7):572. https://doi.org/10.3390/cryst10070572

Chicago/Turabian StyleDing, Qingqing, Hongbin Bei, Xinbao Zhao, Yanfei Gao, and Ze Zhang. 2020. "Processing, Microstructures and Mechanical Properties of a Ni-Based Single Crystal Superalloy" Crystals 10, no. 7: 572. https://doi.org/10.3390/cryst10070572

APA StyleDing, Q., Bei, H., Zhao, X., Gao, Y., & Zhang, Z. (2020). Processing, Microstructures and Mechanical Properties of a Ni-Based Single Crystal Superalloy. Crystals, 10(7), 572. https://doi.org/10.3390/cryst10070572