Characterization of Emissions in Fab Labs: An Additive Manufacturing Environment Issue

Abstract

:1. Introduction

1.1. Introduction of AM Technologies and the Consequences of Air Quality on Health

1.2. Indoor Air Quality (IAQ) Regulations and Policies Issued for AM Environments

1.3. Paper’s Originality and Objective

1.4. Paper Contents and Results

1.5. Paper Structure

2. Materials and Methods

2.1. Methodological Context: Application of the IAQ Monitoring Protocol

- Step 1: Plan

- Step 2: Do

- Step 3: Check

- Step 4: Act

2.2. Step 1: Experimentation Case Study Context

- Machines and materials

- Concerns reported by staff mainly include:

- The non-ventilated area where the 3D printers were located and its potential impact on health (even if the cause–effect relationship between the printers’ fumes (odors) and health issues was not proven by the makers);

- Students’ non-use of the laser cutter ventilation and its potential impact on the surrounding air quality. The fumes and odors emitted in the laser cutter area were particularly strong.

- Measurement protocol application

2.3. Step 2: Sampling Tools and Analysis

3. Results

3.1. Step 3: Results for Ultrafine Particle Emissions

3.1.1. Ultrafine Particle Emissions for Adjunct 3D Printers

3.1.2. Ultrafine Particle Emissions for Laser Cutter

3.2. Step 3: Measurement Results for Gaseous Compound Emissions

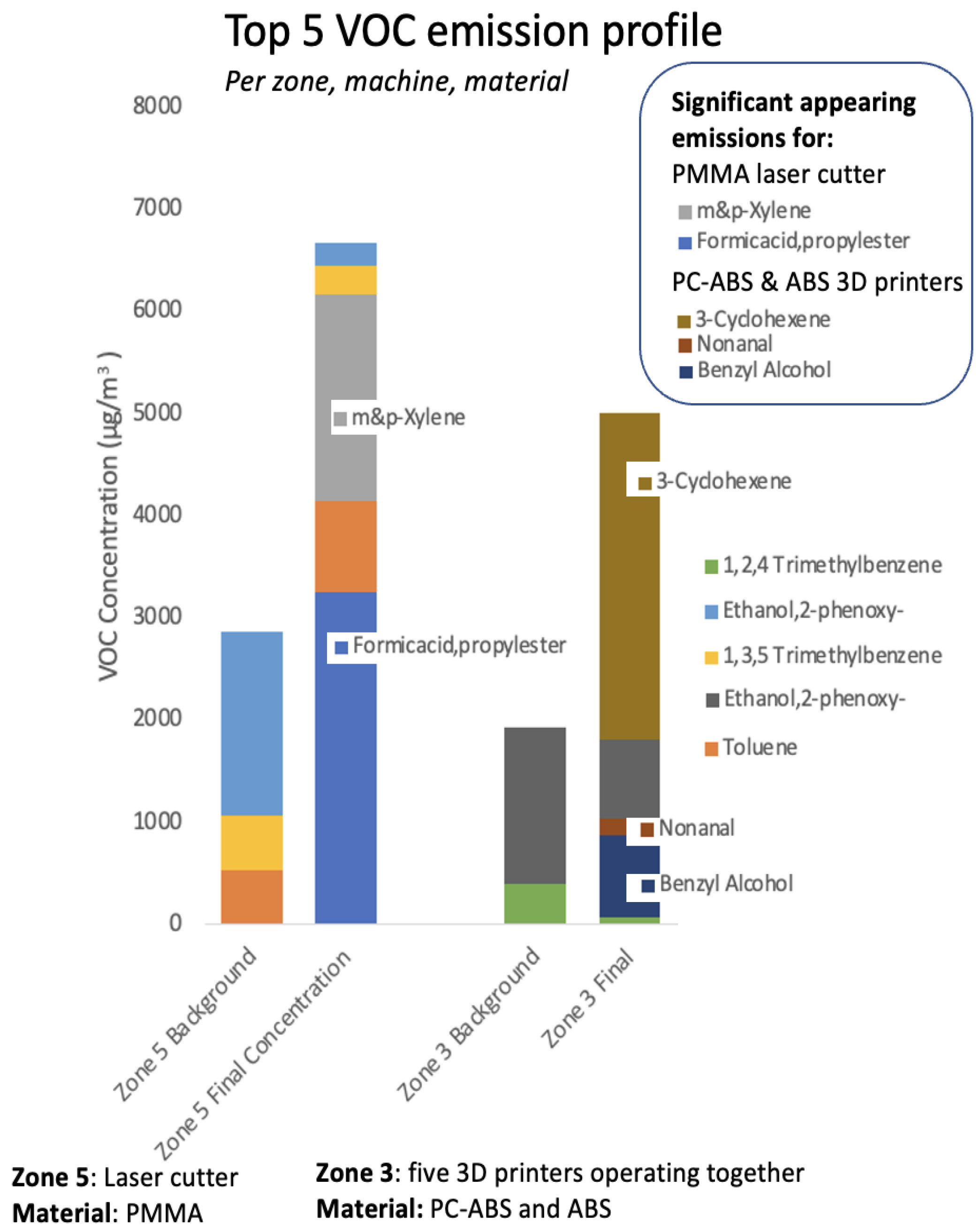

3.2.1. Gaseous Compound Emissions for Adjunct 3D Printers Operating in Zone 3

3.2.2. Gaseous Compound Emissions for Laser Cutter Operating in Zone 5

3.2.3. Significant Gaseous Compound Emissions per Machine and per Material

4. Discussion

4.1. Complementary Measurements and Identification of “Signature” Indoor Pollutants

4.2. TVOC Exposure Level

4.3. Step 4: Adjusting Mitigation Strategies

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chtioui, N.; Raoudha, G.; Benamara, A. Eco-design and Additive Manufacturing: Analysis and proposals. In Proceedings of the 24th Congrès Français de Mécanique, Brest, France, 26–30 August 2019. [Google Scholar]

