Effect of Mineral Fillers on the Mechanical Properties of Commercially Available Biodegradable Polymers

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Compound Preparation

2.3. Mechanical Characterization

2.4. Physical Characterization

2.5. Biodegradation Assessment

3. Results and Discussion

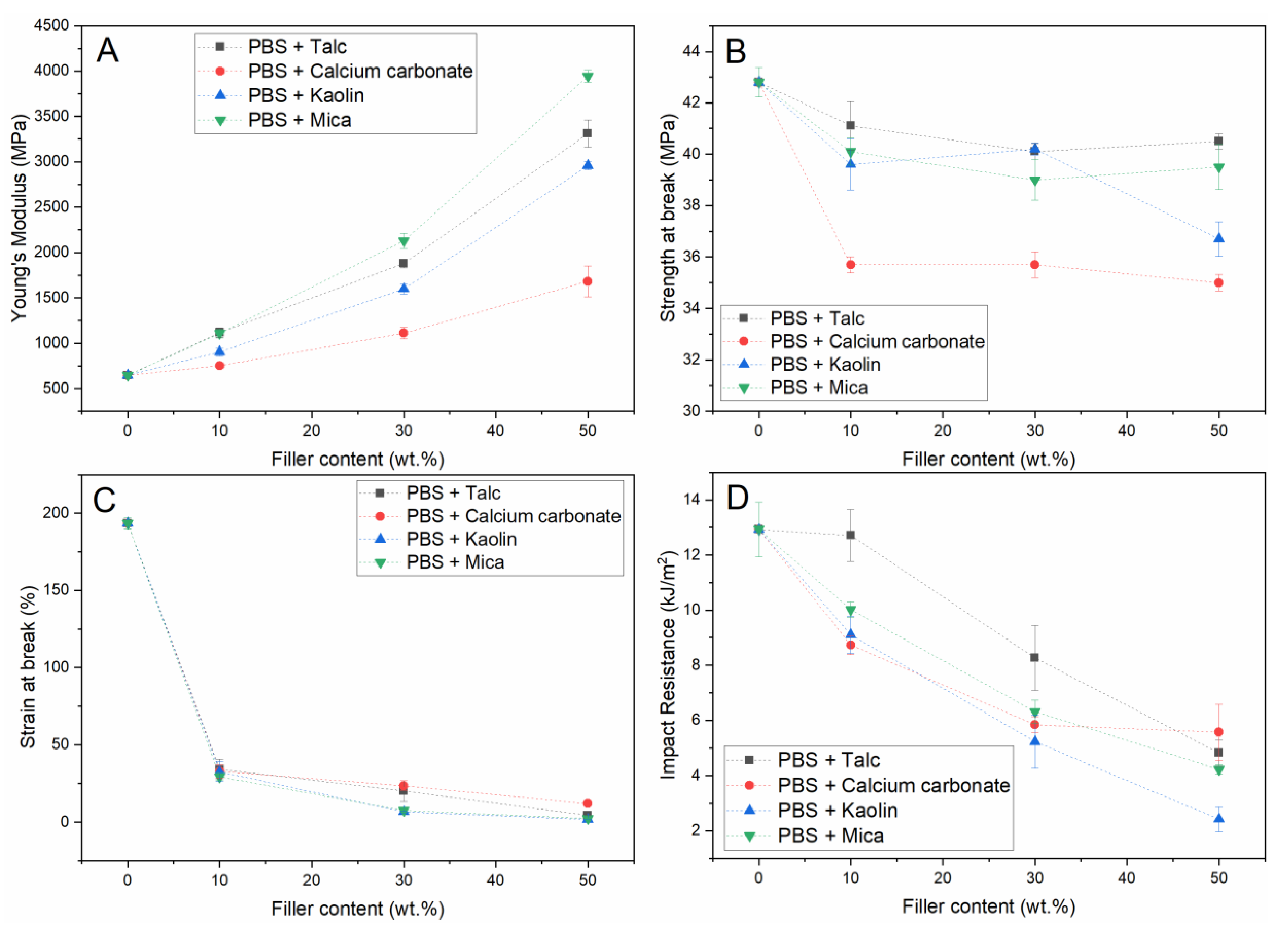

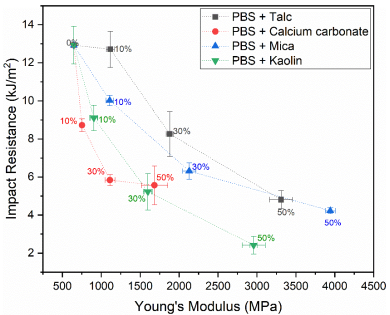

3.1. The Effect of Various Fillers on the Mechanical Properties of PBS

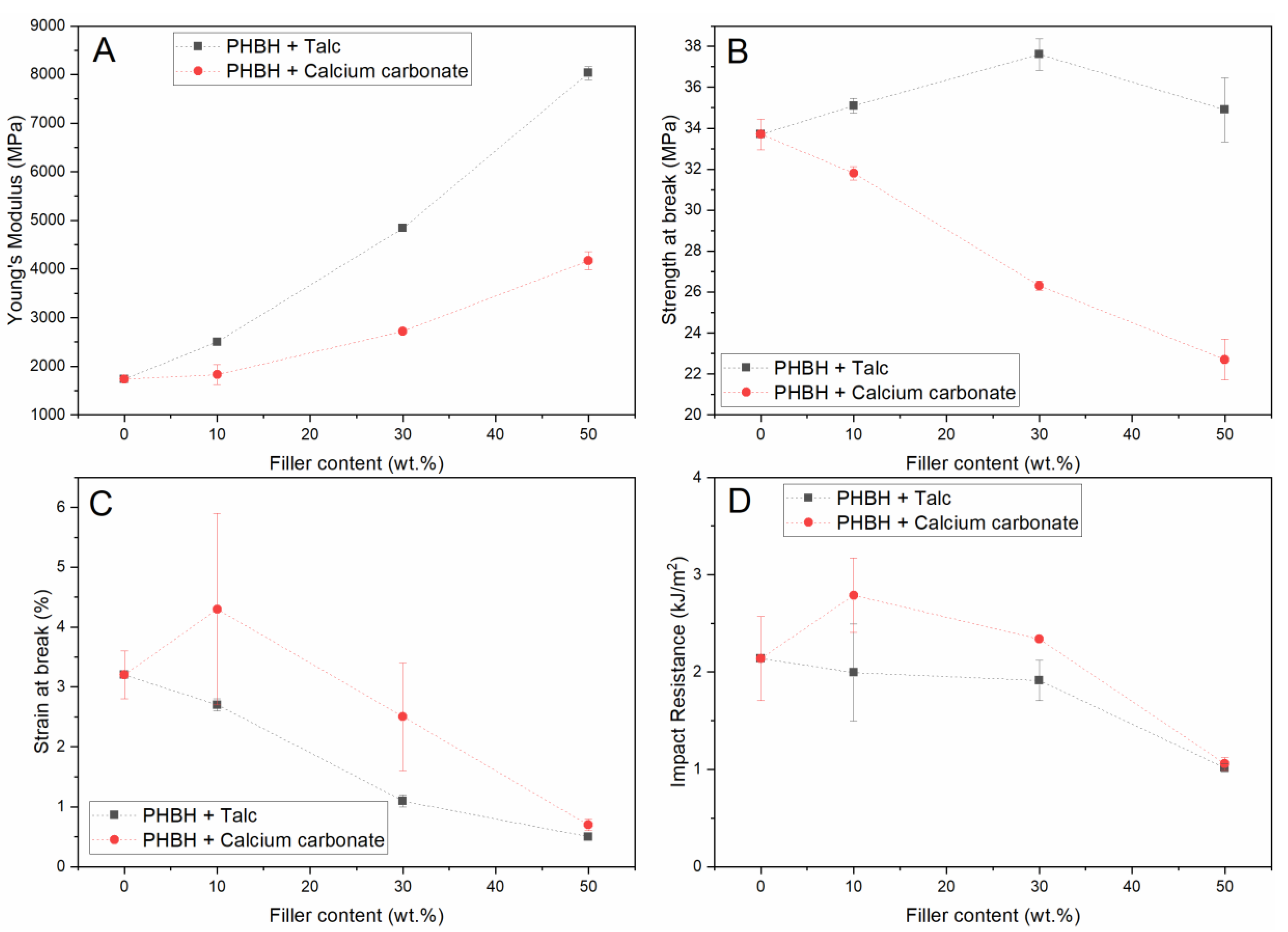