- Kruth, J.-P.; Leu, M.C.; Nakagawa, T. Progress in Additive Manufacturing and Rapid Prototyping. CIRP Ann. 1998, 47, 525–540. [Google Scholar] [CrossRef]

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Luomaranta, T.; Martinsuo, M. Supply chain innovations for additive manufacturing. Int. J. Phys. Distrib. Logist. Manag. 2019, 50, 54–79. [Google Scholar] [CrossRef]

- Huang, Y.; Leu, M.C.; Mazumder, J.; Donmez, A. Additive Manufacturing: Current State, Future Potential, Gaps and Needs, and Recommendations. J. Manuf. Sci. Eng. 2015, 137, 014001. [Google Scholar] [CrossRef] [Green Version]

- Mendes, L.; Kangas, A.; Kukko, K.; Mølgaard, B.; Säämänen, A.; Kanerva, T.; Flores Ituarte, I.; Huhtiniemi, M.; Stockmann-Juvala, H.; Partanen, J.; et al. Characterization of Emissions from a Desktop 3D Printer. J. Ind. Ecol. 2017, 21, S94–S106. [Google Scholar] [CrossRef]

- McDonnell, B.; Jimenez Guzman, X.; Dolack, M.; Simpson, T.W.; Cimbala, J.M. 3D Printing in the Wild: A Preliminary Investigation of Air Quality in College Maker Spaces. In Proceedings of the 27th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 8–10 August 2016; pp. 2456–2469. [Google Scholar]

- Short, D.B.; Sirinterlikci, A.; Badger, P.; Artieri, B. Environmental, health, and safety issues in rapid prototyping. Rapid Prototyp. J. 2015, 21, 105–110. [Google Scholar] [CrossRef]

- Afshar-Mohajer, N.; Wu, C.-Y.; Ladun, T.; Rajon, D.A.; Huang, Y. Characterization of particulate matters and total VOC emissions from a binder jetting 3D printer. Build. Environ. 2015, 93, 293–301. [Google Scholar] [CrossRef]

- Azimi, P.; Zhao, D.; Pouzet, C.; Crain, N.E.; Stephens, B. Emissions of Ultrafine Particles and Volatile Organic Compounds from Commercially Available Desktop Three-Dimensional Printers with Multiple Filaments. Environ. Sci. Technol. 2016, 50, 1260–1268. [Google Scholar] [CrossRef] [PubMed]

- Gu, J.; Wensing, M.; Uhde, E.; Salthammer, T. Characterization of particulate and gaseous pollutants emitted during operation of a desktop 3D printer. Environ. Int. 2019, 123, 476–485. [Google Scholar] [CrossRef] [PubMed]

- John, U.; Matthew, R.C.; Chris, K.; John, J.M. Airborne Emissions of Carcinogens and Respiratory Sensitizers during Thermal Processing of Plastics. Ann. Occup. Hyg. 2013, 57, 399–406. [Google Scholar] [CrossRef]

- Wojtyła, S.; Klama, P.; Baran, T. Is 3D printing safe? Analysis of the thermal treatment of thermoplastics: ABS, PLA, PET, and nylon. J. Occup. Environ. Hyg. 2017, 14, D80–D85. [Google Scholar] [CrossRef]

- Oberdörster, G.; Oberdörster, E.; Oberdörster, J. Nanotoxicology: An Emerging Discipline Evolving from Studies of Ultrafine Particles. Environ. Health Perspect. 2005, 113, 823–839. [Google Scholar] [CrossRef]

- Madl, A.K.; Pinkerton, K.E. Health effects of inhaled engineered and incidental nanoparticles. Crit. Rev. Toxicol. 2009, 39, 629–658. [Google Scholar] [CrossRef] [PubMed]

- Rao, C.; Gu, F.; Zhao, P.; Sharmin, N.; Gu, H.; Fu, J. Capturing PM2.5 Emissions from 3D Printing via Nanofiber-based Air Filter. Sci. Rep. 2017, 7, 10366. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.-H.; Kabir, E.; Kabir, S. A review on the human health impact of airborne particulate matter. Environ. Int. 2015, 74, 136–143. [Google Scholar] [CrossRef]

- Byrley, P.; George, B.J.; Boyes, W.K.; Rogers, K. Particle emissions from fused deposition modeling 3D printers: Evaluation and meta-analysis. Sci. Total Environ. 2019, 655, 395–407. [Google Scholar] [CrossRef] [PubMed]

- Peters, A.; Wichmann, H.E.; Tuch, T.; Heinrich, J.; Heyder, J. Respiratory effects are associated with the number of ultrafine particles. Am. J. Respir. Crit. Care Med. 1997, 155, 1376–1383. [Google Scholar] [CrossRef]

- Lunetto, V.; Catalano, A.R.; Priarone, P.C.; Settineri, L. Comments about the Human Health Risks Related to Additive Manufacturing. In Sustainable Design and Manufacturing 2018; Dao, D., Howlett, R.J., Setchi, R., Vlacic, L., Eds.; Springer International Publishing: Cham, Switzerland, 2019; Volume 130, pp. 95–104. ISBN 978-3-030-04289-9. [Google Scholar]

- Chan, Y.-J.; Yuan, T.-H.; Sun, H.-C.; Lin, T.-C. Characterization and Exposure Assessment of Odor Emissions from Laser Cutting of Plastics in the Optical Film Industry. Aerosol Air Qual. Res. 2016, 16, 2216–2226. [Google Scholar] [CrossRef] [Green Version]

- O’Neill, K. Laser-Generated Airborne Contaminants from a Desktop Laser Cutter and Engraver; University of Oklahoma: Norman, OK, USA, 2017. [Google Scholar]

- Khaki, S.; Rio, M.; Marin, P. Monitoring indoor air quality in additive manufacturing environment. Procedia CIRP 2020, 90, 455–460. [Google Scholar] [CrossRef]

- Yi, J.; LeBouf, R.F.; Duling, M.G.; Nurkiewicz, T.; Chen, B.T.; Schwegler-Berry, D.; Virji, M.A.; Stefaniak, A.B. Emission of particulate matter from a desktop three-dimensional (3D) printer. J. Toxicol. Environ. Health A 2016, 79, 453–465. [Google Scholar] [CrossRef]

- Baumers, M.; Duflou, J.R.; Flanagan, W.; Gutowski, T.G.; Kellens, K.; Lifset, R. Charting the Environmental Dimensions of Additive Manufacturing and 3D Printing: Environmental Dimensions of AM. J. Ind. Ecol. 2017, 21, S9–S14. [Google Scholar] [CrossRef] [Green Version]

- Rejeski, D.; Zhao, F.; Huang, Y. Research needs and recommendations on environmental implications of additive manufacturing. Addit. Manuf. 2018, 19, 21–28. [Google Scholar] [CrossRef] [Green Version]

- Asadi, E.; da Silva, M.C.G.; Costa, J.J. A systematic indoor air quality audit approach for public buildings. Environ. Monit. Assess. 2013, 185, 865–875. [Google Scholar] [CrossRef] [PubMed]

- ISO Standard. ISO 16000 Indoor Air—Part 1: General Aspects of Sampling Strategy. 2004. Available online: https://cobaz.afnor.org/ (accessed on 10 June 2021).