3.2. The Effect of Various Fillers on the Mechanical Properties of PHBH

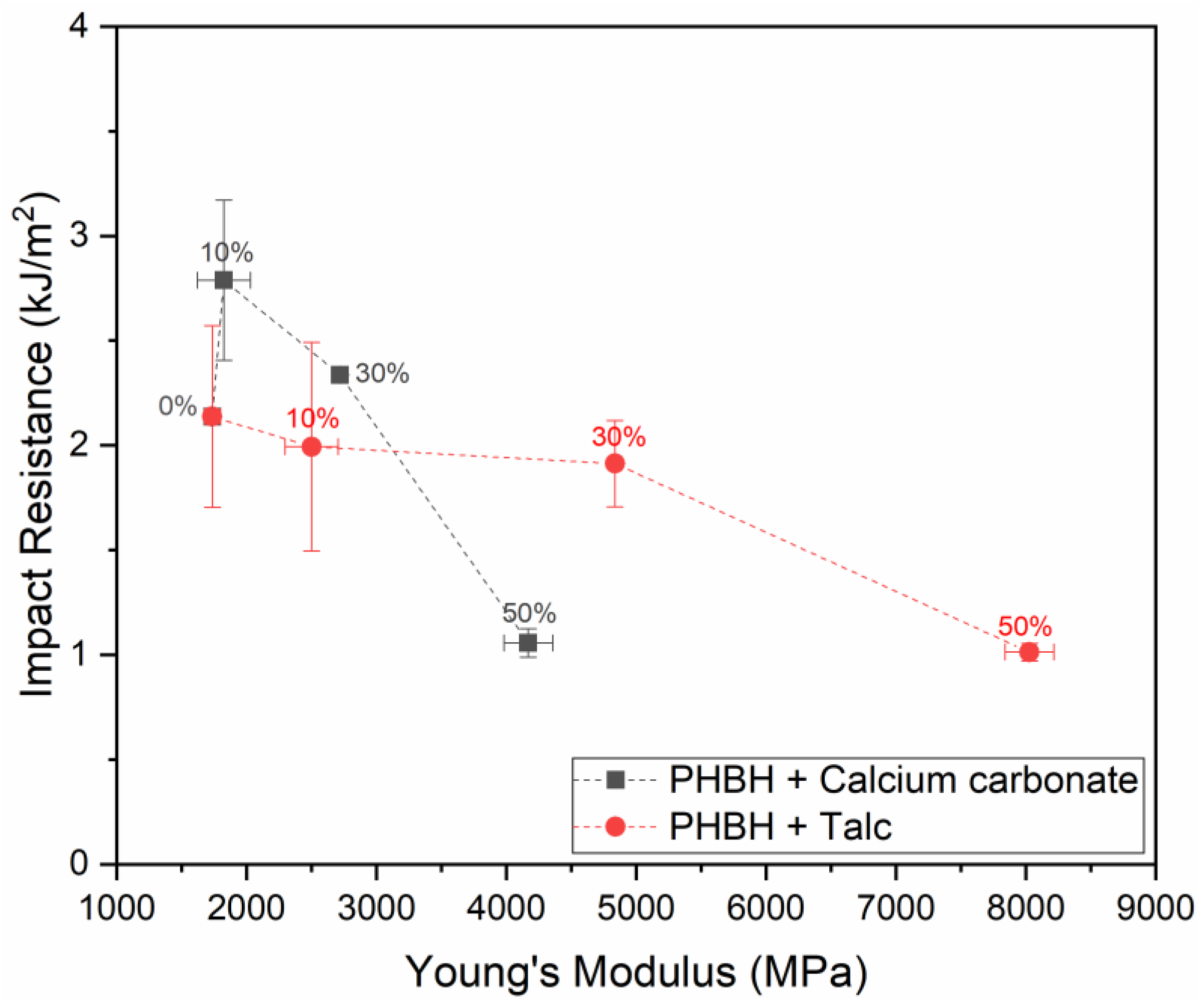

3.3. The Effect of Talc on the Mechanical Properties of Various Biodegradable Polymers

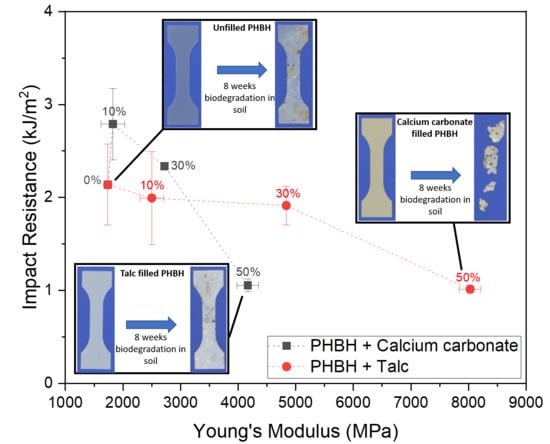

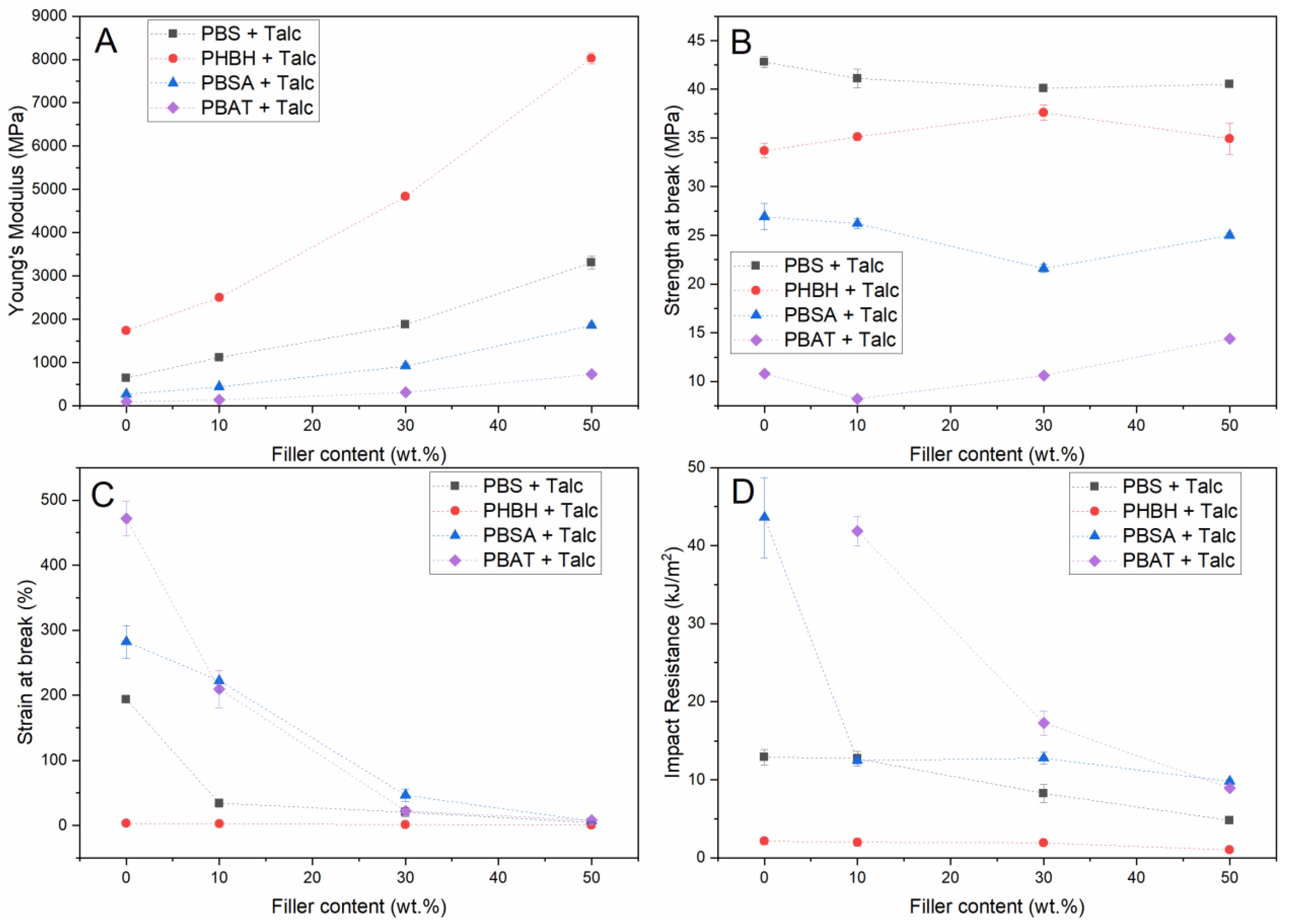