- Moylan, S.; Slotwinski, J.; Cooke, A.; Jurrens, K.; Donmez, M. Proposal for a standardized test artifact for additive manufacturing machines and processes. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2012. [Google Scholar]

- Recuerda, M.A. Risk and Reason in the European Union Law. Eur. Food Feed. Law Rev. 2006, 5, 270. [Google Scholar]

- Deng, Y.; Cao, S.J.; Chen, A.; Guo, Y. The impact of manufacturing parameters on submicron particle emissions from a desktop 3D printer in the perspective of emission reduction. Build. Environ. 2016, 104, 311–319. [Google Scholar] [CrossRef]

- Simon, T.R.; Aguilera, G.A.; Zhao, F. Characterization of particle emission from fuse deposition modeling printers. In Proceedings of the International Manufacturing Science and Engineering Conference, Los Angeles, CA, USA, 4–8 June 2017; American Society of Mechanical Engineers: Los Angeles, CA, USA, 2017; Volume 50732, p. V002T01A040. [Google Scholar]

- Molhave, L.; Clausen, G.; Berglund, B.; Ceaurriz, J.; Kettrup, A.; Lindvall, T.; Maroni, M.; Pickering, A.C.; Risse, U.; Rothweiler, H.; et al. Total Volatile Organic Compounds (TVOC) in Indoor Air Quality Investigations. Indoor Air 1997, 7, 225–240. [Google Scholar] [CrossRef]

- Abdul-Wahab, S.A.; Chin Fah En, S.; Elkamel, A.; Ahmadi, L.; Yetilmezsoy, K. A review of standards and guidelines set by international bodies for the parameters of indoor air quality. Atmos. Pollut. Res. 2015, 6, 751–767. [Google Scholar] [CrossRef]

- Tuomi, T.; Vainiotalo, S. The guideline and target values for total volatile organic compound concentrations in industrial indoor environments in Finland. Indoor Built Environ. 2014, 25, 424–434. [Google Scholar] [CrossRef]

- Stephens, B.; Azimi, P.; El Orch, Z.; Ramos, T. Ultrafine particle emissions from desktop 3D printers. Atmos. Environ. 2013, 79, 334–339. [Google Scholar] [CrossRef]

- Azimi, P.; Fazli, T.; Stephens, B. Predicting Concentrations of Ultrafine Particles and Volatile Organic Compounds Resulting from Desktop 3D Printer Operation and the Impact of Potential Control Strategies: 3D Printer Emissions-Exposure and Control. J. Ind. Ecol. 2017, 21, S107–S119. [Google Scholar] [CrossRef] [Green Version]

- Leso, V.; Ercolano, M.L.; Mazzotta, I.; Romano, M.; Cannavacciuolo, F.; Iavicoli, I. Three-Dimensional (3D) Printing: Implications for Risk Assessment and Management in Occupational Settings. Ann. Work. Expo. Health 2021, 65, 617–634. [Google Scholar] [CrossRef] [PubMed]

| Assessment Parameters | Descriptive Criterion | Results Targeted |

|---|---|---|

| Internal organization | Machine type and usage rate, materials and liquids used, material renewals, production process patterns, fabrication durations, pre- and post-production and cleaning processes | Pollution pattern detection aligned with seasons and time of day and night |

| Makers’ practices and behavior | Time spent inside, personal movements, physical protection | Occupation schedules |

| Building system technology in place, energy policies | IAQ requirement management processes: indicators, measurement devices and technologies, mitigation processes (ventilation and extraction, filters), assessment frequencies, internal/external data processing | Monitoring and control management system operation |

| Machine | Material Type Filament | Location | Duration of Machine Use for Each Print (in minute) | Temperature (in °C) | ||