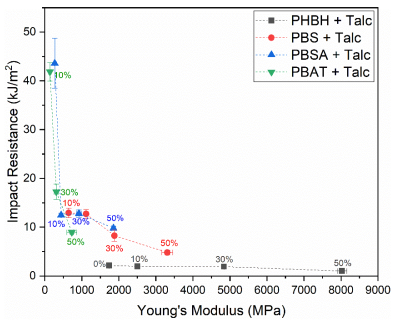

3.4. The Effect of Talc and Calcium Carbonate on the Biodegradation of PHBH in Soil

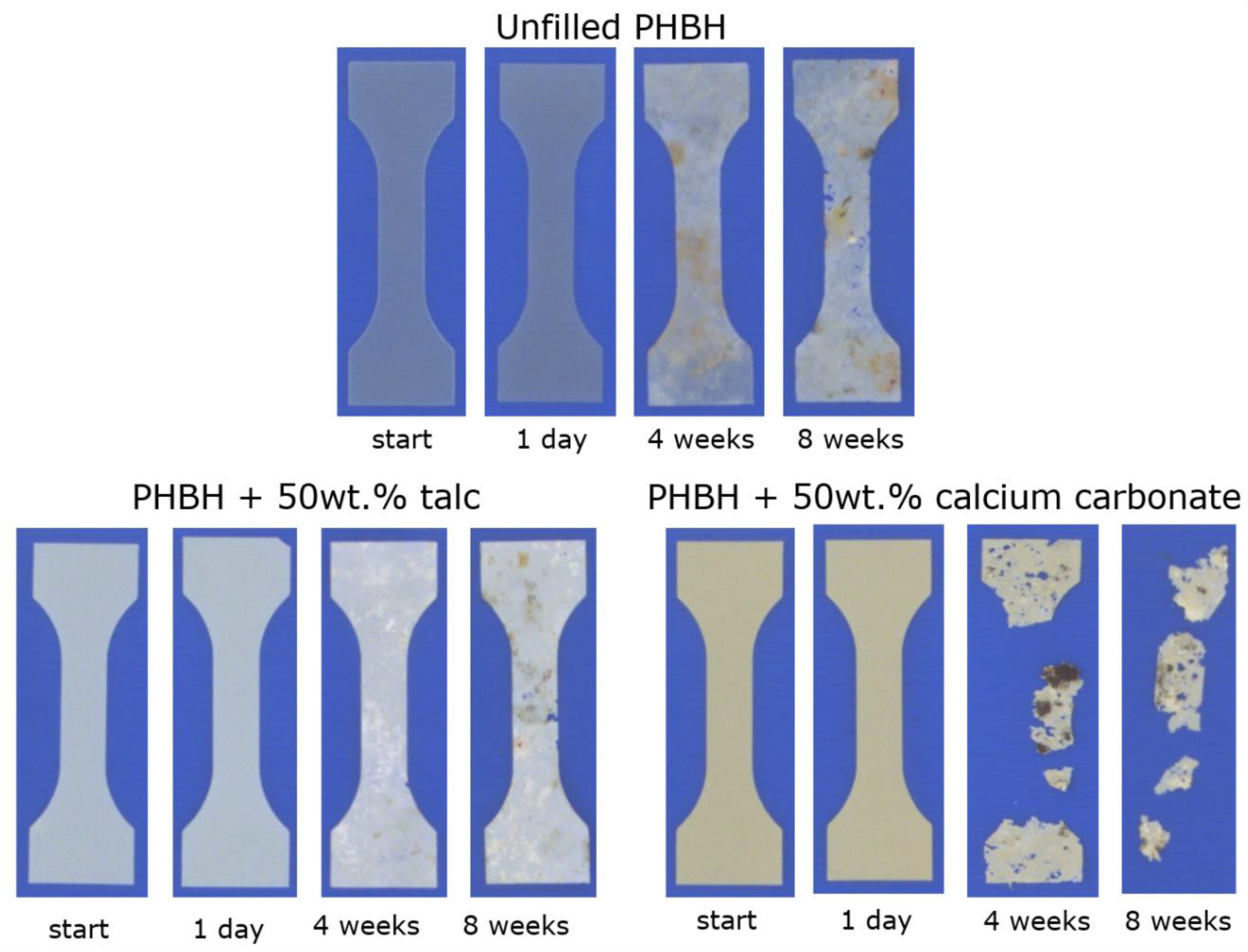

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Van Velzen, E.T.; Jansen, M.; Brouwer, M.T.; Feil, A.; Molenveld, K.; Pretz, T. Efficiency of recycling post-consumer plastic packages. In Proceedings of the 32th International Conference of the Polymer Processing Society, Lyon, France, 25–29 July 2016. [Google Scholar]

- Van den Oever, M.; Molenveld, K. Replacing fossil based plastic performance products by bio-based plastic products—Technical feasibility. New Biotechnol. 2017, 37, 48–59. [Google Scholar] [CrossRef] [PubMed]

- Iles, A.; Martin, A.N. Expanding bioplastics production: Sustainable business innovation in the chemical industry. J. Clean. Prod. 2013, 45, 38–49. [Google Scholar] [CrossRef]

- Van der Zee, M. Methods for evaluating the biodegradability of environmentally degradable polymers. In Handbook of Biodegradable Polymers; De Gruyter: Berlin, Germany, 2020; pp. 1–22. [Google Scholar]

- Lunt, J. Large-scale production, properties and commercial applications of polylactic acid polymers. Polym. Degrad. Stab. 1998, 59, 145–152. [Google Scholar] [CrossRef]

- Puchalski, M.; Szparaga, G.; Biela, T.; Gutowska, A.; Sztajnowski, S.; Krucińska, I. Molecular and Supramolecular Changes in Polybutylene Succinate (PBS) and Polybutylene Succinate Adipate (PBSA) Copolymer during Degradation in Various Environmental Conditions. Polymers 2018, 10, 251. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barron, A.; Sparks, T.D. Commercial Marine-Degradable Polymers for Flexible Packaging. iScience 2020, 23, 101353. [Google Scholar] [CrossRef]

- Dilkes-Hoffman, L.S.; Lant, P.A.; Laycock, B.; Pratt, S. The rate of biodegradation of PHA bioplastics in the marine environment: A meta-study. Mar. Pollut. Bull. 2019, 142, 15–24. [Google Scholar] [CrossRef]

- Siracusa, V.; Lotti, N.; Munari, A.; Rosa, M.D. Poly(butylene succinate) and poly(butylene succinate-co-adipate) for food packaging applications: Gas barrier properties after stressed treatments. Polym. Degrad. Stab. 2015, 119, 35–45. [Google Scholar] [CrossRef]

- Bhatia, A.; Gupta, R.K.; Bhattacharya, S.N.; Choi, H.J. Compatibility of biodegradable poly (lactic acid) (PLA) and poly (butylene succinate) (PBS) blends for packaging application. Korea Aust. Rheol. J. 2007, 19, 125–131. [Google Scholar]

- Barletta, M.; Aversa, C.; Puopolo, M.; Donninelli, A. Effect of micro-lamellar talc on dimensional accuracy and stability in injection molding of PLA/PBSA blends. Polym. Plast. Technol. Mater. 2019, 58, 776–788. [Google Scholar] [CrossRef]

- Gigante, V.; Coltelli, M.-B.; Vannozzi, A.; Panariello, L.; Fusco, A.; Trombi, L.; Donnarumma, G.; Danti, S.; Lazzeri, A. Flat die extruded biocompatible poly(lactic acid) (PLA)/poly(butylene succinate) (PBS) Based Films. Polymers 2019, 11, 1857. [Google Scholar] [CrossRef] [Green Version]

- Yang, S.; Madbouly, S.A.; Schrader, J.A.; Srinivasan, G.; Grewell, D.; McCabe, K.G.; Kessler, M.R.; Graves, W.R. Characterization and biodegradation behavior of bio-based poly(lactic acid) and soy protein blends for sustainable horticultural applications. Green Chem. 2015, 17, 380–393. [Google Scholar] [CrossRef] [Green Version]

- Post, W.; Bose, R.K.; Garcia, S.J.; Van Der Zwaag, S. Healing of Early Stage Fatigue Damage in Ionomer/Fe3O4 Nanoparticle Composites. Polymers 2016, 8, 436. [Google Scholar] [CrossRef] [PubMed]