|---|---|---|---|---|---|---|

| Room | Extruder Nozzle | Build Platform | ||||

| 3D Printers | PLA | Zone 1 | 45 | 27.3 °C | 205 °C | 65 °C |

| PC-ABS | Zone 3 | 55 | 27.3 °C | 295 °C | 95 °C | |

| ABS | Zones 2 and 3 | 55 | 27.3 °C | 275 °C | 80 °C | |

| TPE | Zone 1 | 65 | 27.3 °C | 230 °C | 50 °C | |

| Laser cutter | PMMA 5 mm | Zone 5 | 5 engraving 3 cutting | 27.3 °C | ||

| 3D Printers of Zone 3 | Laser Cutter of Zone 5 | ||||||

|---|---|---|---|---|---|---|---|

| Particulate Matter Concentration (μm2/cm3) | Background | Operation | Final | Background | Engraving | Cutting | Post-operation |

| With HEPA Filtration/Ventilation | 33.4 | 294.15 | 36.63 | 36.53 | 37.01 | 55.06 | 101.54 |

| Without HEPA Filtration/Ventilation | 39.51 | 406.2 | 49.22 | 35.09 | 35.56 | 92.3 | 469.91 |

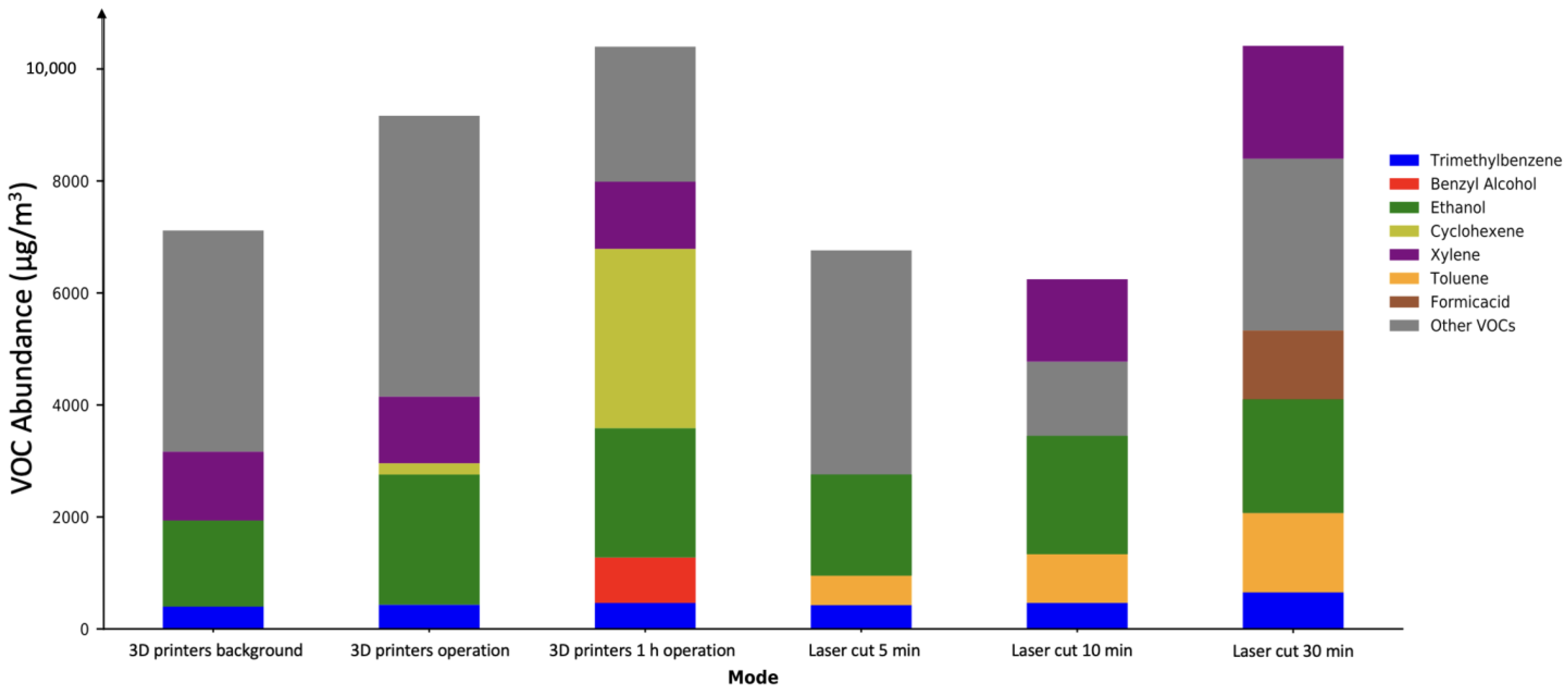

| Organic Compounds Detected (µg/m3) | 3D Printers (Zone 3) | Laser Cutter (Zone 5) | ||||