- Zhong, N.; Post, W. Self-repair of structural and functional composites with intrinsically self-healing polymer matrices: A review. Compos. Part A Appl. Sci. Manuf. 2015, 69, 226–239. [Google Scholar] [CrossRef] [Green Version]

- Armentano, I.; Puglia, D.; Luzi, F.; Arciola, C.R.; Morena, F.; Martino, S.; Torre, L. Nanocomposites Based on Biodegradable Polymers. Materials 2018, 11, 795. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brebu, M. Environmental Degradation of Plastic Composites with Natural Fillers—A Review. Polymers 2020, 12, 166. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pivsa-Art, S.; Pivsa-Art, W. Eco-friendly bamboo fiber-reinforced poly(butylene succinate) biocomposites. Polym. Compos. 2021. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Morreale, M. Green composites: A brief review. Compos. Part A Appl. Sci. Manuf. 2011, 42, 579–588. [Google Scholar] [CrossRef]

- Saba, N.; Tahir, P.M.; Jawaid, M. A review on potentiality of nano filler/natural fiber filled polymer hybrid composites. Polymers 2014, 6, 2247–2273. [Google Scholar] [CrossRef]

- Raquez, J.M.; Nabar, Y.; Narayan, R.; Dubois, P. Novel High-Performance Talc/Poly[(butylene adipate)-co-terephthalate] Hybrid Materials. Macromol. Mater. Eng. 2008, 293, 310–320. [Google Scholar] [CrossRef]

- Sun, B.; Chuai, C.; Luo, S.; Guo, Y.; Han, C. Effect of different amounts of modified talc on the mechanical, thermal, and crystallization properties of poly(butylene succinate). J. Polym. Eng. 2014, 34, 379–385. [Google Scholar] [CrossRef]

- Chen, R.-Y.; Zou, W.; Zhang, H.-C.; Zhang, G.; Yang, Z.-T.; Jin, G.; Qu, J.-P. Thermal behavior, dynamic mechanical properties and rheological properties of poly(butylene succinate) composites filled with nanometer calcium carbonate. Polym. Test. 2015, 42, 160–167. [Google Scholar] [CrossRef]

- Nunes, E.D.C.; de Souza, A.G.; Rosa, D.D.S. Use of a chain extender as a dispersing agent of the CaCO3 into PBAT matrix. J. Compos. Mater. 2020, 54, 1373–1382. [Google Scholar] [CrossRef]

- Kwaśniewska, A.; Chocyk, D.; Gładyszewski, G.; Borc, J.; Świetlicki, M.; Gładyszewska, B. The influence of kaolin clay on the mechanical properties and structure of thermoplastic starch films. Polymers 2020, 12, 73. [Google Scholar] [CrossRef] [Green Version]

- Gu, L.; Zhang, S.; Li, H.; Sun, J.; Tang, W.; Zhao, L.; Gu, X. Preparation of Intumescent Flame Retardant Poly(butylene succinate) Using Urea Intercalated Kaolinite as Synergistic Agent. Fibers Polym. 2019, 20, 1631–1640. [Google Scholar] [CrossRef]

- Sinha Ray, S.; Okamoto, M. Polymer/layered silicate nanocomposites: A review from preparation to processing. Prog. Polym. Science 2003, 28, 1539–1641. [Google Scholar] [CrossRef]

- Zhang, X.; Lin, G.; Abou-Hussein, R.; Hassan, M.K.; Noda, I.; Mark, J.E. Some novel layered-silicate nanocomposites based on a biodegradable hydroxybutyrate copolymer. Eur. Polym. J. 2007, 43, 3128–3135. [Google Scholar] [CrossRef]

- Misra, S.K.; Valappil, S.P.; Roy, A.I.; Boccaccini, A.R. Polyhydroxyalkanoate (PHA)/inorganic phase composites for tissue engineering applications. Biomacromolecules 2006, 7, 2249–2258. [Google Scholar] [CrossRef]

- Tolga, S.; Kabasci, S.; Duhme, M. Progress of disintegration of polylactide (PLA)/poly(butylene succinate) (PBS) blends containing talc and chalk inorganic fillers under industrial composting conditions. Polymers 2021, 23, 10. [Google Scholar]

- Qi, R.; Jones, D.L.; Liu, Q.; Liu, Q.; Li, Z.; Yan, C. Field test on the biodegradation of poly(butylene adipate-co-terephthalate) based mulch films in soil. Polym. Test. 2021, 93, 107009. [Google Scholar] [CrossRef]