|---|---|---|---|---|---|---|

| Background | During Operation | After 1 h Operation | 5 min | 10 min | 30 min | |

| Acetone a | 76.38 | |||||

| Formic acid a | 259.47 | |||||

| Ethanol a | 204.61 | |||||

| 1-Propanol a | 42.57 | 42.52 | 24.02 | 49.10 | 32.27 | |

| Isopropyl Alcohol a | 473.54 | 204.14 | 457.50 | 214.35 | 215.42 | |

| Propane,1-methoxy a | 238.77 | 296.28 | ||||

| Acetaldehyde a | 288.18 | 178.02 | ||||

| Hydrazine a | 360.13 | 150.62 | 232.73 | |||

| Ethanol,2-methoxy- | 168.59 | |||||

| Acetic Acid a | 66.91 | 47.31 | 26.25 | 74.85 | 47.09 | |

| Formic acid,propylester a | 3258.88 | |||||

| Formic acid,1-methylpropylester a | 152.63 | 196.30 | ||||

| 2-Butanol | 197.81 | |||||

| Formicacid,1,1-dimethylethylester a | 261.95 | |||||

| Propane,2-ethoxy a | 223.36 | 278.58 | 331.35 | |||

| 1-Butanol a | 314.23 | 137.05 | 38.51 | |||

| Methyl Methacrylate a | 78.69 | 1656.80 | 51.31 | 361.10 | ||

| Propenoic acid a | 236.95 | 745.76 | ||||

| Toluene | 709.56 | 720.19 | 528.60 | 528.62 | 868.96 | 1419.06 |

| Ethylbenzene | 1260.23 | |||||

| m&p-Xylene | 1229.03 | 1191.34 | 1198.18 | 1470.99 | 2015.18 | |

| o-Xylene | 332.33 | 314.09 | 287.56 | 309.76 | 374.15 | 561.83 |

| Styrene | 6.66 | |||||

| Cyclohexene | 202.37 | |||||

| N-Propyl Benzene | 50.08 | 99.25 | 57.34 | 48.72 | 49.86 | |

| 1,3,5 Trimethylbenzene | 599.03 | 418.17 | 397.48 | 536.79 | 415.43 | 833.17 |

| 1,2,4 Trimethylbenzene | 398.46 | 432.60 | 464.68 | 423.61 | 466.70 | 653.38 |

| Benzyl Alcohol a | 812.57 | 205.92 | 223.99 | |||

| M-Cresol | 49.66 | 32.10 | 11.15 | 52.26 | 65.14 | |

| Nonanal | 160.667 | |||||

| 2-Nonen | 190.89 | |||||

| Ethanol,2-phenoxy- | 1537.31 | 2323.78 | 2308.67 | 1805.67 | 2111.67 | 2027.56 |

| 3-Cyclohexene | 3202.07 | 299.69 | 373.98 | |||

| Isobornyl propionate | 2385.87 | 321.96 | ||||

| 2-Butanone | 674.70 | |||||

| TVOC | 5728.32 | 8038.06 | 9498.46 | 5461.05 | 6299.47 | 8223.16 |

| TVVOC | 1387.78 | 1126.69 | 900.44 | 3105.93 | 2056.93 | 4218.18 |

| 7116.10 | 9164.75 | 10,398.90 | 8566.98 | 8356.40 | 12,441.33 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khaki, S.; Rio, M.; Marin, P. Characterization of Emissions in Fab Labs: An Additive Manufacturing Environment Issue. Sustainability 2022, 14, 2900. https://doi.org/10.3390/su14052900

Khaki S, Rio M, Marin P. Characterization of Emissions in Fab Labs: An Additive Manufacturing Environment Issue. Sustainability. 2022; 14(5):2900. https://doi.org/10.3390/su14052900

Chicago/Turabian StyleKhaki, Shirin, Maud Rio, and Philippe Marin. 2022. "Characterization of Emissions in Fab Labs: An Additive Manufacturing Environment Issue" Sustainability 14, no. 5: 2900. https://doi.org/10.3390/su14052900

APA StyleKhaki, S., Rio, M., & Marin, P. (2022). Characterization of Emissions in Fab Labs: An Additive Manufacturing Environment Issue. Sustainability, 14(5), 2900. https://doi.org/10.3390/su14052900