- Van den Oever, M.; Molenveld, K. Creep deflection of Wood Polymer Composite profiles at demanding conditions. Case Stud. Constr. Mater. 2019, 10, e00224. [Google Scholar] [CrossRef]

- Ramos, M.; Dominici, F.; Luzi, F.; Jiménez, A.; Garrigós, M.C.; Torre, L.; Puglia, D. Effect of almond shell waste on physicochemical properties of polyester-based biocomposites. Polymers 2020, 12, 835. [Google Scholar] [CrossRef] [Green Version]

- Mazur, K.; Jakubowska, P.; Romańska, P.; Kuciel, S. Green high density polyethylene (HDPE) reinforced with basalt fiber and agricultural fillers for technical applications. Compos. Part B Eng. 2020, 202, 108399. [Google Scholar] [CrossRef]

- International, A. ASTM G160—12(2019) Standard Practice for Evaluating Microbial Susceptibility of Nonmetallic Materials by Laboratory Soil Burial; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Mallick, P.K. 2.09—Particulate and Short Fiber Reinforced Polymer Composites, in Comprehensive Composite Materials; Kelly, A., Zweben, C., Eds.; Pergamon: Oxford, UK, 2000; pp. 291–331. [Google Scholar]

- Kauffman, S.; Leidner, J.; Woodhams, R.; Xanthos, M. The preparation and classification of high aspect ratio mica flakes for use in polymer reinforcement. Powder Technol. 1974, 9, 125–133. [Google Scholar] [CrossRef]

- Leong, Y.W.; Abu Bakar, M.B.; Ishak, Z.M.; Ariffin, A.; Pukanszky, B. Comparison of the mechanical properties and interfacial interactions between talc, kaolin, and calcium carbonate filled polypropylene composites. J. Appl. Polym. Sci. 2004, 91, 3315–3326. [Google Scholar] [CrossRef]

- Ashby, M. Materials Selection in Mechanical Design, 5th ed.; Elsevier Science & Technology: Oxford, UK, 2016; 660p. [Google Scholar]

- Tüv Austria Belgium. OK biodegradable MARINE. In Bio Products—Degradation in Seawater; Tüv Austria Belgium: Mechelen, Belgium, 2019; p. 5. [Google Scholar]

- Xiang, H.; Wen, X.; Miu, X.; Li, Y.; Zhou, Z.; Zhu, M. Thermal depolymerization mechanisms of poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Prog. Nat. Sci. Mater. Int. 2016, 26, 58–64. [Google Scholar] [CrossRef] [Green Version]

| Compound | Mass Average Molar Mass (kg/mol) | Melt Flow Index (g/10 min) |

|---|---|---|

| PBS | 124 | 3.5 |

| PBS + 50 wt.% talc | 137 | 1.8 |

| PBS + 50 wt.% calcium carbonate | 172 | 0.5 |

| PHBH | 283 | 16.4 |

| PHBH + 50 wt.% talc | 140 | 79.4 |

| PHBH + 50 wt.% calcium carbonate | 183 | 74.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Post, W.; Kuijpers, L.J.; Zijlstra, M.; van der Zee, M.; Molenveld, K. Effect of Mineral Fillers on the Mechanical Properties of Commercially Available Biodegradable Polymers. Polymers 2021, 13, 394. https://doi.org/10.3390/polym13030394

Post W, Kuijpers LJ, Zijlstra M, van der Zee M, Molenveld K. Effect of Mineral Fillers on the Mechanical Properties of Commercially Available Biodegradable Polymers. Polymers. 2021; 13(3):394. https://doi.org/10.3390/polym13030394

Chicago/Turabian StylePost, Wouter, Lambertus J. Kuijpers, Martin Zijlstra, Maarten van der Zee, and Karin Molenveld. 2021. "Effect of Mineral Fillers on the Mechanical Properties of Commercially Available Biodegradable Polymers" Polymers 13, no. 3: 394. https://doi.org/10.3390/polym13030394

APA StylePost, W., Kuijpers, L. J., Zijlstra, M., van der Zee, M., & Molenveld, K. (2021). Effect of Mineral Fillers on the Mechanical Properties of Commercially Available Biodegradable Polymers. Polymers, 13(3), 394. https://doi.org/10.3390/polym13030394